Patents

Literature

163results about "Eggs preservation by heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chia seed beverage and related method

InactiveUS20090181114A1Enhancing heart healthImprove regularityBiocideDigestive systemFruit juiceFlavored water

A beverage is disclosed that is effective for enhancing gastrointestinal regularity and heart health. It is formed by a liquid comprising fruit derived juices, water or naturally or artificially flavored water. A composition of matter is mixed within the liquid in a shelf stable pasteurized beverage form and formed from sterilized whole seed extracted from Salvia hispanica L. The resulting beverage exhibits a pH dependent viscosity requiring no additional thickening agents and suitable as a beverage for human consumption.

Owner:US NUTRACEUTICALS LLC

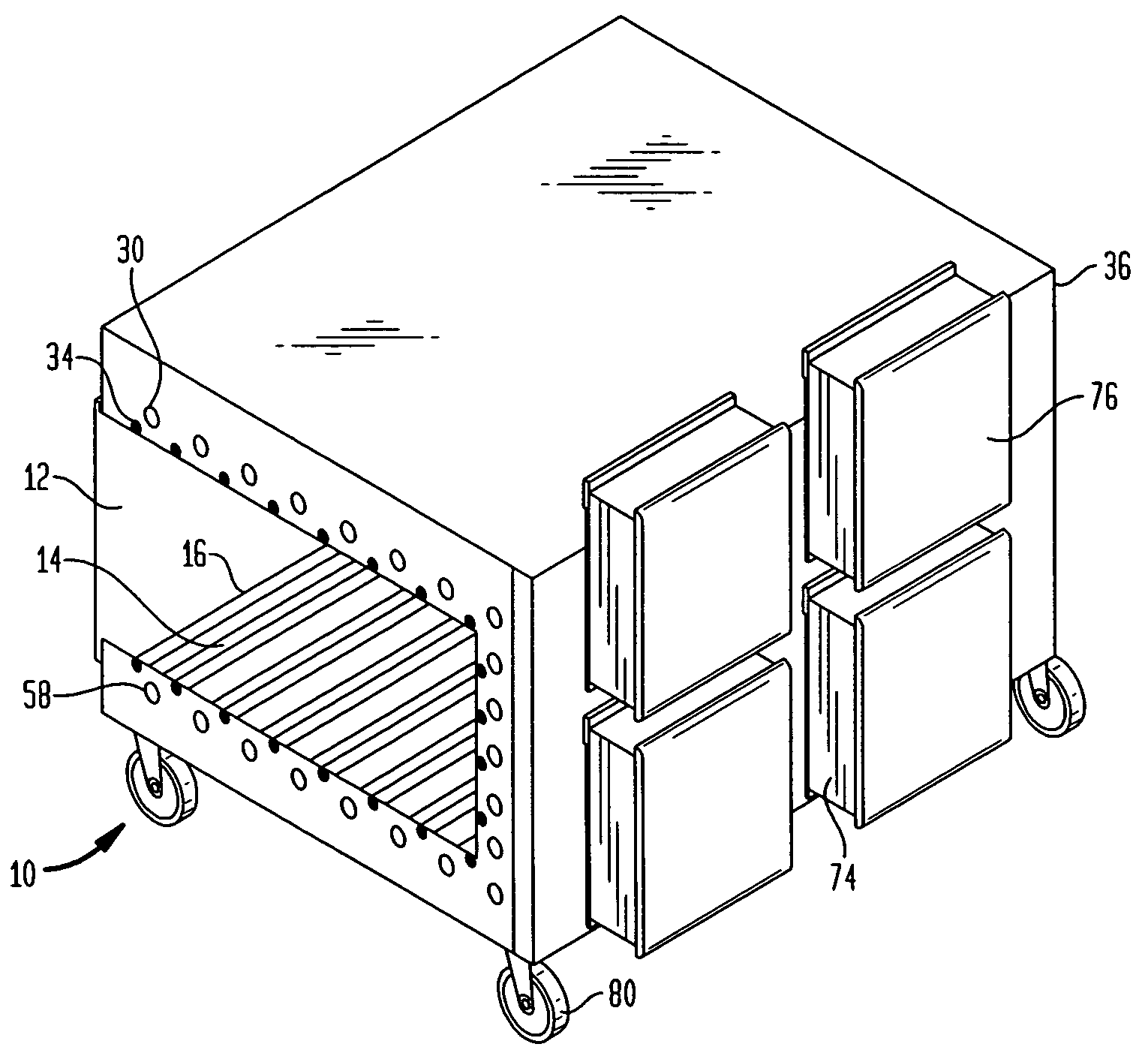

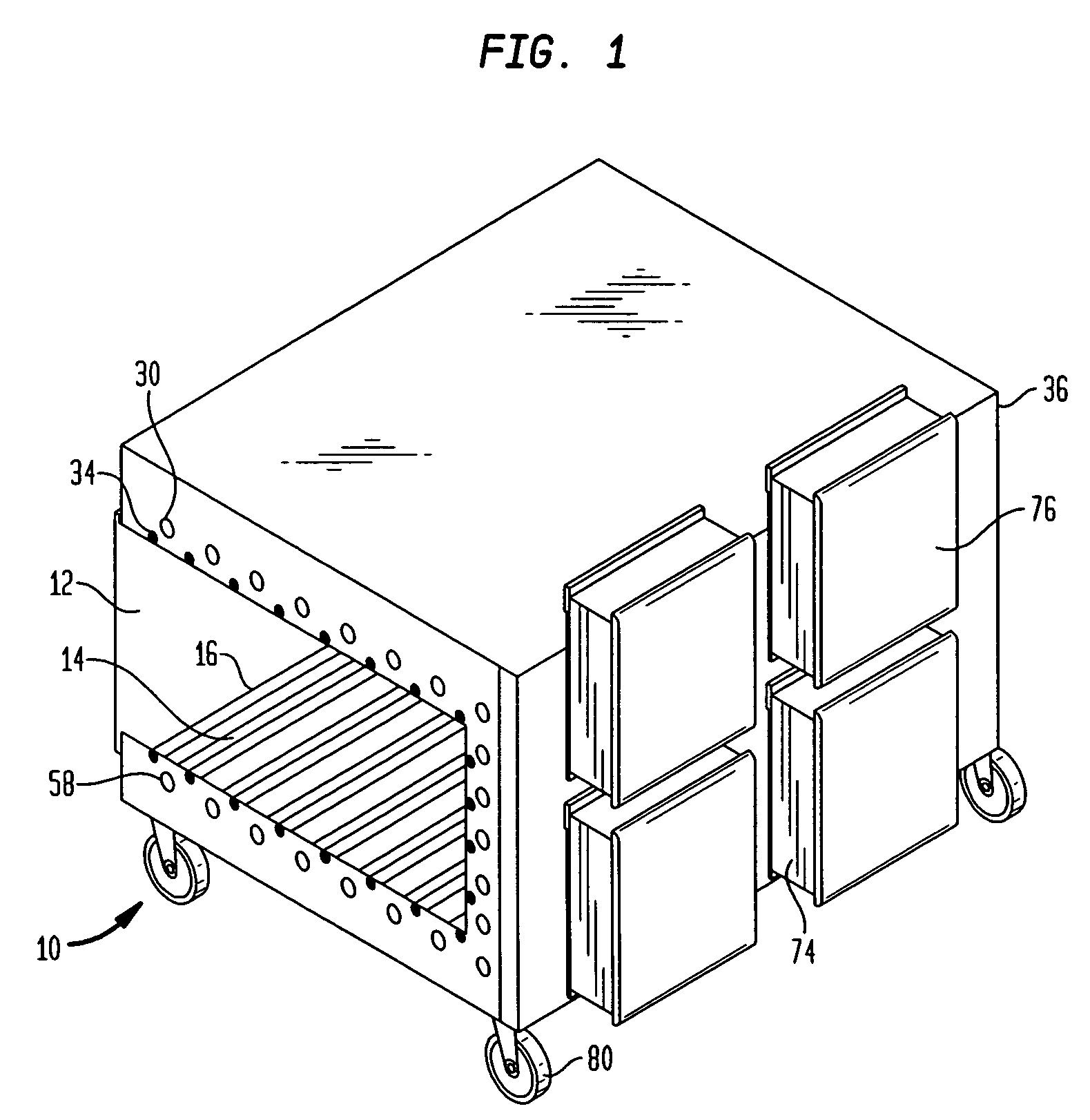

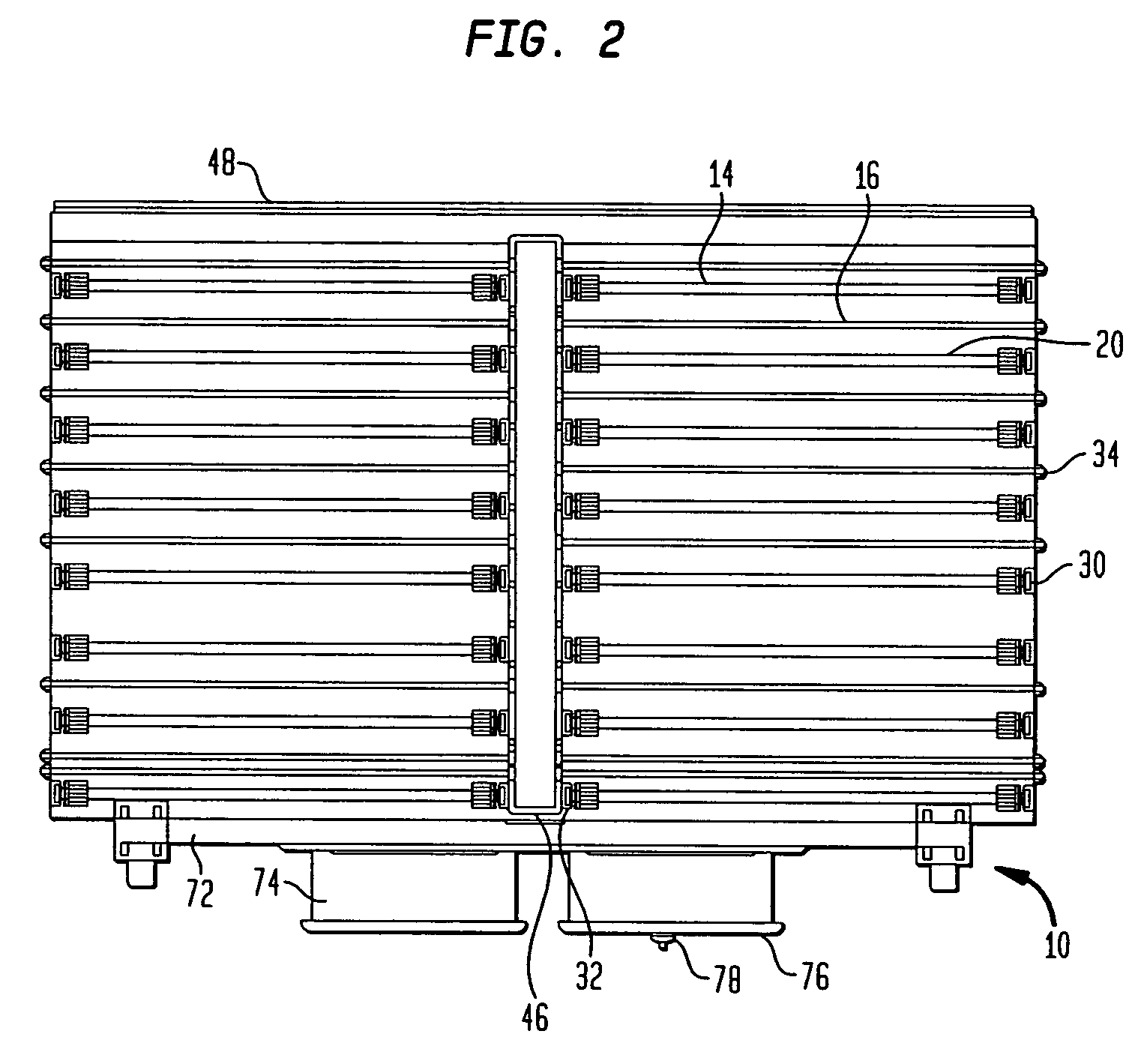

Food surface sanitation tunnel

InactiveUS7160566B2Efficient use ofImprove efficiencyMilk preparationDough treatmentSuperoxideCopper

This invention is a modular, adjustable, easy to maintain, portable or fixed food sanitation tunnel, comprising an enclosing means for subjecting food to sanitizers including UV light, ozone, hydroperoxides, superoxides and hydroxyl radicals, and a method for using the system. The enclosing means includes one or more UV radiation sources and one or more target rods located within a tunnel, such as a c-shaped shell. The UV radiation sources are preferably UV light sources that emit UV light of approximately 185 to 254 nm. The target rods are approximately up to 0–30% titanium dioxide, up to 0–30% silver and up to 0–30% copper, by weight. The system may include a mister for the efficient production of hydroxyl radicals by the UV light sources. Parts of the system are easily removable for cleaning and for maintenance. Also, in an alternative embodiment, the tunnel is located on a frame, and the frame is on wheels.

Owner:BOC INC

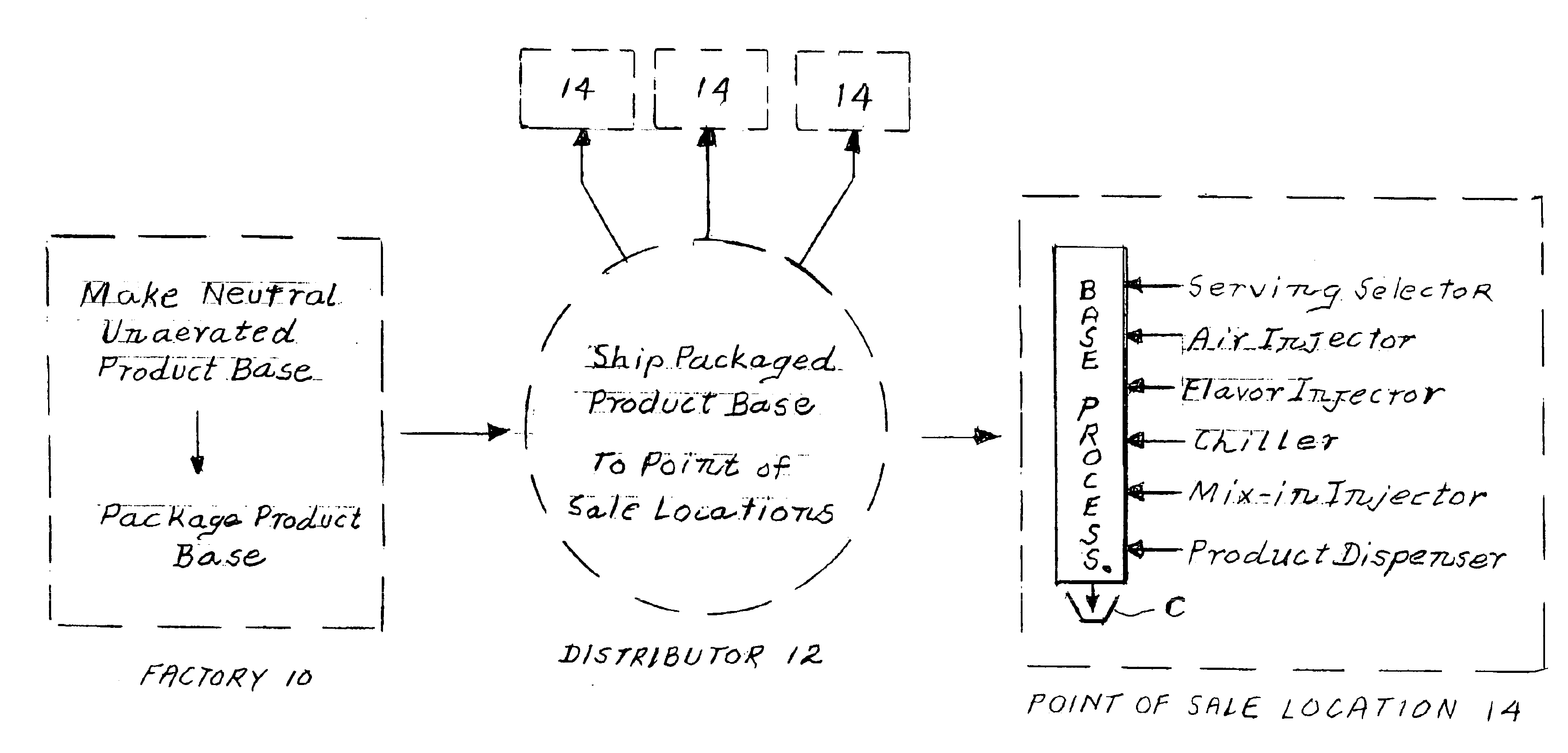

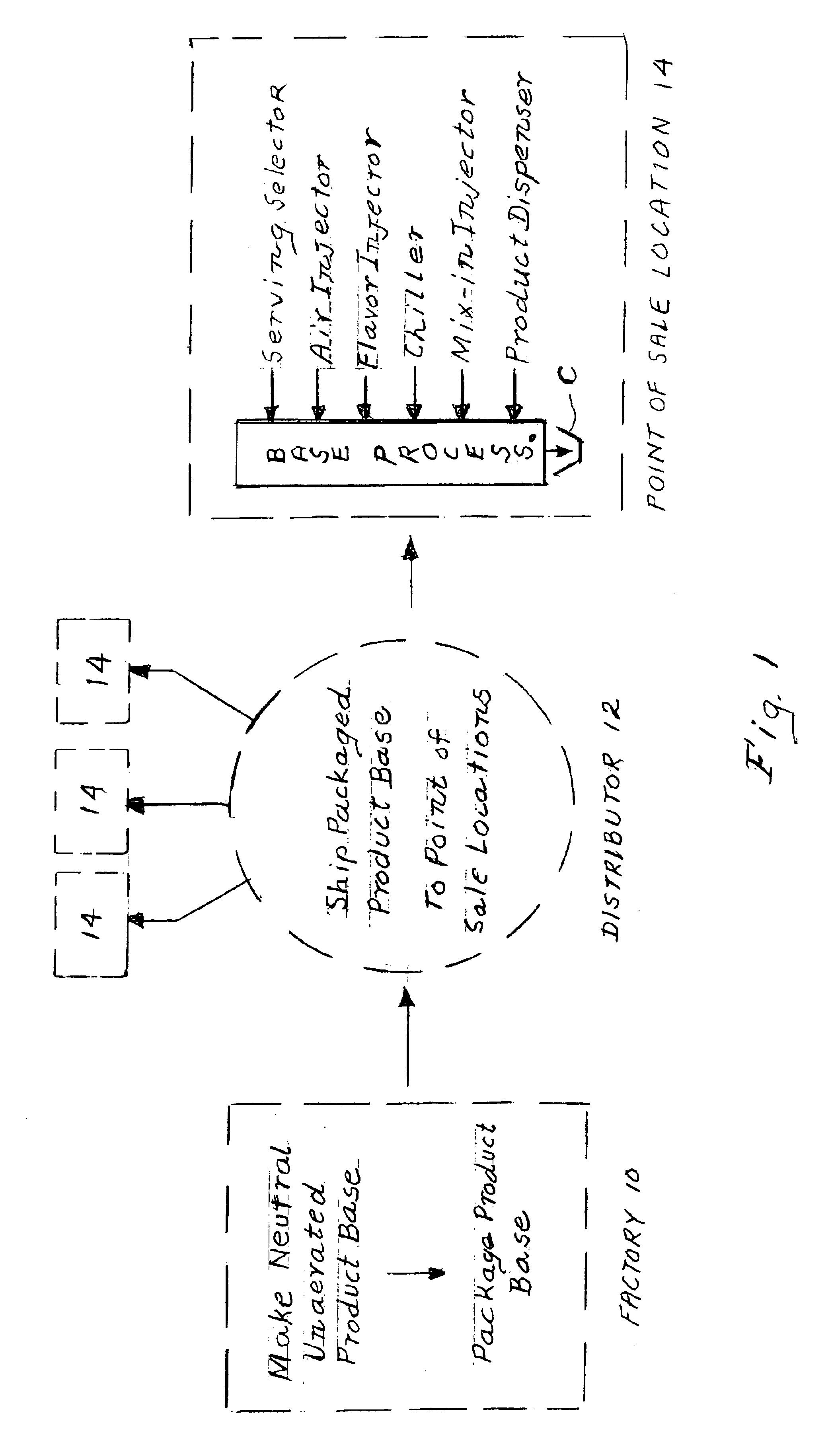

Efficient manufacture and distribution of chilled solid food products

InactiveUS6941858B2Lower requirementImprove production efficiencyMilk preservationMilk treatmentDistribution systemCommon carrier

An efficient manufacturing and distribution system for food products that are normally served at temperatures well below ambient uses a two stage manufacturing process. In the first stage, a neutral base product is prepared in bulk and is shipped to point of sale at ambient temperatures by common carrier, private trucking, parcel express, mail, etc. At the point of sale, a user selected quantity of it is finished to the specification of the user by aerating it, adding flavorings, mix-ins, etc. as desired, chilling it, and delivering it to the consumer.

