Patents

Literature

227results about "Packaging milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

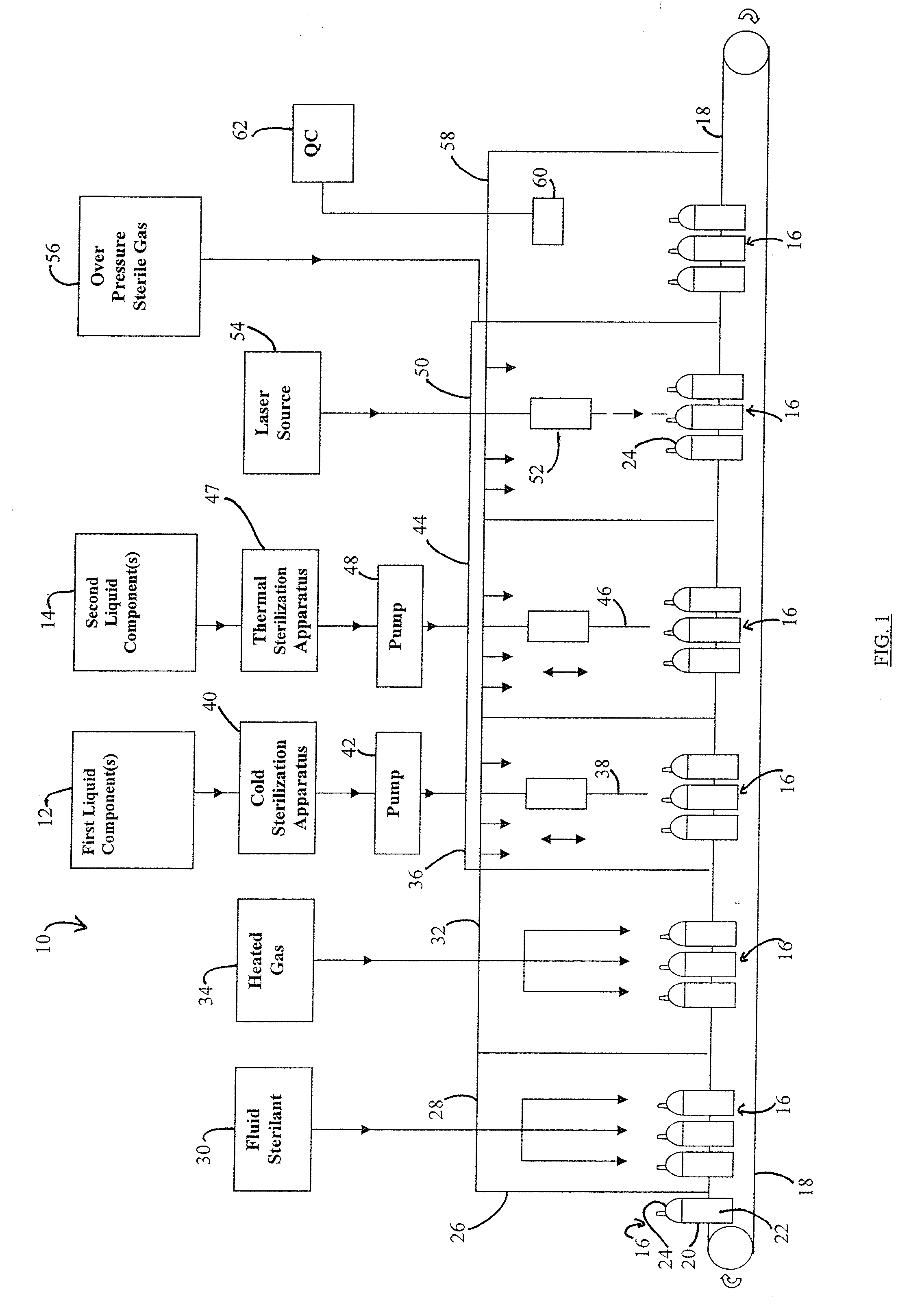

Method for formulating and aseptically filling liquid products

InactiveUS20090098250A1Readily apparentMilk preparationFruit and vegetables preservationFirst FillLiquid product

An apparatus and method are provided for formulating and aseptically filling liquid products. A first liquid source includes at least one first liquid component; a second liquid source includes at least one second liquid component; and a container includes a body defining an empty, sterile storage chamber therein that is sealed with respect to ambient atmosphere. The container is introduced into a sterile filling chamber. A first filling member coupled in fluid communication with the first liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the first liquid component is aseptically introduced through the first filling member and into the storage chamber. A second filling member coupled in fluid communication with the second liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the second liquid component is aseptically introduced through the second filling member and into the storage chamber and, in turn, the first and second liquid components are combined into a liquid product formulation within the sterile chamber of the container. The first and second filling members are withdrawn from fluid communication with the storage chamber of the container located within the sterile filling chamber, and the filled storage chamber is sealed with respect to ambient atmosphere to hermetically seal the liquid product formulation within the storage chamber of the container.

