Patents

Literature

77results about How to "Increase stack height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

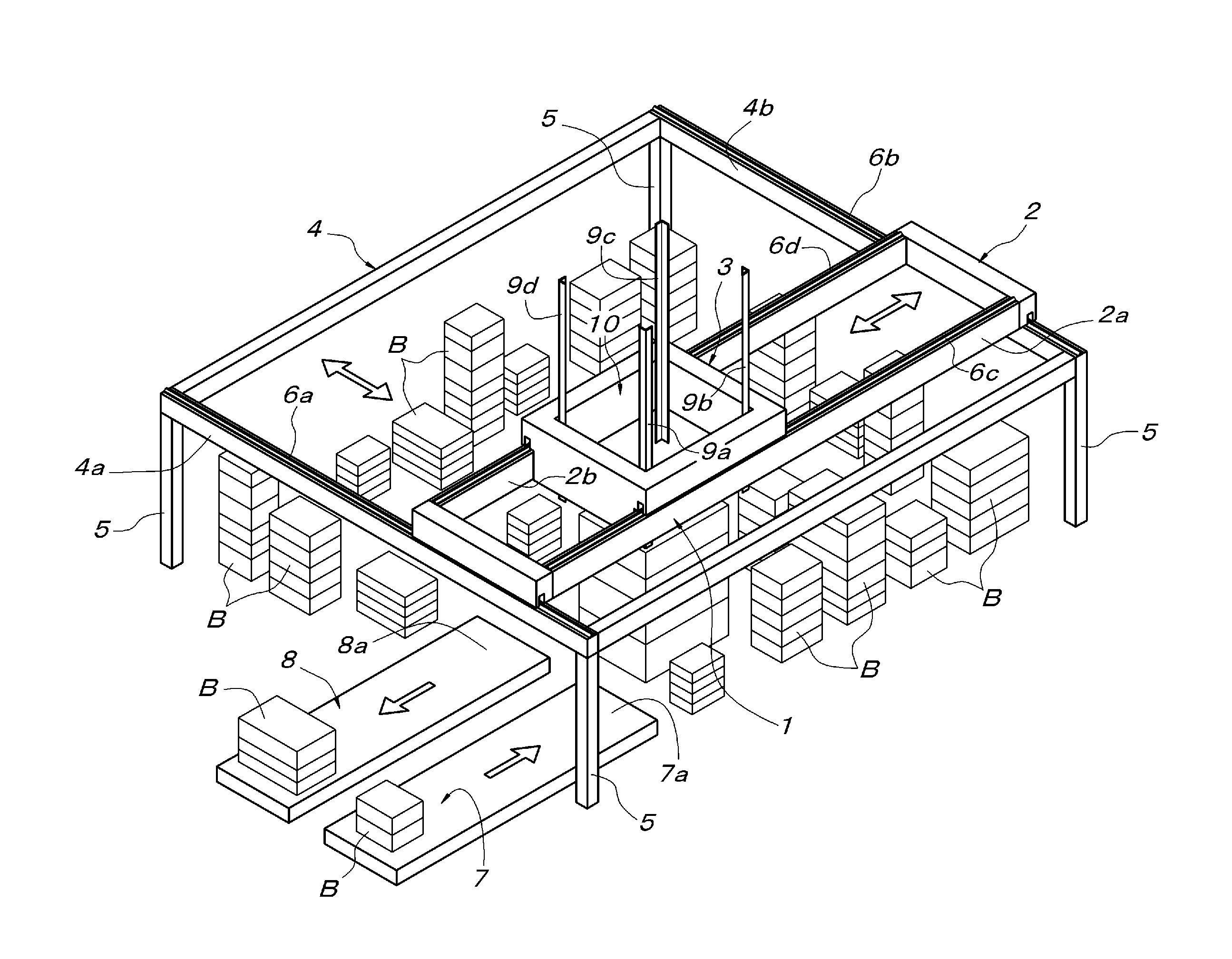

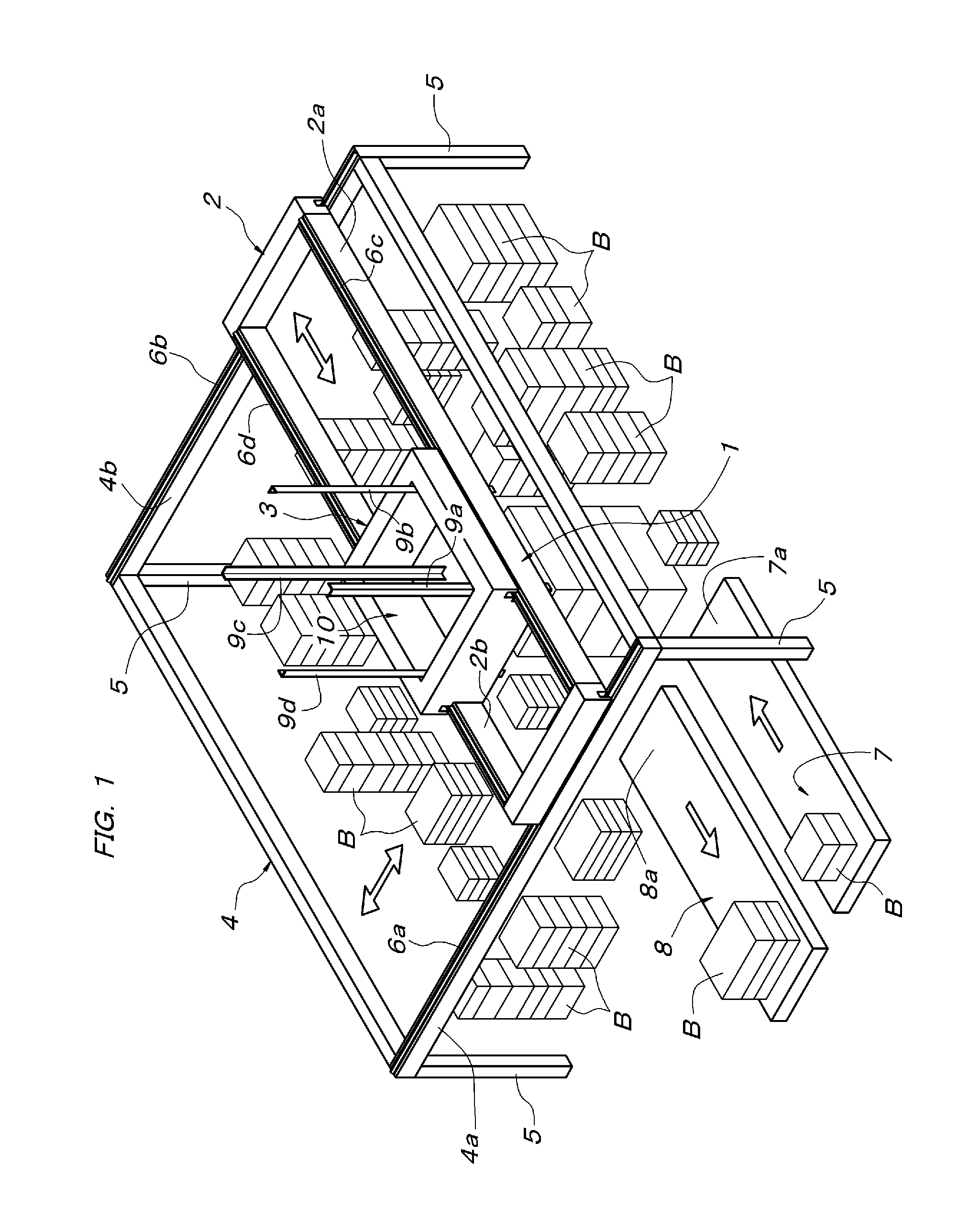

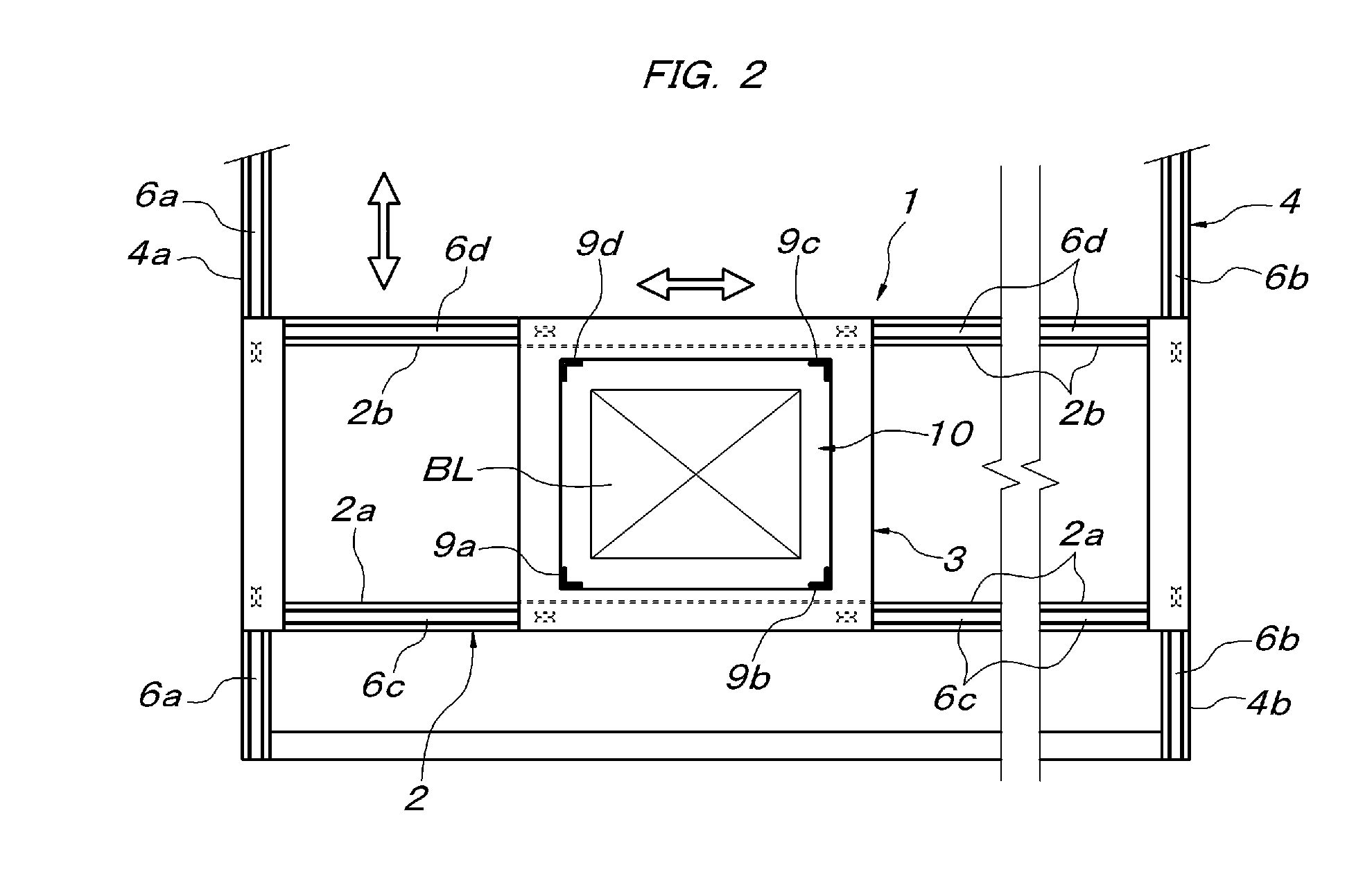

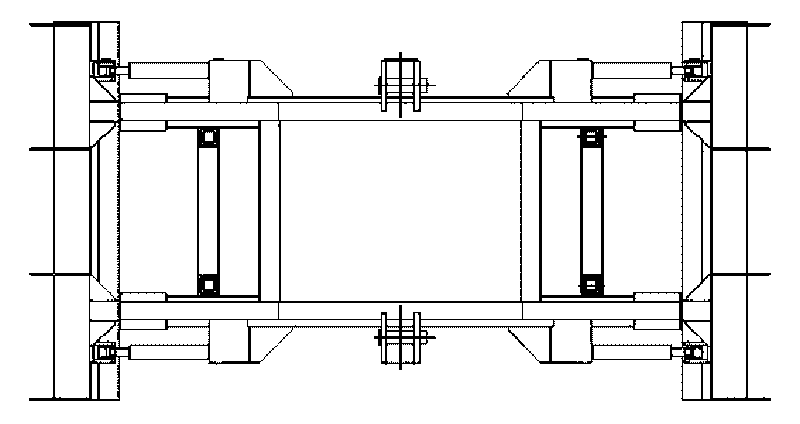

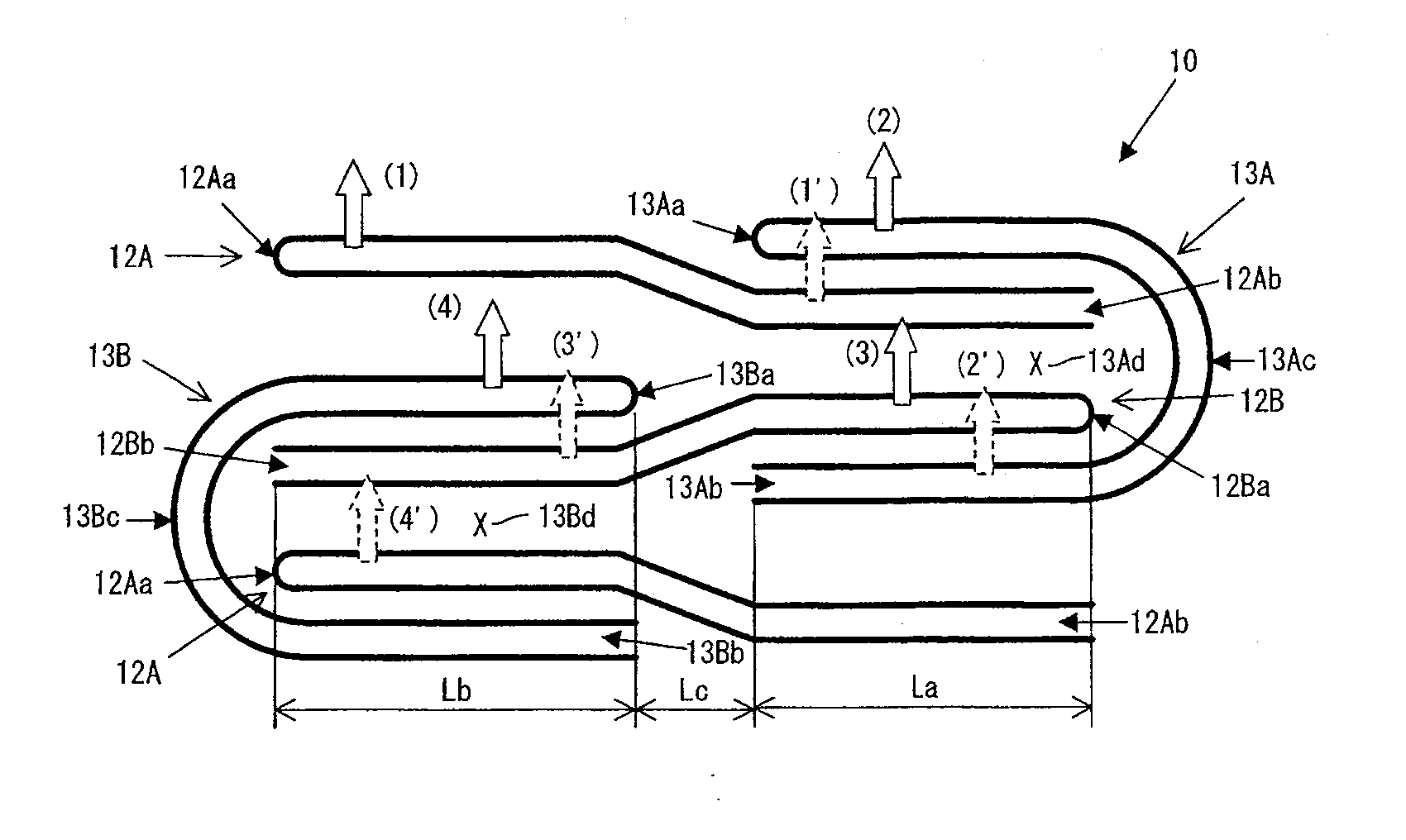

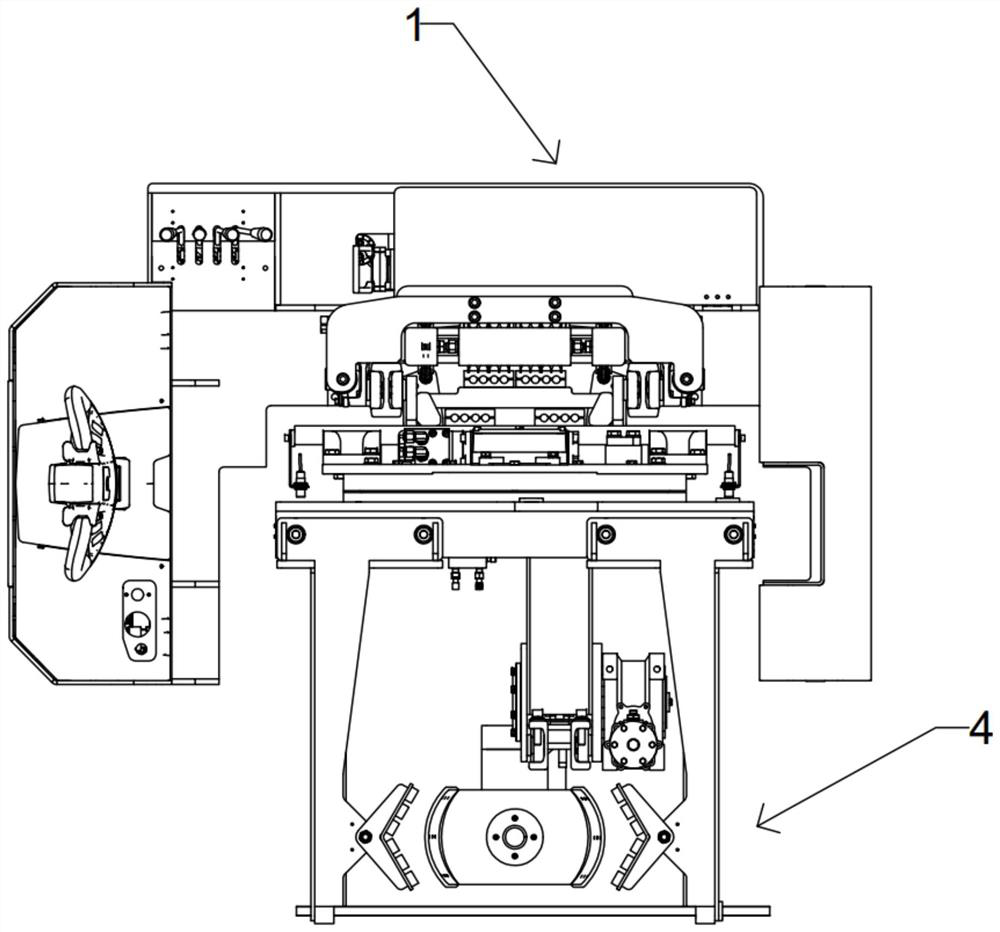

Transport Device For Article Transport Boxes

InactiveUS20160001992A1Reliably and firmly gripped and transportedHigh strengthStacking articlesDe-stacking articlesEngineeringPallet

A transport device for article transport boxes for storing or sorting stacked box-type pallets has four vertically movable gripping columnar members on a transporting traveling body horizontally travelable on an upper side of a storage area. The gripping columnar members have an angular shape in cross section and have gripping faces pressure-contacted to both sides of each corner of an article transport box. An elevating drive means and a gripping drive means of the gripping columnar members are provided to the transporting traveling body. The gripping drive means moves at least three gripping columnar members of the four gripping columnar members horizontally between a retracting position of being away outside from each corner of the article transport box, and a gripping position of gripping the article transport box via the four corners thereof by way of the four gripping columnar members.

