Testing apparatus of impact vibration of general CAB

A shock vibration and test device technology, which is applied in the mechanical field, can solve the problems of enlarged vibration frequency coverage, low test accuracy, and complex structure, and achieve the effects of expanding frequency coverage, reducing welding deformation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing.

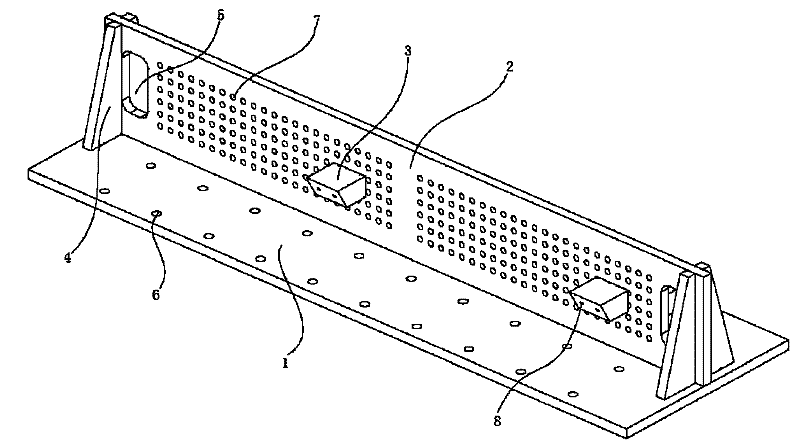

[0019] The general-purpose CAB shock vibration test device in the present invention, hereinafter referred to as: test device, mainly includes base plate, main base plate, reinforcing rib, connection block, bolt, see image 3 , Figure 4 ,in,

[0020] Bottom plate 1: It is mainly used to fix the entire test device. It is made of aluminum alloy plate. Mounting holes 6 can be arranged in advance on the bottom plate 1. Part of the mounting holes 6 is used to connect the main substrate 2, and the other part is used to fix on the vibration table.

[0021] Main substrate 2: The main function is to carry the curtain airbag to be tested. It is made of aluminum alloy plate and processed by CNC machine tools. In order to carry the curtain airbag to be tested, several fixing holes 7 are distributed. These fixing holes 7 pass through The bolts are connected with the connecting block 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com