Electric press device

A technology of electric stamping and electric motors, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., and can solve problems such as inability to implement fixed-point processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

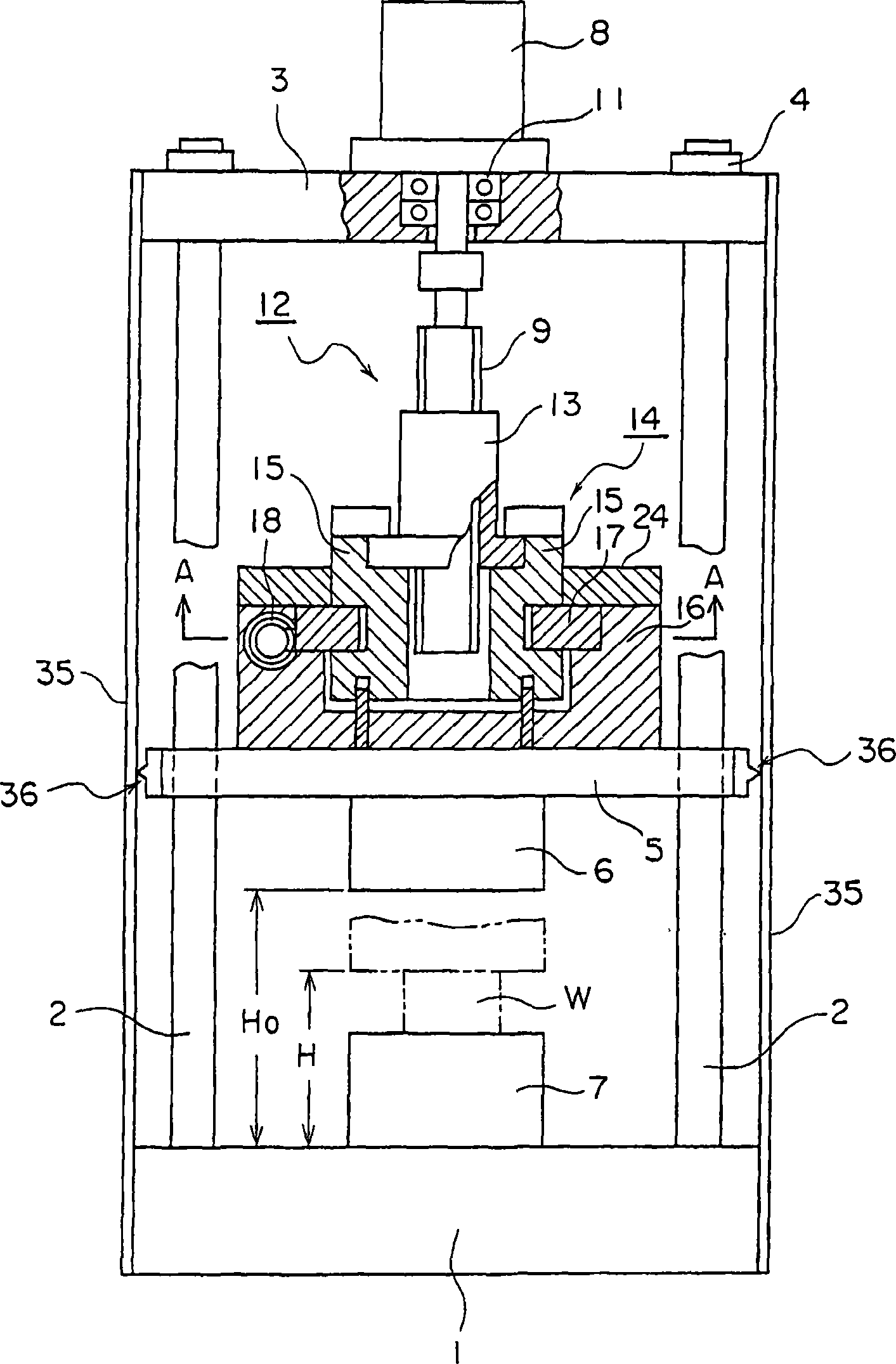

[0051] figure 1 It is a front view of an embodiment in which a part of the main part of the electric press device of the present invention is in cross section.

[0052] exist figure 1 In the figure, reference numeral 1 is a substrate, which is formed in, for example, a rectangular flat plate, and columnar guide rods (guide bodies) 2 are erected at four corners thereof. A rectangular flat support plate 3 is fixed to an upper end portion of the guide rod 2 via a connecting member 4 .

[0053] Symbol 5 is a sliding plate, which is slidably engaged with the guide rod 2 and can be slid up and down, and the push piece 6 is fixed at the bottom. Reference numeral 7 denotes a table, which is provided on the substrate 1 and on which the workpiece W is placed.

[0054] A motor (first motor) 8 with a built-in encoder is provided on the support plate 3, and a ball screw shaft 9 is freely rotatably connected to its shaft via a thrust bearing 11 provided on the support plate 3. The ball...

