Milk packaging barrel

A technology for packaging barrels and milk, applied in the field of packaging barrels, can solve problems such as unfavorable smooth circulation of packaging barrels, blowing down and cracking of milk packaging barrels, etc., and achieve the effects of increasing milk stacking volume, increasing stacking height, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

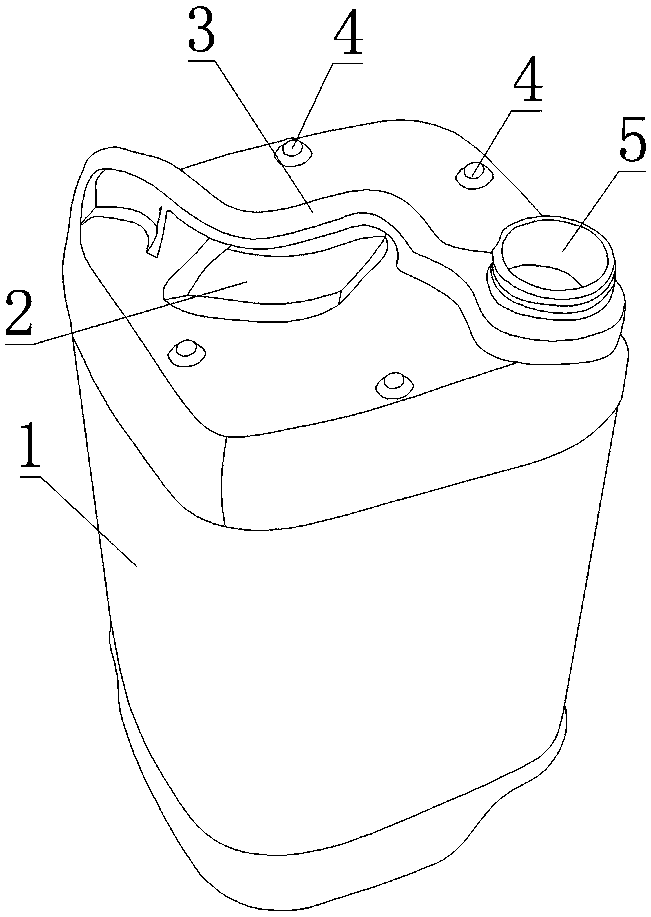

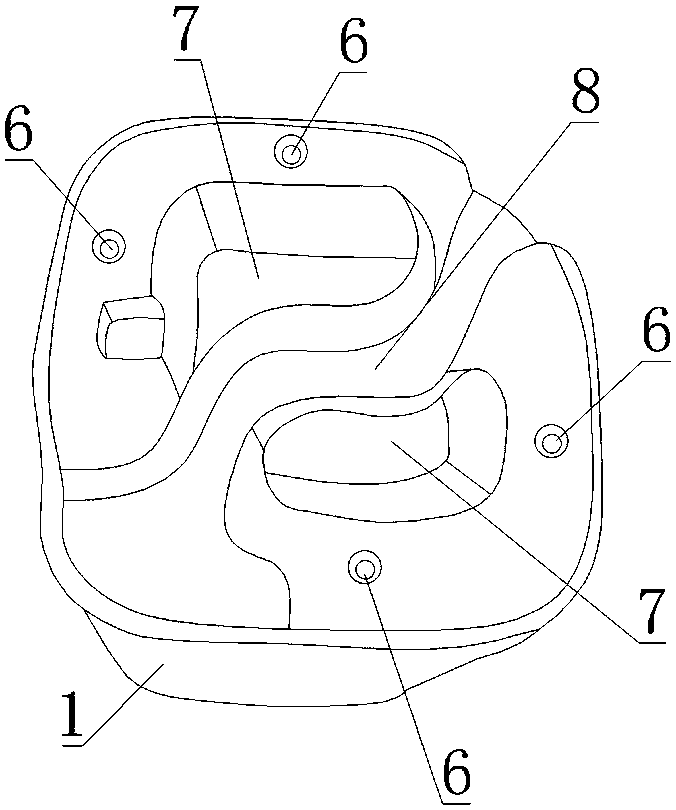

[0013] As shown in the figure, the milk packaging barrel disclosed by the present invention includes a square barrel body 1, a handle 3 is connected to the top of the square barrel body 1 and a filling port 5 is set at one corner, and the handle 3 is arranged along the diagonal of the square barrel body 1 , both ends of the handle 3 are connected to the square barrel body 1, and the middle of the handle 3 is provided with a transverse bend, which is not easy to slip when holding the handle 3, which effectively improves the practicability of the handle 3. The bottom of the square barrel body 1 is provided with Corresponding to the anti-wrong movement groove 8 of the handle 3, when two packaging barrels are stacked up and down, the diagonally arranged handle 3 will be stuck in the anti-wrong movement groove 8, so that the square barrel body 1 can move forward, backward, left and right. Neither sideways movement can occur, and the horizontal bending provided in the middle of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com