Patents

Literature

79results about How to "Consistent flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

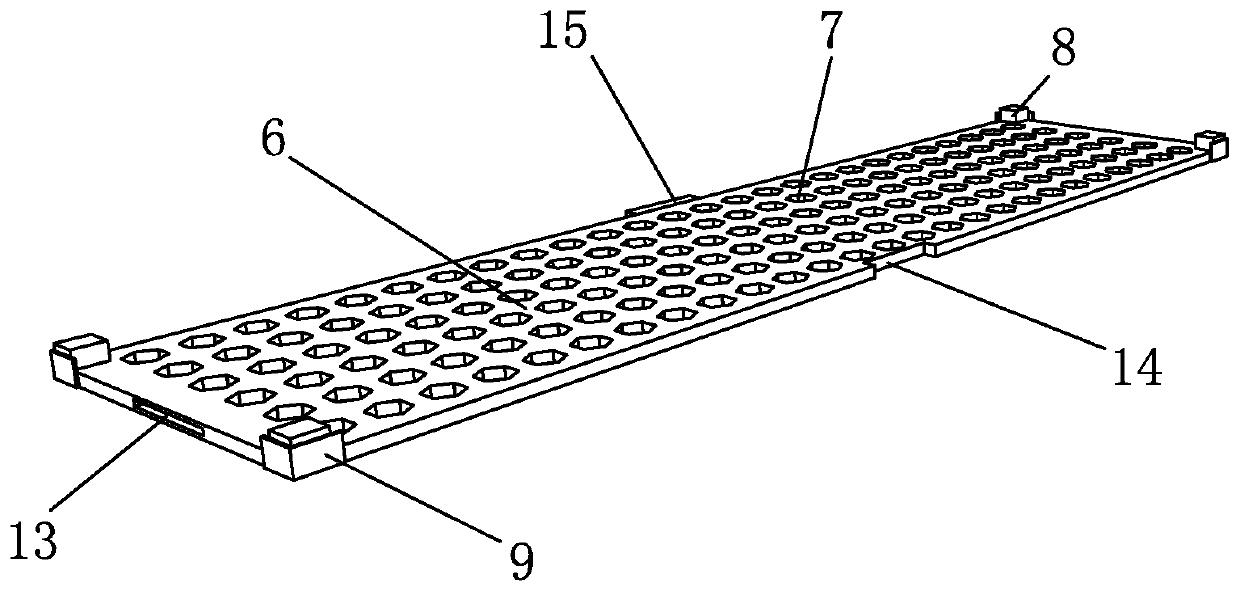

Adjustable leveling guide rail and leveling method thereof

InactiveCN101775905AHigh leveling accuracyReduce weightBuilding material handlingClean environmentEngineering

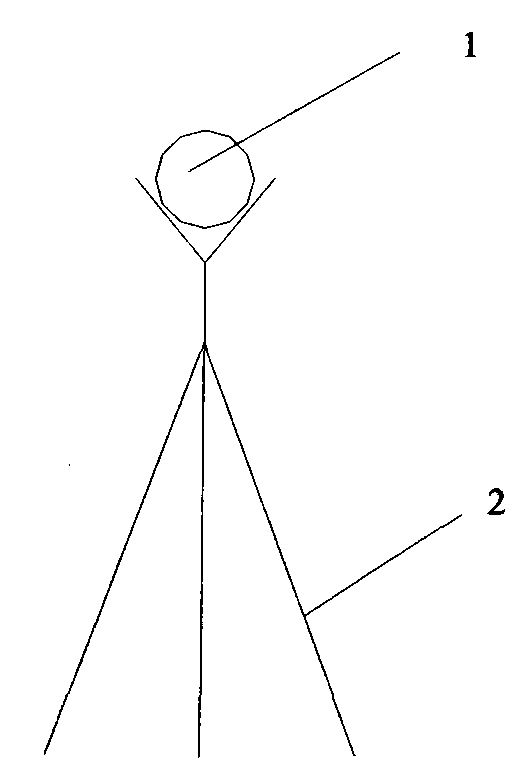

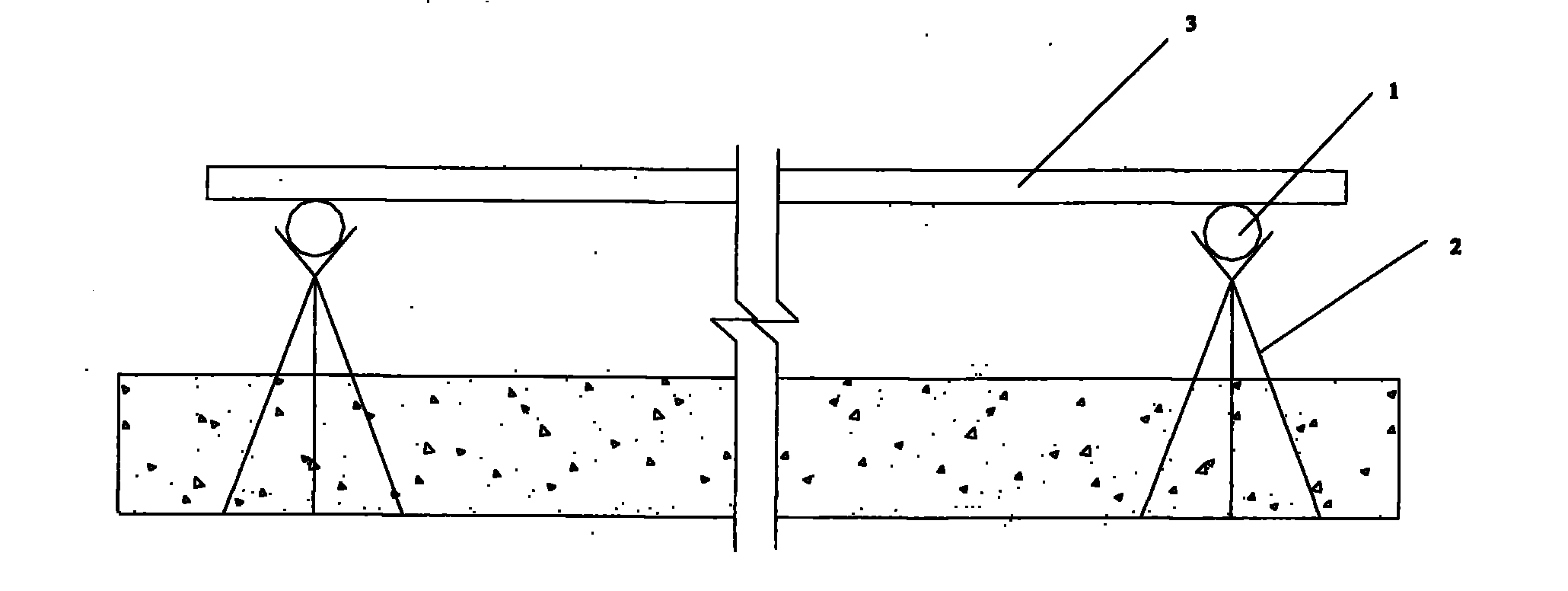

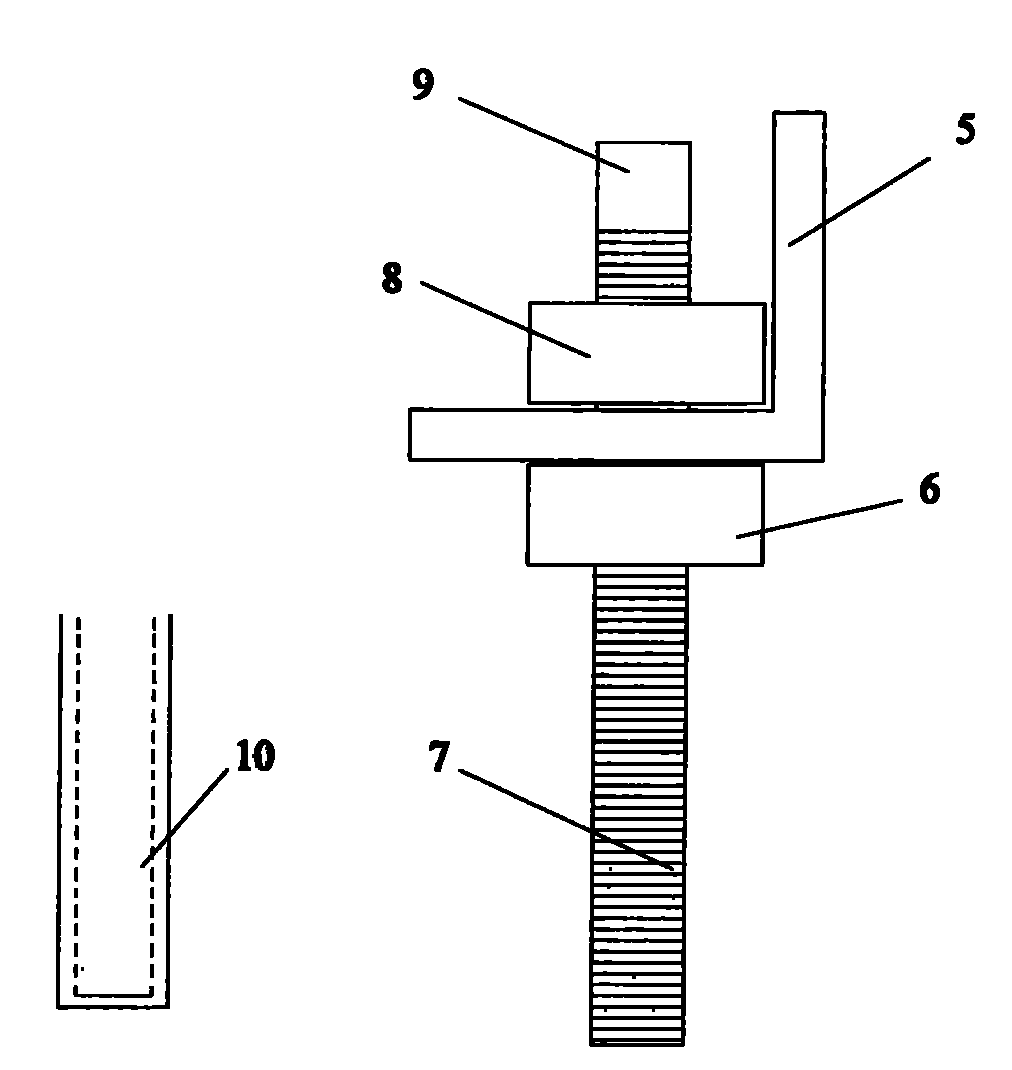

The invention provides an adjustable leveling guide rail. The adjustable leveling guide rail comprises a guide rail beam and a plurality of supporting pieces, wherein each supporting piece comprises a screw rod and a nut; the screw rod is connected with the guide rail beam through the nut; the end part of the screw rod is provided with a fixing block which is hexagonal, tetragonal or triangular; the fixing block is connected with the screw rod in an integral molding mode or the fixing block is detachably connected with the screw rod; and the supporting piece also comprises a positioning piece connected with the screw rod in a fitting mode. The invention also provides a leveling method for realizing the leveling guide rail, namely, the levelness of the leveling guide rail is adjusted by rotating a leveling nut and a positioning nut. In a construction process, instant leveling is realized by clamping the fixing block, fixing the screw rod and adjusting the levelness of the guide rail by screwing the positioning nut and the adjusting nut respectively. The adjustable leveling guide rail has high leveling accuracy, can realize instant leveling in the construction process and has the advantages of low cost, convenient detachment, easy construction, clean environment, green construction and the like.