Owner:MOOBELLA ACQUISITION +1

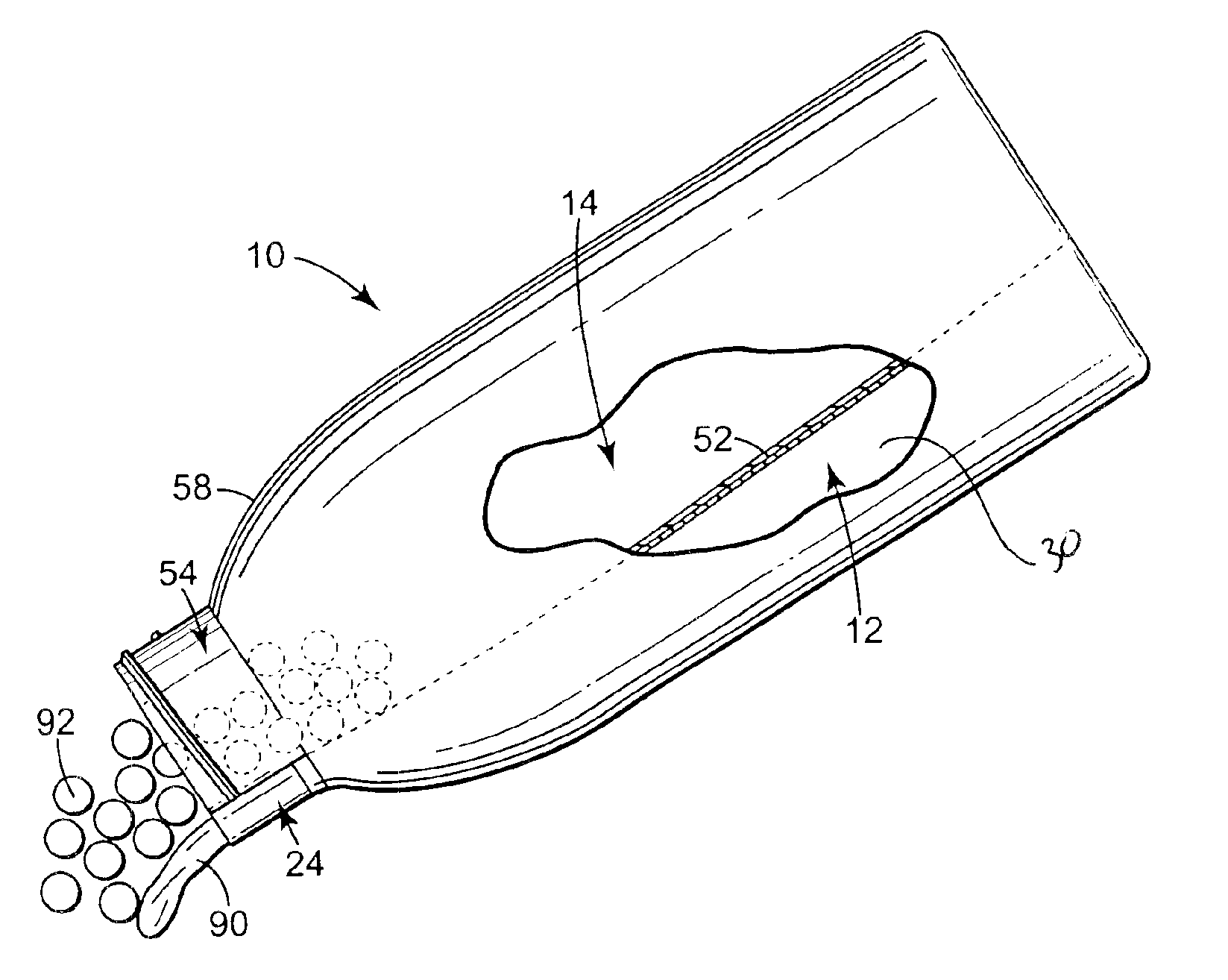

Portable, side-by-side compartment container and method for separately storing and dispensing two consumable products, especially cereal and milk

InactiveUS6913777B2Optimize allocationReduce consumptionBottlesEggs preservation by heatingBiomedical engineeringSingle use