Owner:DAIFUKU CO LTD

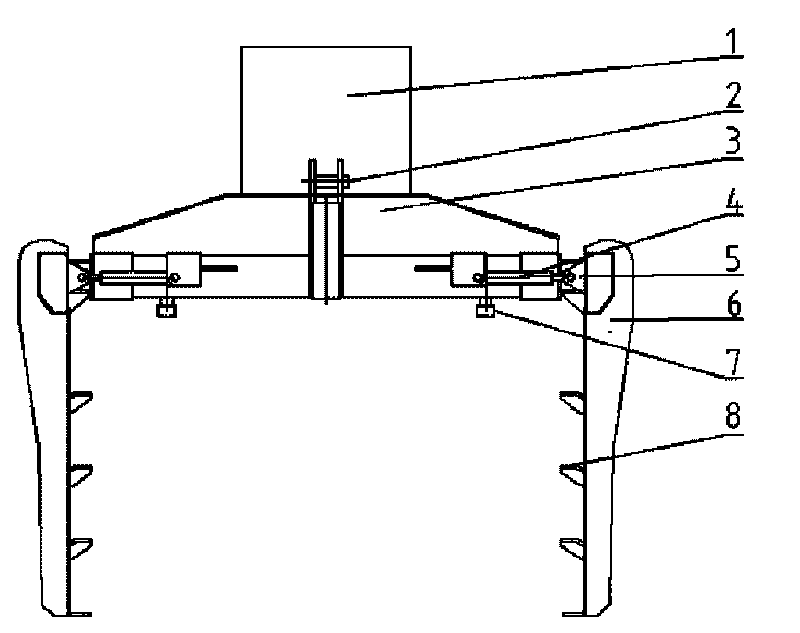

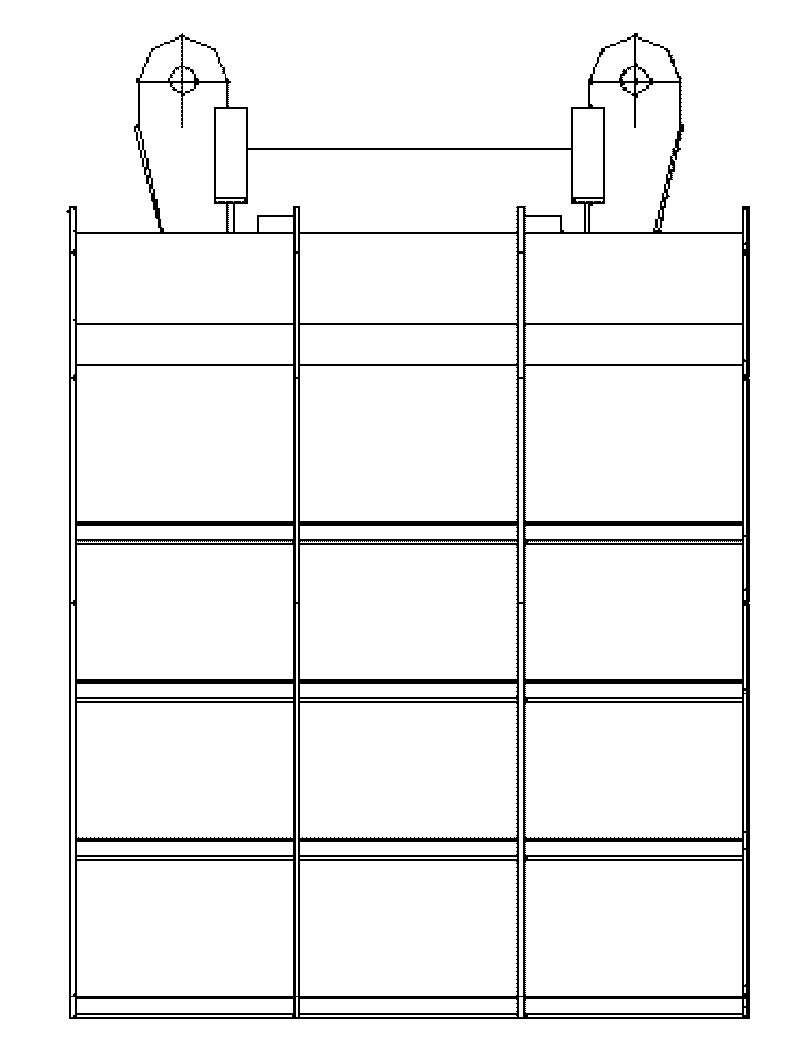

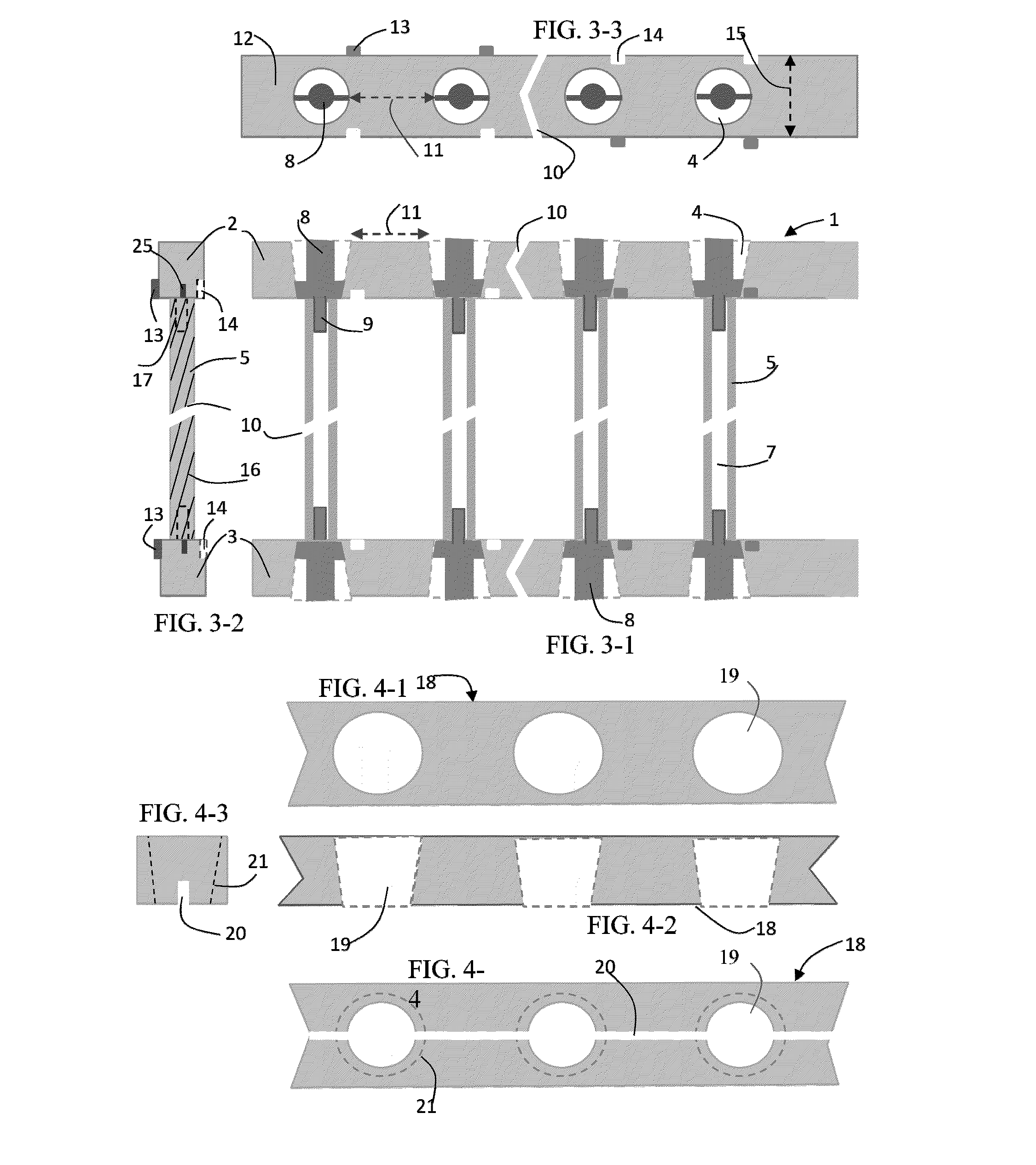

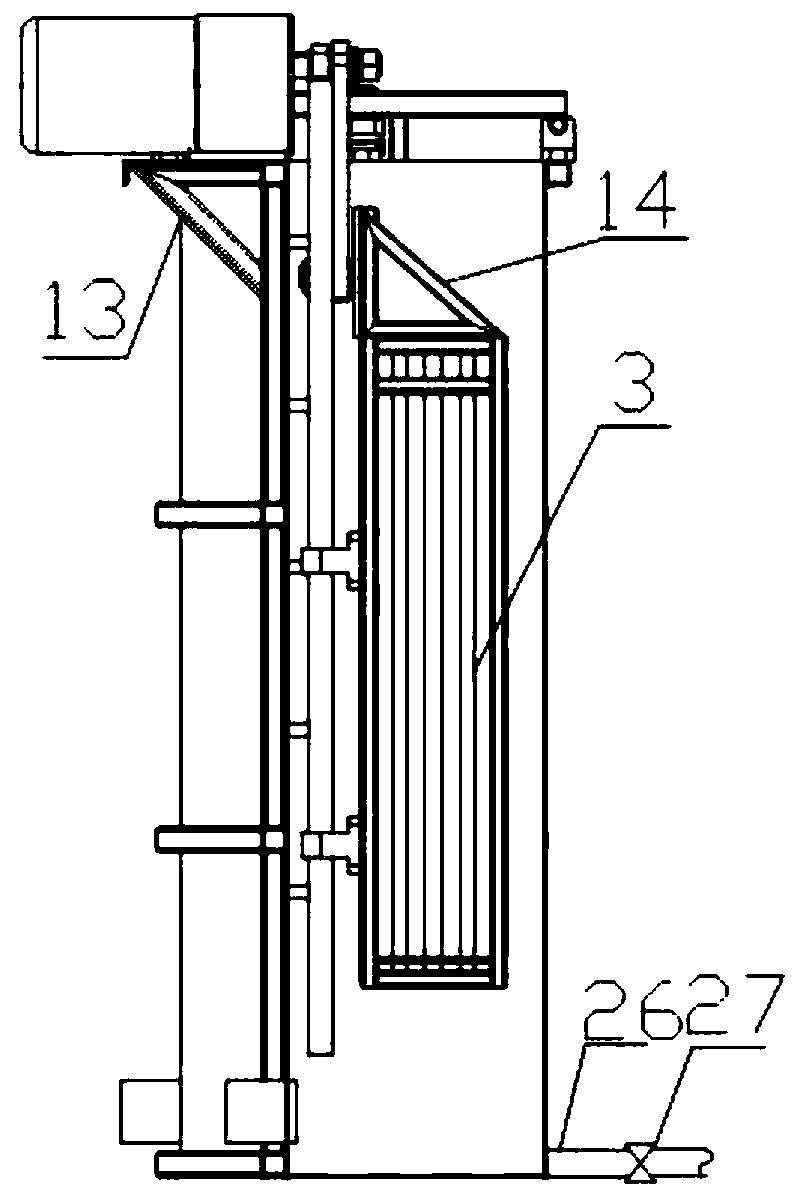

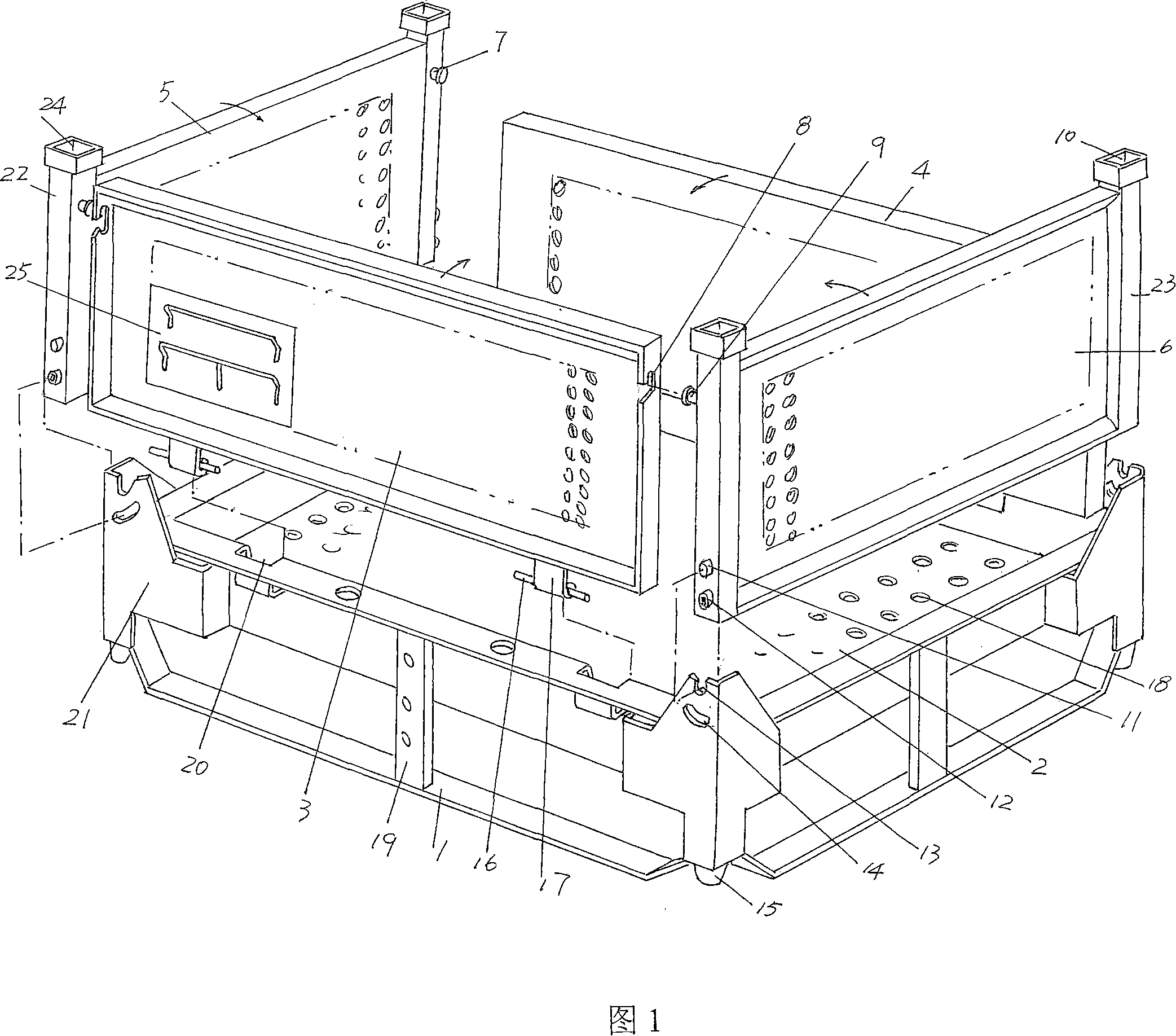

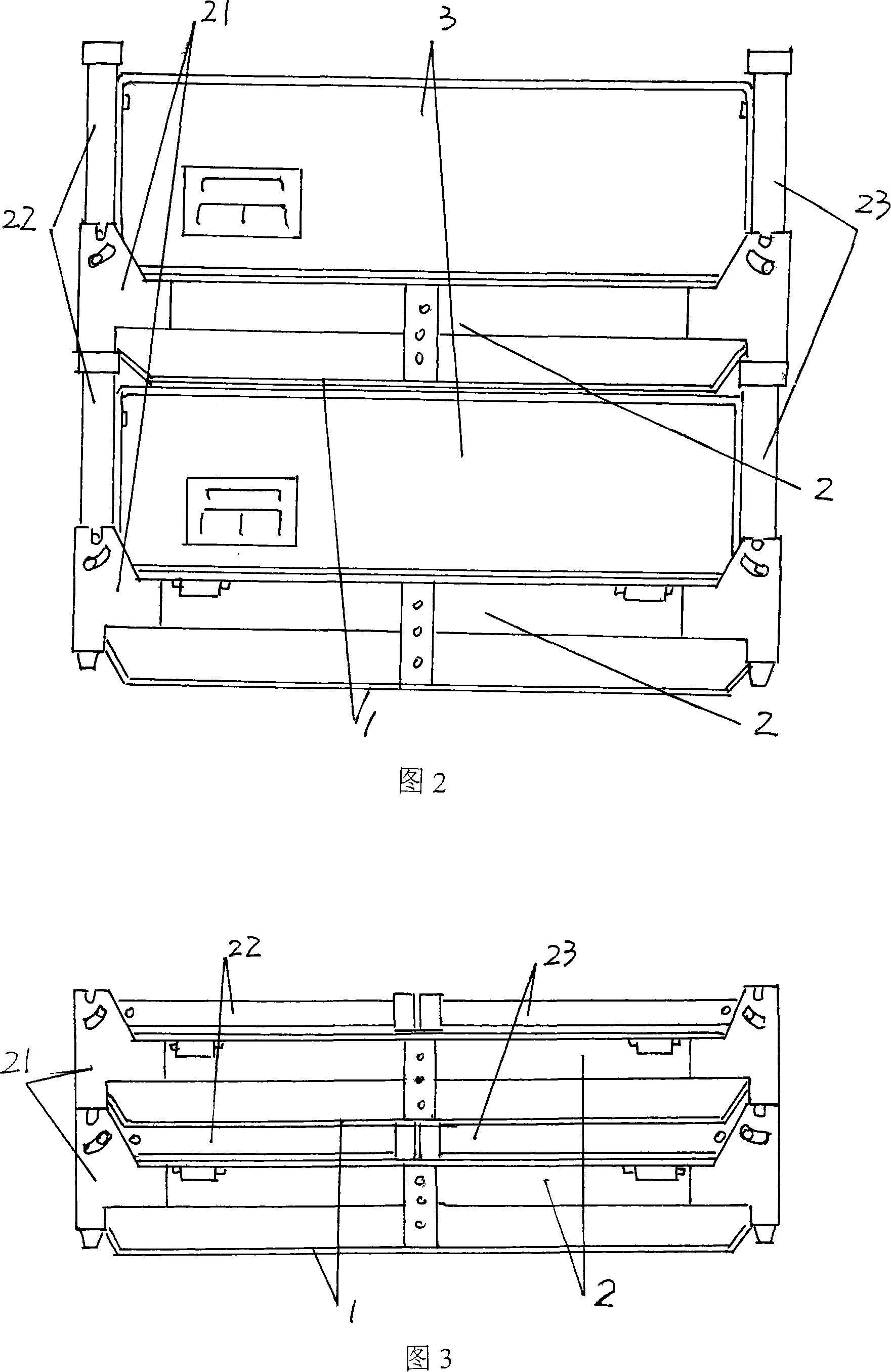

Hydraulic hanger of double block type sleeper for passenger special line

InactiveCN101708803ASmooth liftSmall force without deformationLoad-engaging elementsEngineeringMechanical engineering

The invention relates to a hydraulic hanger of a double block type sleeper for a passenger special line, belonging to double block type sleeper product pile and loading devices and comprising a small-sized hydraulic station, lifting eyes, a fixed hanger frame, an execution oil cylinder, a movable telescopic link, movable telescopic integrated suspension arms, a buffer positioning protective rod and movable arm lifting support plates; the movable telescopic integrated suspension arms capable of stretching and retracting are respectively arranged at two ends of the fixed hanger frame so as to form a door type structure, i.e. two movable telescopic integrated suspension arms are respectively connected with two ends of the fixed hanger frame through the execution oil cylinder and the movable telescopic rod which are fixedly arranged on the fixed hanger frame; the fixed hanger frame is symmetrically provided with the lifting eyes; the hydraulic station is arranged on the fixed hanger frame; the buffer positioning protective rod is arranged below the fixed hanger frame; evenly-distributed movable arm lifting support plates are longitudinally arranged inside the movable telescopic integrated suspension arms; and opposite movable arm lifting support plates are positioned on the same plane. The hydraulic hanger has the advantages of flexible operation, orderly piling, safety and reliability, improves the operation efficiency, reduces the labor intensity and ensures the quality of products.