Embodiment 2

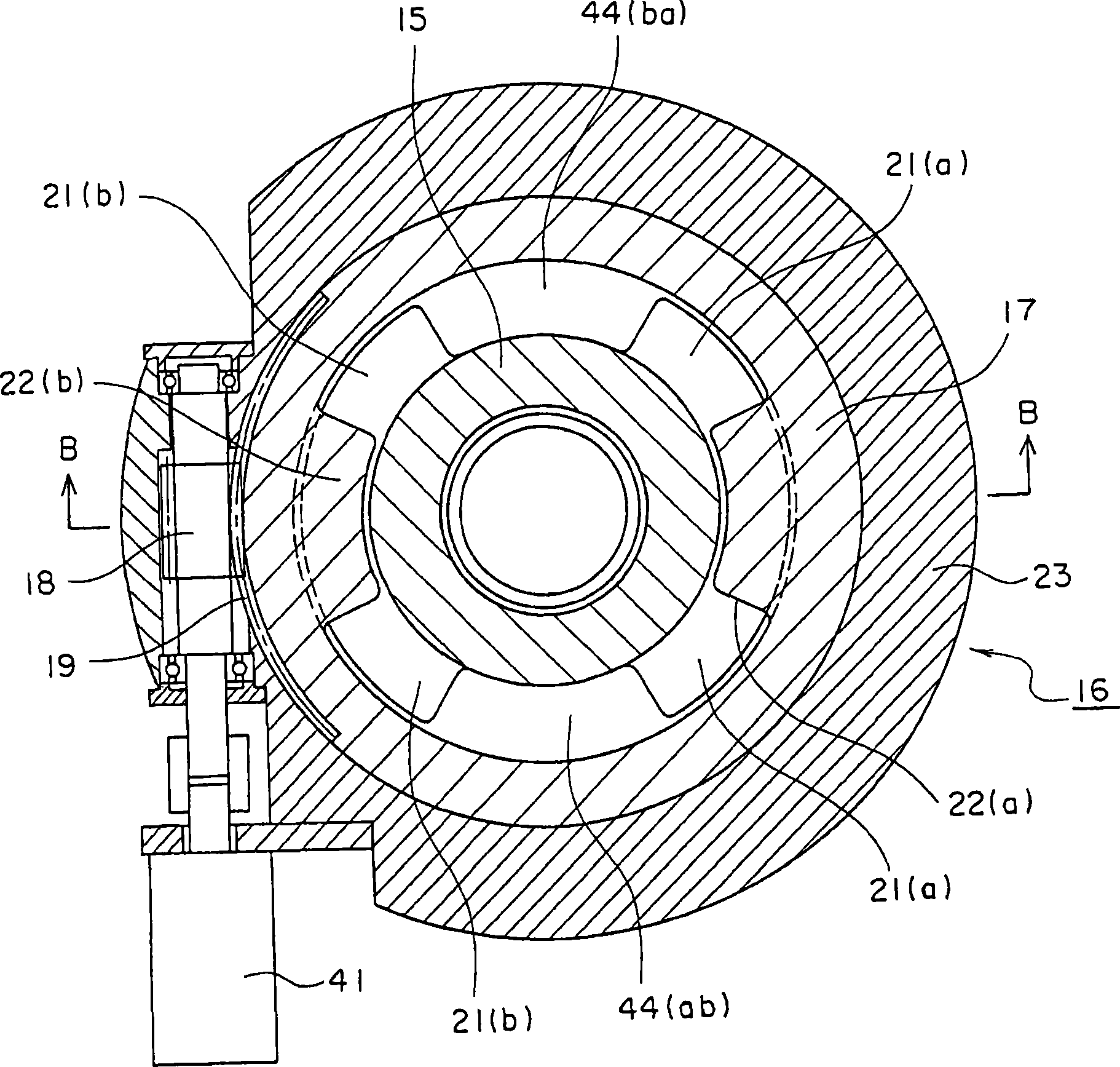

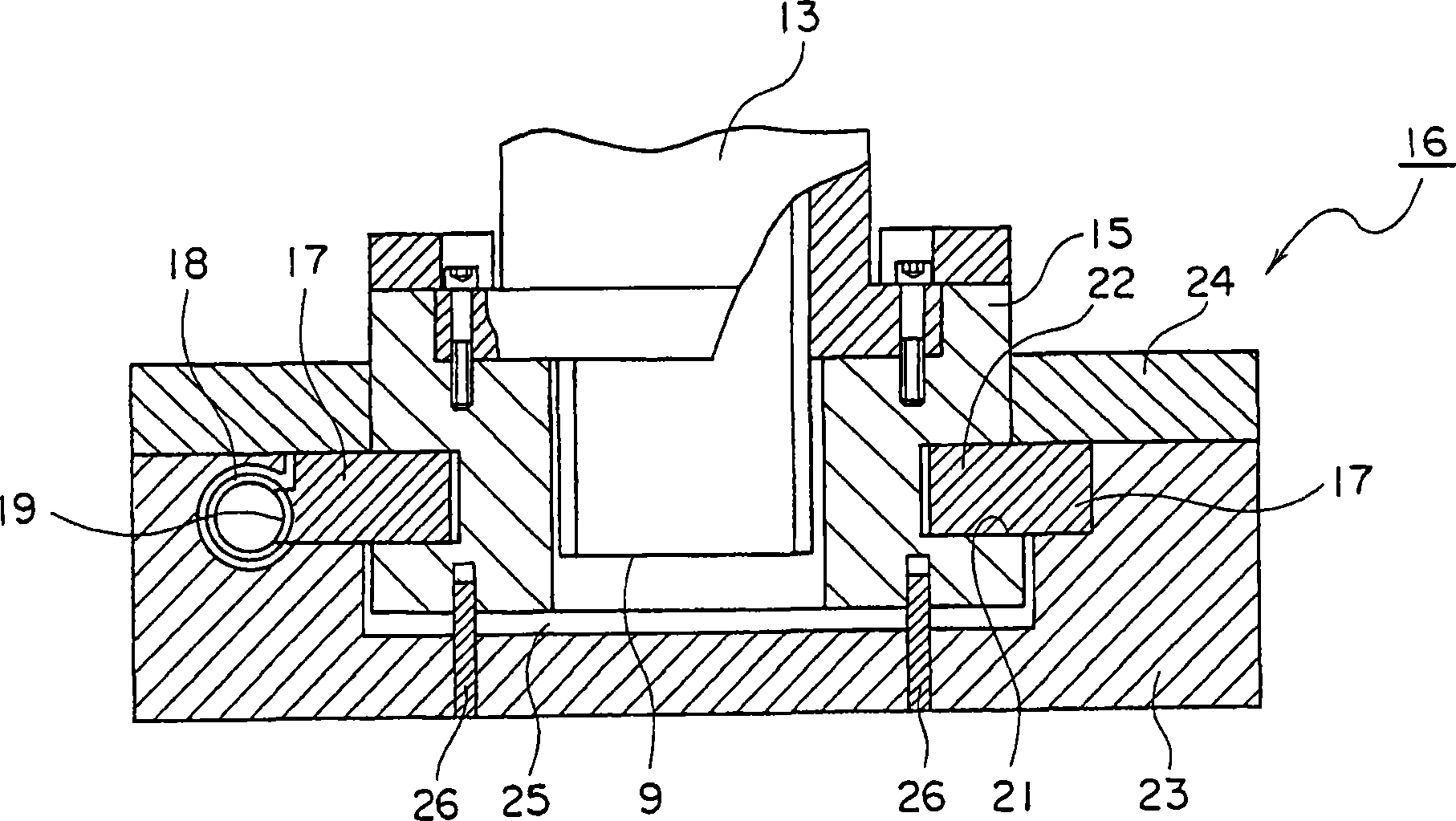

[0059] figure 2 with image 3 A detailed diagram showing the differential mechanism, figure 2 for figure 1 A-A direction view, image 3 for figure 2 B-B direction view. The symbols in the figure and figure 1 correspond.

[0060] A worm gear 19 that meshes with a worm 18 provided in the storage body 16 is provided on the nut lifting plate 17 . In addition, a helical sliding groove 21 (refer to FIG. 5 which exaggerates the angle of the sliding groove 21 ) is formed at the central part of the outer peripheral surface of the nut lifting sleeve 15 , and on the inner periphery of the nut lifting plate 17 A guide engaging portion 22 (refer to FIG. 5 exaggerating the angle of the guide engaging portion 22 ) is provided on the surface, and the guide engaging portion 22 is slidably engaged with the slide groove 21 running in a helical shape of the nut elevating sleeve 15 .

[0061] The housing 16 is formed by a housing member 23 and a ring member 24. The housing member 23 s...

Embodiment 3

[0088] Figure 15 with Figure 16 Another embodiment of the differential mechanism is shown, Figure 15 for with image 3 corresponding figure, Figure 16 for with figure 2 corresponding figure.

[0089] Symbol numbers 9, 13 (15), 17, 18, 19, 21, 22, 23, 24, 26, 44 and figure 2 or image 3 correspond.

[0090] exist Figure 15 with Figure 16 case of the example shown, with figure 2 with image 3 Compared with the illustrated embodiment, the difference is actually the following two points.

[0091] one of which is figure 2 with image 3 The shown nut member 13 is constructed as one piece with the nut lifter sleeve 15 . where the second point is with figure 2 with image 3 There are three guide joints corresponding to the guide joints 22 of the nut lifting plate 17 at intervals of 120°, and there are three cutouts corresponding to the cutouts 44 of the nut lifter sleeve 15 at intervals of 120°. The sliding groove corresponding to the groove 21 is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com