Owner:GENERAL MILLS INC

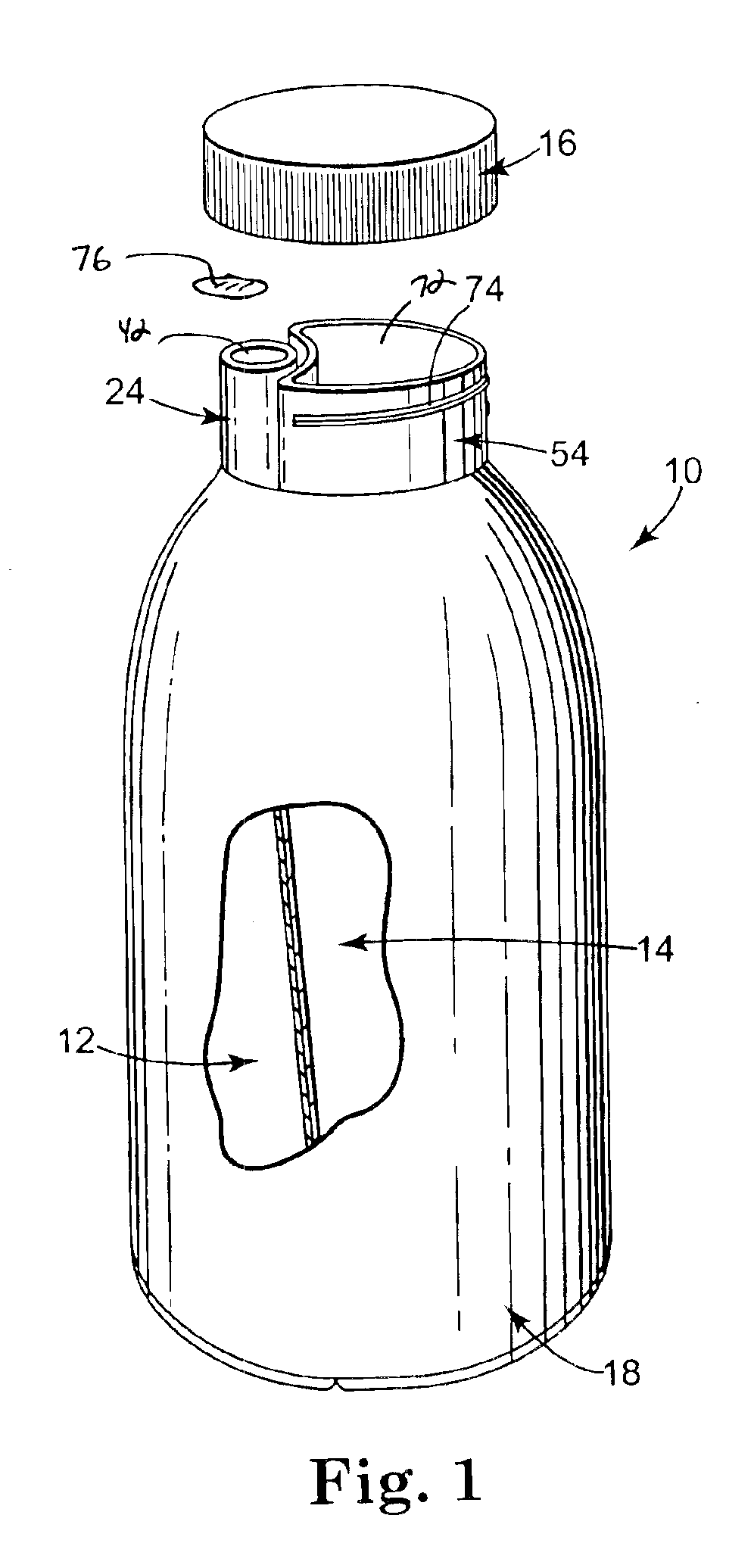

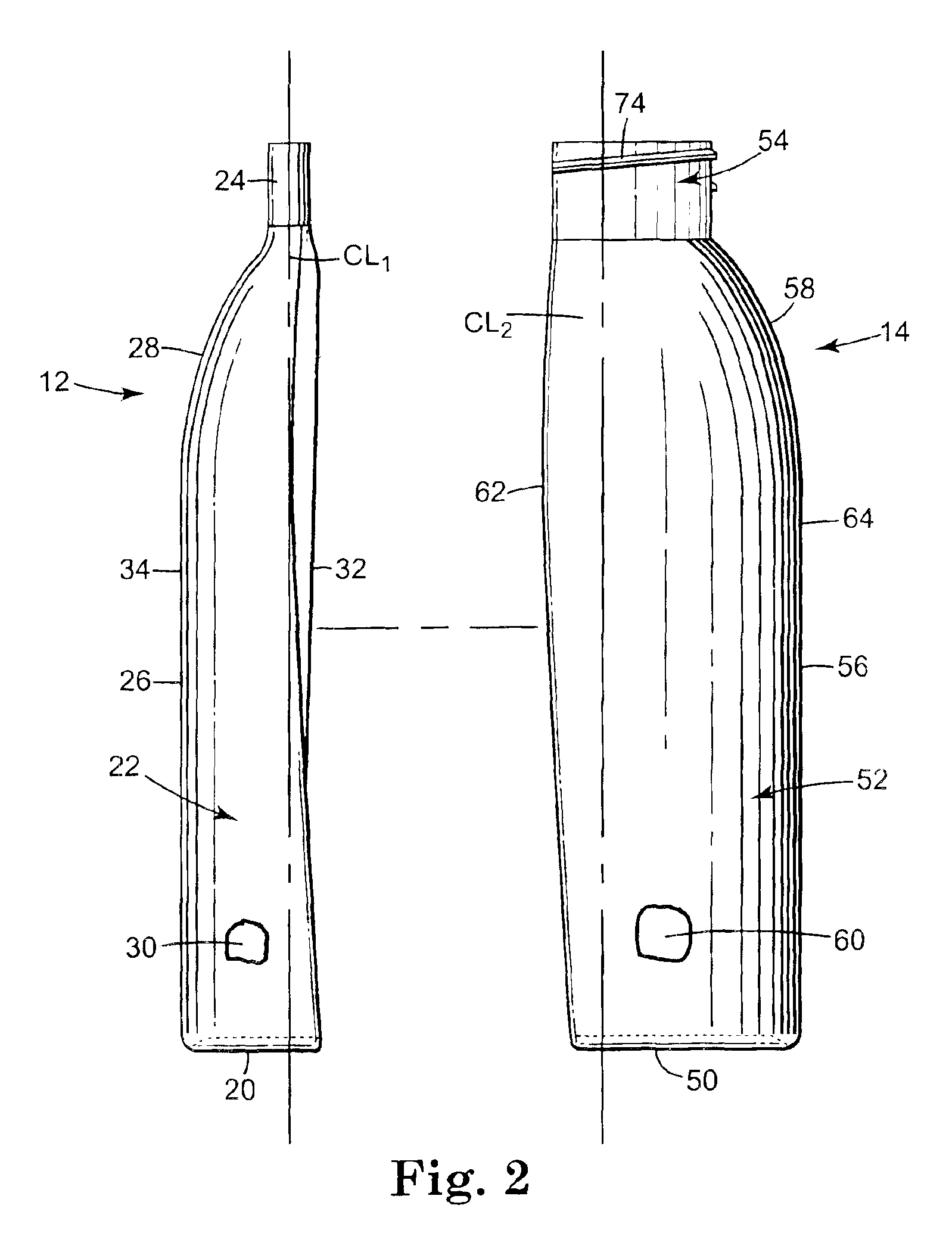

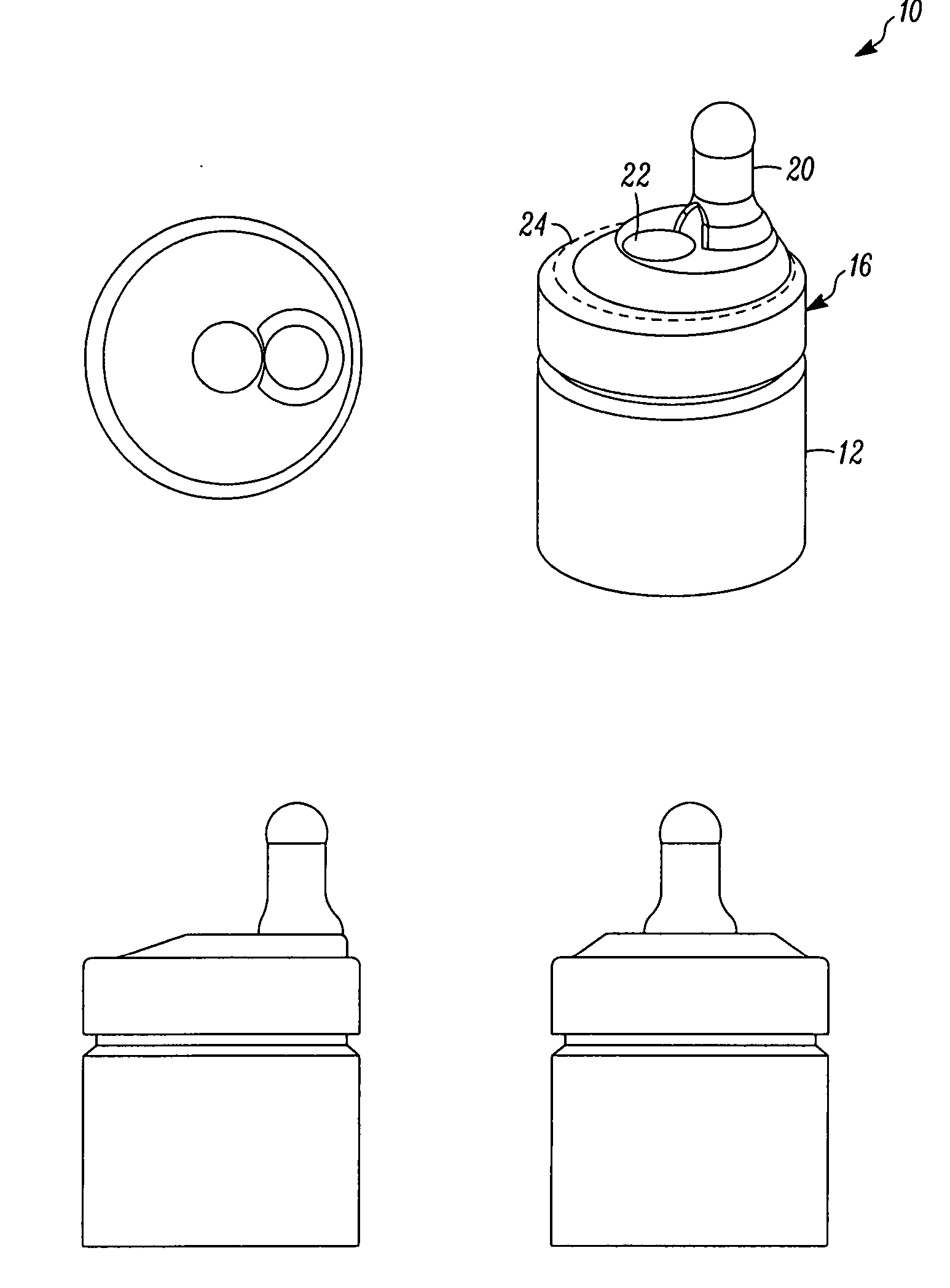

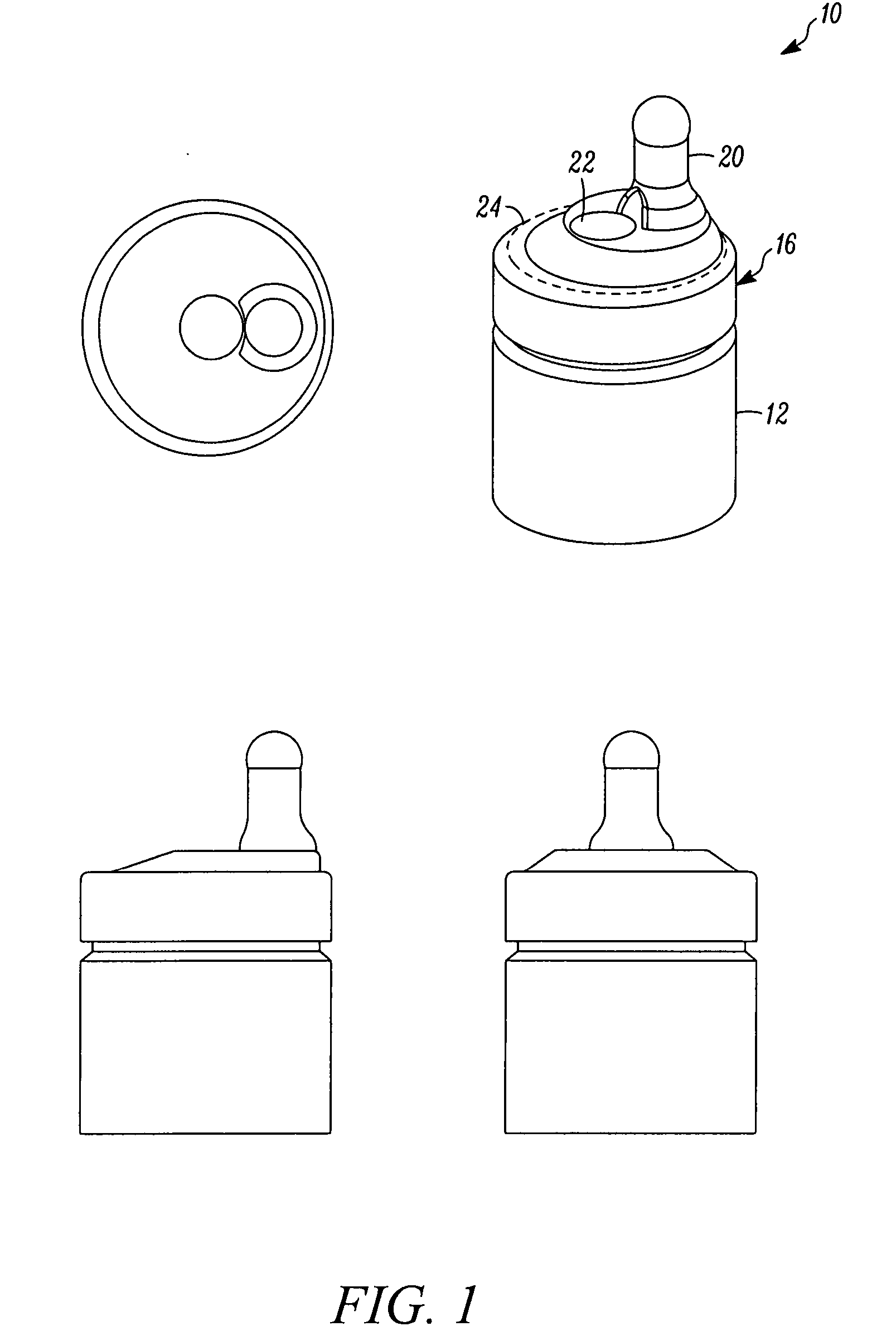

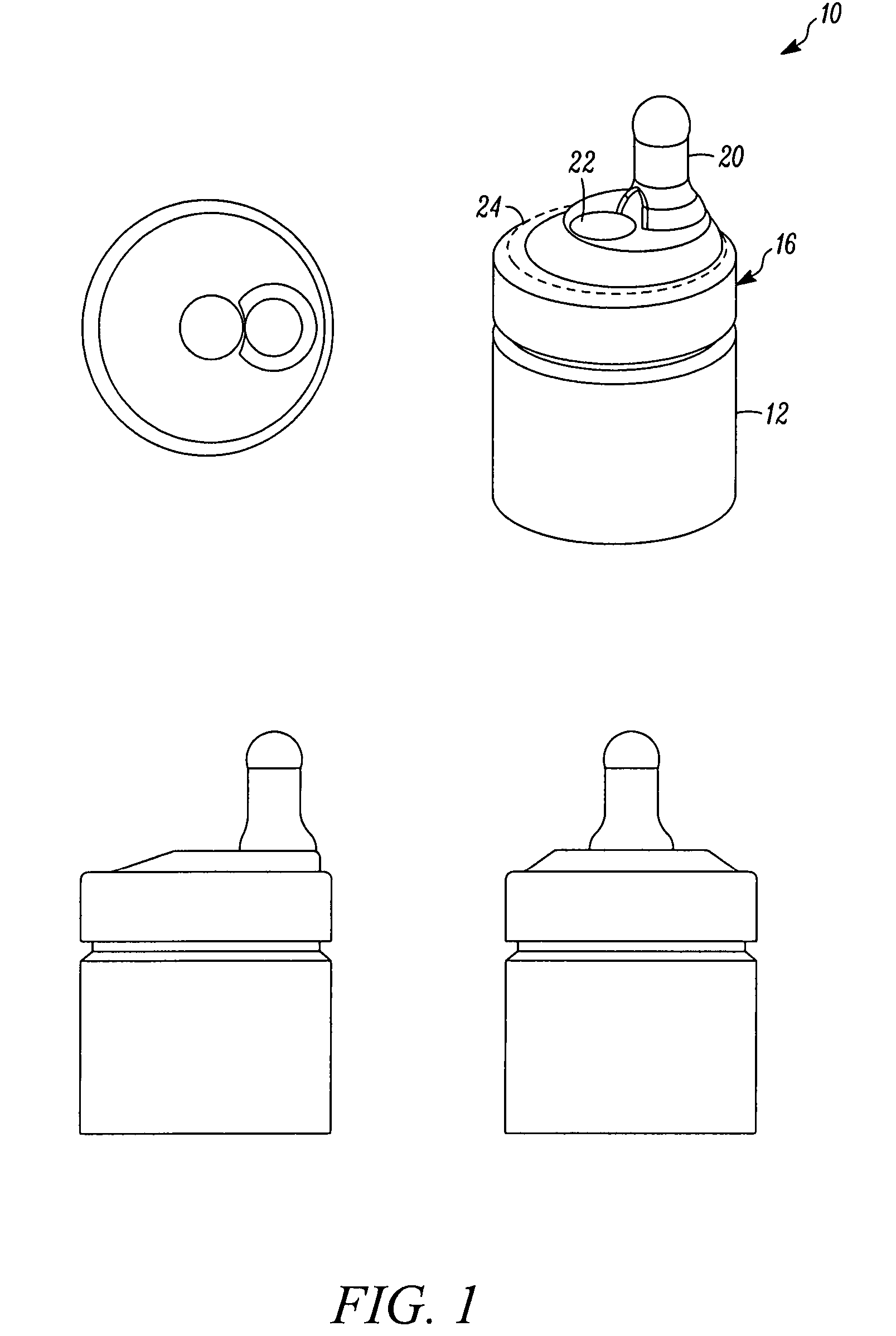

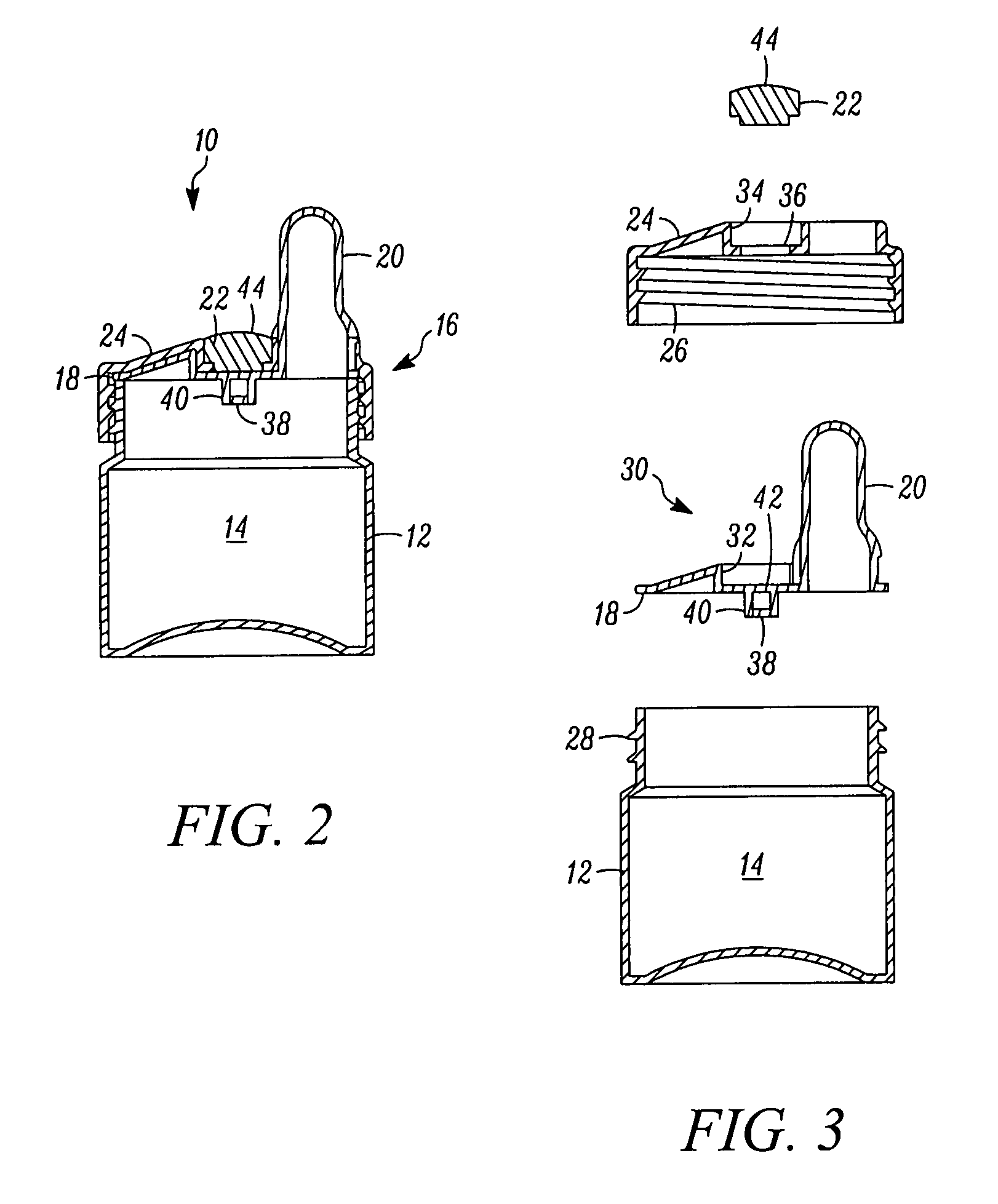

Ready to drink container with nipple and needle penetrable and laser resealable portion, and related method

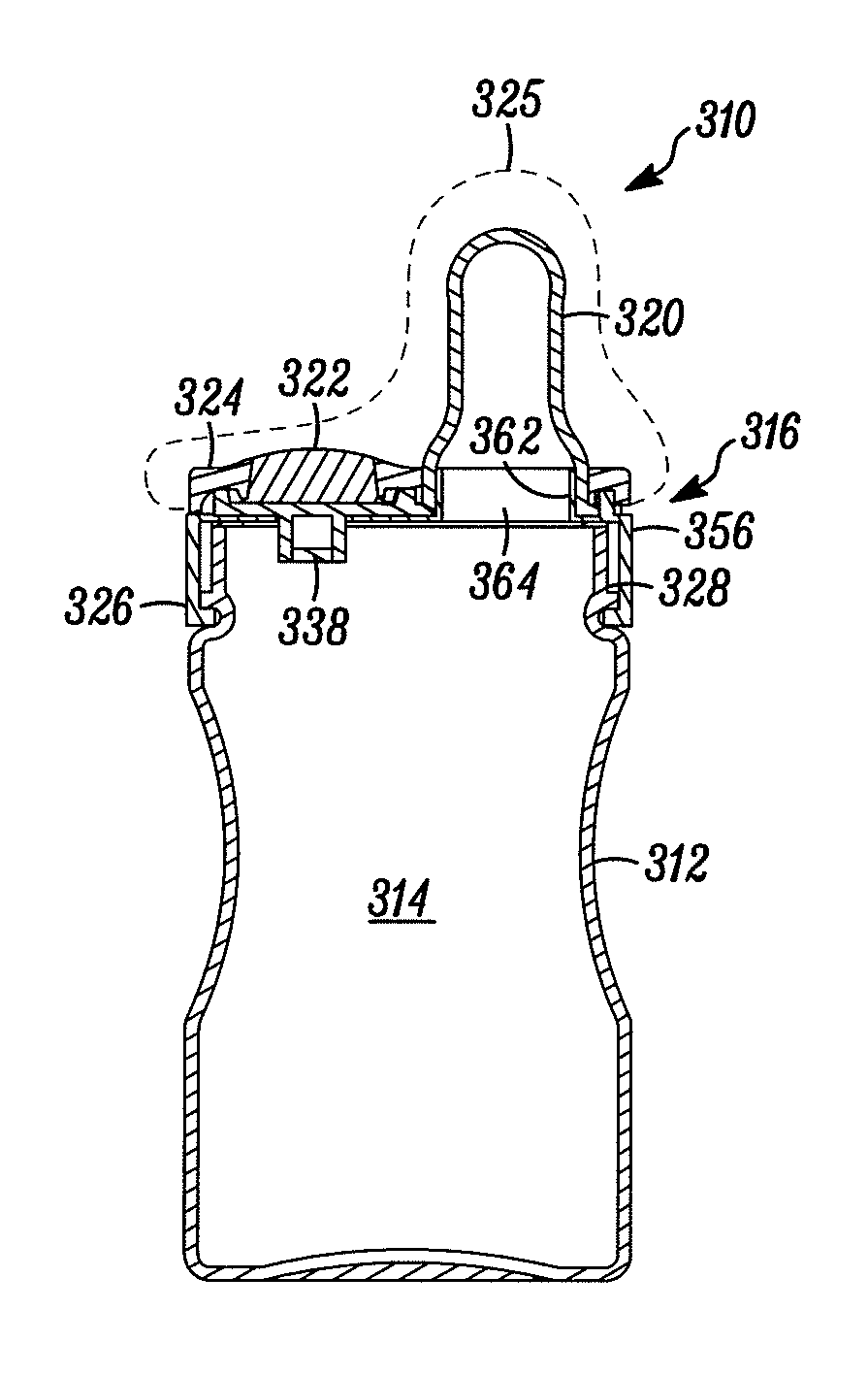

A container is provided for storing a product, such as a fat containing liquid product, and includes a body defining a chamber for receiving the product; and a container closure including a sealing portion for sealing the product within the chamber. The container closure includes a member forming a substantially fluid-tight seal between the container closure and the body; a nipple in fluid communication with the chamber that seals the chamber with respect to the ambient atmosphere during storage of the product in the chamber and that can be opened to dispense product from the chamber therethrough; and a needle penetrable and laser resealable portion that is penetrable by the needle for aseptically filling the chamber with the product, and that is thermally resealable by the application of laser radiation thereto to seal the product within the chamber.