Owner:HAOHE ENG & CONSTR

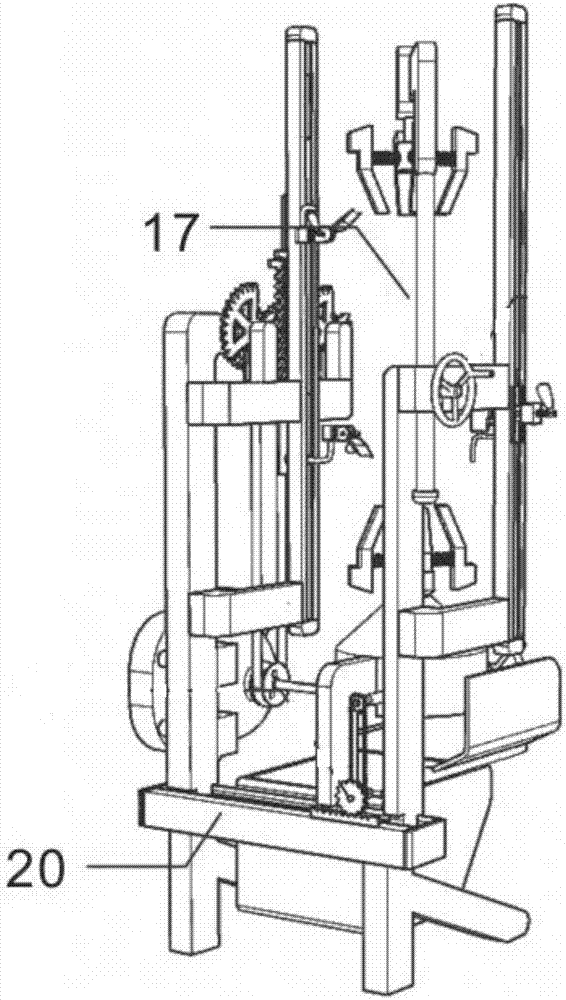

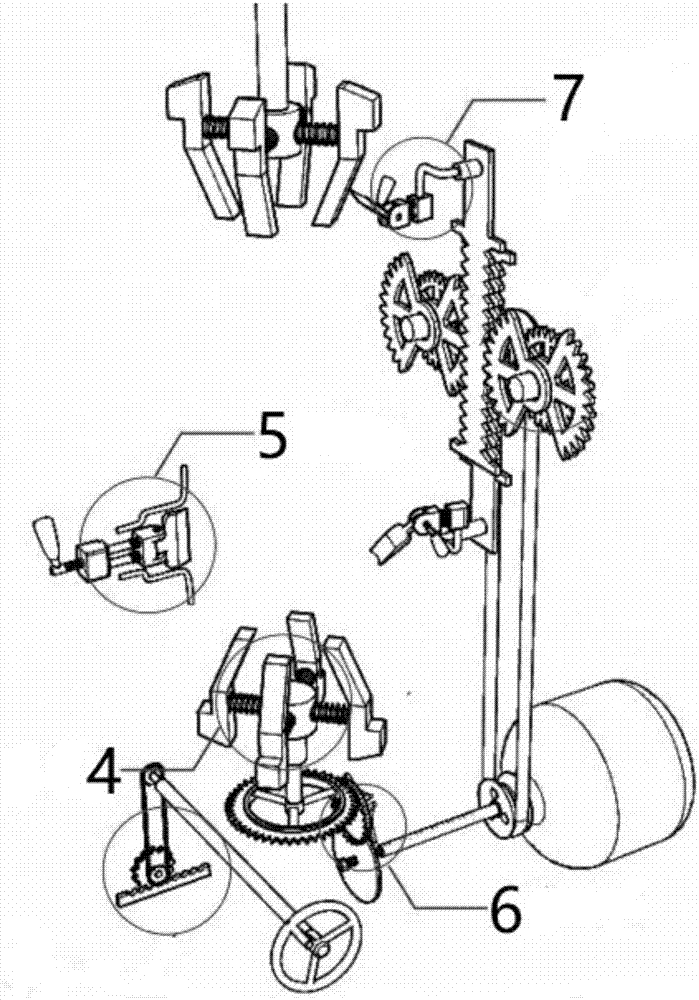

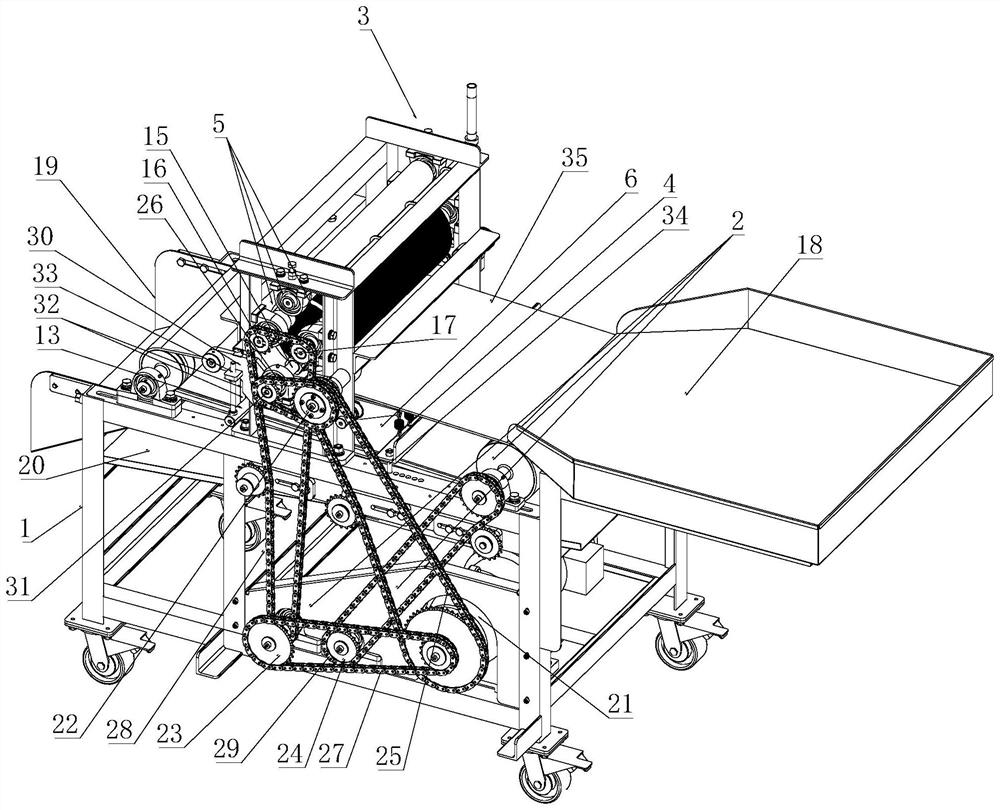

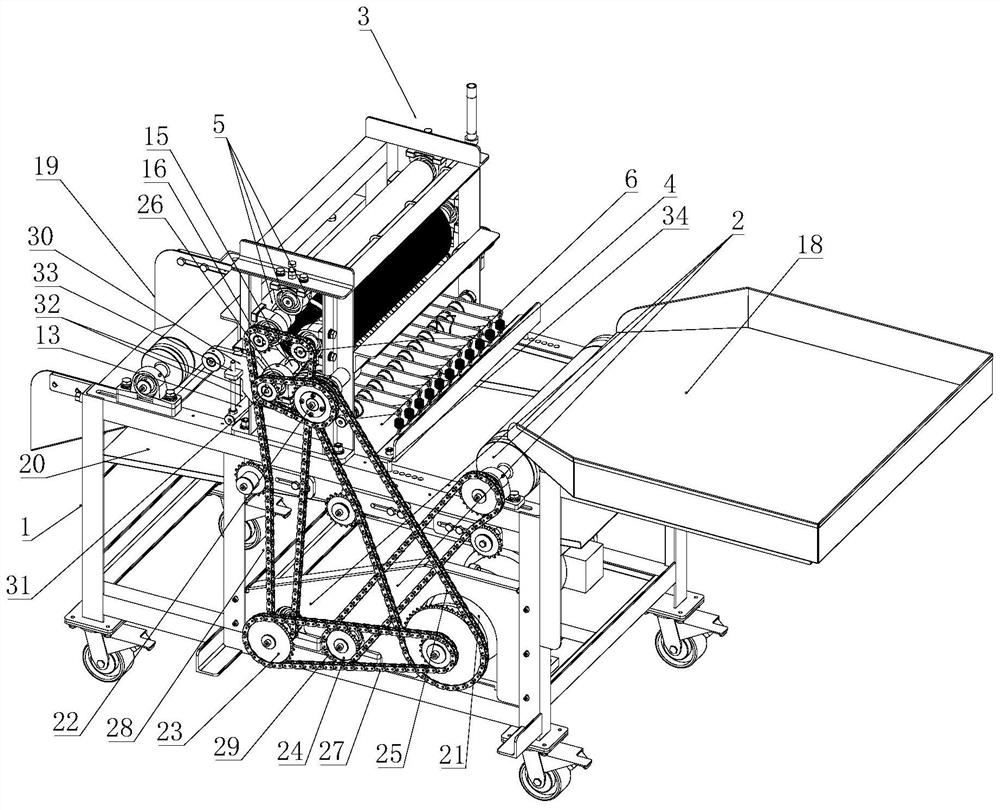

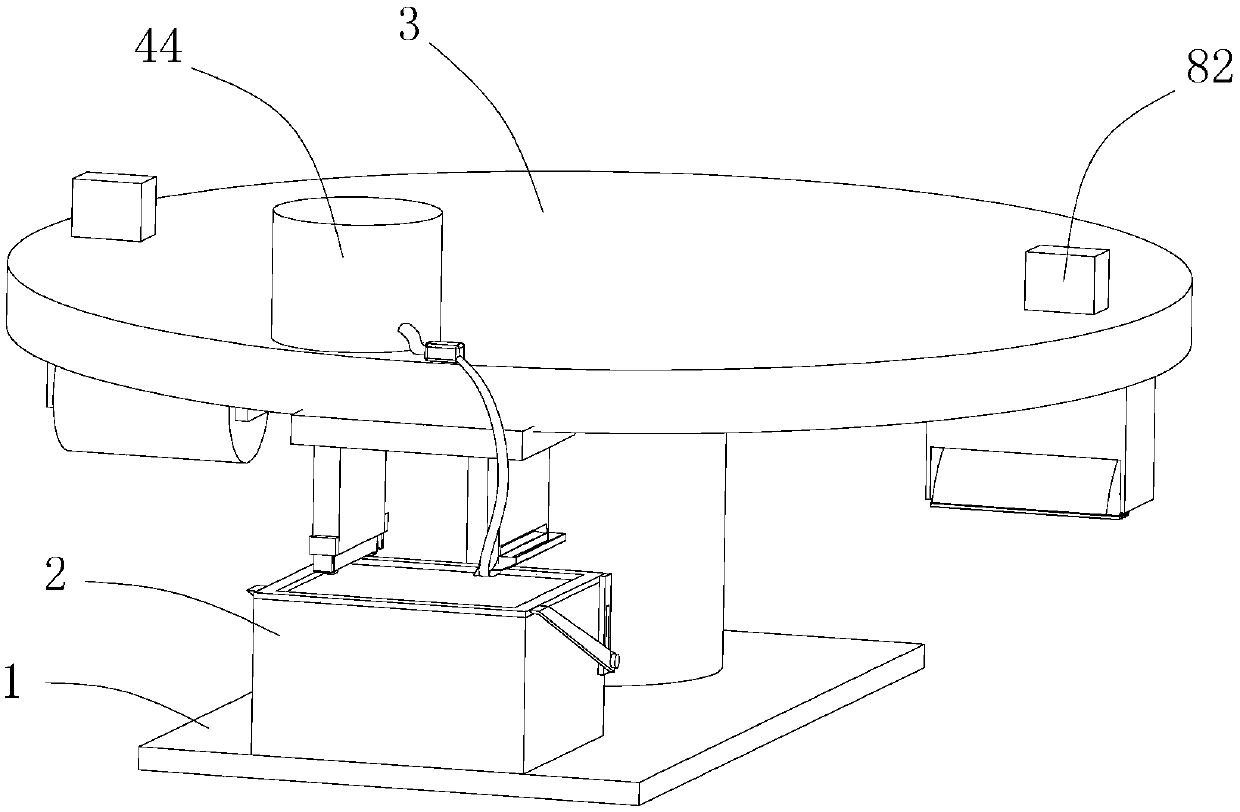

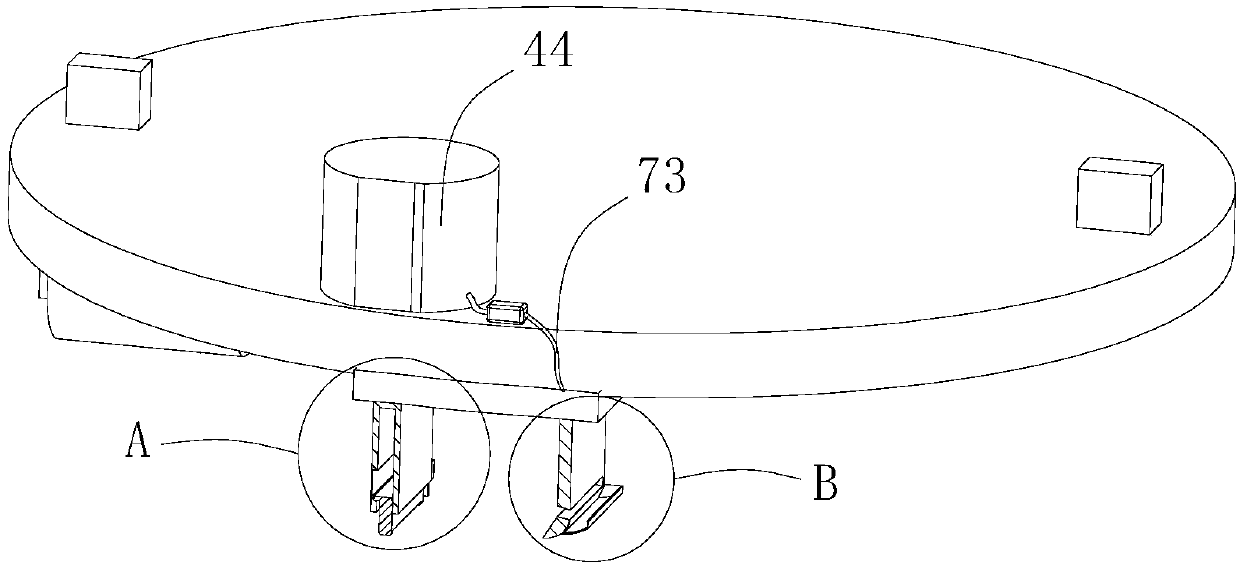

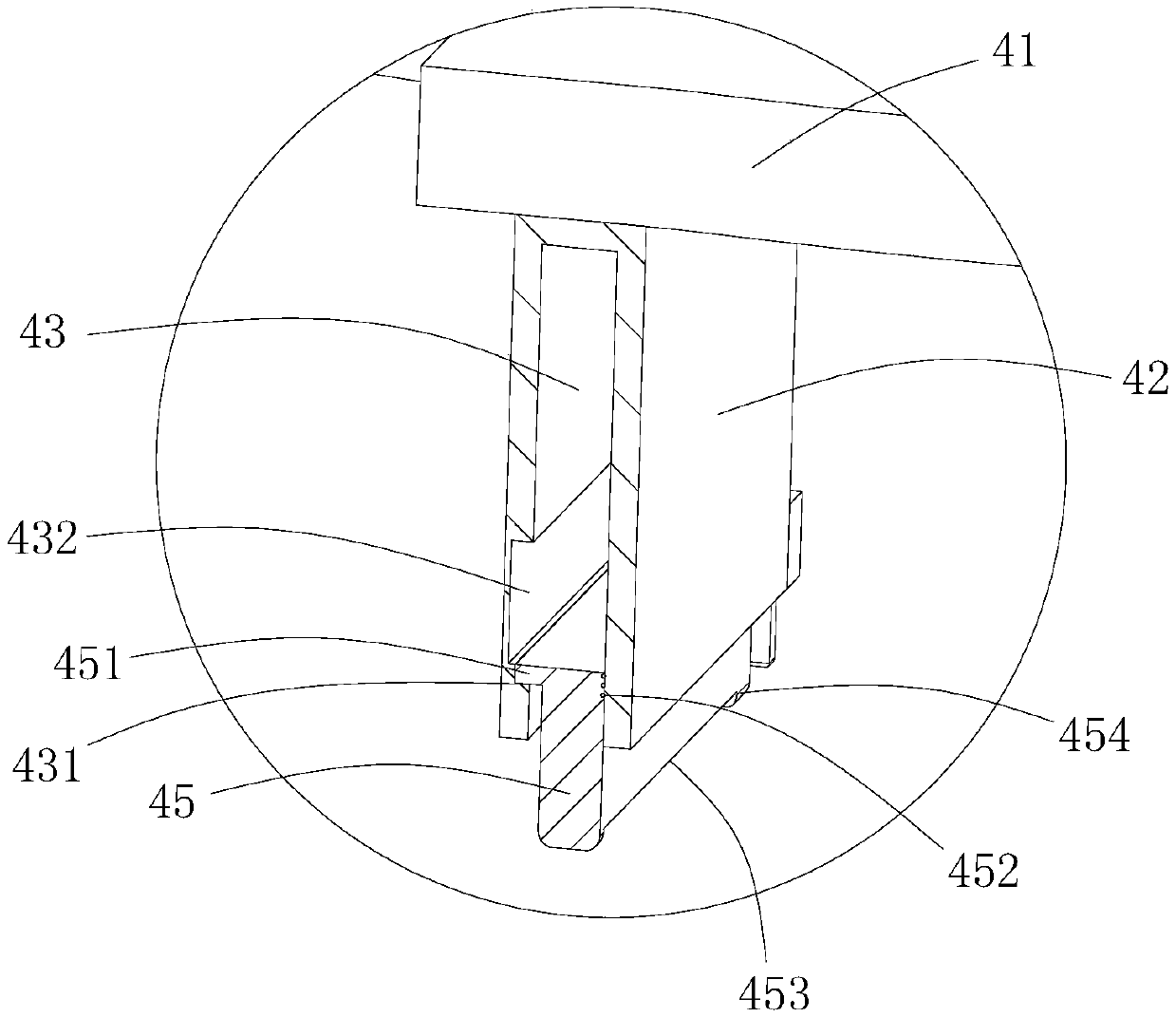

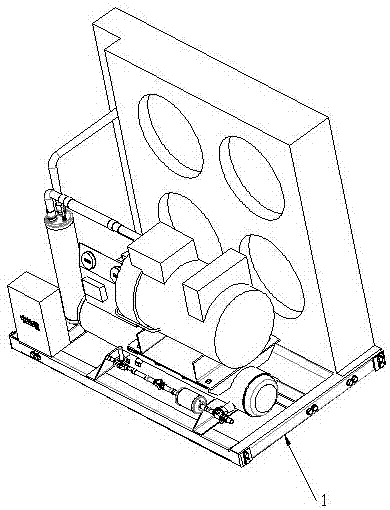

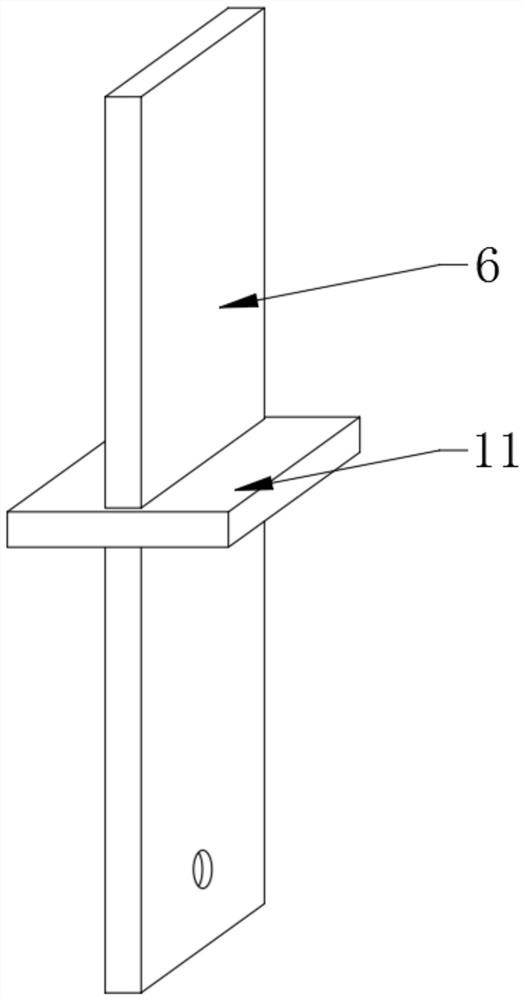

Bamboo joint removing and bamboo outer skin scraping integration machine

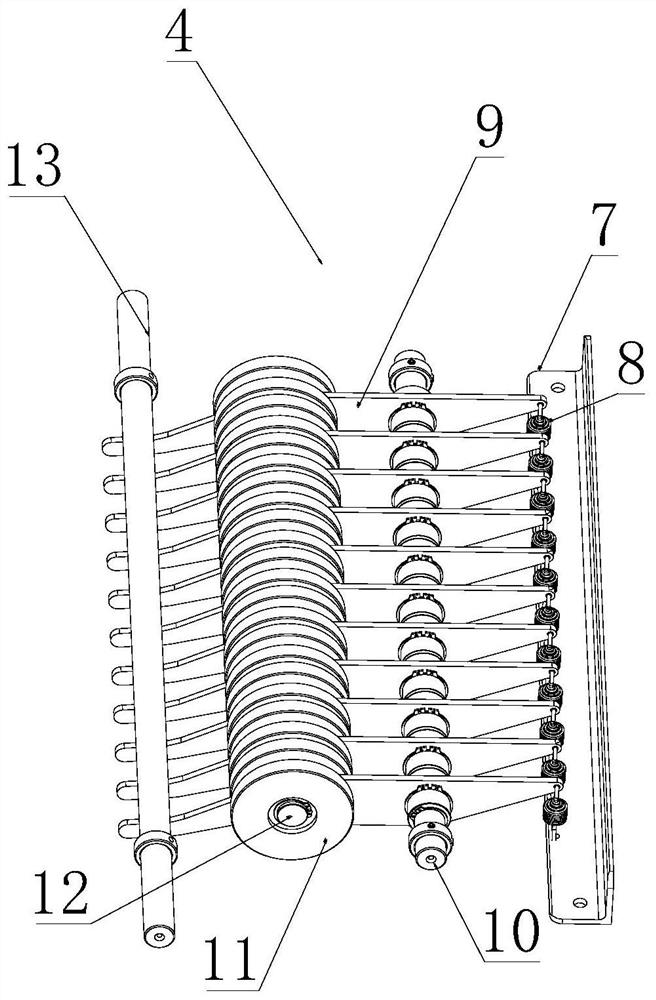

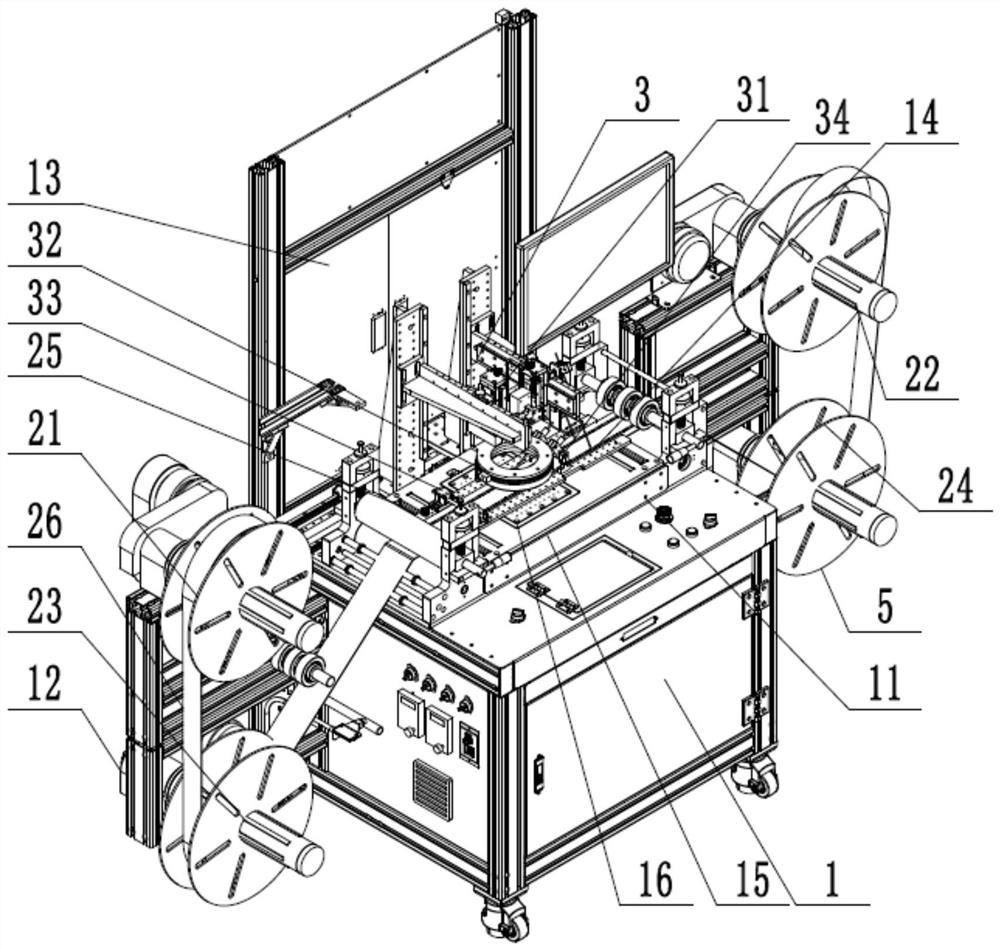

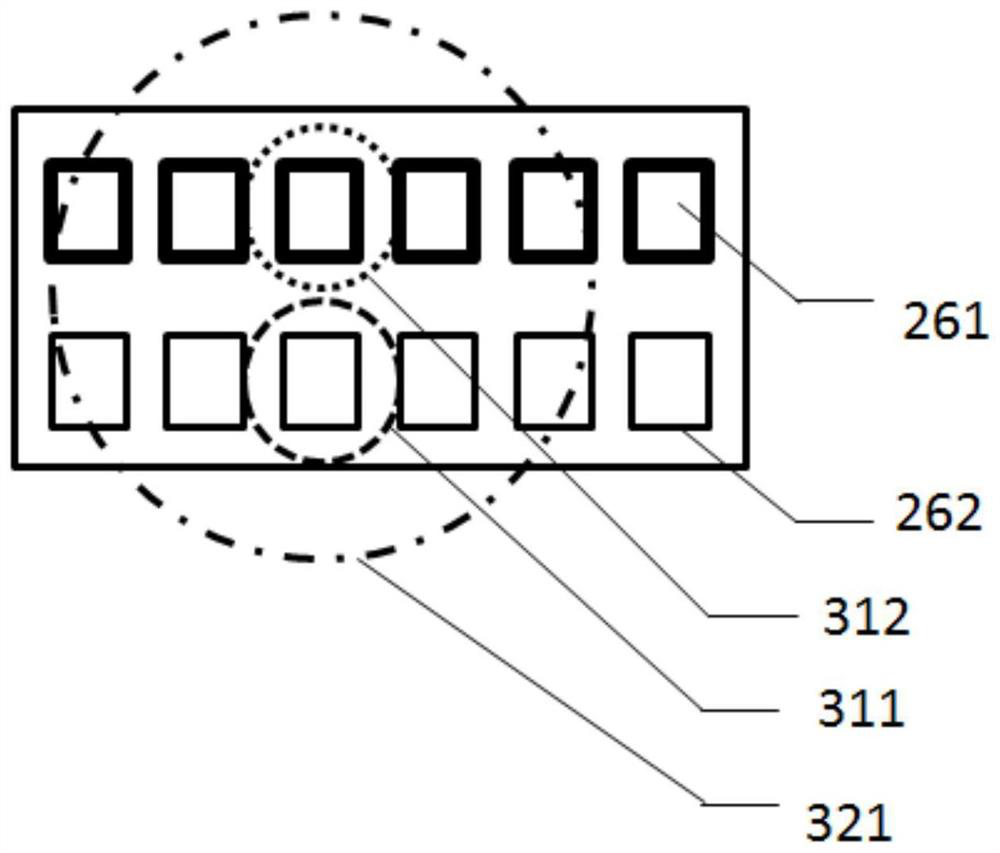

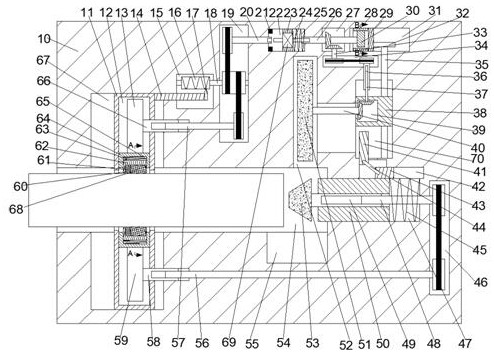

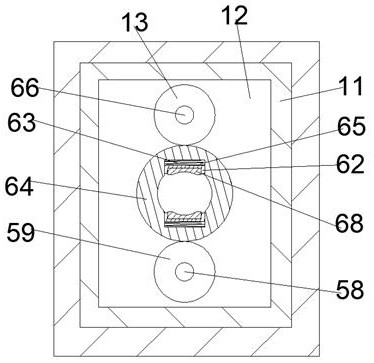

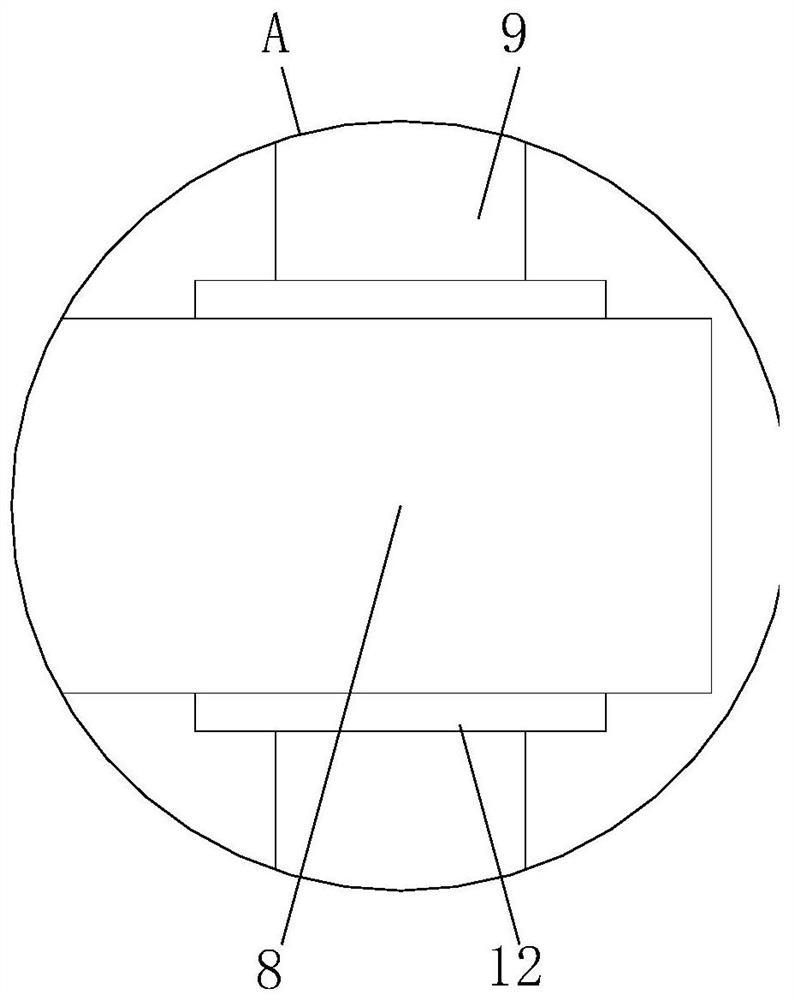

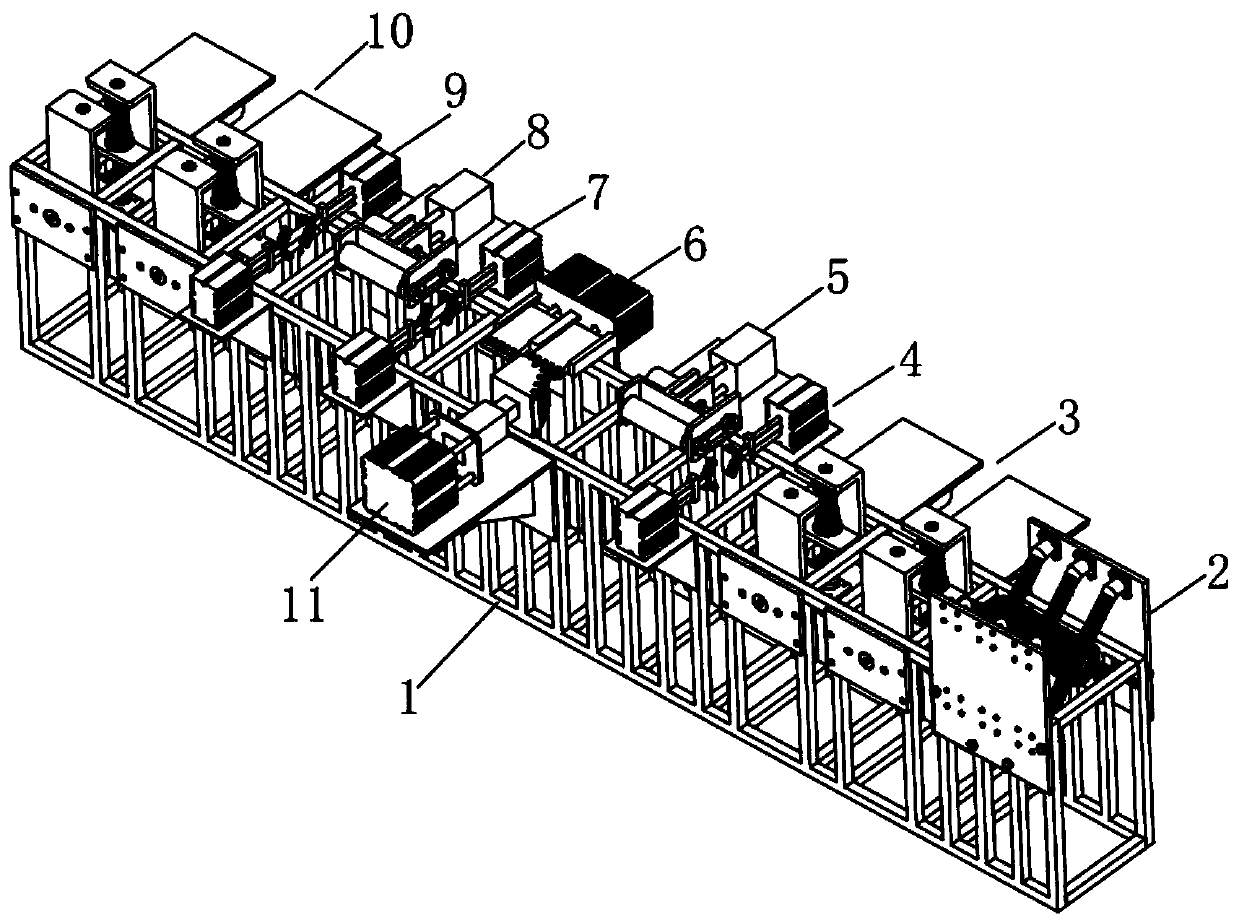

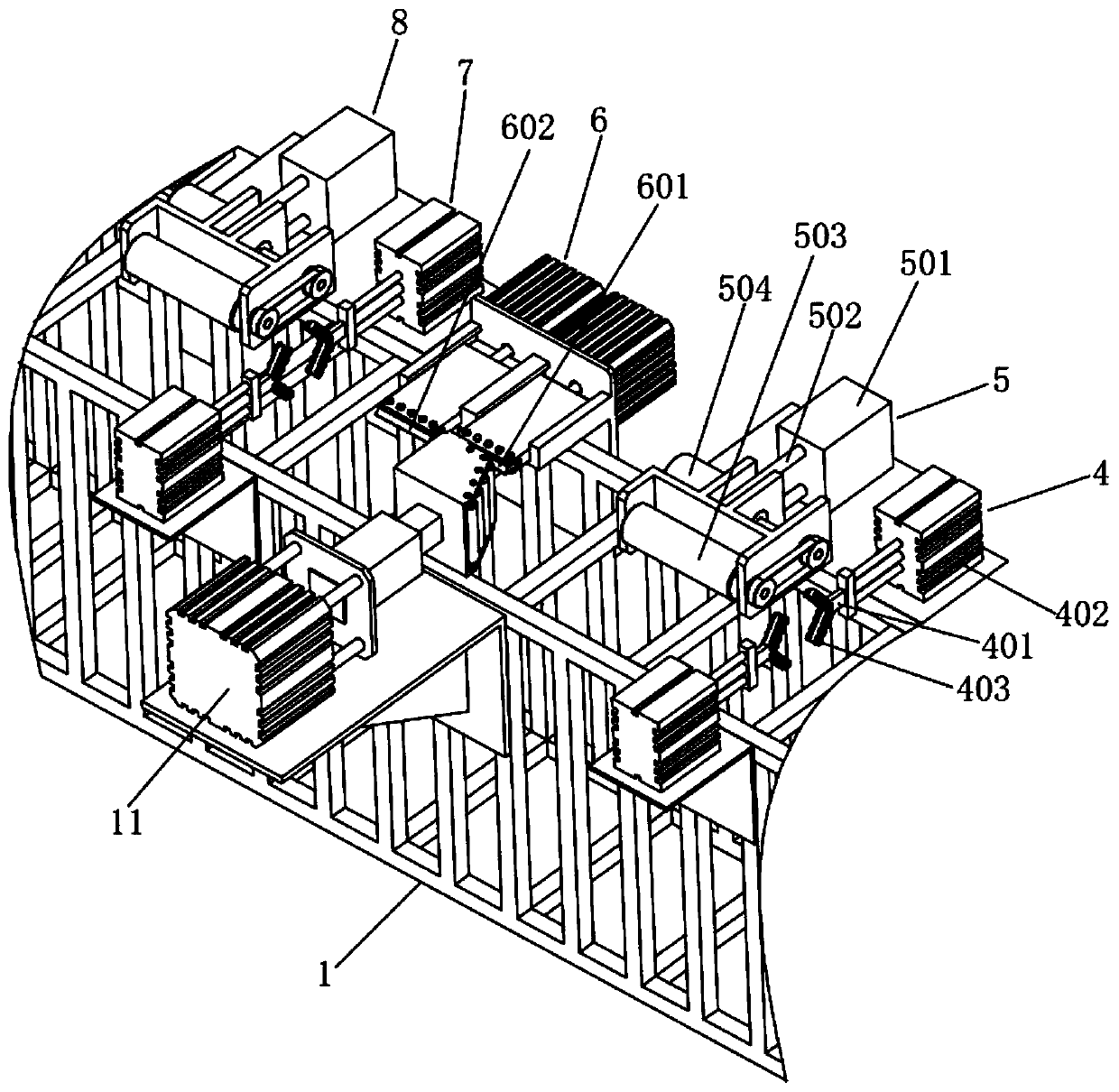

PendingCN107336301AConsistent smoothnessConsistent flatnessCane mechanical workingIrregularity removal devicesIntermittent motionReciprocating motion