Owner:MEDINSTILL DEV

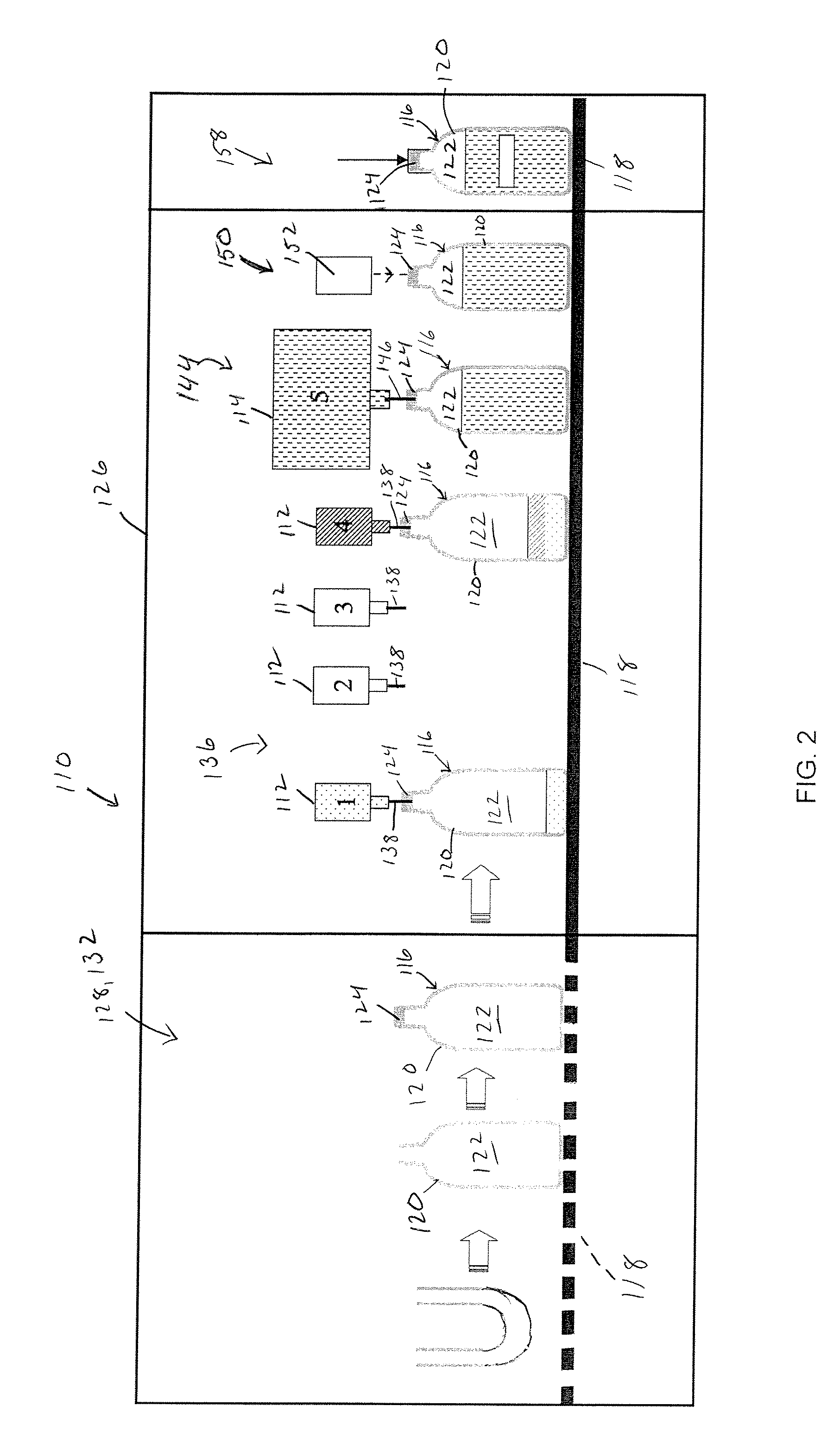

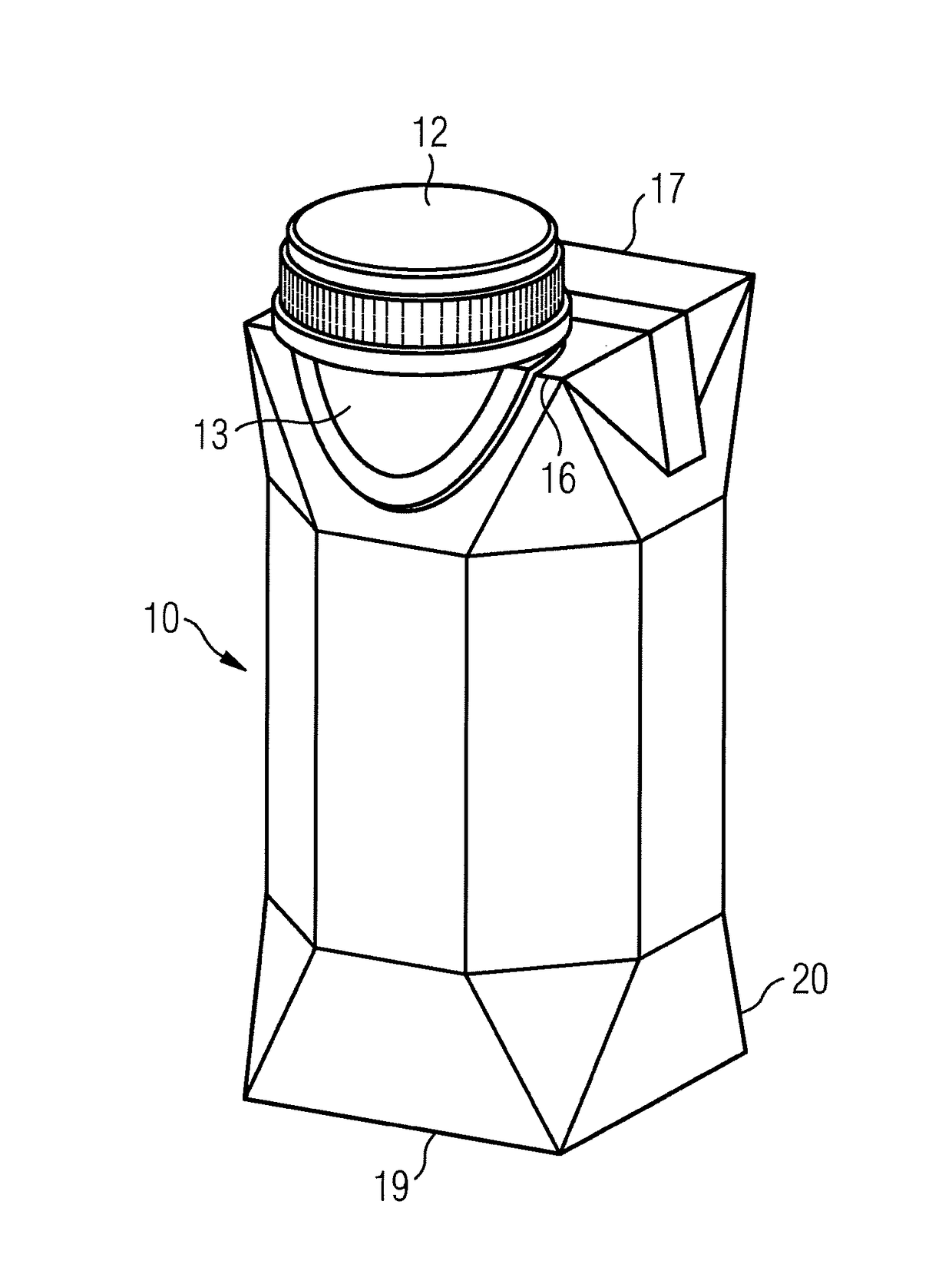

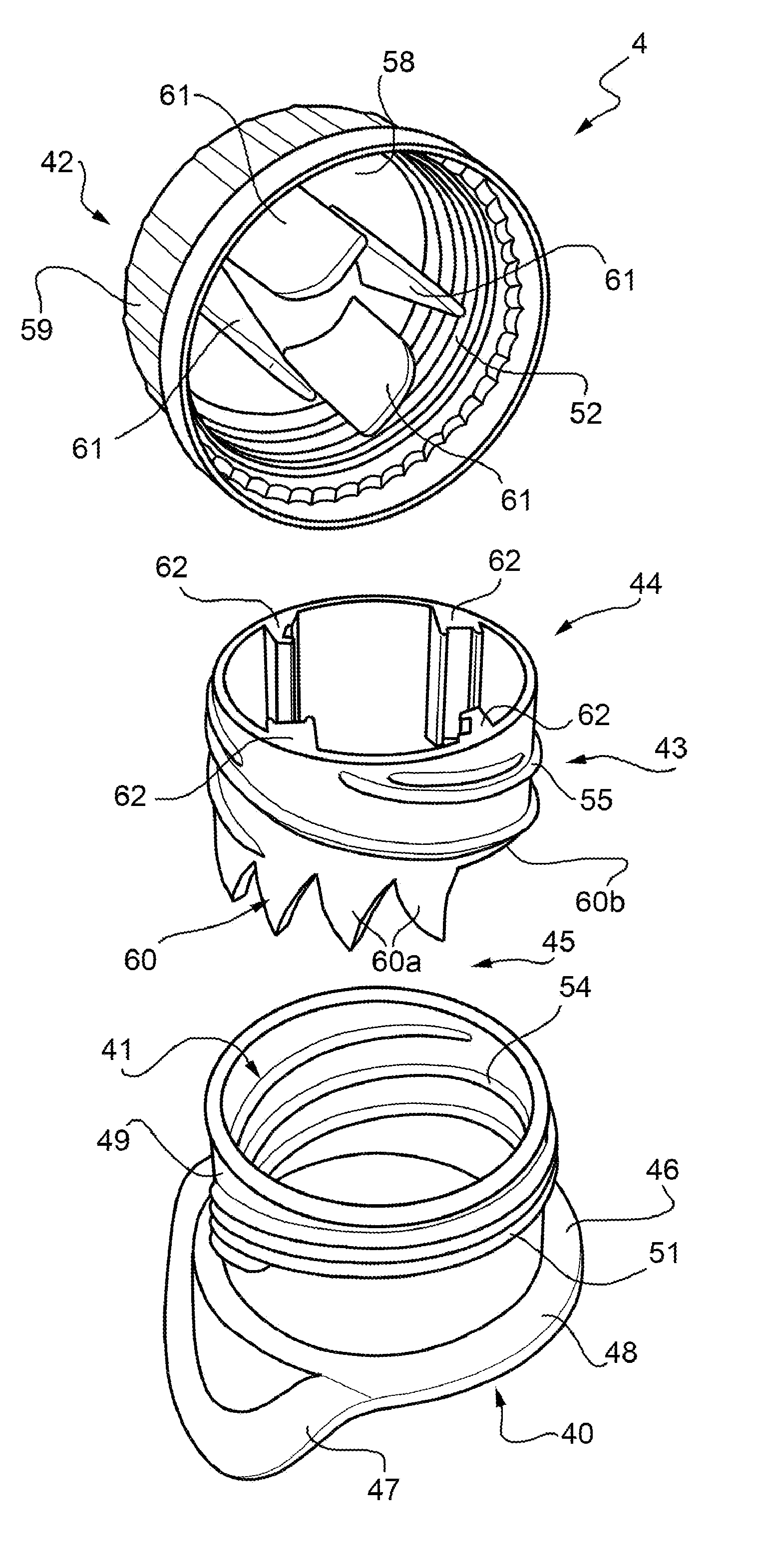

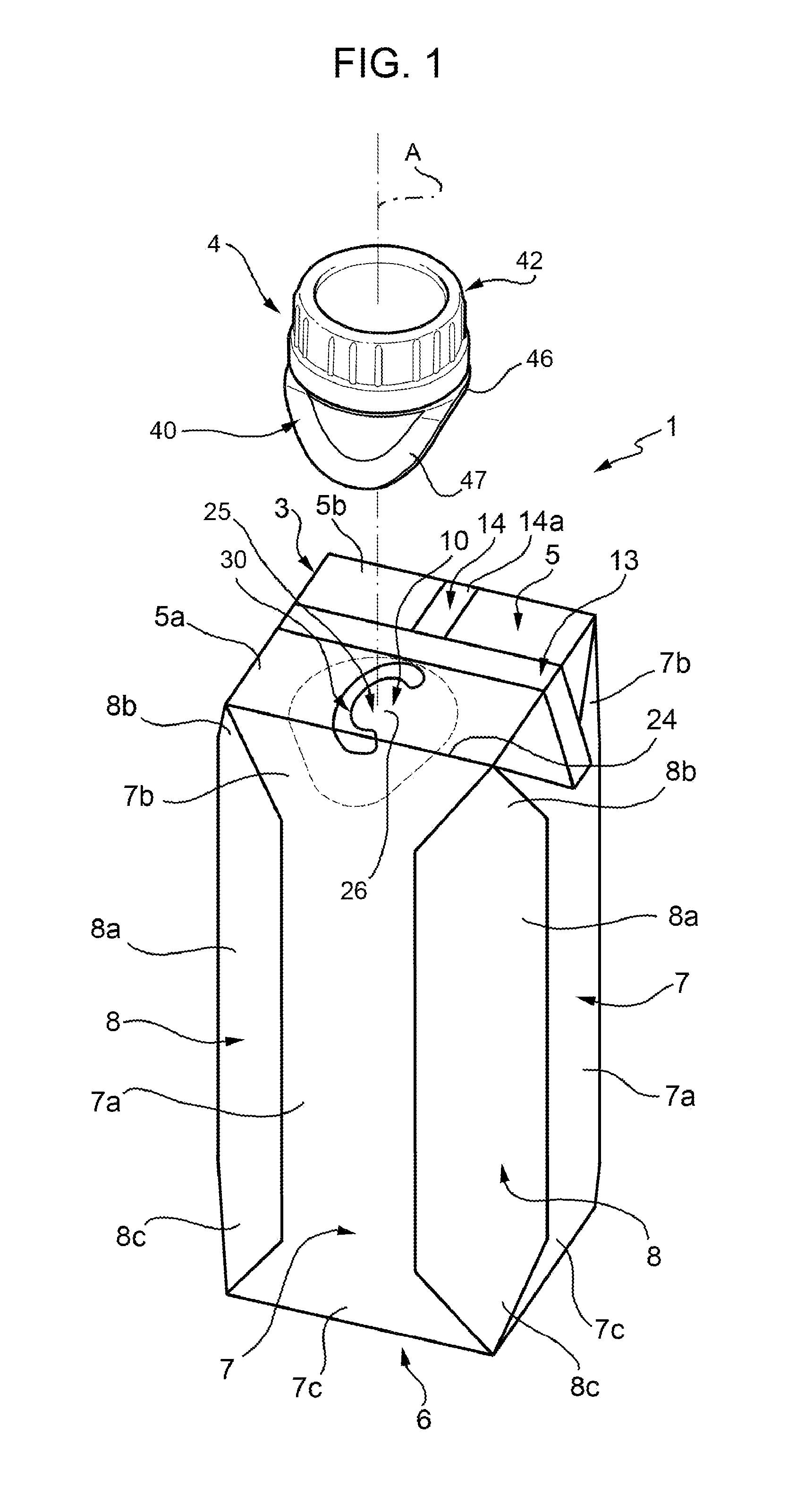

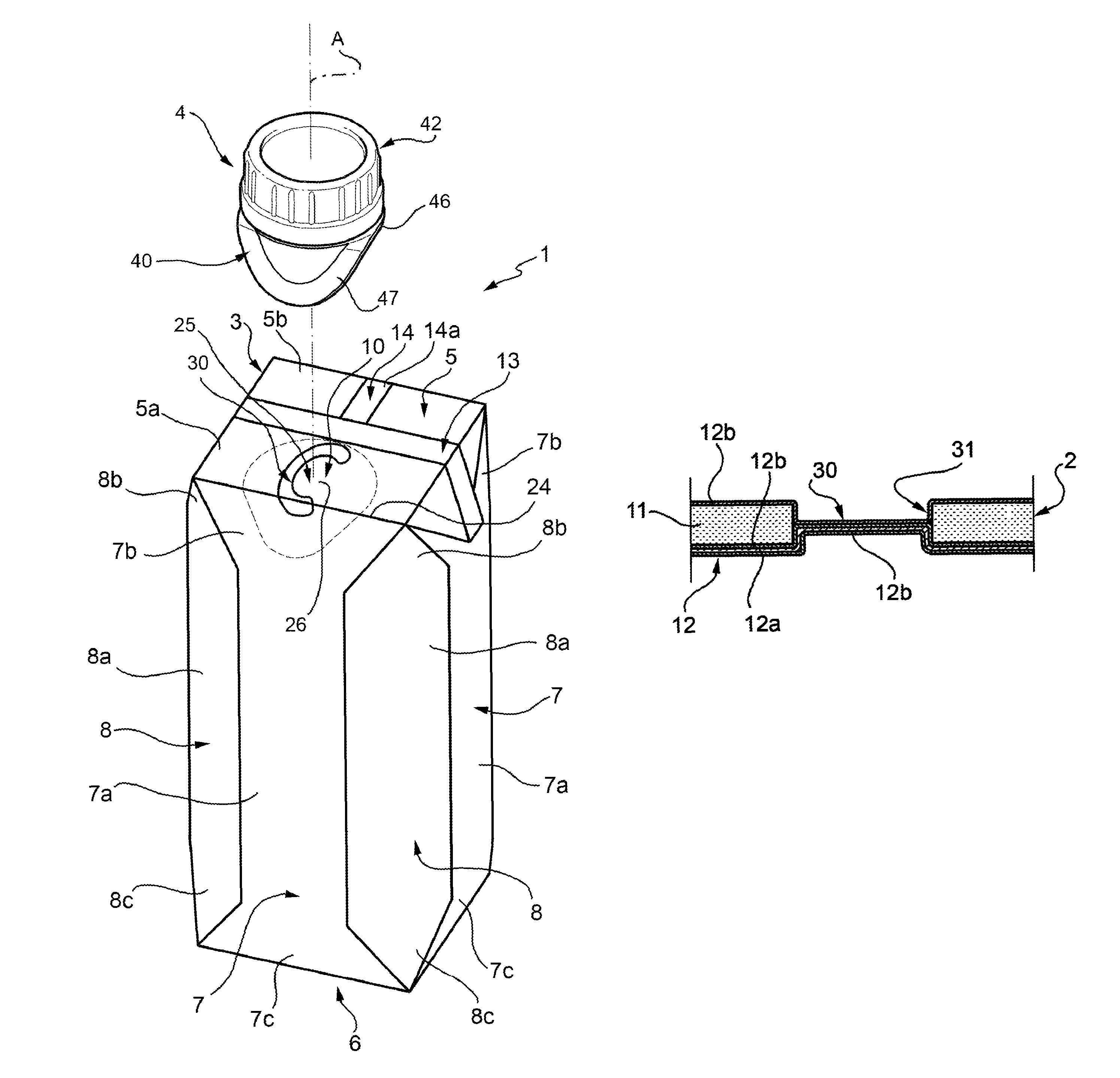

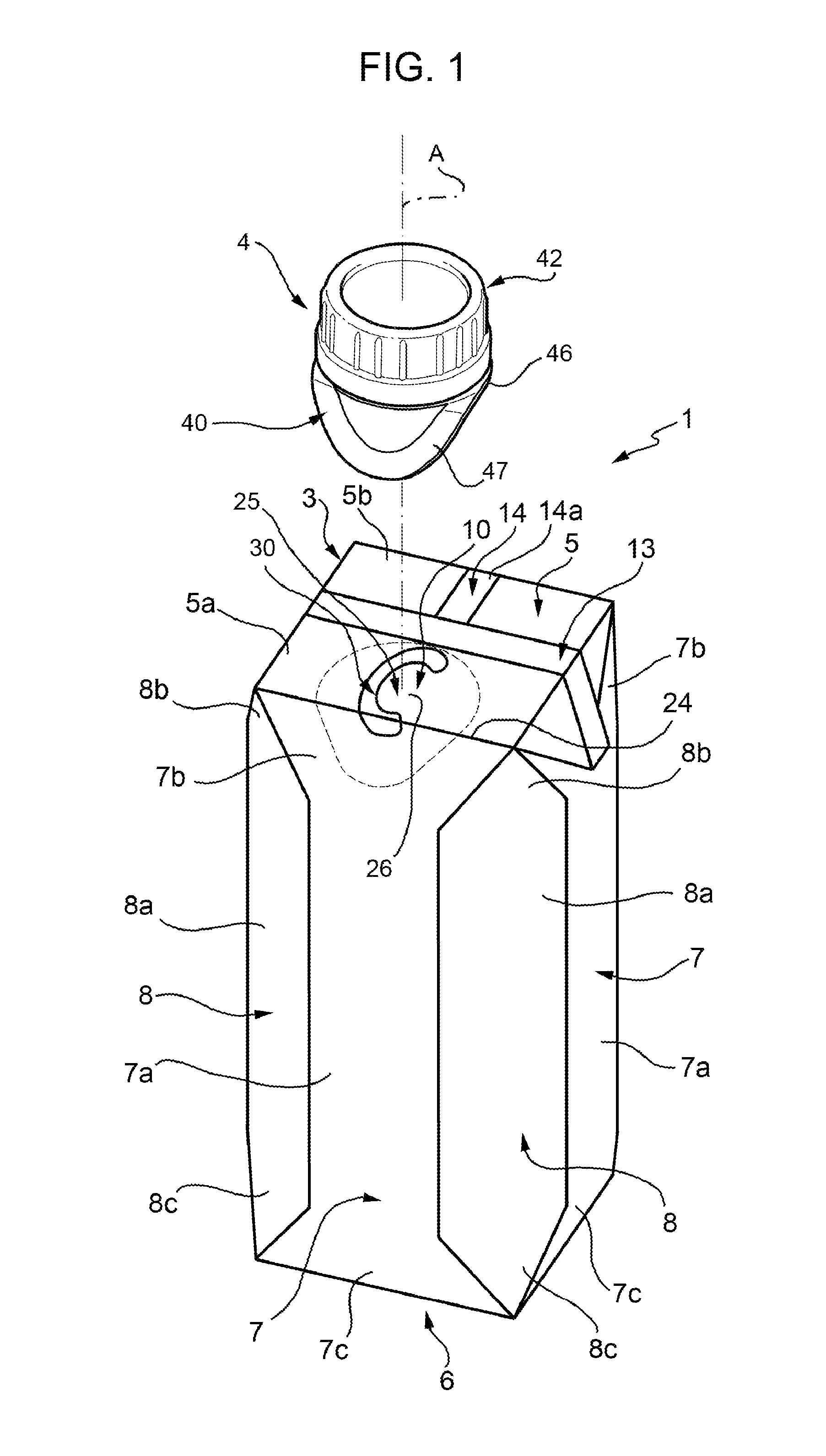

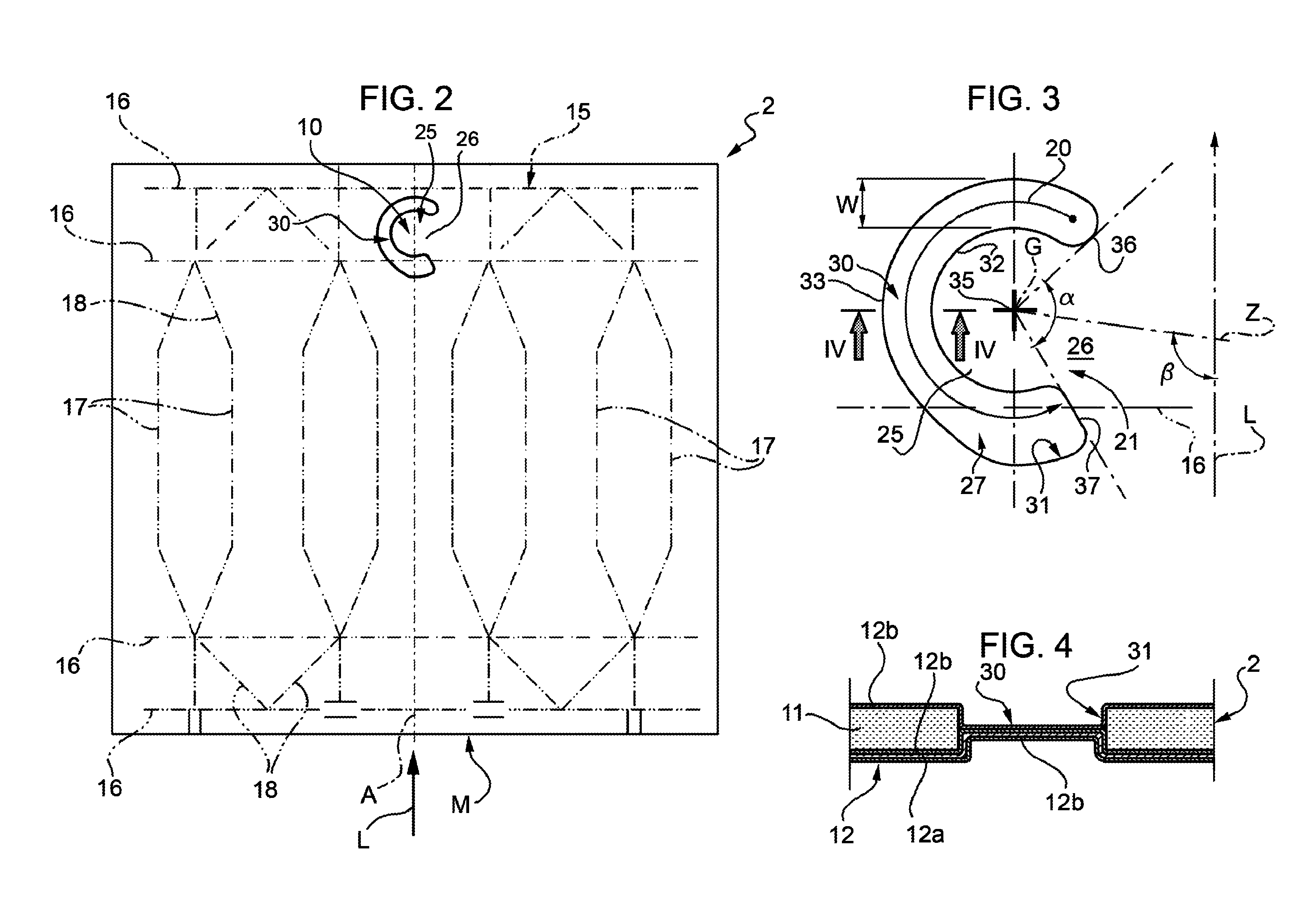

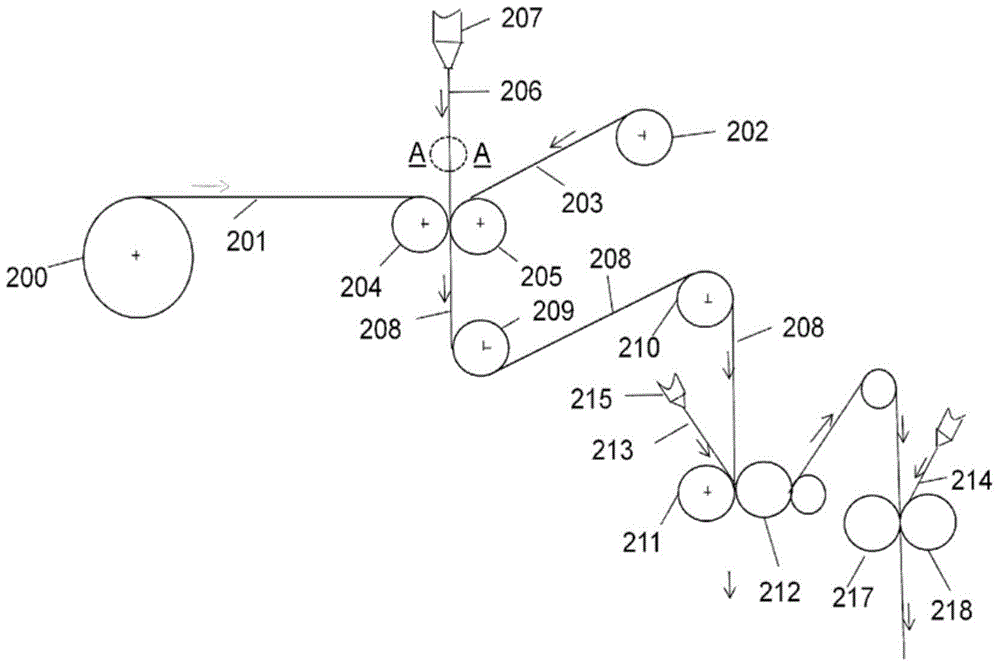

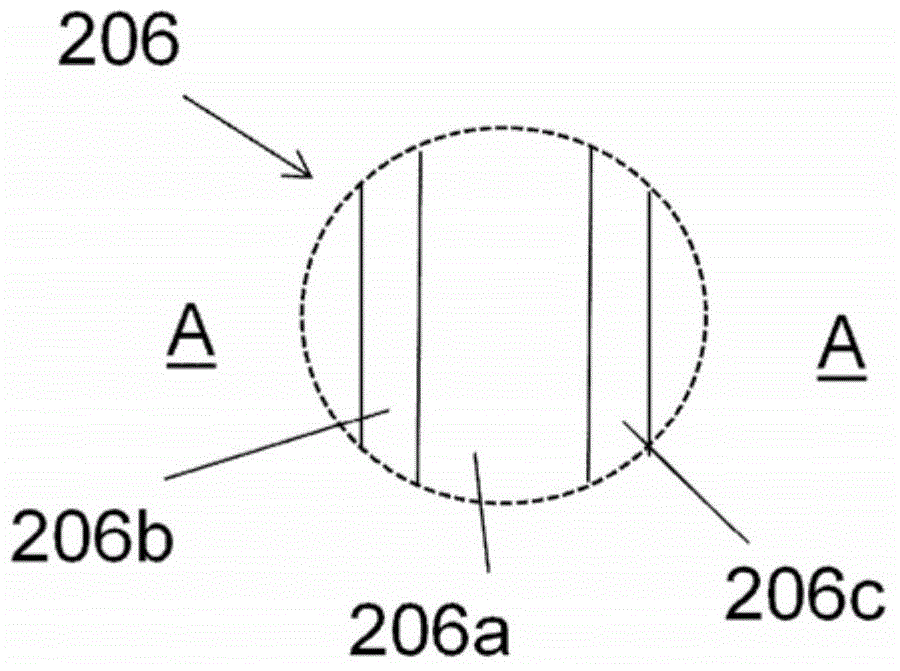

Sheet of packaging material for producing a container and method for producing containers

ActiveUS20170073102A1Broaden applicationInhibit productionContainer decorationsLevel indicationsBiomedical engineering

A sheet of packaging material to form a package, comprises a receiving region to receive an opening device of the package attached thereon, the sheet of packaging material further comprises two reference marks detectable by a detecting unit of an applying device arranged for applying the opening device on the receiving region. A method for producing a package comprises folding, filling and sealing a sheet of packaging material to obtain the package, the packaging material comprising a receiving region to receive an opening device and two reference marks, the method comprising detecting the reference marks and selecting a subsequent action to be performed on the package and / or the opening device on the basis of the detected position of the reference marks.

Owner:TETRA LAVAL HLDG & FINANCE SA

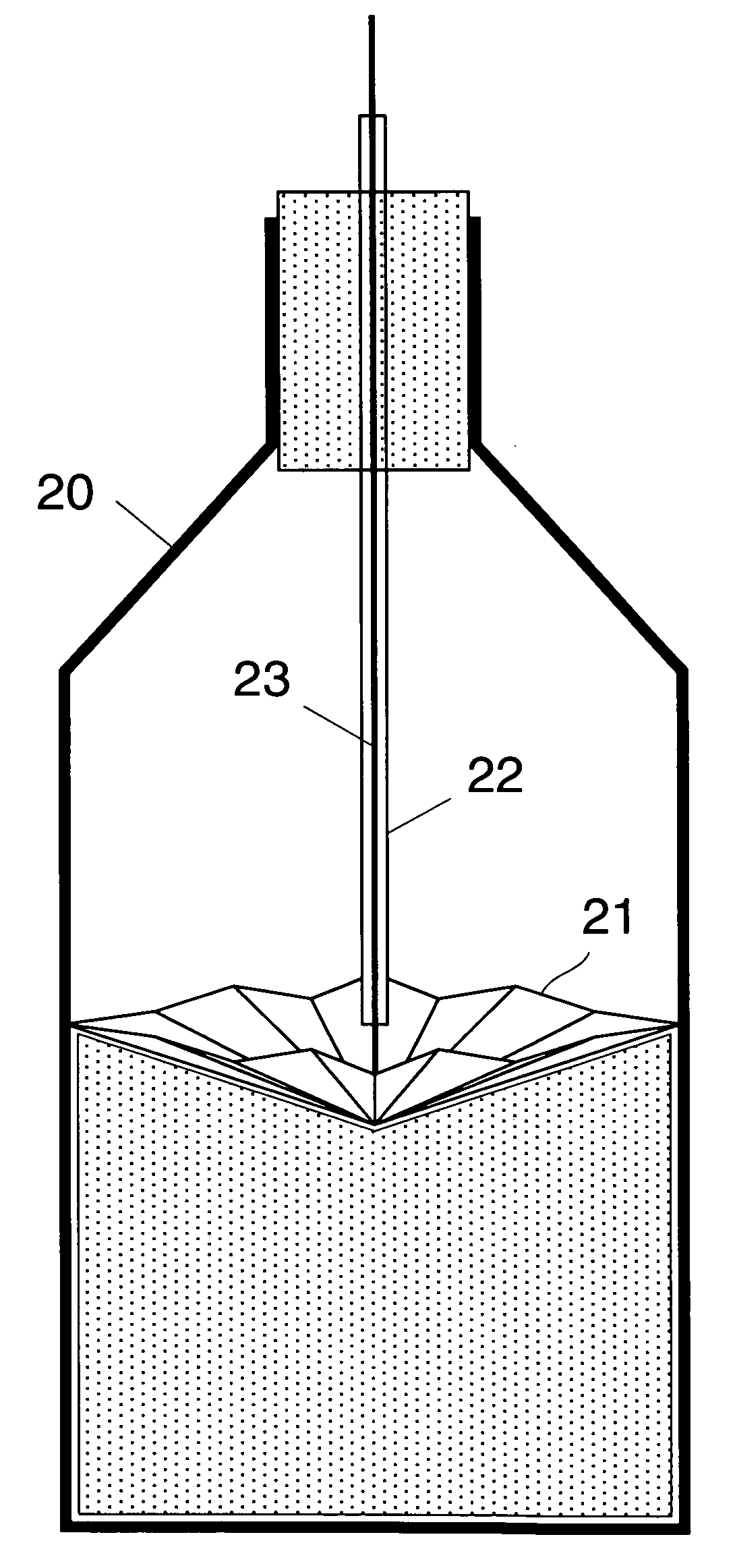

Process for the Heterotrophic Production of Microbial Products with High Concentrations of Omega-3 Highly Unsaturated Fatty Acids

A process for the heterotrophic or predominantly heterotrophic production of whole-celled or extracted microbial products with a high concentration of omega-3 highly unsaturated fatty acids, producible in an aerobic culture under controlled conditions using biologically pure cultures of heterotrophic single-celled fungi microorganisms of the order Thraustochytriales. The harvested whole-cell microbial product can be added to processed foods as a nutritional supplement, or to fish and animal feeds to enhance the omega-3 highly unsaturated fatty acid content of products produced from these animals. The lipids containing these fatty acids can also be extracted and used in nutritional, pharmaceutical and industrial applications.

Owner:DSM IP ASSETS BV

Packaging shaped articles, e.g., opaque bottles, and process for the manufacture thereof

InactiveUS20070063394A1Improve stabilityReduce light transmittanceWrappersFilament/thread formingBlow moldingPolyester

Packaging / storage shaped articles, for example, opaque bottles suited for storing and shielding such products as milk away from the adverse effects of visible and UV radiation, are manufactured by first providing / formulating precursor compositions which comprise a polyester or polylactone thermoplastic matrix having at least one mineral filler distributed therethrough, the mineral filler containing a titanium oxide and / or zinc sulfide and also comprising from 2% to 40% by weight of the composition, and thence converting the composition into such packaging / storage shaped article, notably by injection-blow molding.

Owner:TERGAL FIBERS

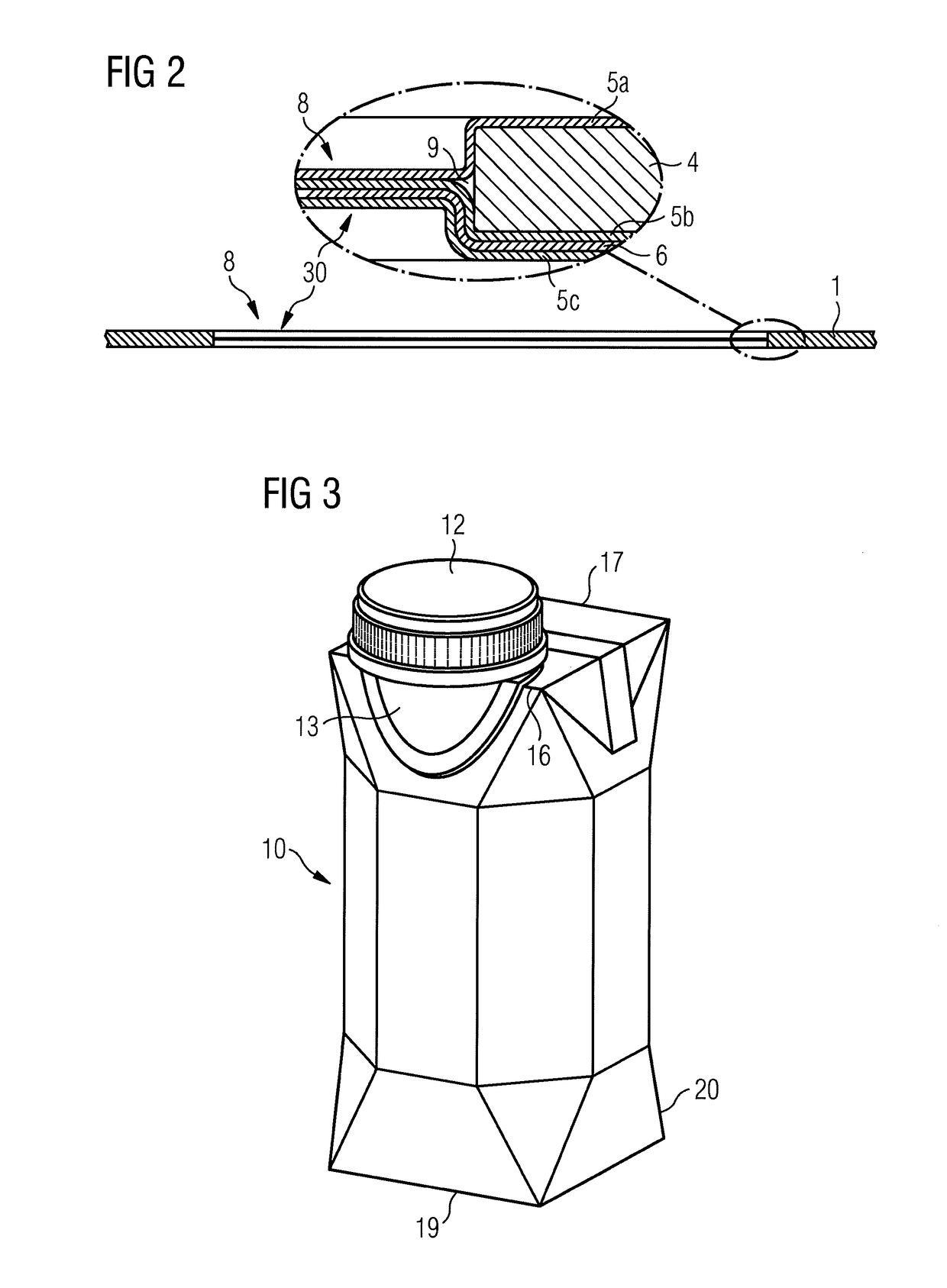

Sheet packaging material for producing sealed packages of pourable food products

InactiveUS20120138634A1Improve lamination qualityIncrease speedStampsFlexible coversBiomedical engineeringFood products

A sheet packaging material for producing a sealed package of a pourable food product comprises one base layer, a number of lamination layers covering both sides of the base layer, and a removable portion which, in use, can be detached partly from the rest of the packaging material along at least one arc-shaped cutting line and folded at a folding zone extending between opposite ends of the cutting line to free a pour opening; the removable portion comprises a central area made of whole packaging material and which, in use, remains attached to the rest of the packaging material through a permanent bridge defined by the folding zone, and a peripheral area for cutting interaction, extending around part of the central area, containing the cutting line and including at least one pre-laminated opening formed by a through slot at least in the base layer and covered by one or more of the lamination layers.