Owner:中铁株洲桥梁有限公司

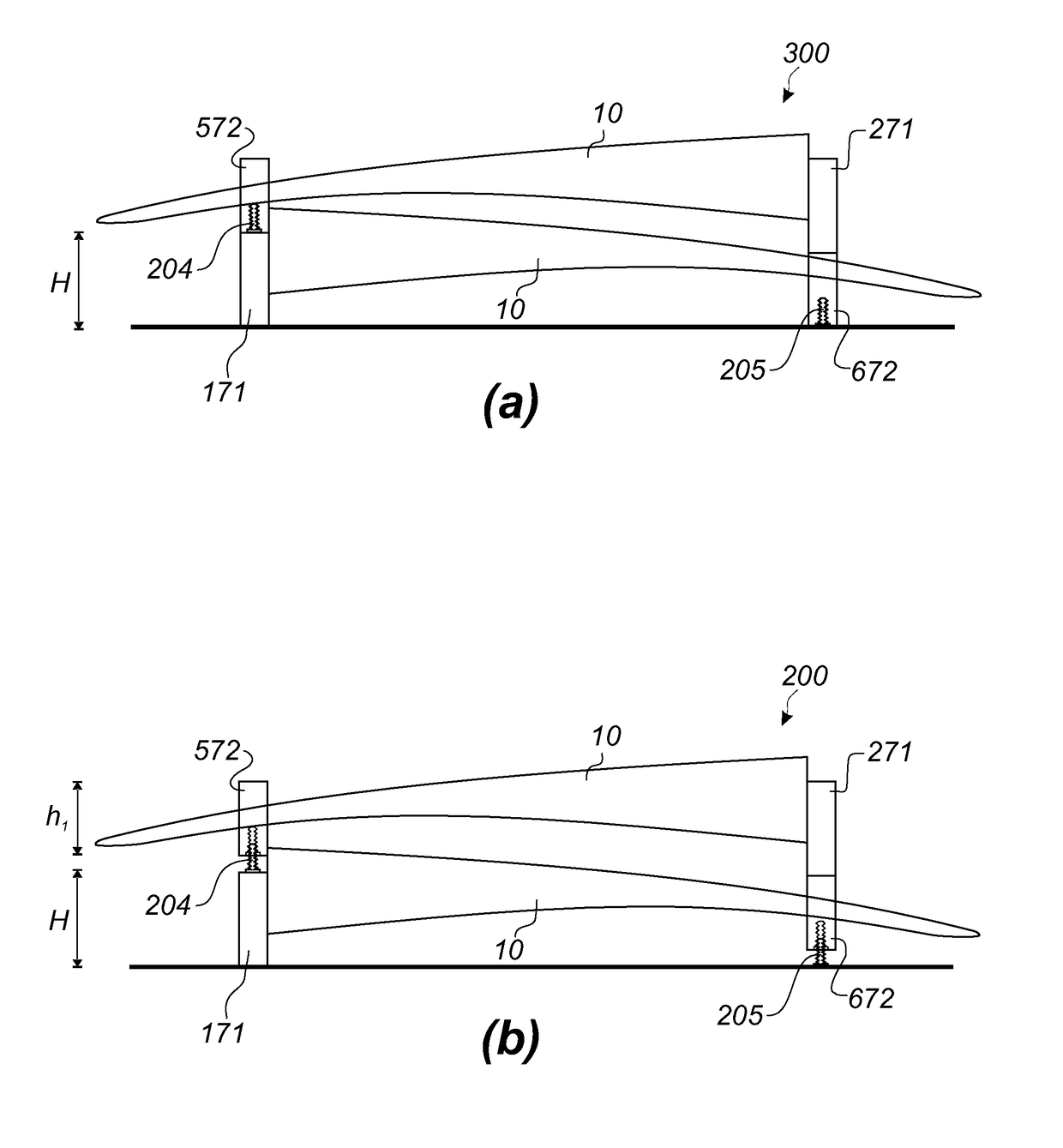

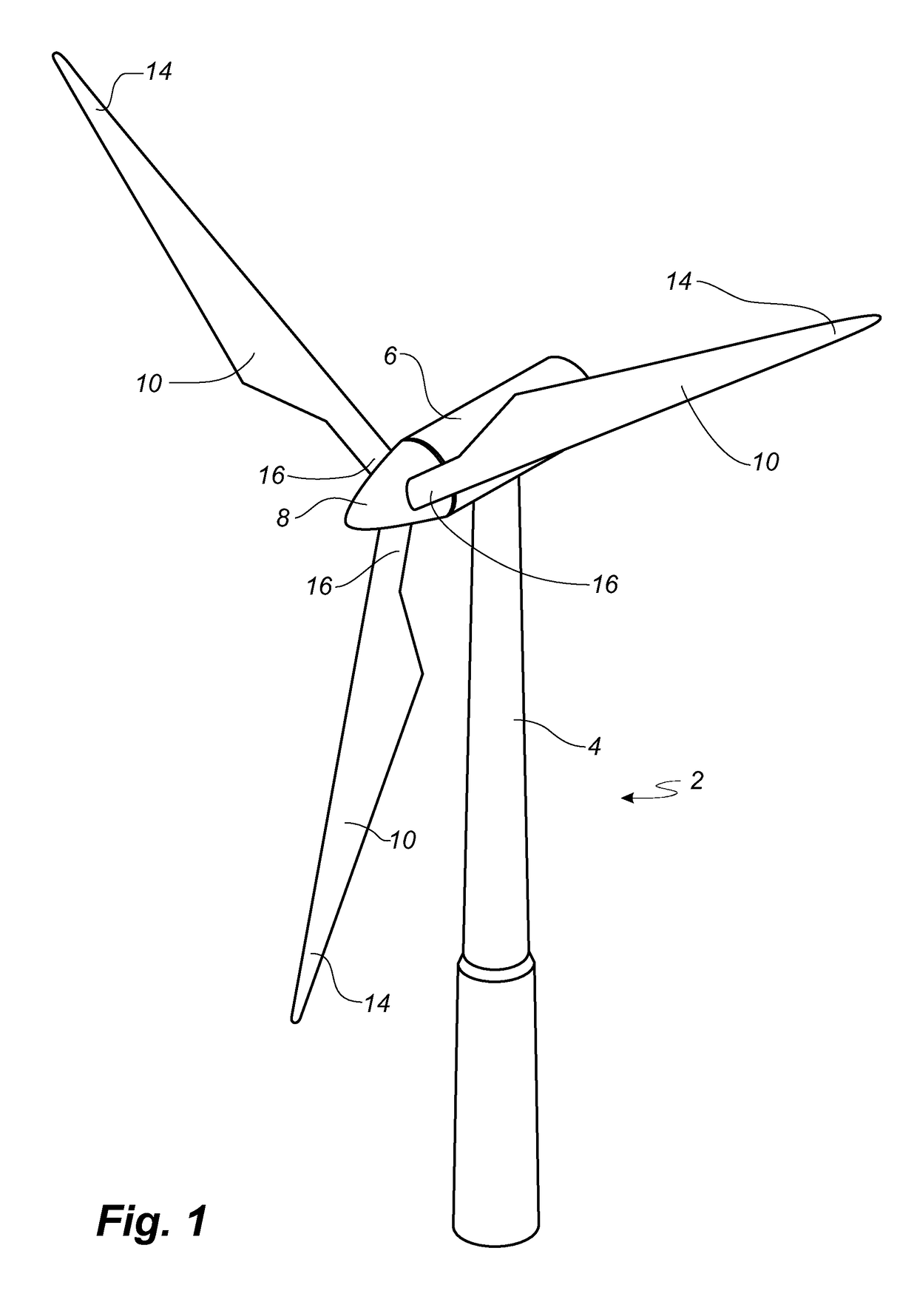

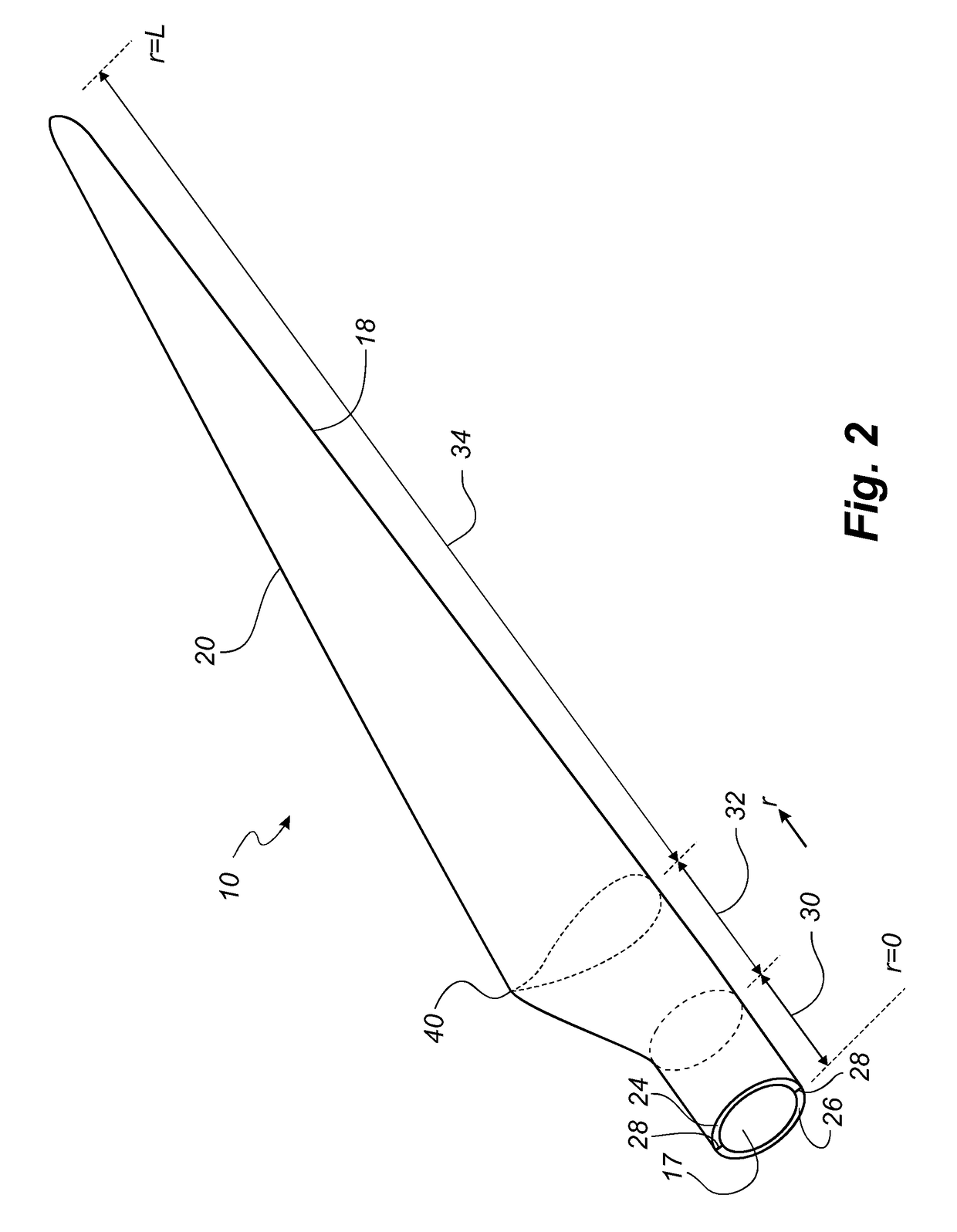

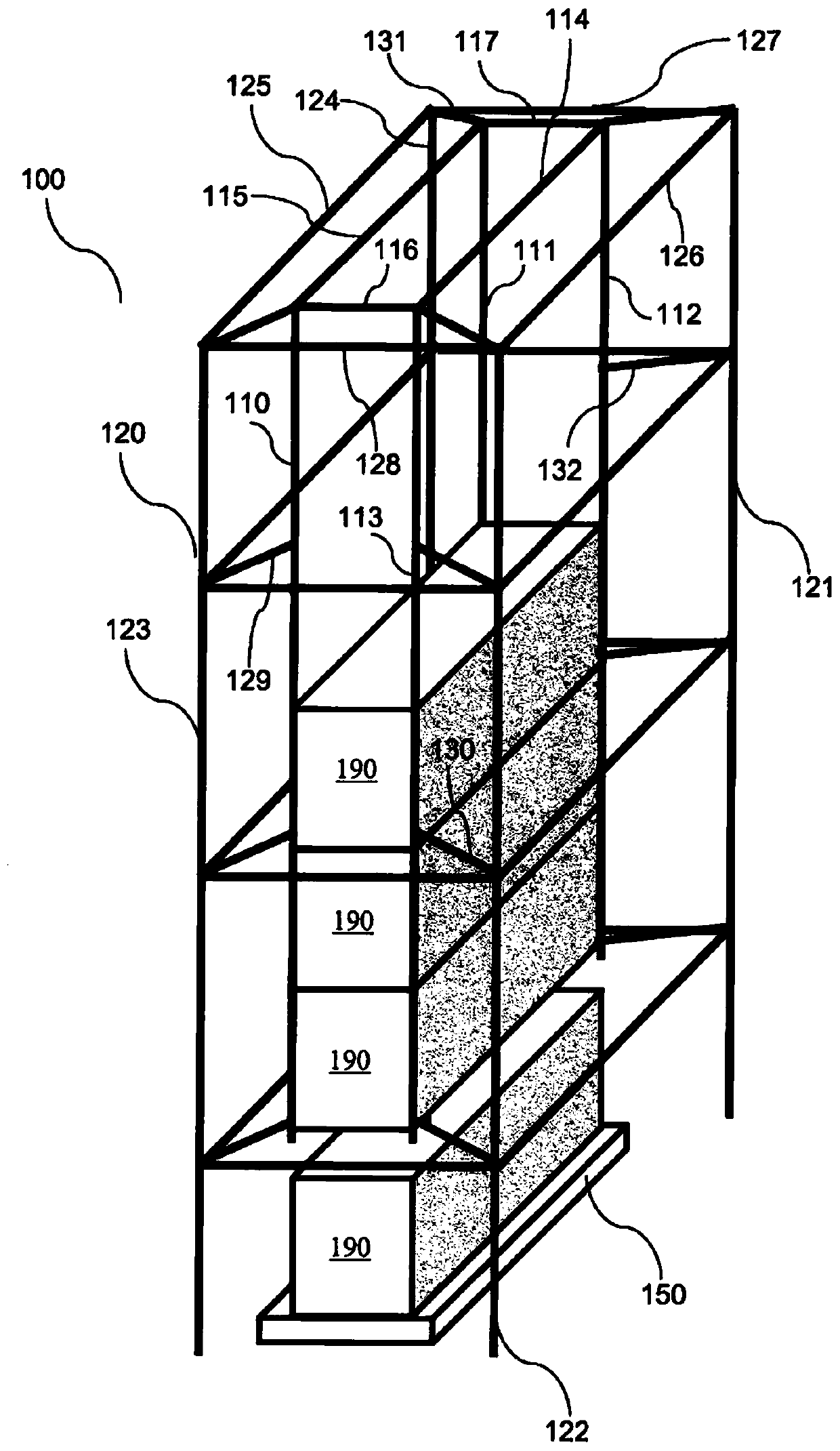

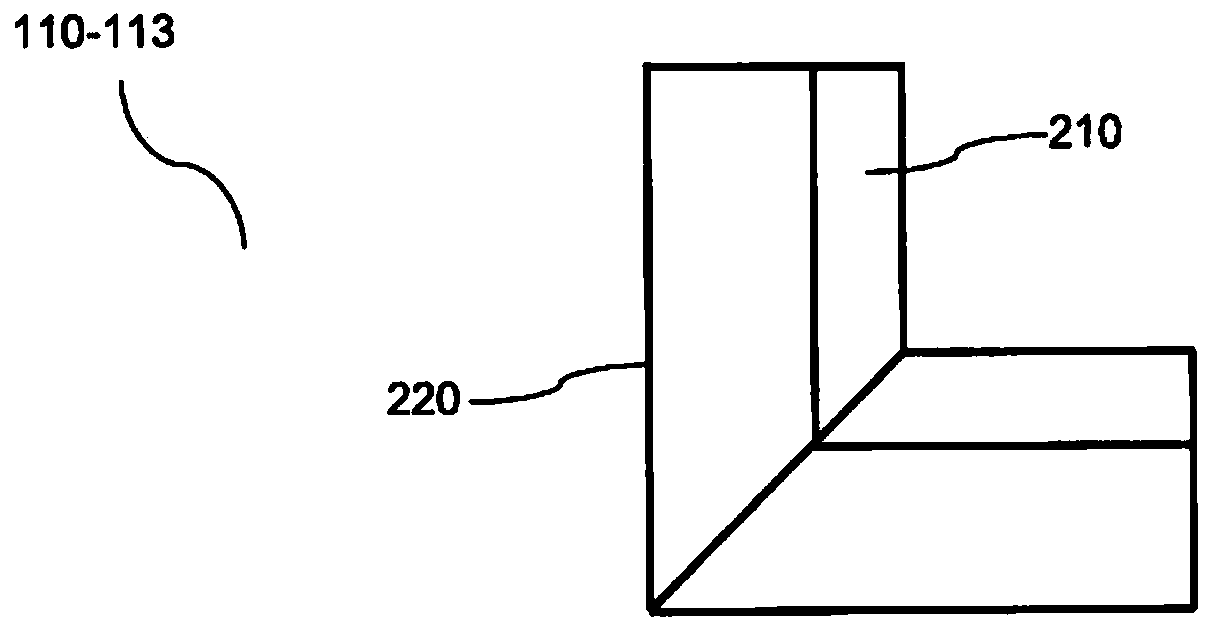

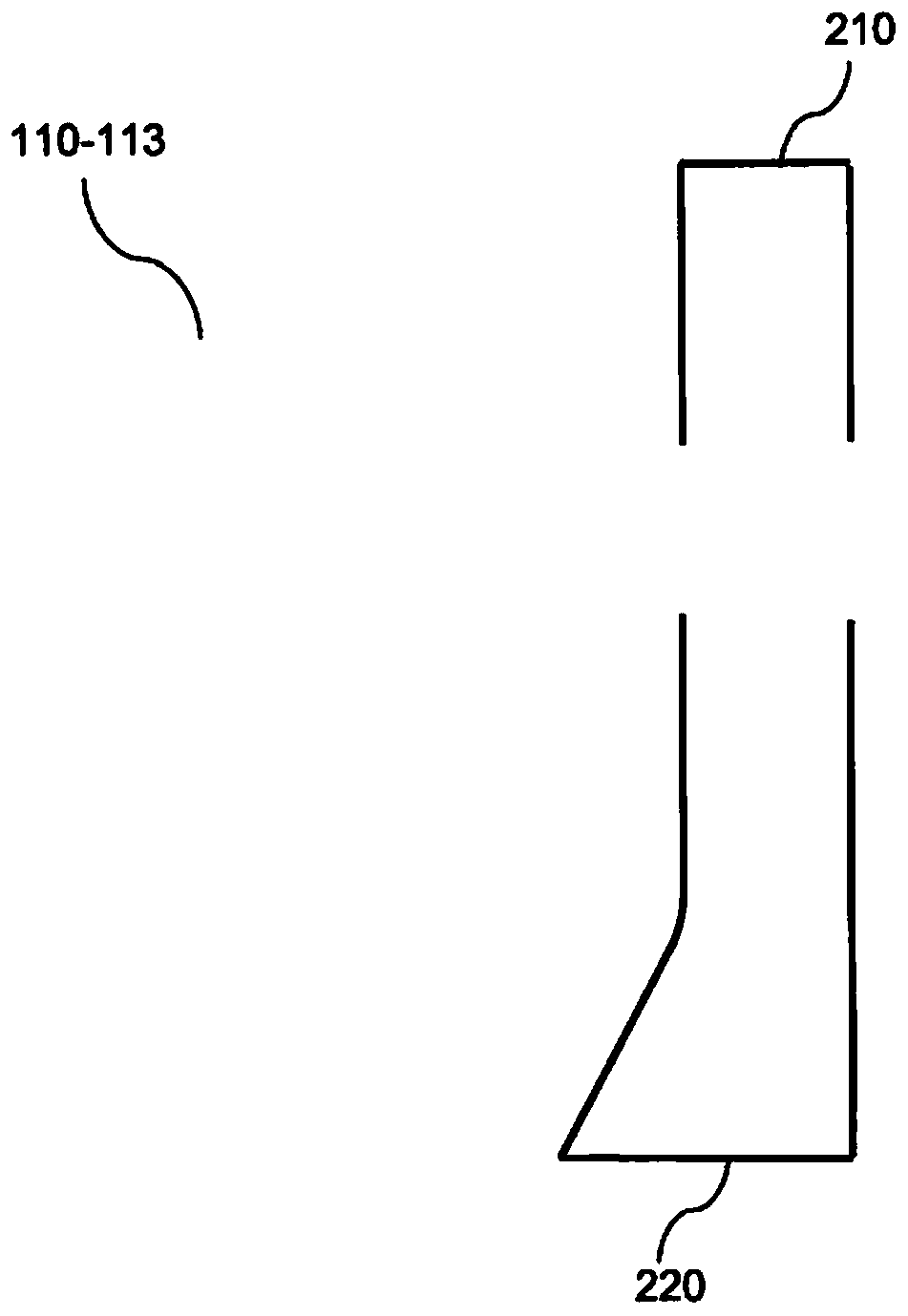

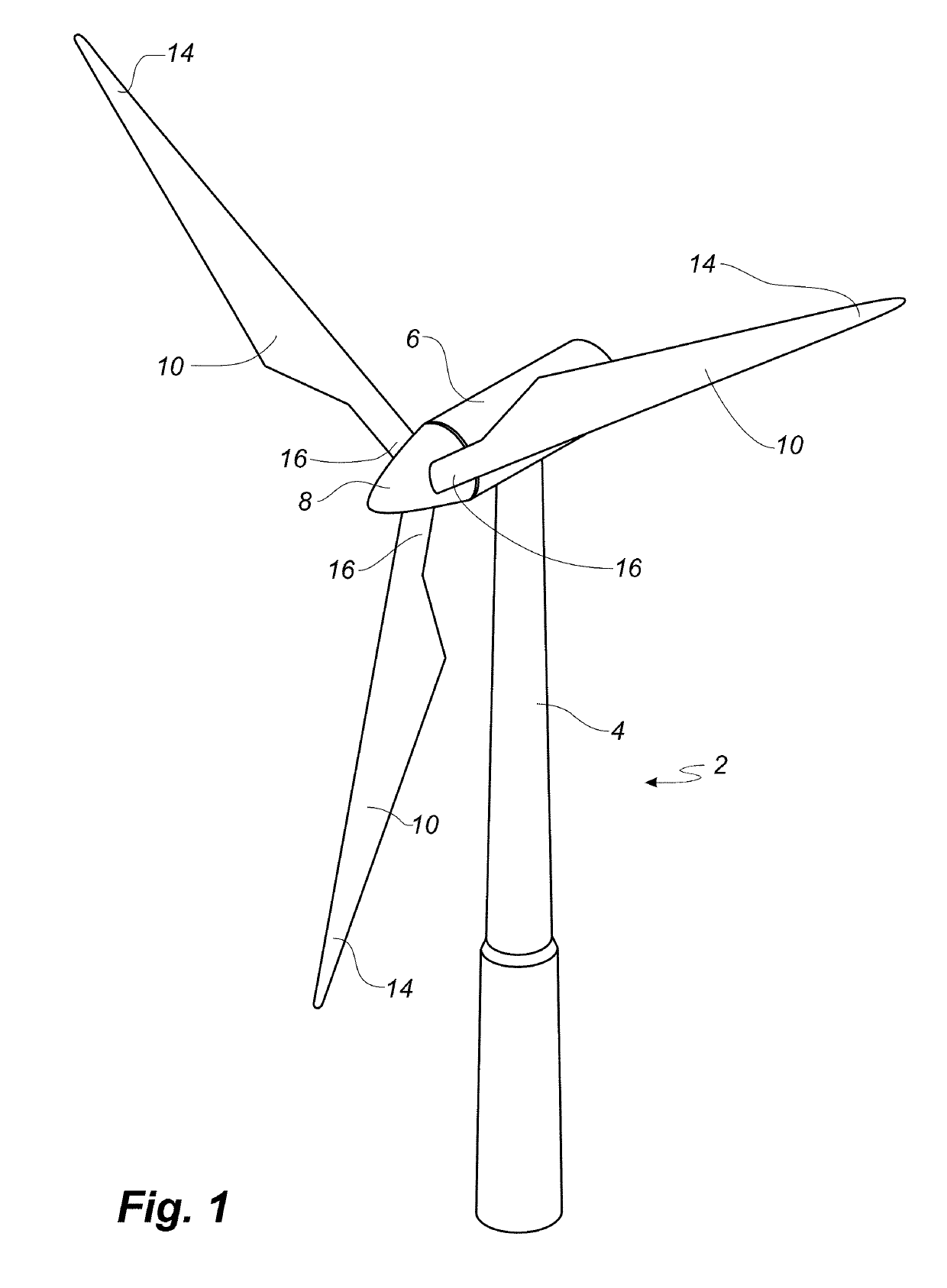

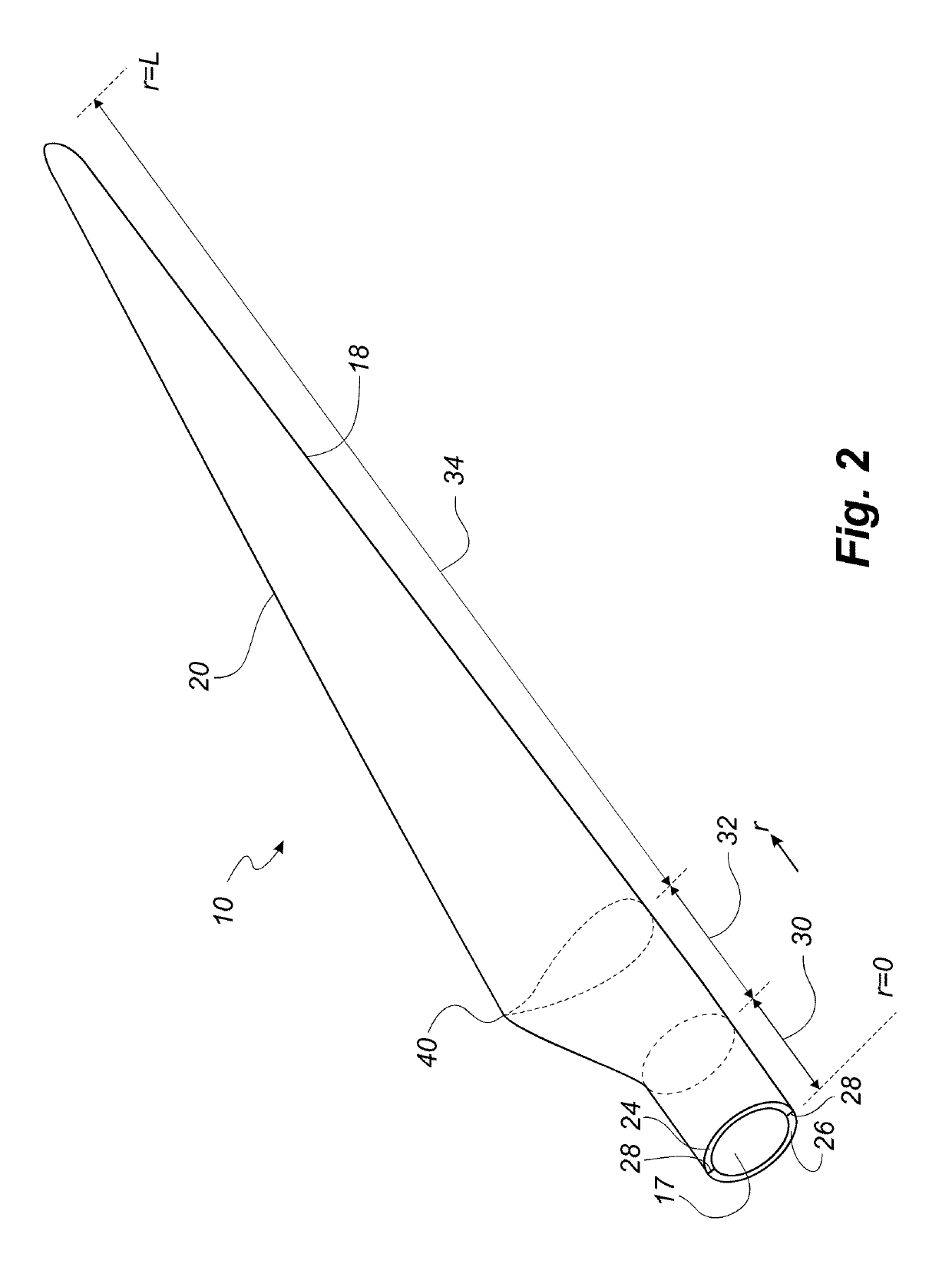

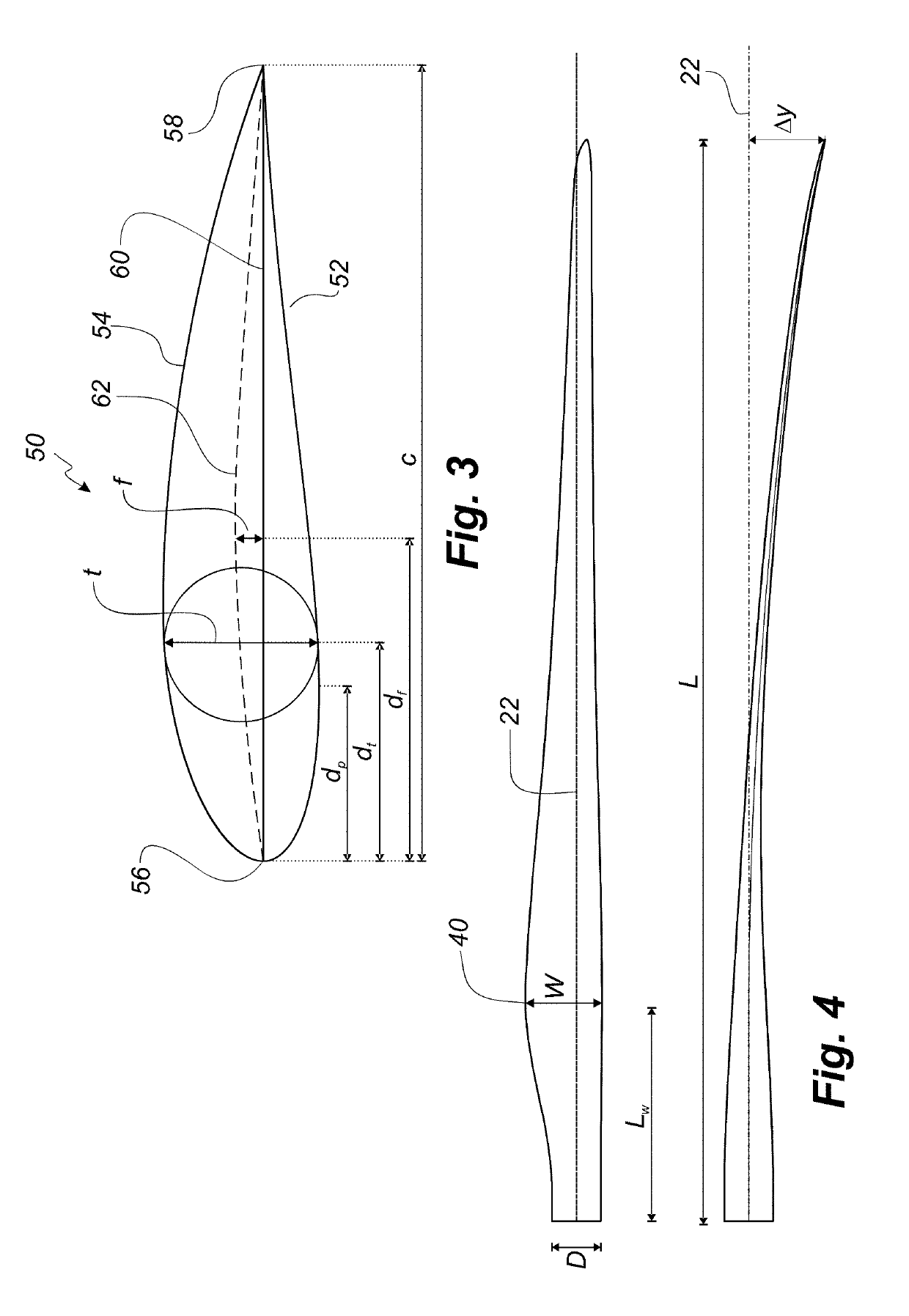

Modular System for Transporting Wind Turbine Blades

ActiveUS20170211548A1Increase flexibilityMinimize heightAccommodation for deck loadsEngine fuctionsTurbine bladeModularity

A modular system for transporting wind turbine blades in at least two different spatial arrangements comprising two or more root end transport frames having a height H for supporting the root end, wherein H<D (D=bolt circle diameter), and two or more first tip end transport frames having a height H1 for supporting the blade towards the tip end, each first tip end transport frame has a base frame and a support bracket provided on top of the base frame, wherein each first tip end transport frame is stackable on top of a root end transport frame and vice versa, so the system is operable to stack successive blades in an alternating root end to tip end arrangement. The first tip end transport frame is replaceable with a second end transport frame that increase the inter-blade spacing, or with a tip end or a root end distance piece.