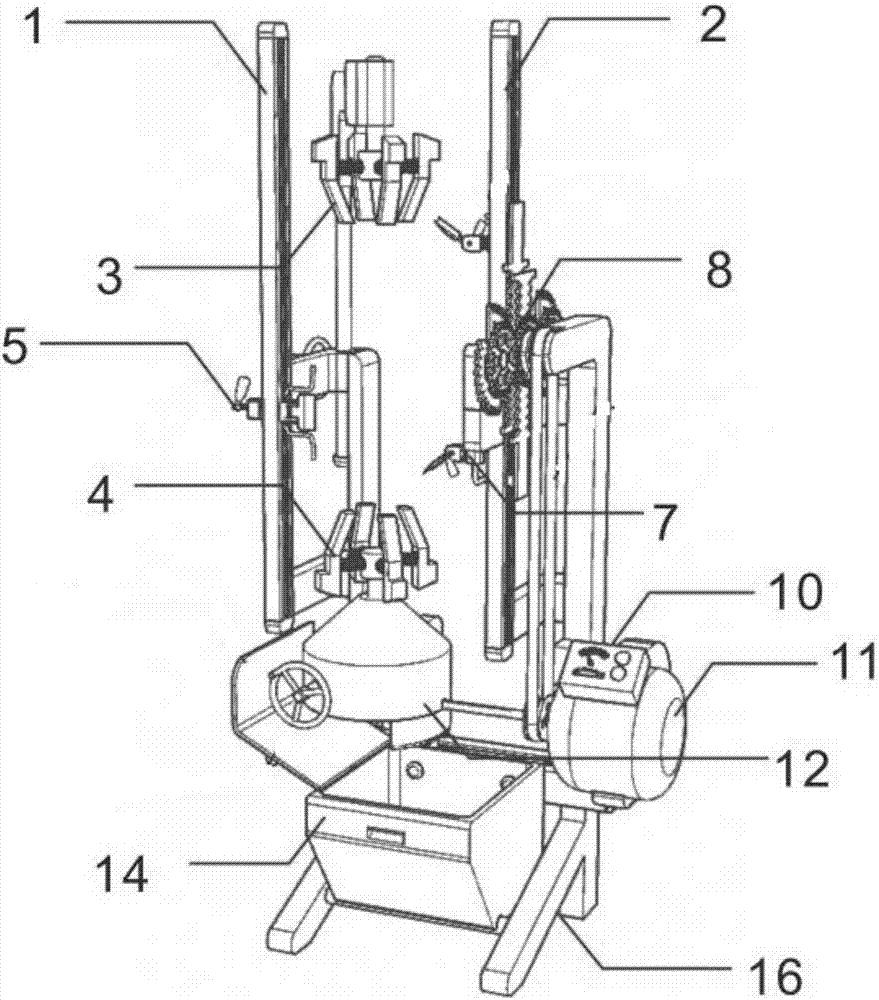

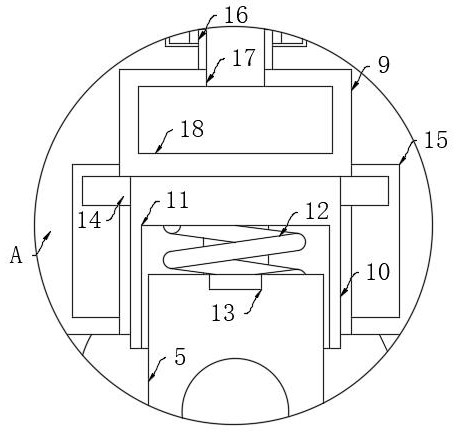

The invention discloses a bamboo joint removing and bamboo outer skin scraping integration machine. The bamboo joint removing and bamboo outer skin scraping integration machine comprises a first fixture, a second fixture, a driving device, a bamboo joint removing assembly, a bamboo outer skin scraping assembly, an intermittent motion mechanism and a linear reciprocating motion mechanism, wherein both the first fixture and the second fixture can rotate and are used for fixing the two ends of bamboo separately; the bamboo joint removing assembly can move in the axial direction of the bamboo so as to align bamboo joints; the driving device drives the second fixture through the intermittent motion mechanism to intermittently rotate by a preset angle; the driving device drives the bamboo outer skin scraping assembly through the linear reciprocating motion mechanism to conduct linear reciprocating motion in the axial direction of the bamboo; the linear reciprocating motion mechanism is matched with the intermittent motion mechanism, so that the bamboo outer skin scraping assembly finishes one-time linear reciprocating motion when the second fixture stops rotating. The technical problems that smoothness and flatness of bamboo surfaces are inconsistent in existing bamboo joint removing and bamboo outer skin scraping methods and two processes of bamboo joint removing and bamboo outer skin scraping cannot be carried out at the same time are solved.

Owner:GUANGDONG UNIV OF TECH

Device for testing heat insulating property of fabrics

Owner:南通大学技术转移中心有限公司

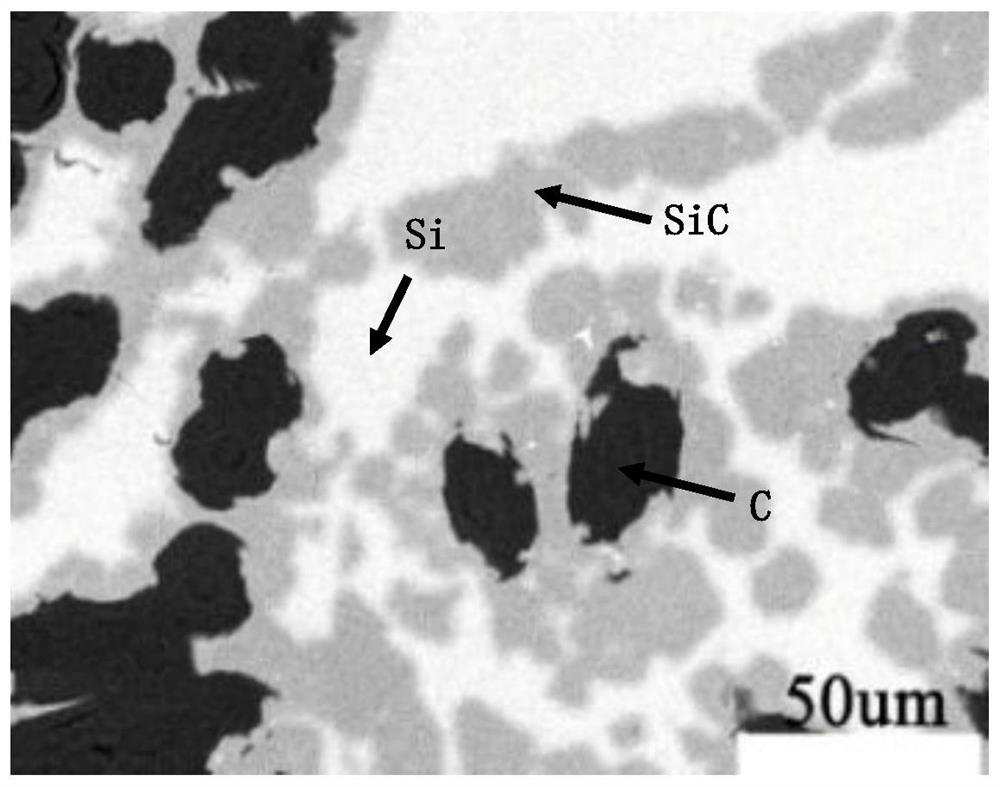

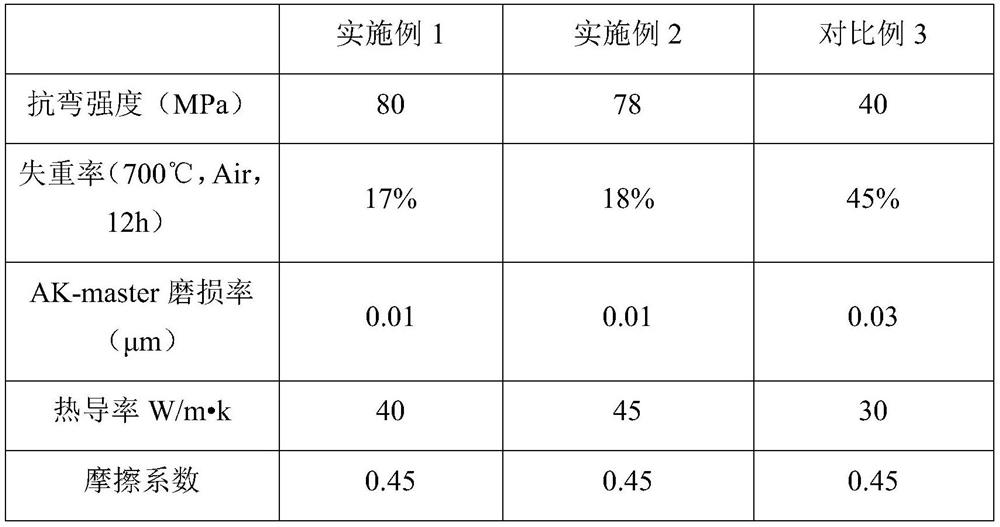

Preparation method of wear-resistant carbon/ceramic brake material

ActiveCN112409008AImprove mechanical propertiesImprove thermal conductivityFriction liningActuatorsCarbon compositesFiber

The invention provides a preparation method of an anti-wear carbon / ceramic brake material. The preparation method comprises the following steps: firstly, preparing a three-dimensional tire net needling prefabricated body by utilizing a short fiber tire net, and then carrying out high-temperature heat treatment, vacuum pressure impregnation in a resin solution, drying, hot-pressing curing and carbonization treatment to obtain a carbonized prefabricated body; then carrying out vacuum pressure impregnation on a phenolic resin solution containing ceramic powder or a furfuryl ketone resin solutioncontaining ceramic powder, carrying out curing and carbonization treatment, and repeating the above steps to prepare a carbon-carbon composite material with the density of 1.01.7 g / cm<3>; and finally,carrying out high-temperature heat treatment and siliconizing treatment to obtain the wear-resistant carbon / ceramic brake material with the density of 1.9 g / cm<3>-3.0g / cm<3>. According to the preparation method disclosed by the invention, on the basis of ensuring the mechanical properties and the thermal physical properties of the obtained material, the production period of the carbon / ceramic brake material is shortened, the wear resistance and the oxidation resistance of the material are improved, and the purposes of reducing the production cost and improving the brake performance are achieved.

Owner:山东道普安制动材料有限公司

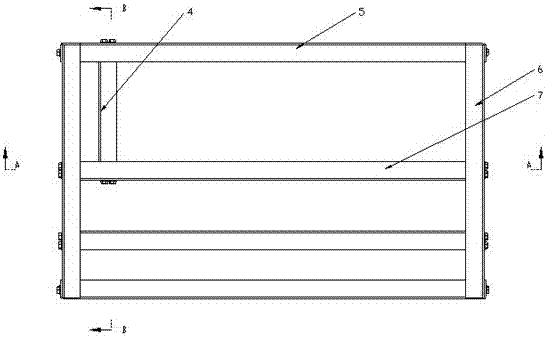

Heat-insulation performance testing device of heat-insulation coating for textile

ActiveCN102507645ASame effective areaConsistent flatnessMaterial heat developmentSoftware engineering

The invention discloses a heat-insulation performance testing device of a heat-insulation coating for a textile, and the heat-insulation performance testing device disclosed by the invention comprises a heat insulation box and a textile tensioning device which is placed in the heat insulation box in a testing process. The heat-insulation performance testing device provided by the invention has the advantages of reasonable structure, convenience in installation and reliable test result.

Owner:南通大学技术转移中心有限公司

Paint-spraying-free repair process for moderate and severe scratches of automobile

InactiveCN110293041AAvoid secondary damageCause secondary damagePretreated surfacesCoatingsFine lineEngineering

The invention provides a paint-spraying-free repair process for moderate and severe scratches of an automobile. Only a scratched part is grinded in the foundation grinding process, so that secondary damage to automobile paint in the foundation grinding process is avoided; before point compensation, the automobile paint is mixed to obtain the uniformly mixed automobile paint, and only the mixed automobile paint is used for point compensation in the point compensation process, so that the phenomena of exposed fine lines, bubbles and layering of inner layers caused by the multiple layers of automobile paint with different textures are avoided; in the process of point compensation, a method that the paint surface is 0.5-1 mm higher than the original vehicle paint surface after a plurality of times of point compensation is adopted, and then a mode of combining scraping, grinding and polishing is carried out to gradually remove the redundant vehicle paint. Through the repair in the process,the automobile scratches are effectively repaired, the scratches are flat and free of grooves after the repair, and the periphery of the scratches is free of chromatic aberration, no water-free sand marks, no aperture and no glare from the original automobile paint.

