Fingerprint module manufacturing method

A production method and technology of fingerprint modules, which are applied in the directions of acquiring/organizing fingerprints/palmprints, character and pattern recognition, instruments, etc., can solve the problem of high probability of fingerprint module deviation and bubbles, poor flatness, and long production time and other problems, to achieve the effect of improving the quality and work efficiency of the module, reducing the probability of fitting deviation and the degree of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, a method for manufacturing a fingerprint module provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

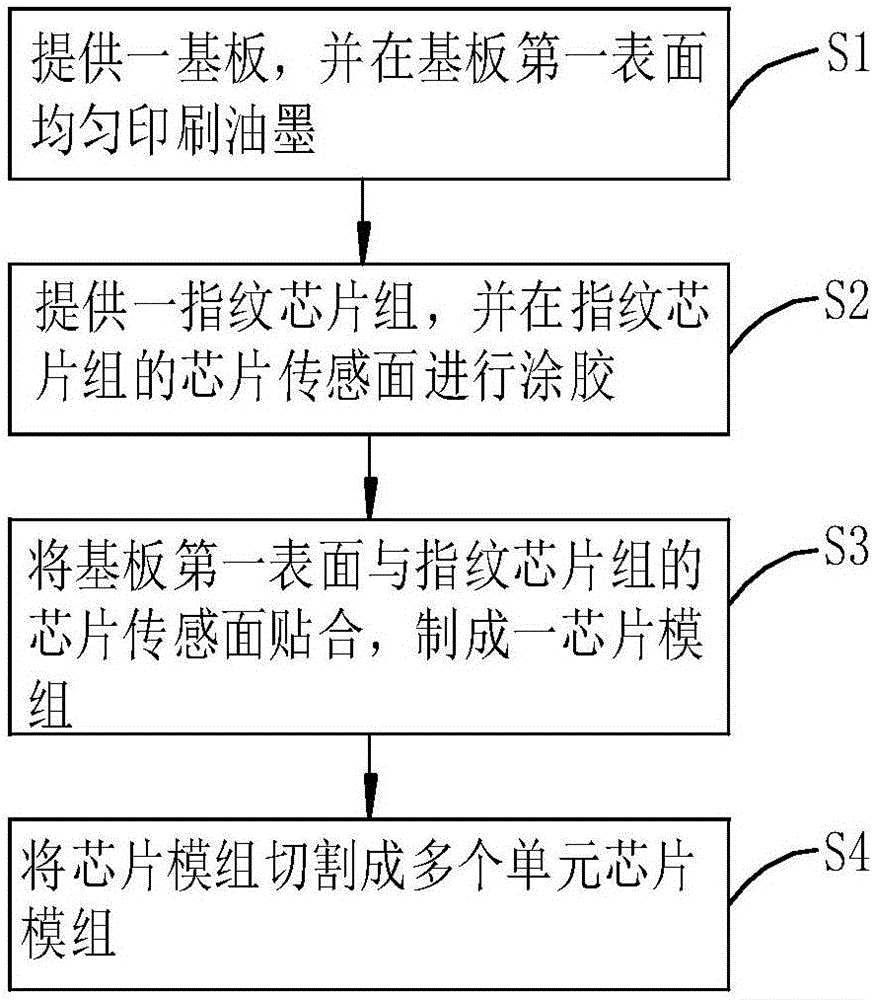

[0030] like figure 1 Shown is a schematic flow chart of the manufacturing method of the fingerprint module of the present invention, and the manufacturing method of the fingerprint module specifically includes the following steps:

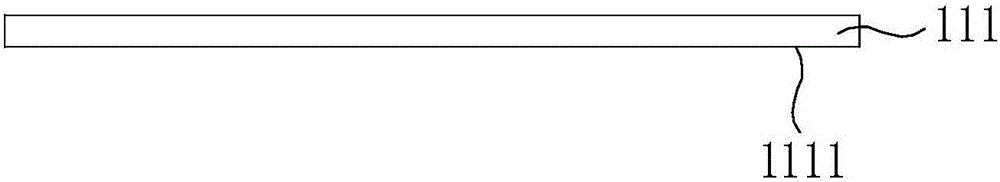

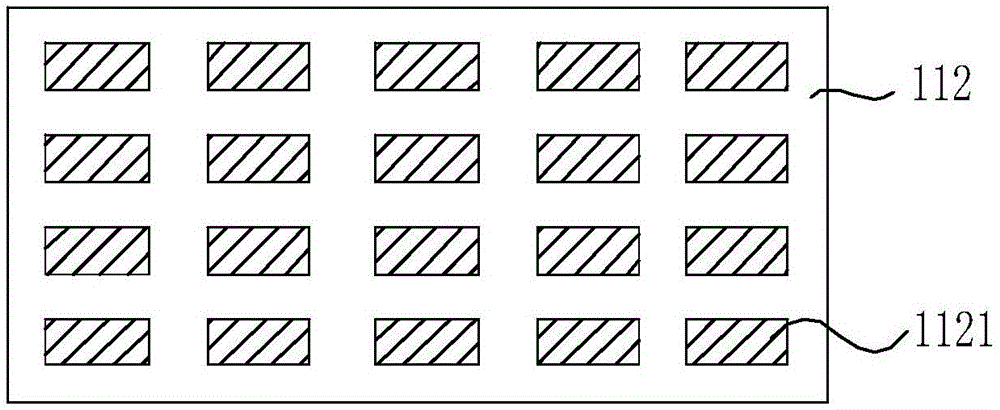

[0031] refer to figure 1 and figure 2 , S1: providing a substrate 111, and uniformly printing ink on the first surface 1111 of the substrate 111;

[0032] Among them, the substrate 111 may include but not limited to glass substrates, ceramic substrates and sapphire substrates. Specifically, the material can be selected according to actual needs, and the present invention is not limited; the substrate 111 may include but not limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com