Owner:TETRA LAVAL HLDG & FINANCE SA

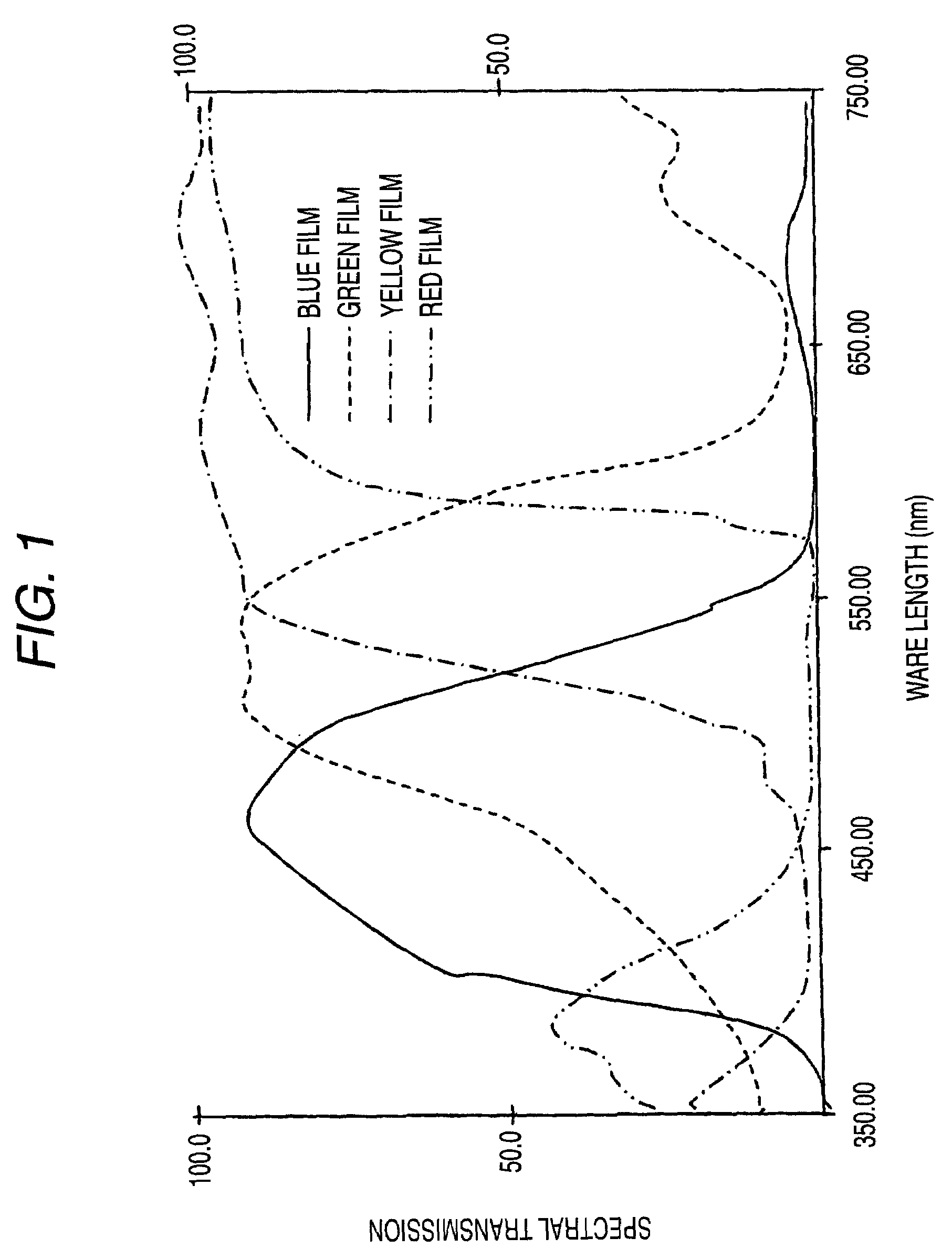

Milk-type food and drink packed in transparent container and process for producing the same

An object of the present invention is to provide a milk-type food and drink including cow's milk packed in a transparent container such as a PET bottle, which does not generate off-flavor due to photoinduction even when the milk-type food and drink is a store-displaying commercial product which is apt to come under the influence of sunlight and fluorescent light. The invention relates to a milk-type food and drink packed in a transparent container which substantially shields light in the wavelength region of 550 to 720 nm, and a process for producing a milk-type food and drink, which comprises packing a milk-type food and drink in a transparent container which substantially shields light in the wavelength region of 550 to 720 nm.

Owner:MEIJI CO LTD

Multilayer coextruded liquid packaging film capable of reducing leakage rate

InactiveCN102020056AAdjust the crystallization rateGood compatibilityFlexible coversWrappersEngineeringPolypropylene

A liquid packaging film mainly used in the current market is a polyethylene (PE) thin film, and the total thickness of the various structural films of the liquid packaging film is 85 to 120 microns, wherein the PE has lower physical strength and mechanical strength because of a molecular structure; and the leakage rate is about 0.05 to 0.1 percent during filling, selling and transportation of various liquid food enterprises. After intensive research, an inventor discovers that the multilayer film which at least comprises a heat-sealing layer consisting of PE and a heat sealing reinforcing agent and reinforcing layers (a middle layer and an outer layer) made of the PE can unexpectedly reduce the total thickness of the film and has the leakage rate of less than 0.005 percent in the entire process of packaging, selling and transportation of liquid foods, wherein the heat-sealing layer is preferably made of mixture of polypropylene (PP), high-density polyethylene (PE) and a compatilizer.

Owner:刘建林

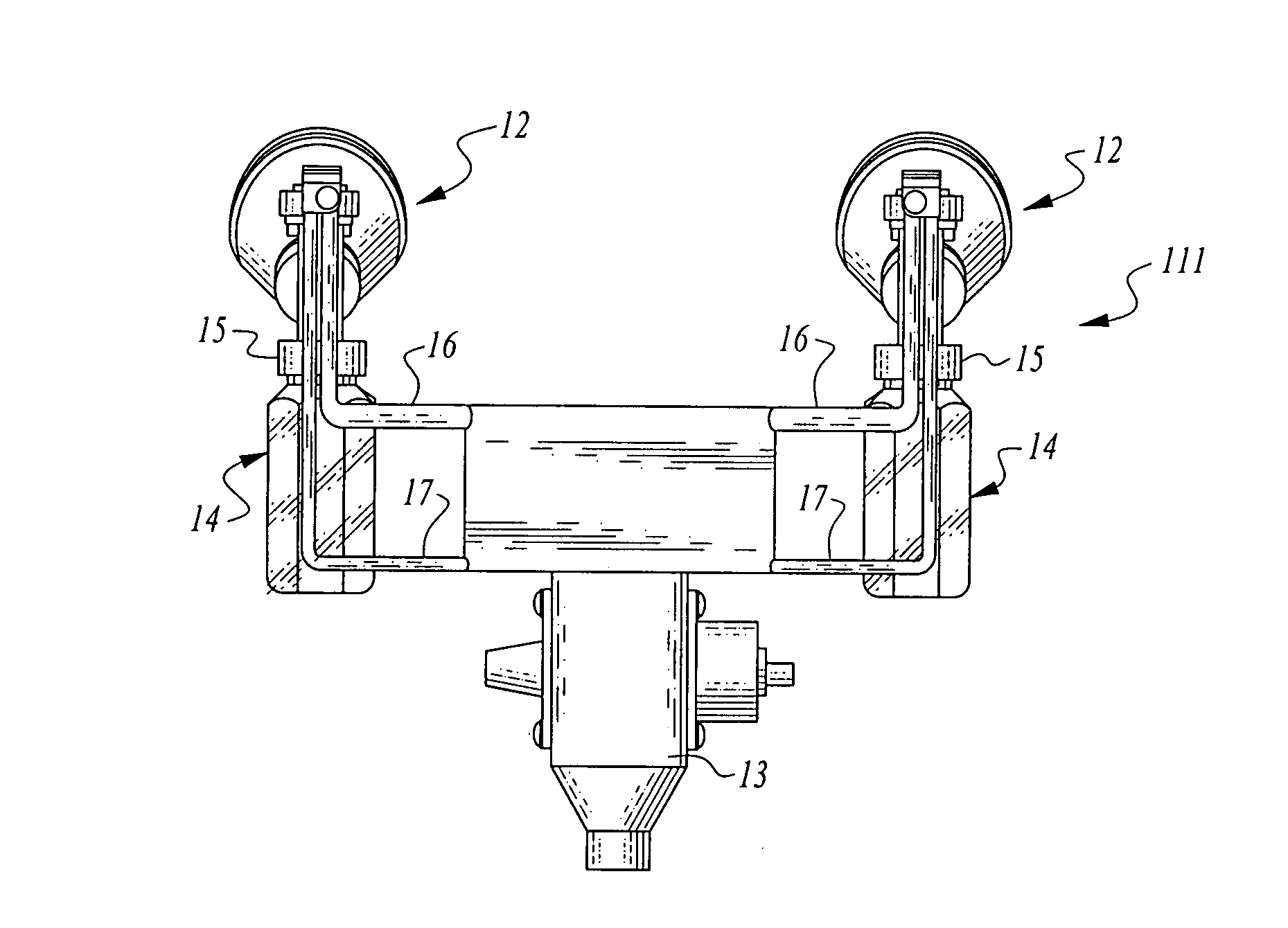

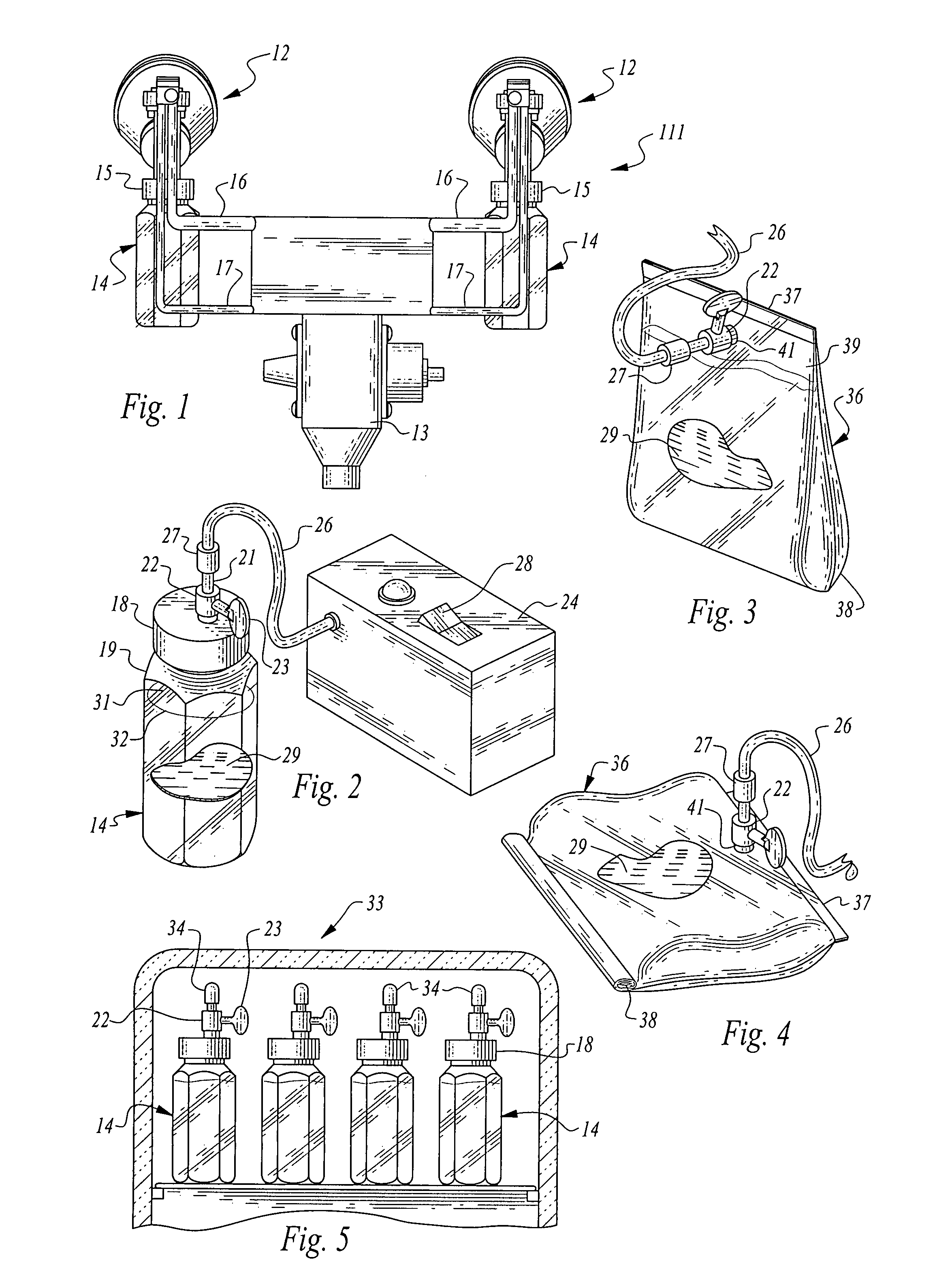

Methods to store human breast milk

InactiveUS8671701B2Enhanced preservation of natural flavor and nutritional attributeMilk preparationMilk preservationIsolation valveFood flavor

Owner:L JASON CLUTE

New environmentally friendly food products and methods to produce them

InactiveUS20120021096A1Lessening environmental footprintReduce the environmentConfectionerySweetmeatsWater useCarbon footprint

The invention relates to reducing or minimising the environmental footprint comprising a water footprint and a carbon footprint of a food product.

Owner:RAISIO NUTRITION LTD

Inside creasing

InactiveCN101827754AEasy to foldUltimately folds easilyFlexible coversMechanical working/deformationCardboardBiomedical engineering

A packaging laminate for forming packaging containers has a core of paper or cardboard, and a first side forming the outside of a packaging container and a second side forming the inside of the packaging container. The packaging laminate is provided with crease lines defining folding locations usable during forming of the packaging containers, and each crease line defines a linear protrusion on one side of the laminate and a corresponding linear depression on the opposite side of the laminate. The packaging laminate is characterized in that at least one crease line, which forms a corner edge of the packaging container, has its linear protrusion on the first side of the packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Container-packed milk coffee beverage

Disclosed is a container-packed milk coffee beverage which has an excellent hypertension ameliorating effect and can be ingested in an ordinary manner. A container-packed milk coffee which has a pH falling within the range from 5 to 7 and satisfies the following requirements (A) to (C): (A) a chlorogenic acid: 0.01 to 1% by mass; (B) hydroxyhydroquinone: 0.08% by mass or less relative to the mass of the chlorogenic acid; and (C) the chlorogenic acid / a coffee solid content ≧0.03 (by mass).

Owner:KAO CORP

Modifying Flavor Experience Via Aroma Delivery

InactiveUS20100055245A1High sweetnessReduce the amount requiredReady-for-oven doughsFruit and vegetables preservationFruit juiceFood flavor

A method for modifying flavor experience via aroma delivery including applying at least one aroma on a comestible's packaging, the aroma causing the consumer to perceive a modified flavor of the comestible upon ingestion of the comestible. The comestible may be a beverage, such as a carbonated soft drink, fruit juice, water or grain-based beverage.

Owner:PEPSICO INC

Process for Preparation of Packaged Heat-Preserved Aqueous Drink Comprising Casein Micelles and Tryptophan-Rich Peptides, and Products so obtained

InactiveUS20090269443A1High blood plasma tryptophan/LNAA ratioHigh tryptophan/LNAA ratioMilk preparationMilk preservationCasein micellesTryptophan

A process to prepare packaged pasteurized or sterilized aqueous drinkable products which comprise casein micelles (e.g. from dairy protein) and peptide-fractions, which peptide fractions are rich in tryptophan, and the products so-obtained. The process requires a heat preservation at a specific pH.

