Hydraulic hanger of double block type sleeper for passenger special line

A passenger dedicated line, double-block technology, applied in transportation and packaging, load hanging components, etc., can solve the problems of large span of gantry crane, unsuitable sleepers for long-distance transportation, low operation efficiency, etc., and achieve the effect of stable lifting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described with reference to above-mentioned accompanying drawing:

[0019] A double-block sleeper hydraulic spreader for passenger dedicated lines, characterized in that it includes:

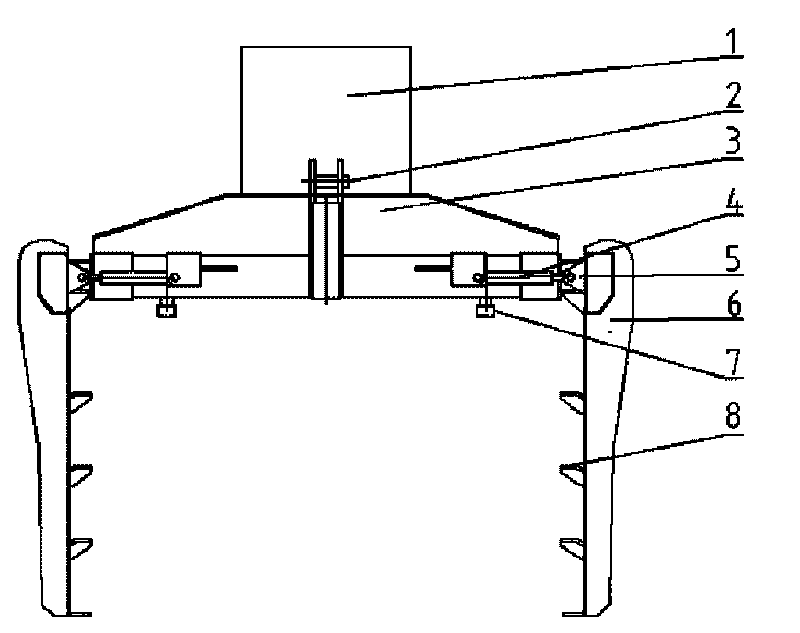

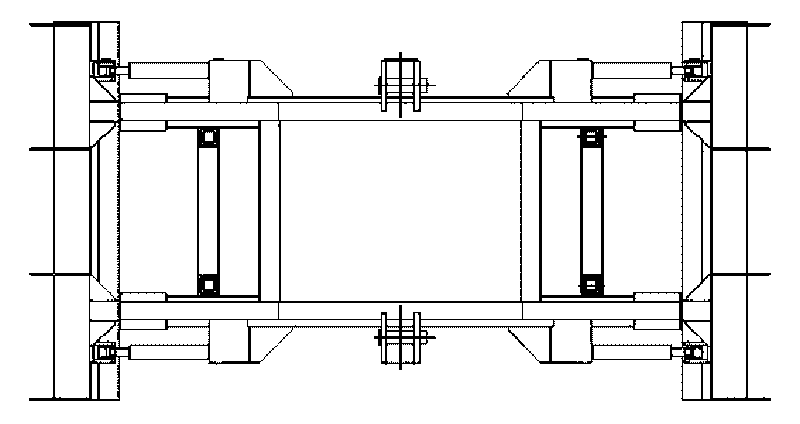

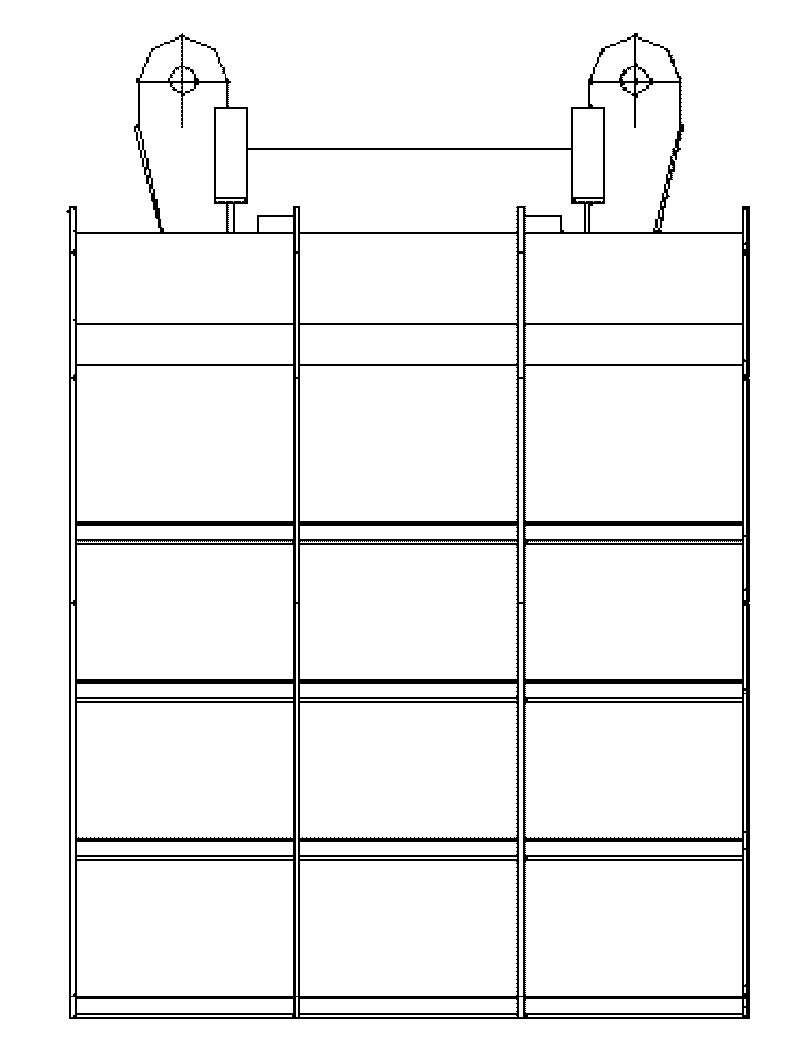

[0020] The fixed hanger 3 of a frame structure, the two ends of the fixed hanger 3 are respectively provided with a movable telescopic integrated boom 6 that can be opened and retracted to form a portal structure, that is, two movable telescopic integrated booms 6 each The two ends of the fixed hanger 3 are respectively connected by the executive oil cylinder 4 and the movable telescopic rod 5. The front and rear sides of the fixed hanger 3 are symmetrically provided with a pair of lifting lugs 2 corresponding to the double hooks of the gantry crane. The lower part of the fixed hanger 3 Two buffer positioning protection rods 7 are respectively arranged on the front and rear sides symmetrically; according to whether fasteners are installed during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com