Owner:张锡泰

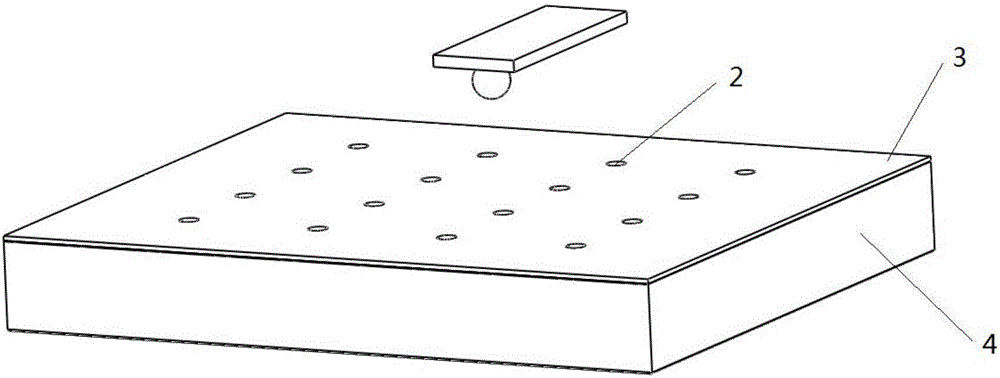

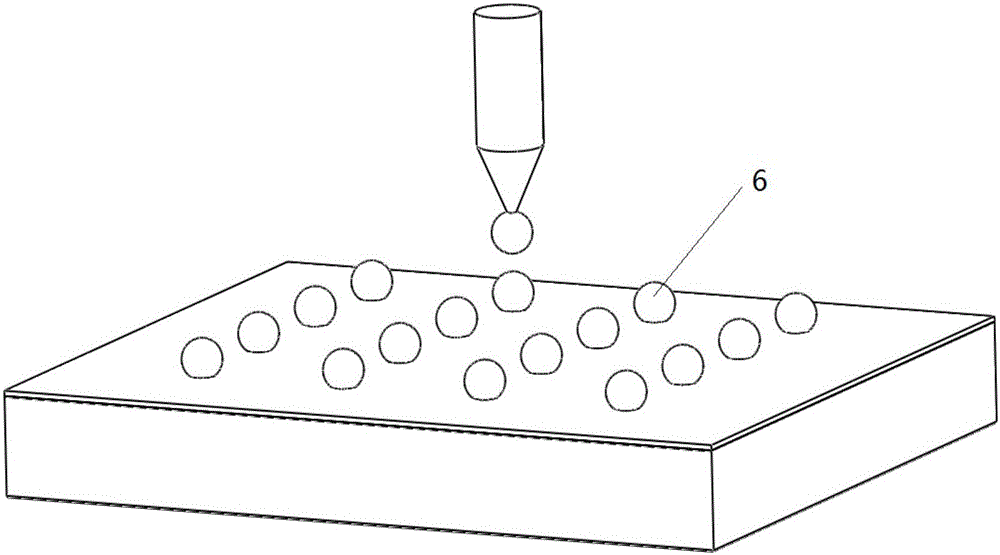

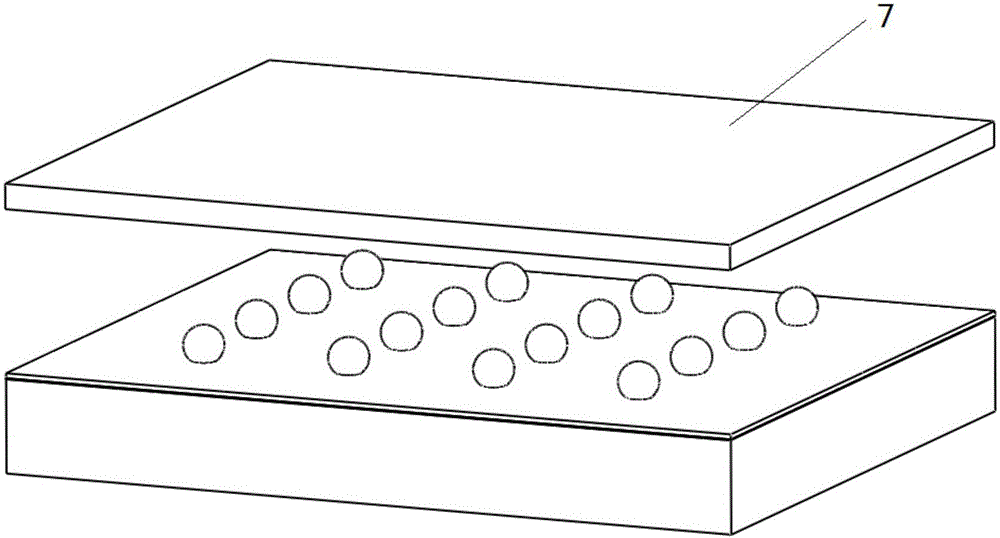

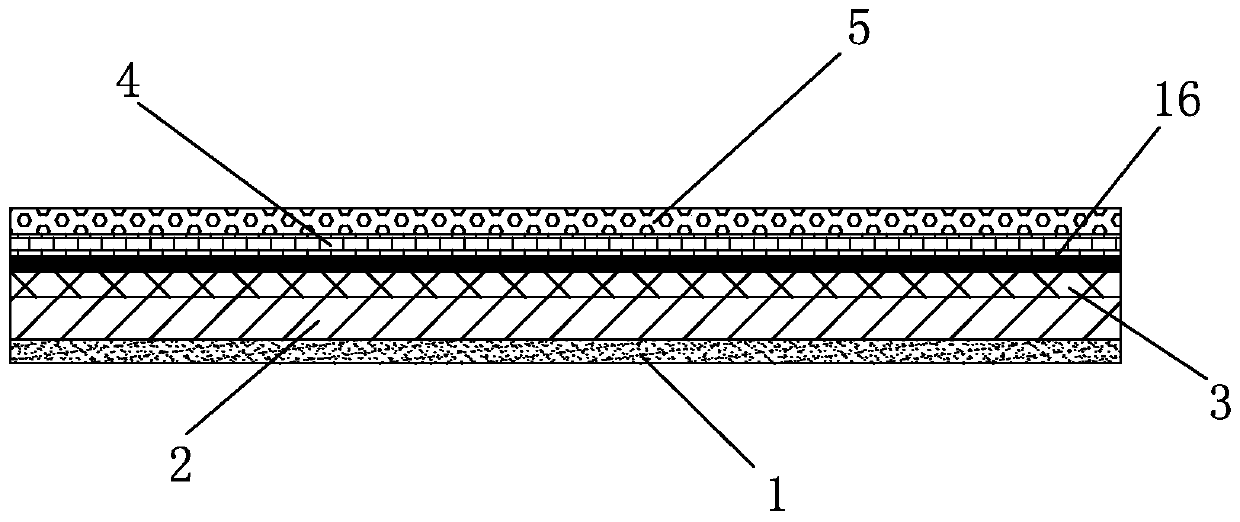

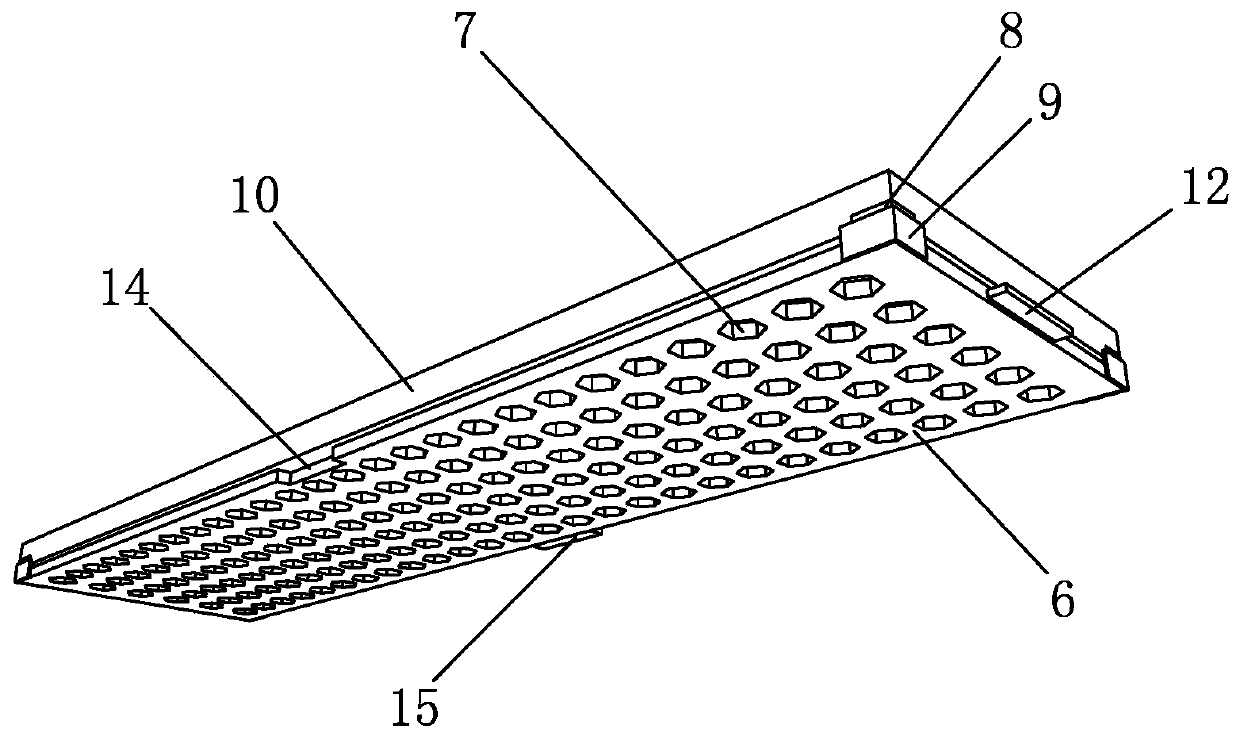

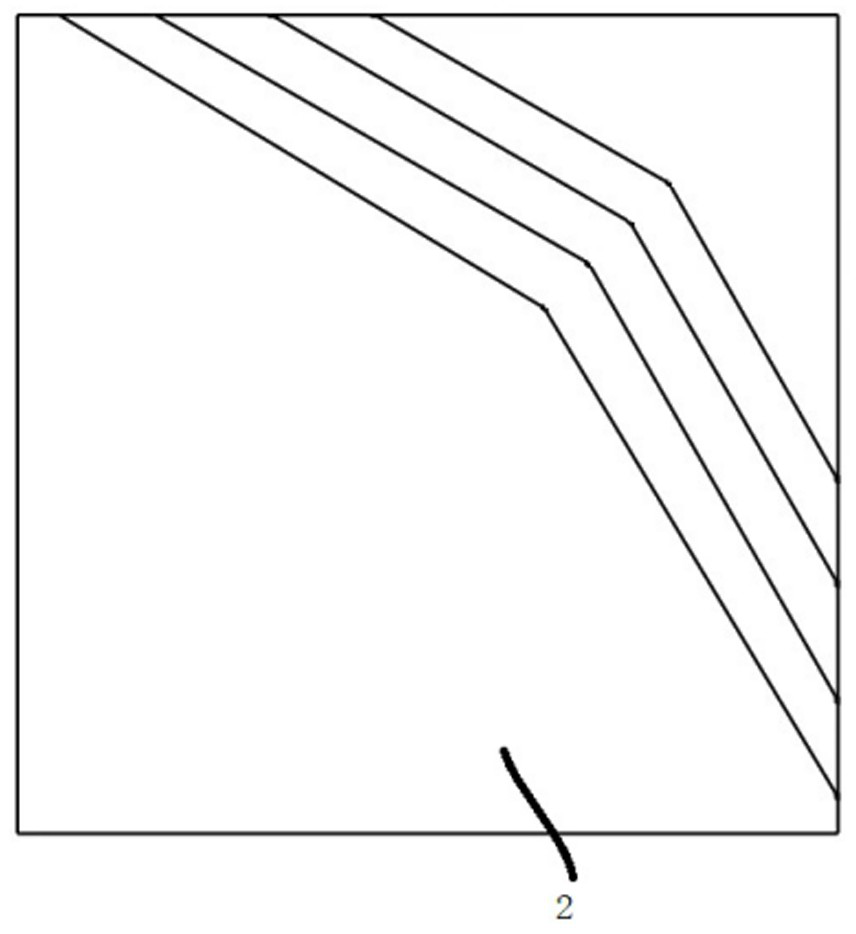

Preparation method of planeness-self-compensating multi-tip array for large area micromachining

ActiveCN105858595AAvoid height inconsistenciesHighly consistentPrecision positioning equipmentSoldering apparatusWaxMicrosphere

The invention discloses a preparation method of planeness-self-compensating multi-tip array for large area micromachining, comprising the following steps: plating a layer of wax sheet film (3) on a glass slide (4), and forming uniformly arranged grooves (2) on the wax sheet film (3); adding microspheres (6) into each groove (2) one by one, further pressing the microspheres (6) into the wax sheet film through a slide (7) to make all the microspheres (6) contact the glass slide (4); adhering an elastic material sheet (10) on a flat tip plate (8), and further applying a layer of UV gel (11); flat pressing the UV gel of the tip plate (8) on the microspheres (6), simultaneously carrying out ultraviolet radiation on the UV gel, thereby solidifying the UV gel, and adhering the microspheres (6) on the tip plate (8); and finally, melting the wax sheet film, taking the glass slide (4) away, washing away the residual wax on the surface of the microspheres (6), thereby obtaining the multi-tip array. With the method provided by the invention, the obtained mutli-tip array has good planeness, and height of each tip is consistent; and preparation of the multi-tip array is simple, low-cost and easy to carry out.

Owner:SOUTHWEST JIAOTONG UNIV

Anti-seepage structure for balcony and construction method of anti-seepage structure

InactiveCN110005049AStable structureNot easy to deform and misplaceBalconiesBuilding insulationsEngineeringProtection layer

The invention discloses an anti-seepage structure for a balcony. The anti-seepage structure comprises a waterproof coating layer, a coiled material waterproof layer, an anti-seepage film layer and a protecting layer, the protecting layer comprises a supporting plate layer and a ceramic tile layer which are arranged from bottom to top, the supporting plate layer is formed by supporting plates in anassembled mode, clamping blocks are arranged on the corners around the top face of each supporting plate correspondingly, the ceramic tile layer is formed by ceramic tiles in an assembled mode, clamping grooves are formed in the corners around the bottom face of each ceramic tile correspondingly, and the clamping blocks and the clamping grooves are matched. A construction method comprises the following steps of (1) base layer treatment, (2) treatment of the waterproof coating layer, (3) laying of the coiled material waterproof layer, (4) layering of the anti-seepage film layer and (5) layingof the protecting layer. The anti-seepage structure for the balcony is ingenious and reasonable in overall structural design, through the anti-seepage structure, the anti-seepage effect of the balconycan be improved effectively, the protecting layer is divided into the supporting plate layer and the ceramic layer, the waterproof effect of the balcony can be further improved under the situation ofensuring the surface attractive degree of the balcony, and the upper ceramic tile layer can also be conveniently laid through the supporting plate layer.

Owner:ZHEJIANG COLLEGE OF CONSTR

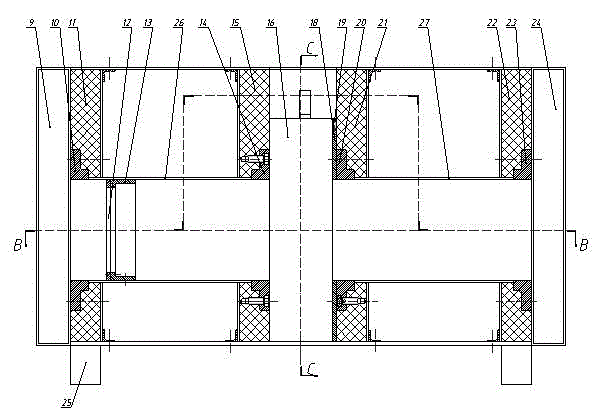

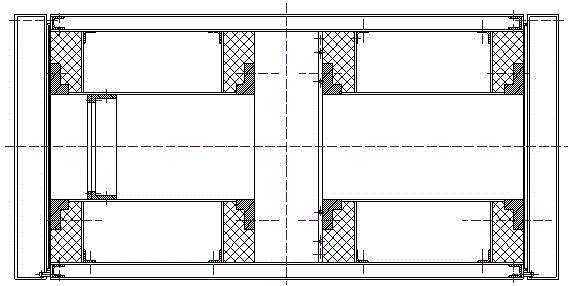

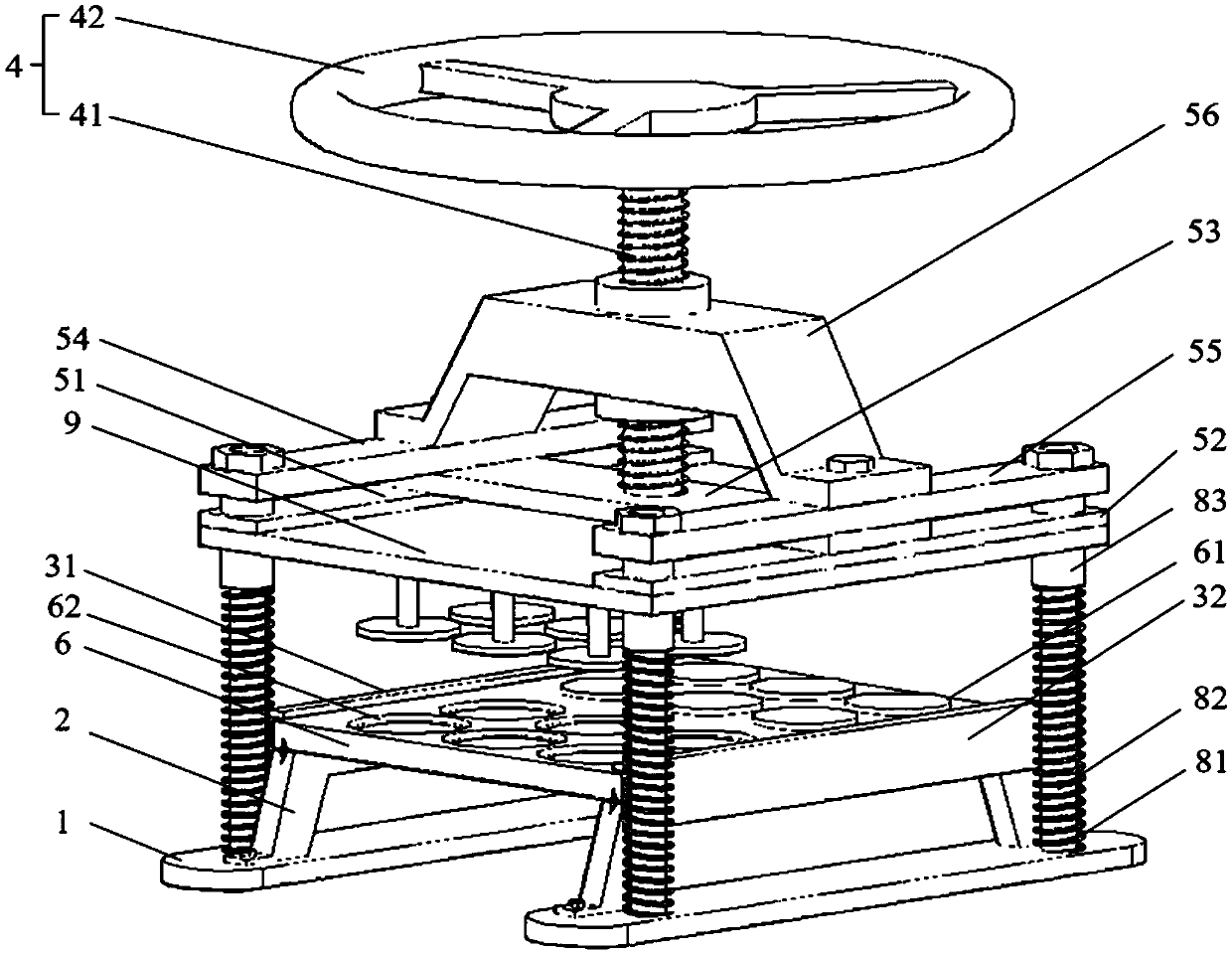

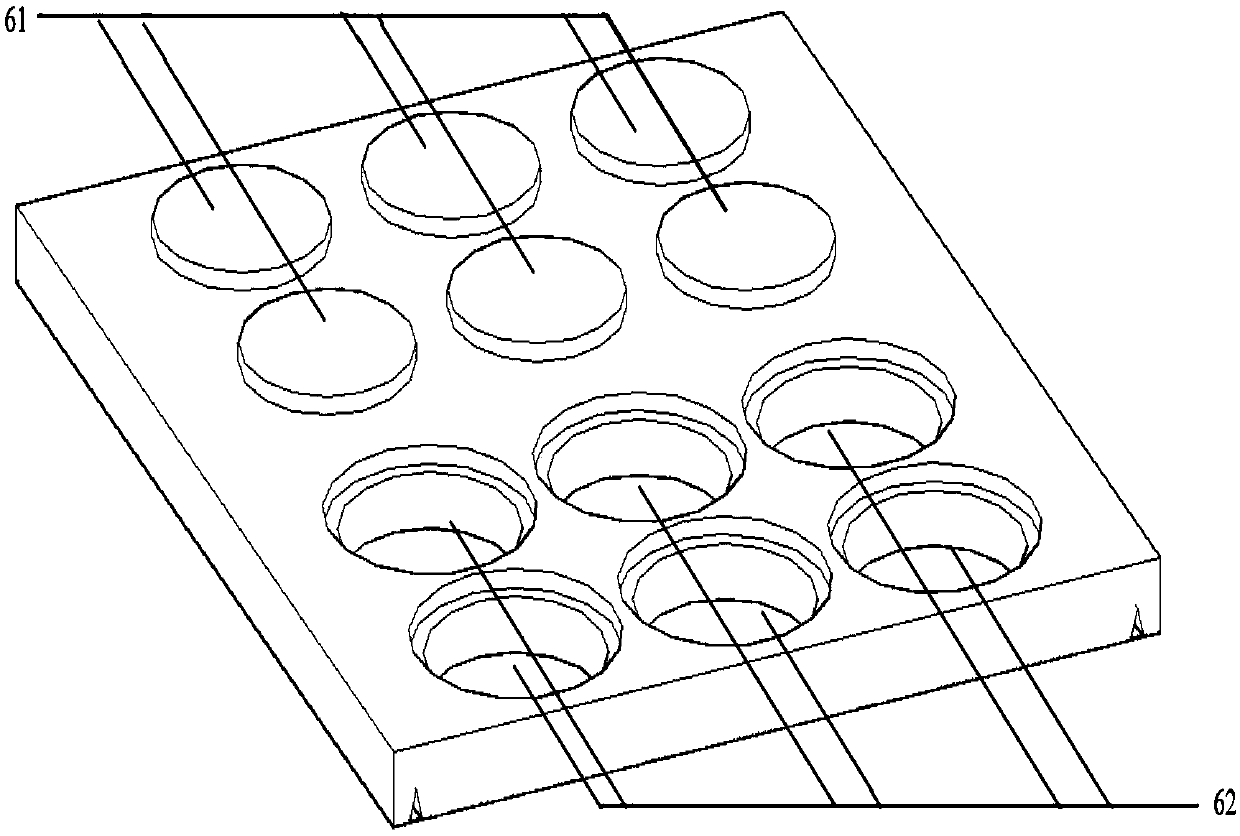

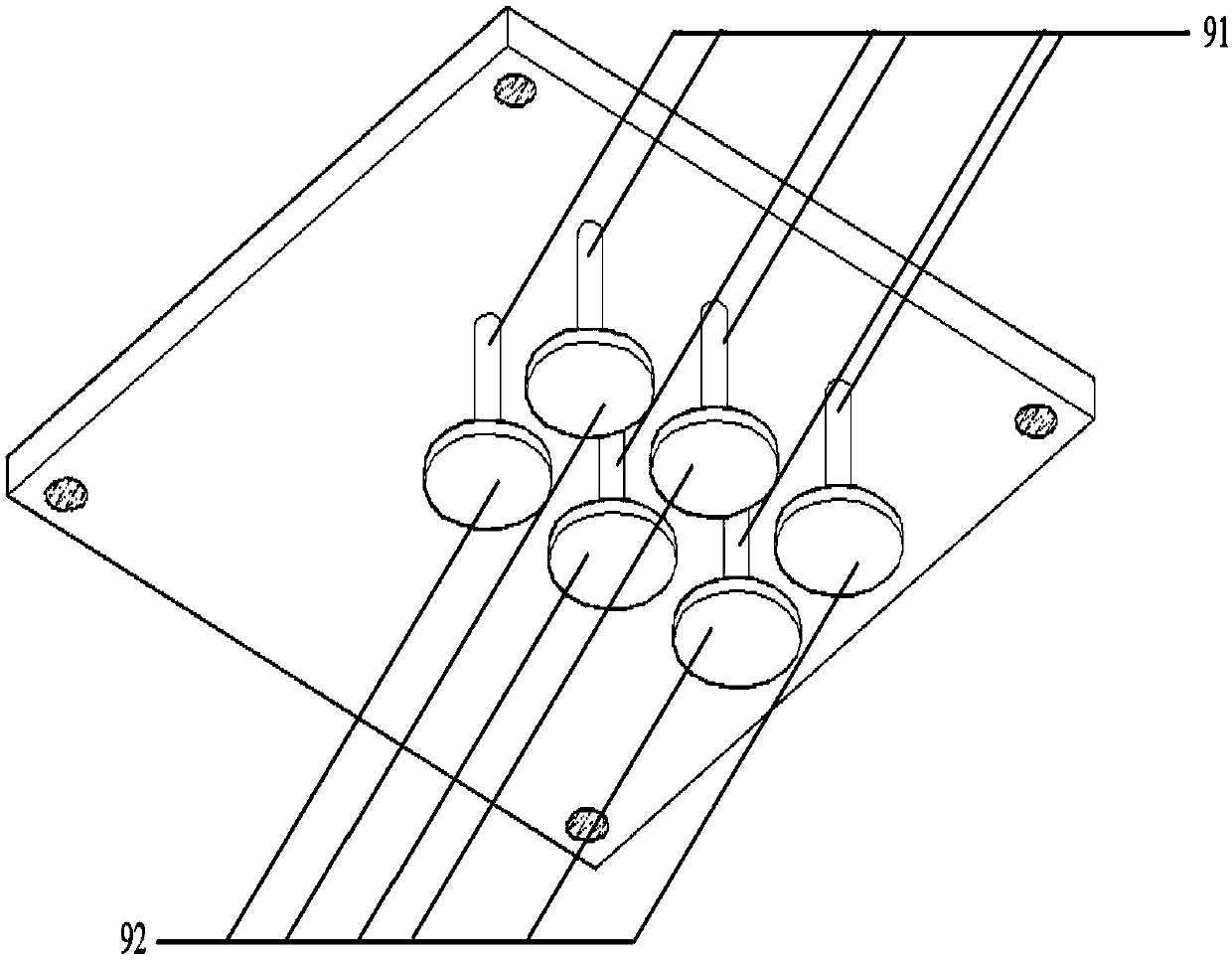

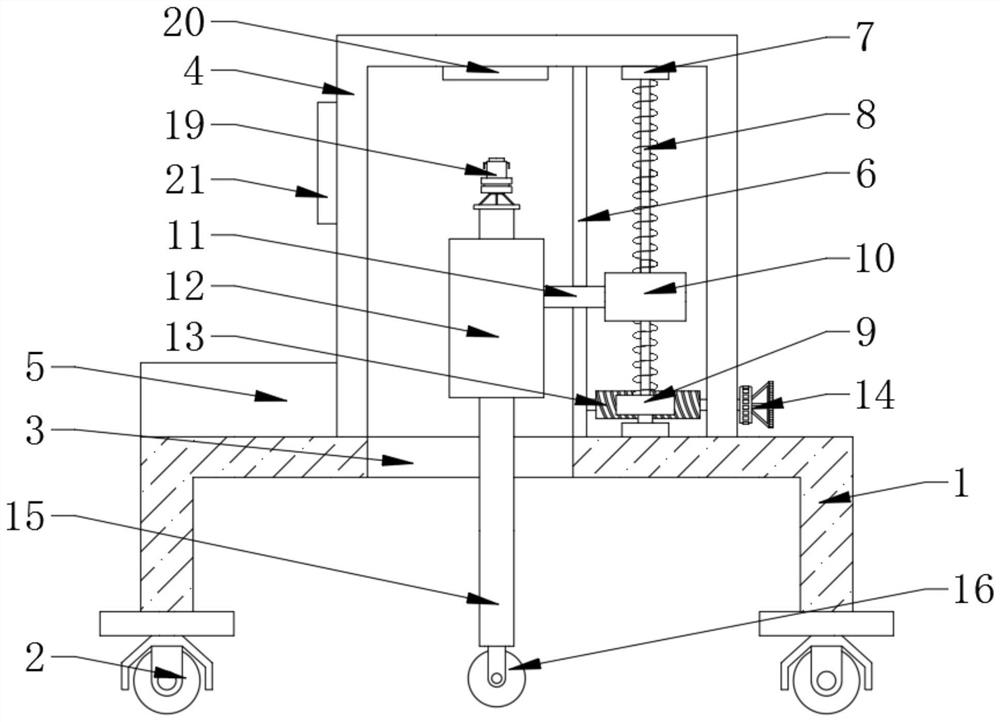

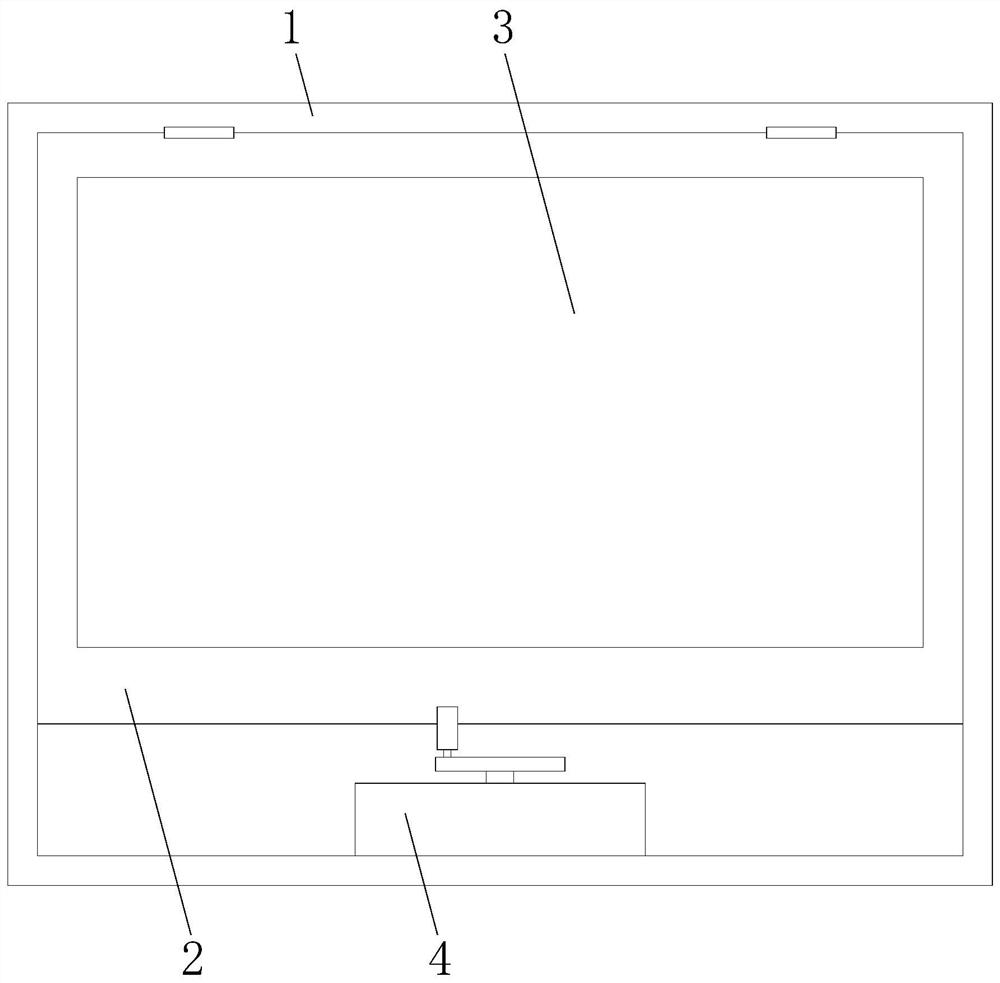

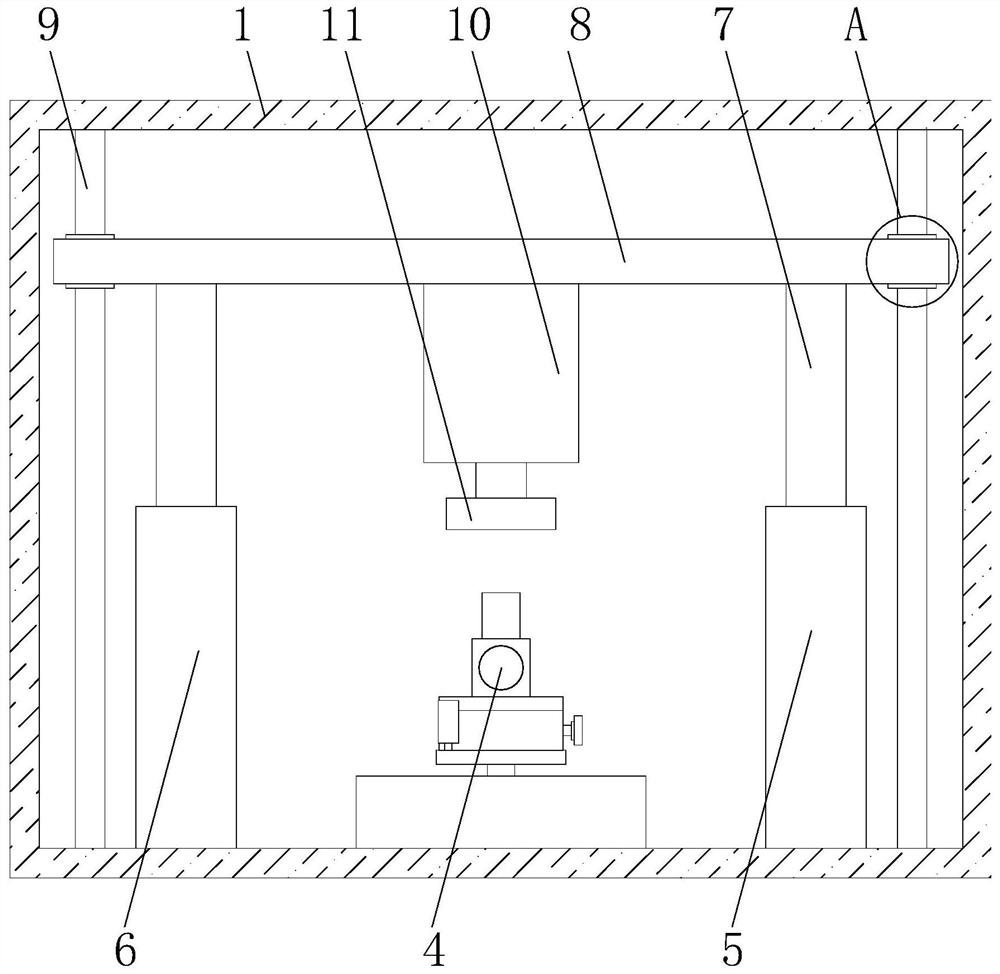

Soil post sample making machine

ActiveCN109668769AEven by forceEliminate the step of desamplingPreparing sample for investigationPunchingEngineering