Owner:MEDINSTILL DEV

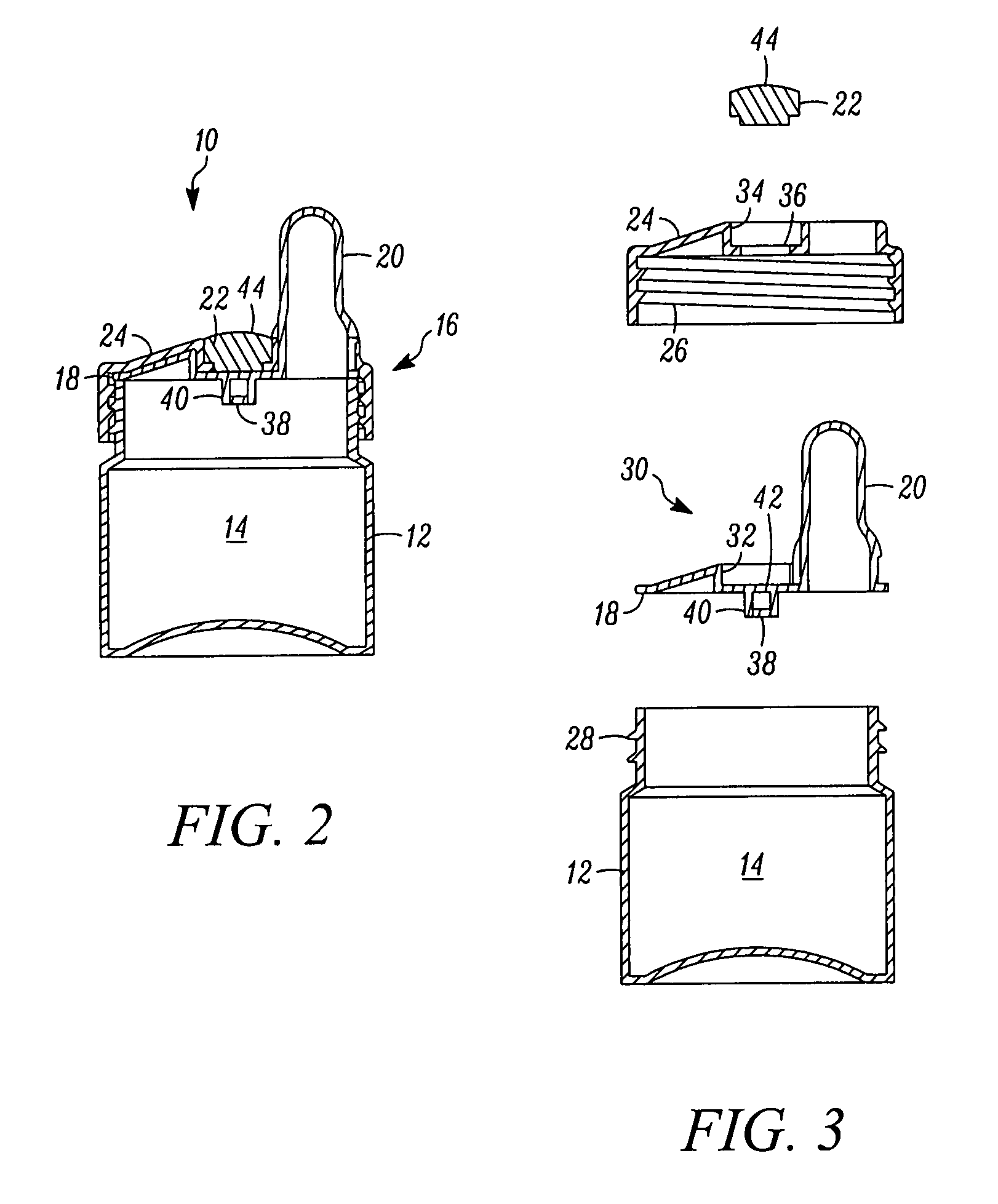

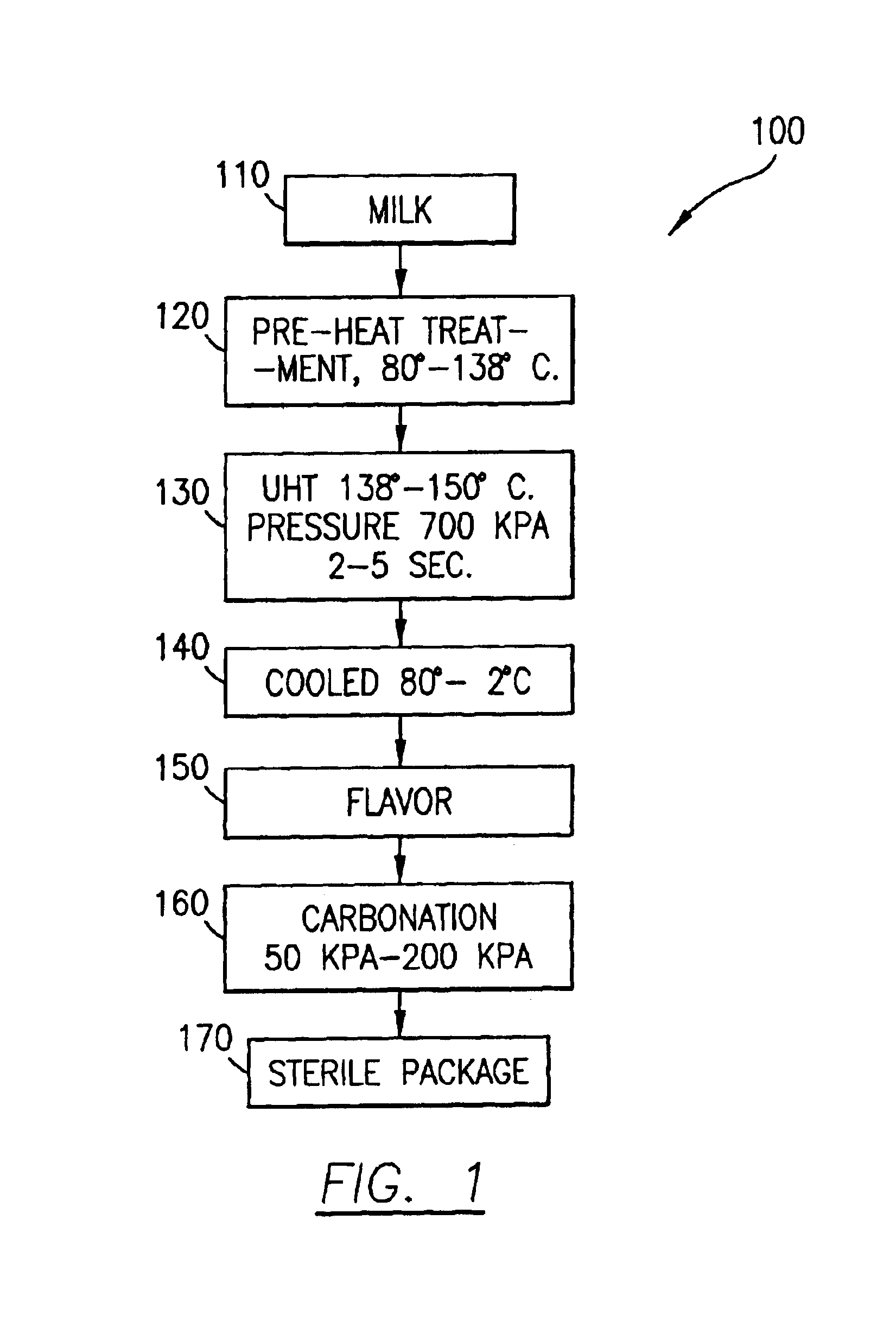

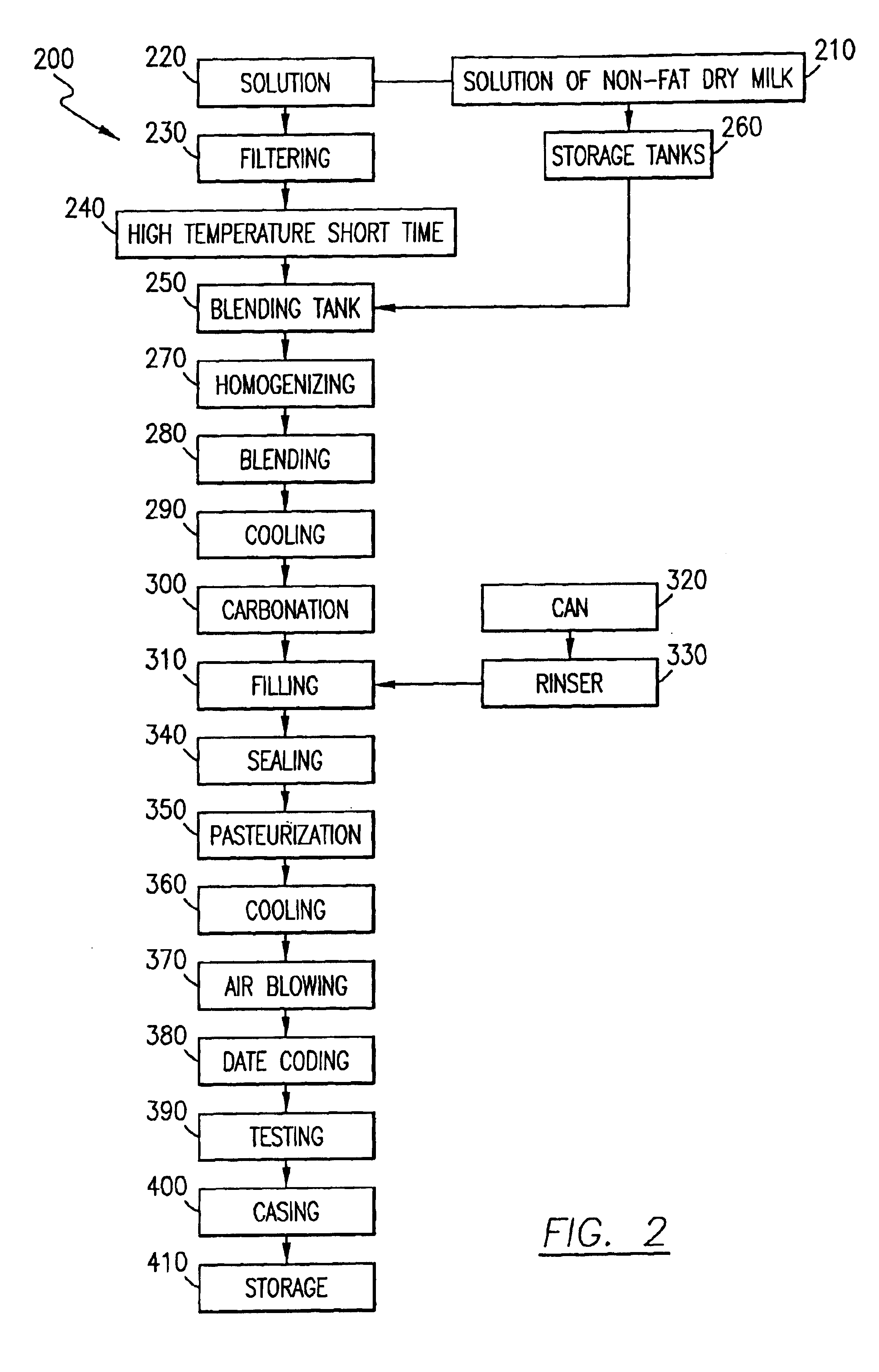

Process for making shelf-stable carbonated milk beverage

An aerated or carbonated milk product drink having a shelf stable pre-heated and pressurized ultra-heat treated milk product which has been carbonated with a gas or gases under pressure and packaged into a container. The milk product may be natural or artificial milk product including dairy products and non-dairy milk products and includes combinations of milk products with other beverages such as fruit juices. The method of producing the shelf-stable carbonated milk product of the present invention comprises injecting under pressure carbon dioxide gas or a mixture of gases into the milk product at low temperature of less than 10 degrees centigrade and high pressure of from 50 kpa to 200 kpa. The carbonated milk product remains carbonated and shelf stable in the package until opened.

Owner:KROLL DIANE +1

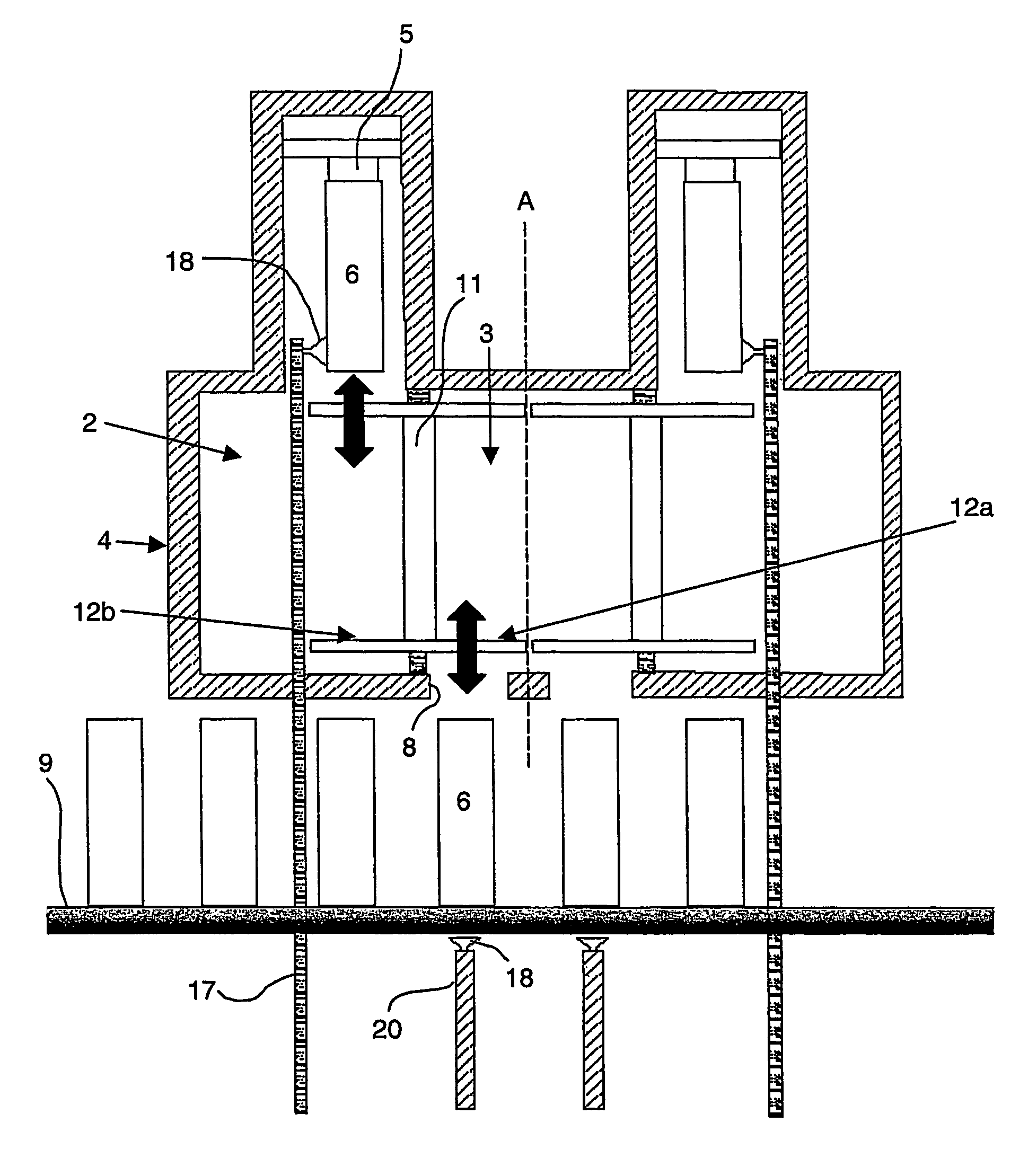

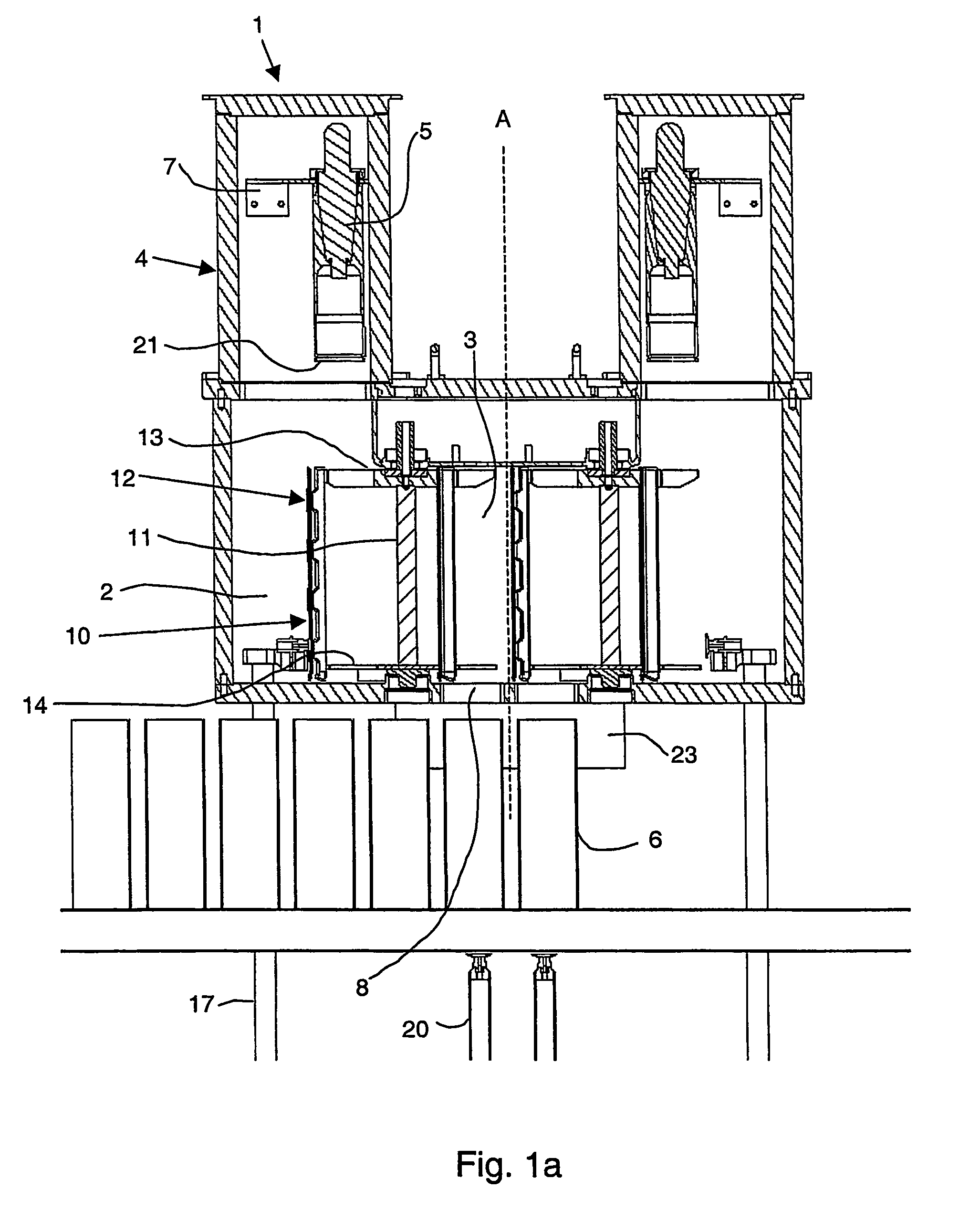

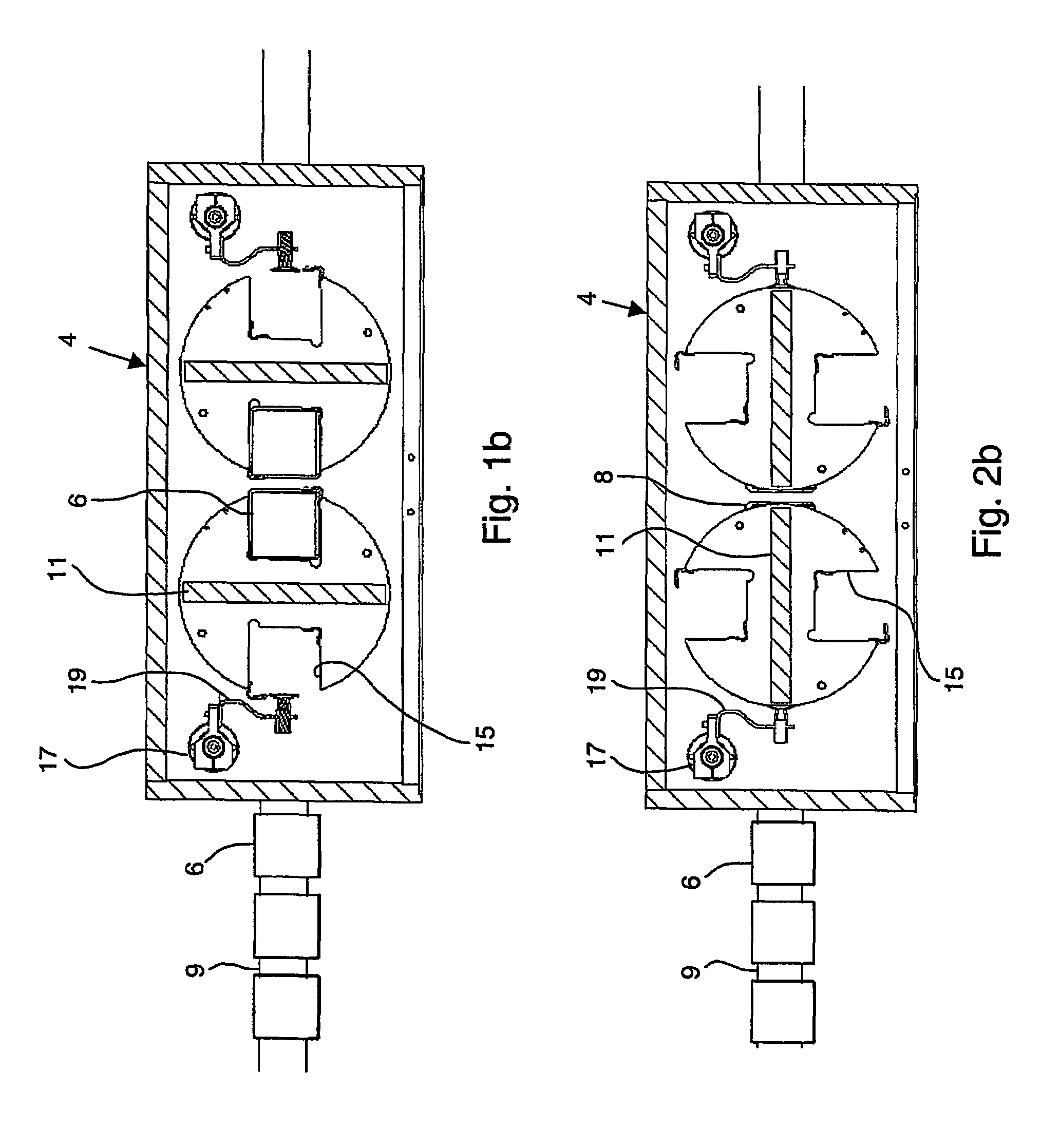

Device and method for sterilization

InactiveUS20060159583A1Risk minimizationEffectively and reliably dischargedElectrolysis componentsPackage sterilisationEngineeringBiomedical engineering

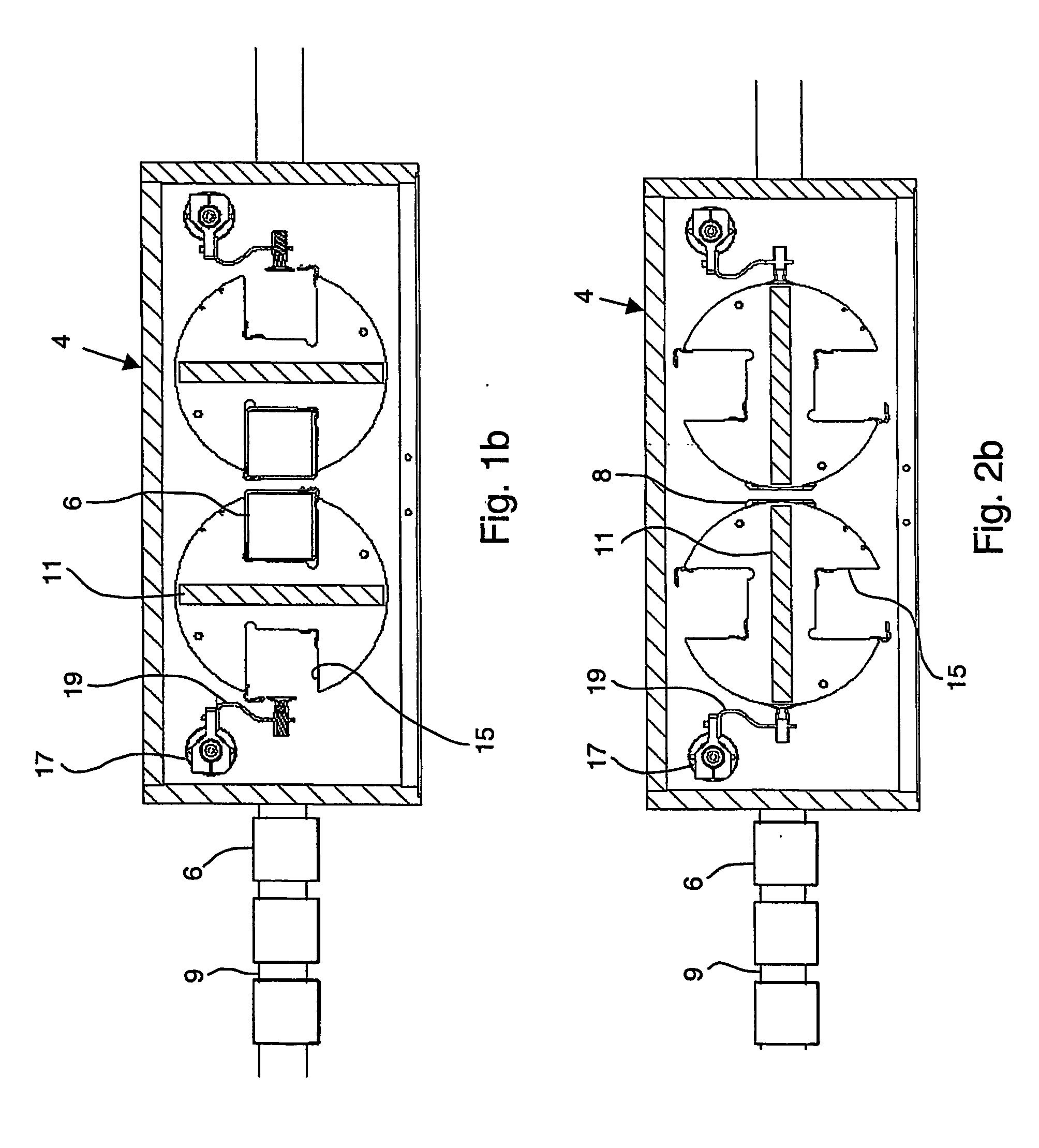

The invention refers to a device (1) and method for sterilizing partly formed packages (6) in a packaging machine. The device (1) comprises an inner chamber (2) and an outer chamber (3), the inner chamber (2) being provided with a sterilization unit (5). Further, it comprises a carrier unit (10), comprising a separating member (11) and a package carrying member (12), which is being adapted to rotate between a first position in which the package carrying member (12) is located in the outer chamber (3), and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3), and a second position in which the carrier unit (10) has rotated a package (6) into the inner chamber (2) and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3).