Owner:CONOPCO INC D B A UNILEVER

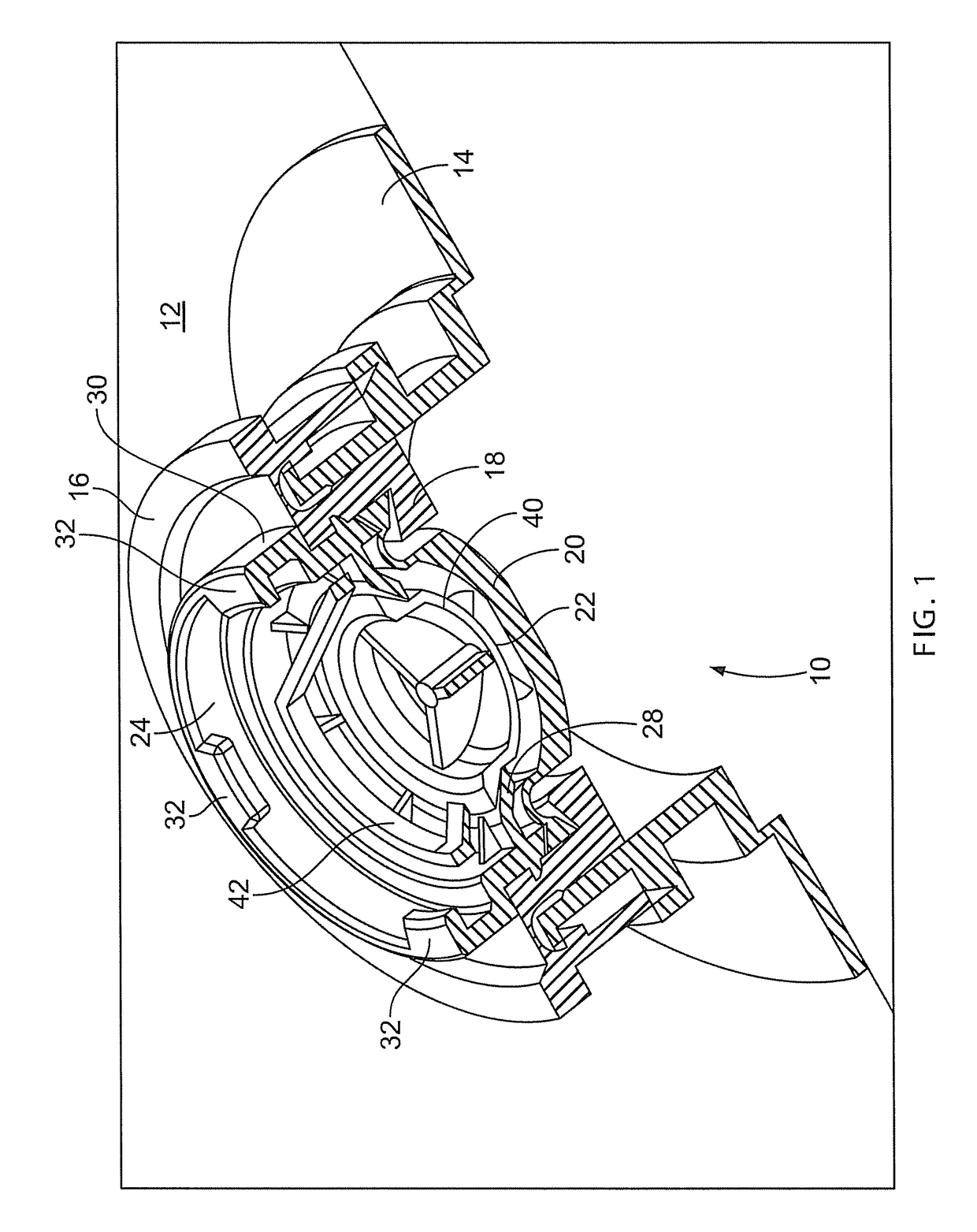

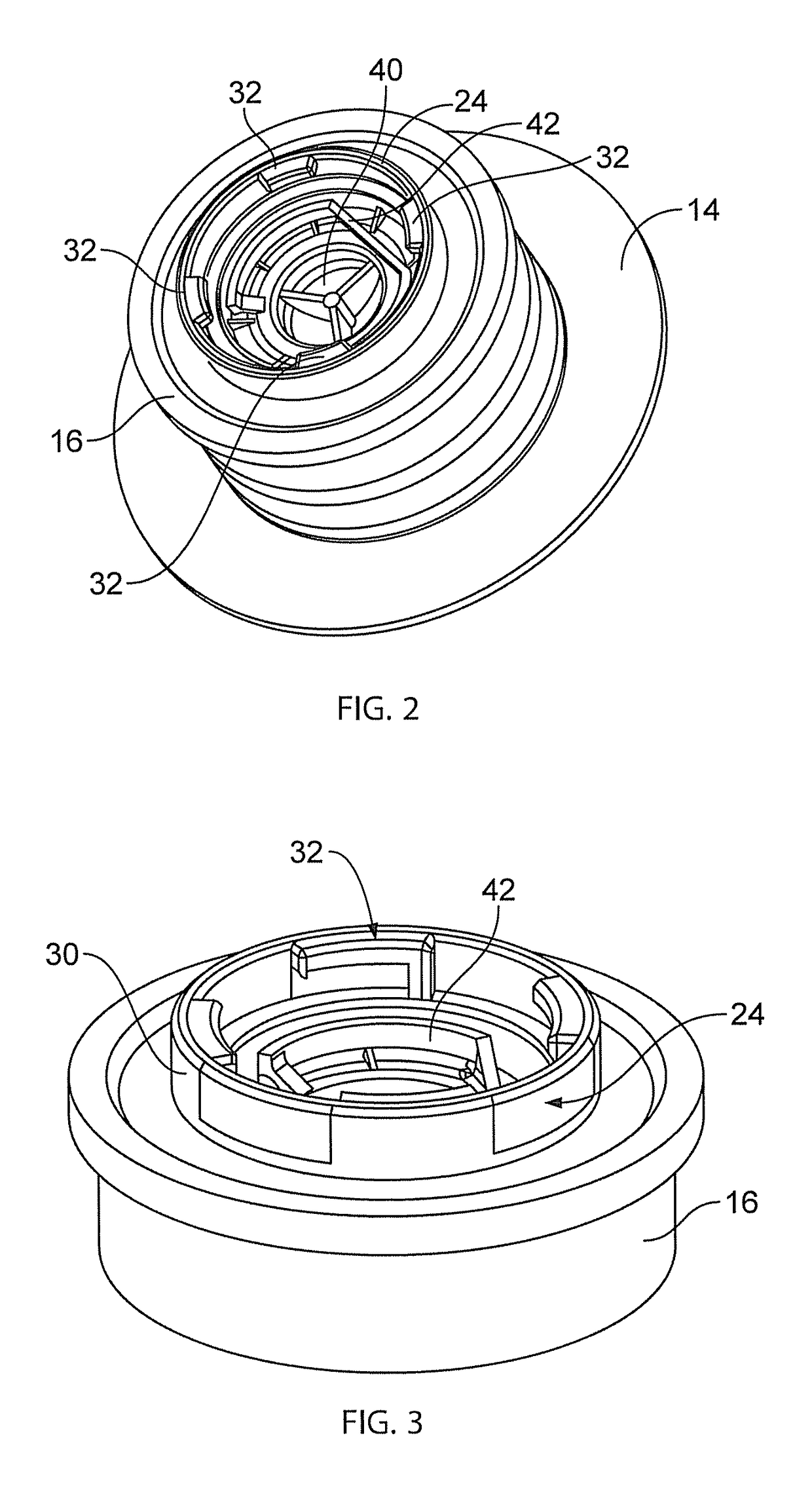

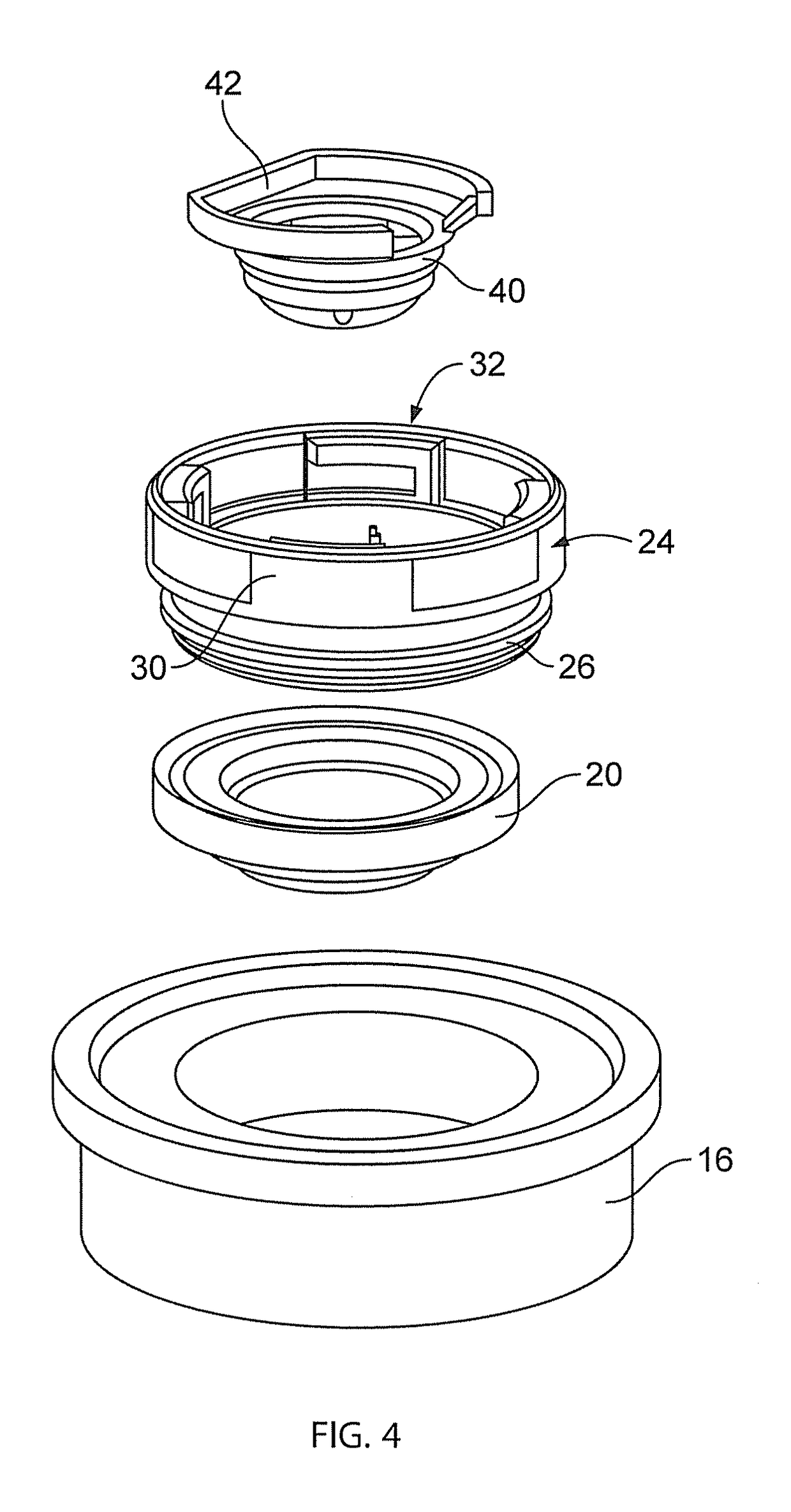

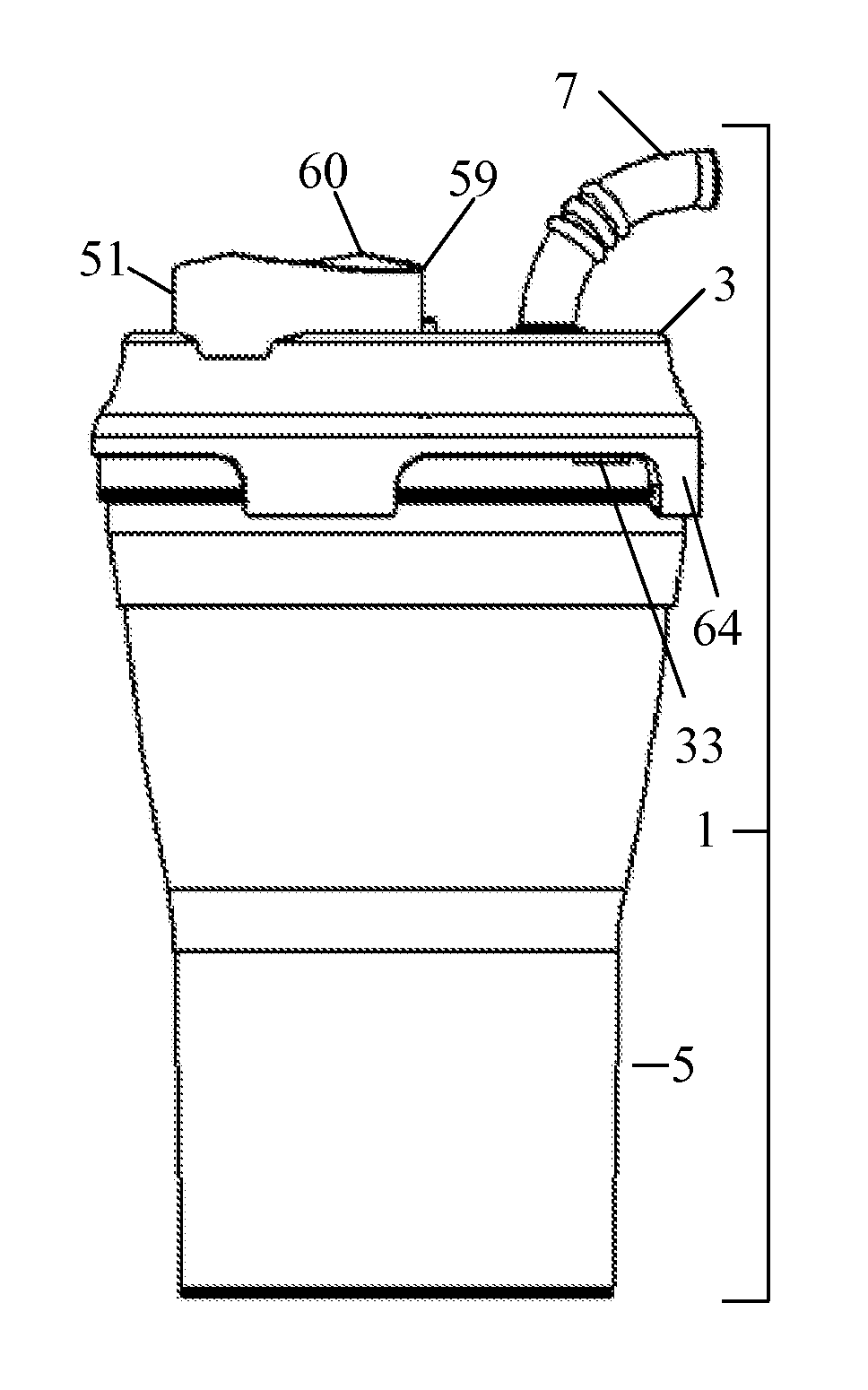

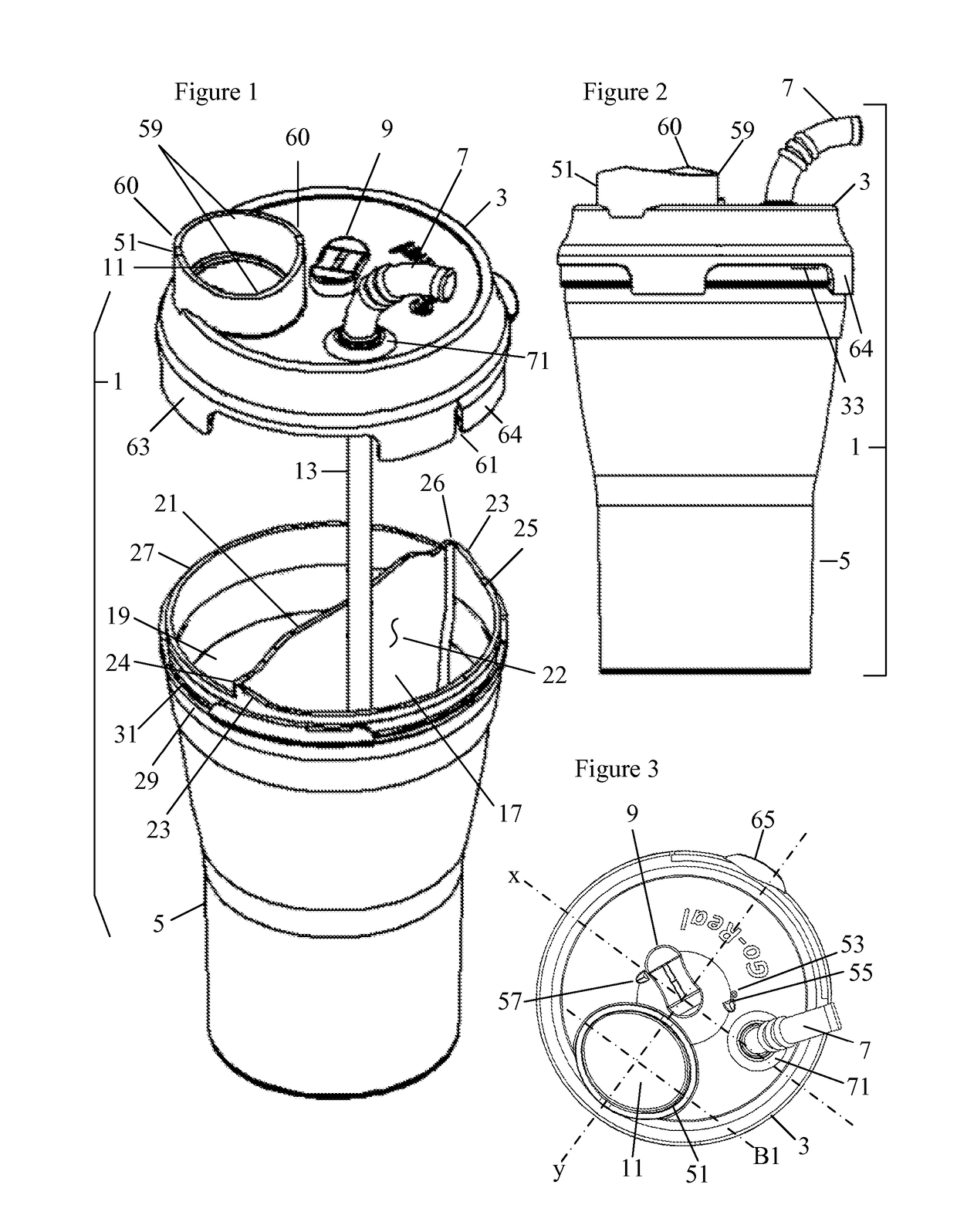

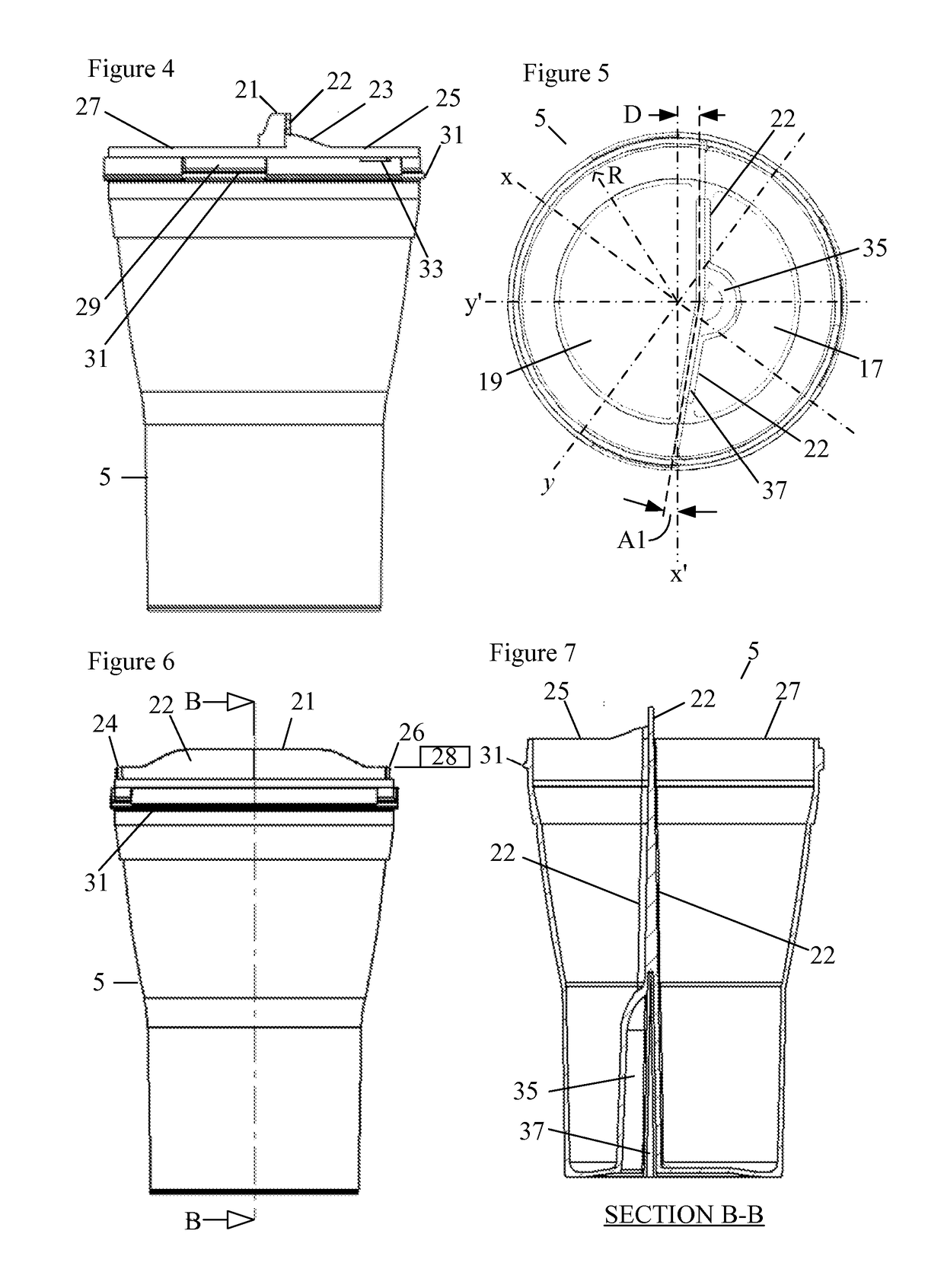

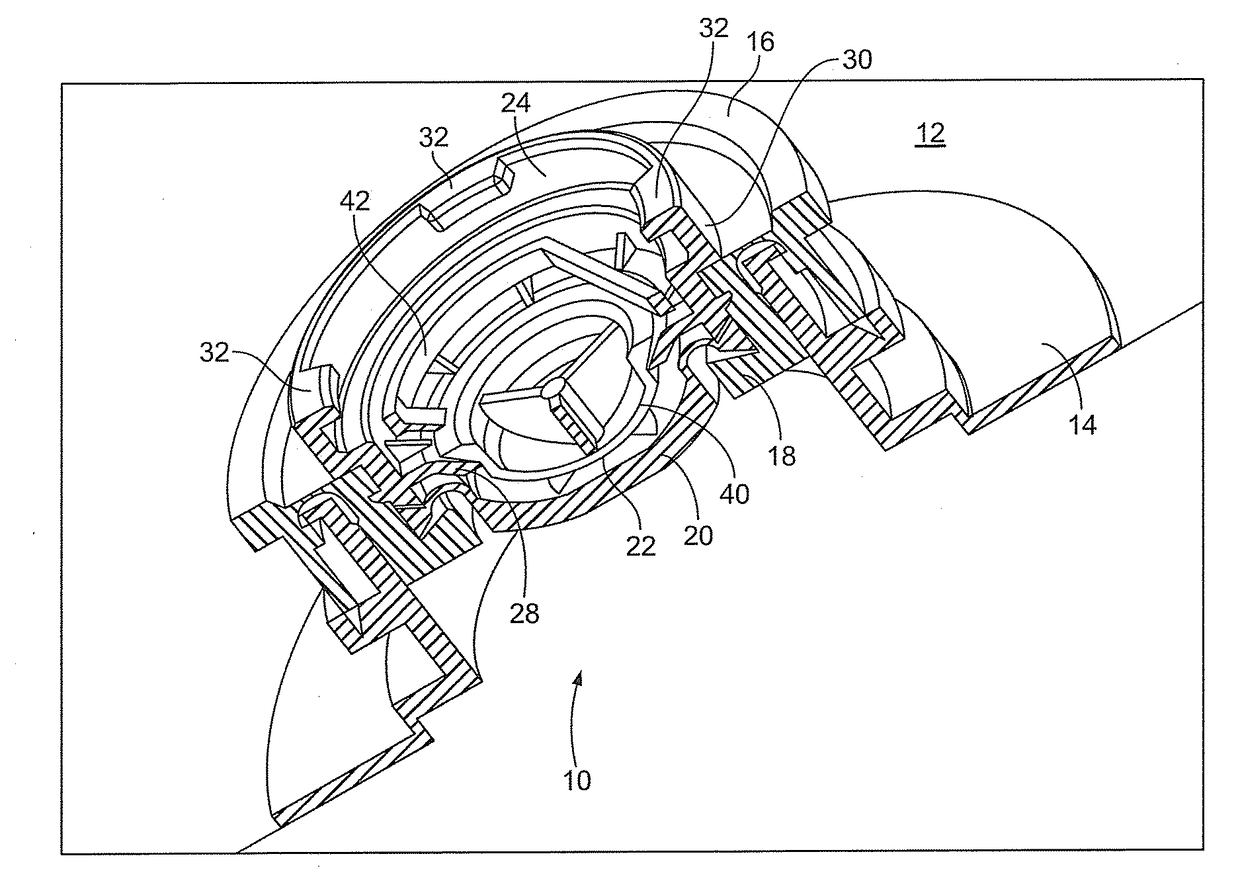

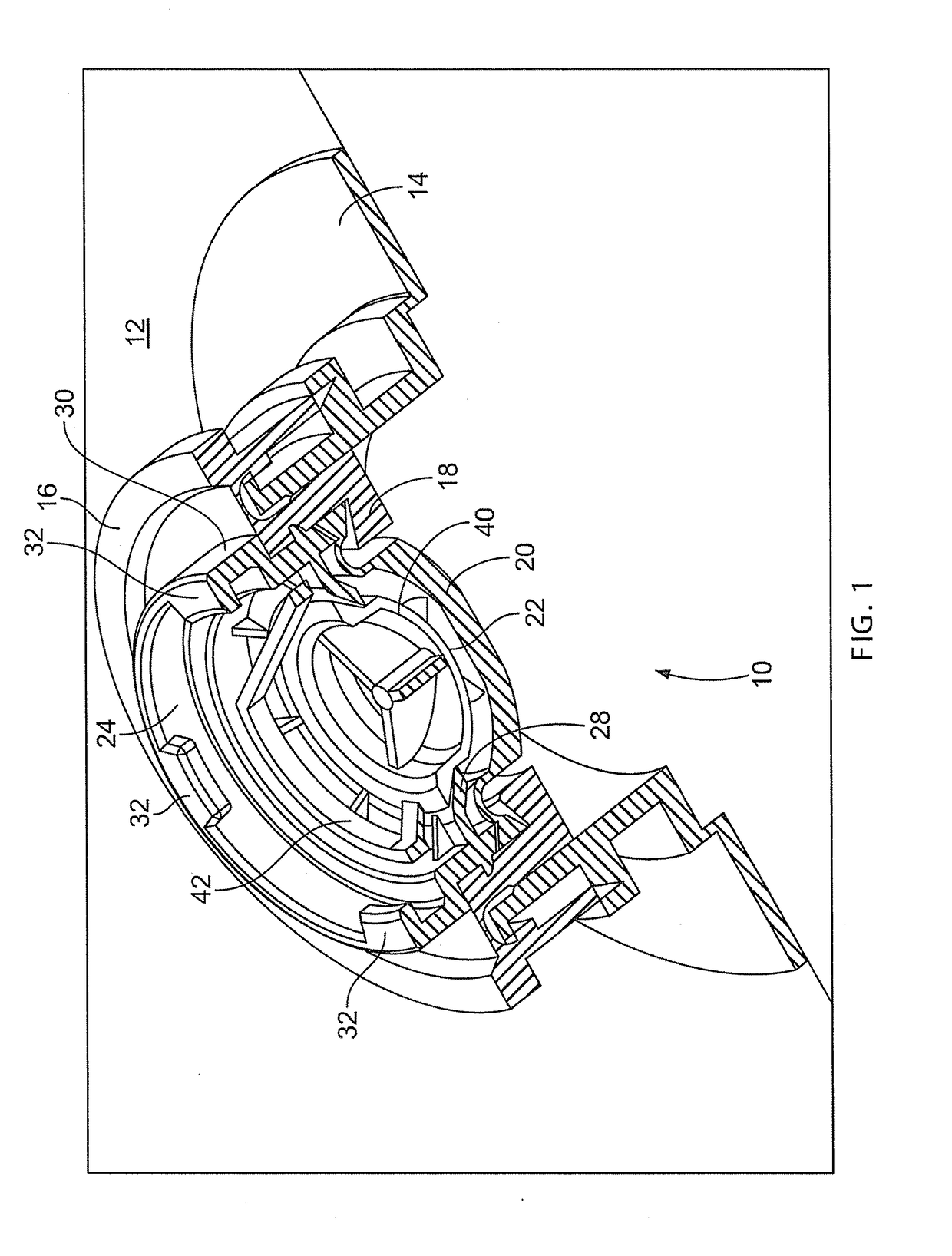

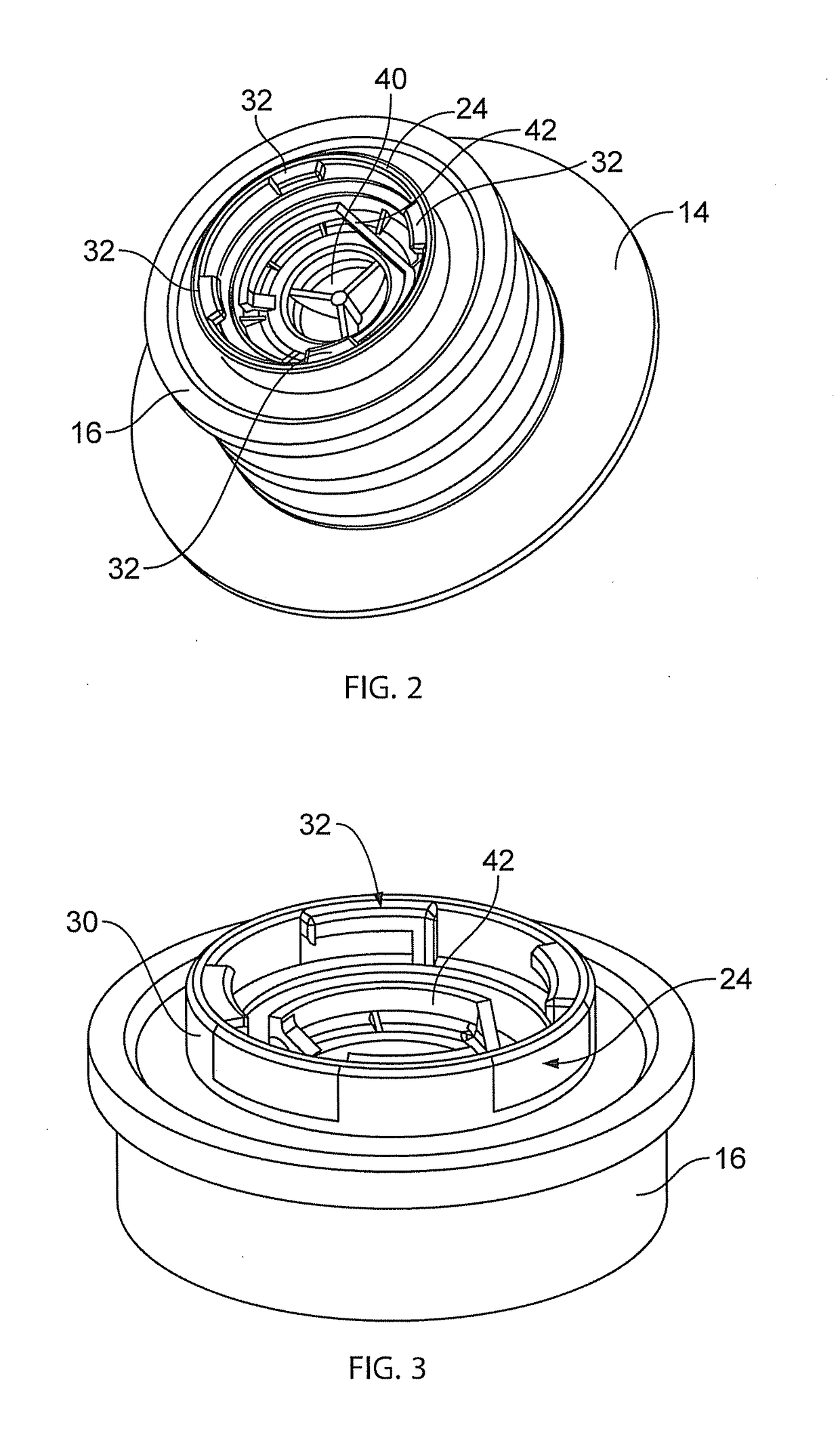

Dispensing assembly

A dispensing assembly for a liquid container including a ring part configured to be mounted to a liquid container, a resilient member positioned in the ring part to be in contact with the liquid contents of the liquid container, a ring member mountable to the ring part to secure the resilient member to the ring part, and a hollow connecting member with an outlet. The connecting member is releasably securable to the ring member and includes a hollow projecting member which, when the connecting member is secured to the ring member, engages the resilient member so as to urge an opening in the resilient member to permit liquid in the container to pass into the connecting member and subsequently out through the outlet.