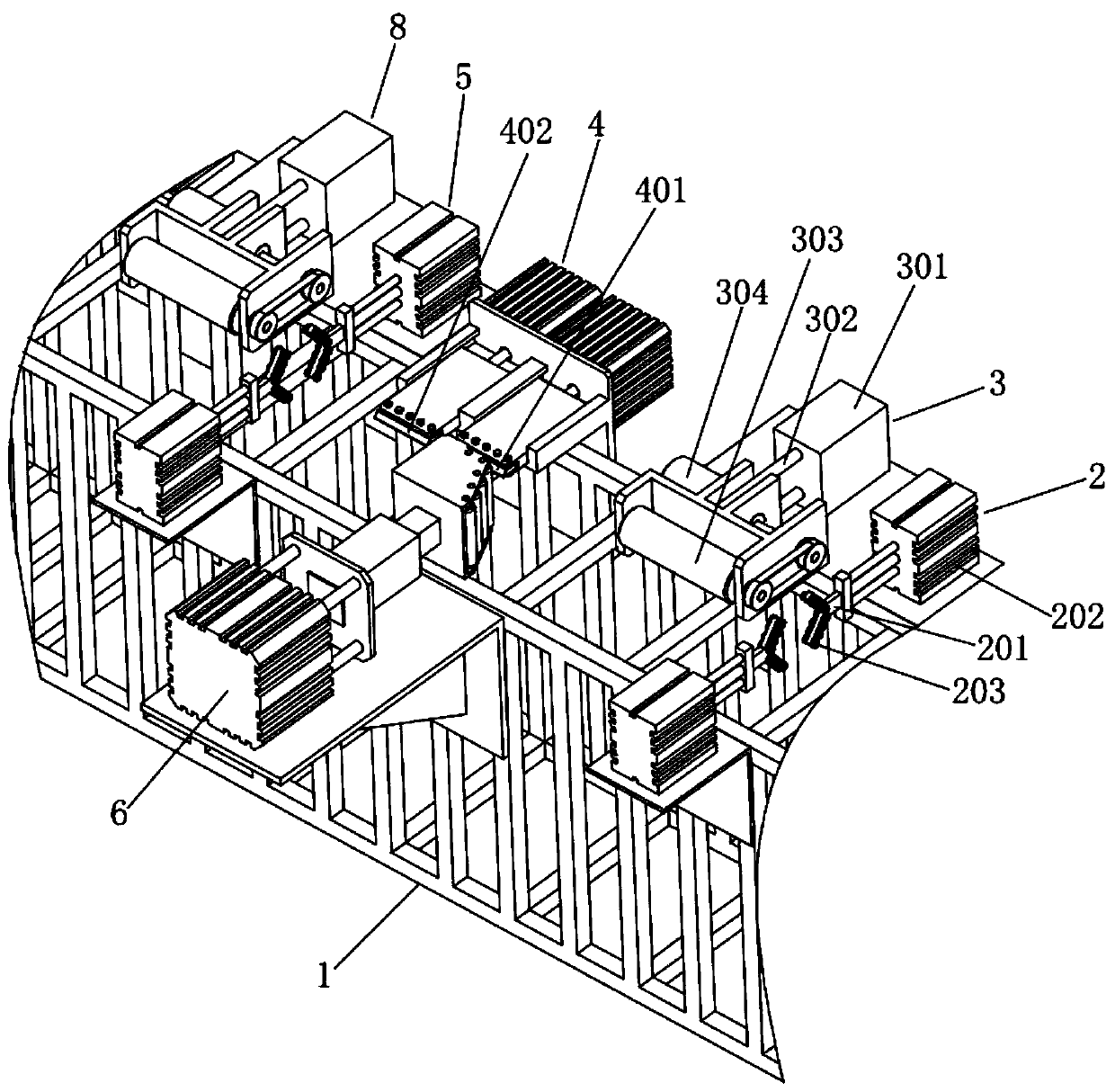

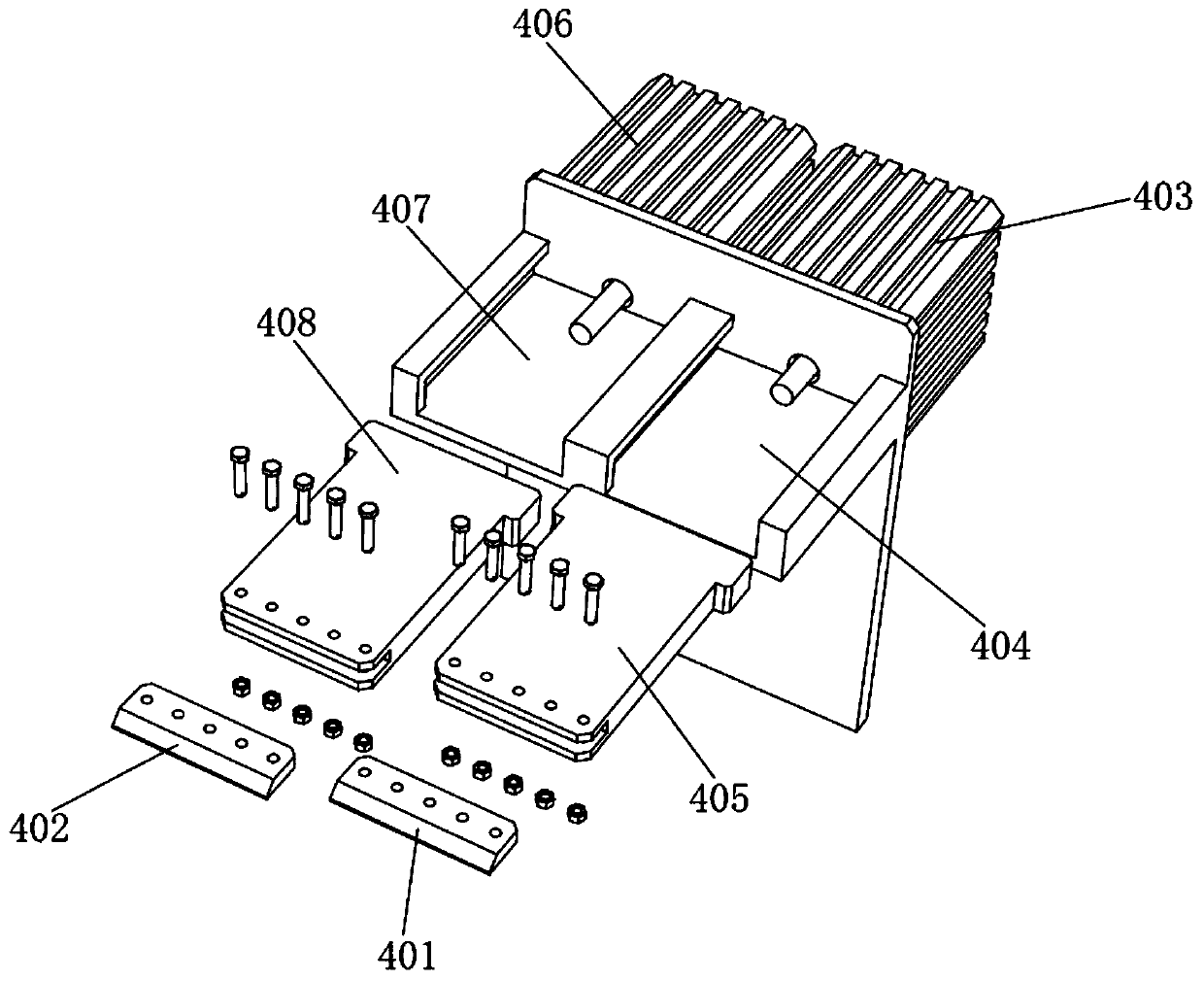

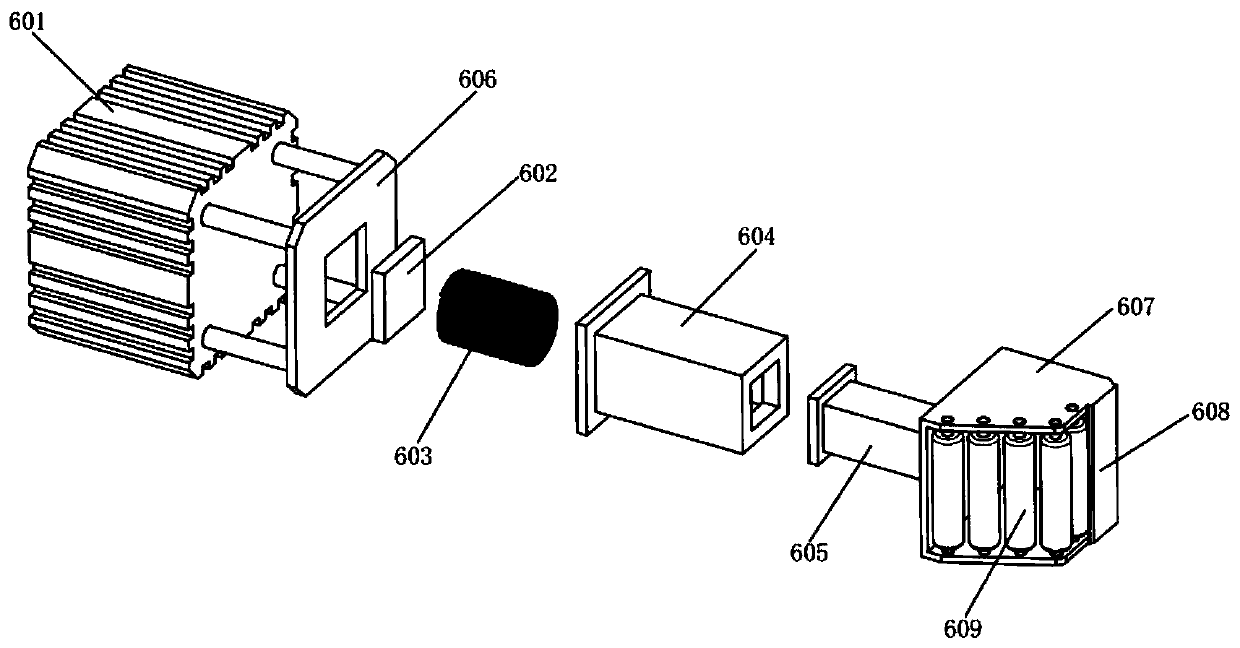

The invention belongs to the field of geotechnical tests, and discloses a soil post sample making machine. The soil post sample making machine comprises a base, a base table frame, a position limitingassembly, a driving assembly, a supporting support frame, a punching plate, a mold plate, a spring, a sample making tube and a pad block, wherein the base table frame is welded at the upper end of the base; the upper end of the supporting support frame supports the driving assembly; the driving assembly drives the punching plate to vertically slide; the mold plate horizontally slides between thebase table frame; the sample making tube is put on the mold plate; the pad block is arranged at the upper side of the sample making tube; the position limiting assembly is fixedly arranged on the basetable frame; the lower end of the spring is abutted and connected with the base. The structure is simple; the operation is convenient; precision and high efficiency are realized; in the sample makingprocess, the soil post stress is uniform; the manufactured soil posts have basically identical height, flatness and dry density; the quality of the manufactured soil posts can meet the test teachingrequirements of scientific research and college and university geotechnical tests; the manufacturing efficiency of the soil posts is greatly improved; a great amount of labor is saved.

Owner:CENT SOUTH UNIV

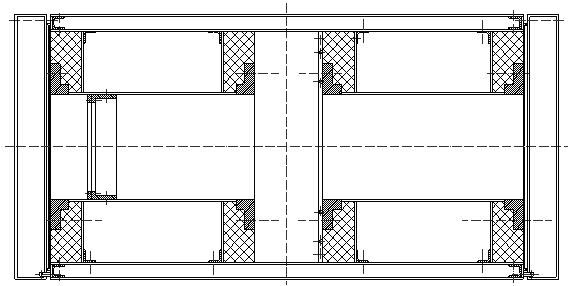

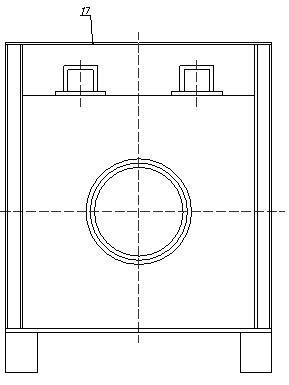

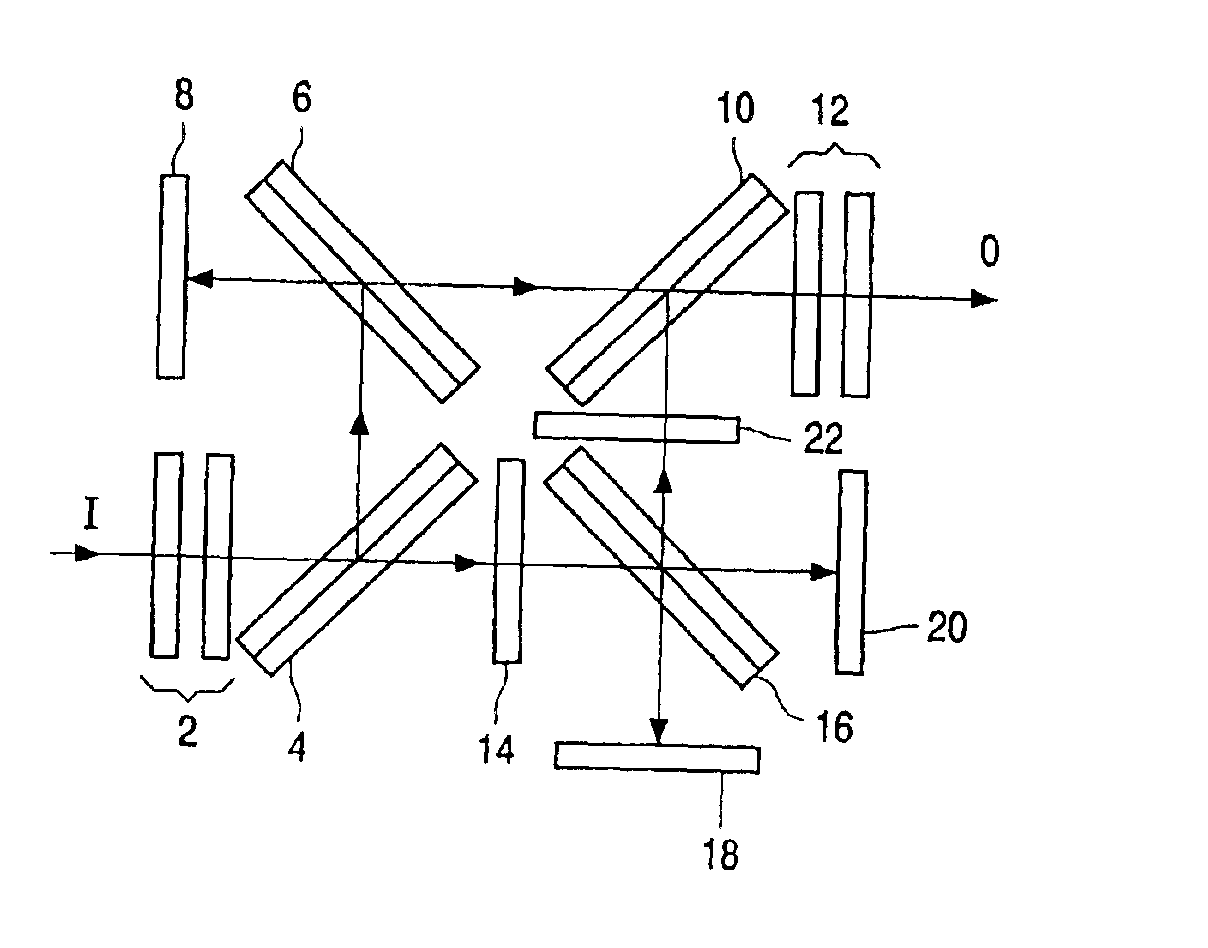

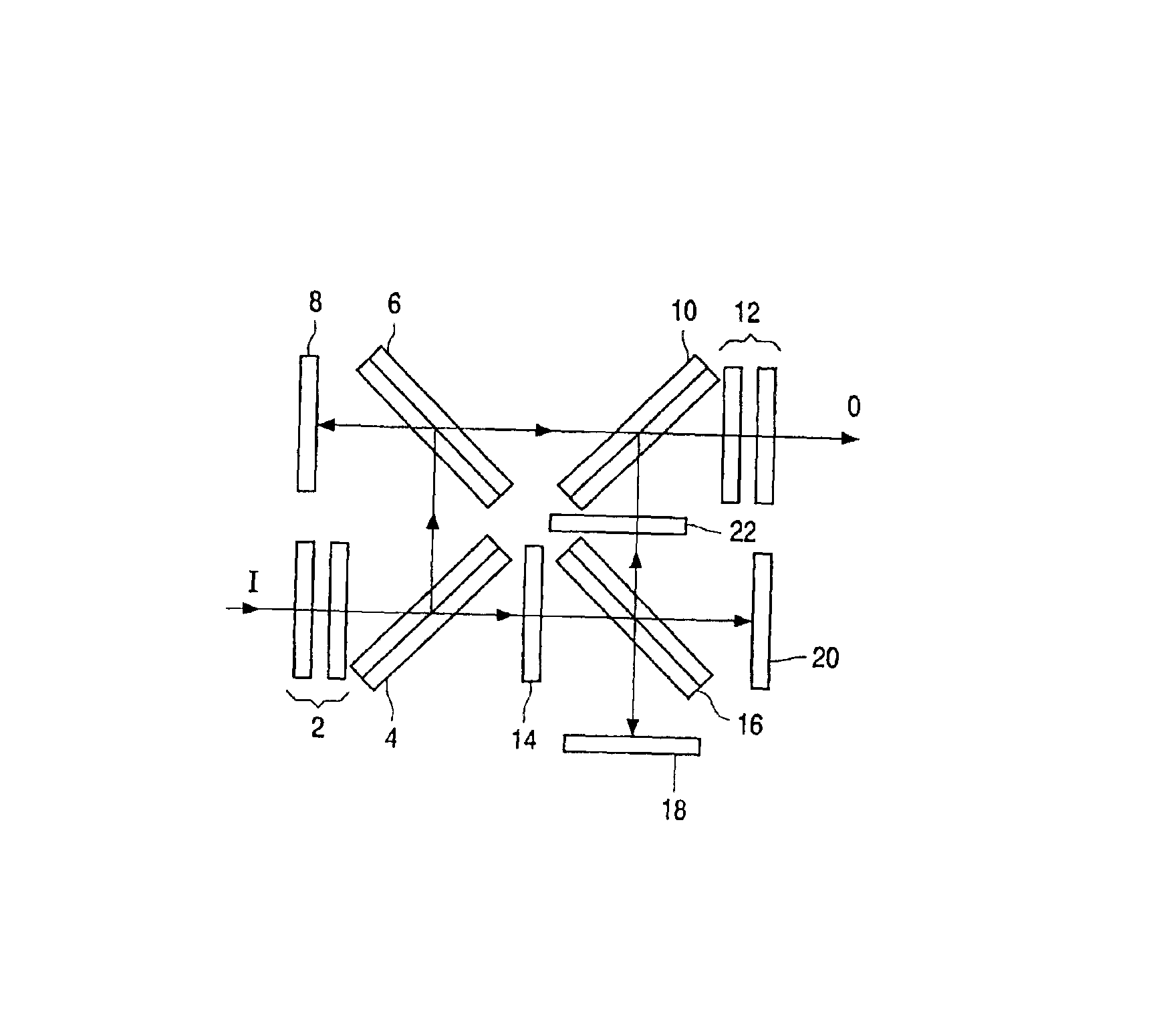

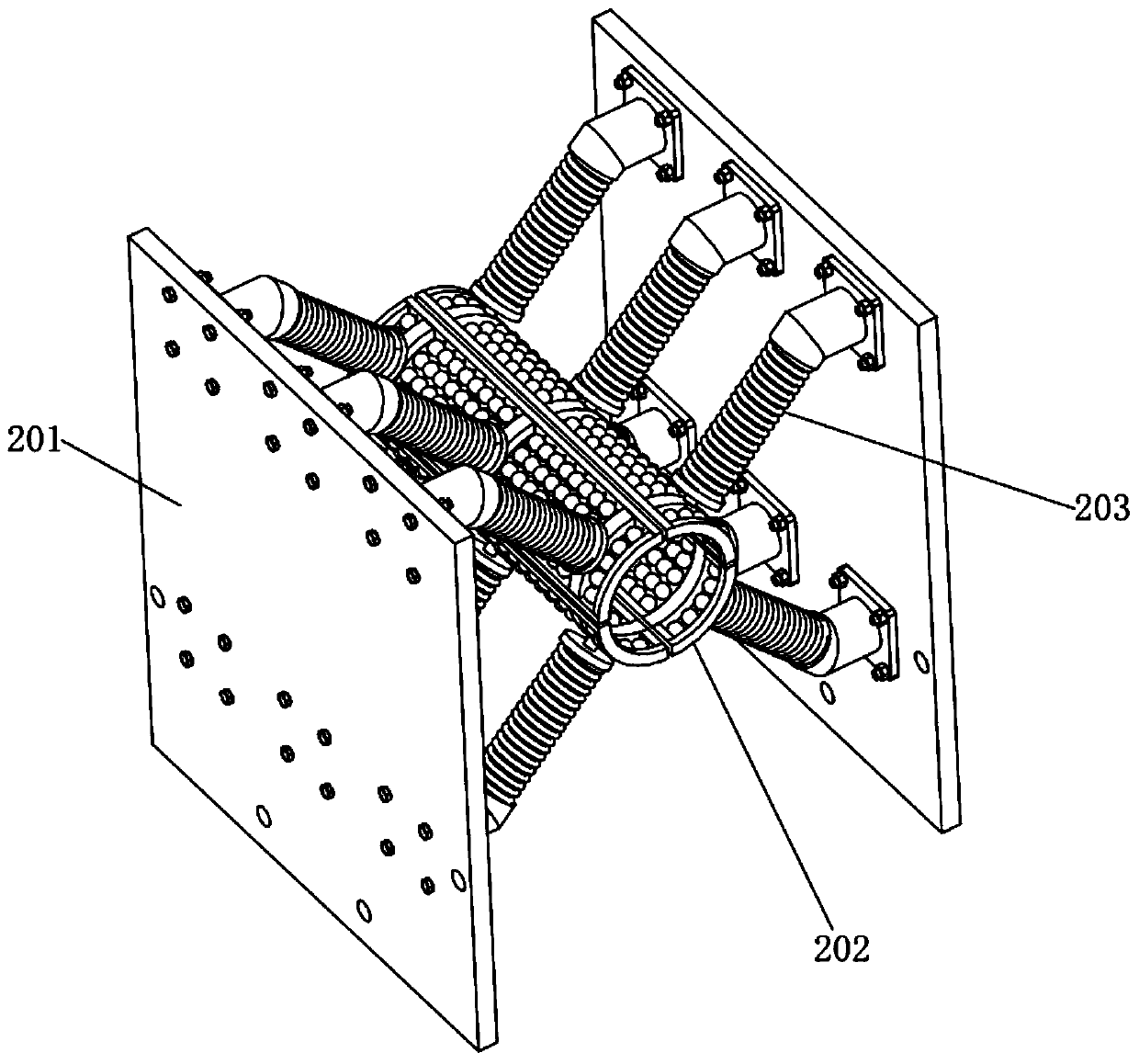

Projection device with wire grid polarizers

InactiveUS6873469B2Eliminate the effects ofReduce stressProjectorsPolarising elementsBeam splitterWire grid