Owner:LM WP PATENT HLDG

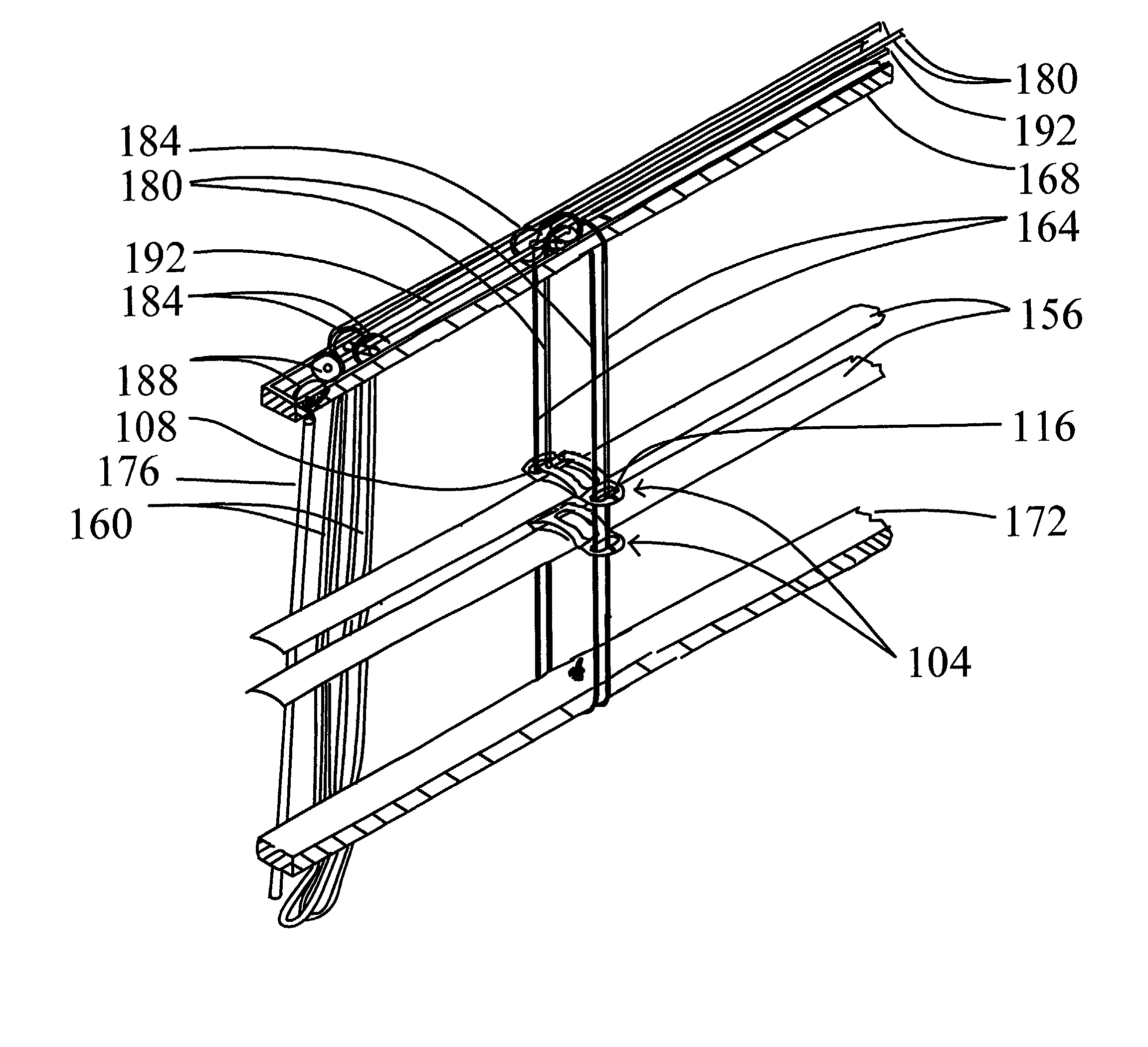

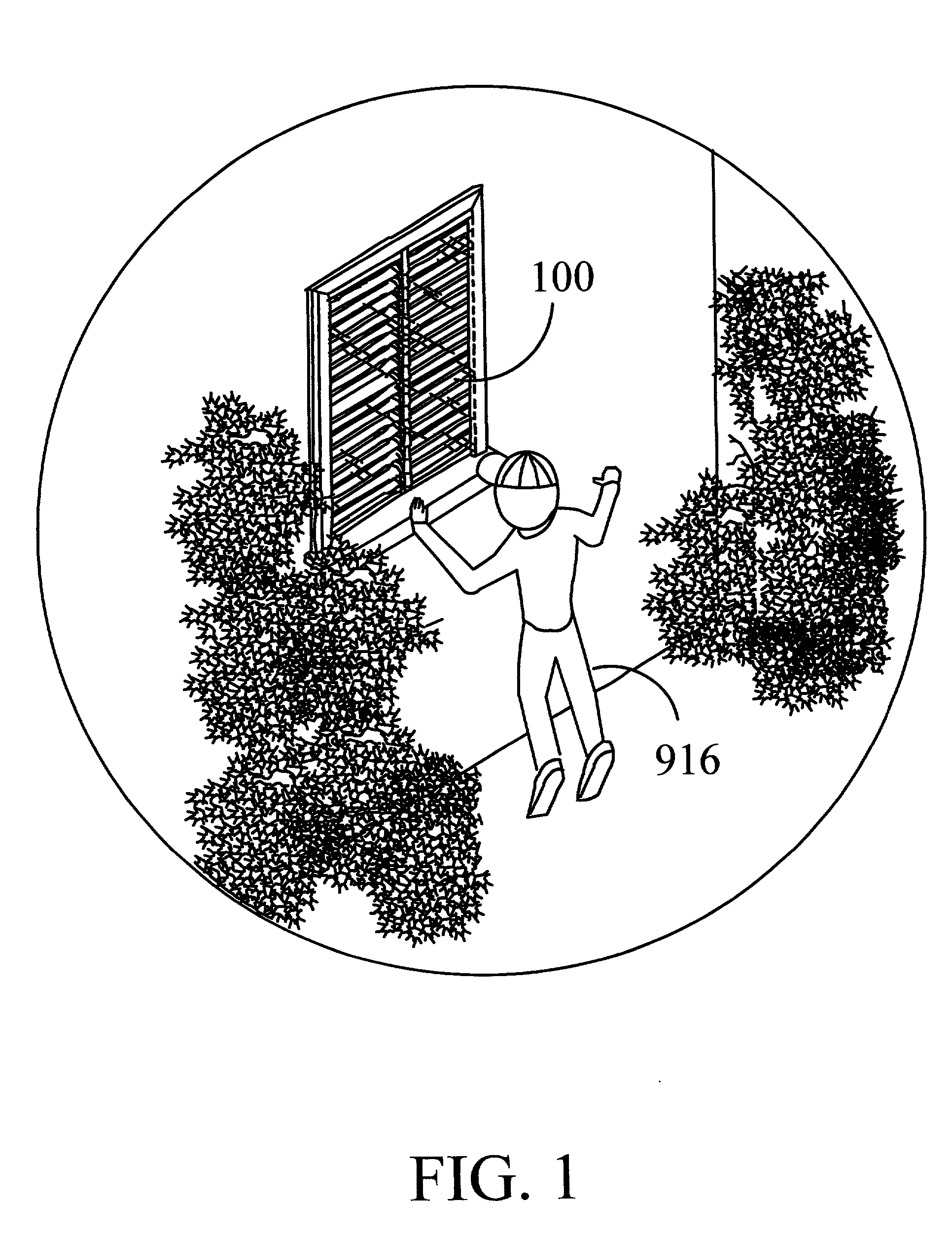

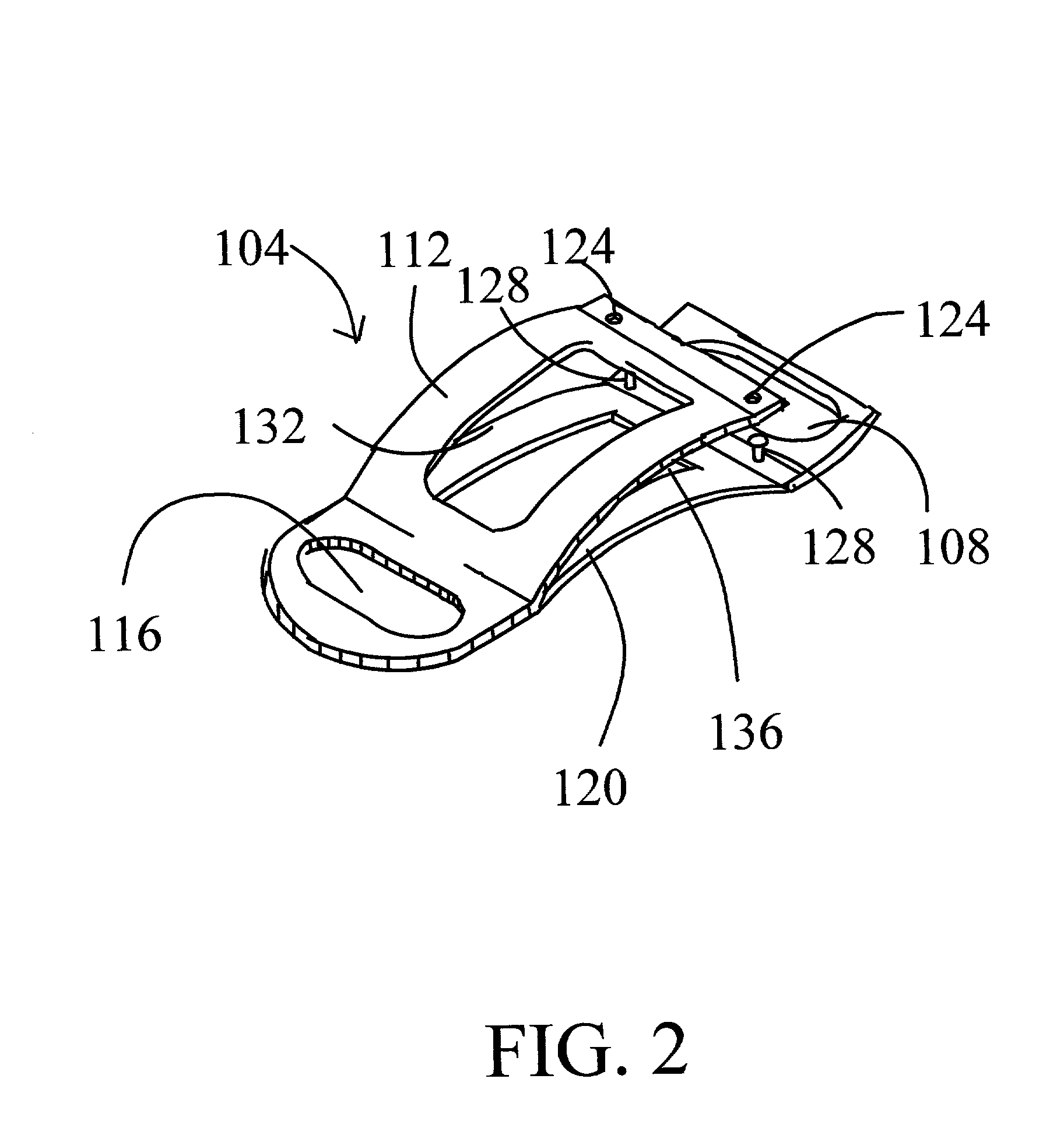

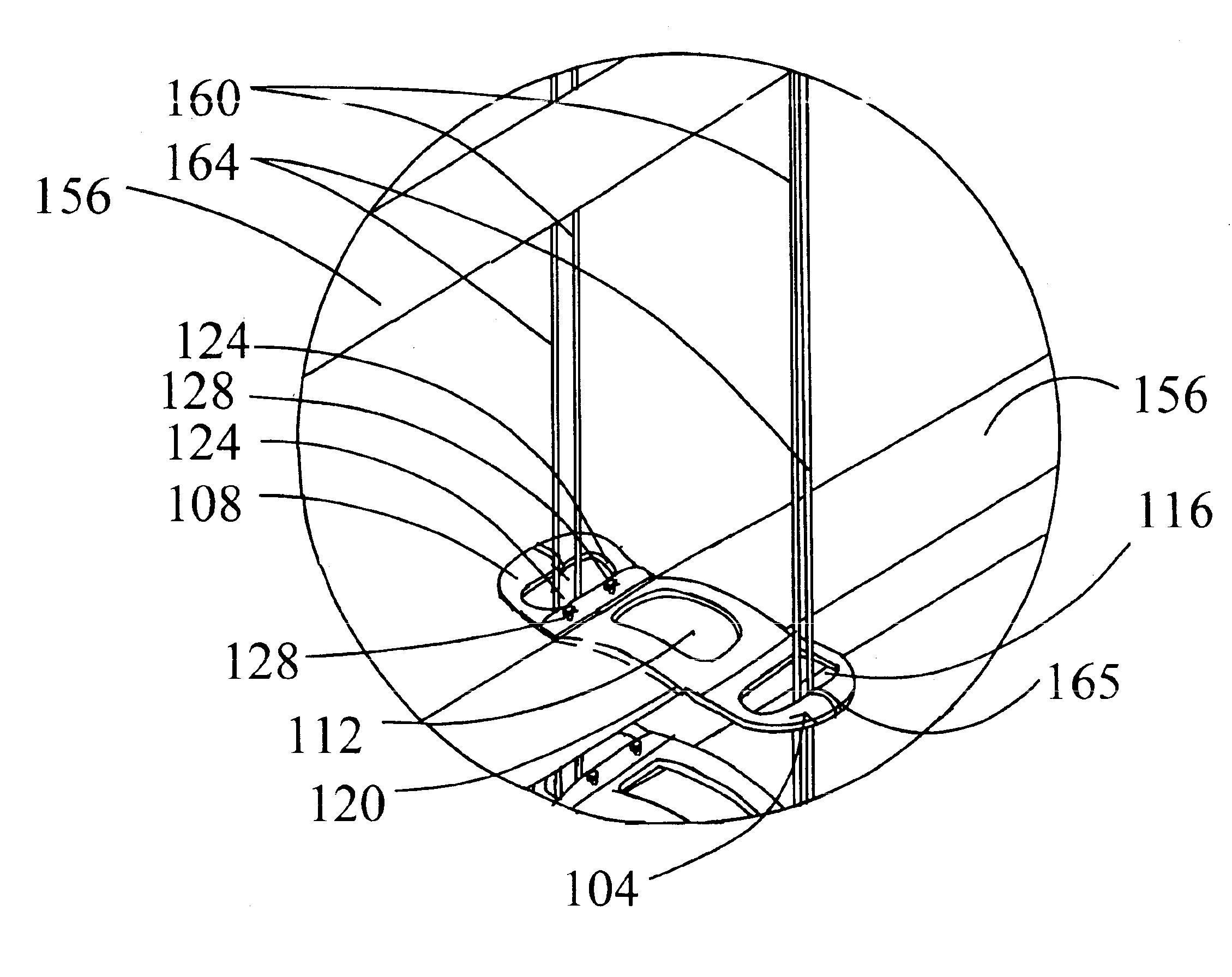

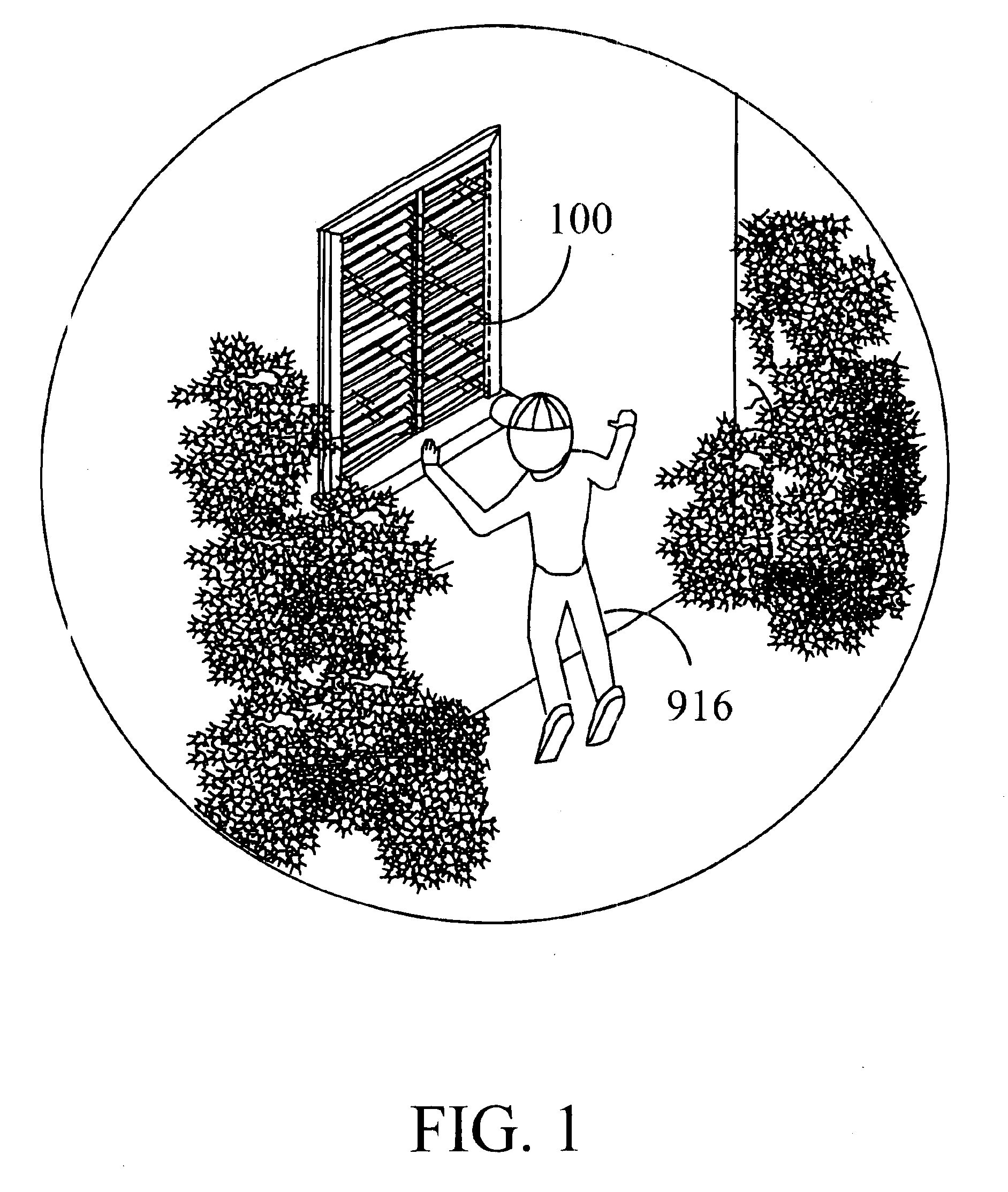

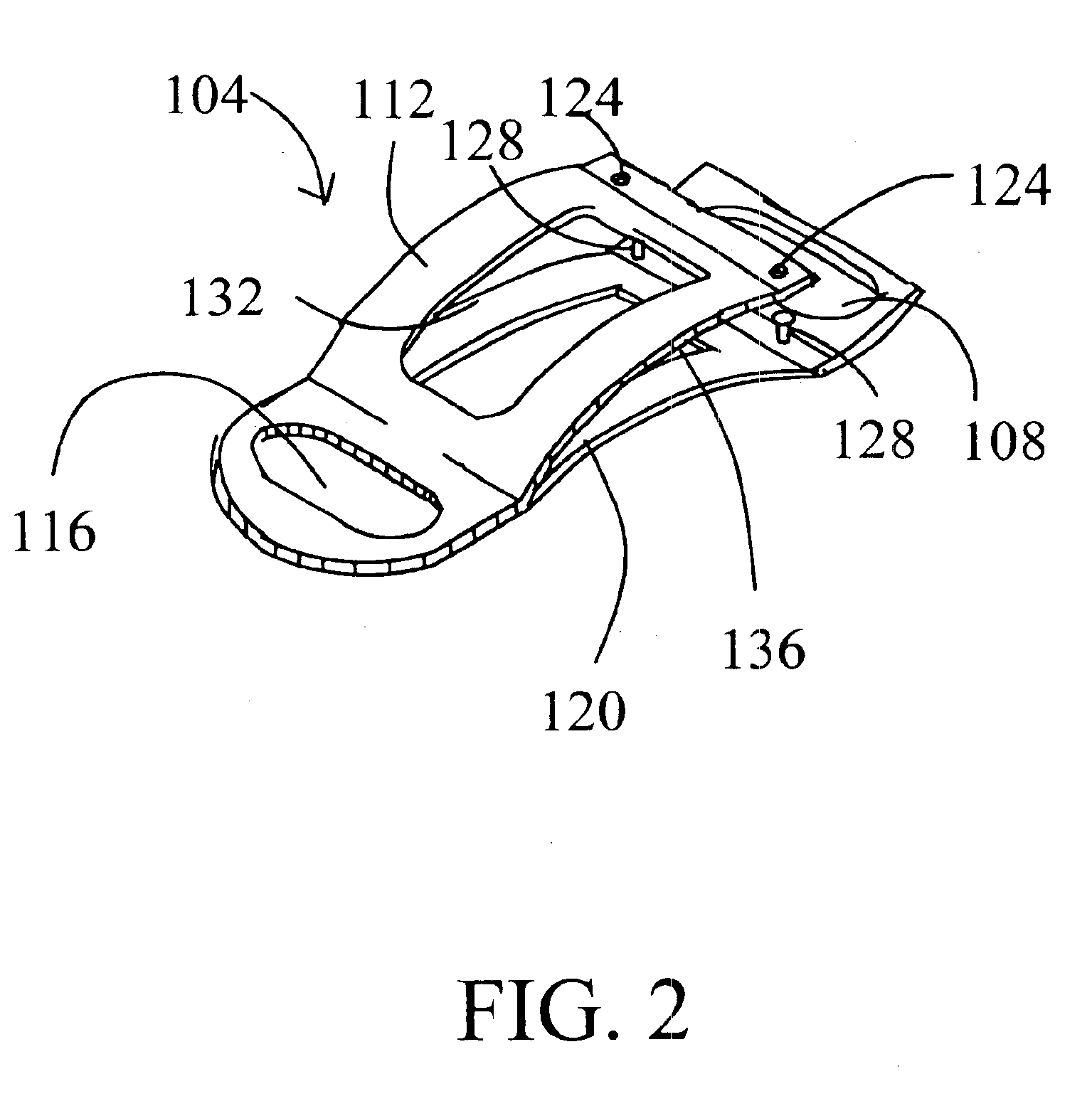

High privacy horizontal window blind having slats with no cord holes and a special clip

InactiveUS20020050326A1Operation is compromisedImprove light leakageLight protection screensSealing arrangementsWindow shutterSimulation

Owner:KAWABOINGO R

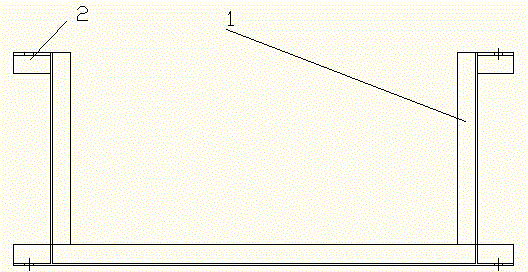

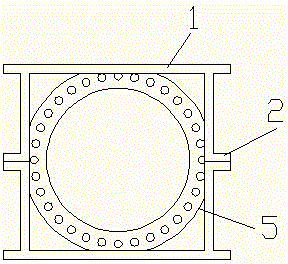

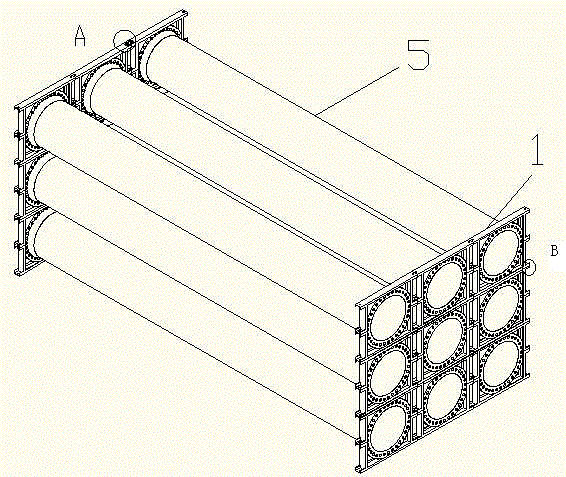

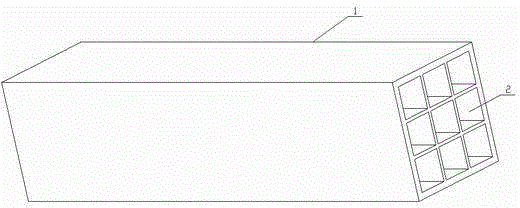

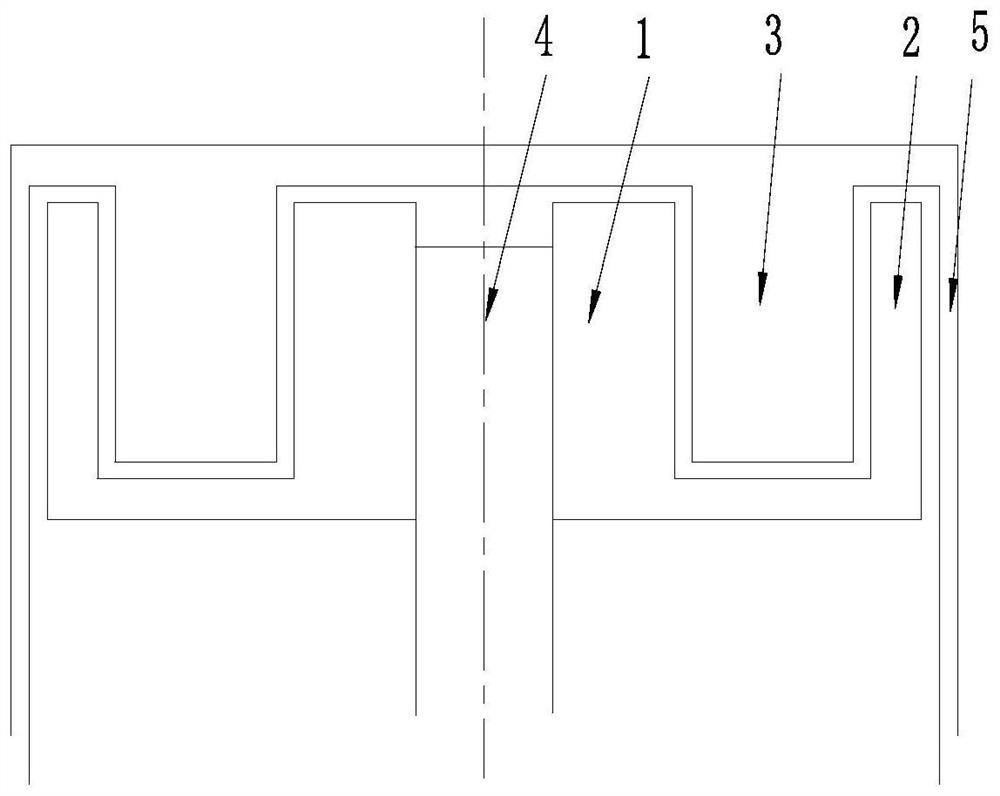

Transportation tool for finished pipelines with flanges

InactiveCN105270762AEasy to get materialsEasy to installRigid containersContainers with multiple articlesEngineeringFlange

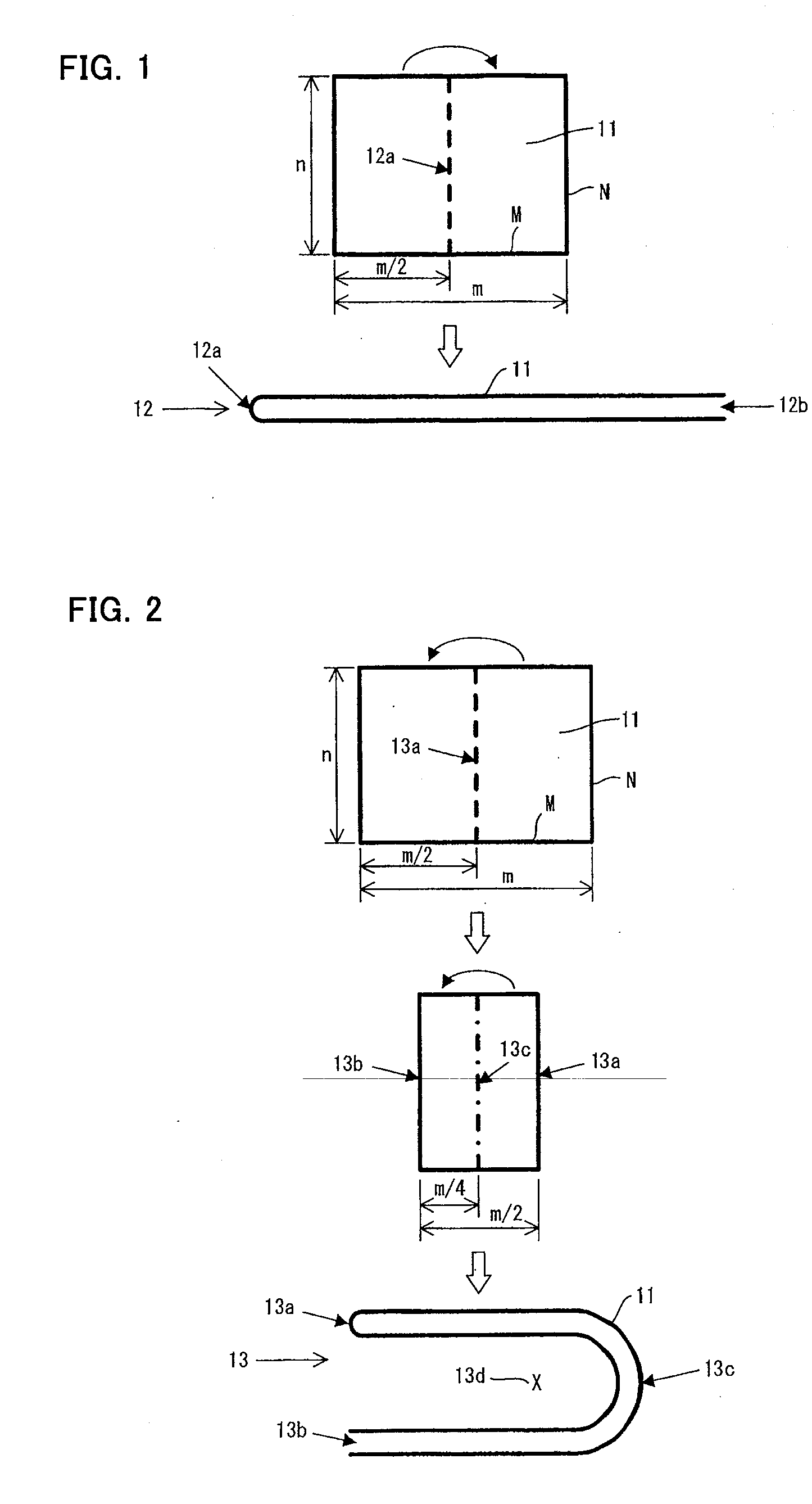

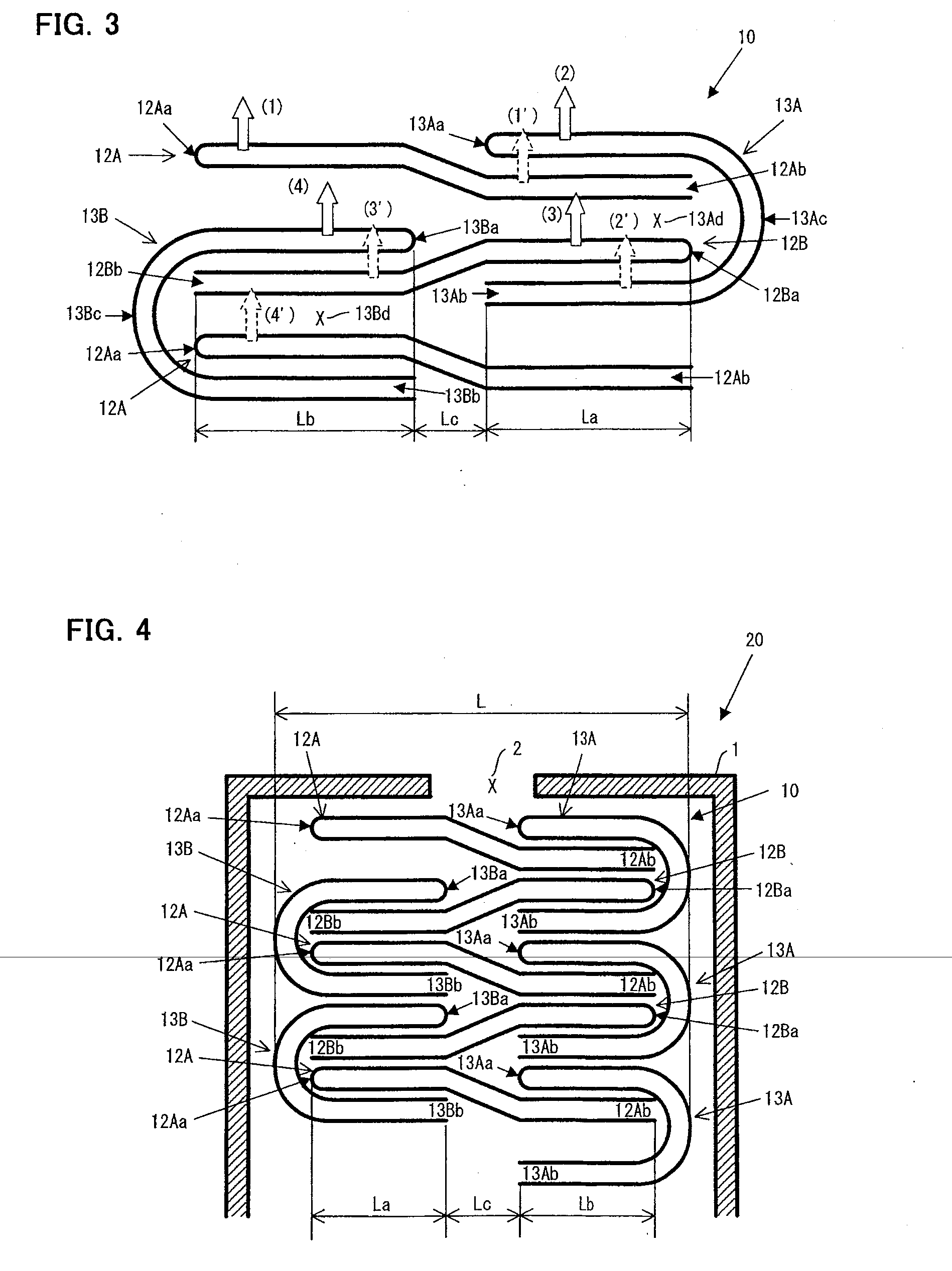

The invention relates to finished pipelines, in particular to a transportation tool for finished pipelines with flanges. The transportation tool for the finished pipelines with the flanges comprises m*n units, wherein m and n are both larger than or equal to two. Each unit is a square box which is formed by two flange clamping racks in a splicing mode. The dimensions of the square boxes are matched with those of flanges of pipelines to be transported. Connecting edges are arranged at the splicing portions of every two flange clamping racks and are fixedly connected through bolts and nuts. The flanges at the two ends of each finished pipeline with the flanges are clamped into the corresponding units respectively. According to the transportation tool, the original mode of stacking of the flanges and pipe bodies is changed to the mode of stacking of the flanges, stacking of the flanges can bear large pressure, and the stacking height of the pipelines is greatly increased. The units can be connected horizontally and longitudinally, and the stability of the pipelines in the stacking and transportation process is improved.

