Wo2009055633

A technology for pipe joints and pipes, applied in the field of pipe joints, can solve the problems of ineffective locking and the inability of the locking piece to withstand the connecting end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

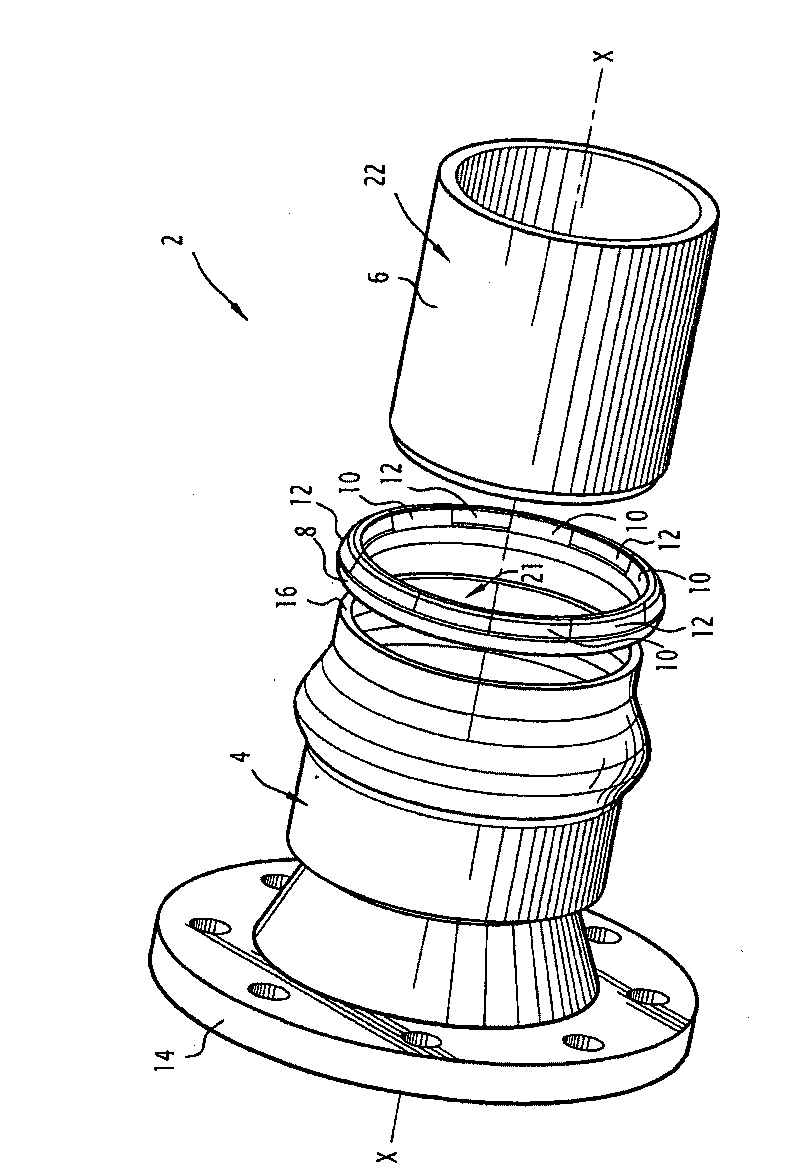

[0046] figure 1 A pipe connection according to the invention is shown, designated as a whole by the reference numeral 2 .

[0047] The pipe connection 2 has a first pipe part with a joint end 4 , a second pipe part with a coupling end 6 , a sealing ring 8 , an anti-extrusion part 10 and a locking part 12 .

[0048] The pipe joint 2 defines a central axis X-X. "Axial", "radial" and "circumferential" in the following description are all relative to the central axis X-X.

[0049] The engagement end 4 and the coupling end 6 are made of cast iron, for example. In addition, the piping members may be covered with a protective layer not shown.

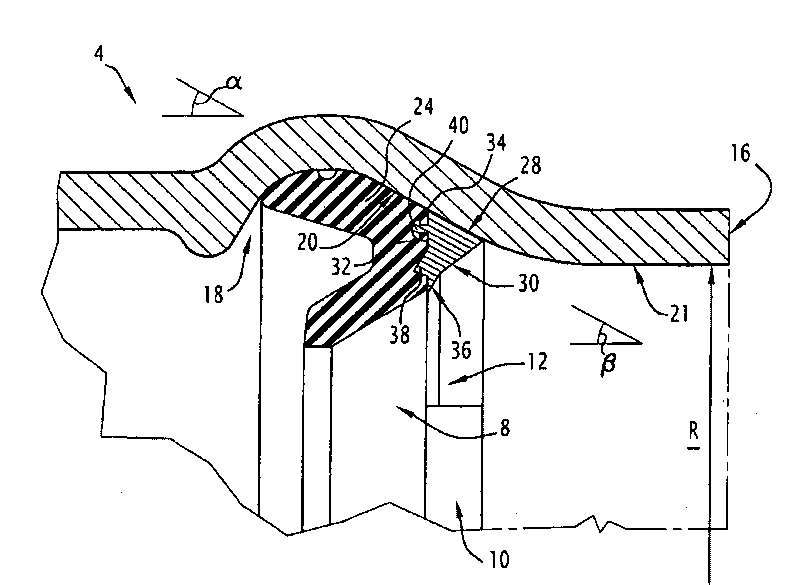

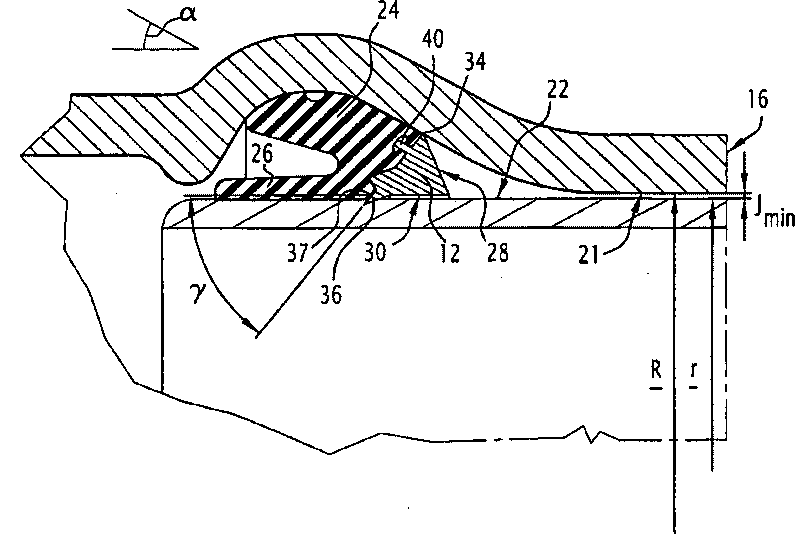

[0050] The joint end 4 has a fixed flange 14 for assembly with a pipe member (not shown) with a corresponding flange and a free end 16 facing the coupling end 6 in the unassembled state. The joint end 4 also has an annular inner groove 18 (see figure 2 ). Here, the inner groove 18 has a substantially circular cross-section, but other sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com