An optical device for processing radiation that includes a beam splitter and a plurality of radiation processing parts arranged to process the characteristics of different radiation components separately, The polarizing beam splitter includes a wire grid polarizer, a first transparent plate arranged adjacent one side of the polarizer and a second transparent plate arranged adjacent the other side. Each of the first and second plates have substantially equal optical thickness profile.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Self-adaptive squid pattern cutting device

PendingCN111631250AConsistent flatnessSoftCephalopods processingStructural engineeringControl theory

The invention discloses a self-adaptive squid pattern cutting device. A belt self-adaptive adjusting mechanism is arranged in a belt running gap formed by a conveying belt; tension springs are distributed at the upper end of a adaptive base at intervals; adaptive shaft penetrates through the side portions of multiple parallel adaptive keys; the adaptive keys penetrate through gaps of multiple parallel tensioning wheels; tensioning shafts penetrate through the adaptive keys and tensioning wheels; the tail ends of the adaptive keys are located below a pressing shaft, and the pressing shaft applies pressure to the tail ends of the adaptive keys so that the tension springs can be tensioned; the inner edges of a plurality of annular outer cutter rings are arranged in annular grooves of a firstgrooved shaft and a second grooved shaft; annular inner cutters, the first grooved shaft and the second grooved shaft are distributed in the annular outer cutter rings in a triangular shape; the conveying belt penetrates through a gap between the belt self-adaptive adjusting mechanism and a pattern cutting cutter assembly; and materials located on the conveying belt are pressed on the belt self-adaptive adjusting mechanism through the pattern cutting cutter assembly. Flatness adaptation is conducted on the pattern cutting surface of squid, and consistency of the pattern cutting depth of the squid is guaranteed.

Owner:烟台福德食品机械有限公司

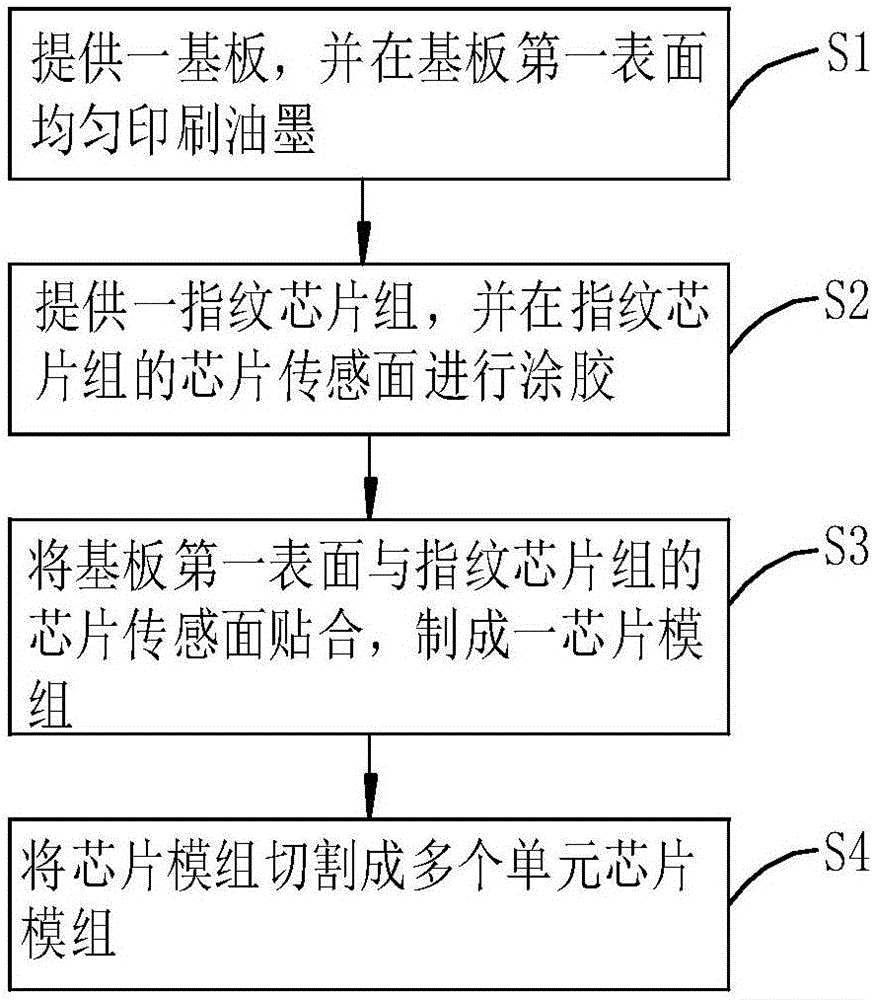

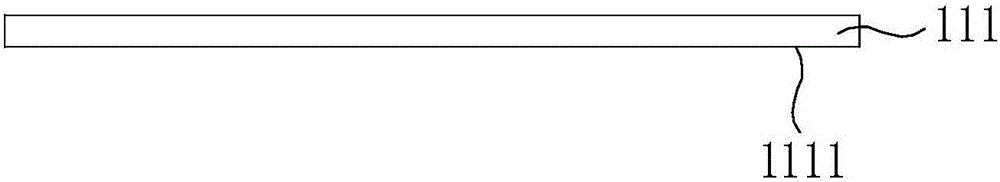

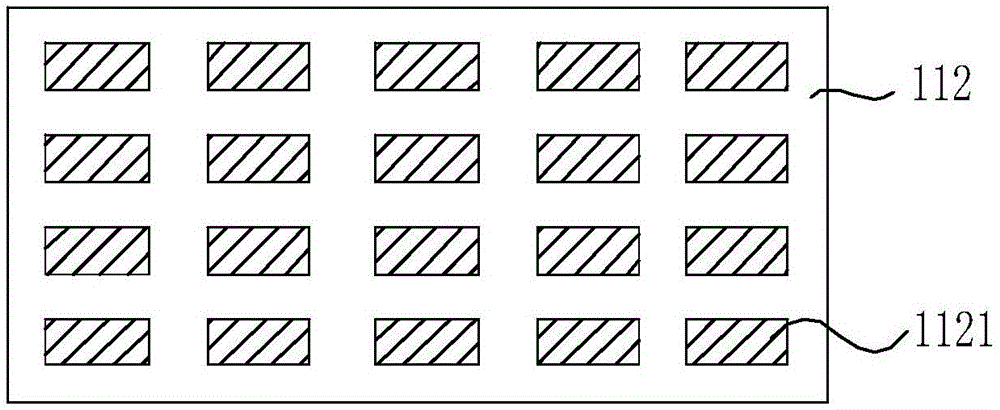

Fingerprint module manufacturing method

InactiveCN106295593AReduce fitDegree of reductionAcquiring/reconising fingerprints/palmprintsAdhesiveEngineering

The invention discloses a fingerprint module manufacturing method. The method comprises: a substrate is provided, and ink is printed on a first surface of the substrate evenly; a fingerprint chipset is provided, and adhesive is spread on a chip sensing surface of the fingerprint chipset; the first surface of the substrate is attached to the chip sensing surface of the fingerprint chipset, and a chip module is produced; the chip module is cut into a plurality of unit chip modules. Through the method, the attaching bias probability and bias degree are reduced during fingerprint module manufacturing, so that the probability of bubble appearance and the number of bubbles appearing during fingerprint module manufacturing are reduced; and the adhesive is spread on the whole chipset, so that the chip adhesive thickness is consistent, thus the flatness of the fingerprint module is consistent, the manufacturing time is shortened, and the quality and work efficiency of the fingerprint module are improved.

Owner:SHENZHEN TINNO WIRELESS TECH

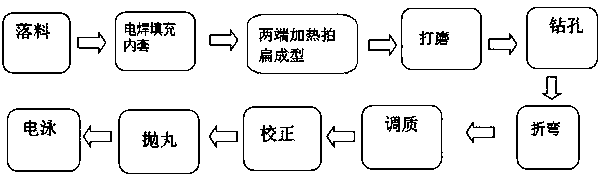

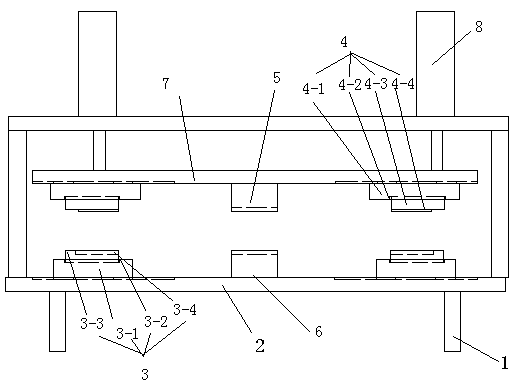

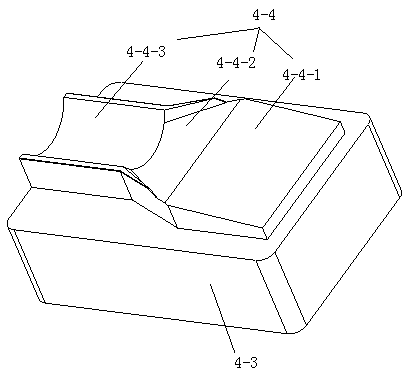

Hollow stabilizer bar producing process

ActiveCN110802378ASimplify the production processReduce the number of operatorsPhysicsMoulding device

The invention discloses a hollow stabilizer bar producing process. The process specifically includes the following steps of firstly, performing blanking; secondly, performing electric welding on filling inner sleeves, inserting the filling inner sleeves in the two ends of a blanked bar correspondingly, ensuring that the end faces of the filling inner sleeves are slightly 2-3 mm inward than the endfaces of a bar body, and then fixing the filling inner sleeves to the end faces through a spot welding method; thirdly, performing heating, flattening and forming on the two ends, putting the two ends, provided with the filling inner sleeves in the second step, of the bar body into an induction coil to be heated at the same time, transferring the heated workpiece onto a flattening and forming device at a flattening station, and performing extrusion forming on the two ends of the workpiece at the same time; fourthly, performing grinding; fifthly, performing drilling; sixthly, performing bending; seventhly, performing tempering; eighthly, performing correcting; ninthly, performing shot blasting; and tenthly, performing electrophoresis. The process is reasonable in step design, the whole production process is simplified, operators are reduced, operation intensity is lowered, and production efficiency is improved; and by performing flattening on the two ends at the same time, it can be ensured that the two ends are consistent in flatness, and the product quality is ensured.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

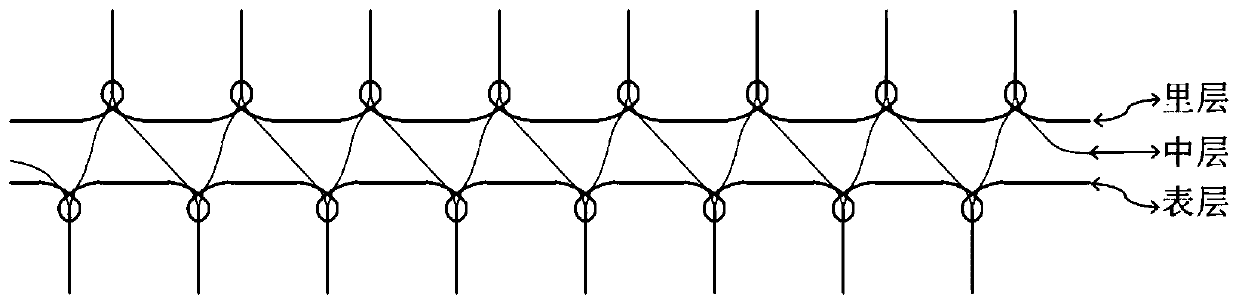

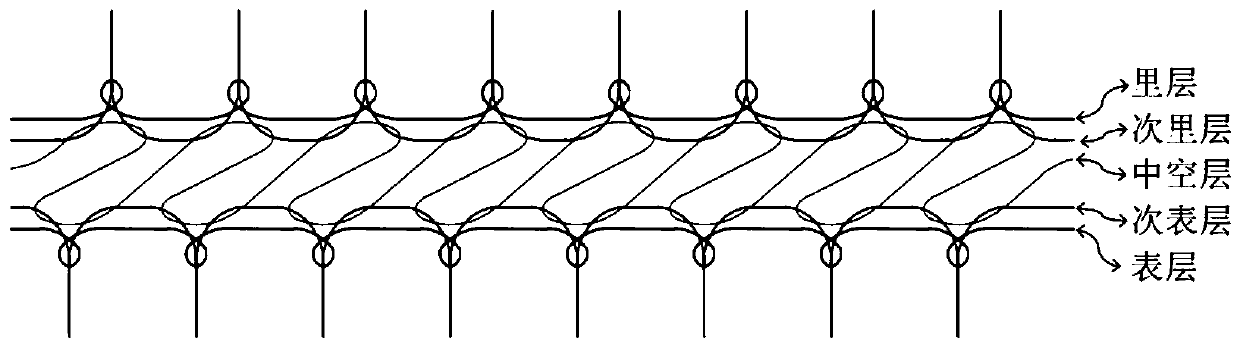

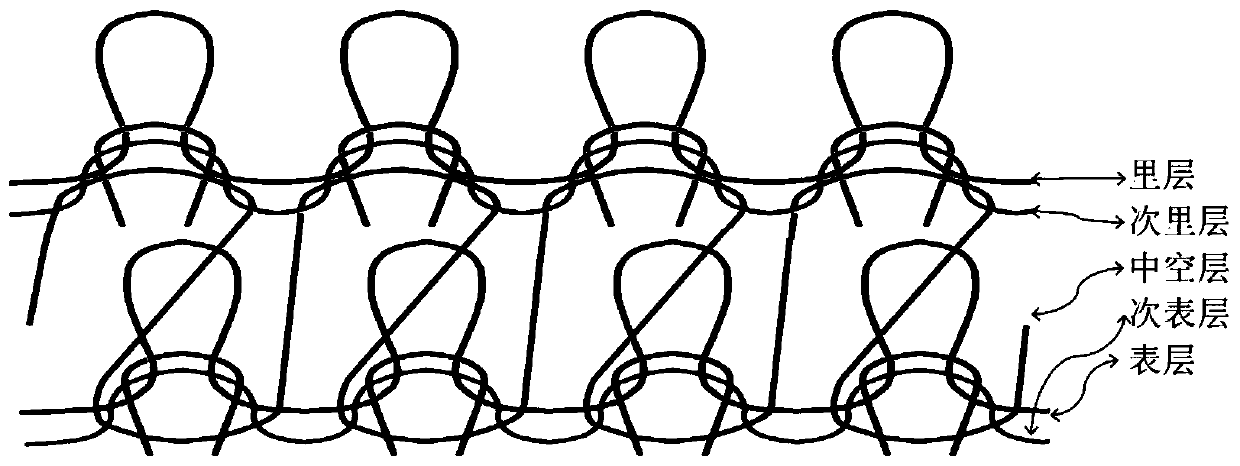

Air layer knitted fabric and preparation method thereof

PendingCN110438636AFlat surfaceConsistent flatnessWeft knittingOrnamental textile articlesThermal insulationEngineering

The invention relates to an air layer knitted fabric and a preparation method thereof. The air layer knitted fabric sequentially comprises a surface layer, a sub-surface layer, a hollow layer, a sub-inner layer and an inner layer, the hollow layer is connected with the sub-surface layer and the sub-inner layer, micro-denier filaments of the sub-surface layer and the sub-inner layer are interlockedin a penetrating and sleeving manner, so that filaments of the hollow layer are separated from the surface layer and the inner layer, the sub-surface layer and the surface layer are woven by a plaiting structure, yarn counts of the surface layer completely cover those of the sub-surface layer, the sub-inner layer and the inner layer are woven by a plaiting structure, and the yarn counts of the inner layer completely cover those of the sub-inner layer. The surface of the air layer knitted fabric is flat, the flatness of the surfaces of the inner layer and the outer layer is consistent with that of a single jersey, anti-pilling performance is enhanced and can reach grade 3 or more, the surface of the fabric is fluffy, and the fabric is thick and excellent in thermal insulation property.

Owner:NINGBO DAQIAN TEXTILE

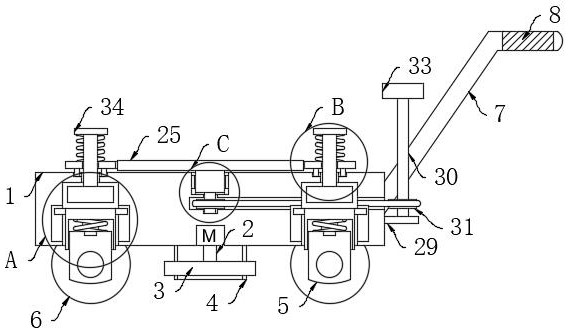

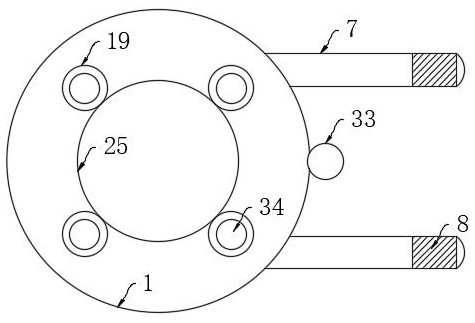

Lawn trimming equipment for garden landscape design

The invention provides lawn trimming equipment for garden landscape design. The lawn trimming equipment for garden landscape design comprises a motor fixedly installed on a vehicle body, the output end of the motor is fixedly connected with a driving rod, a cutting knife is fixedly installed at the end, extending out of the vehicle body, of the driving rod, and a protective cover matched with thecutting knife is fixedly installed on the vehicle body; two handles are fixedly installed on the vehicle body, the two handles are both fixedly sleeved with anti-skid sleeves, a plurality of installation bases are installed on the vehicle body, each installation base is rotatably connected with wheels, and a plurality of lifting grooves are formed in the vehicle body. The lawn trimming equipment has the advantages that the height of the vehicle body relative to the ground can be adjusted according to requirements, so that the reserved height after lawn trimming is controlled, the application range is relatively wide, shape design of the whole lawn is facilitated, the possibility and amplitude of shaking when the lawn trimming equipment moves on uneven grassland can be reduced, the flatnessof the trimmed lawn is kept consistent, and the overall attractive degree of the lawn is ensured.

Owner:杭州长风市政园林建设股份有限公司

Bamboo green and bamboo joint removal device and method

ActiveCN111571743AAutomatic removalConsistent flatnessCane mechanical workingIrregularity removal devicesAgricultural engineeringStructural engineering

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for patching leather with patching paste

InactiveCN109576422AConsistent flatnessImprove flatnessLeather surface finishingMaterials scienceMechanical engineering

The invention discloses a method for patching leather with patching paste. The method includes steps: (1) cleaning and airing or drying leather requiring patching, and using a grinding tool for grinding defective parts of the leather; (2) manually repairing serious defective parts; (3) coating the defective parts of the leather with the patching paste by patching equipment, and performing paste scraping, drying and polishing operations; (4) coating the leather with the patching paste again by the patching equipment, and performing paste scraping, drying and polishing operations; (5) coloring to finish patching. By emphasized repair at the defective parts, smoothness uniformity of the defective parts and the leather is kept, smoothness after leather patching is improved, and patching quality is improved as well. In addition, by coating of two patching paste layers including a bottom paste layer and a surface paste layer, smoothness at the defective parts is further improved, and patching quality is improved.