Owner:RAPAK INC

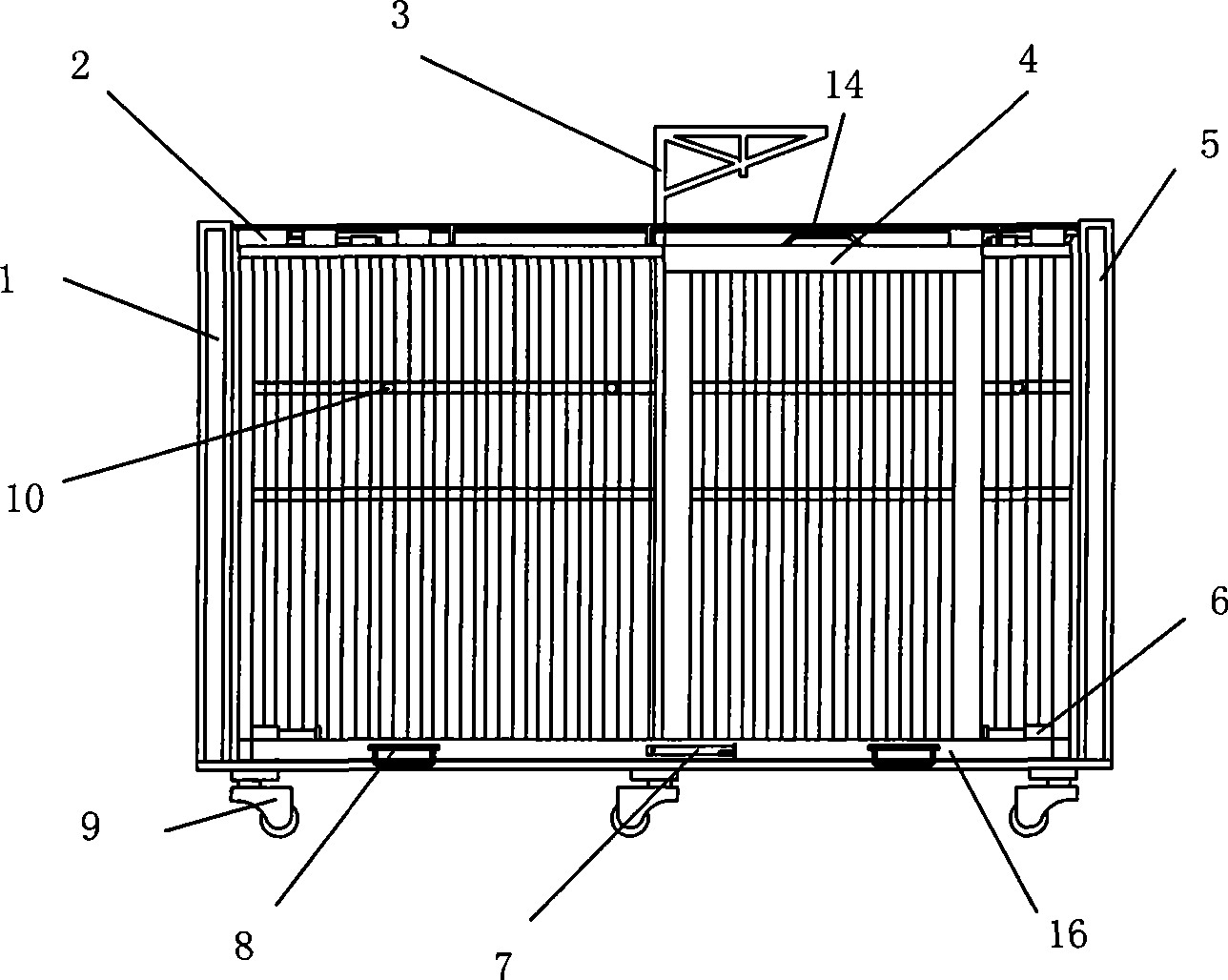

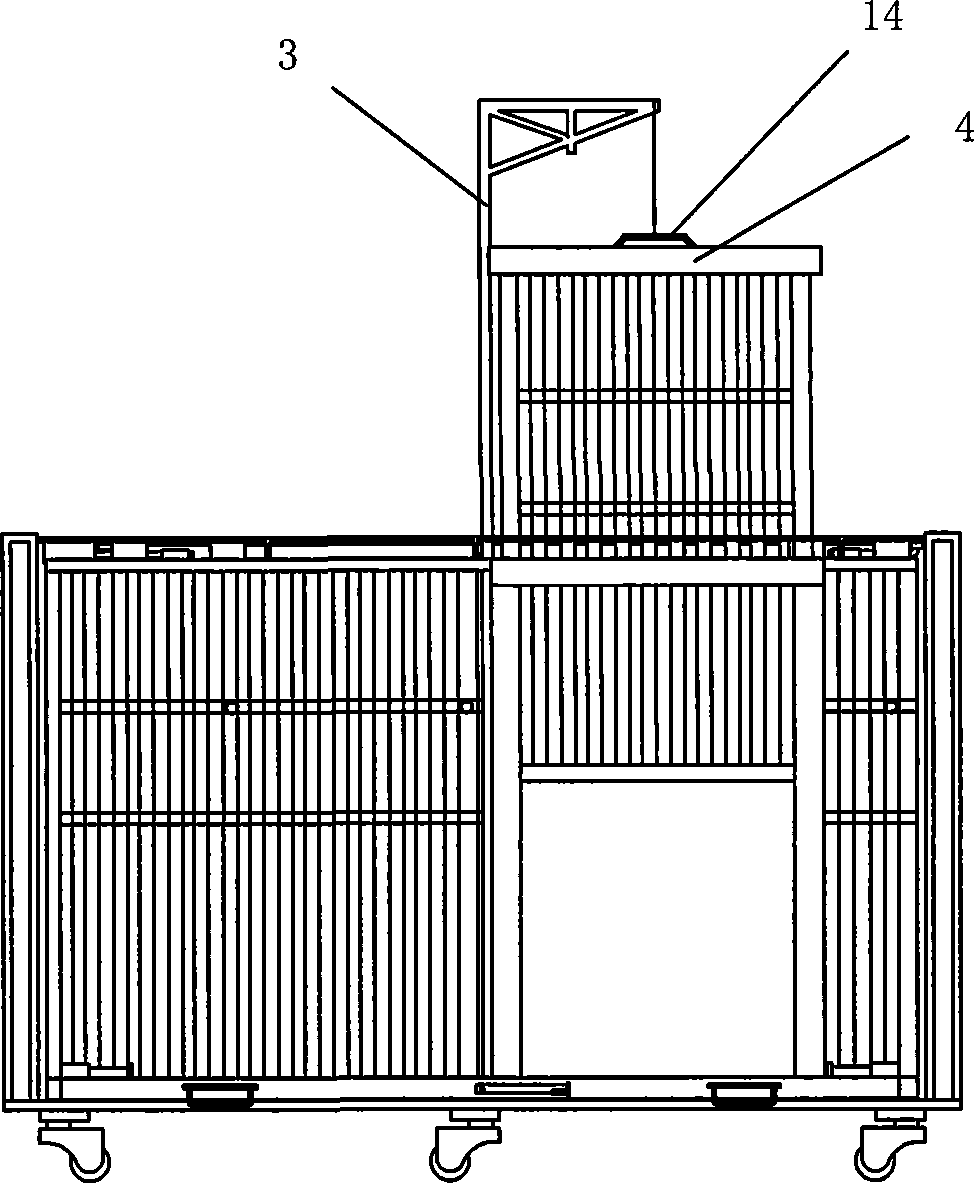

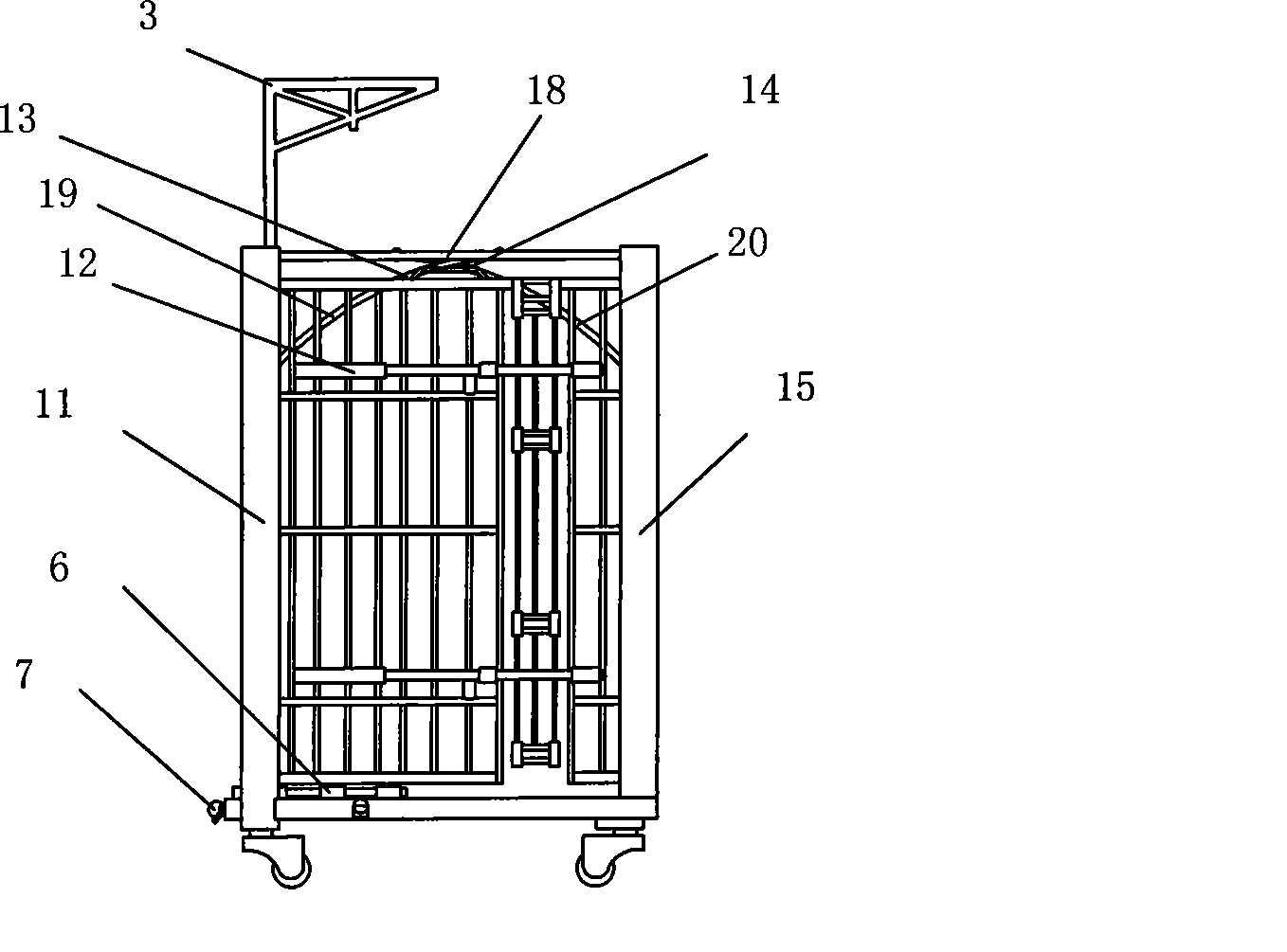

Folding type across cage device for beasts

InactiveCN101438680AHeight adjustableWith folding shrinkagePackaging milkAnimal housingEngineeringIndividual animal

The invention discloses a foldable transit cage for mammals. A base plate of the cage consists of two hinged base plates; a right cage slab is fixedly arranged at the right side of the base plate of the cage, and a left cage slab is inserted into the left side of the base plate of the cage; the base plate of the cage and the bottom of the left cage slab are provided with roller wheels; a cage roof capable of moving up and down is arranged between the left cage slab and the right cage slab; the cage roof is composed of left movable edge grid plates and right movable edge grid plates which are alternatively and movably connected; two ends between the left cage slab and the right cage slab are provided with a front cage door and a back cage door which can be movably opened; the left cage slab or the right cage slab is provided with a side cage door capable of being opened movably; and the front cage door and the back cage door consist of two hinged cage door planks. The invention discloses the foldable transit cage for mammals which has the advantages of foldable and shrinkable structure, adjustable width of the cage body and adjustable height inside the cage, guiding the mammals into the cages with high security, simple structure, convenient manufacturing and reliable performance.

Owner:长沙动物园

High-strength water-resistance soy protein isolate packing film, and its preparing method and use

This invention discloses a kind of soy protein isolate packaging film with water resistance and high-strength and its preparation method. By dissolving the soy protein isolate bought from the market, glycerine, stearic acid, filmogen and elasticizer into water which contain the following constituents by weight: water in 100 portions, soy protein isolate in 20-40 portions and polyvinyl alcohol in 8-12 portions, and then the film materials are formed by coating method. The said film has advantages of high strength, water resistance, simple preparation technique, low price, no pollution to environment and so on. It can be used in package of meat product, dried food, sour milk, medicinal powder and food ingredients, as well as preservative package for vegetables and fruits.

Owner:TIANJIN UNIV OF COMMERCE

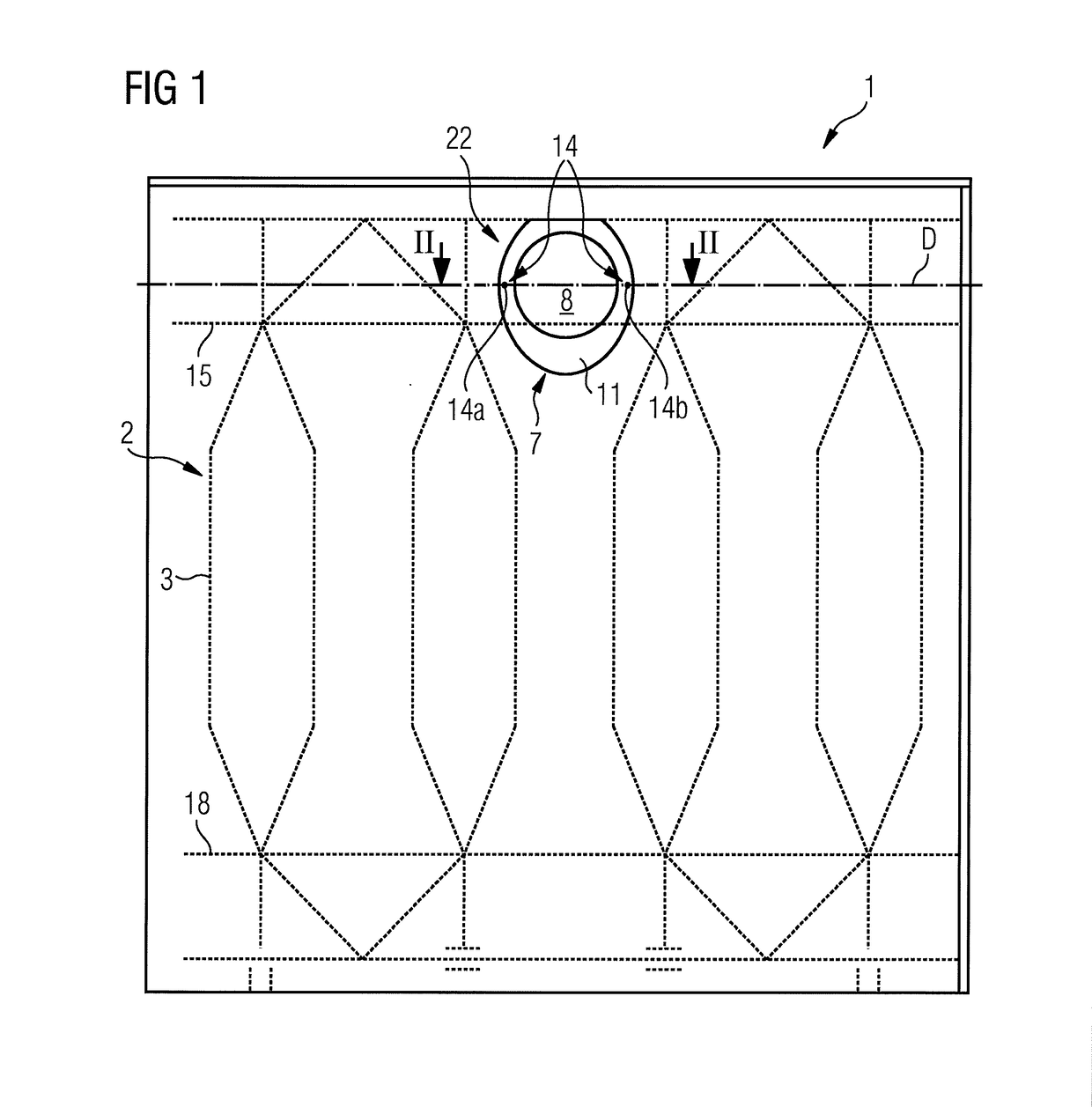

Sheet packaging material for producing sealed packages of pourable food products

InactiveUS9487324B2Improve lamination qualityIncrease speedPackaging milkThin material handlingEngineeringBiomedical engineering

A sheet packaging material for producing a sealed package of a pourable food product comprises one base layer, a number of lamination layers covering both sides of the base layer, and a removable portion which, in use, can be detached partly from the rest of the packaging material along at least one arc-shaped cutting line and folded at a folding zone extending between opposite ends of the cutting line to free a pour opening; the removable portion comprises a central area made of whole packaging material and which, in use, remains attached to the rest of the packaging material through a permanent bridge defined by the folding zone, and a peripheral area for cutting interaction, extending around part of the central area, containing the cutting line and including at least one pre-laminated opening formed by a through slot at least in the base layer and covered by one or more of the lamination layers.

Owner:TETRA LAVAL HLDG & FINANCE SA

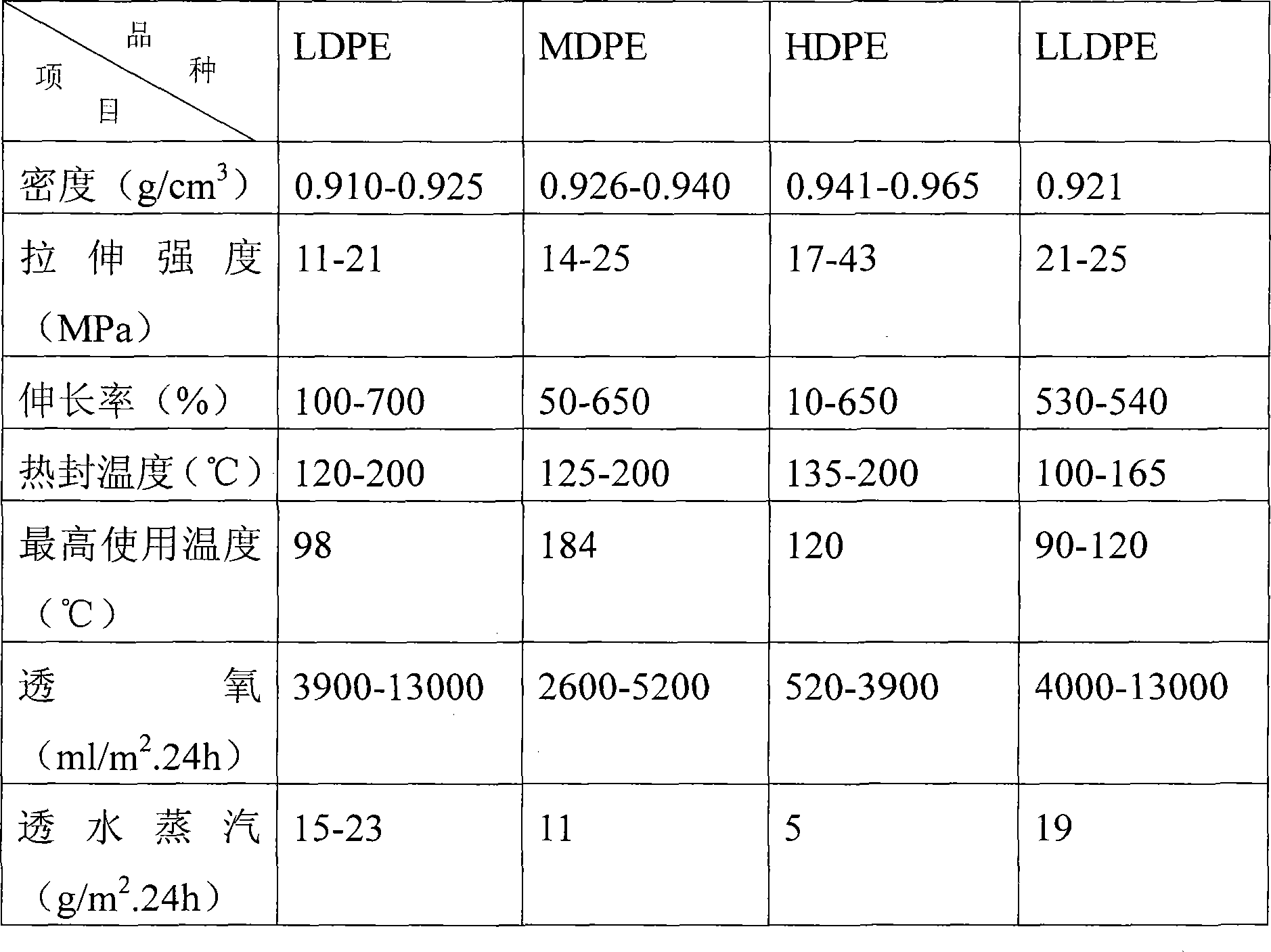

Polythene packaging film for soymilk

InactiveCN101100523AQuality improvementLight in massPackaging milkMasterbatchLinear low-density polyethylene

A packing film of polyvinyl soymilk is prepared by taking HDPE, LLDPE and color mother material as raw materials and extruding. It's cheap, light, convenient and non-toxic. It has uniform thickness, excellent heat-sealing performance and heat resistance and no environmental pollution. It can be used for automatic soft packed canned soymilk.