Owner:TETRA LAVAL HLDG & FINANCE SA

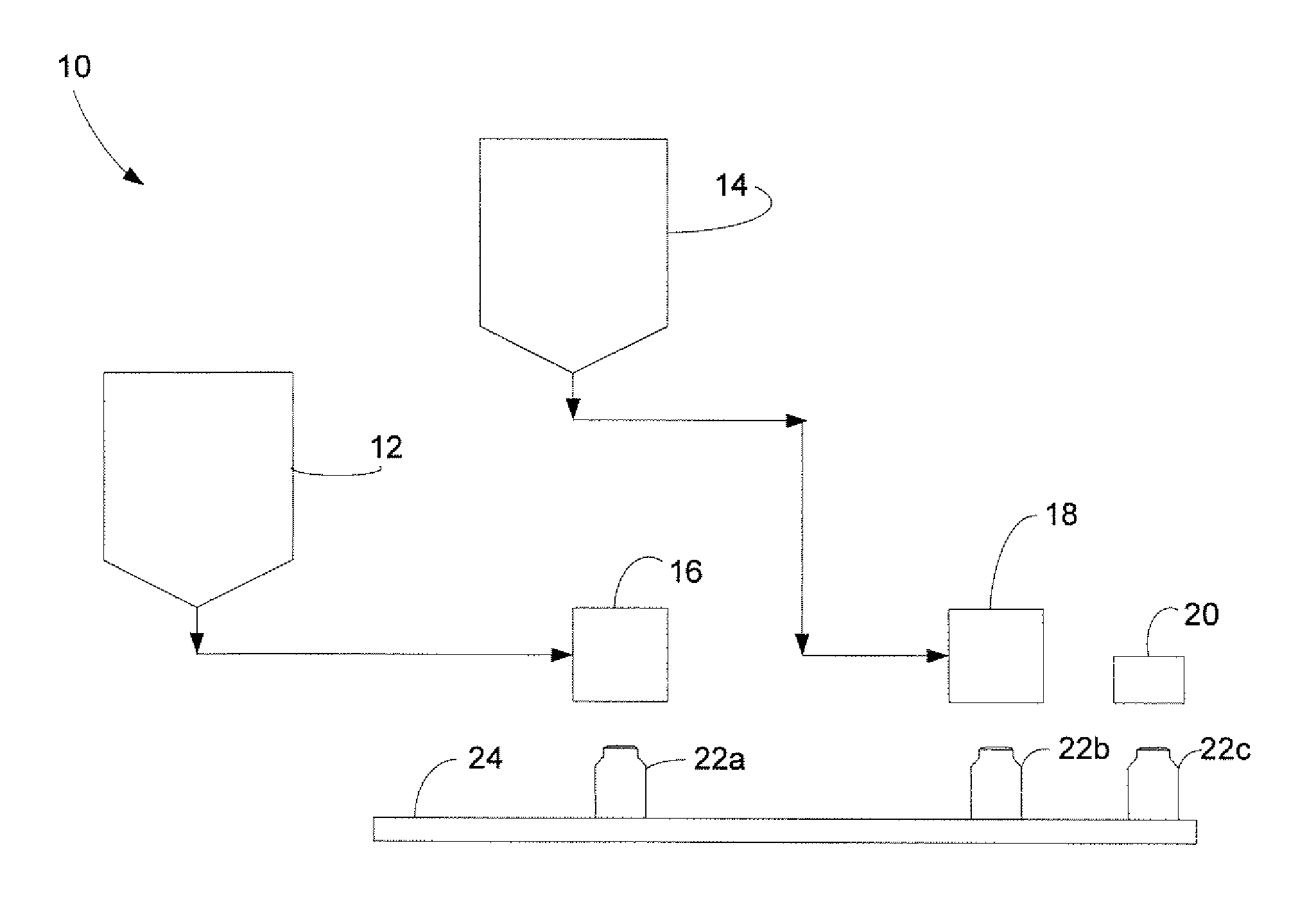

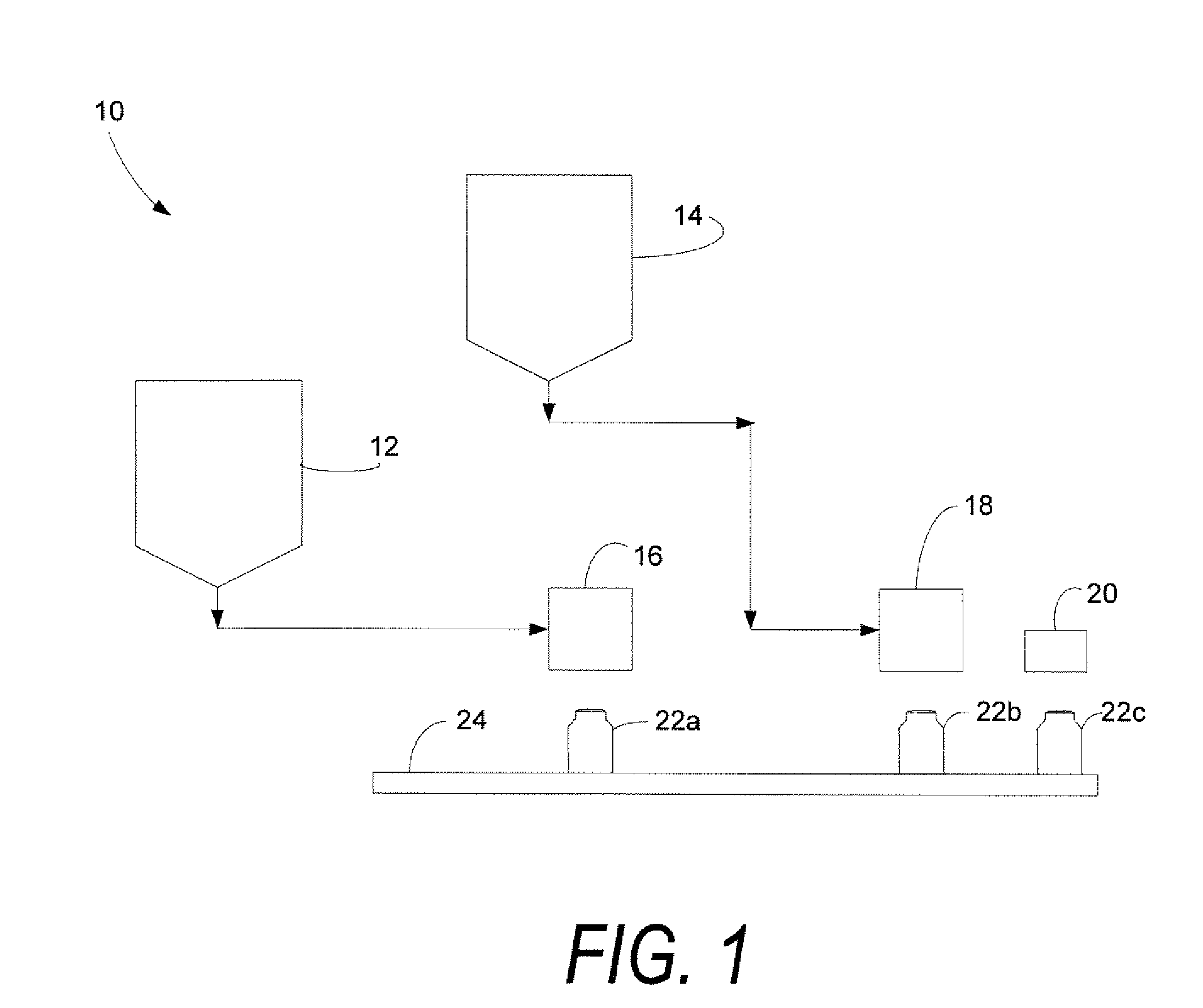

Method for formulating and aseptically filling liquid products

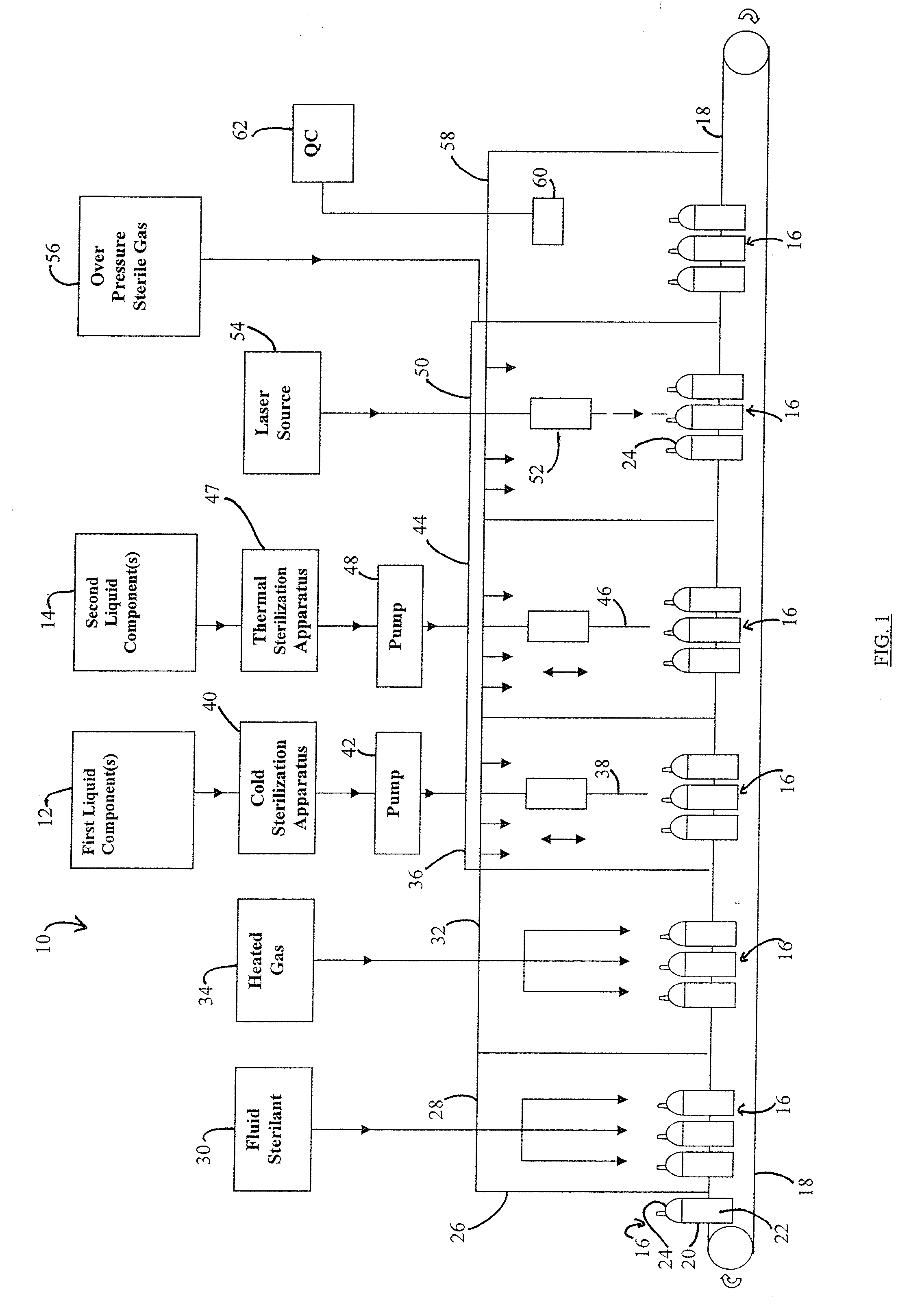

InactiveUS20090098250A1Readily apparentMilk preparationFruit and vegetables preservationFirst FillLiquid product

An apparatus and method are provided for formulating and aseptically filling liquid products. A first liquid source includes at least one first liquid component; a second liquid source includes at least one second liquid component; and a container includes a body defining an empty, sterile storage chamber therein that is sealed with respect to ambient atmosphere. The container is introduced into a sterile filling chamber. A first filling member coupled in fluid communication with the first liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the first liquid component is aseptically introduced through the first filling member and into the storage chamber. A second filling member coupled in fluid communication with the second liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the second liquid component is aseptically introduced through the second filling member and into the storage chamber and, in turn, the first and second liquid components are combined into a liquid product formulation within the sterile chamber of the container. The first and second filling members are withdrawn from fluid communication with the storage chamber of the container located within the sterile filling chamber, and the filled storage chamber is sealed with respect to ambient atmosphere to hermetically seal the liquid product formulation within the storage chamber of the container.

Owner:MEDINSTILL DEV

Ready to drink container with nipple and needle penetrable and laser resealable portion, and related method

A container is provided for storing a product, such as a fat containing liquid product, and includes a body defining a chamber for receiving the product; and a container closure including a sealing portion for sealing the product within the chamber. The container closure includes a member forming a substantially fluid-tight seal between the container closure and the body; a nipple in fluid communication with the chamber that seals the chamber with respect to the ambient atmosphere during storage of the product in the chamber and that can be opened to dispense product from the chamber therethrough; and a needle penetrable and laser resealable portion that is penetrable by the needle for aseptically filling the chamber with the product, and that is thermally resealable by the application of laser radiation thereto to seal the product within the chamber.

Owner:MEDINSTILL DEV

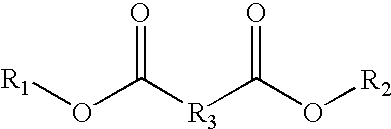

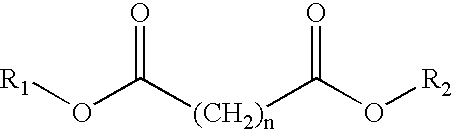

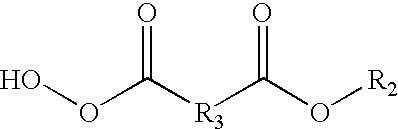

In situ mono-or diester dicarboxylate compositions

InactiveUS7060301B2Reduce the populationMicroorganism population reductionBiocideOrganic chemistryPharmaceutical industryCarboxylic acid

The present invention relates to in situ compositions of mono- or diester dicarboxylates, methods employing these in situ compositions, and methods of making these in situ compositions. More particularly, the invention relates to mono- or diester dicarboxylate antimicrobial compositions that can reduce the population of microbes on various surfaces such as facilities, containers, or equipment found in food, beverage, or pharmaceutical processing, or in food, beverage, or pharmaceutical industries, at temperatures between about −70° C. to about 100° C.

