Transmission-driving unit with electronic interface which can be locked

A drive unit and electronic interface technology, applied in the direction of electrical components, electric components, electromechanical devices, etc., can solve problems such as unproven intervention, and achieve the effect of saving parts and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

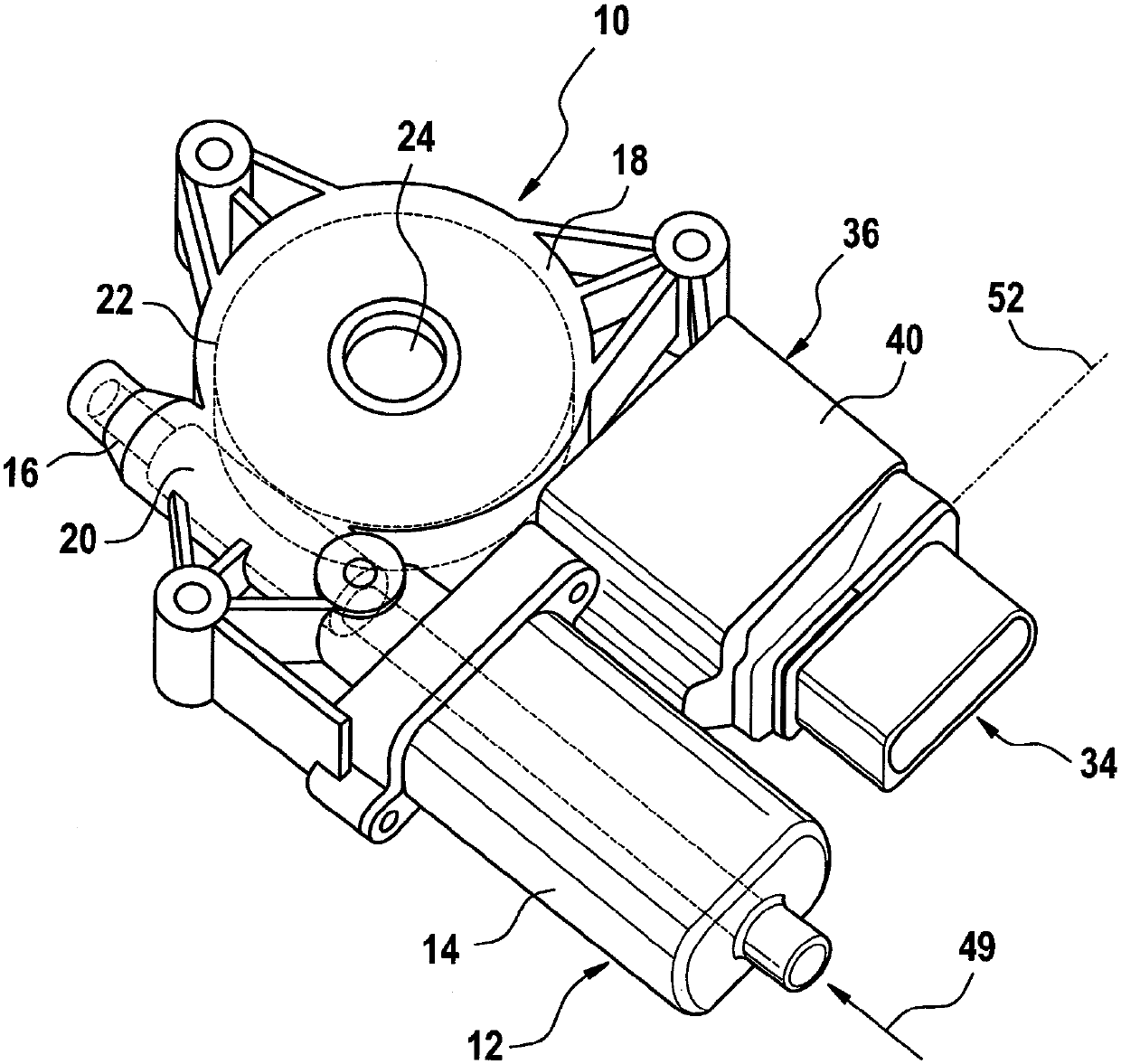

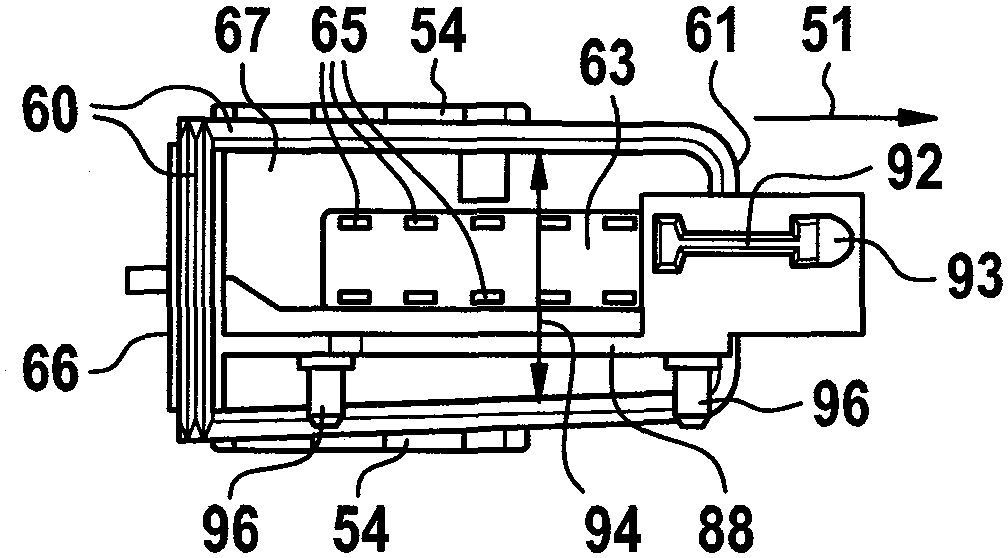

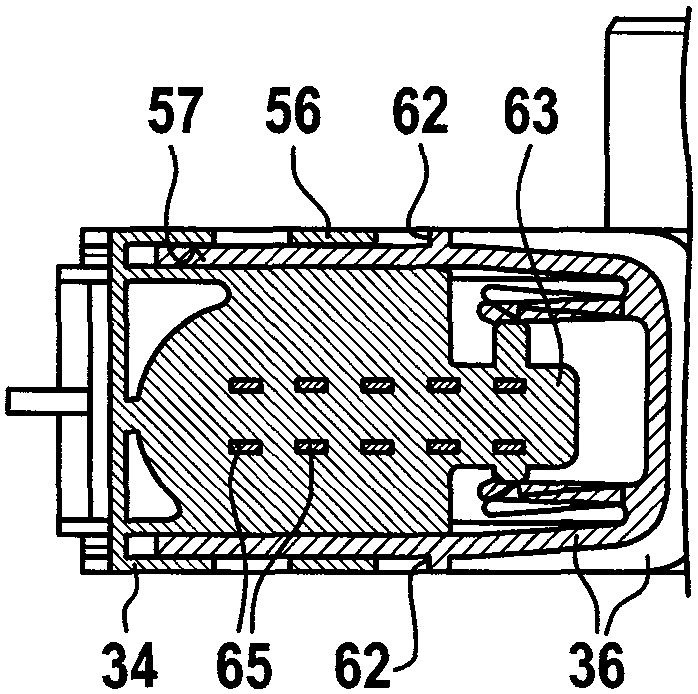

[0026] figure 1 and figure 2 The transmission drive unit 10 , in particular a transmission drive unit 10 for a window regulator, is shown after insertion of the electronics module 34 and before the insertion of the electronics module 34 . The rotor shaft 16 protrudes from the pole shoe 14 of the electric motor 12 into the transmission housing 18 . Arranged on the rotor shaft 16 is a worm 20 which meshes with a worm wheel 22 and transmits the force via a drive pinion 26 mounted on its shaft 24 to a window lifter (not shown in detail) Fensterhebermechanik). For detecting the position of the adjustable component, for example a ring magnet is arranged on the rotor shaft 16 in the region of the transmission housing 18 , which interacts with a Hall sensor 30 arranged on a printed circuit board 32 of an electronics module 34 . . For insertion of the electronics module 34 , the transmission drive unit 10 has an electronics interface 36 which is formed integrally with the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com