Owner:广西塑料研究所有限公司

Multi-compartment snack storage and dispensing appliance

ActiveUS20180312321A1Easy to fillMaximizes freshnessPackage recyclingPackaging milkEngineeringFood item

Owner:WONDKA ANTHONY DAVID

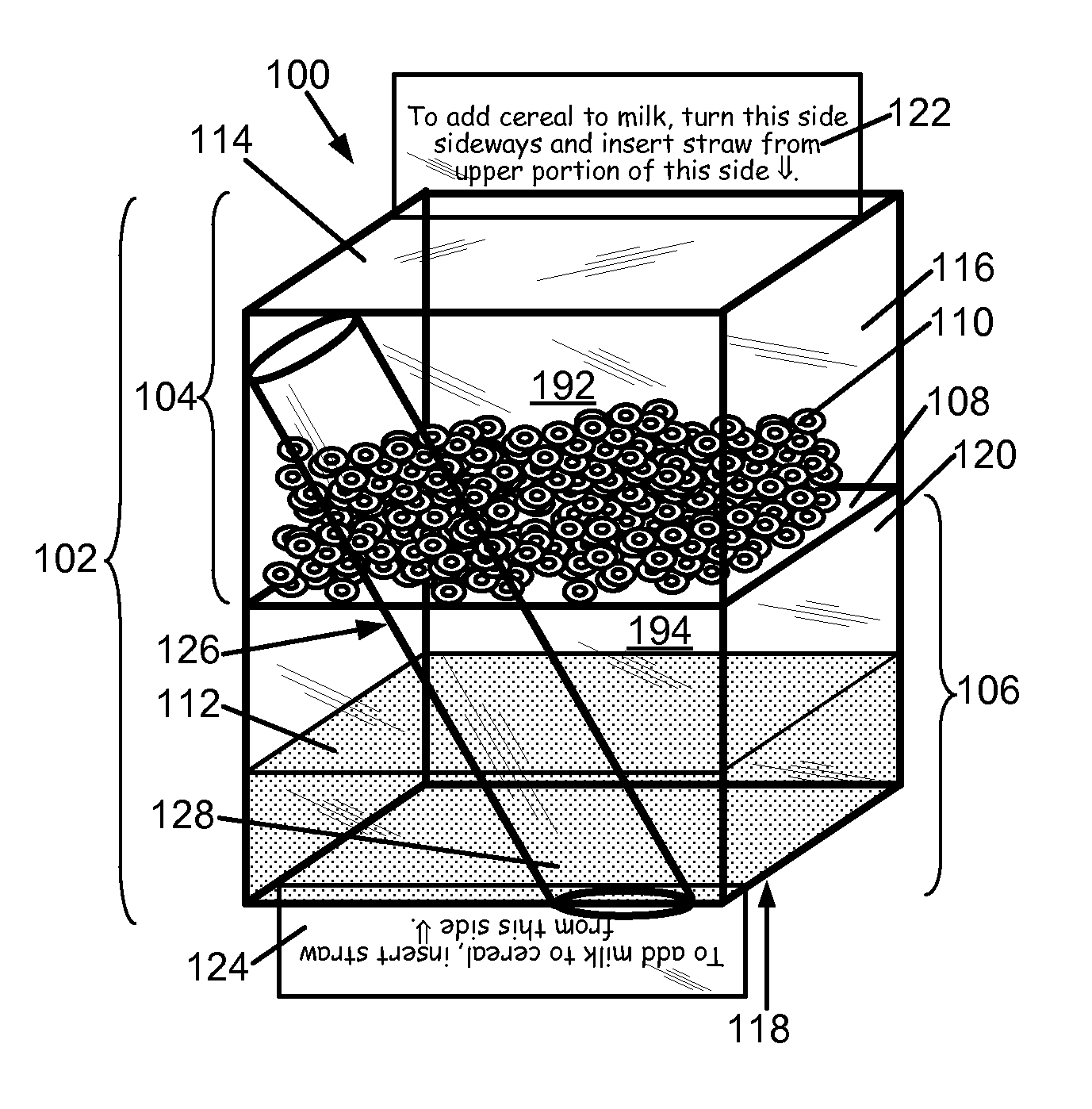

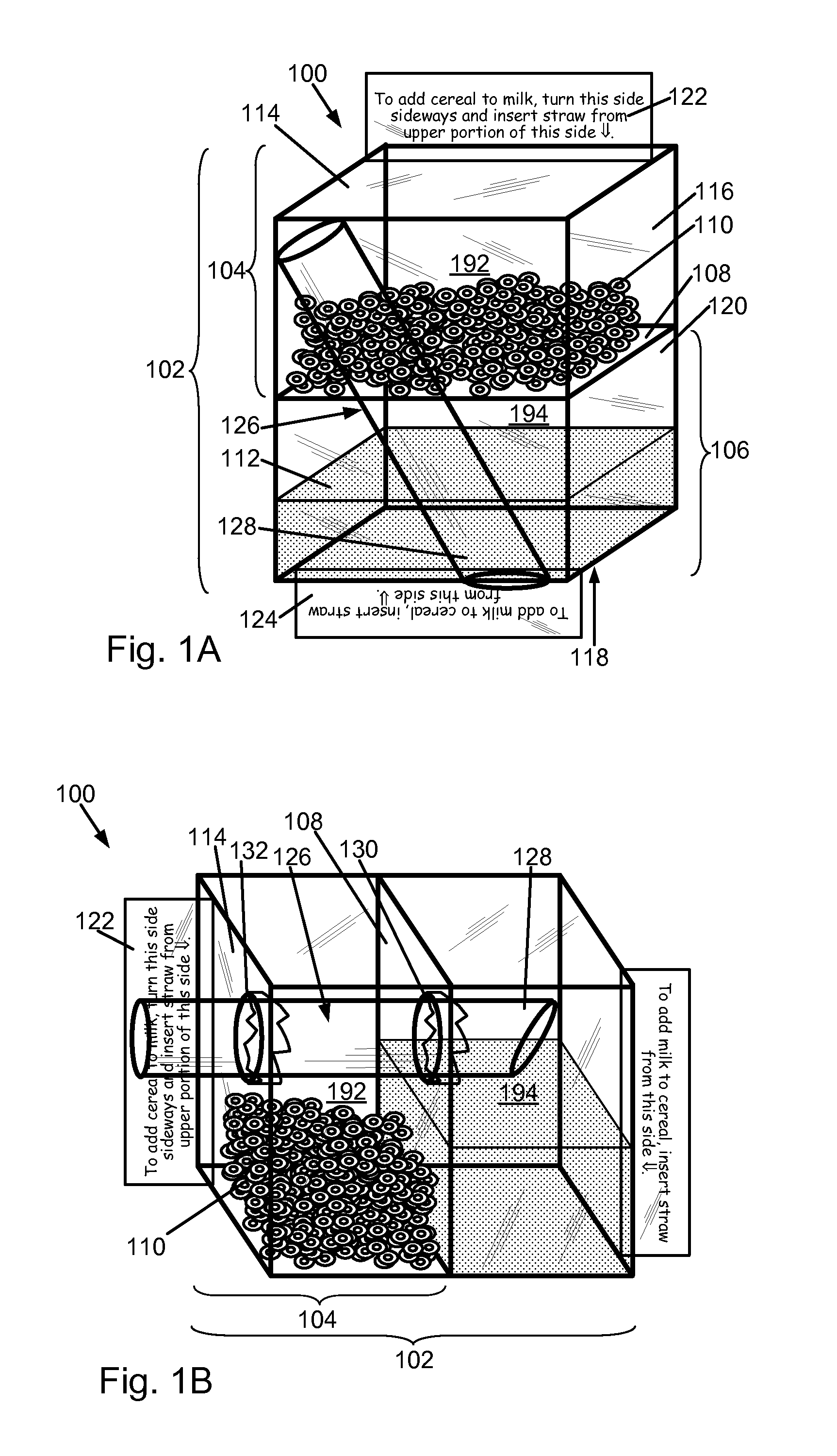

Systems and methods for facilitating intake of edible substances

A system for facilitating a user's intake of edible substances. The system may include a first portion, a second portion, and a partition unit disposed between the first portion and the second portion. A first space may be located between the first portion and the partition unit for containing a first edible substance. A second space may be located between the second portion and the partition unit for containing a second edible substance. The system may also include a tube for causing a change at the partition unit to open an opening between the first space and the second space, and for transmitting a portion of an edible mixture to the mouth of the user. The edible mixture may include part of the first edible substance provided from the first space and part of the second edible substance provided from the second space.

Owner:TSENG YI MING

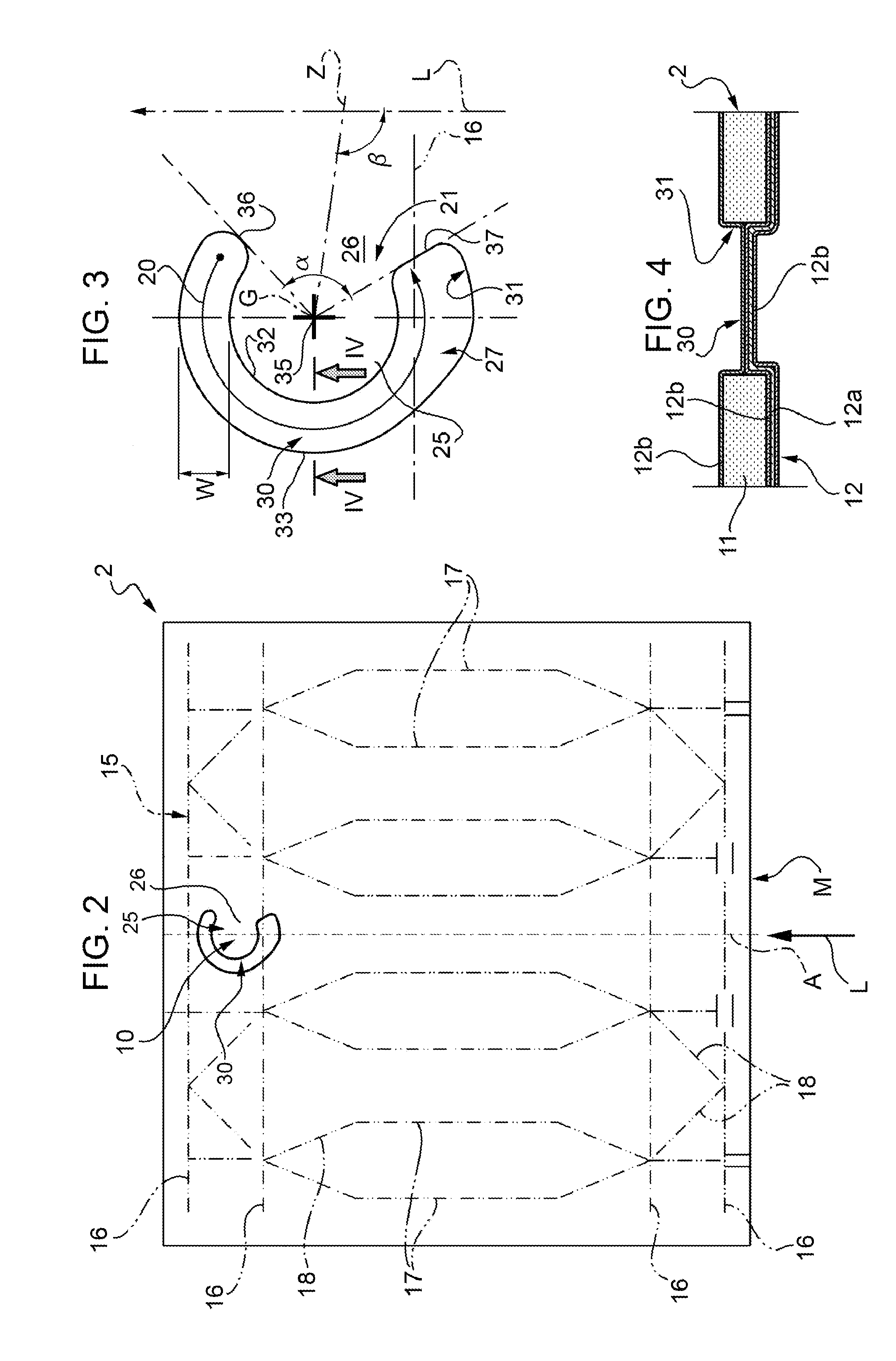

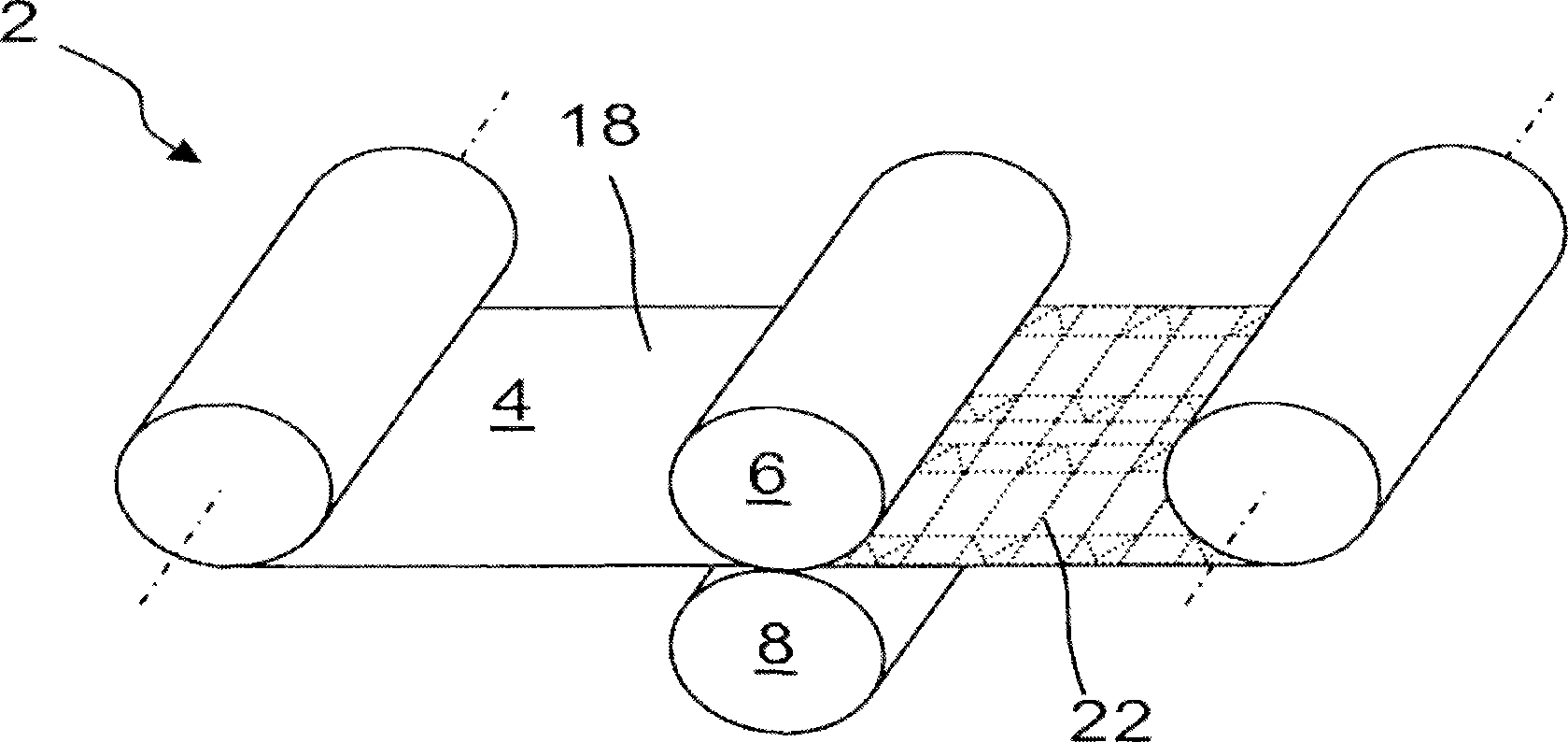

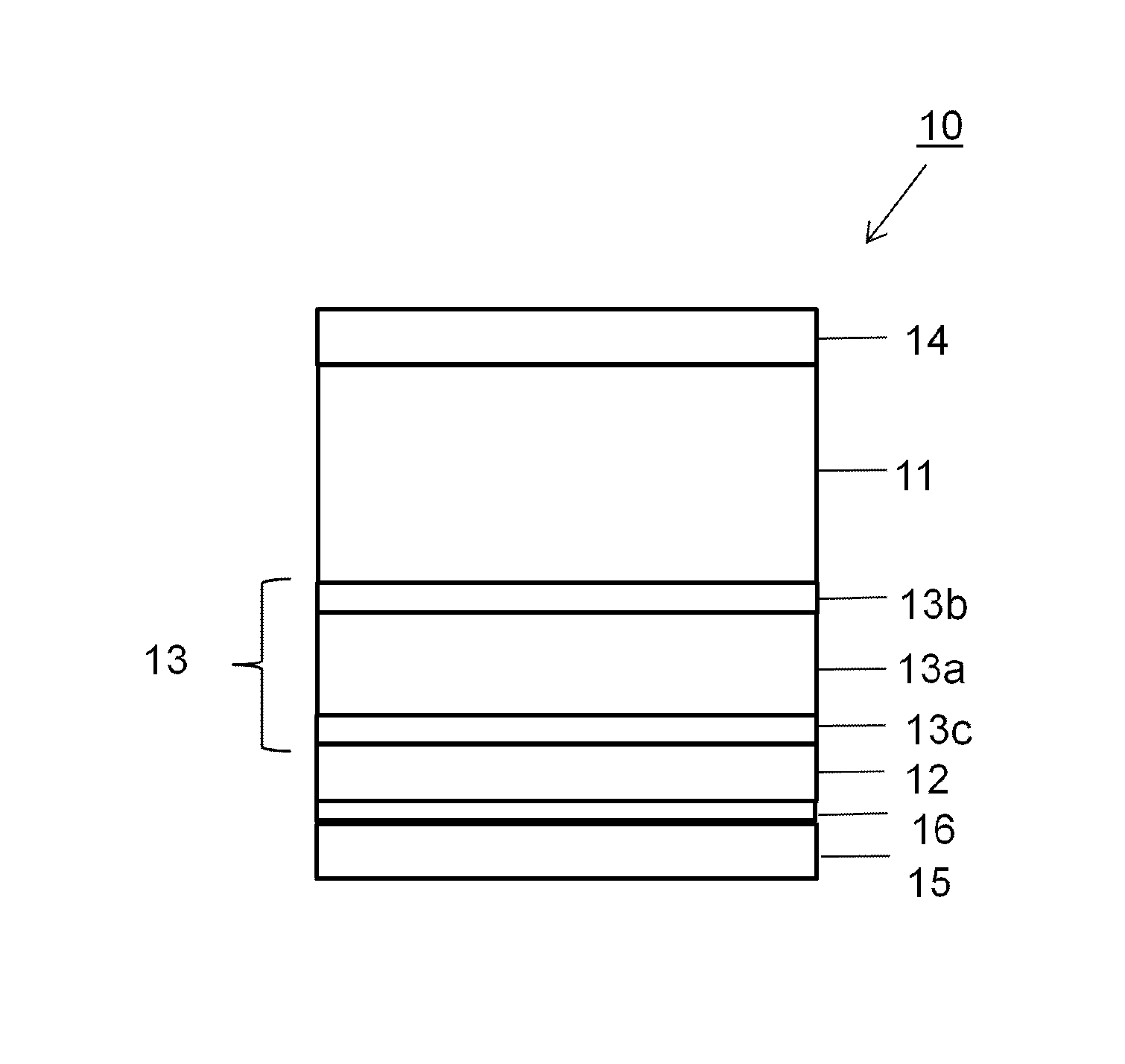

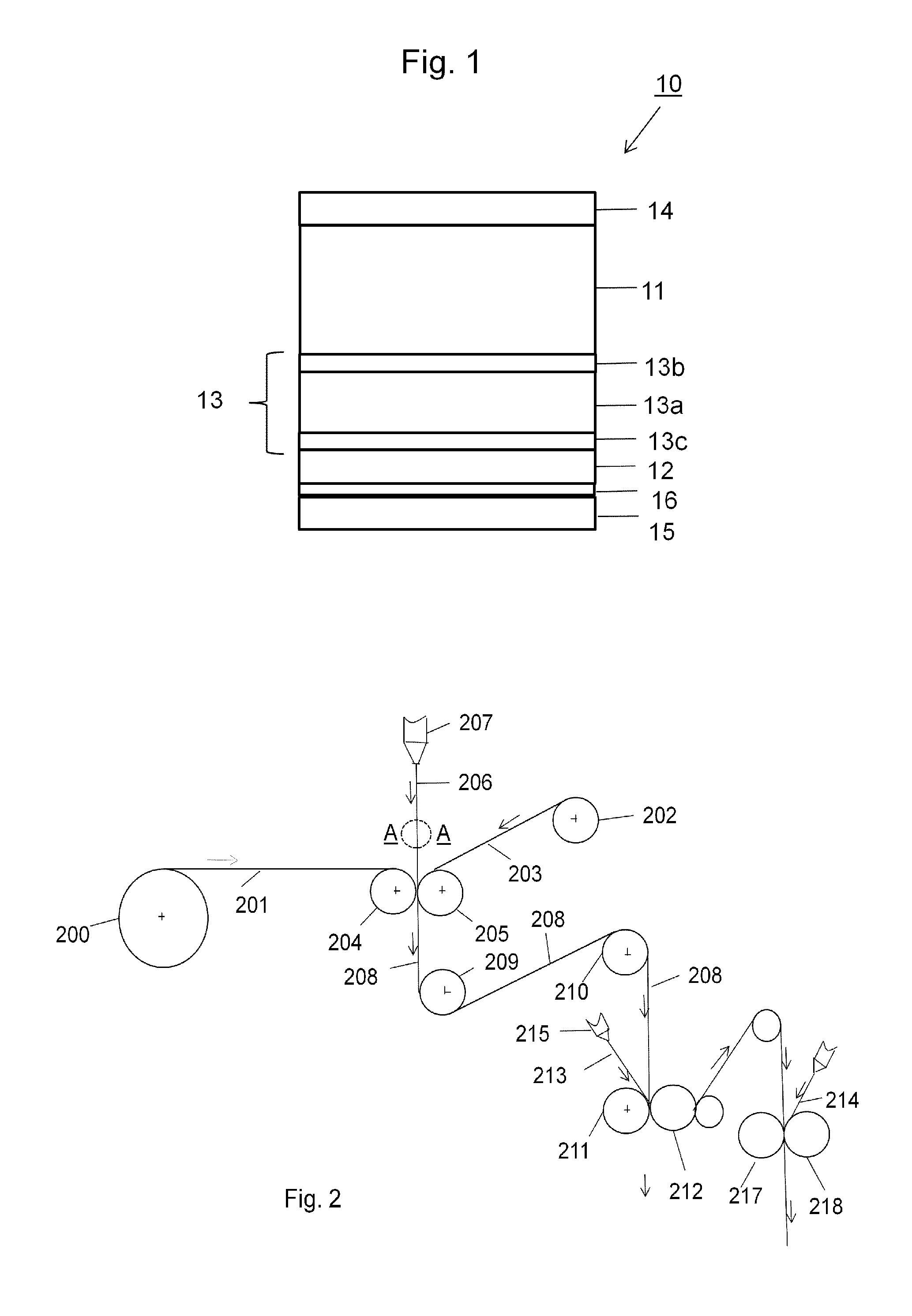

Packaging laminate, method for producing same, and packaging container produced from the packaging laminate

InactiveUS20150375484A1Without unnecessarily excessive consumption of energyImprove barrier propertiesPackaging milkSynthetic resin layered productsAdhesivePaperboard

Packaging laminate for a packaging container for oxygen-sensitive liquid food, such as milk, juice, wine and cooking oil. The packaging laminate has a layer of paper or paperboard, and a layer serving as gas barrier and composed of a material with barrier properties against gases, in particular oxygen. The layer serving as gas barrier is bonded to the paper or paperboard layer by a lamination layer, which has a central layer of polymer and outer layers of an adhesive on both sides of the polymer layer. The packaging laminate also has outer liquid-tight coatings on both sides of the paper or paperboard layer.