Owner:CHINA MCC20 GRP CORP

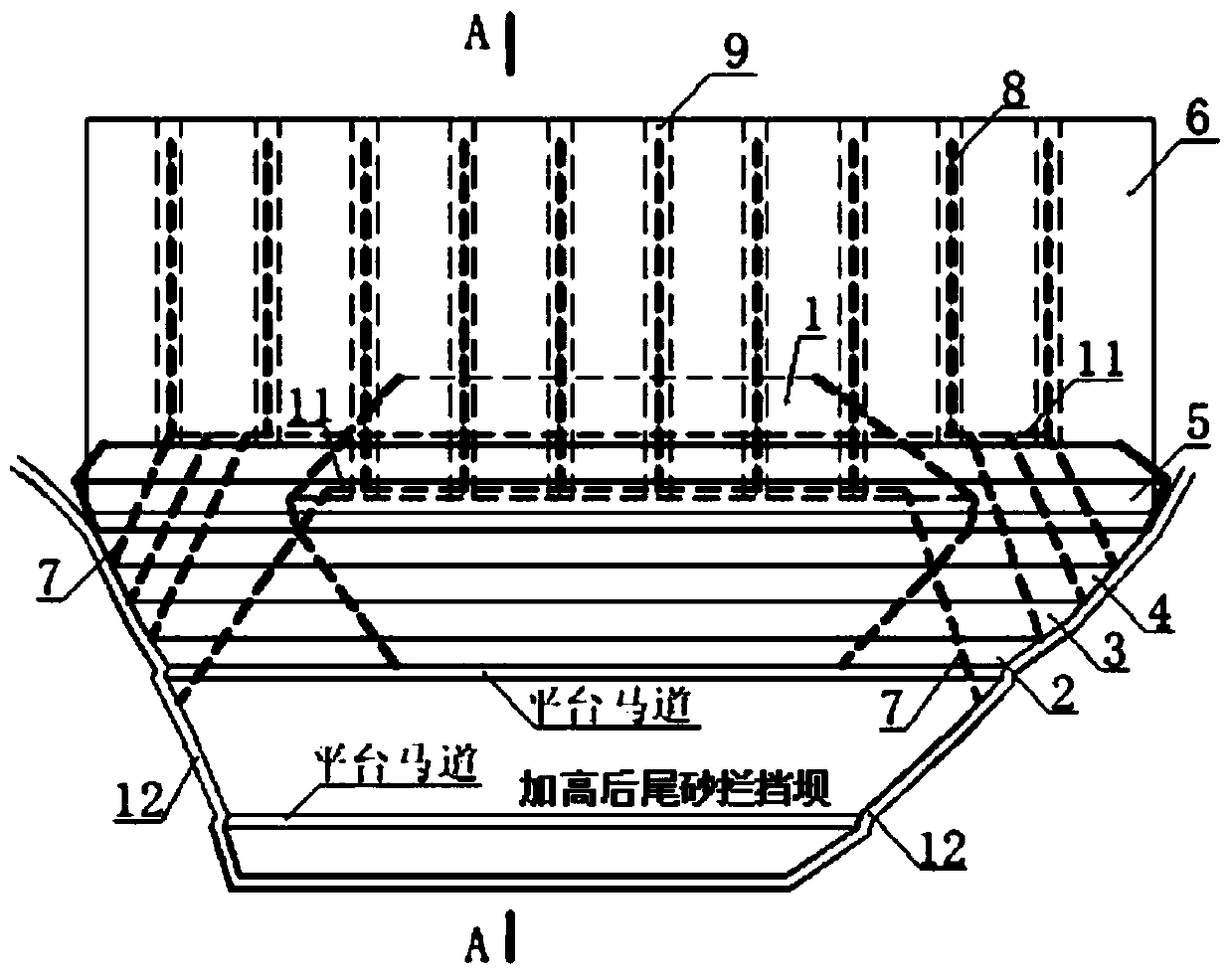

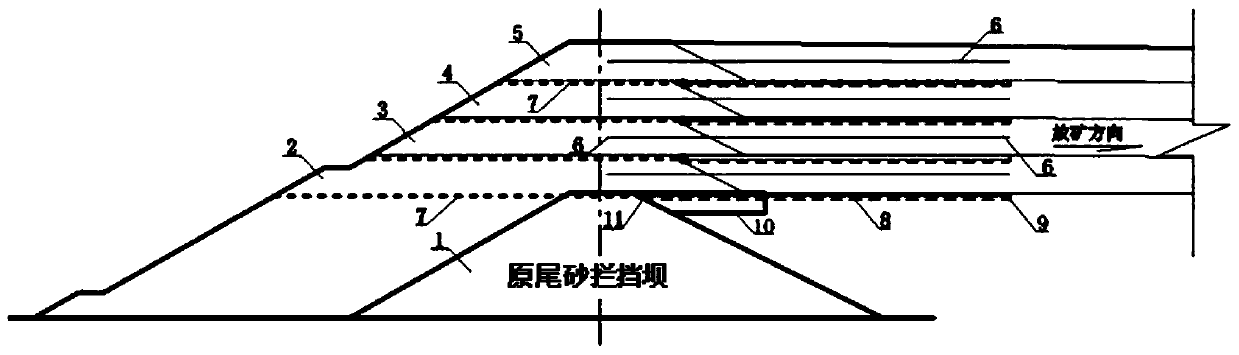

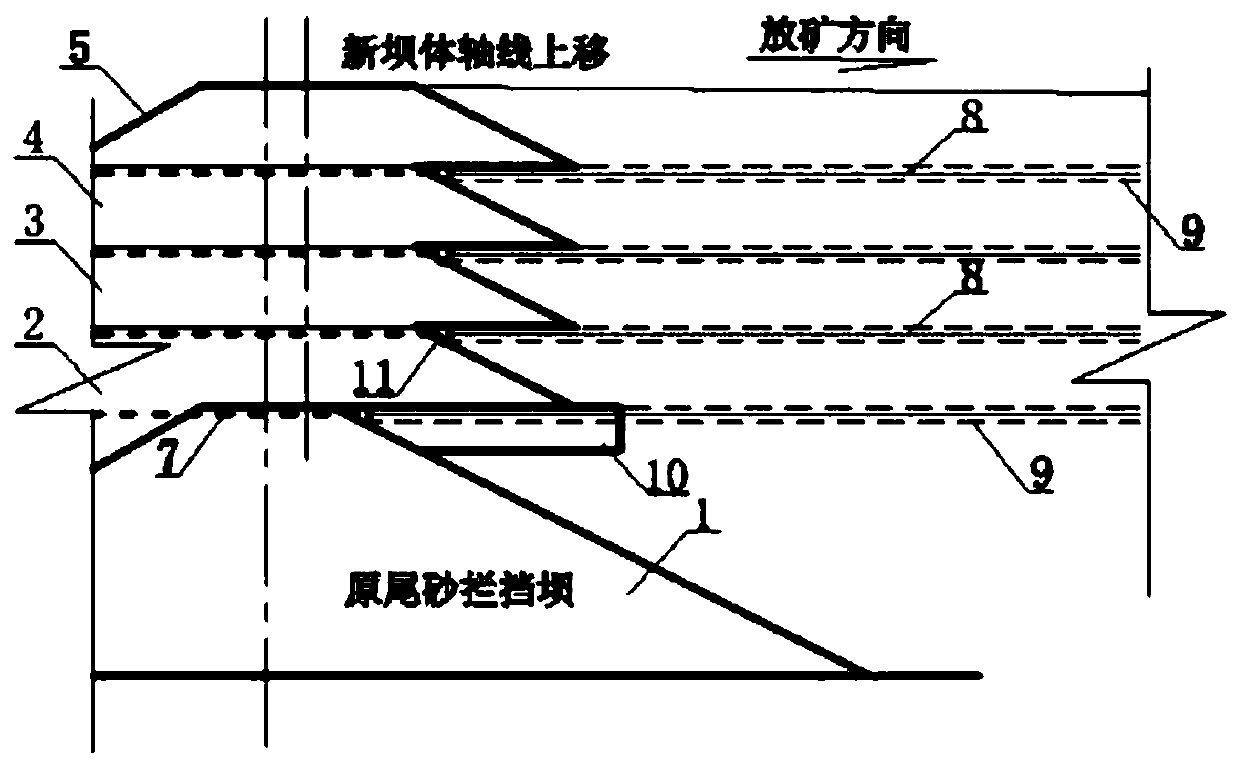

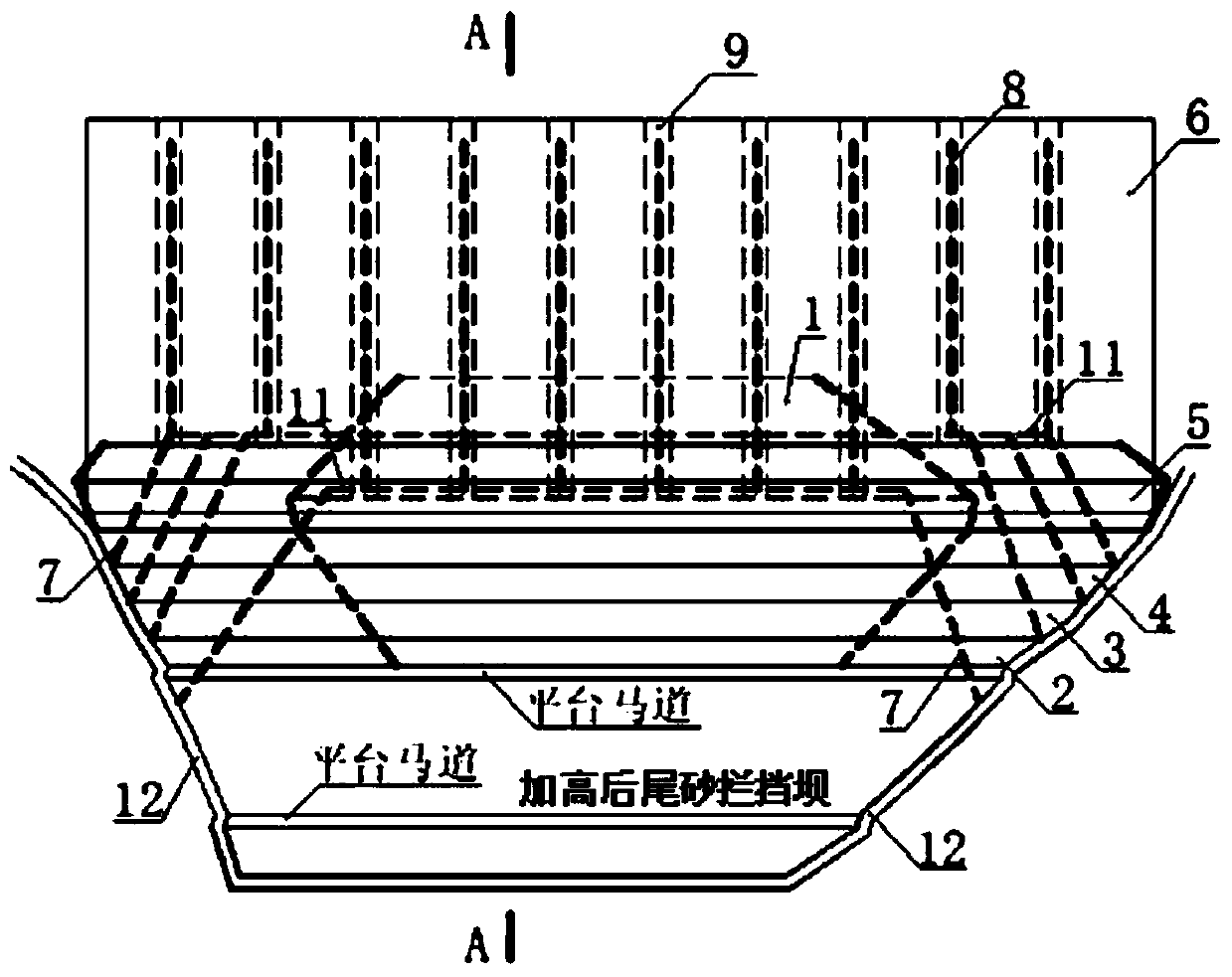

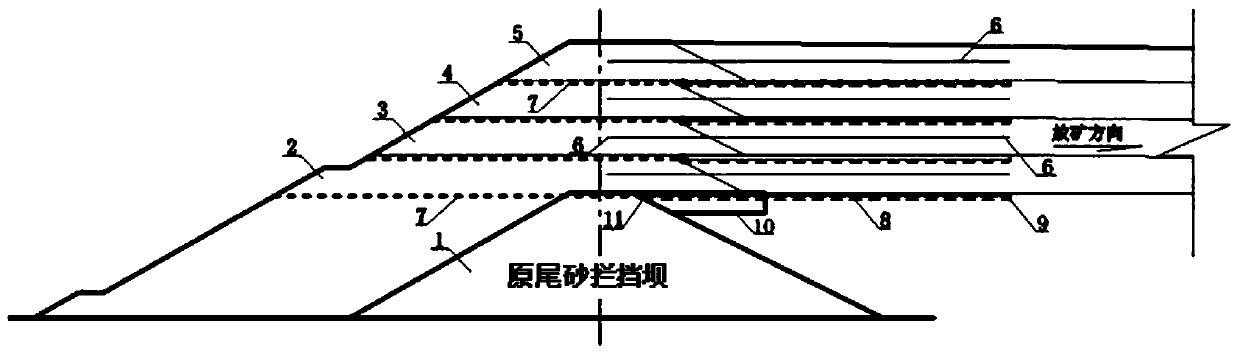

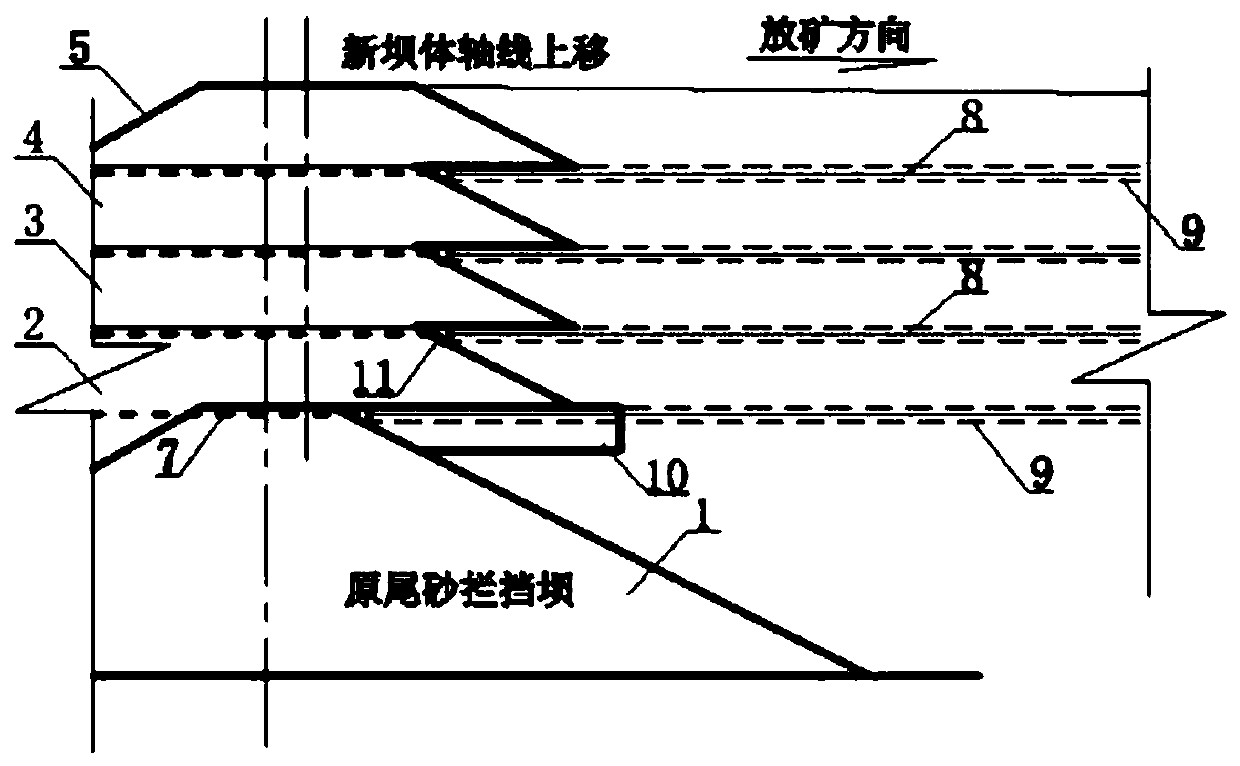

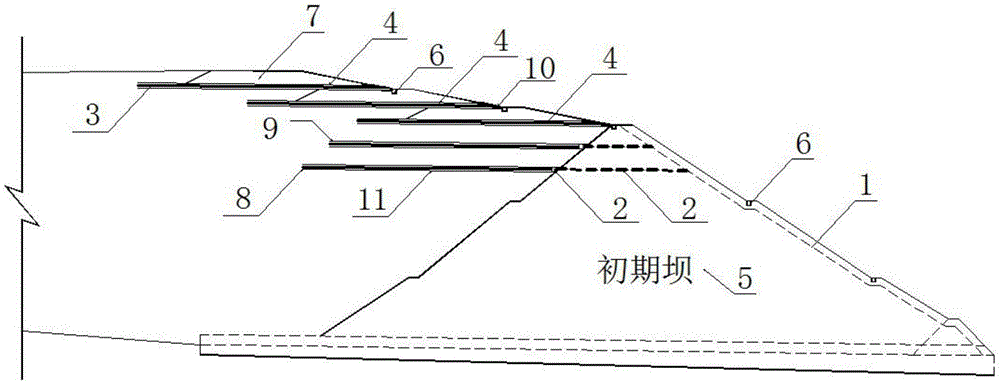

Superfine particle tailing reservoir heightening and capacity expanding stacking-discharging structure capable of achieving one-time dam building by adopting center line method

ActiveCN111305210AIncrease storage capacityExtend production service lifeEarth-fill damsRock-fill damsWaste dumpAbutment

The invention discloses a superfine particle tailing reservoir heightening and capacity expanding stacking-discharging structure capable of achieving one-time dam building by adopting a center line method. The structure is formed by combining an original tailing blocking dam (1), a dam abutment flood intercepting trench (12), a first-stage heightening dam body (2), a second-stage heightening dam body (3), a third-stage heightening dam body (4),..., and an nth-stage heightening dam body; a row of medium-coarse tailing drainage blind drains (9) which are parallel to one another and perpendicularto the axis of the corresponding dam body are constructed in the portion on the top layer of each stage of heightening dam body; draining communication pipes (7) and underground water collecting pipes (11) are laid; drainage floral tubes (8) are buried in the medium-coarse sand drainage blind drains (9); and layers of high-strength anti-corrosion geogrid (6) are laid every 0.5-1.0 m of verticalinterval. According to the invention, solidification of fine particle tailings is accelerated, the mechanical strength index of the fine particle tailings is improved and increased, thus, the capacityof a tailing reservoir is remarkably increased, the production service life is prolonged, and meanwhile, the problems that the capacity of parts of waste dumps are not enough, and mining waste rock is stacked are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

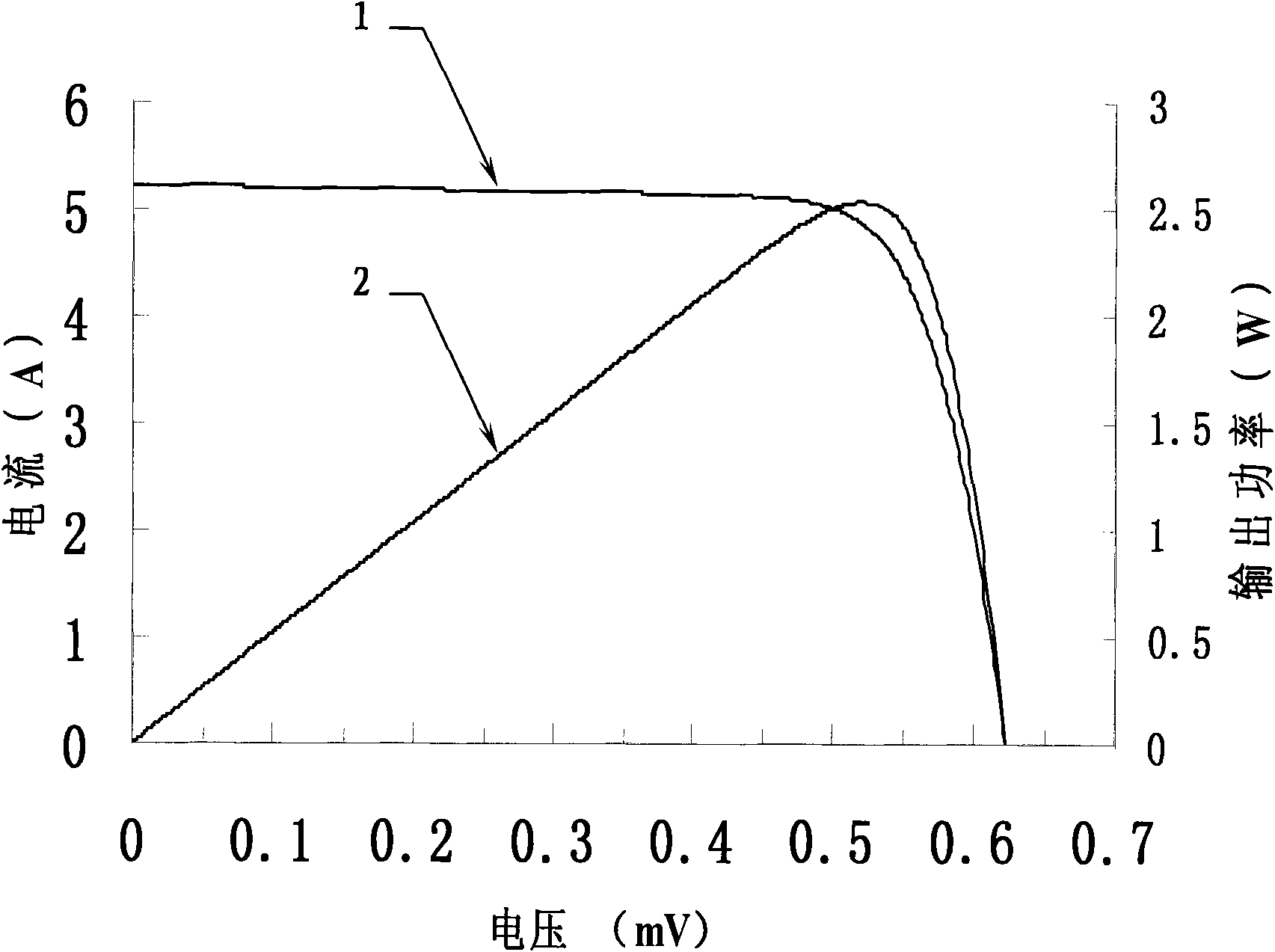

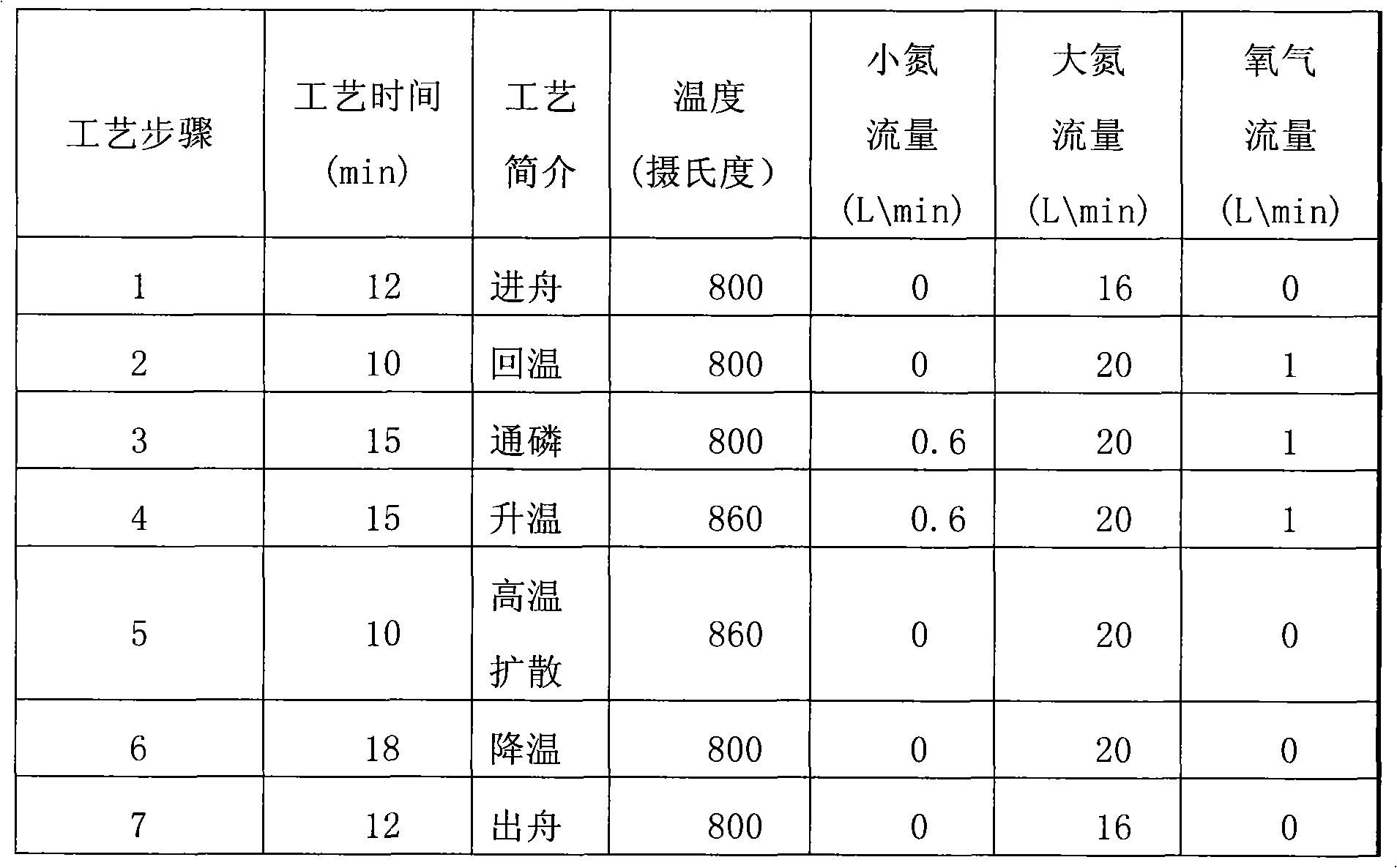

Low-temperature sintering technology suitable for high square resistance

InactiveCN101908577ASolve the difficulties of printingIncrease the open circuit voltageMuffle furnacesFinal product manufactureHorizon effectOpen-circuit voltage

The invention discloses a low-temperature sintering technology suitable for high square resistance, aiming to overcome the defects that silver is deeply driven, which causes a high-conductivity phosphorous diffusion area to be closed, and the like in the prior art. The technology comprises the following steps of: regulating a square resistor to be diffused to 66-75 ohms; printing silver on the square resistor according to a wet weight of 0.4-0.6g; and traversing the square resistor through a low-temperature sintering furnace at 200-450 DEG C at a speed of 3,000-5,000mm / min for sintering. The invention can form good ohmic contact under the conditions of shallow diffused junction and low concentration and promote the short-circuit current and the open-circuit voltage, thereby overcoming the defect of low conversion efficiency brought by a dead horizon effect; the silver and silicon can form a good ohmic contact at low temperature to obtain lower serial resistance and higher fill factors and short-circuit current; and the ohmic contact with an N type diffusion region can be realized through sintering and traversing without damaging nearby junction regions.

Owner:胡本和

Packaging substrate with tactile images

Provides is a method for forming tactile images or a combination of tactile and regular images on a flexible packaging substrate comprising: depositing an ultraviolet curable phase change ink composition comprising an optional colorant and a phase change ink vehicle comprising a radiation curable monomer or prepolymer; a photoinitiator; a reactive wax; and a gellant directly onto a flexible packaging substrate or depositing the ink onto an intermediate transfer member, in an image area to form a tactile image area or a combination of tactile image area and regular image; forming the tactile image by depositing multiple layers of the ink in locations of the tactile image area or portion thereof; when an intermediate transfer member is used, transferring the deposited ink from the intermediate transfer member to the flexible packaging substrate; and curing the ink.

Owner:XEROX CORP +1

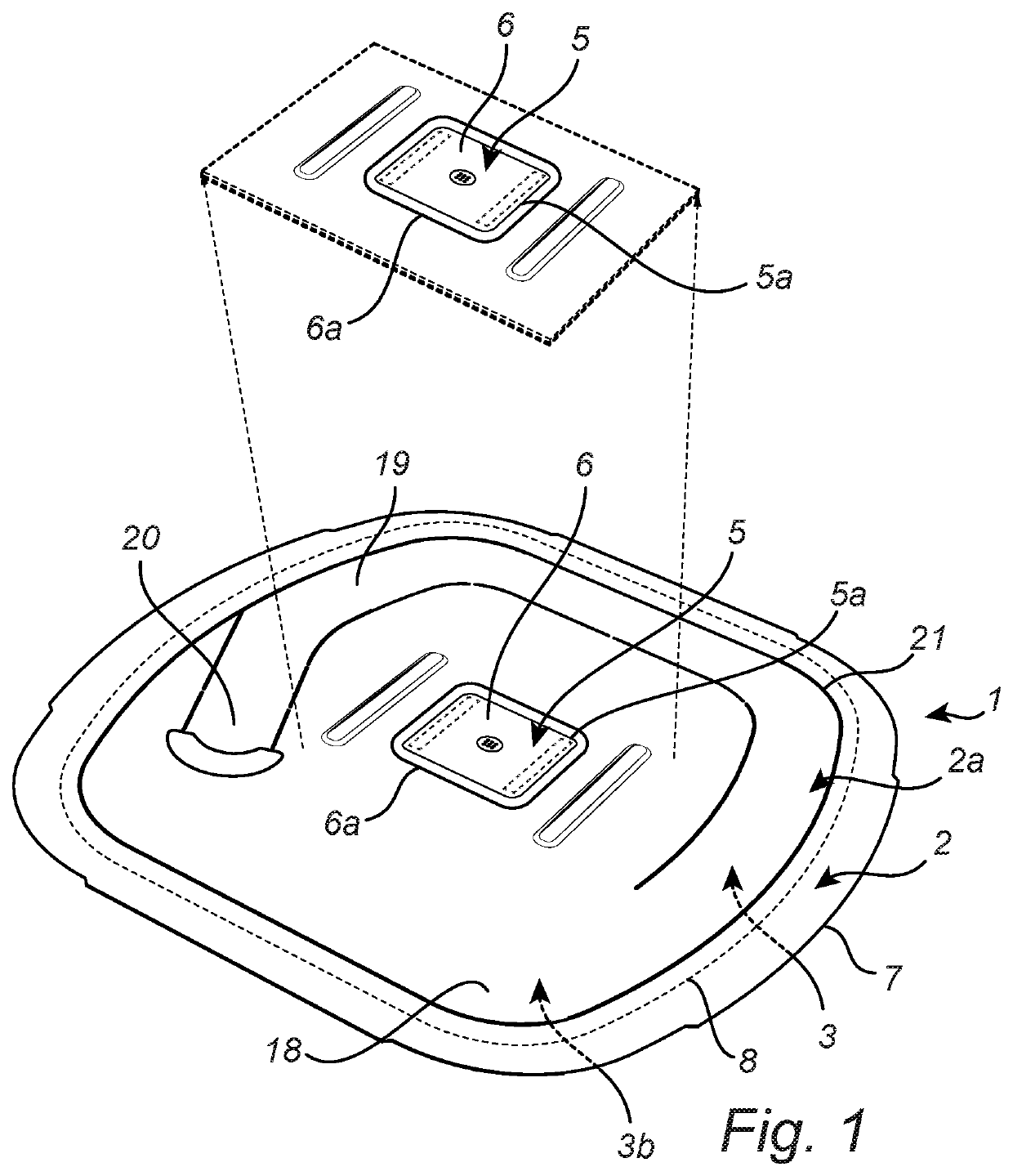

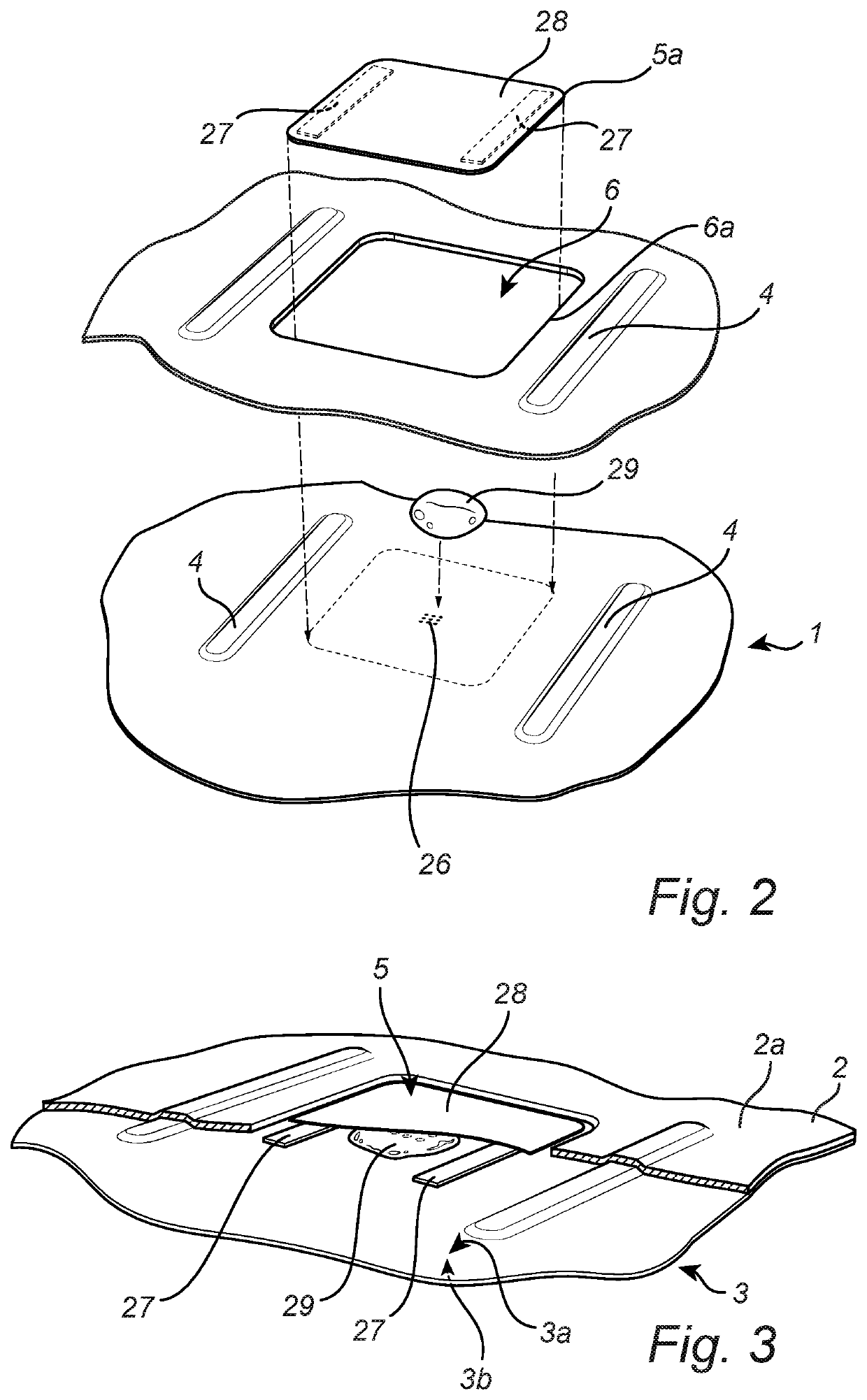

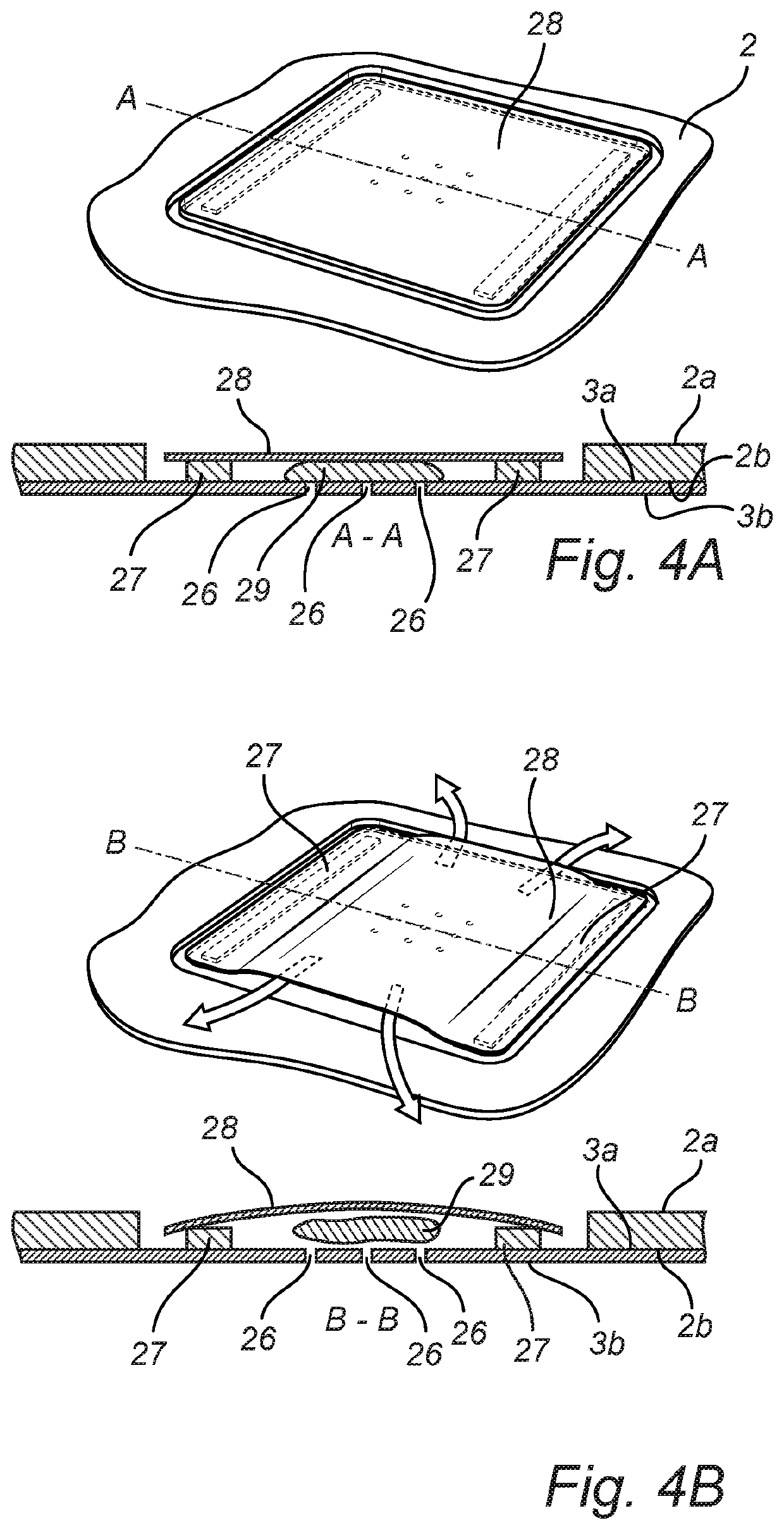

Stack of sheets and sheet container

InactiveUS20110095042A1Improve usabilityReduce stack heightLayered productsFlat article dispensingEngineeringMechanical engineering

Owner:UNI CHARM CORP

Plastic Tube Screen Fills and Fabrication Thereof

ActiveUS20150123297A1Save a lotKeep the spiral corrugated tube robustTransportation and packagingUsing liquid separation agentWaddingMechanical engineering