Owner:磐安县宸熙工艺品有限公司

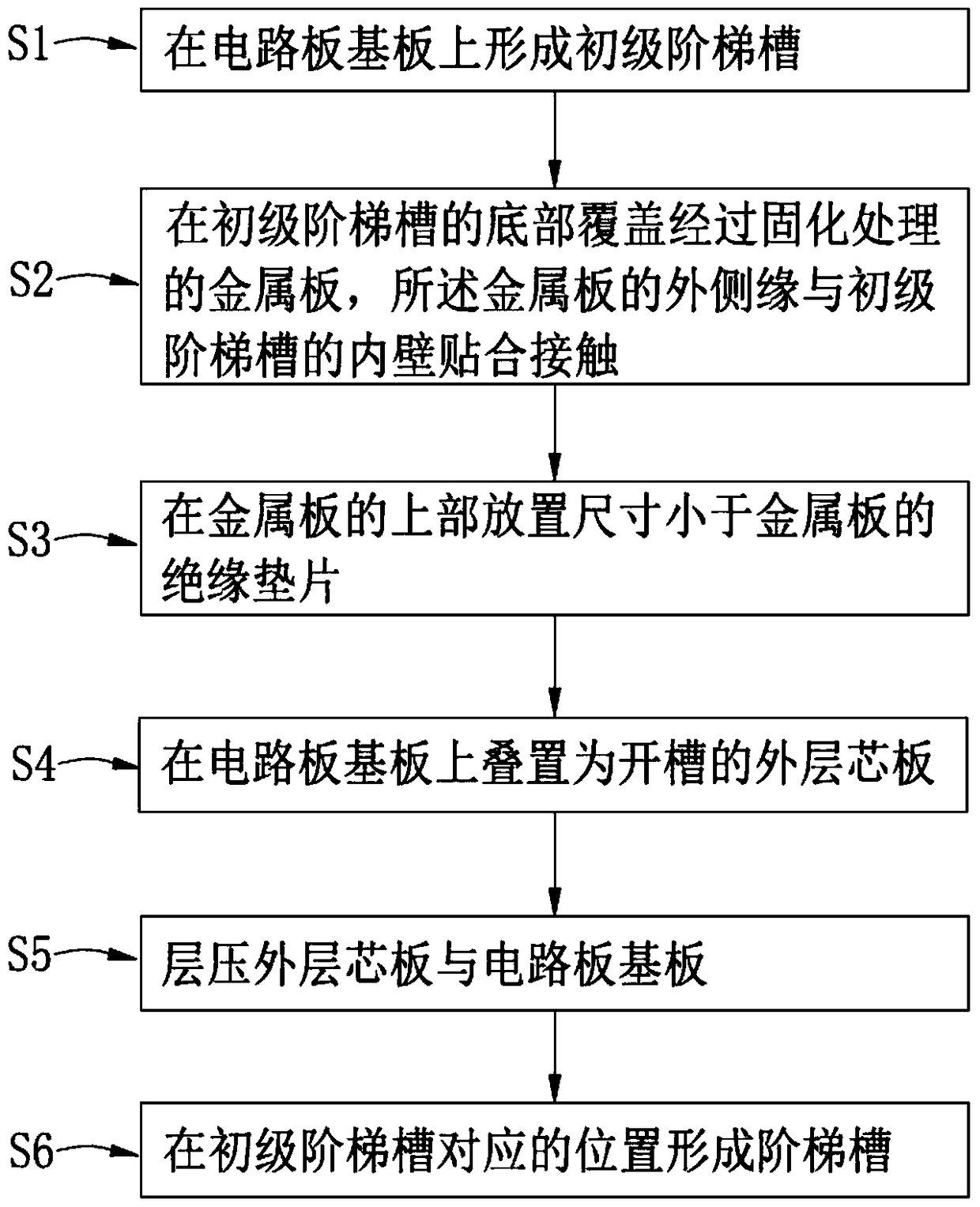

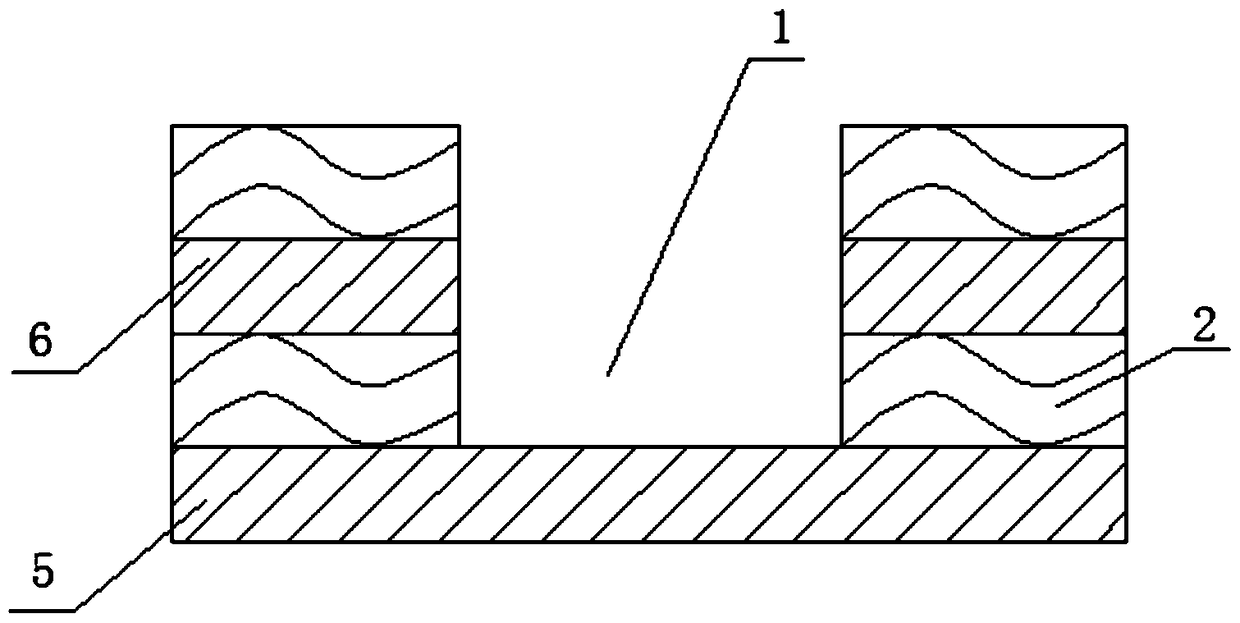

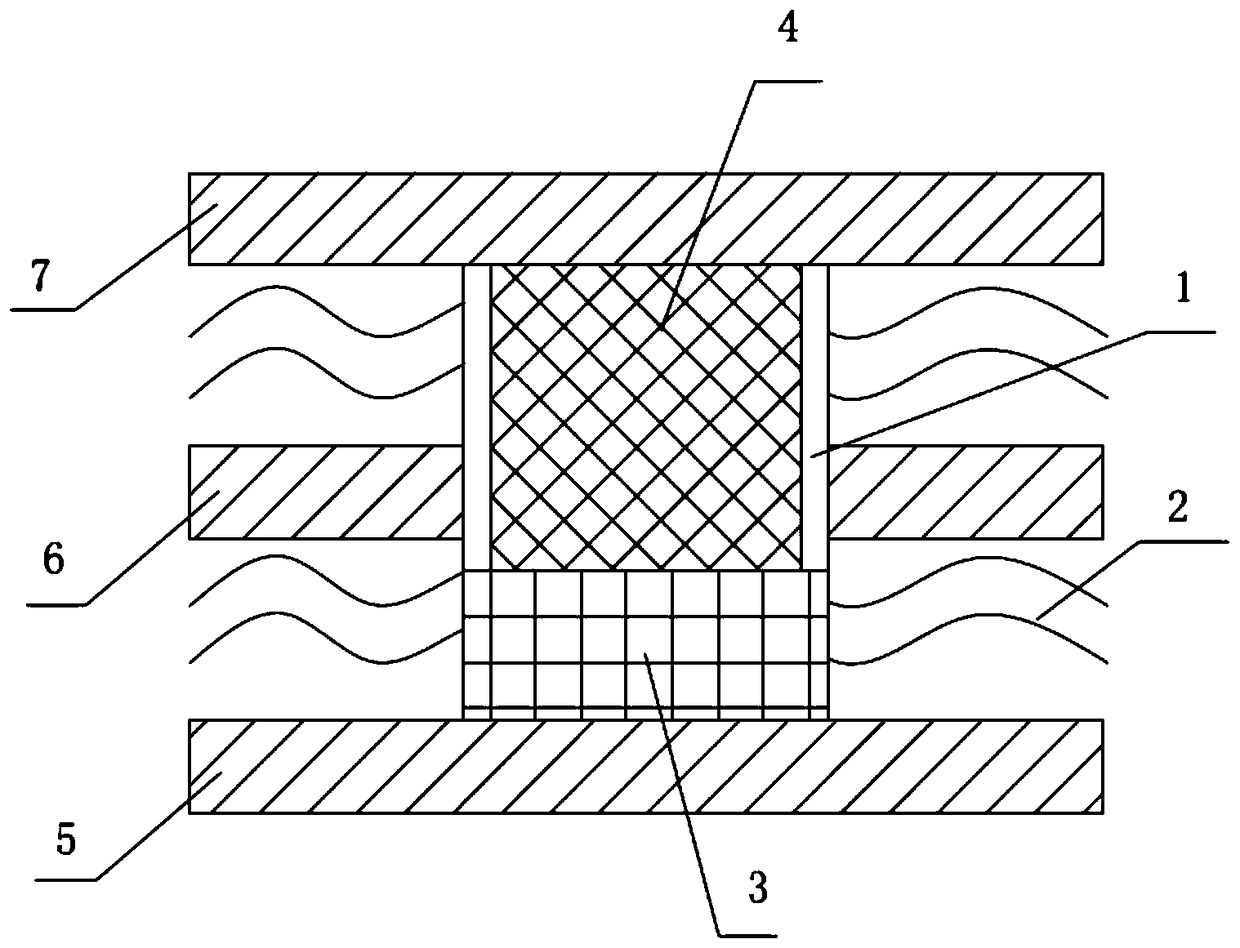

Preparation method of stepped groove of stepped circuit board and stepped circuit board

ActiveCN105338727BSame sizeConsistent flatness3D rigid printed circuitsMultilayer circuit manufactureCopperMetal

Owner:NEW FOUNDER HLDG DEV LLC +1

High-temperature-resistant self-adhesive pure polyethylene protective film and preparation method thereof

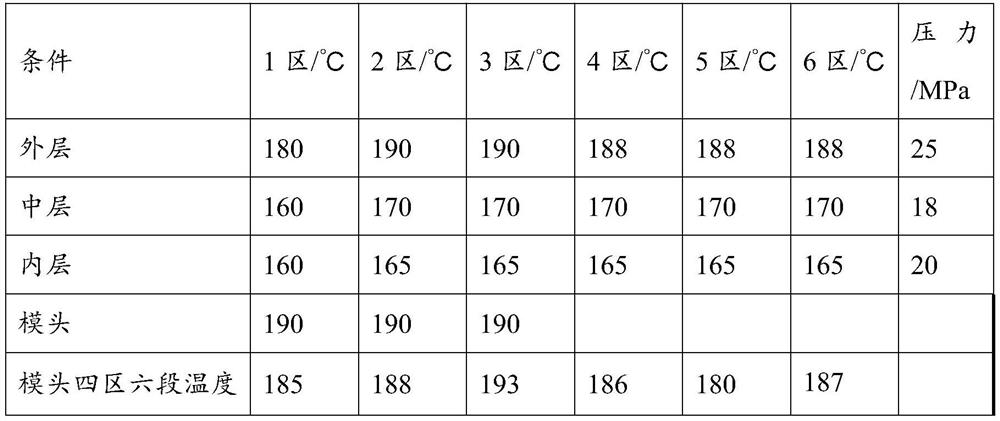

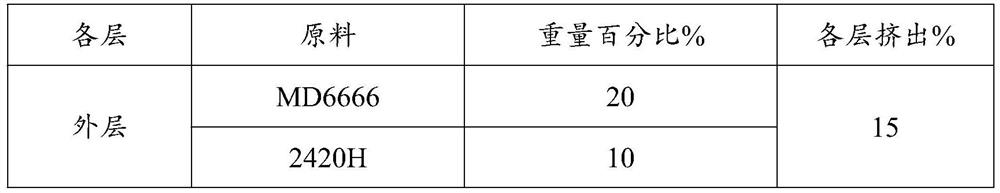

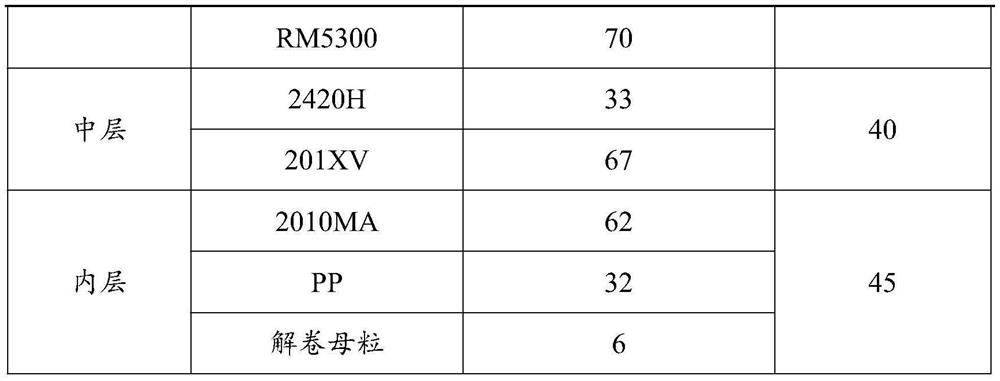

ActiveCN114083856AImprove uniformityImprove flatnessSynthetic resin layered productsFlat articlesTemperature controlPolymer science

The invention relates to the technical field of optical protective films, and provides a high-temperature-resistant self-adhesive pure polyethylene protective film and a preparation method thereof. The high-temperature-resistant self-adhesive pure polyethylene protective film is prepared by co-extrusion film blowing of an outer layer, a middle layer and an inner layer. A polyolefin plastomer is added to the outer layer, so that the autohension of the outer layer is improved. The middle layer and the inner layer are made of high-pressure low-density polyethylene and high-density polyethylene, so that the transparency and temperature resistance of the film are improved. Meanwhile, metallocene medium-density polyethylene is added into the middle layer, and the temperature resistance is further improved while the stiffness of the film is improved. The invention also provides a preparation method of the high-temperature-resistant self-adhesive pure polyethylene protective film. Six sections of heating are arranged in a fourth heating area of a die head, independent temperature control is carried out on each section, temperature control is finer, and therefore the uniformity and flatness of the film are improved. An annular six-section heating system is arranged outside a die head adjusting ring, and the effect that the thickness of a discharged film is uniform and smooth is achieved by adjusting the temperature of each heating section.

Owner:江门市华龙膜材股份有限公司

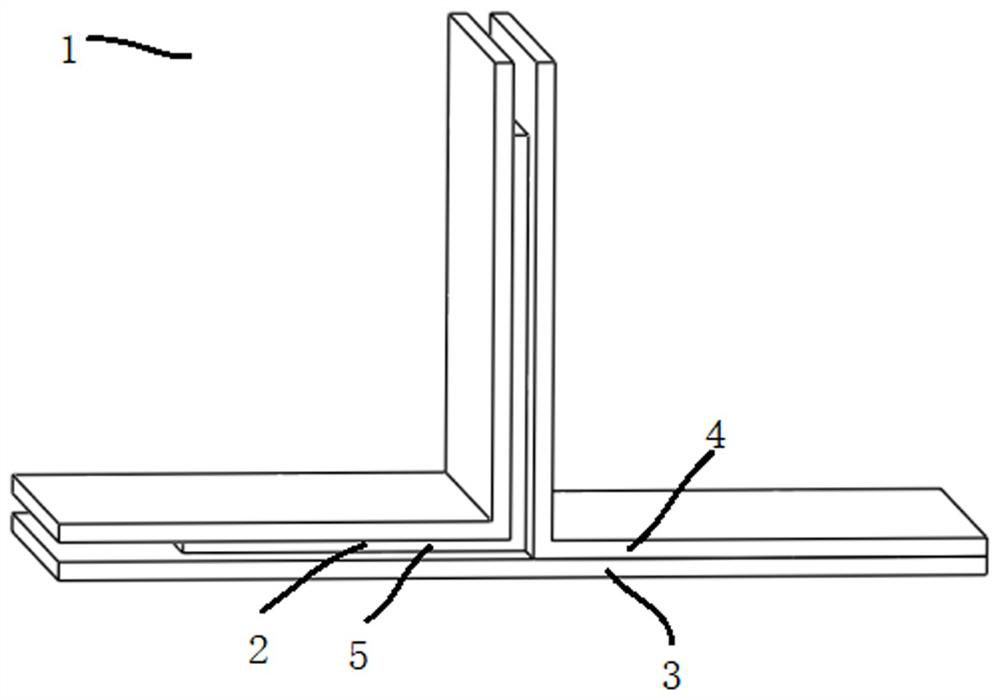

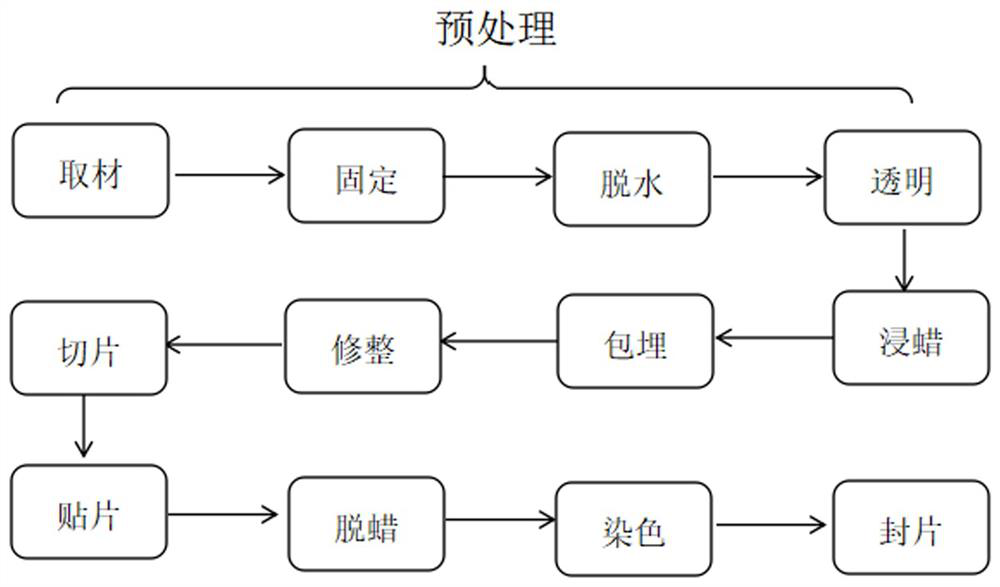

Multi-view tumor tissue pathological section and preparation method thereof

InactiveCN112798381AObserve growth characteristicsReduce difficultyPreparing sample for investigationAnatomyTumor tissue

The invention discloses a multi-view tumor tissue pathological section. The pathological section comprises a tumor tissue, a glass slide, a supporting cover glass and an overlying cover glass, wherein the supporting cover glass and the overlying cover glass are oppositely distributed; the tumor tissue is pasted among the glass slide, the supporting cover glass and the overlying cover glass; the tumor tissue is of a cylinder structure, and the cross section is V-shaped with different included angles; the thickness of each part of the tumor tissue is 4-6 microns, and the flatness of each part is kept consistent; the supporting cover glass and the overlying cover glass are matched with different models according to the V-shaped included angles of the sections of the tumor tissues, and the tumor tissues with different included angles can be packaged. According to the pathological section, the form of a tumor tissue can be observed from X, Y and Z visual angles, and the three-dimensional whole tissue state of the tumor tissue is observed, so the growth characteristics of forward tissue textures and reverse tissue textures of the tumor tissue are effectively observed, difficulty of clinical pathology judgment is reduced, and accuracy of clinical pathology judgment is improved.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

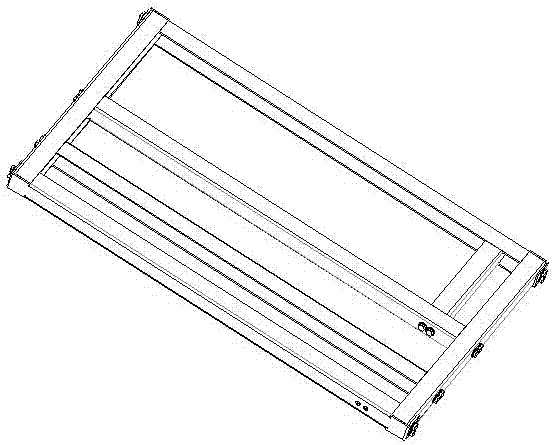

Detachable refrigerating compressor unit rack

ActiveCN107191744AAchieve levelingAchieve connectionMachine framesCompression machines with non-reversible cycleRefrigeration compressorBolt connection

Owner:NANTONG OEM REFRIGERATION EQUIP

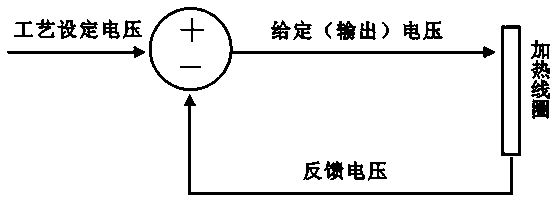

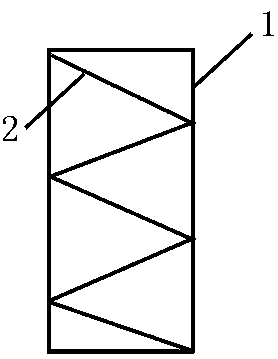

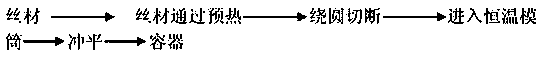

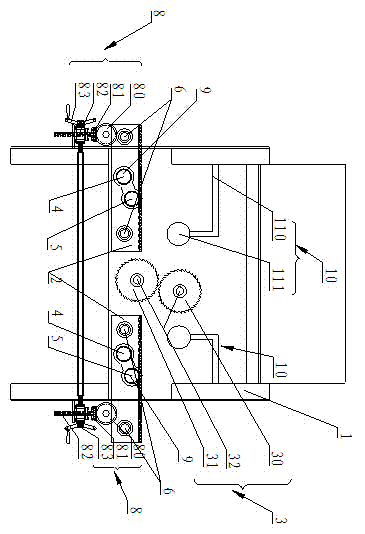

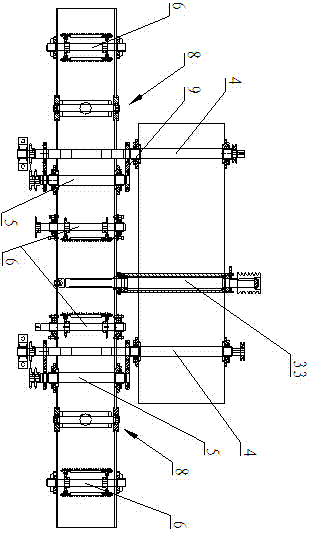

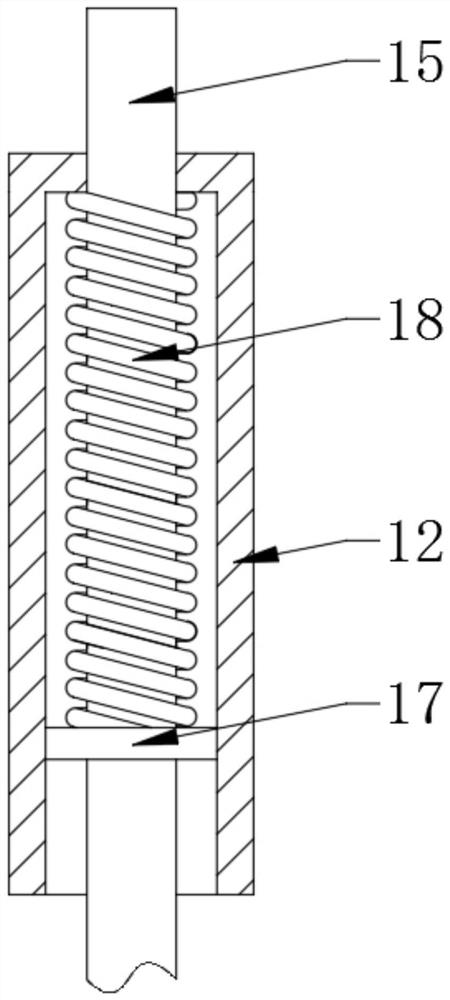

Welding ring product flatness control process

InactiveCN110227742AStable temperatureConsistent flatnessShaping toolsMechanical engineeringVoltage controller

The invention discloses a welding ring product flatness control process which involves a voltage controller and a heating coil. The process is characterized in that a wire is heated to be surrounded into a circle, and the surrounded circle is cut off to fall down into a constant temperature mold barrel, is punched by a punch pin in the constant temperature mold barrel and flattened, and falls intoa container from the constant temperature mold barrel. By means of the process, the disqualification ratio of welding rings is effectively reduced, and the yield is improved and can be improved by 2%about.

Owner:新乡市七星钎焊科技有限公司

Swing arm elevated working platform square wood multi-chip saw and use method thereof

ActiveCN104511948AConsistent flatnessEnsure the quality is qualifiedFeeding devicesCircular sawsControl engineeringStructural engineering

The invention relates to a swing arm elevated working platform square wood multi-chip saw which comprises a frame. Both an inlet end and an outlet end of the frame are provided with a conveying mechanism for conveying square wood through a conveying spindle, one end of each conveying mechanism is positioned on the outer side of the frame, the other end of each conveying mechanism extends into the frame, a cutting saw blade is arranged between the conveying mechanisms and mounted in the middle of the inner side of a machine tool, a swing shaft for supporting each conveying mechanism is arranged on the corresponding conveying mechanism and positioned obliquely below one side of the corresponding conveying spindle, two ends of each swing shaft are connected with the corresponding conveying spindle through a connecting rod, the swing shafts are mounted on the frame, the conveying spindles are respectively connected with a lifting mechanism for driving the conveying mechanisms to vertically move, and the lifting mechanisms are connected in a matched manner through a driving connecting rod to realize synchronous driving. The swing arm elevated working platform square wood multi-chip saw has the advantages that the saw is simple in structure and easy to implement, and planeness of the conveying mechanisms can be kept consistent.