Owner:TETRA LAVAL HLDG & FINANCE SA

Thermostable polystyrene packing composition and preparing method

InactiveCN101746556AEvenly dispersedHigh elongation at breakFlexible coversWrappersPolystyrenePolypropylene

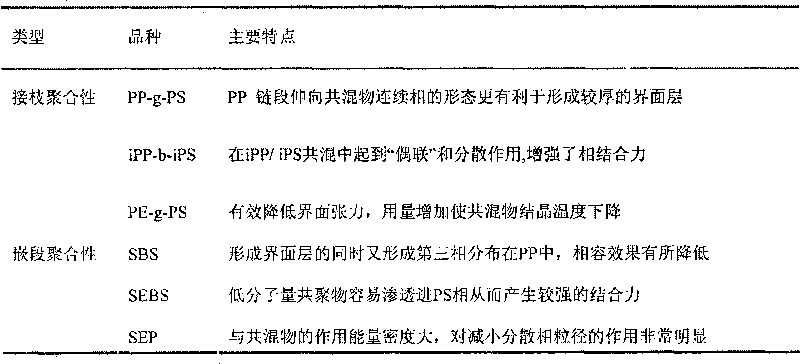

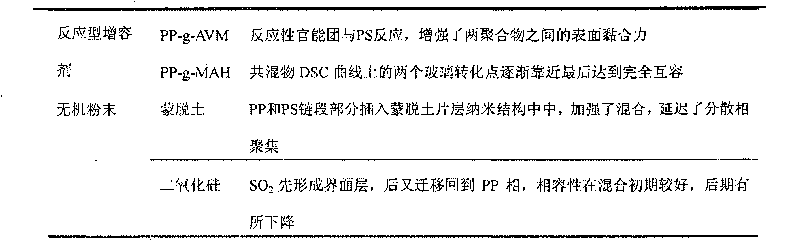

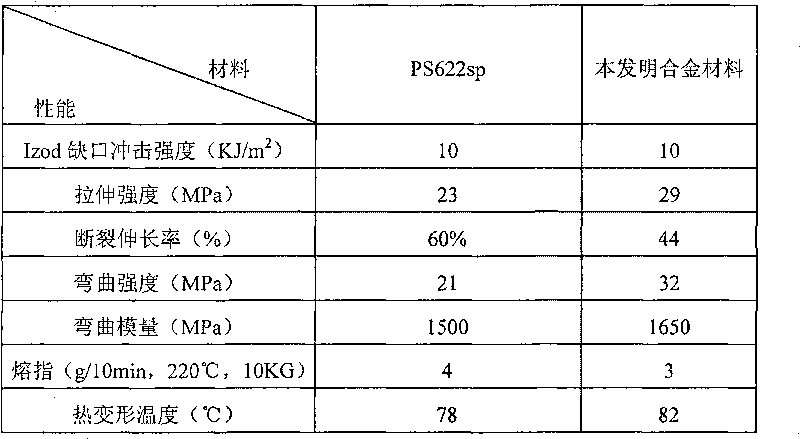

The present invention provides a novel material for producing yoghurt cups by extrusion molding, particularly a polystyrene (PS) / polypropylene (PP) alloy material having the advantages of good ductility, high strength, good stiffness, thermostability, large molding processing range and low cost on account of problems existing in the PS yoghurt packaging. The material consists of 40 to 70% by weight of PS, 15 to 85% by weight of PP, 8% by weight of inorganic mineral powder and 6 to 10% by weight of auxiliary. The raw materials are premixed, and extruded and pelletized by a double-screw extruder under common processing conditions, and a basic resin is produced. Then, a product mutually attached is made by taking the material as a middle layer and taking general purpose polystyrene (GPPS) layers as a top layer and a bottom layer by a three-layer co-extrusion molding processing technique, and the product is molded by co-extrusion without adhesive bonding.

Owner:SICHUAN KINGFA TECH DEV

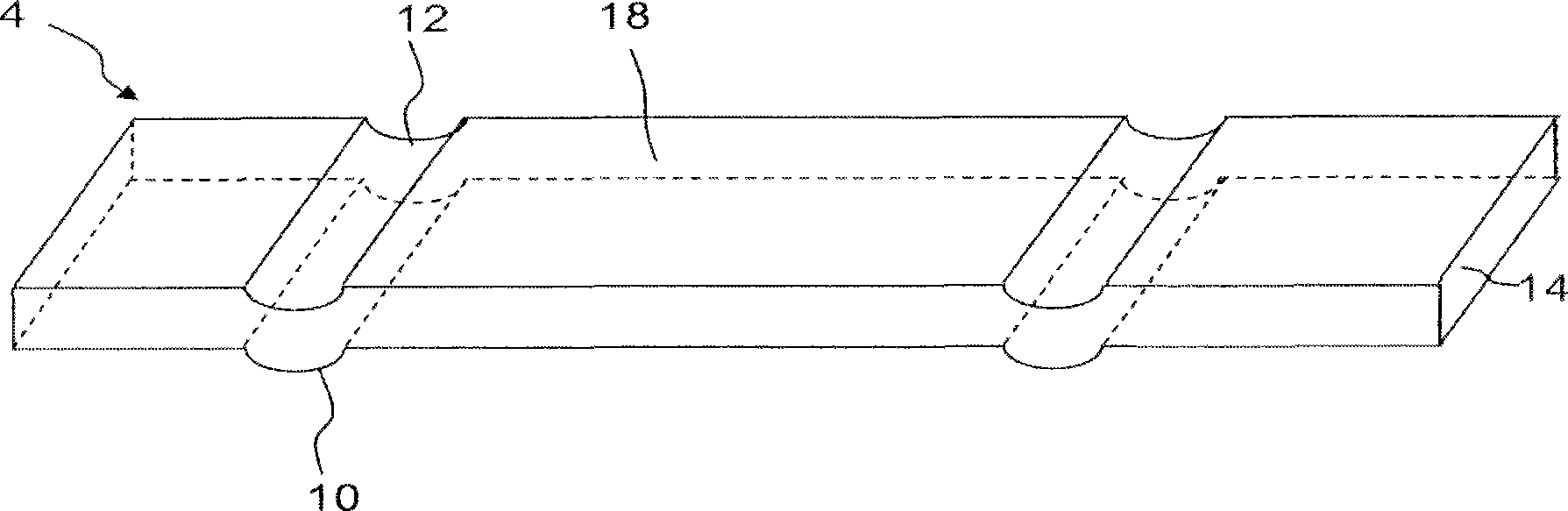

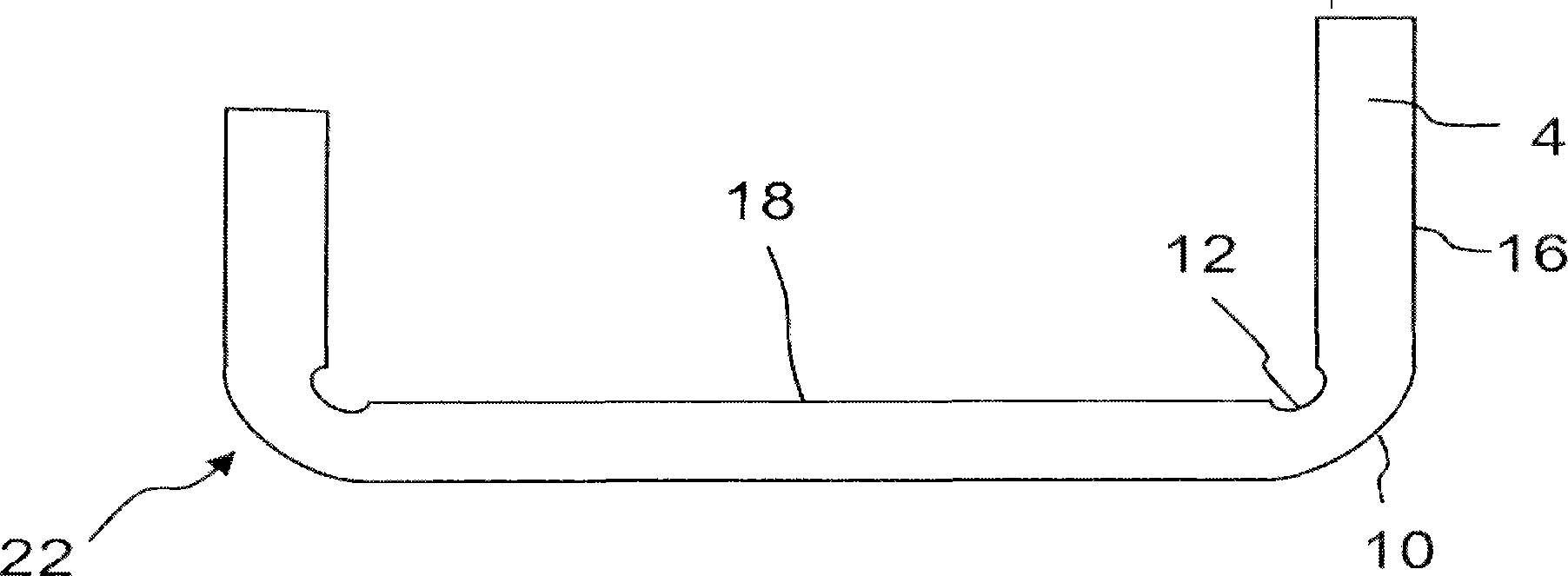

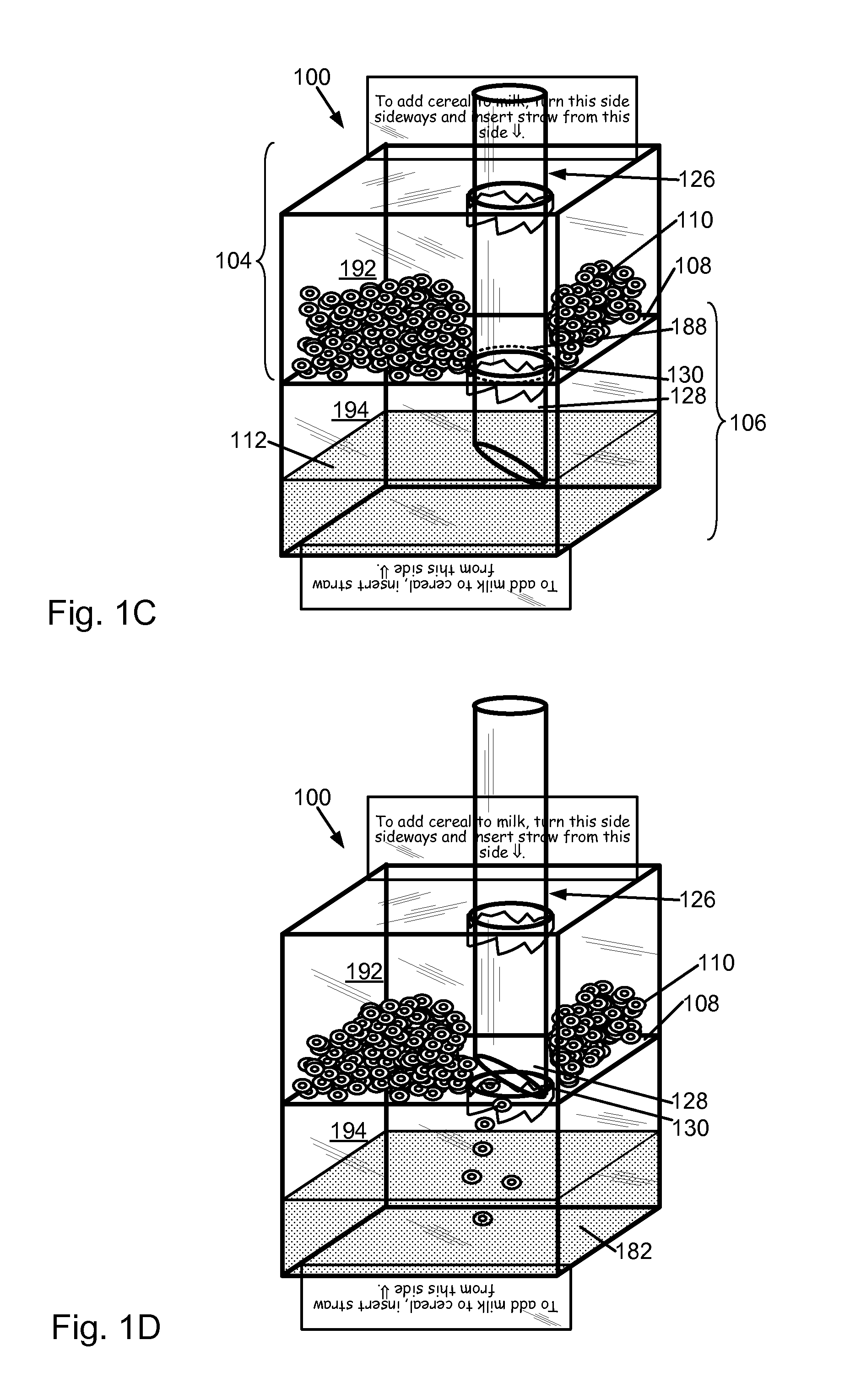

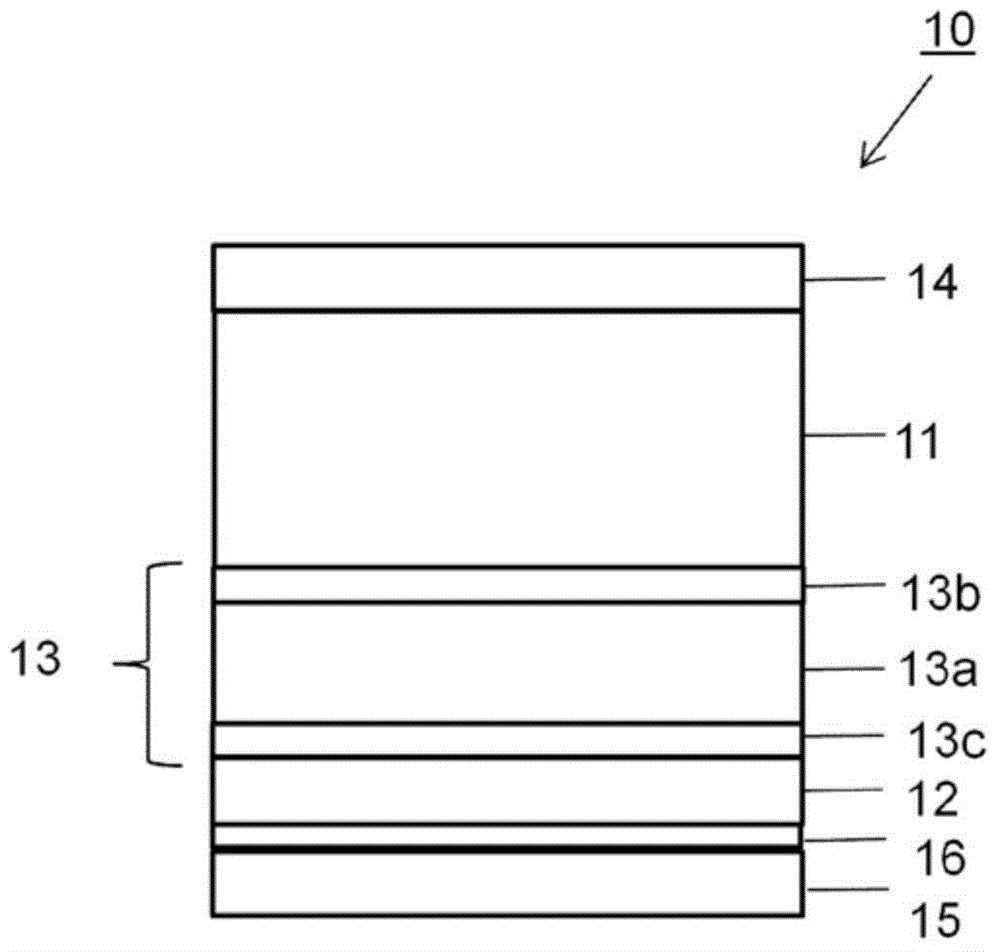

Packaging laminate, method for producing same, and packaging container produced from the packaging laminate

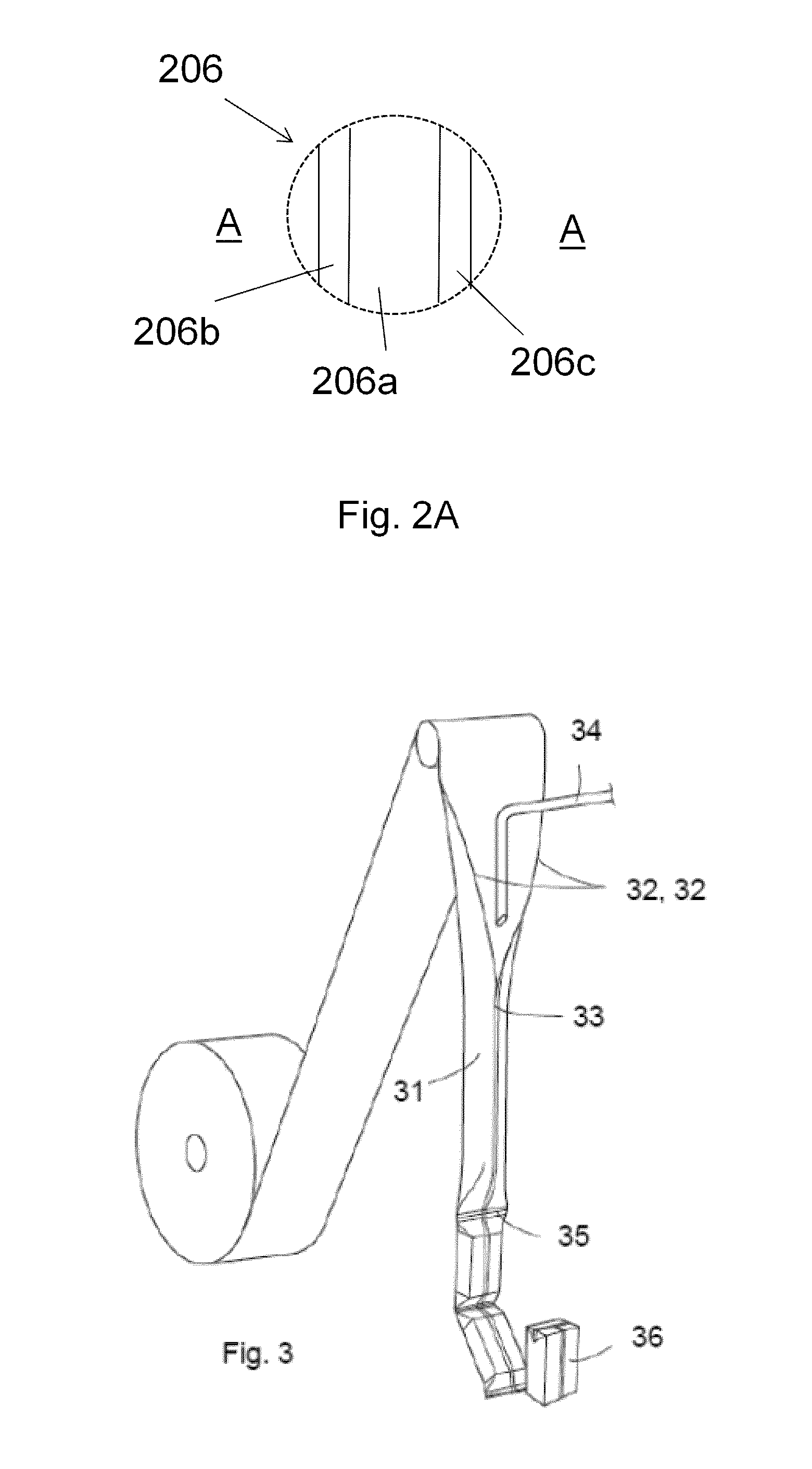

Packaging laminate for a packaging container for oxygen-sensitive liquid food, such as milk, juice, wine and cooking oil. The packaging laminate (10) has a layer (11) of paper or paperboard, and a layer (12) serving as gas barrier and composed of a material with barrier properties against gases, in particular oxygen. The layer (12) serving as gas barrier is bonded to the paper or paperboard layer (11) by a lamination layer (13), which has a central layer (13a) of polymer and outer layers (13b and 13c) of an adhesive on both sides of the polymer layer (13a). The packaging laminate (10) also has outer liquid-tight coatings (14 and 15) on both sides of the paper or paperboard layer (11).

Owner:TETRA LAVAL HLDG & FINANCE SA

Dispensing assembly

A dispensing assembly for a liquid container including a ring part configured to be mounted to a liquid container, a resilient member positioned in the ring part to be in contact with the liquid contents of the liquid container, a ring member mountable to the ring part to secure the resilient member to the ring part, and a hollow connecting member with an outlet. The connecting member is releasably securable to the ring member and includes a hollow projecting member which, when the connecting member is secured to the ring member, engages the resilient member so as to urge an opening in the resilient member to permit liquid in the container to pass into the connecting member and subsequently out through the outlet.