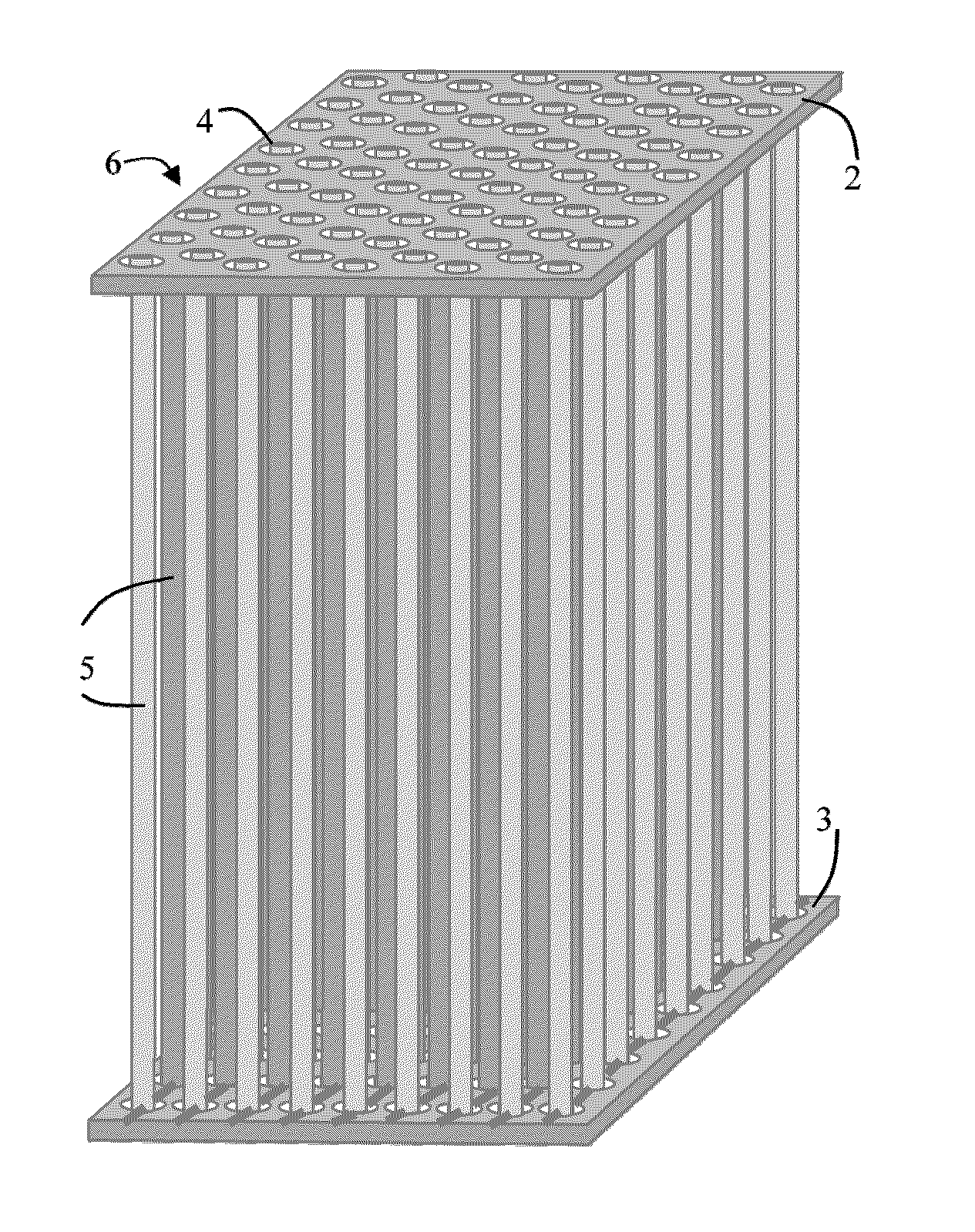

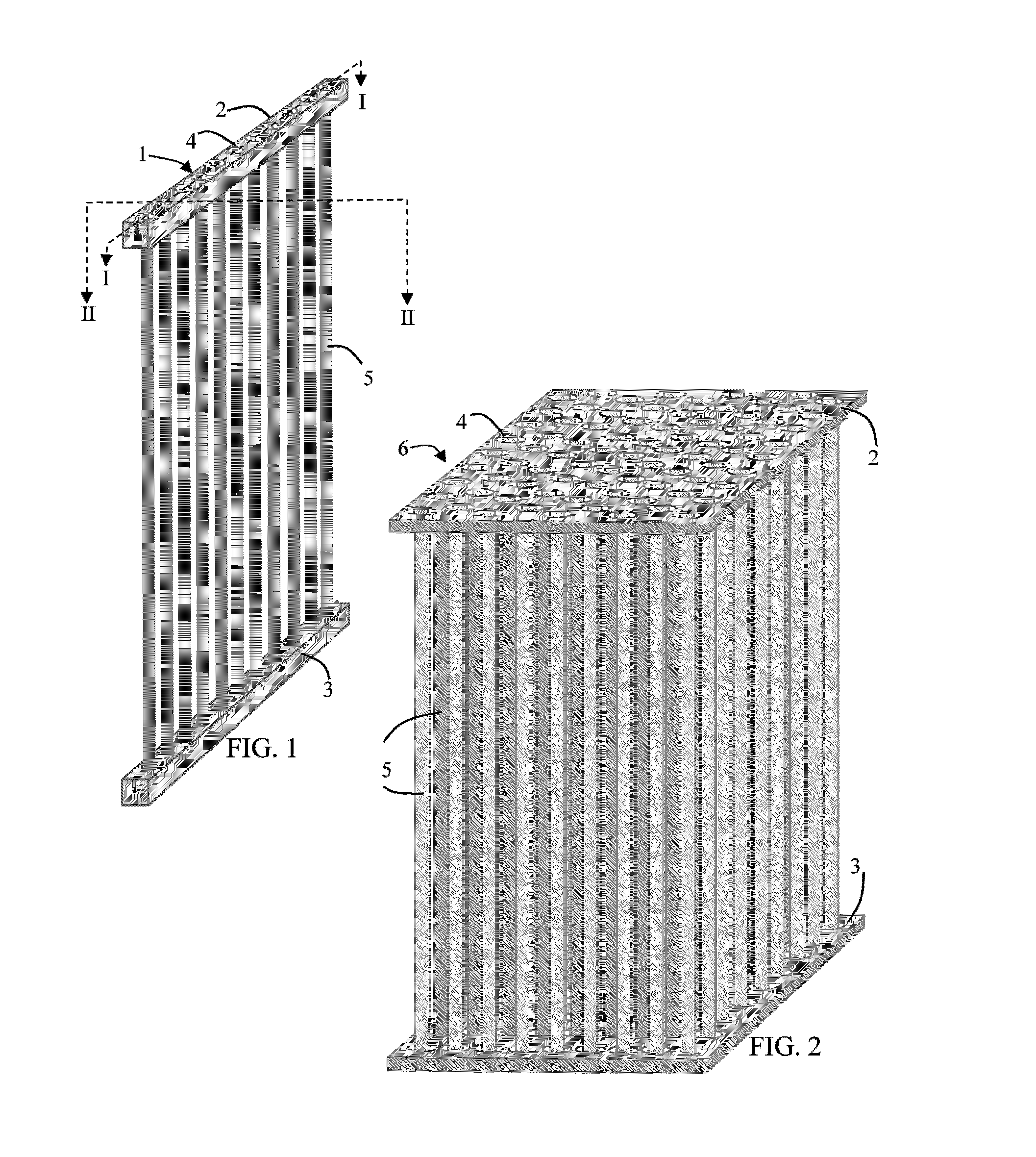

The present invention involves a fabrication of plastic-tube-screen-fill using plastic tubes. The plastic-tube-screen-fill consists of several plastic tubes suspending between top and bottom tube holding perforated frames in the shape of a rectangular thin plate as a vertical string screen. The tube holding perforated frames are in same configuration to be used in two ways and fabricated by assembling a perforated frame and tube holding frame. The tube holding frame is a straight male band connector with several short solid rods positioned and fixed on band for push-fitting into the holes on perforated frame. The short solid rod on tube holding frame has a male push-fit connector on its lower part to be push-fitted into one edge of tube. The tubes used in the present invention are spiral corrugated tubes. Fabrication and assembling method of perforated frames, tube holding frames, and spiral corrugated tubes are described in the present invention.

Owner:PARK CHONG MOOK

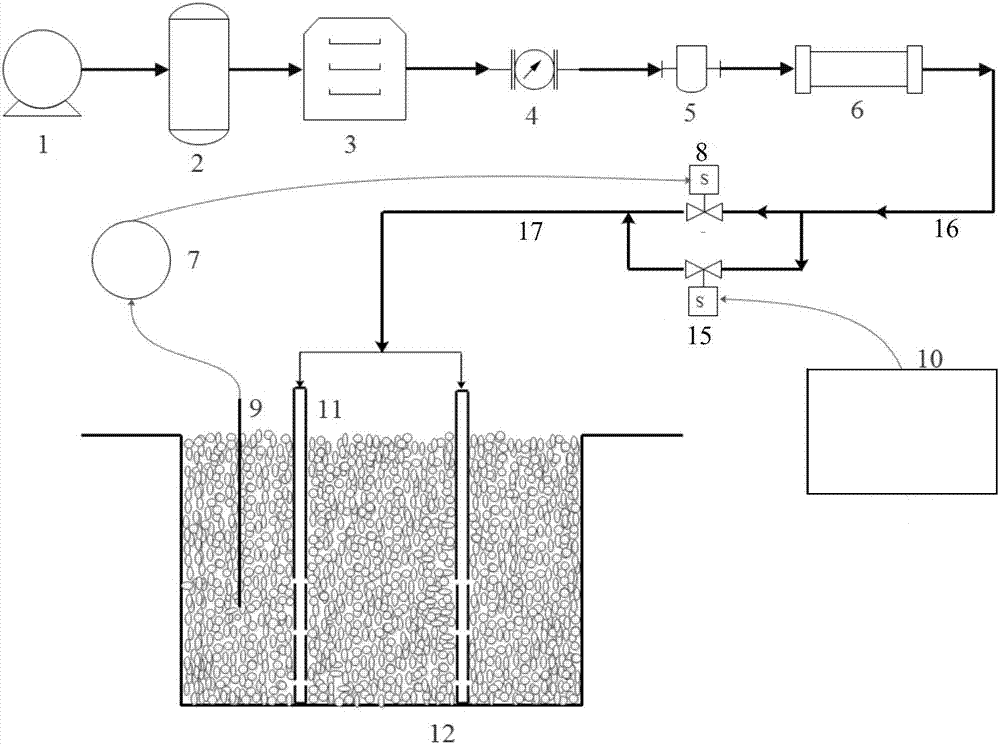

Honeycomb-shaped activated coke for flue gas purification and production method thereof

The invention relates to honeycomb-shaped activated coke for flue gas purification and a production method thereof. The effective ingredient of the honeycomb-shaped activated coke is activated coke / carbon, meanwhile other auxiliary additives are added, and the additives include an adhesion agent, a lubricating agent, extrusion aid and a fiber framework. The invention further discloses a preparation method of the honeycomb-shaped activated coke for flue gas purification. Pug with good plasticity is obtained after material mixing and kneading are conducted, then an activated coke honeycomb body is obtained trough extrusion molding, and finally the honeycomb-shaped activated coke is obtained through drying and baking. The honeycomb-shaped activated coke can be used for desulfuration, denitration and other purification processes of boiler flue gas, can greatly lower high wind resistance and high electric consumption in an existing activated coke flue gas process, meanwhile improves the activated coke stack height on the basis of basically maintaining the macro ratio surface and lowers the occupied area of the process, the honeycomb-shaped activated coke for flue gas purification and the production method thereof are simple in preparation process and do not involve a high-temperature process, and strength of the honeycomb-shaped activated coke is increased while energy consumption is lowered.

Owner:FUJIAN NEWLAND ENTECH CO LTD

Method for producing biological feed through aerobic anaerobic coupling fermentation

PendingCN107950753APromote growth and reproductionReal-time temperature monitoringFood processingTemperatue controlEcological environmentBacillus g

The invention discloses a method for producing biological feed through aerobic anaerobic coupling fermentation. According to the method, mixed bacteria of bacilli, lactobacilli and saccharomycetes serve as a fermentation strain of the biological feed; the biological feed is produced by using the aerobic anaerobic coupling solid state fermentation technology, and sterile constant-temperature air isintroduced into a deep material intermittently in the fermentation process, so that growth and propagation of aerobic microorganisms in a lower layer material are facilitated, and the product qualitystability is also improved; the stacking height of material layers can be increased under the ventilation and heat dissipation conditions, and the production capacity of equipment is improved. In addition, the fermented biological feed contains a lot of probiotic bacteria capable of improving intestinal health of animals, the micro-ecological environment of the gastrointestinal tracts can be improved after the animals are fed, and the immunity of organisms can be improved. Besides, the biological feed is rich in lactic acid and has strong mellow fragrance so that the palatability of the feedcan be remarkably improved, the animal feed intake can be improved, the rapid growth of the animals can be promoted, and the production capacity of the breeding industry can be improved.

Owner:ANIMAL SCI RES INST GUANGDONG ACADEMY OF AGRI SCI

High privacy horizontal window blind having slats with no cord holes and a special clip

InactiveUS6877547B2Improve light leakageIncrease stack heightLight protection screensSealing arrangementsElectrical and Electronics engineeringEngineering

Owner:KAWABOINGO R

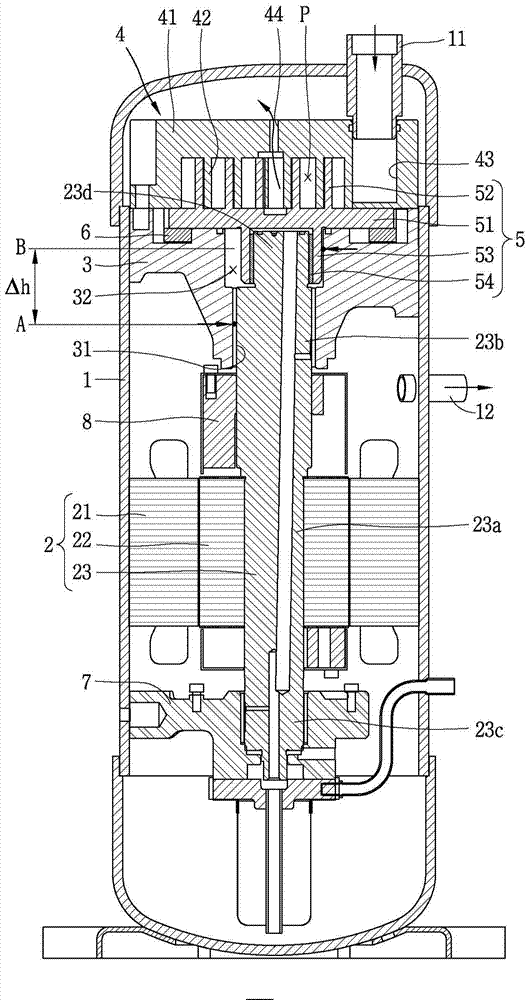

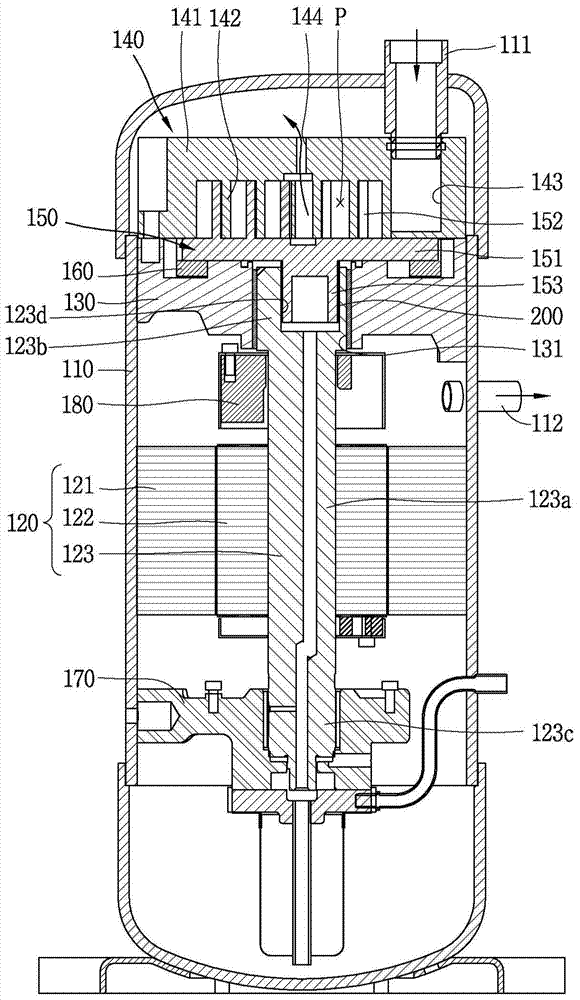

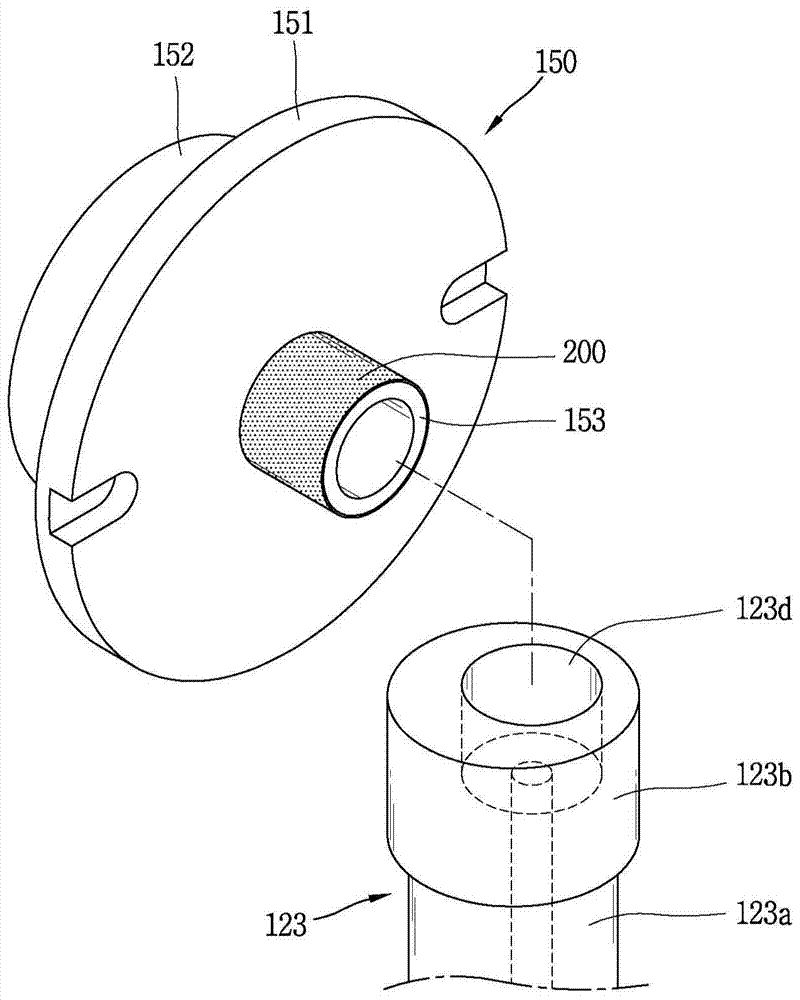

Scroll compressor

InactiveCN104214092ASmall amount of deformationReduce eccentric loadRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFriction lossCrankshaft

In a scroll compressor the present invention, a boss portion of an orbiting scroll is inserted to be coupled to a boss coupling recess of a crank shaft, and thus, friction loss of the bearing portion is reduced, enhancing compression efficiency and reliability and reducing noise and material costs Also, a bush bearing is coated to be formed on the boss portion of the orbiting scroll, a thickness of a bearing portion may be reduced. Also, since an outer circumferential surface of the bearing portion is in contact with an inner circumferential surface of the boss coupling recess, damage to the bearing portion may be prevented.

Owner:LG ELECTRONICS INC

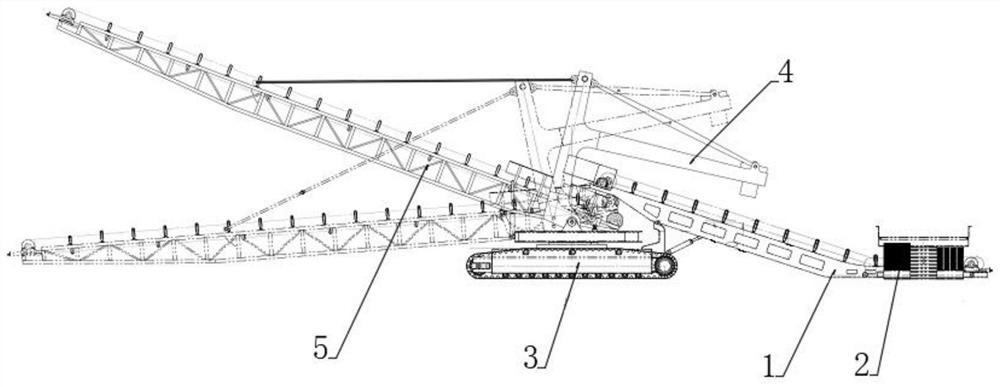

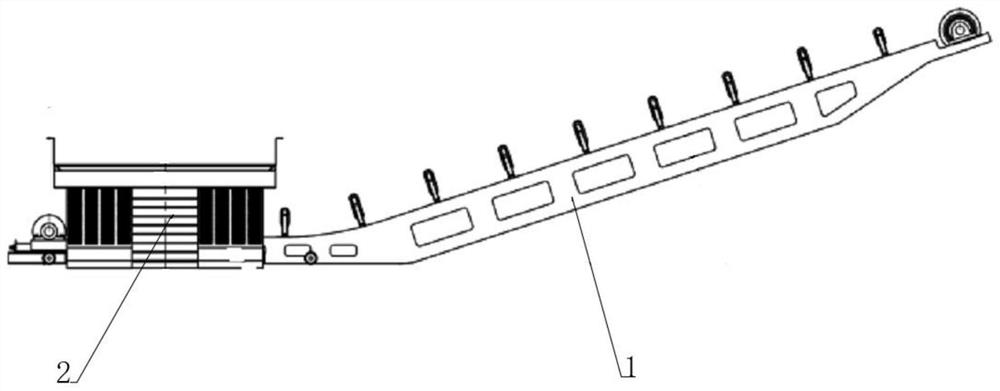

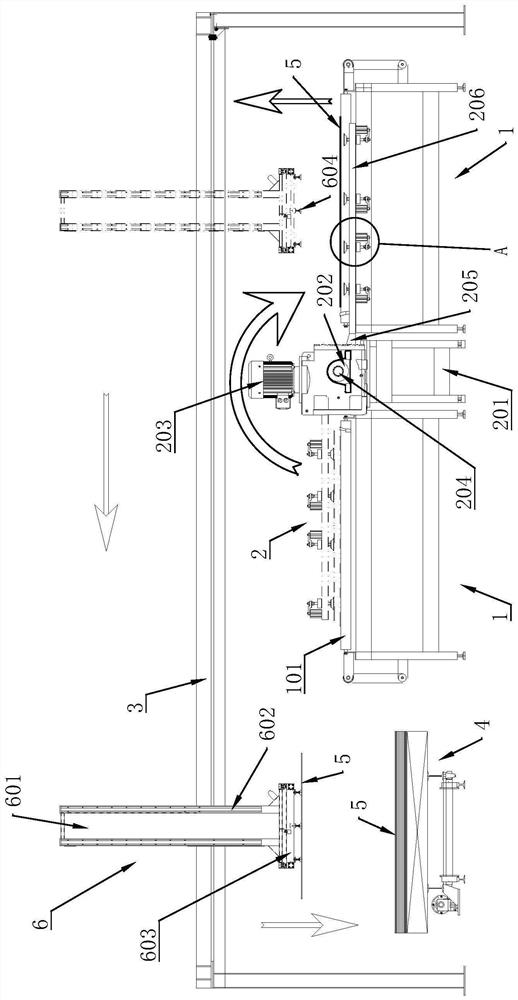

Crawler belt moving type automatic feeding machine facilitating concentrated material stacking in harbor district

InactiveCN113003252AStrong wear resistanceReduce maintenanceConveyorsSupporting framesCantileverBelt conveyor

The invention discloses a crawler belt moving type automatic feeding machine facilitating concentrated material stacking in a harbor district, and belongs to the technical field of feeding machine equipment. A cantilever feeding belt conveyor, a feeding mechanism, a rotation driving mechanism and a cantilever discharging belt conveyor are matched, and a feeding platform is in mechanical buckle type connection with the cantilever feeding belt conveyor during operation and is driven by a walking mechanism. When the feeding machine is transferred, the feeding mechanism can be tripped, a platform slope plate is lifted up during transferring, discharging is conducted through the cantilever discharging belt conveyor, and the feeding machine has the advantages of being high in production efficiency, large in stacking height, large in stacking radius, high in abrasion resistance, small in maintenance amount and the like; and meanwhile, the feeding speed and the discharging speed are high, operation is convenient, and moving is made free. The requirement for frequent stockpiling operation of a port wharf can be effectively met to a certain degree, the problems that the sites are scattered, dirty and disordered due to the fact that stockpiling is large in occupied area and difficult to stack high in the harbor district are effectively solved, and the stockpiling environment of the harbor district is effectively improved.

Owner:WENZHOU CITY HUADA ELECTRIC POWER & METALLURGICAL EQUIP CO LTD +1

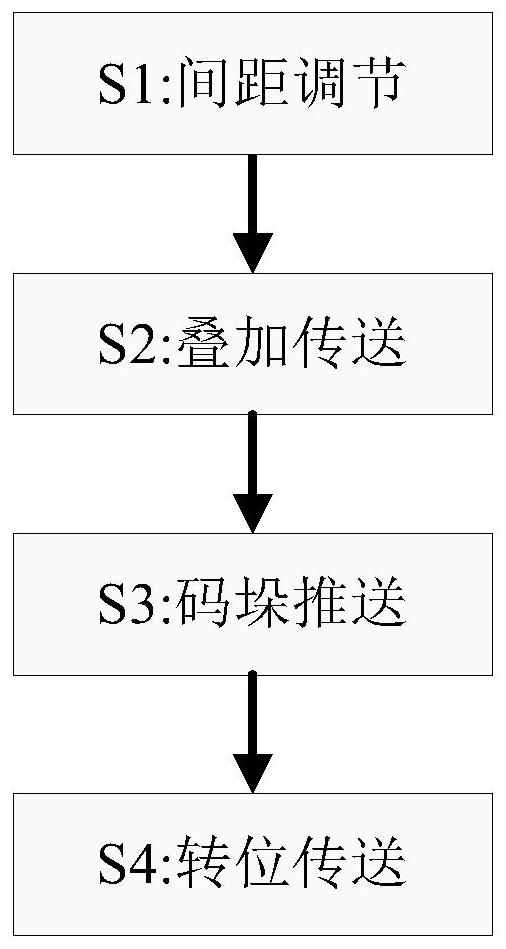

Printing waste recycling treatment process

ActiveCN111646176AImprove palletizing efficiencyWide versatilityConveyorsStacking articlesPaper dustCarton

The invention provides a printing waste recycling treatment process. The printing waste recycling treatment process comprises a rotary mechanism, clamping mechanisms and an overlying conveying mechanism; the rotary mechanism is installed on the overlying conveying mechanism, the plurality of sets of clamping mechanisms are arranged on the rotary mechanism, and the rotary mechanism and the clampingmechanisms are located in front of the overlying conveying mechanism. According to the printing waste recycling treatment process, the problems that in the current waste carton recycling process canbe solved, specifically, cartons are treaded to be flat through feet of field workers, then the cartons are stacked and conveyed to the follow-up recycling link, the recycling mode wastes physical strength, the labor intensity of the workers is enhanced, in the flattening process, the cartons can generate some tiny paper scraps, the tiny paper scraps fly in air, the indoor environment can be polluted, the human body is influenced, and when the cartons are stacked, the cartons are fluffy, so that space waste is caused.