Owner:FUJIAN YUAN CHUANG ELECTRICAL & MECHANICAL CO LTD

Surface defect detection equipment based on machine vision

PendingCN111665256AAvoid liftingAvoid dentsOptically investigating flaws/contaminationMachine visionEngineering

The invention aims to provide surface defect detection equipment based on machine vision, which is used for surface defect detection of a film roll and comprises a rack, a film roll assembly and a vision detection system, the rack comprises an operation table, a side bracket and an upper frame, and the operation table comprises a detection area; the film roll winding comprises a feeding roll shaft, a release paper collecting roll shaft, a tightening roll shaft, a release paper feeding roll shaft and a discharging roll shaft which are connected in sequence. The visual detection system comprisesan industrial camera, a light source and a PLC. The visual detection system is installed on the rack through a system support and arranged above the detection area, after a product enters the detection area, the PLC sends a camera trigger signal to take a picture, and after picture taking analysis processing of the camera, the PLC controls an executing mechanism to act. According to the method, the position of the defect area can be quickly and efficiently found and found as soon as possible, and defect films can be treated from the source.

Owner:苏州元承科技有限公司

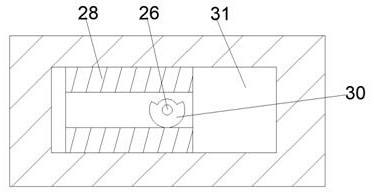

Burr removing device for steel pipe cut opening

InactiveCN111774978ASimple welding processImprove cutting and grinding efficiencyEdge grinding machinesGrinding work supportsPipeSteel tube

The invention discloses a burr removing device for a steel pipe cut opening. The burr removing device comprises a machine body, wherein a grinding cavity with a leftward opening is formed in the machine body, a recovery cavity with a leftward opening is formed in the right end wall of the grinding cavity, and a grinding device is arranged in the recovery cavity; and a plane grinding cavity with adownward opening is formed in the right side of the upper end wall of the grinding cavity, and a lifting cavity with part of an opening facing the left is formed in the right side of the plane grinding cavity. According to the burr removing device for the steel pipe cut opening, a steel pipe can be mechanically clamped, and it is guaranteed that subsequent grinding of the cut position of the steelpipe is carried out in order, so that the flatness of the cut face of the steel pipe is kept consistent, the subsequent welding process of the steel pipe is facilitated, and meanwhile, compared withplane grinding carried out by a common grinding machine, the grinding quality can be better guaranteed.

Owner:WENZHOU ANPA TECH CO LTD

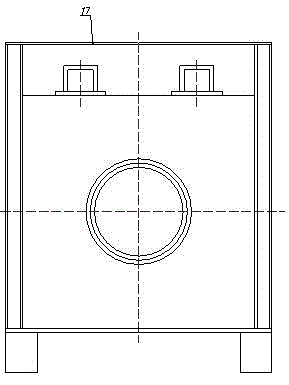

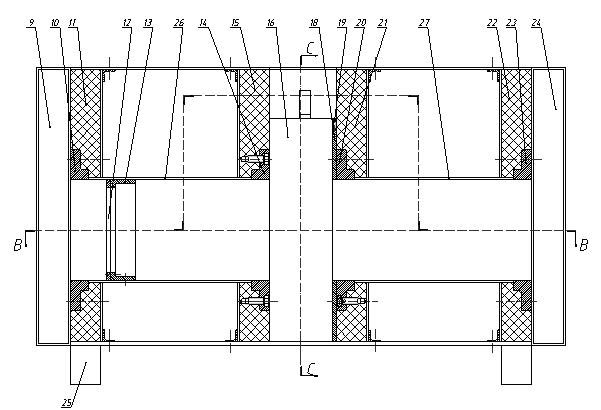

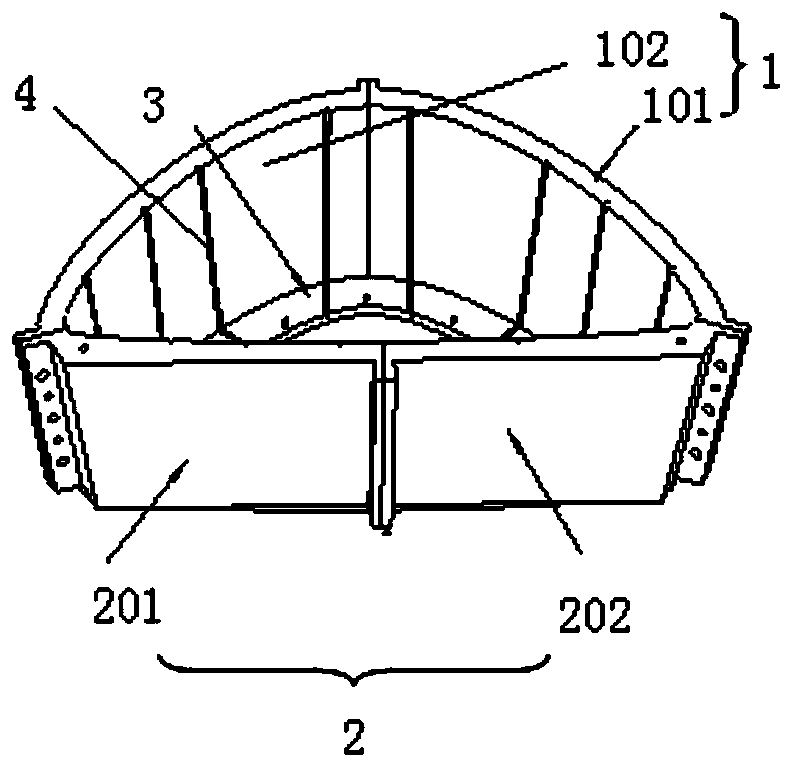

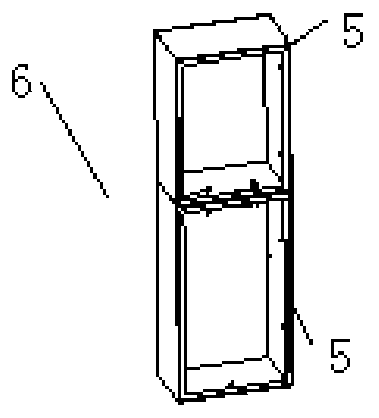

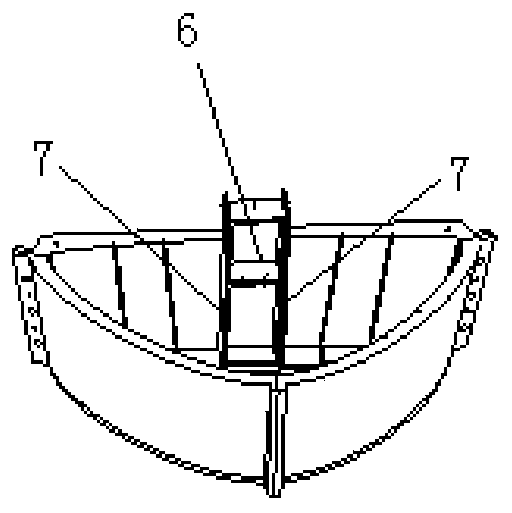

Shaping tool and C/SiC composite structural part forming method adopting shaping tool

The invention belongs to C / SiC composite preform forming tools and methods, and provides a shaping tool and a C / SiC composite structural part forming method adopting the shaping tool in order to solvethe problems that the forming process that after single parts are formed, then rivet welding and assembling are carried out is adopted by an existing C / SiC composite structural part, during assembling, the local space is narrow, operation is difficult, and the assembling precision is low. The shaping tool comprises an arch-shaped shaping top plate, and the shaping top plate is mounted on a shaping bottom plate. The back sides of the shaping top plate and the shaping bottom plate are bent inwards to form shaping supporting edges, multiple limiting grooves are formed in the shaping top plate and the shaping bottom plate, and limiting slabs are clamped in the limiting grooves. According to the forming method, shaping supporting is carried out through a box-shaped assembly, the thickness of carbon fiber cloth of the box-shaped assembly is adjusted through the limiting grooves and the limiting slabs, and the smoothness and thickness consistency of the carbon cloth is guaranteed. Laying whole cloth is subjected to flanging treatment, a flanged and cut opening is reinforced, and therefore the overall strength of a composite is guaranteed. A C / SiC composite structural part is firstly shaped and then deposited.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

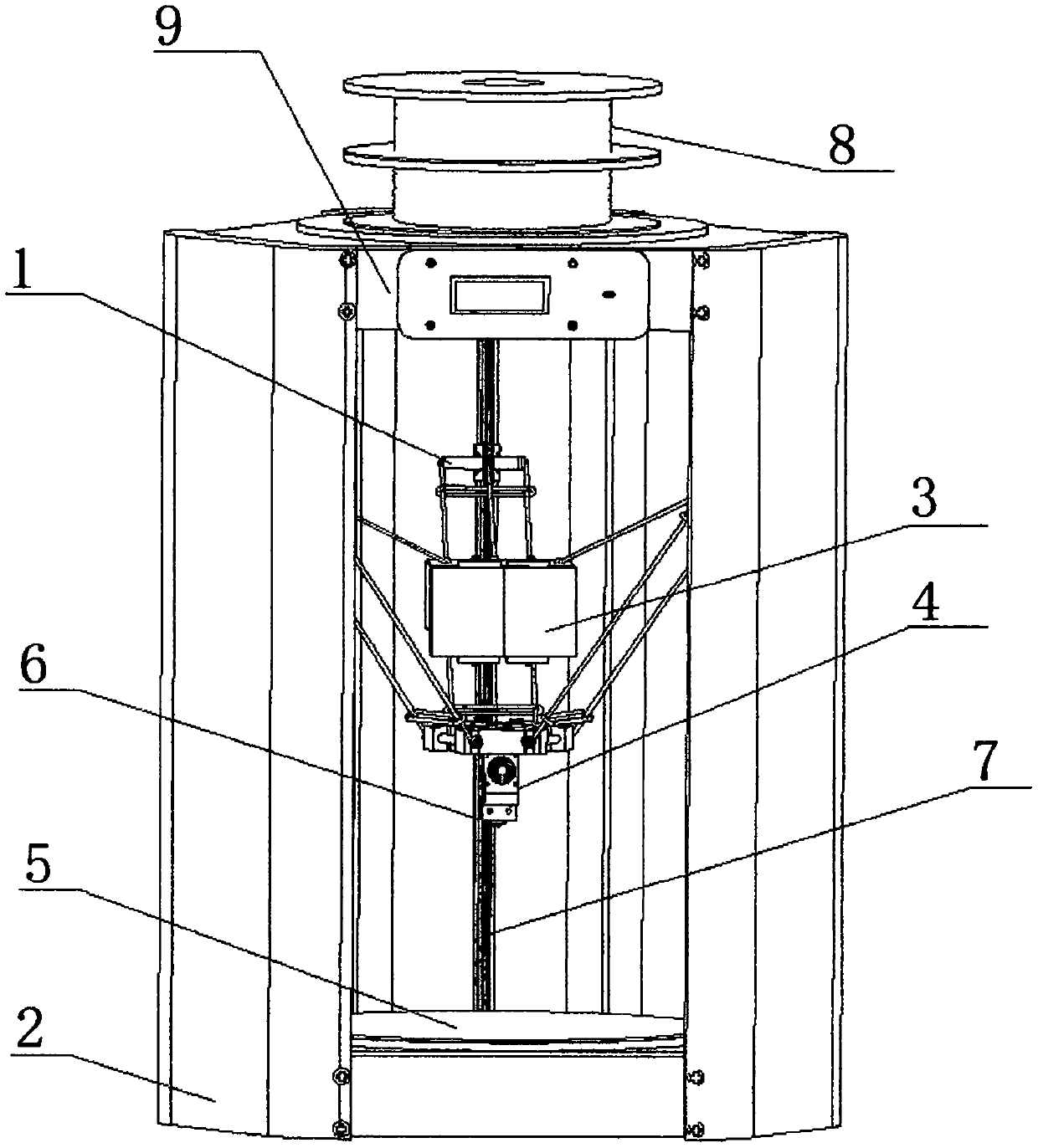

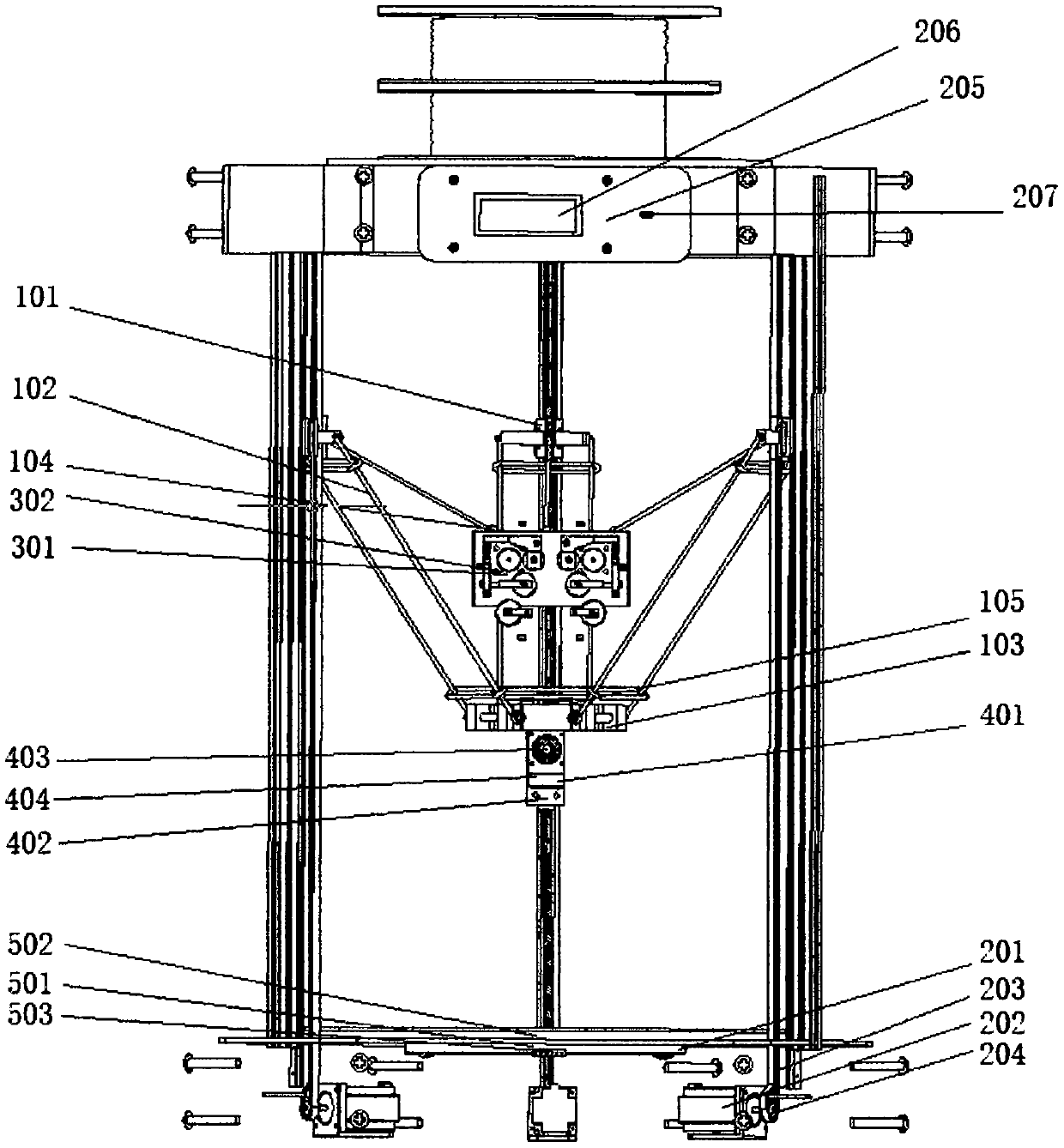

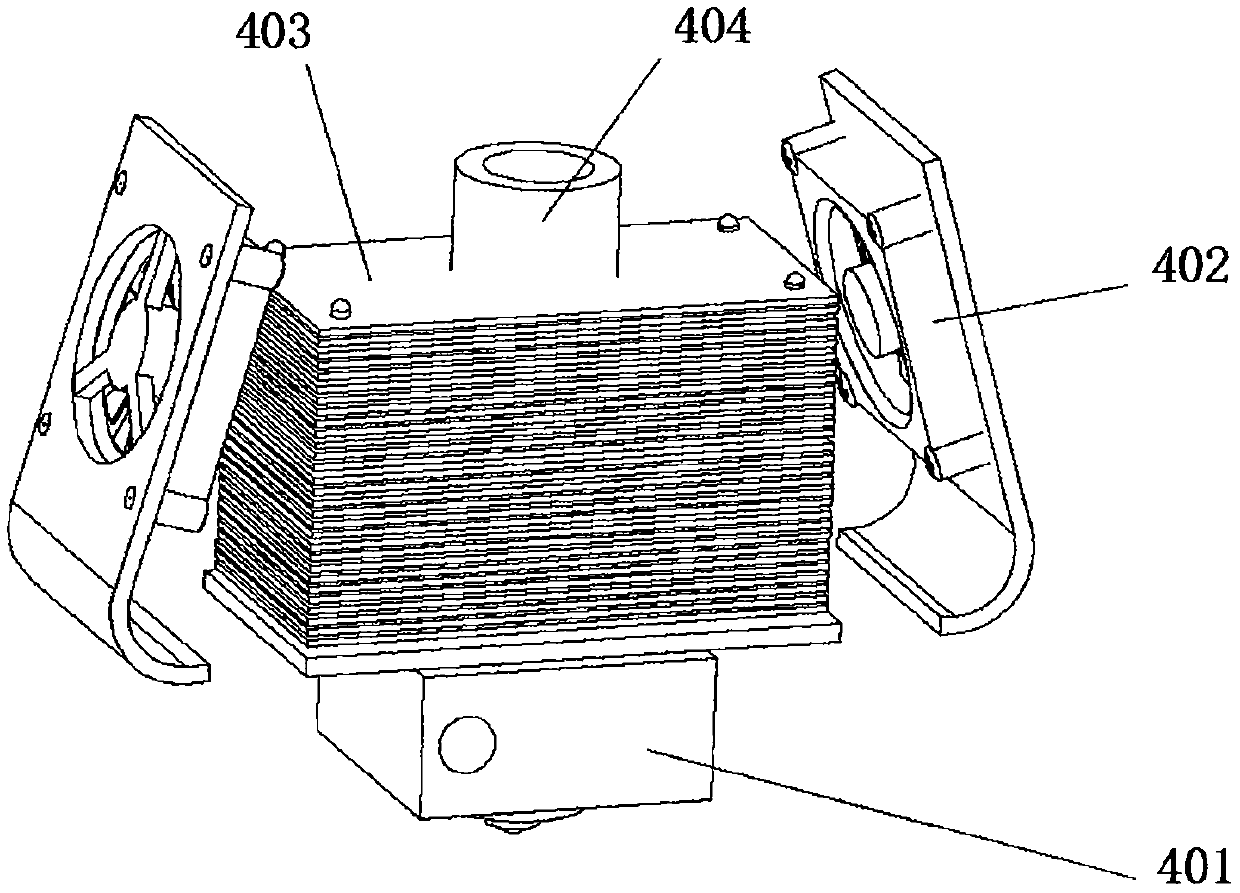

Three-dimensional printer

InactiveCN110539486AGuaranteed to be tightLines are clearAdditive manufacturing apparatus3D object support structuresSprayerEngineering

The invention discloses a three-dimensional printer. The three-dimensional printer comprises an integrated framework, wherein a synchronous belt is arranged inside the integrated framework; a paralleldriving mechanism is arranged on the synchronous belt; the lower end of the parallel driving mechanism is provided with a double-spray constant-stroke closed wire feeding system; the lower end of thedouble-spray constant-stroke closed wire feeding system is provided with an effector; the lower end of the effector is connected with a printing sprayer; the bottom end of the interior of the integrated framework is provided with a hot bed which is located under the printing sprayer; consumables are arranged at the upper end of the integrated framework; and an integrated controller is arranged inside the integrated framework. The three-dimensional printer is high in rigidity, stable in structure, high in freedom degree, capable of eliminating the staircase effect of the traditional 3D printing, excellent in mechanical property of printed finished products, easy to maintain, capable of overcoming the defects of the 3D printing in the existing market and wide in the application range.

Owner:宁波智能制造技术研究院有限公司

Intelligent road flatness detection equipment and method

PendingCN114152220AConsistent flatnessReasonable structural designHeight/levelling measurementUsing optical meansFixed frameEngineering

The invention discloses intelligent road flatness detection equipment in the technical field of road flatness detection equipment, a threaded seat is assembled on the outer side wall of a screw rod in a threaded connection mode, and a guide cylinder movably assembled on the outer wall of a guide plate in a sleeving mode is fixed to the left side of the threaded seat; a worm engaged with the worm gear is movably assembled at the bottom of the right side wall of the guide plate through a bearing, a supporting spring arranged on the outer side wall of the guide rod in a sleeving mode is fixed to the outer edge of the top of the limiting plate, and a laser plumb aligner is fixedly assembled to the top end of the guide rod after the top end of the guide rod extends out of the protective cylinder. A glass light target matched with the laser plumb aligner is fixed to the top of the inner side of the fixing frame, the distance variation between the laser plumb aligner and the glass light target directly and equivalently replaces the fluctuation amplitude and fluctuation frequency of the ground flatness of the road section, and complete and effective replacement can be completed. Therefore, inaccurate measurement results caused by data measurement errors caused by single data measurement can be avoided, and effective flatness detection is completed.

Owner:云南路一试验检测有限公司

Automobile part machining device

The invention relates to the technical field of grinding equipment, and discloses an automobile part machining device. The device comprises a large-model grinding box, a protection plate is hinged tothe top of the front face of the grinding box through a hinge, a rotating mechanism is arranged at the bottom in the grinding box, the rotating mechanism comprises a transmission box, a first rotatingshaft, a rotating disc, a crank, a first gear, a second gear, a second rotating shaft, a moving block, a threaded hole, a lead screw, a fixed rotary knob, sliding grooves, a movable frame, a fixed plate, a threaded rod, chucks, anti-skid pads and an adjusting rotary knob, the transmission box is fixedly installed at the bottom in the grinding box, the first rotating shaft penetrates through the top of the transmission box and is in rotary connection with the transmission box, the rotating disc is fixedly connected to the top of the first rotating shaft, the crank is rotationally connected with the top of the rotating disc, the first gear is fixedly installed on the portion, located in the transmission box, of the first rotating shaft, and the second gear is engaged with the first gear. The automobile part machining device solves the problems that the surfaces of automobile parts are polished unevenly and the automobile parts cannot be assembled.

Owner:浙江共创机械设备有限公司

Device for automatically removing bamboo outer skin and bamboo joints

ActiveCN111571742AControl positionAutomatic removalMechanical diameter measurementsCane mechanical workingStructural engineeringMechanical engineering

The invention discloses a device for removing bamboo outer skin and bamboo joints. The device comprises a frame, wherein the frame is sequentially provided with a guide mechanism, a first conveying mechanism, a first supporting mechanism, a first bamboo rod driving mechanism, a bamboo outer skin and bamboo joint removing mechanism, a second supporting mechanism, a second bamboo rod driving mechanism, a third supporting mechanism and a second conveying mechanism from front to back; the first conveying mechanism and the second conveying mechanism are used for conveying a bamboo rod from the front side of the frame to the rear side of the frame; the guide mechanism is used for guiding the directions for the bamboo rod; the first supporting mechanism, the second supporting mechanism and the third supporting mechanism are used for supporting the bamboo rod; the first bamboo rod driving mechanism and the second bamboo rod driving mechanism are used for driving the bamboo rod to rotate; and the frame is further provided with a bamboo joint detection mechanism for detecting the positions of bamboo joints on the bamboo rod. The device for removing the bamboo outer skin and the bamboo jointscan automatically remove the outer skin and the joints of the whole bamboo rod without manual cutting, both time and effort are saved, and the working efficiency is greatly improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com