Movable concrete mixing plant

A technology for mixing equipment and concrete, applied in mixing plants, clay preparation equipment, cement mixing equipment, etc., can solve the problems of complex structure and inability to use flexibly enough, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

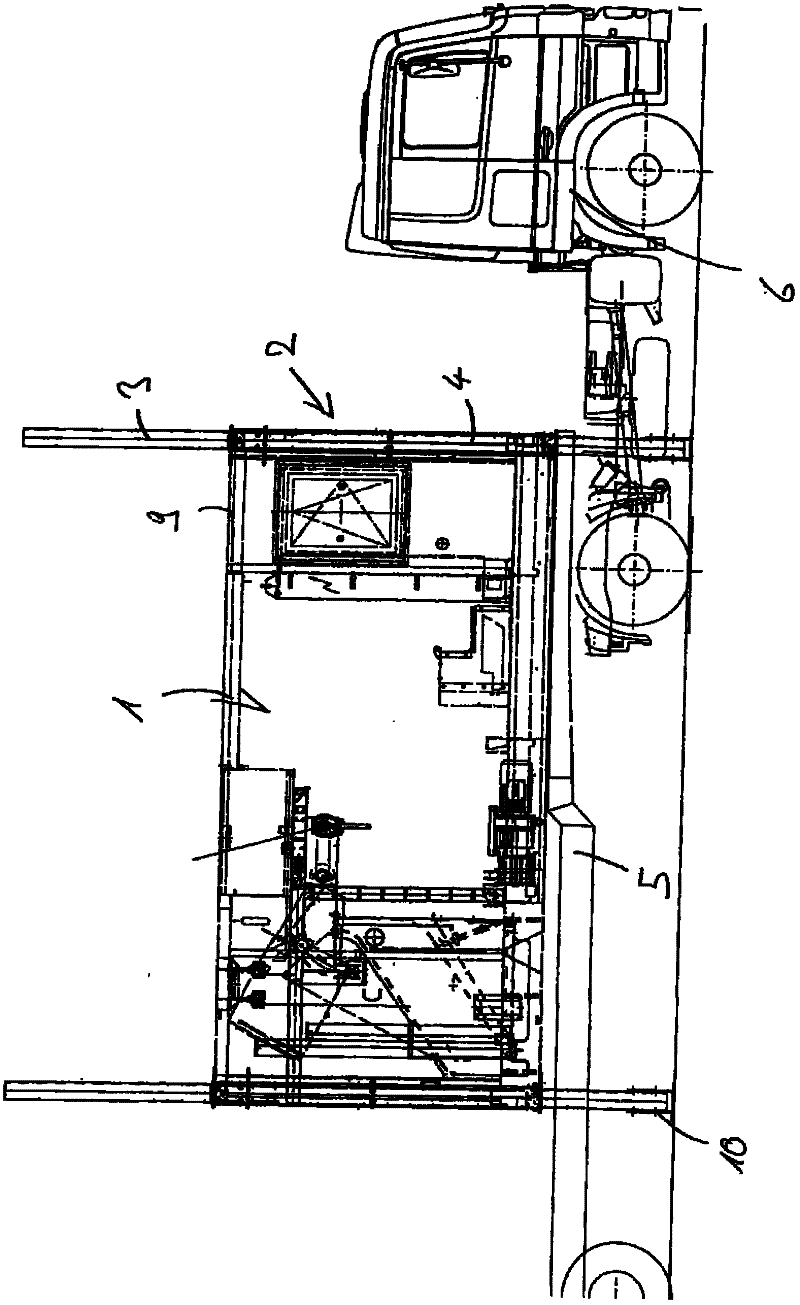

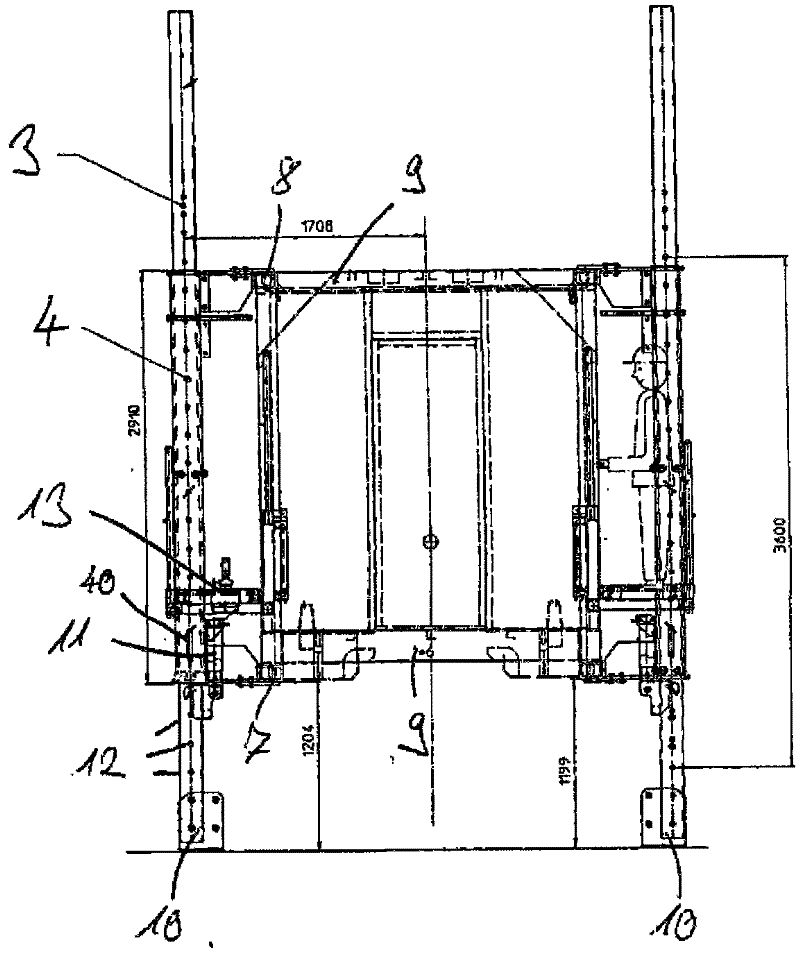

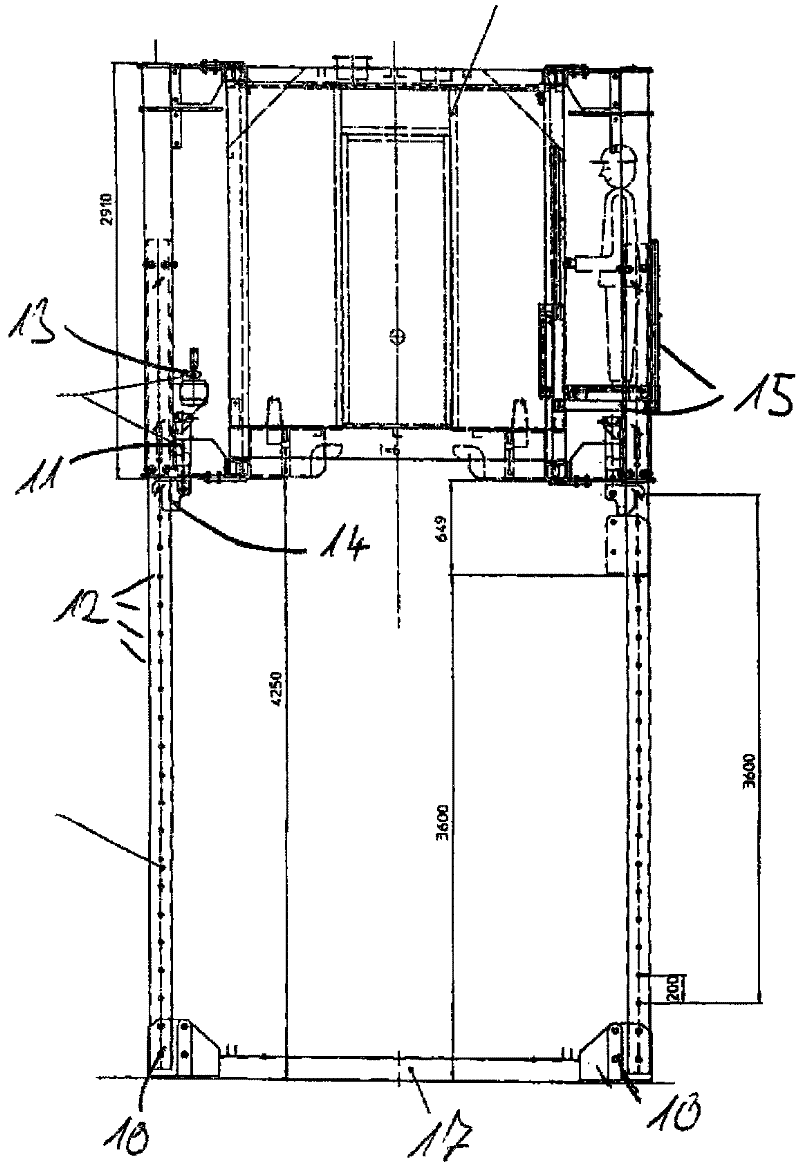

[0051] now by means of Figures 1 to 4 A first embodiment of the mixing unit of the mobile concrete mixing plant according to the present invention is shown in detail. Here, the mixing unit 1 has the shape of a container. For this purpose, the stirring unit has a cuboid-shaped frame 9 consisting of corresponding metal supports, which frame forms the supporting structure of the stirring unit 1 . The mixing unit 1 can thus be transported without problems on the loading surface 5 of the transport trolley 6 . In this case, it is provided in the exemplary embodiment that the mixing unit has the dimensions of a typical 20-inch container. Here, the stirring unit is a pre-installed functional unit.

[0052] In order to operate a mobile concrete mixing plant, the mixing unit must be lifted into a working position in which a concrete mixer truck can drive under the mixing unit and fill it with concrete from above. In particular, a working height of 4.25 meters is required for this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com