Owner:ECOLAB USA INC

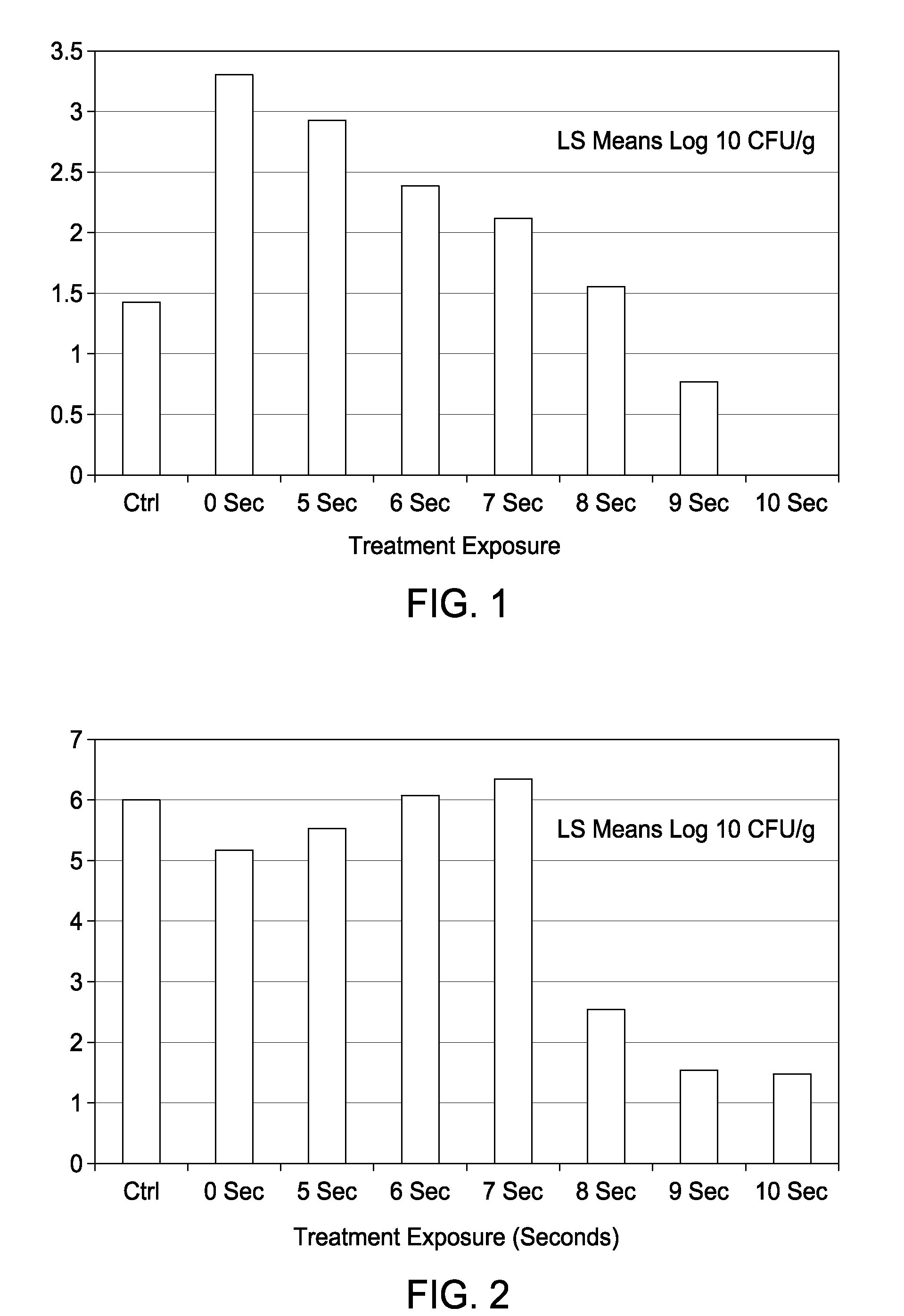

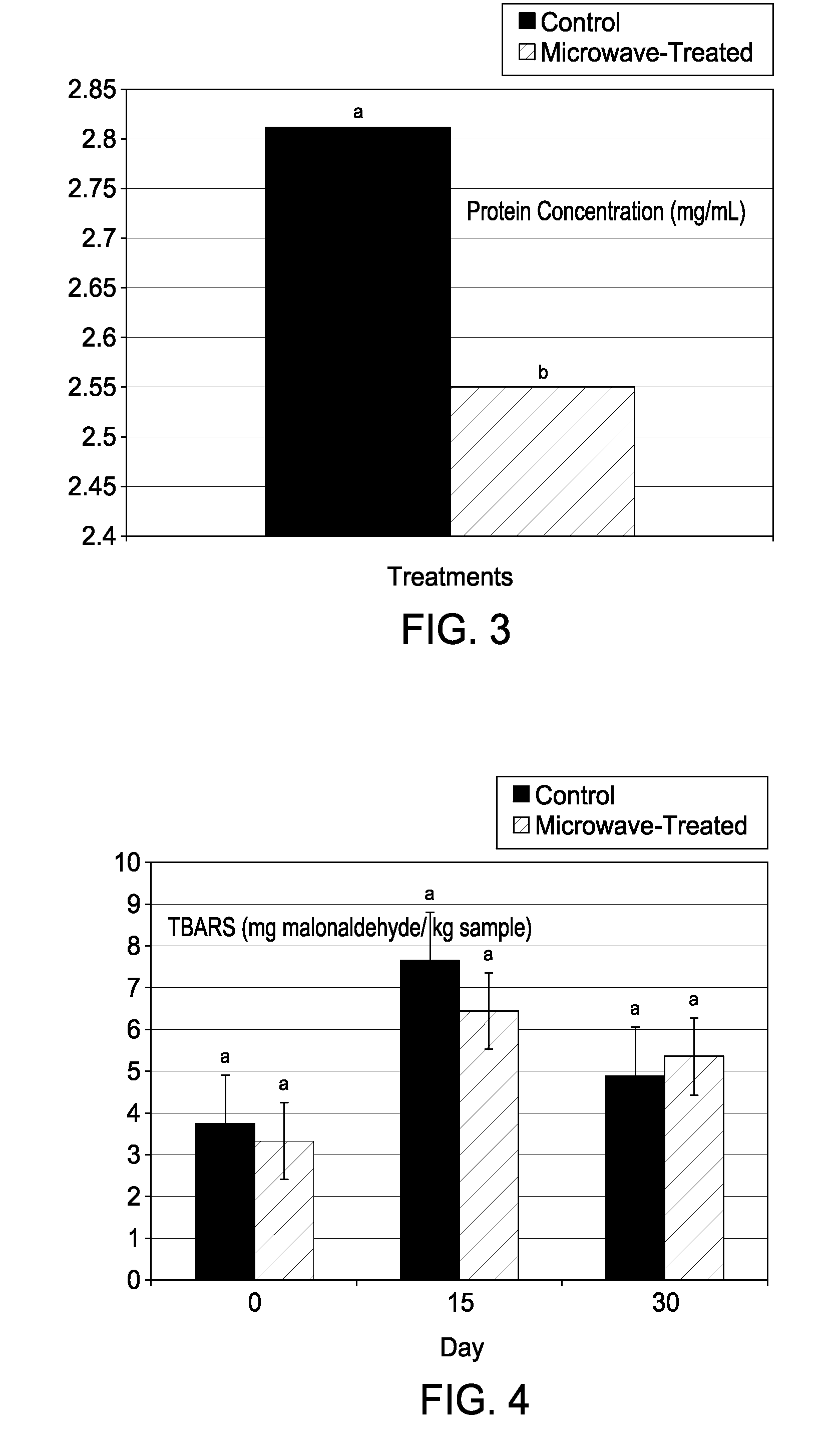

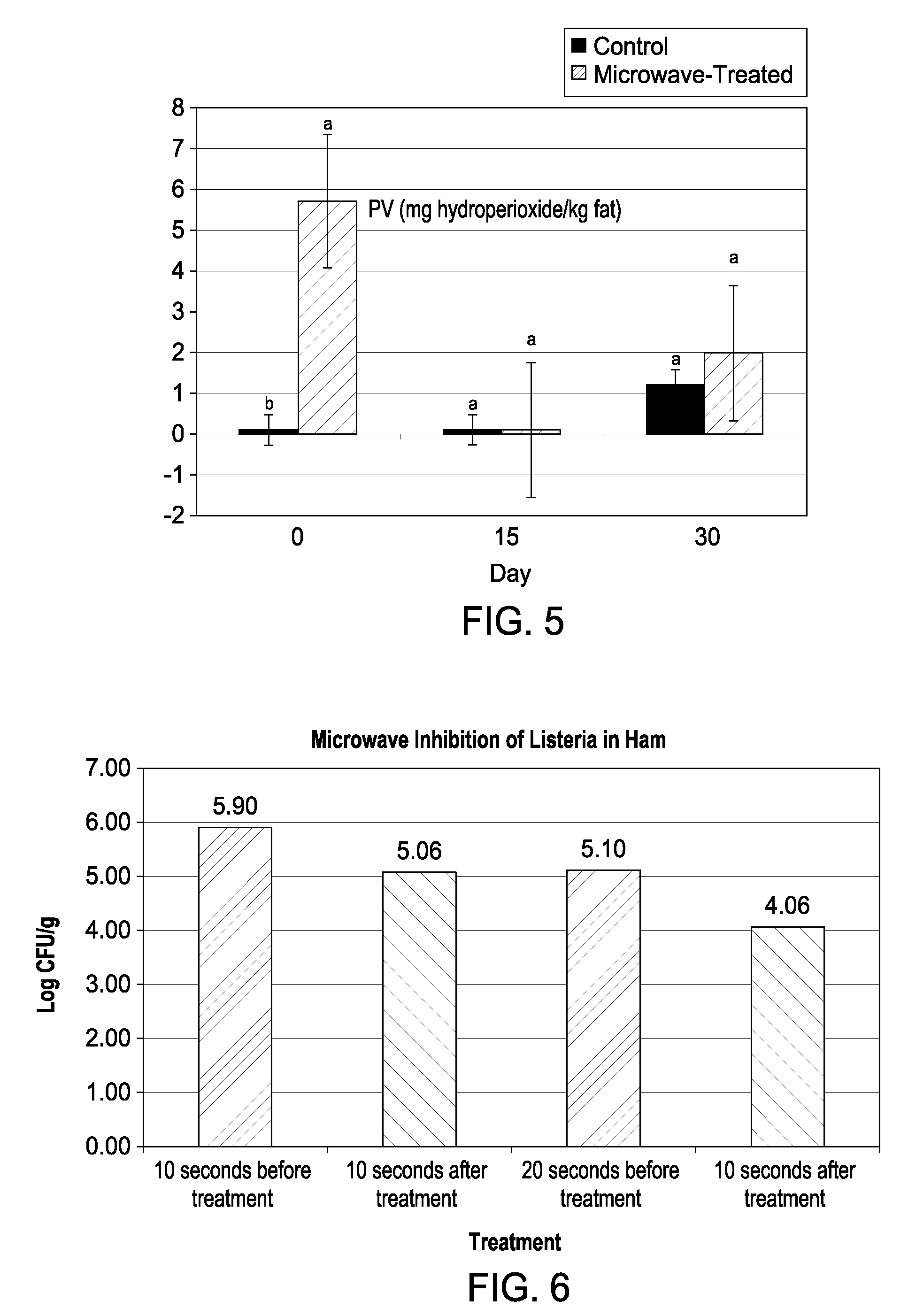

Method and system for preserving food

ActiveUS20090092708A1Easy to storeExtended shelf lifeMilk preparationReady-for-oven doughsMicrowavePreserved Foods

The present invention includes a method for extending the shelf-life of one or more foods by exposure to one or more pulses of microwave radiation for at least seven (7) seconds. The present invention may also be used to reduce pathogenic organisms in food. The one or more foods may be packaged within a container, sealed and stored.

Owner:TEXAS TECH UNIV SYST

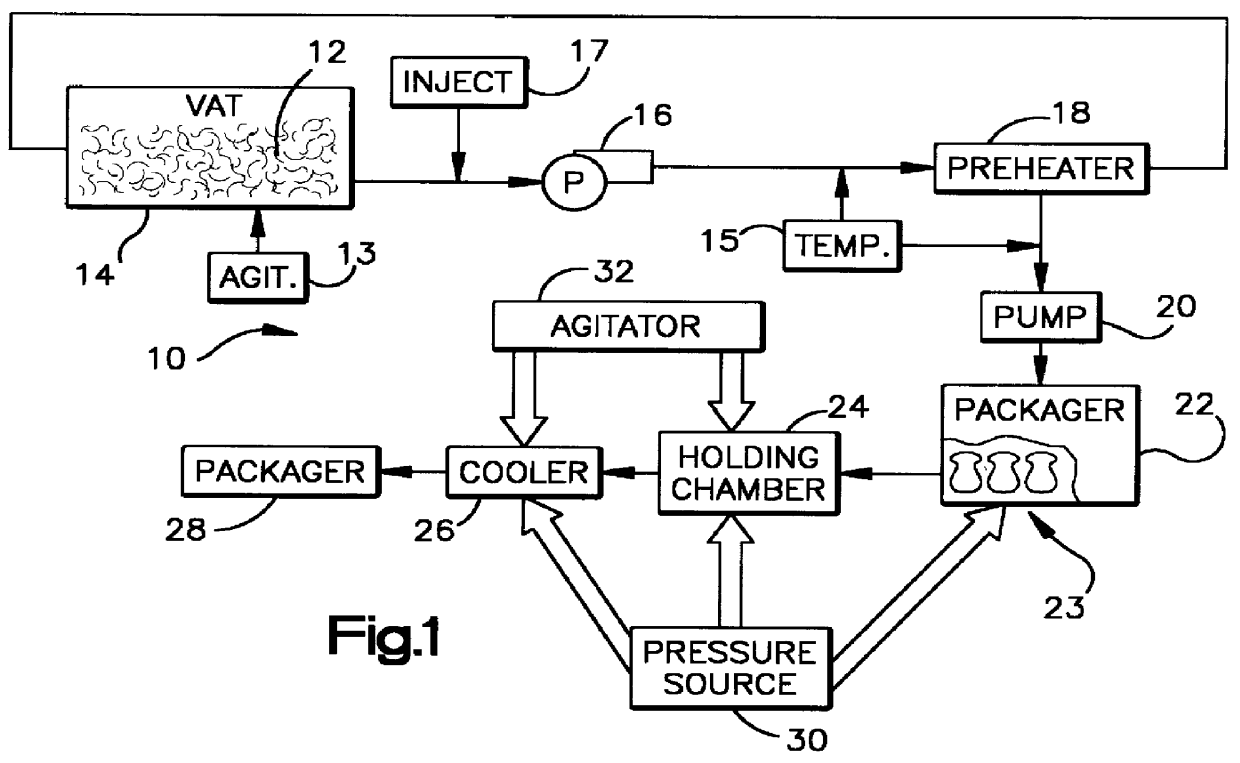

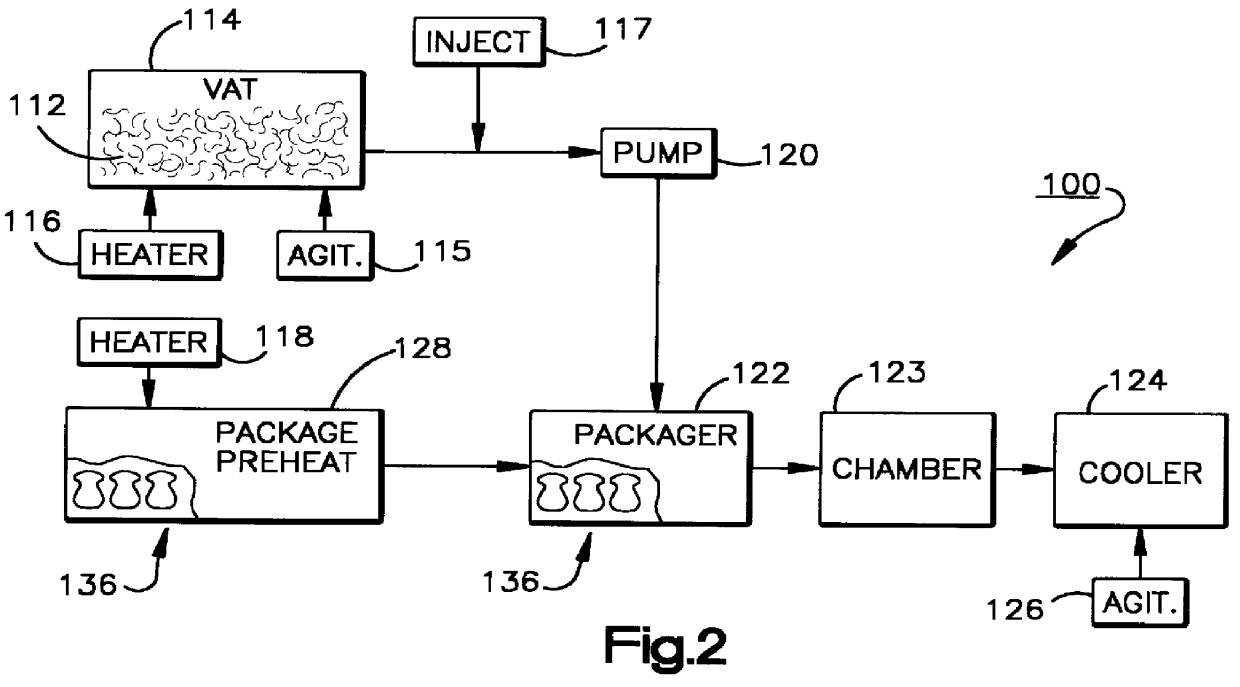

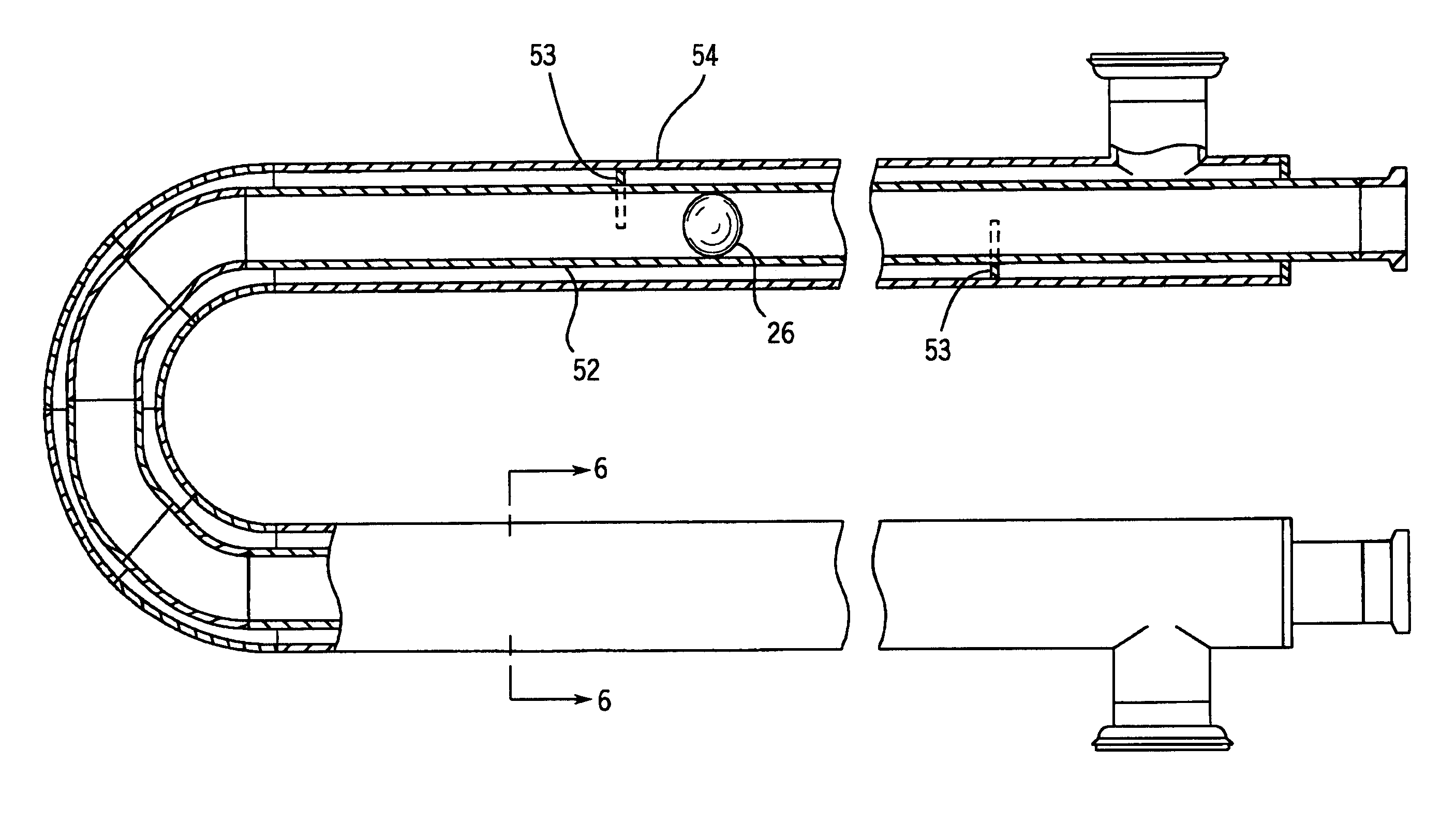

Egg processing system and method of using same to extend the refrigerated shelf life of liquid egg product

InactiveUS6090425AExtend refrigerated shelf lifeIncrease capacityEggs preservation by heatingPackaging protectionRefrigeration temperatureBiology

A process for producing pasteurized liquid egg product utilizing a vat or tank for holding raw egg product. The raw egg product is preheated as rapidly as possible to a temperature of about 140 DEG F. and then, without holding the temperature at a constant level, the preheated raw egg is transferred to a suitable package. The package containing the preheated raw egg product is then sealed and heated and maintained at a suitable temperature in order to pasteurize the liquid raw egg products in the packages. The heated containers and pasteurized liquid egg product are then cooled rapidly to a refrigeration temperature to further inhibit germination of any remaining bacterial spores. The containers are then stored in refrigeration conditions for distribution and use. In another embodiment, an egg product package is preheated to a temperature between 71.1 DEG C. and 55 DEG C. and then hot filled with a egg product treated to about the same temperatures as the package. The hot filled package is then sealed and allowed to stand for about 30 seconds and then it is rapidly cooled to at least about 5 DEG C. in a cooling time period of about 5 mintues.

Owner:SAMIMI MOHAMMAD H

Surface pasteurization of cooked food products

InactiveUS7285299B1Satisfies needReduce decreaseReady-for-oven doughsMilk preservationProcess engineeringPasteurization

A method of surface pasteurizing precooked food products which are contained in packages. The method preferably comprises the steps of continuously heating the packages of the precooked food product such that the outer surfaces of the products contained within the packages are taken to an effective pasteurization temperature and then continuously cooling the packages of product. The heating and cooling steps are preferably conducted in a manner such that no more than a 10° temperature increase and preferably substantially no temperature increase occurs in the internal core of the product as a result of the heating step.