Owner:安徽蕴辉科技有限公司

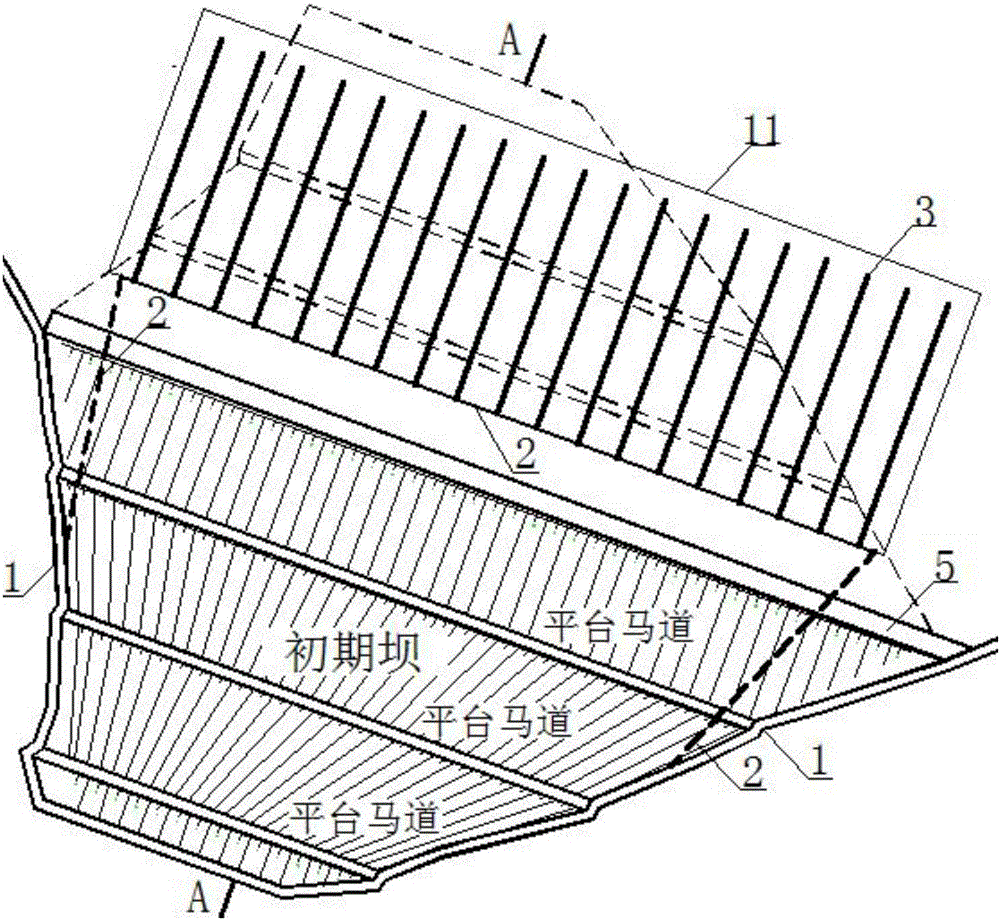

Novel heightening expanding method for one-time constructed dam ultra-fine tailings pond through midline method

ActiveCN111305211AIncrease storage capacityExtend production service lifeSewer pipelinesBulkheads/pilesDitchGeogrid

The invention discloses a novel heightening expanding method for a one-time constructed dam ultra-fine tailings pond through a midline method. The method is characterized in that heightening expandingis carried out through a grading and staging construction method, a first-stage heightening dam body (2), a second-stage heightening dam body (3), a third-stage heightening dam body (4) and the likeare sequentially piled and constructed; a row of medium-coarse sand seepage drainage blind ditches (9) which is parallel among each other and perpendicular to the axis of each dam body are constructedin the top layer of the heightened dam body; water drainage communicating pipes (7) and underground water collecting pipes (11) are laid; seepage drainage floral pipes (8) are buried in the medium-coarse sand seepage drainage blind ditches (9) of the heightening dam bodies; and a layer of high-strength corrosion-resistant geogrid (6) is fully paved at every vertical interval of 0.5-1.0 m. According to the novel method, the consolidation of fine tailings is accelerated, the mechanical strength index of the fine tailings is improved, the storage capacity of the tailings pond is remarkably increased, the production service life is prolonged, the pressure of tailings discharge of enterprise production is relieved, and meanwhile the problems that the capacity of part of dumping sites is insufficient and mining waste rocks are piled up are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

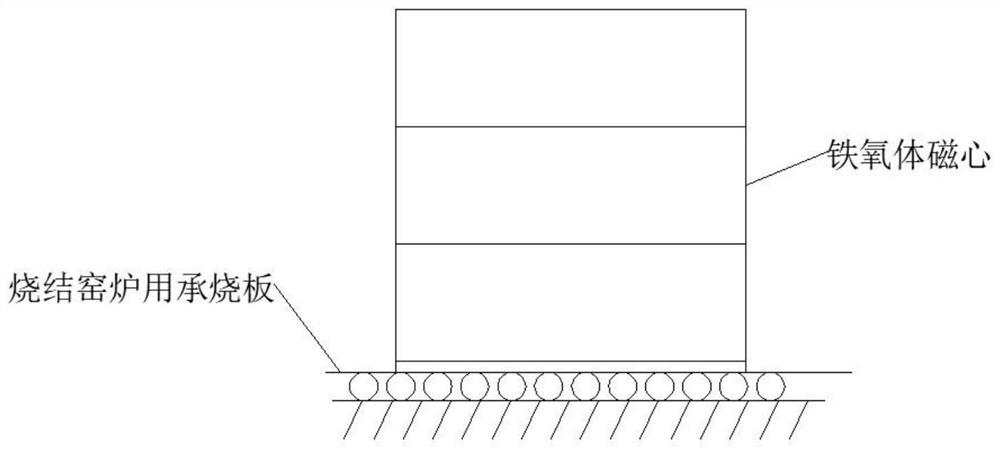

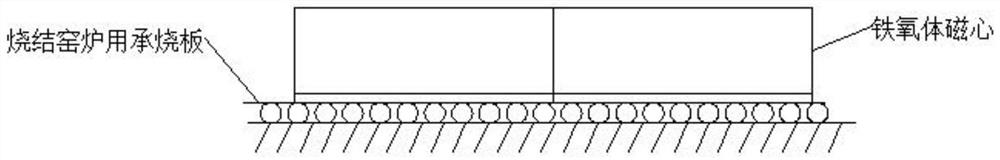

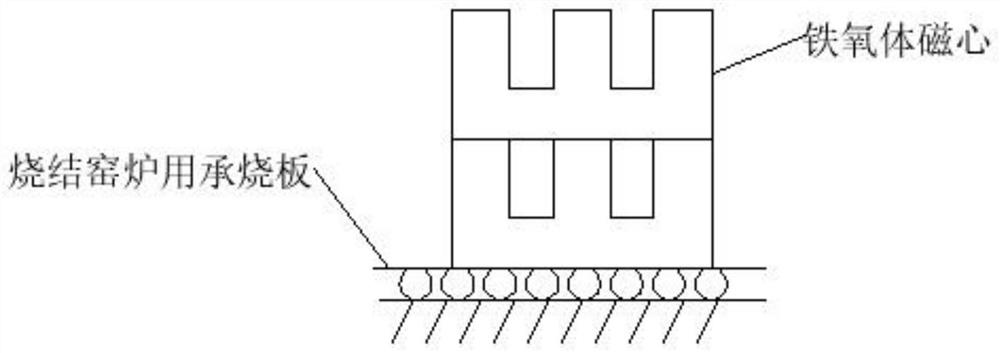

Ferrite blank sintering process

The invention discloses a ferrite blank sintering process which comprises the following steps: according to preset placement positions of a plurality of ferrite blanks, coating contact surfaces of adjacent ferrite blanks with an anti-adhesion coating; the anti-adhesion coating is prepared by mixing and stirring water and emery according to the mass ratio of (2-3): 1; and after a plurality of ferrite blanks are coated and stacked in place, sintering is carried out. The invention further discloses an anti-adhesion coating and application of the anti-adhesion coating in ferrite blank sintering pretreatment. The anti-adhesion coating is prepared by mixing and stirring water and emery according to the mass ratio of (2-3): 1. According to the ferrite blank sintering process disclosed by the invention, the adhesion problem occurring when the ferrite blanks are placed side by side or stacked together for high-temperature sintering can be solved; the ferrite magnetic core blank is large in size specification, different in upper end face and lower end face and not sealed after being sintered.

Owner:北京七星飞行电子有限公司

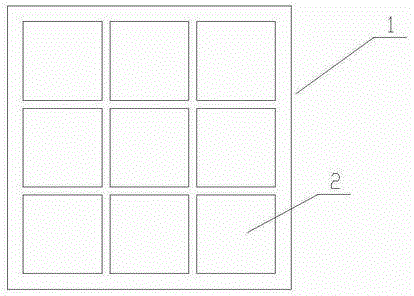

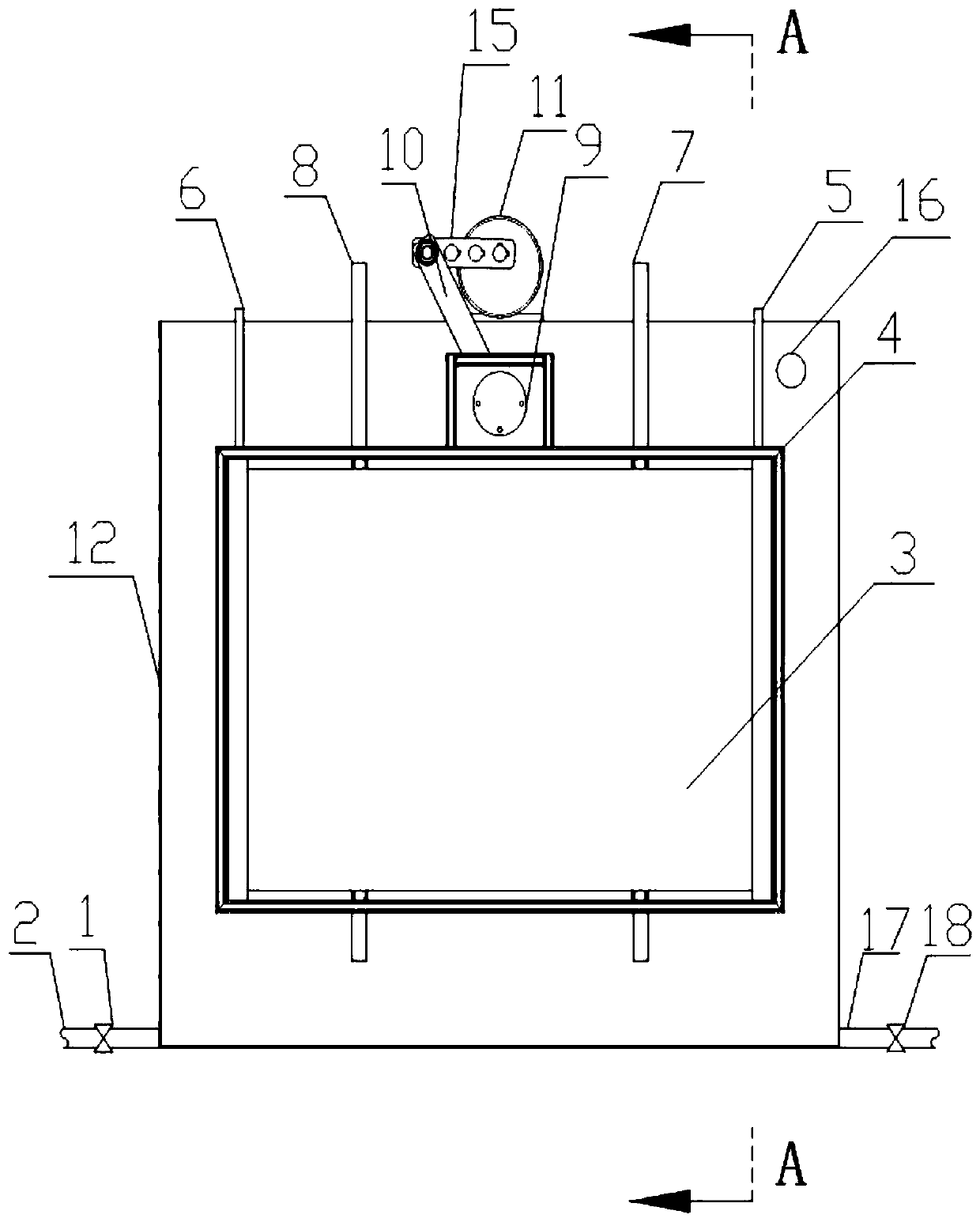

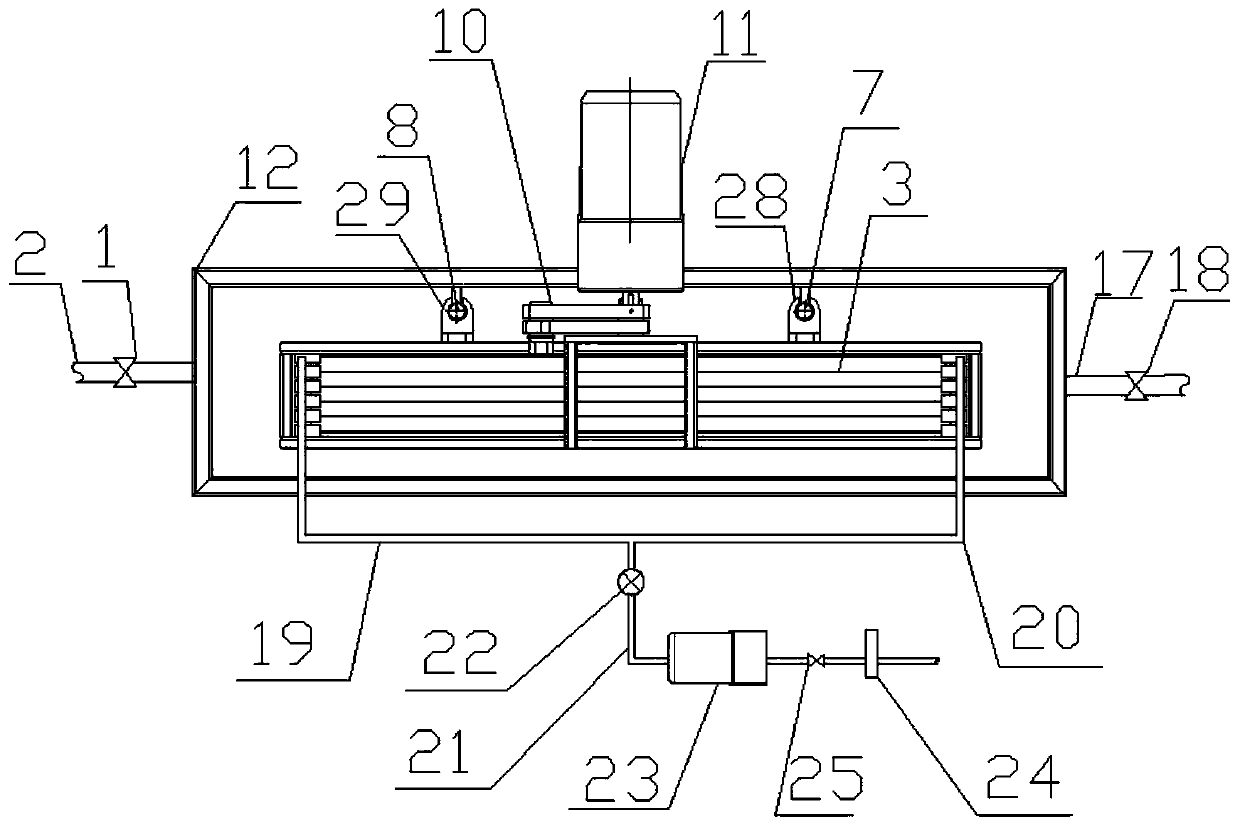

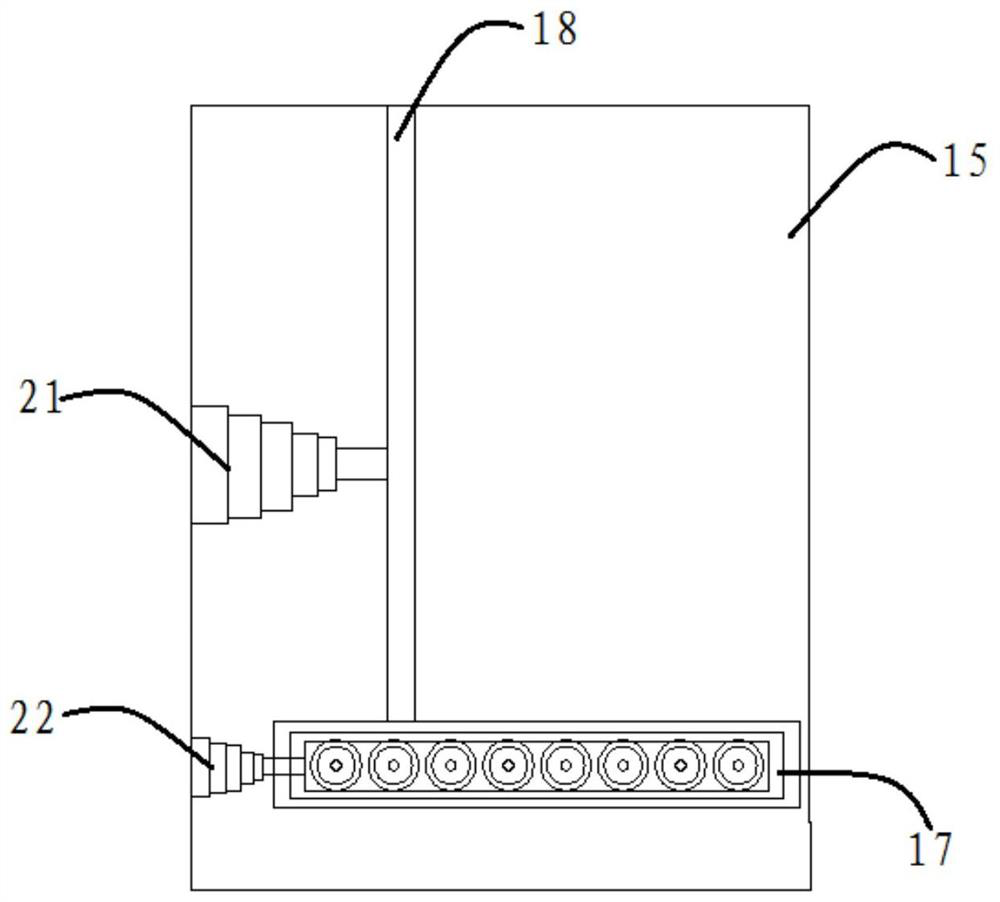

Longitudinally-vibrating MBR corrugated membrane device

InactiveCN111439842AReduce cloggingReduce pollutionSpecific water treatment objectivesBiological treatment apparatusReciprocating motionMembrane fouling

The invention provides a longitudinal vibration MBR corrugated membrane device, and belongs to the technical field of membrane bioreactors. The longitudinal vibration MBR corrugated membrane device comprises a box body, wherein the upper portion of the box body is provided with a driving device, the box body is internally provided with a membrane module device, the driving device is connected withthe membrane module device through a connecting device and drives the membrane module device to do reciprocating motion in the box body in the vertical direction through the connecting device, a supporting frame is arranged on the rear side of the box body, the driving device is mounted at the top of the supporting frame, and the membrane module device comprises a membrane box and a plurality ofcorrugated membrane sheets arranged in the membrane box. According to the invention, aeration is replaced by vibration, so that the possibility of membrane blockage and pollution is reduced, membranepollution is relieved to a great extent, the cleaning frequency is reduced, and the operation period is prolonged; the vibration form enables a mixed solution to form a local anoxic environment, so that the effluent quality is improved, and the problem of continuous accumulation of hair in the end area is avoided; and in-situ cleaning can be adopted, only vibration is adopted, suction is avoided,mud cakes are removed, pollution is relieved, the offline cleaning period is prolonged, and the anti-pollution characteristic of the membrane module device is further improved.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

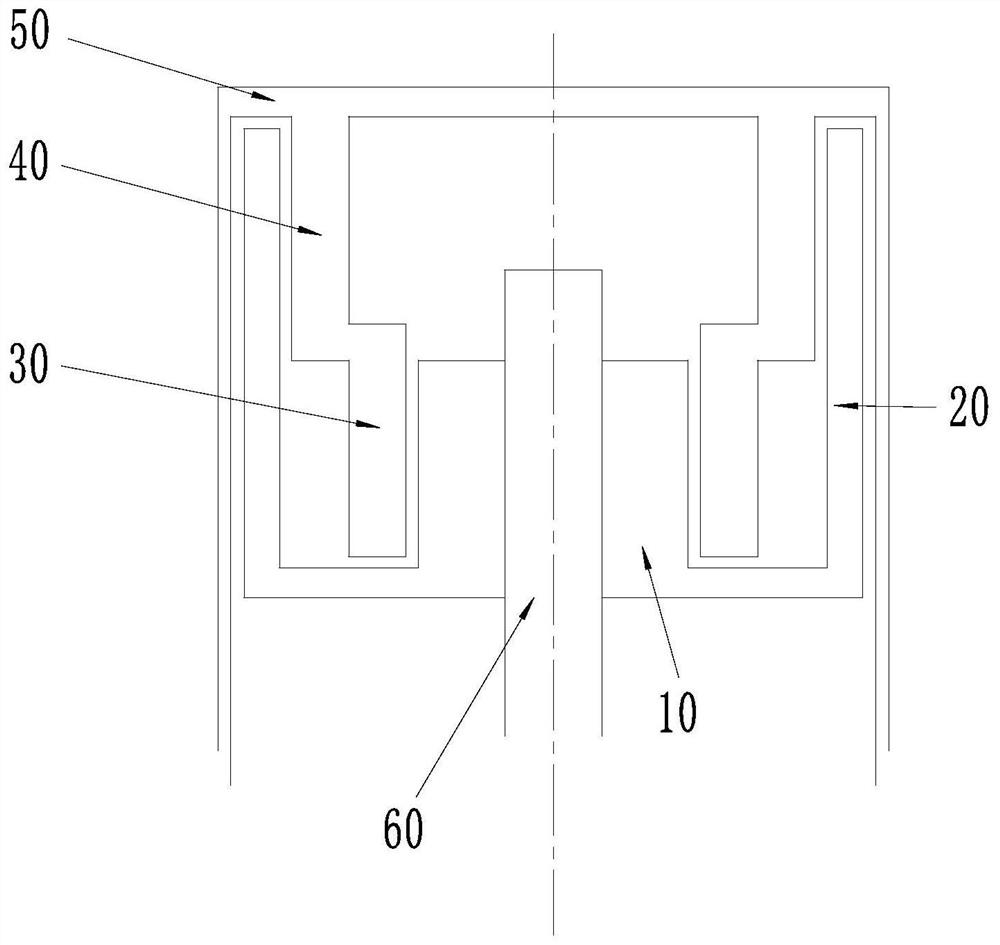

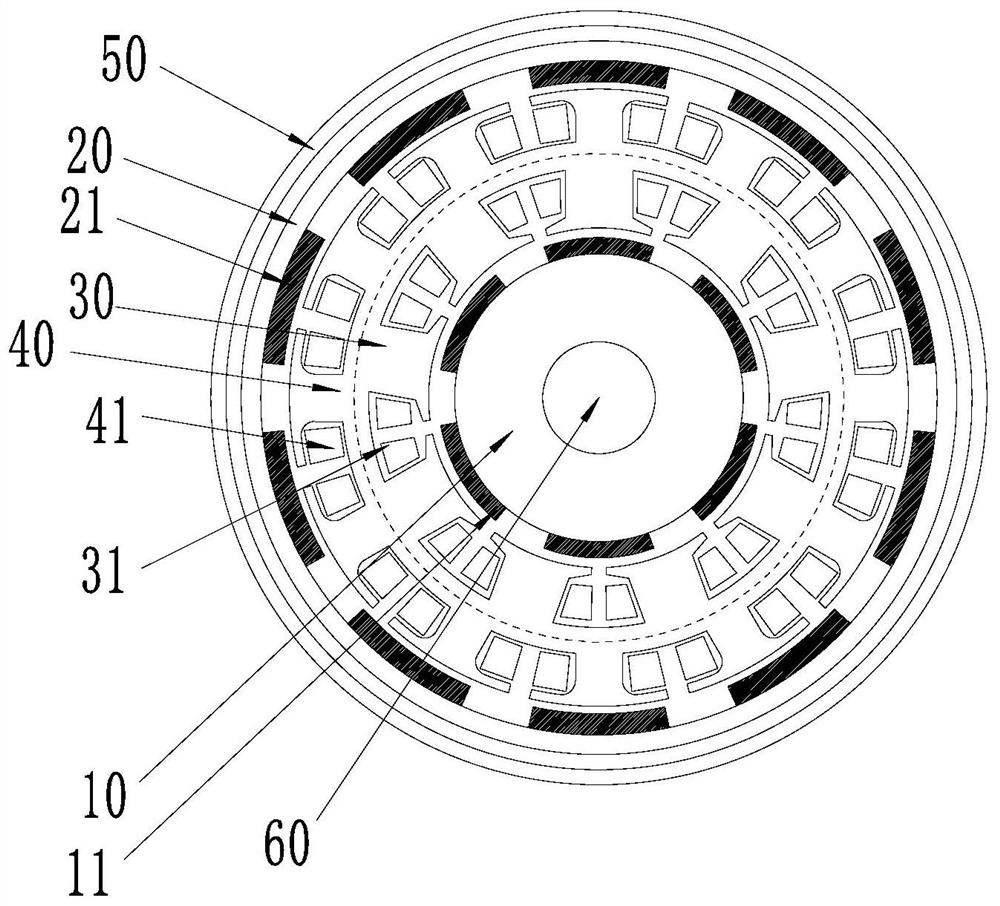

Double-rotor motor and air conditioning unit

ActiveCN112234785AIncrease stack heightIncrease the moment of inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineEngineering

The invention provides a double-rotor motor and an air conditioning unit. The double-rotor motor comprises a stator, an outer rotor and an inner rotor, the stator is fixedly arranged, the stator formsan outer stator section and an inner stator section which are connected along the height direction of the stator, the outer rotor is arranged on the outer side of the outer stator section, and the inner rotor is arranged on the inner side of the inner stator section. By means of the technical scheme, only the stacking height of the outer rotor with the large radius can be increased, the increasedcost is small, and the brought rotational inertia is obviously increased. The moment of inertia of the motor is increased, the torque fluctuation of low-frequency operation of a compressor is reduced, the low-frequency operation current fluctuation is reduced, the current harmonic content is reduced, the compression low-frequency operation rotating speed is more stable, and the efficiency of thecompressor in low frequency operation is enhanced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

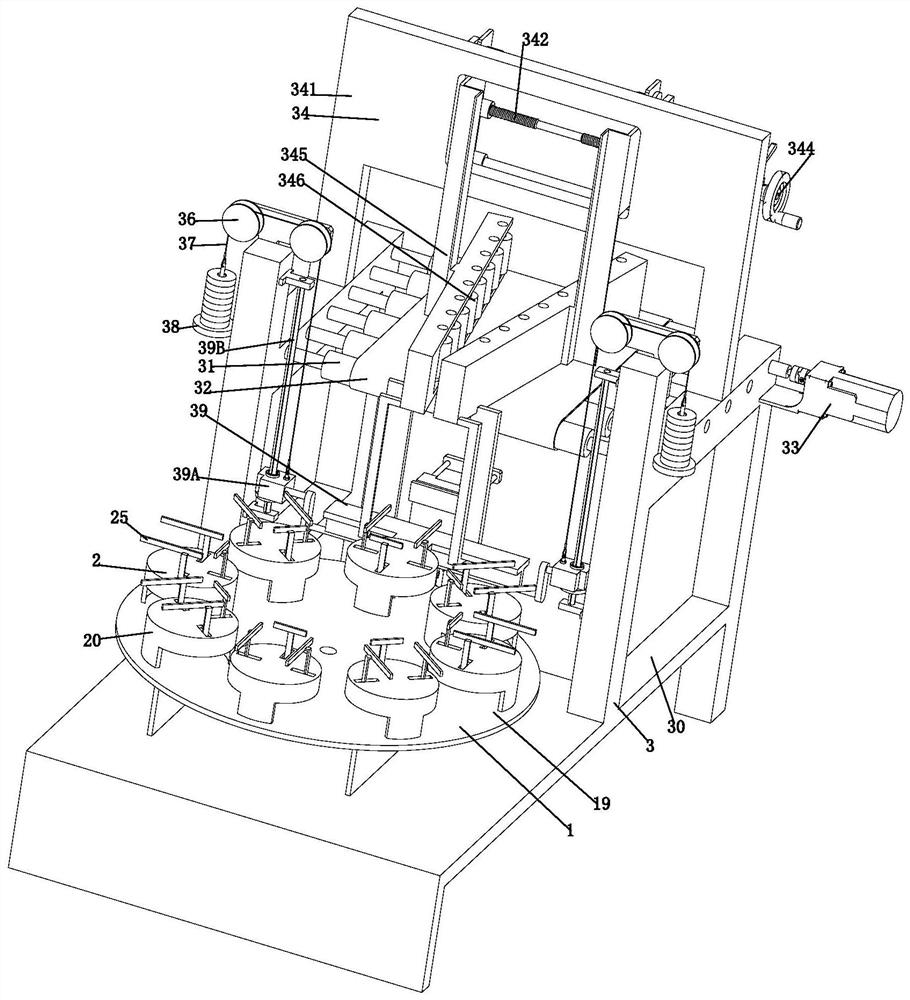

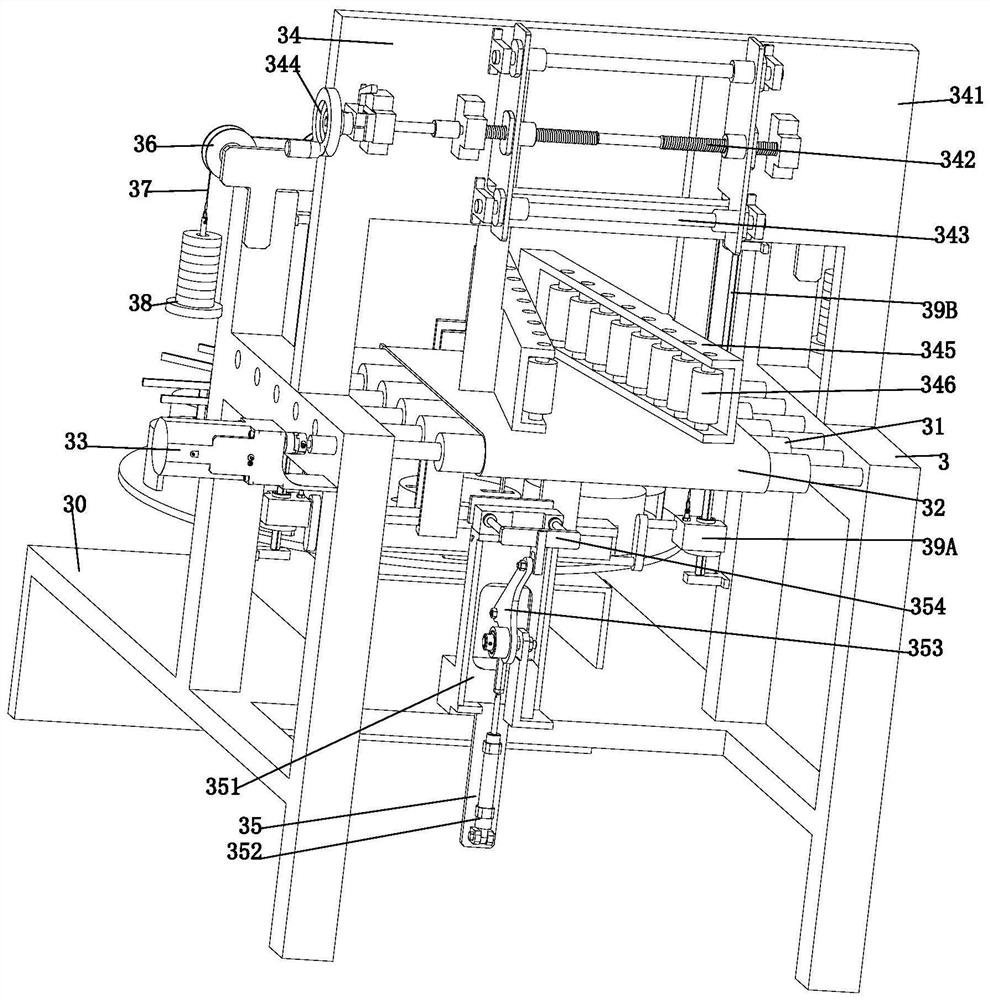

Plate overturning and stacking device

PendingCN111776751AGuaranteed front-to-sideIncrease heightStacking articlesClassical mechanicsEngineering

Owner:张家港市弘扬机械设备有限公司

Storage cage

InactiveCN101088874AReasonable cooperationEasy to plug inRigid containersEngineeringMechanical engineering