Owner:RAPAK INC

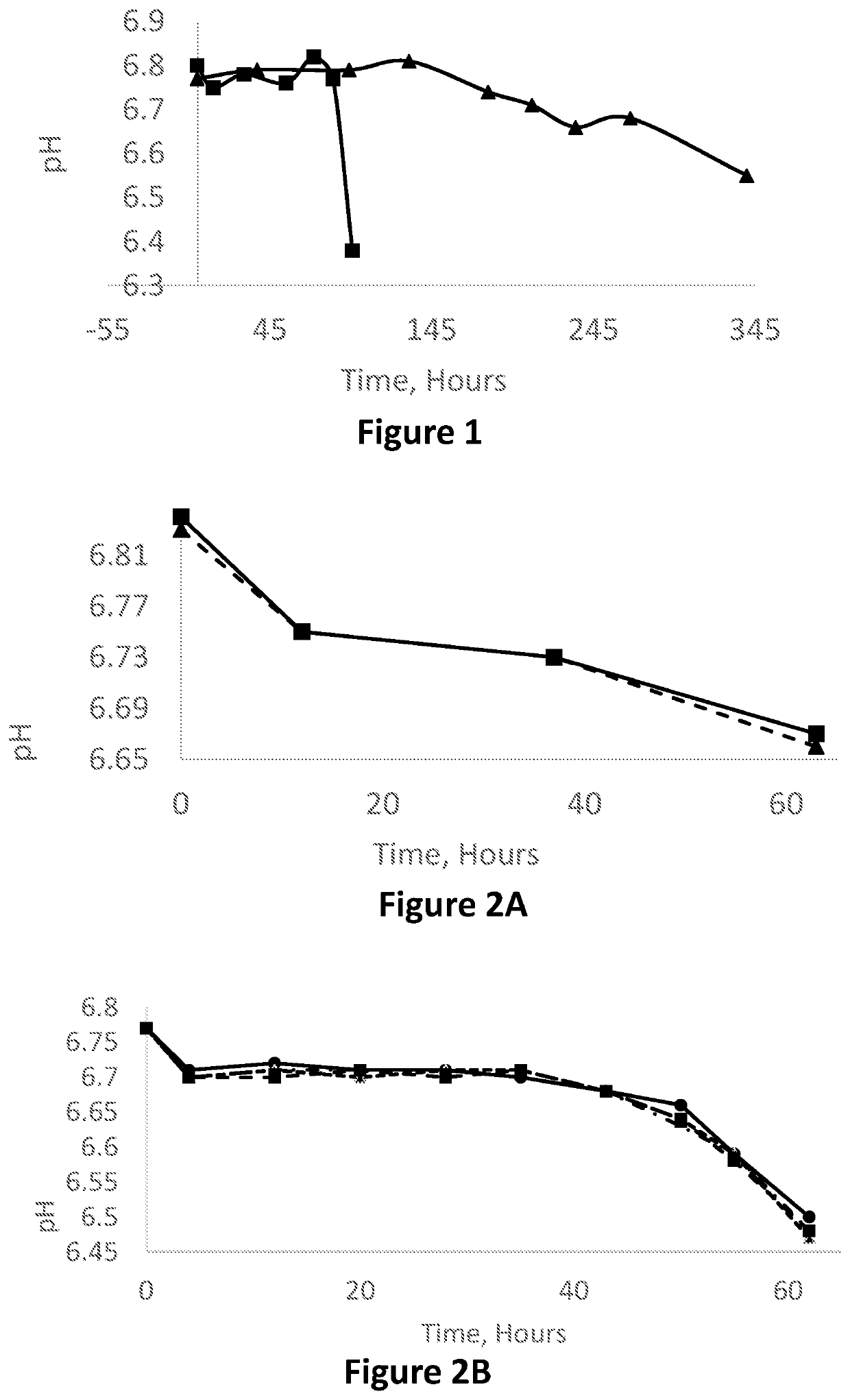

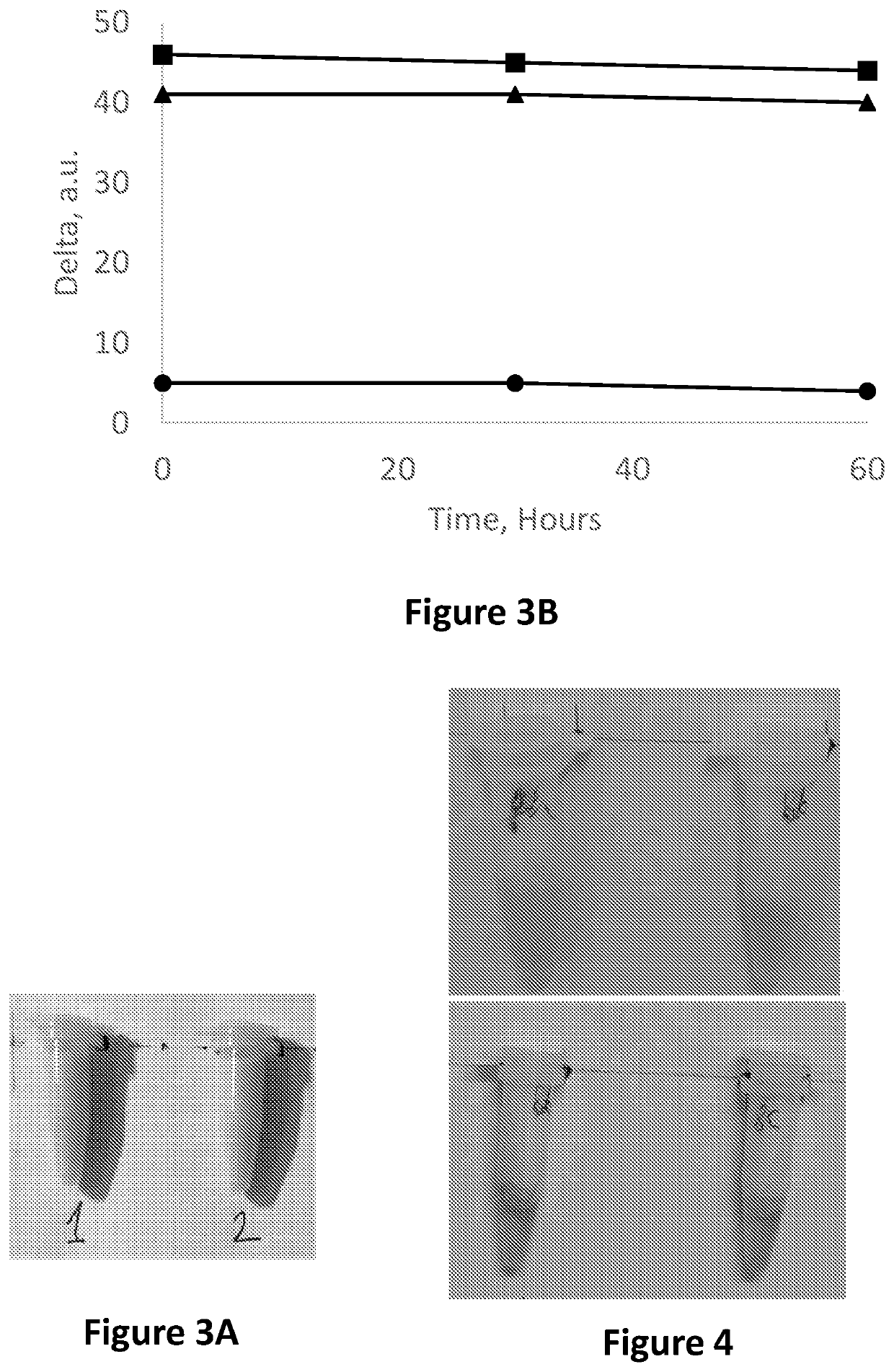

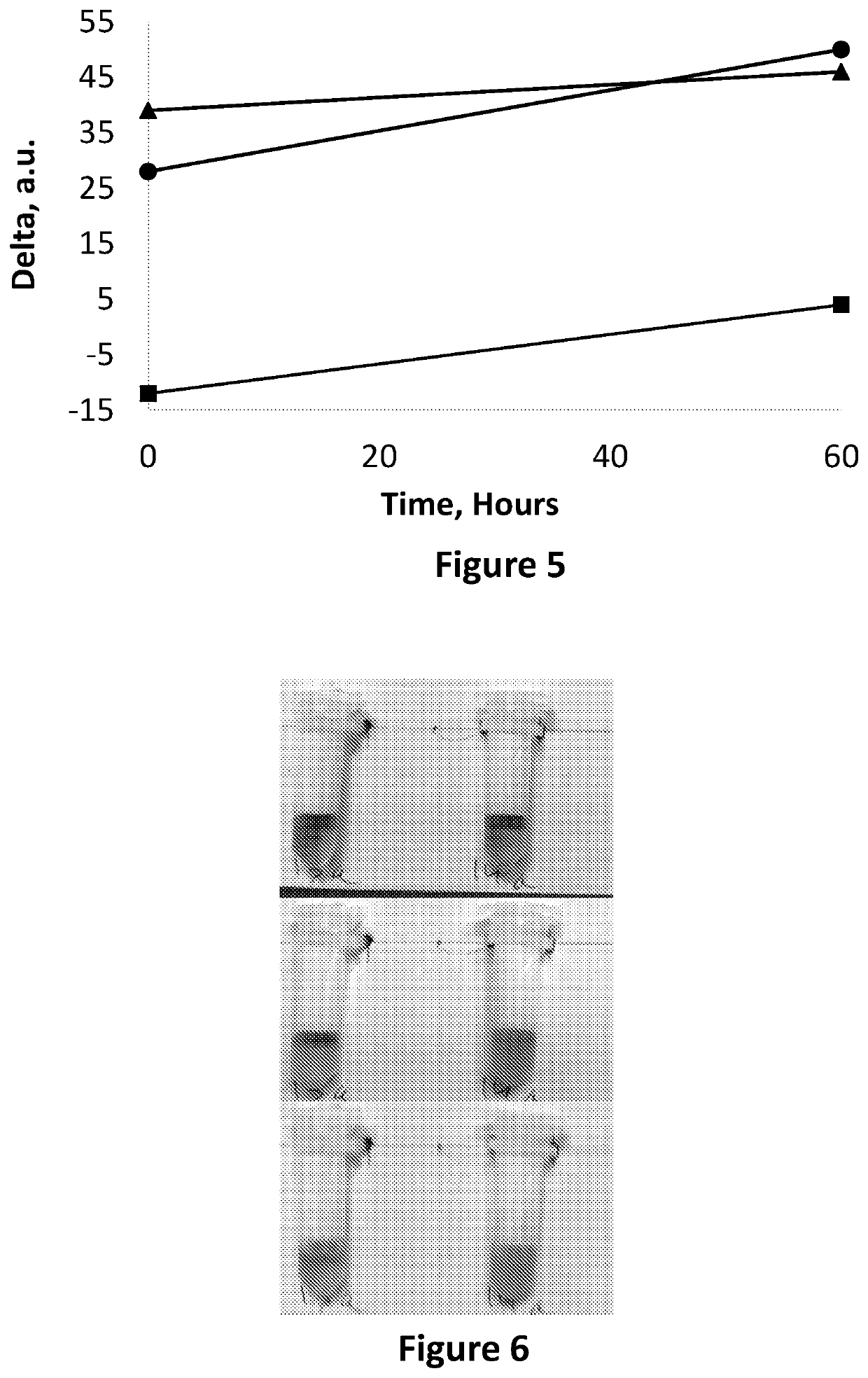

Devices for monitoring food freshness and methods of using same

The present invention provides devices for real-time, continuous, detection of spoilage and freshness of food products.

Owner:GRANEVITZE ZUR

Residual-prevention yoghourt bottle

Owner:顾钰锋

Packaging shaped articles, e.g., opaque bottles, and process for the manufacture thereof

InactiveUS7544405B2Easy to recycleNot degrade intrinsic property of materialEnvelopes/bags making machineryWrappersBlow moldingPolyester

Owner:TERGAL FIBERS

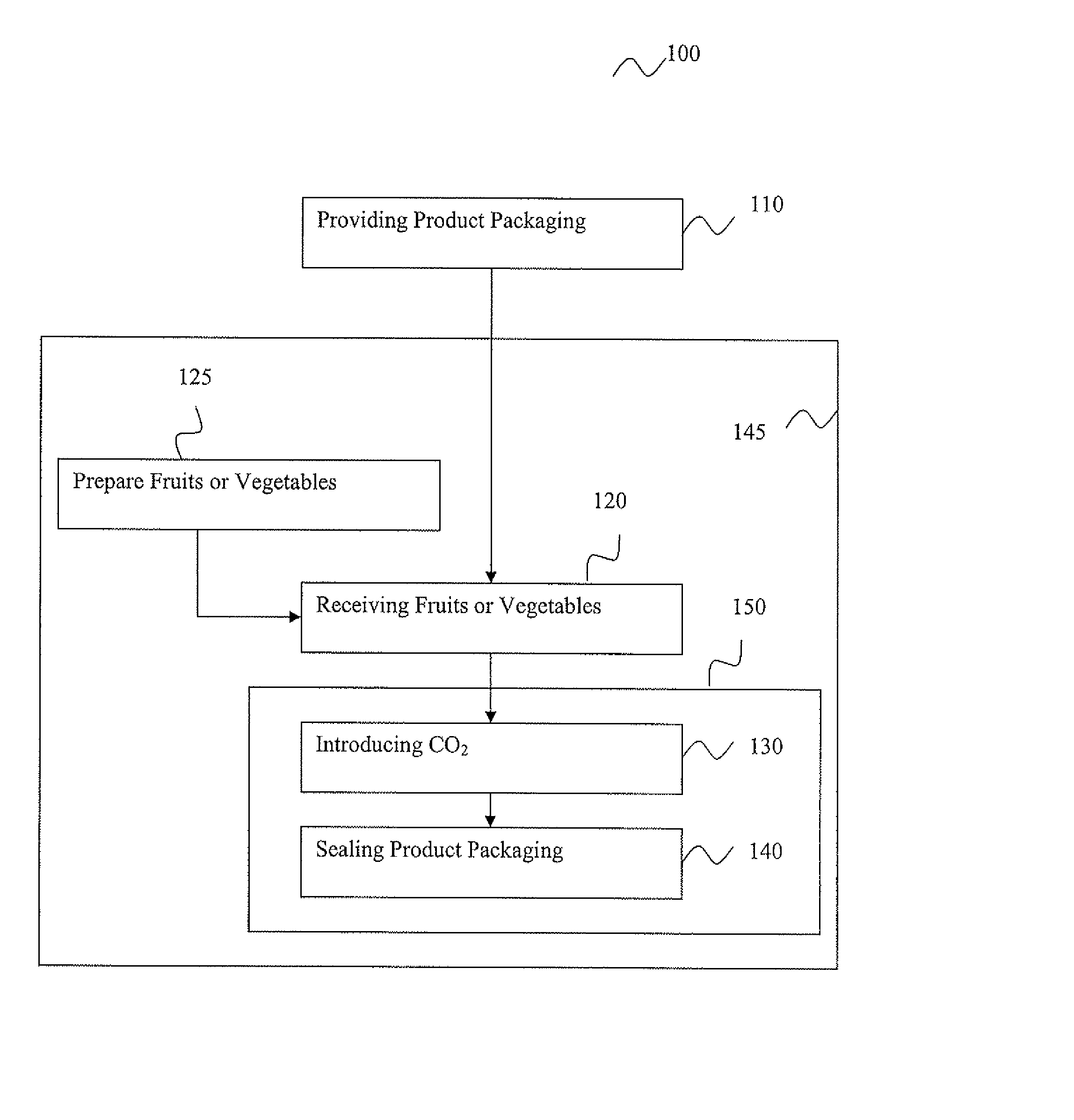

Packaged flavor enhanced food products

Enhancing the flavor of food products within its product packaging to extend its shelf-life and to allow for mass production and mass distribution, and the packaged flavor enhanced food products produced. The method comprises providing product packaging capable of retaining a positive pressure of CO2, receiving food products such as fruits or vegetables into the product packaging, introducing CO2 into the product packaging, and sealing the product packaging containing the fruits or vegetables and CO2, wherein the fruits or vegetables absorb CO2 within the packaging thereby enhancing the flavor of the fruits or vegetables. The packaged flavor enhanced food products may comprise, for example, carbonated or “fizzed” fruit or vegetable pieces in yogurt, fruit or vegetable pieces in ice cream or sorbet, or other food items that may contain carbonated fruit or vegetable pieces, purees, sauces, or the like.

Owner:FIZZYFRUIT +1

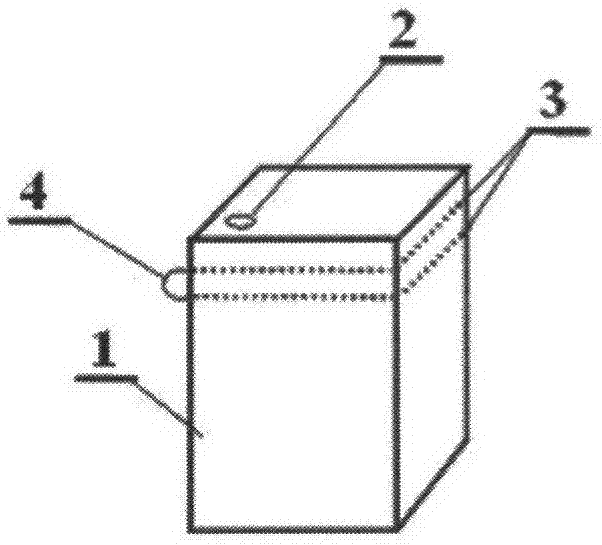

Beverage box with edible film

The invention provides a beverage box with an edible film. The beverage box comprises a beverage box body (1), a port (2) for a straw to insert, press cutting lines (3) easy to tear, a ring pull handle (4), an outer package (5) and the edible film (6). The port (2) for the straw to insert is formed in one corner of the upper portion of the beverage box body (1), the press cutting lines (3) easy to tear are arranged on the upper half portion of the beverage box body (1), the ring pull handle (4) is arranged at one corner of the beverage box body (1), the press cutting lines easy to tear are two lines arranged in parallel with the interval as 5-10mm. The edible film (6) is arranged on the inner side of the beverage box body (1). When beverages in the beverage box cannot be sucked, people can tear off the beverage box and eat the edible film and residual beverage, so that the aims of saving beverage and facilitating beverage box recycle are achieved, and the society can be benefited.

Owner:辛秋朋

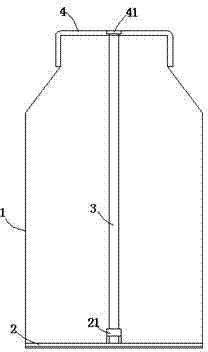

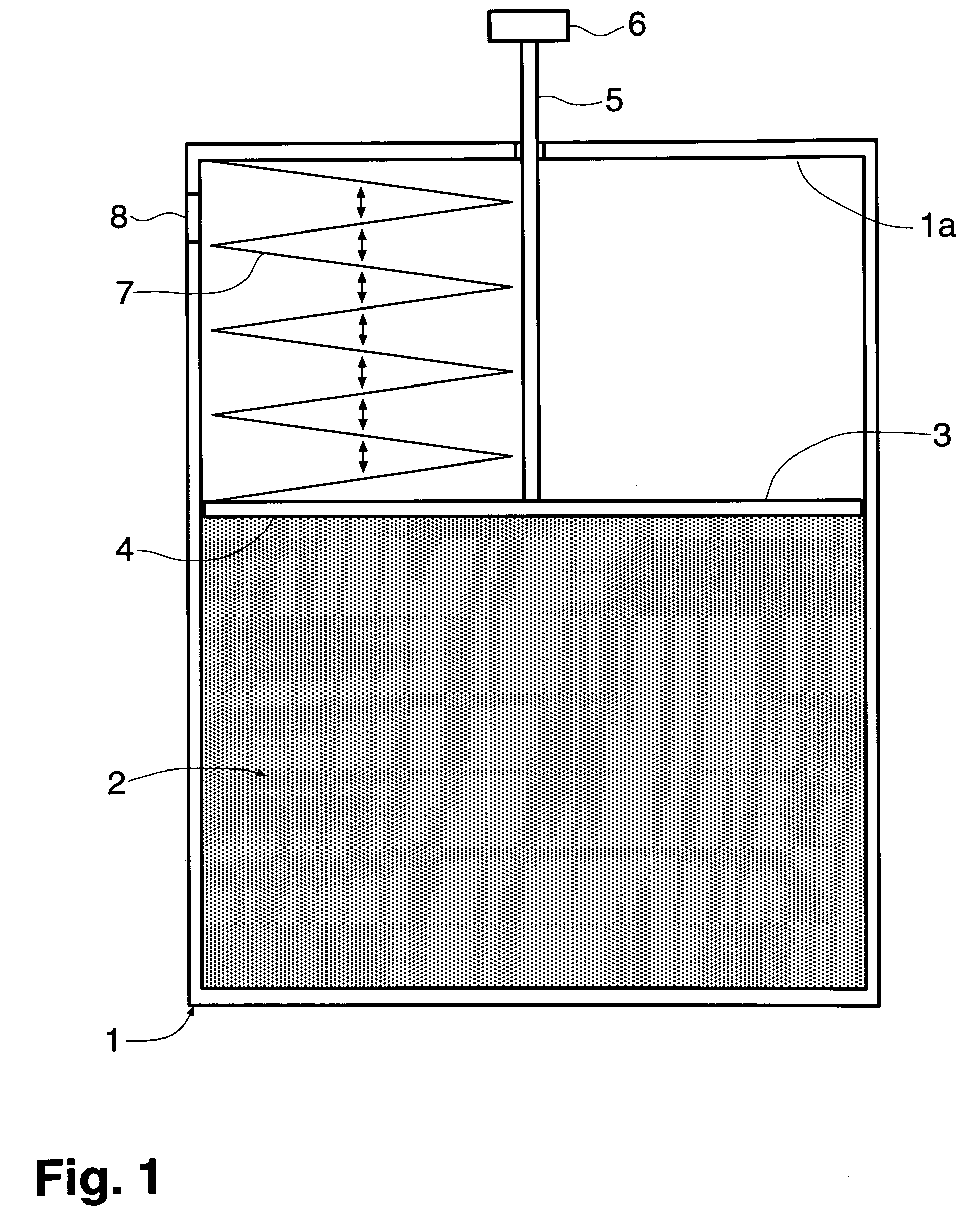

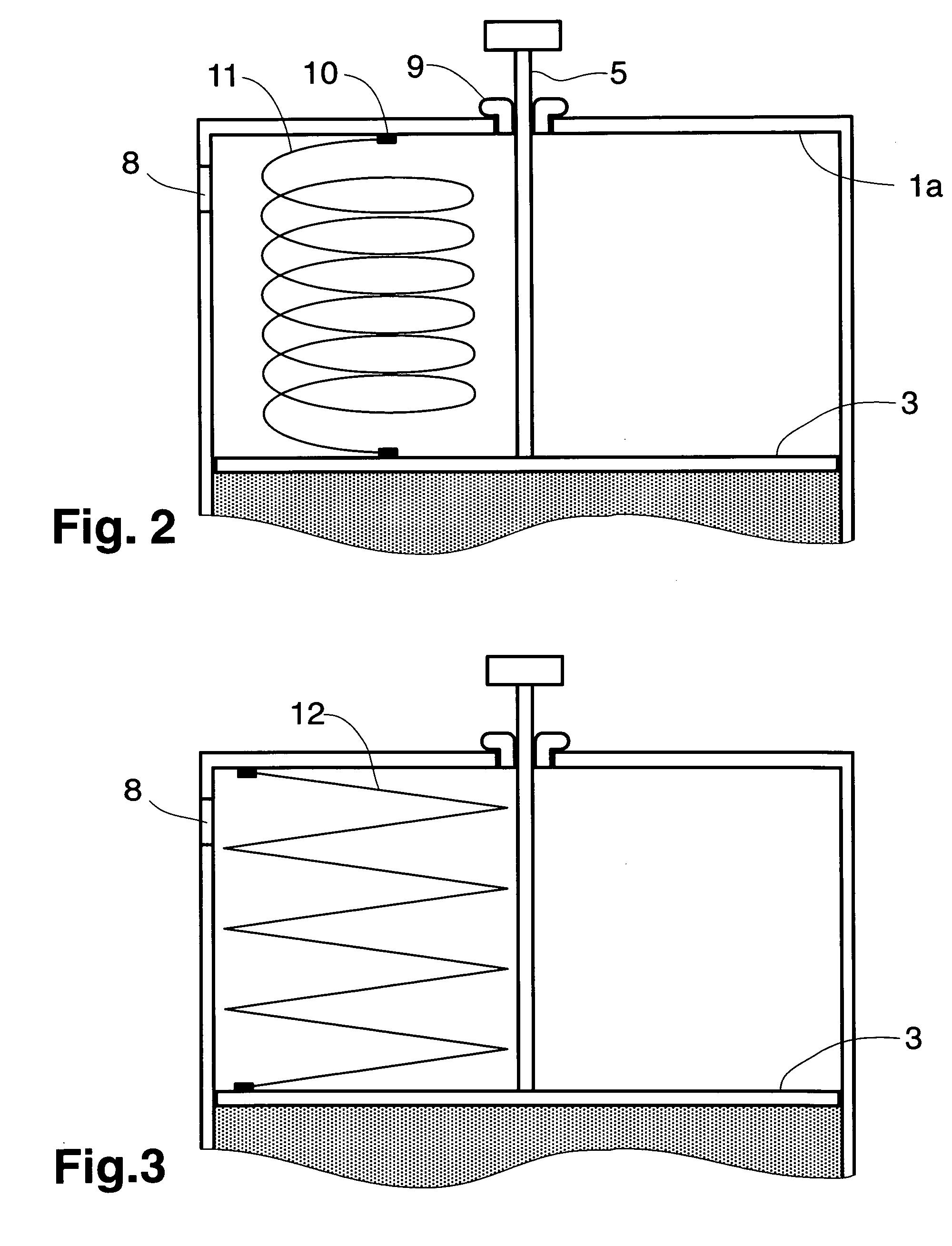

Freshness prolonging smart beverage container

InactiveUS20100098816A1Avoid contactImprove freshnessReady-for-oven doughsPackaging milkFruit juiceEngineering

The invention is a container for liquids, such as milk, juices and wines, which are subject to spoilage enhanced by contact with air. The container may be partially filled with liquid in a sub-chamber made anaerobic by a divider plate positioned on-the surface of the liquid and fitting sufficiently snugly within the container. The divider plate prevents contact between the beverage and air and thus reduces air-induced spoilage. Various embodiments provide springs and divider pullers to place the divider at the liquid surface, easy pouring and easy cleaning. A significant intended use is prolonging freshness of beverages in environments lacking refrigeration.

Owner:ANVIK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com