Owner:UNITHERM FOOD SYST LLC

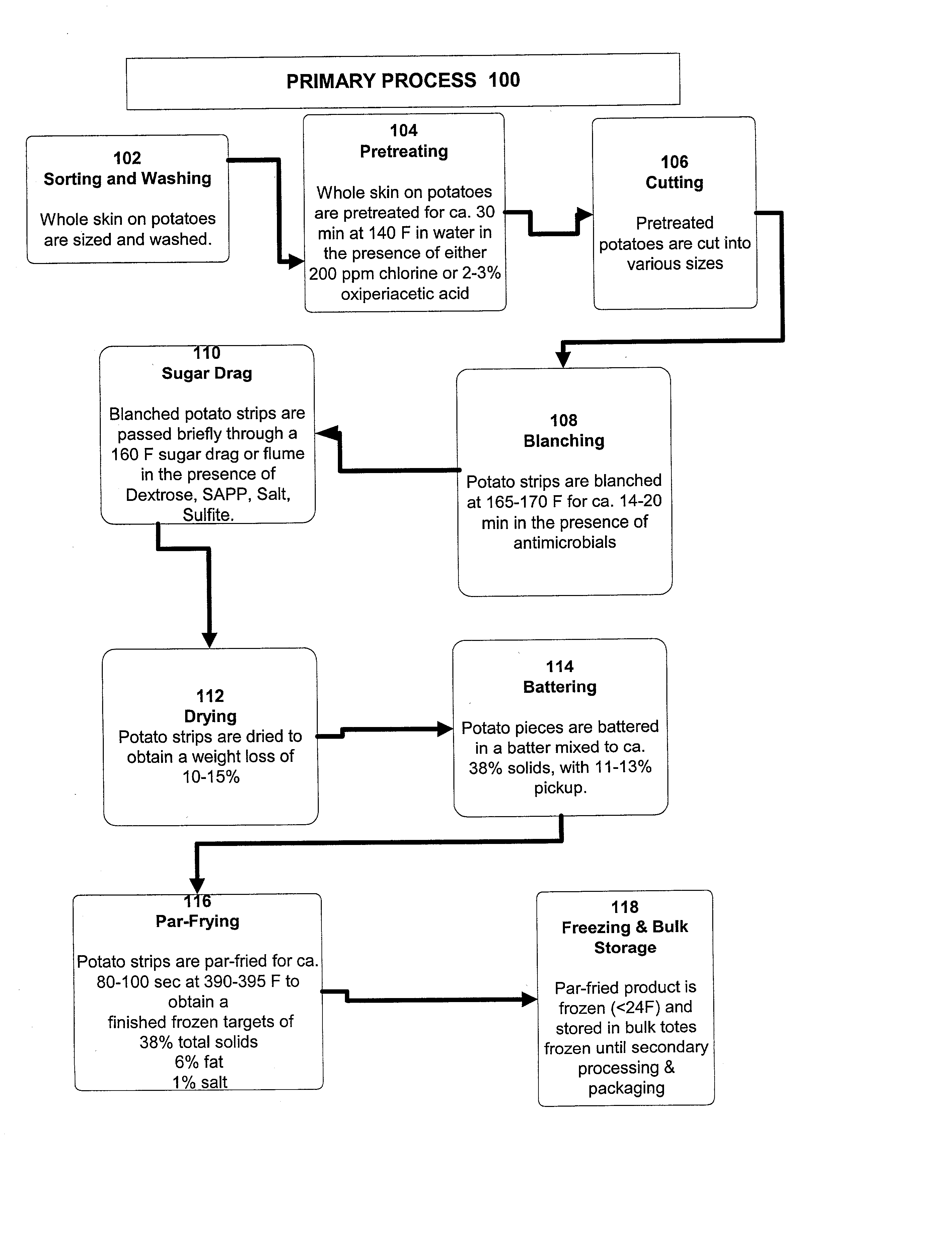

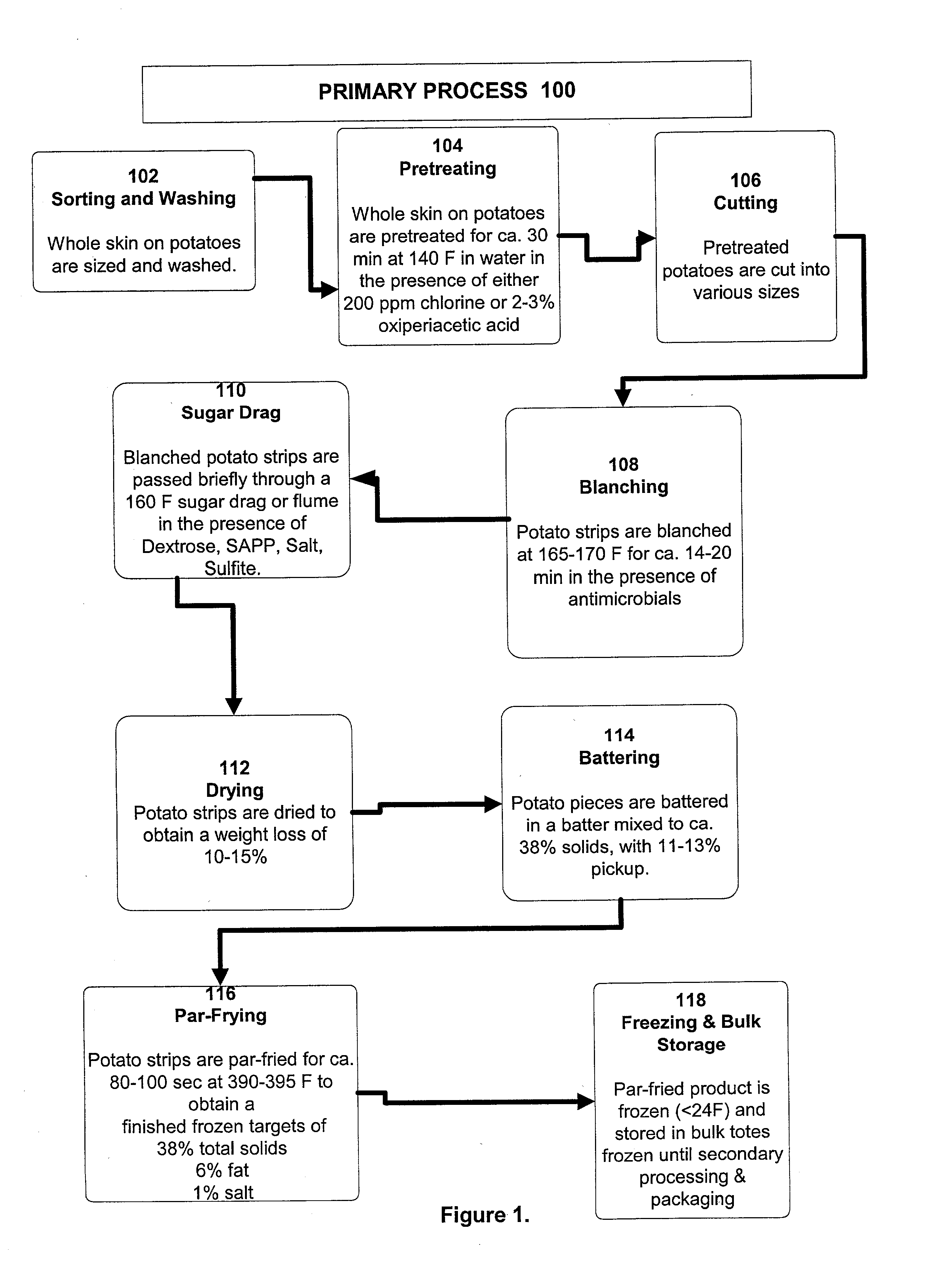

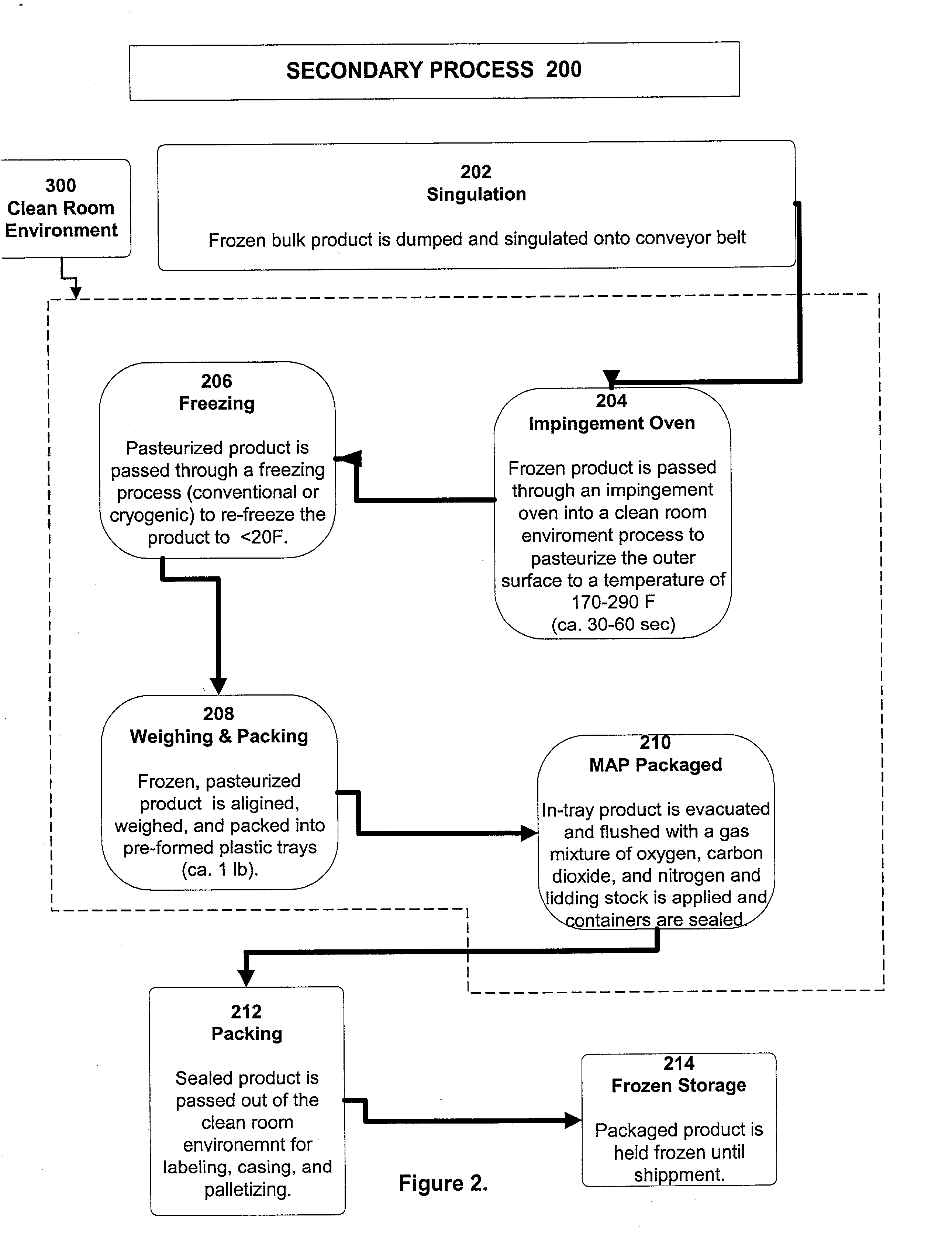

Process for preparing french fried potatoes having an extended shelf life at refrigerated temperatures and a reduced reconstitution time

InactiveUS20020127315A1Meat/fish preservationFruits/vegetable preservation by heatingRadurizationUltraviolet

Potato pieces are processed after a primary process by passing the potato products, preferably frozen or chilled, through a pasteurization process. The pasteurization process includes passing the potato products through an impingement oven, a steam tunnel, an ultra violet (UV) light exposure tunnel, radurization equipment, or combinations thereof, for thermal and / or non-thermal pasteurizing, in a clean room, to reduce or eliminate microbial load on the potato pieces.

Owner:HEINZ

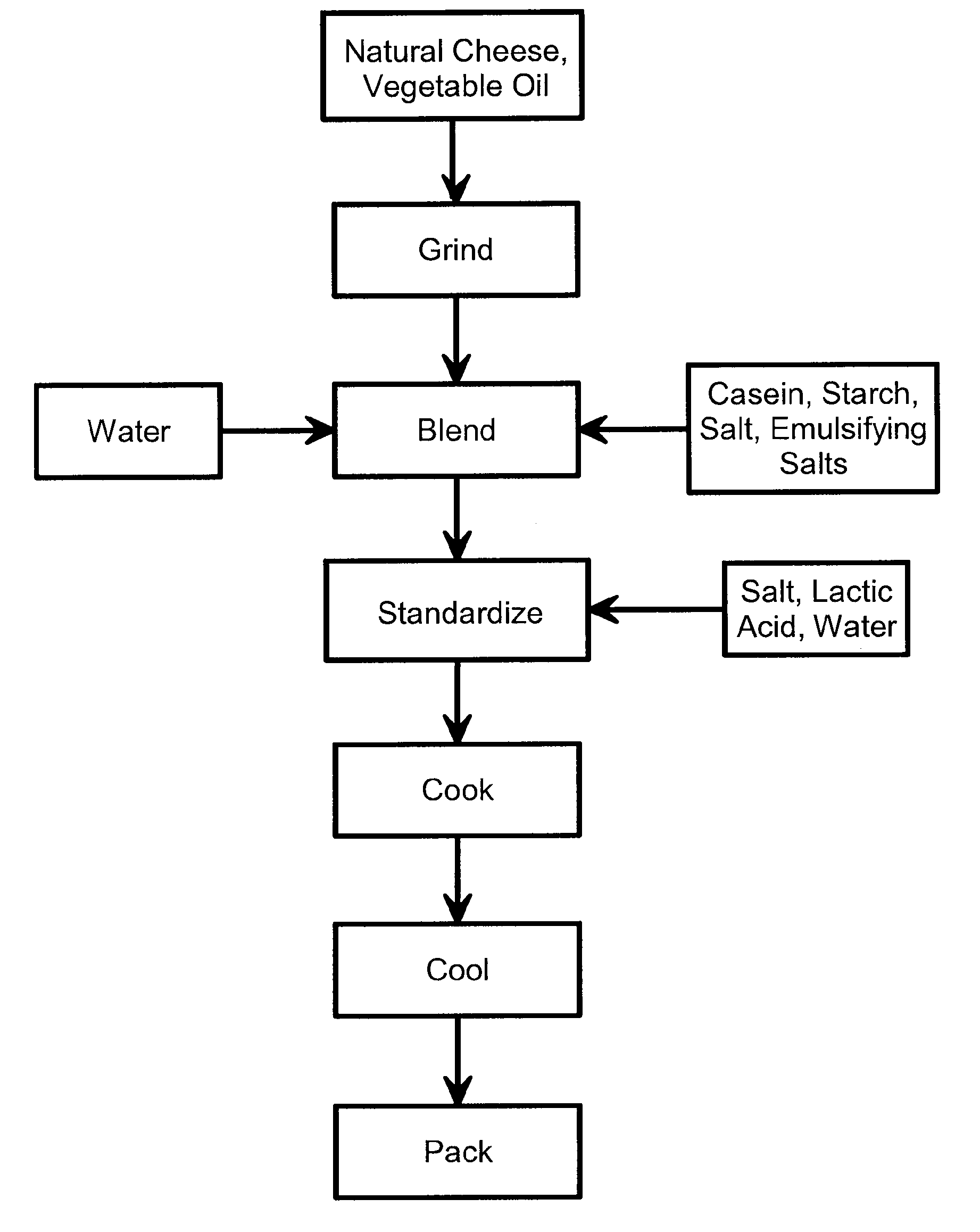

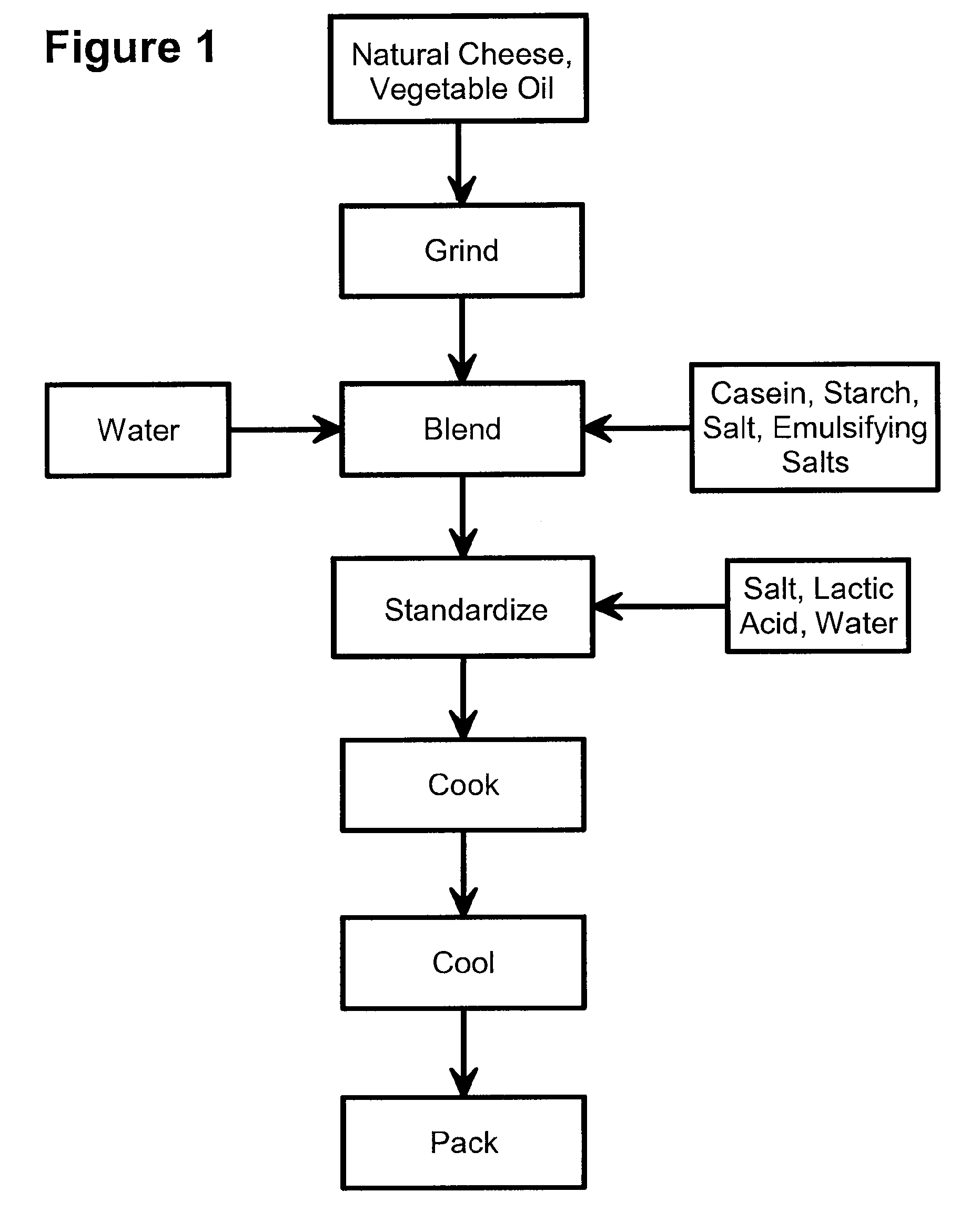

Process Cheese Products with Dual Functionality

InactiveUS20090061065A1Eggs preservation by coatingEggs preservation by irradiation/electric treatmentMultiple formsFood products