Owner:SUZHOU PINGFANG IND CO LTD

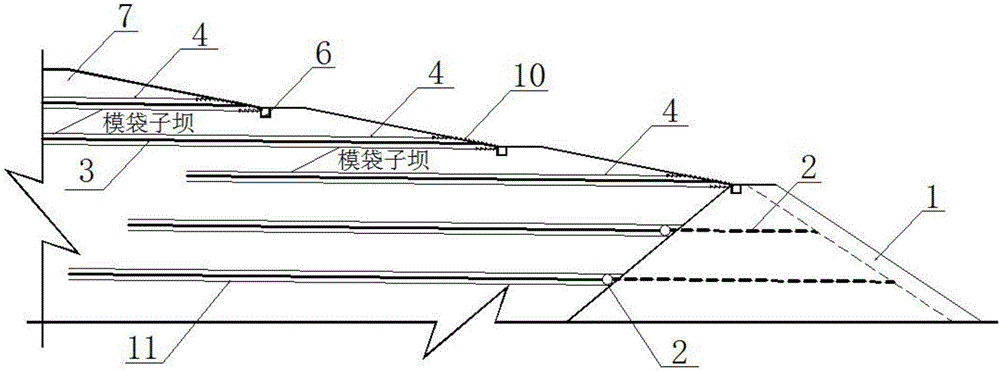

Method for preventing earthquake liquefaction instable failure for superfine grain upstream method tailing damming

ActiveCN106759174ALower Wetting LineAccelerated consolidationDamsClimate change adaptationEngineeringAbutment

The invention discloses a method for preventing earthquake liquefaction instable failure for superfine grain upstream method tailing damming. The burying depth of a first earthquake liquefaction preventing medium-coarse sand draining and seeping layer and the burying depth of a second earthquake liquefaction preventing medium-coarse sand draining and seeping layer are determined according to the earthquake fortification intensity of an earthquake of a region, wherein each of the first earthquake liquefaction preventing medium-coarse sand draining and seeping layer and the second earthquake liquefaction preventing medium-coarse sand draining and seeping layer is composed of a medium-coarse sand draining and seeping layer (11) and a row of slot draining and seeping pipes (3) laid in the medium-coarse sand draining and seeping layer (11), wherein the slot draining and seeping pipes (3) communicate with a water draining communication pipe (2) through a tee pipe (12), and the outer end of the water draining communication pipe (2) is connected with a dam abutment flood interception trench (1). By means of the method, the earthquake liquefaction preventing capability and stability of a superfine grain tailing fill dam are improved, the bearing force and the liquefaction preventing capability of superfine grain tailings are improved, earthquake liquefaction subsidence of a superfine grain tailing fill dam foundation is eliminated, the earthquake liquefaction instable failure phenomenon is avoided, and stability of the superfine grain tailing fill dam is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

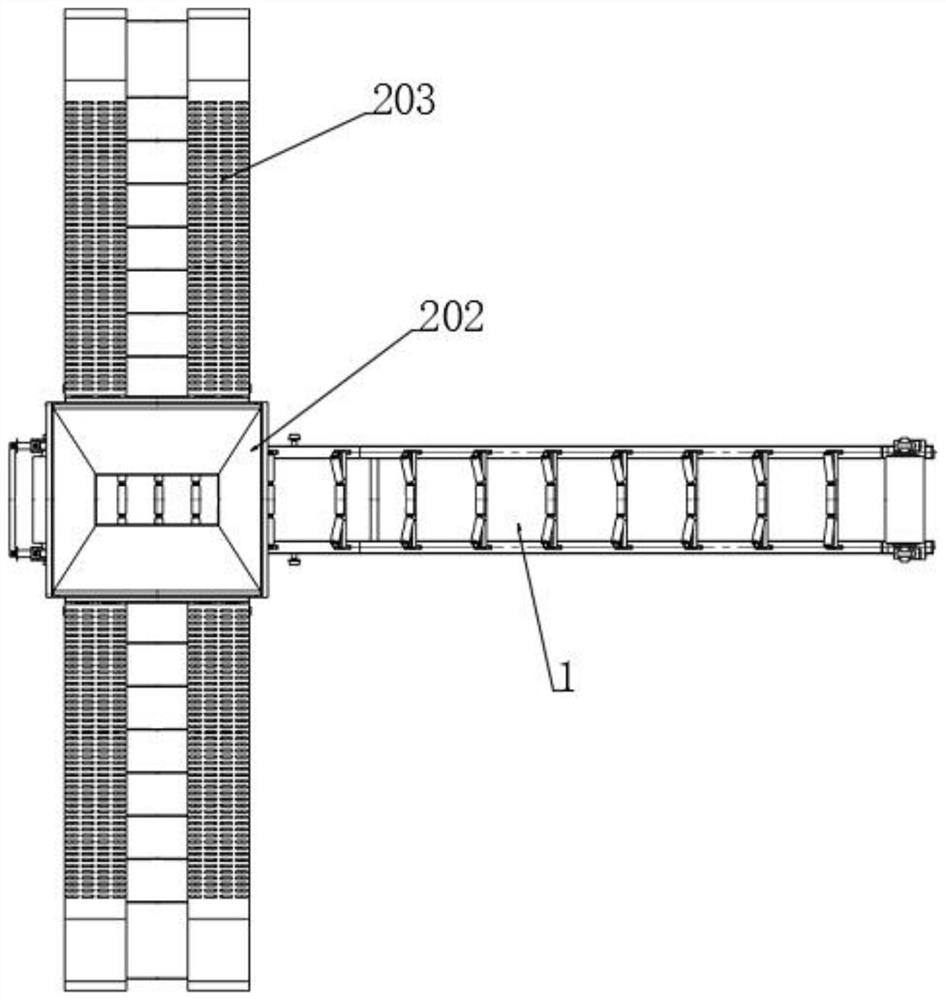

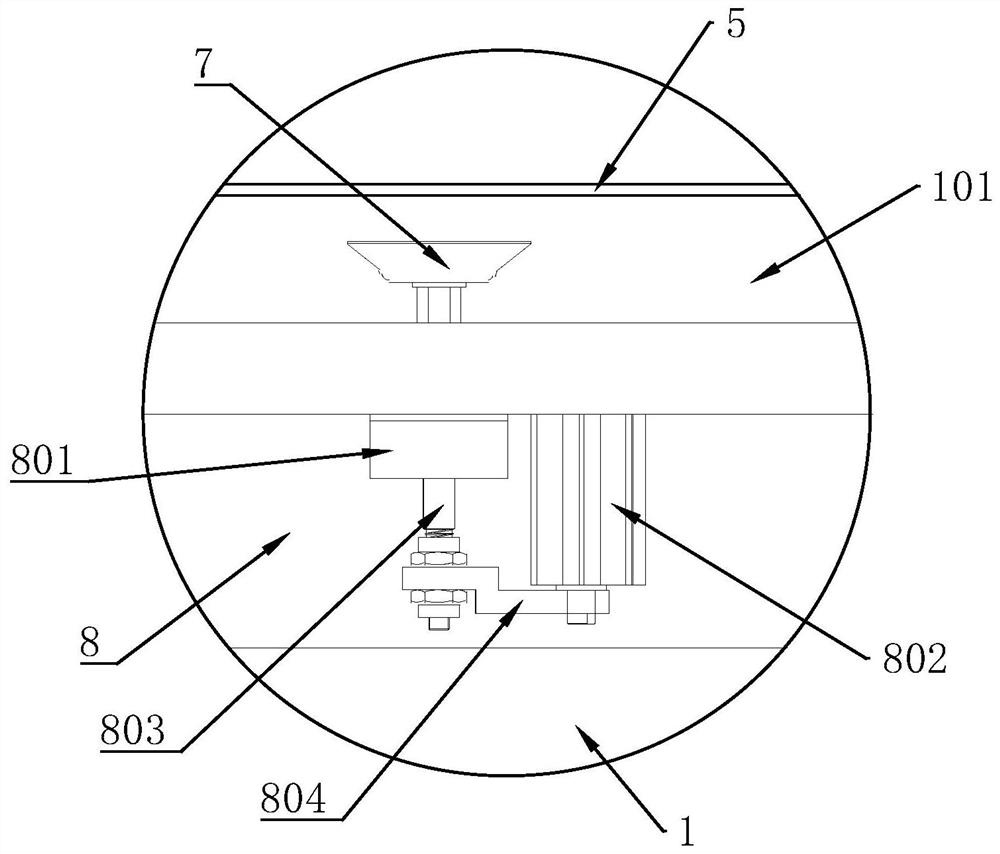

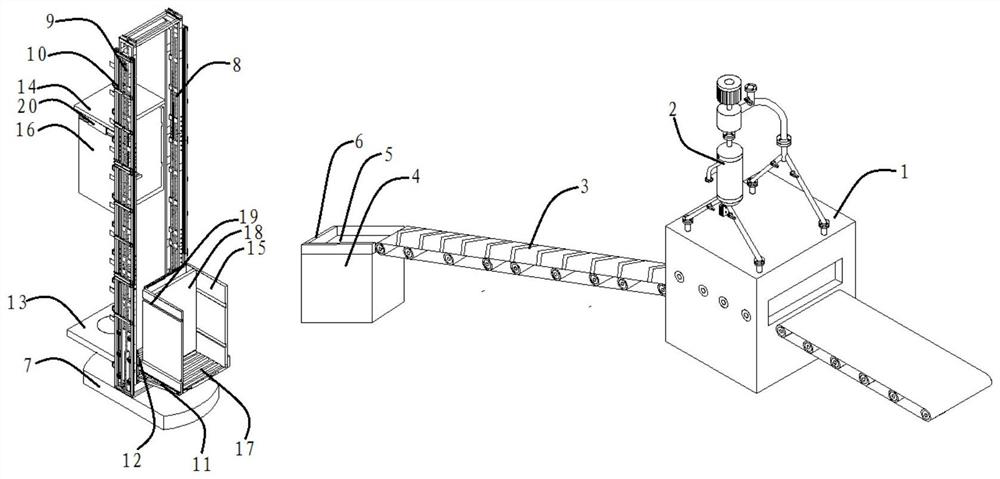

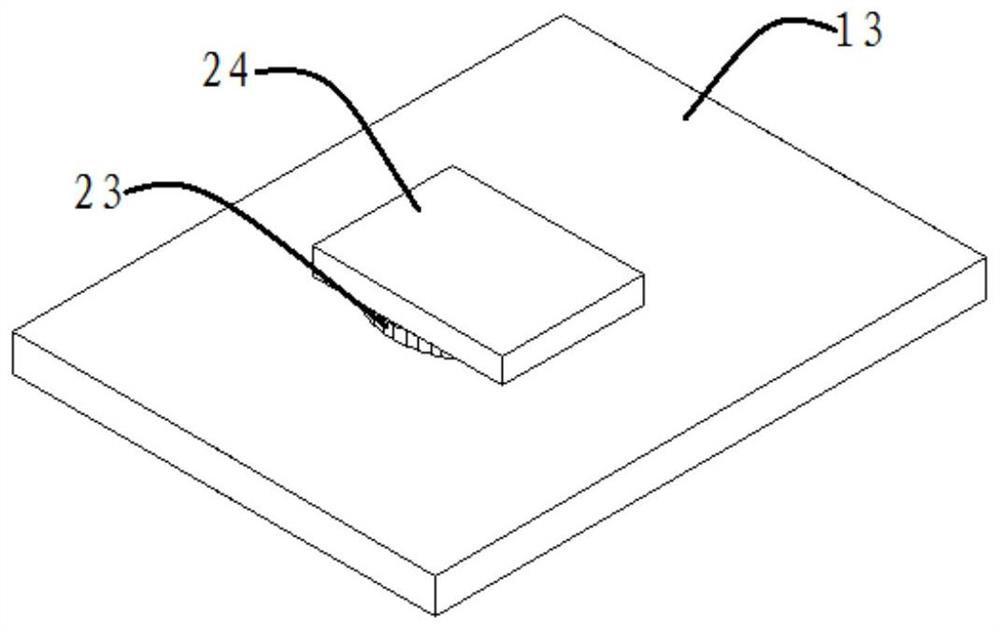

Full-automatic stacking and loading equipment applied to corrugated board lamination

ActiveCN113460361AIncrease the stacking heightIncrease stack heightPaper article packagingLifting devicesEngineeringStructural engineering

The invention discloses full-automatic stacking and loading equipment applied to corrugated board lamination. The full-automatic stacking and loading equipment comprises drying treatment equipment, a packaging device and lifting and loading equipment; the lifting and loading equipment comprises a gantry vertical frame, a lifting platform and an elevating platform; the lifting and loading equipment further comprises a plurality of bearing boxes, and a multi-stage push plate mechanism is arranged in each bearing box; the lifting and loading equipment further comprises a fixed table, and a rotating mechanism is arranged on the fixed table; a friction roller device is arranged on the lifting platform; when the lifting platform moves to be flush with the height of the fixed table, the friction roller device conveys the bearing boxes and clamps the bearing boxes on the rotating mechanism; and the lifting platform is connected with the bearing boxes through elastic clamping assemblies. According to the full-automatic stacking and loading equipment applied to corrugated board lamination, automatic packaging is carried out through the packaging device; and the packaged corrugated boards are conveyed to the interiors of the bearing boxes to be stacked, the direction of the bearing boxes is changed on the rotating mechanism, the stacked corrugated boards are pushed to a conveying station through the multi-stage push plate mechanism, meanwhile, the stacking height is increased through the elevating platform, and the bearing boxes are conveyed back to the lifting platform to be subjected to assembly line operation.

Owner:宁夏成峰包装印刷有限公司

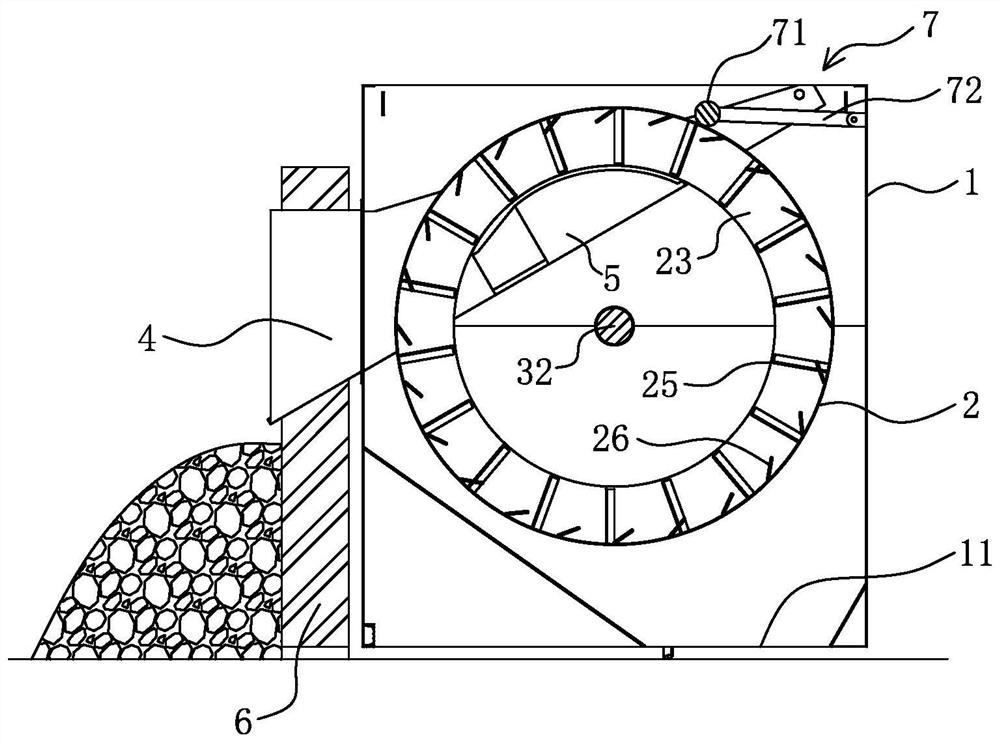

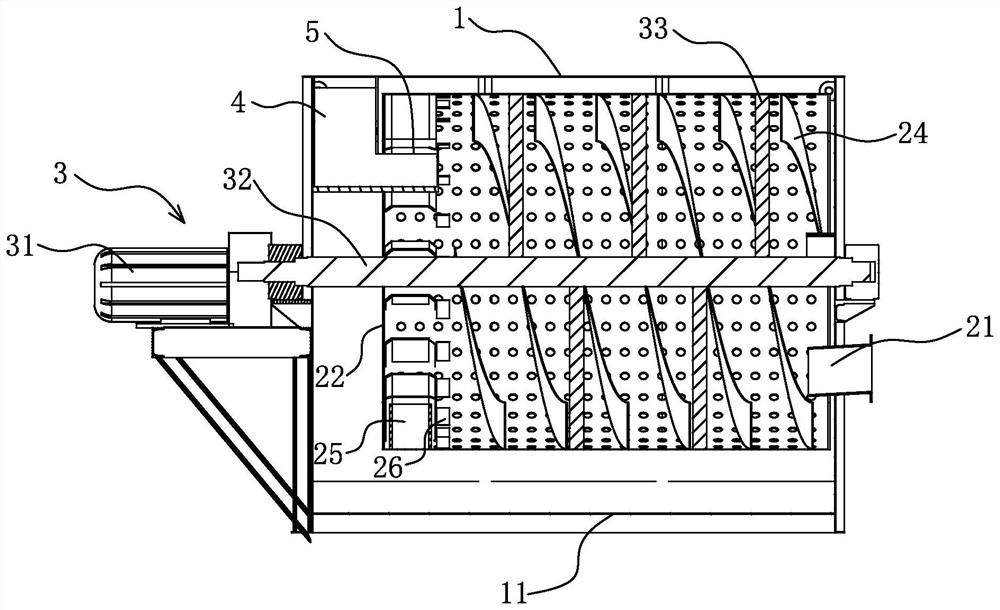

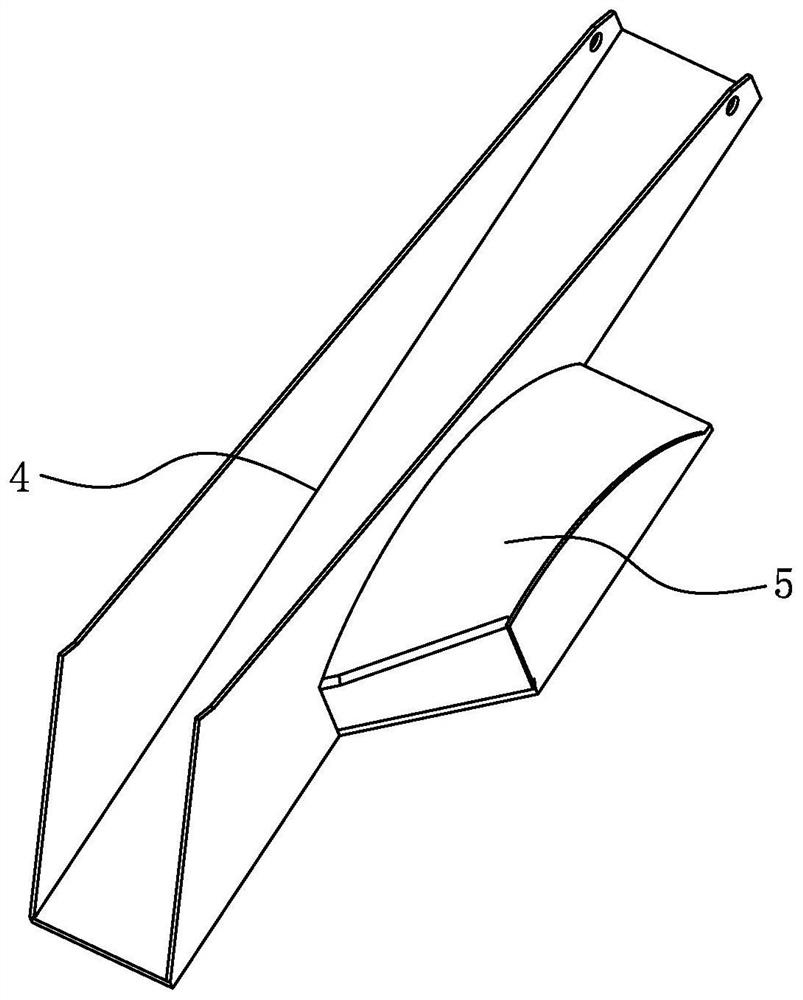

Screw roller screen for separating concrete to recycle gravels

PendingCN111889350AIncrease stack heightImprove work efficiencySievingScreeningHelical bladeClassical mechanics

The invention relates to the technical field of roller screen equipment, in particular to a screw roller screen for separating concrete to recycle gravels. The screw roller screen comprises a roller,a driving mechanism, a discharge chute and a receiving groove. Screw blades and a plurality of material lifting blades are arranged in the roller. The screw blades are arranged around the inner wall of the roller and drive materials to be pushed to a discharge port during rotating of the roller. The material lifting blades are arranged on the inner wall, close to the discharge port, of the rollerin an encircling mode. The discharge chute is obliquely arranged outside the discharge port of the roller. The receiving groove communicates with the discharge chute and is embedded in the roller fromthe discharge port. The material lifting blades drive the materials to go up from a low place and fall at a high place to go into the receiving groove during rotating of the roller. Through cooperation of the material lifting blades, the receiving groove and the discharge chute, the screw roller screen discharges the separated and output material from the high place, improves the stacking heightof the materials, improves the working efficiency without addition of extra equipment and is small in occupied area.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

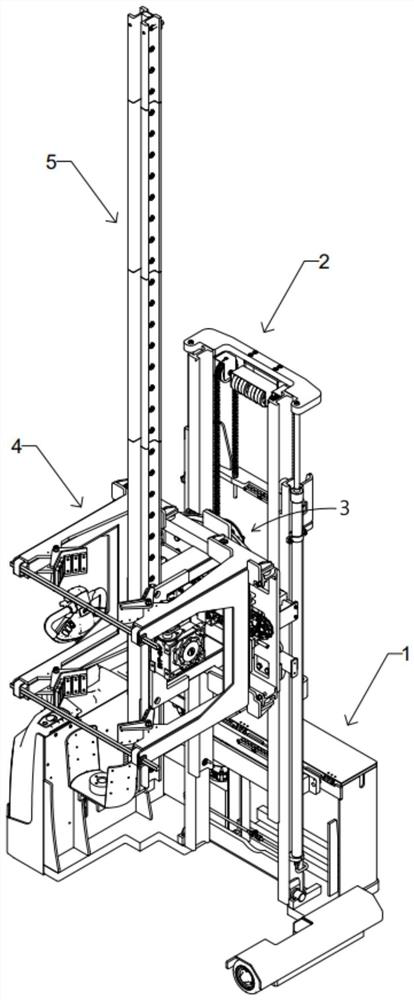

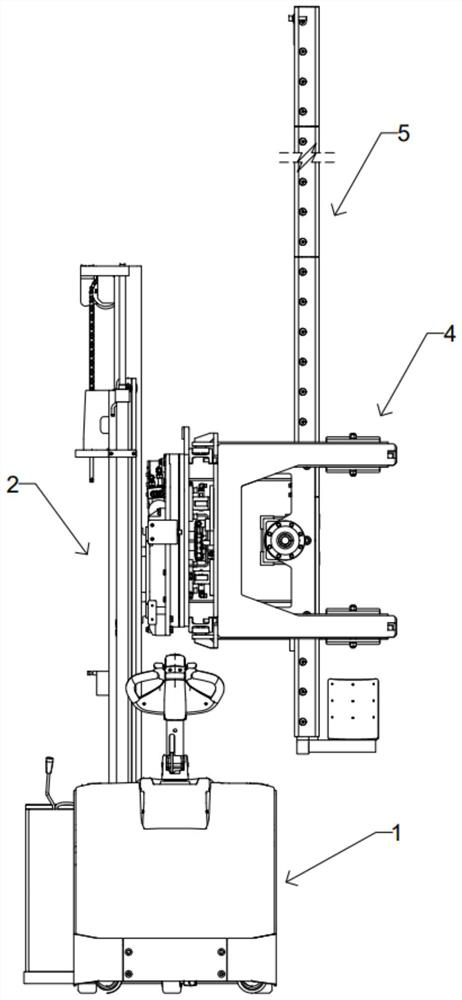

Carrying vehicle and hydraulic control system

PendingCN113428808AIncrease the stacking heightImprove vehicle adaptabilityLifting devicesHydraulic controlControl system

The invention discloses a carrying vehicle and a hydraulic control system. The carrying vehicle comprises a vehicle body, a door frame assembly, a rotating assembly, a holding and clamping assembly and a lifting assembly; the door frame assembly is vertically installed on the vehicle body and used for driving a rod-shaped object to ascend and descend; the rotating assembly is connected with the door frame assembly and used for driving the rod-shaped object to rotate in a vertical plane; the holding and clamping assembly is fixedly connected with the rotating assembly; and the lifting assembly is arranged on the holding and clamping assembly and used for bearing the rod-shaped object and providing additional lifting motion for the rod-shaped object, and the lowest point of downward motion of the lifting assembly is lower than the vehicle body. The lifting assembly capable of providing an additional lifting function for the rod-shaped object is arranged in the holding and clamping assembly, a hydraulic motor drives a reduction gearbox to move, a lifting guide rail is driven to move up and down along a shaft head fixing plate under the action of a gear and a rack, and finally a crystal bar on a tray is linked to move up and down; and due to the arrangement of the lifting assembly, the whole vehicle has an additional lifting function besides the portal assembly, the stacking height of the whole vehicle is greatly increased, and the adaptability of the whole vehicle is improved.

Owner:BANYITONG SCI & TECH DEVING

Reverse stacking cell guide for storing of iso shipping containers

InactiveCN110198903AIncrease stack heightIncrease usageLarge containersStacking articlesShipping container

This invention relates to a method for stacking ISO shipping containers to a reverse stacking cell guide comprising a number of angle bars arranged vertically to fit four corners of the ISO shipping containers and a number of secure pins provided proximate a bottom end of each of the angle bars. The method comprises loading a first ISO shipping container on a lifting system, elevating the liftingsystem to a first height such that bottom end fittings of the first ISO shipping container are aligned with the secure pins, and moving the secure pins of the reverse stacking cell guide to a locked position such that the first ISO shipping container is locked within the reverse stacking cell guide.

Owner:迪巴柏塔班納吉

Flexible Membrane With Valve

PendingUS20210206544A1Increase heightIncrease spacingFlexible coversWrappersEngineeringHermetic packaging

Owner:GPI SYST AB

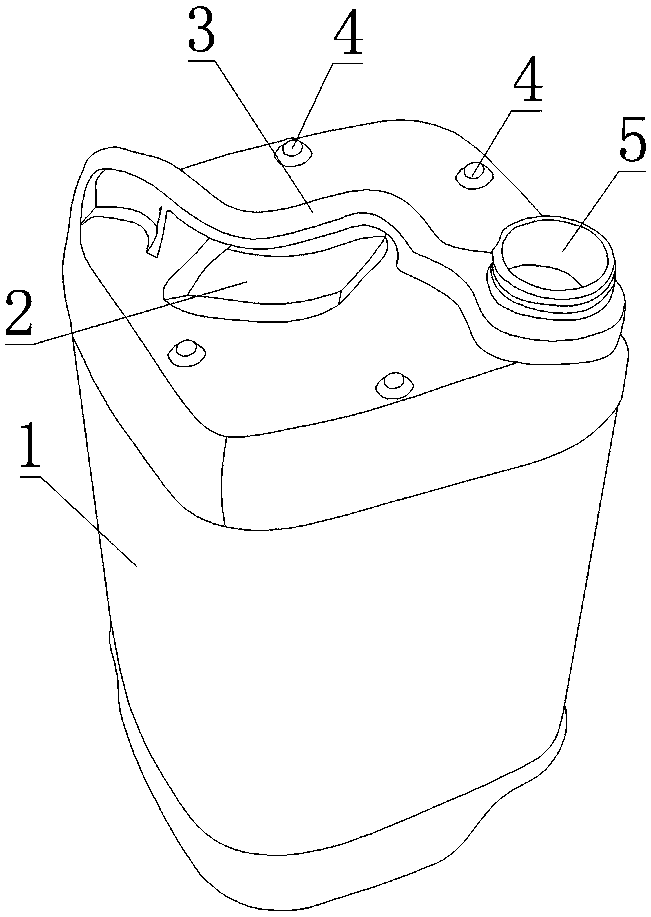

Milk packaging barrel

PendingCN108502309AImprove stabilityNo lateral shiftPackaging milkRigid containersEngineeringCow milk

The invention discloses a milk packaging barrel. The milk packaging barrel comprises a square barrel body, a handle is connected to the top of the square barrel body, and a filling port is formed in one corner of the square barrel body. The milk packaging barrel is characterized in that the handle is arranged along the diagonal line of the square barrel body, the two ends of the handle are connected to the square barrel body, a transverse bent part is arranged in the middle of the handle, an anti-offset groove corresponding to the handle is formed in the bottom of the square barrel body, a sunken part is formed in the highest point position in the center of the top of the square barrel body, and the height of the highest point of the top of the square barrel body is enabled to be smaller than the height of the neck of the filling port. The milk packaging barrel has the advantages that stacking of packaging barrels can be facilitated, relative lateral shift does not occur between the vertical stacked packaging barrels, large lateral wind force can be borne, the stacking stability is good, and storage and workshop circulation can be facilitated; and in addition, no air exists in thepackaging barrel filled with milk, so that the milk can be guaranteed to not go bad in a long time.

Owner:浙江百强乳业有限公司

Modular system for transporting wind turbine blades

ActiveUS10428800B2Increase flexibilityMinimize heightAccommodation for deck loadsEngine fuctionsTurbine bladeClassical mechanics

A modular system for transporting wind turbine blades in at least two different spatial arrangements comprising two or more root end transport frames having a height H for supporting the root end, wherein H<D (D=bolt circle diameter), and two or more first tip end transport frames having a height H1 for supporting the blade towards the tip end, each first tip end transport frame has a base frame and a support bracket provided on top of the base frame, wherein each first tip end transport frame is stackable on top of a root end transport frame and vice versa, so the system is operable to stack successive blades in an alternating root end to tip end arrangement. The first tip end transport frame is replaceable with a second end transport frame that increase the inter-blade spacing, or with a tip end or a root end distance piece.

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com