Owner:INTERCONTINENTAL GREAT BRANDS LLC

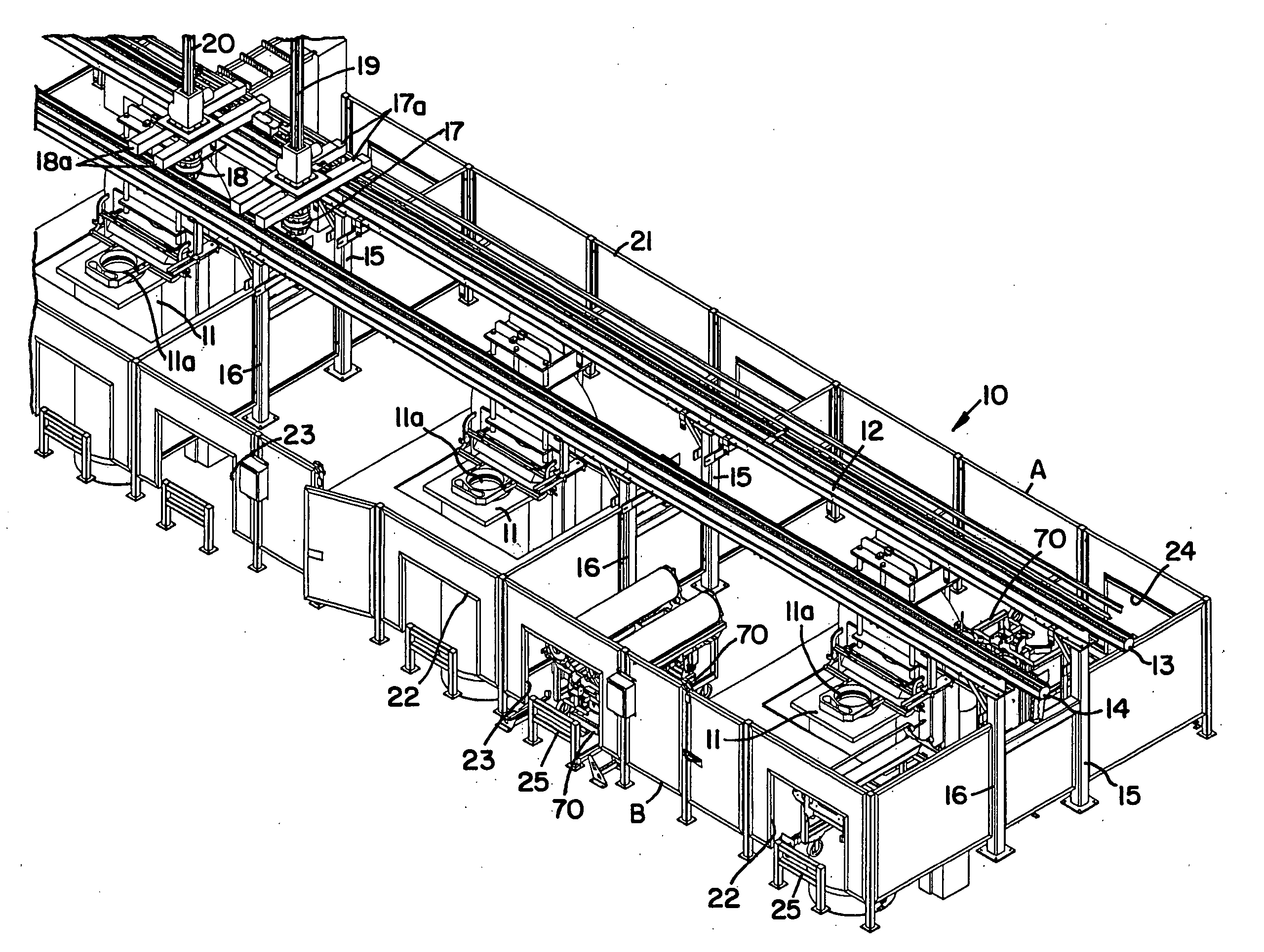

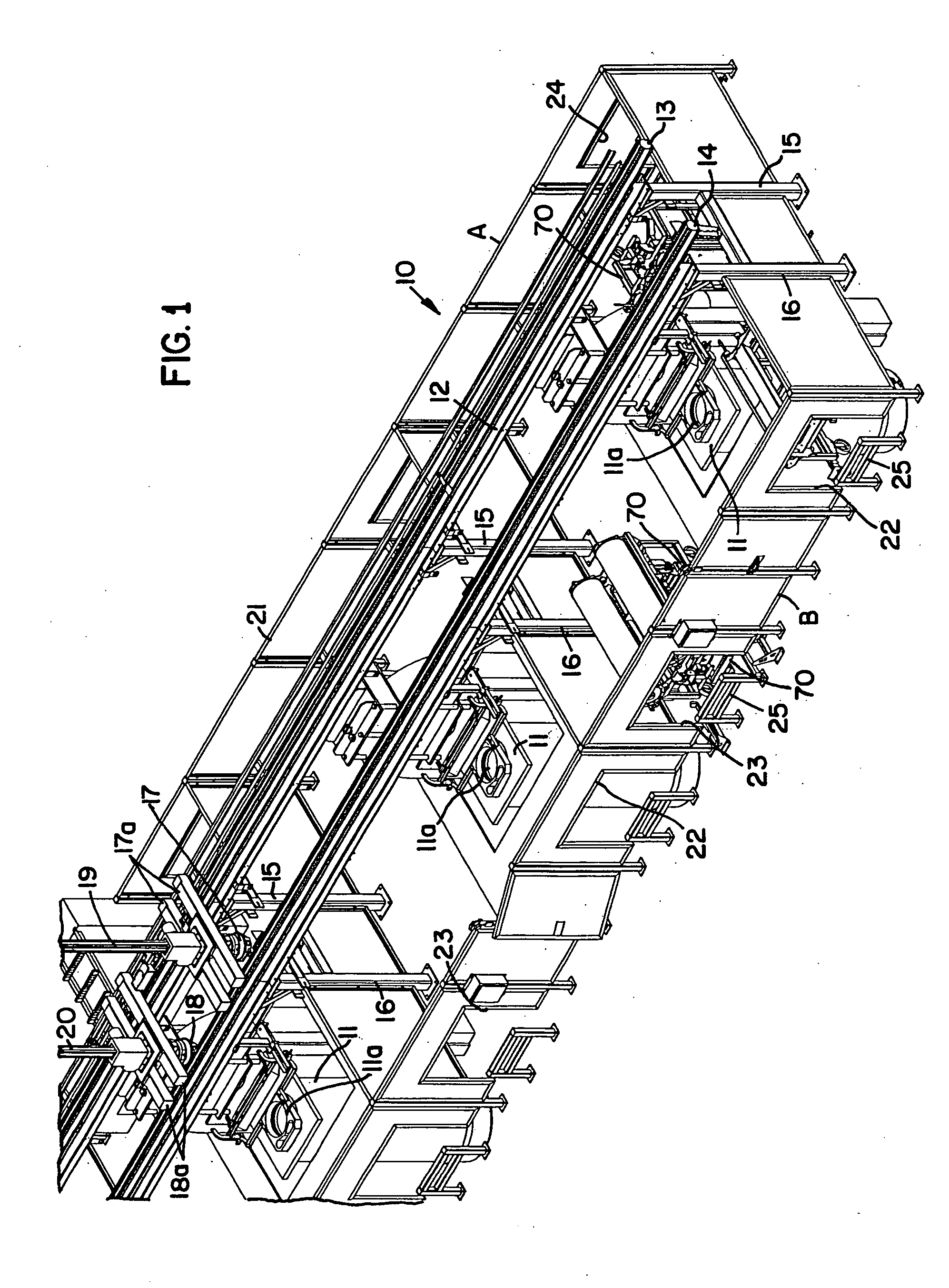

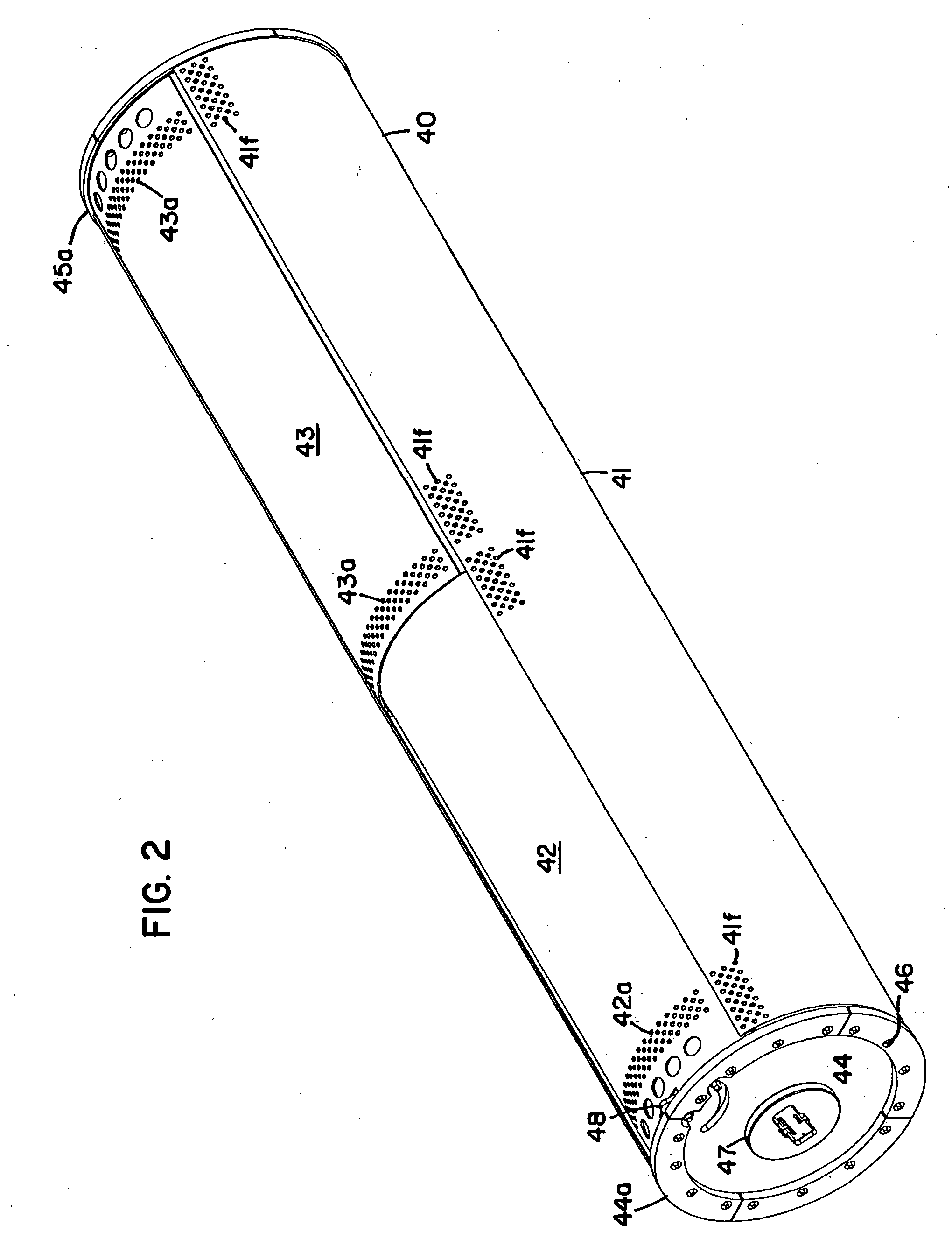

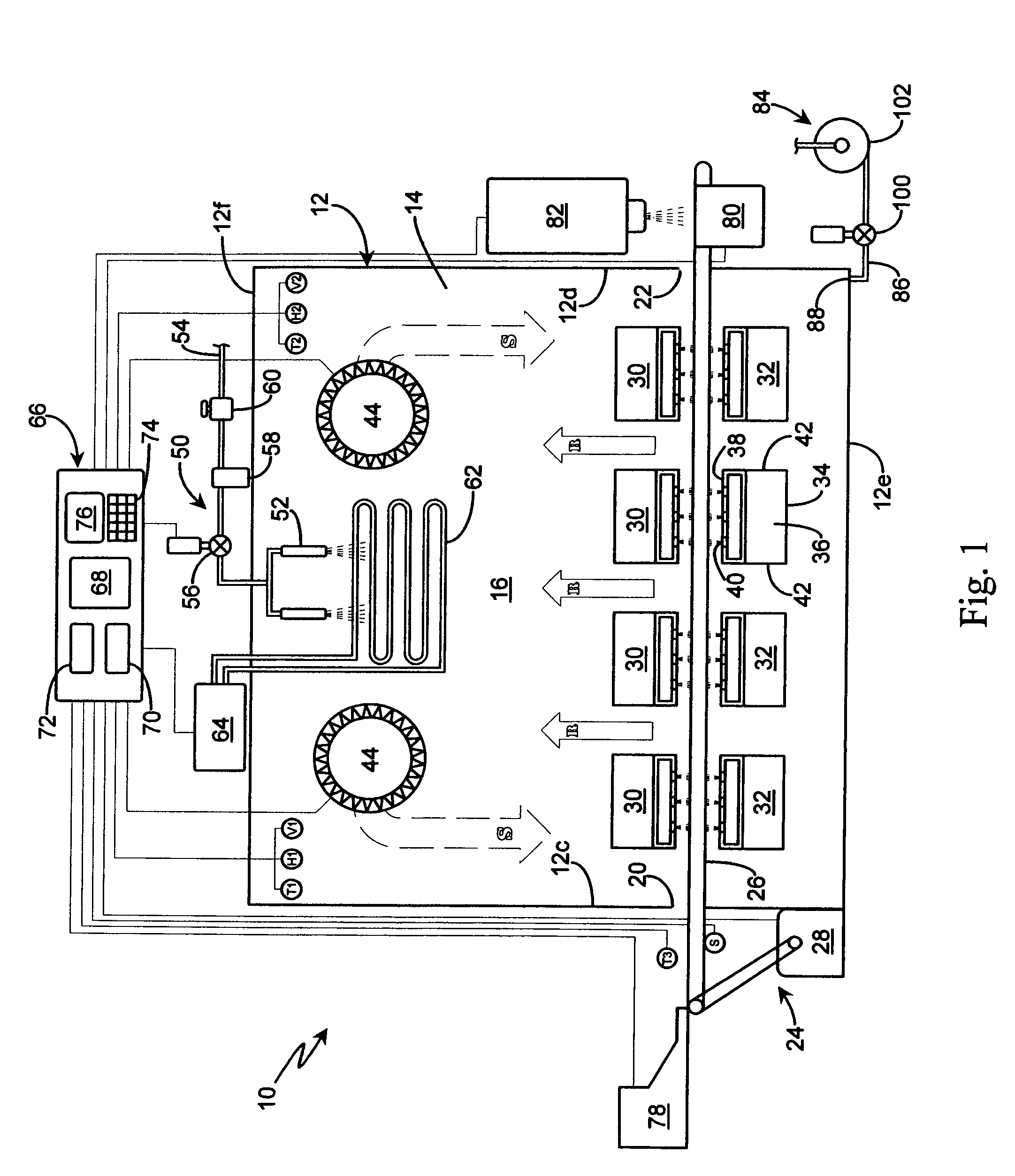

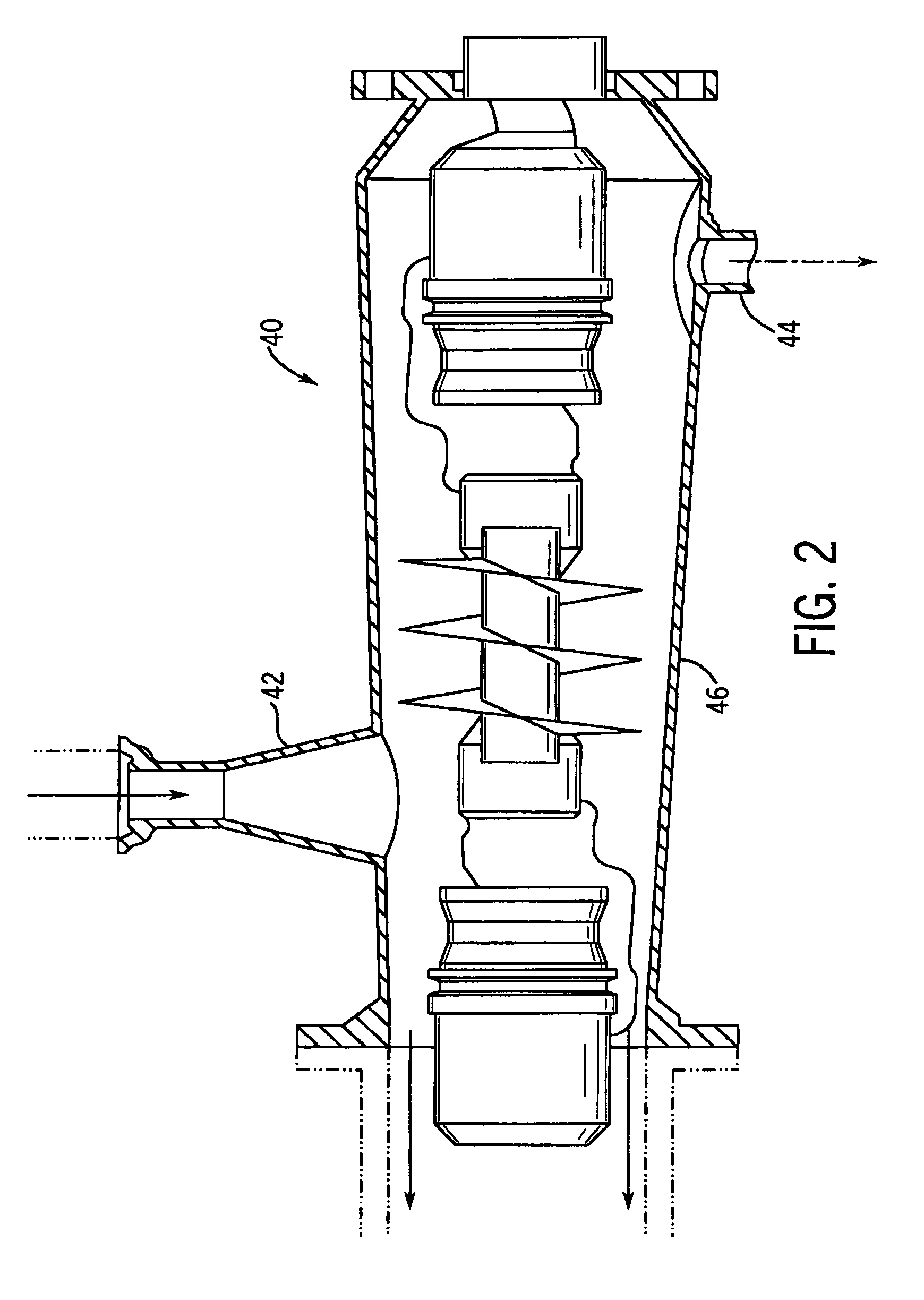

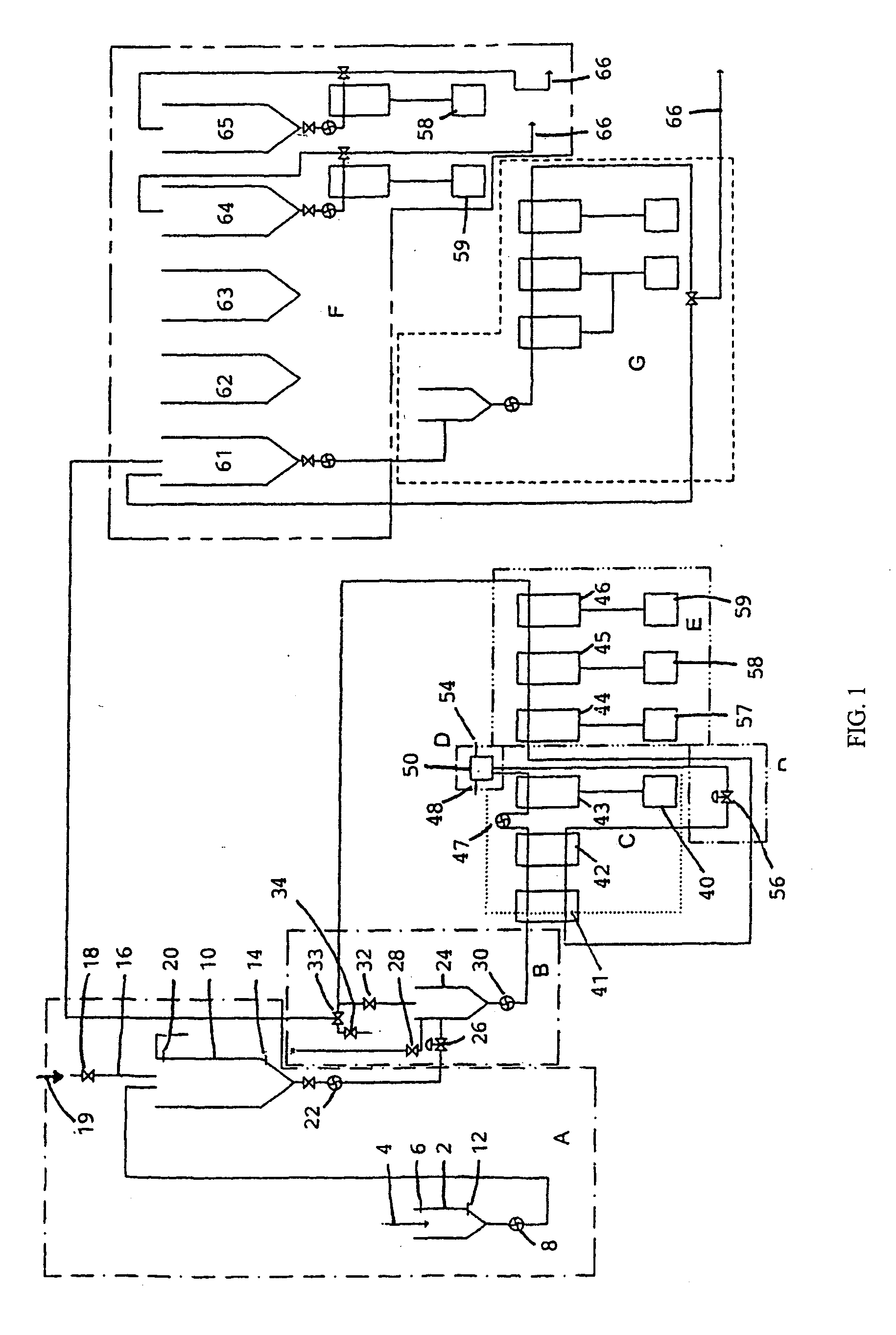

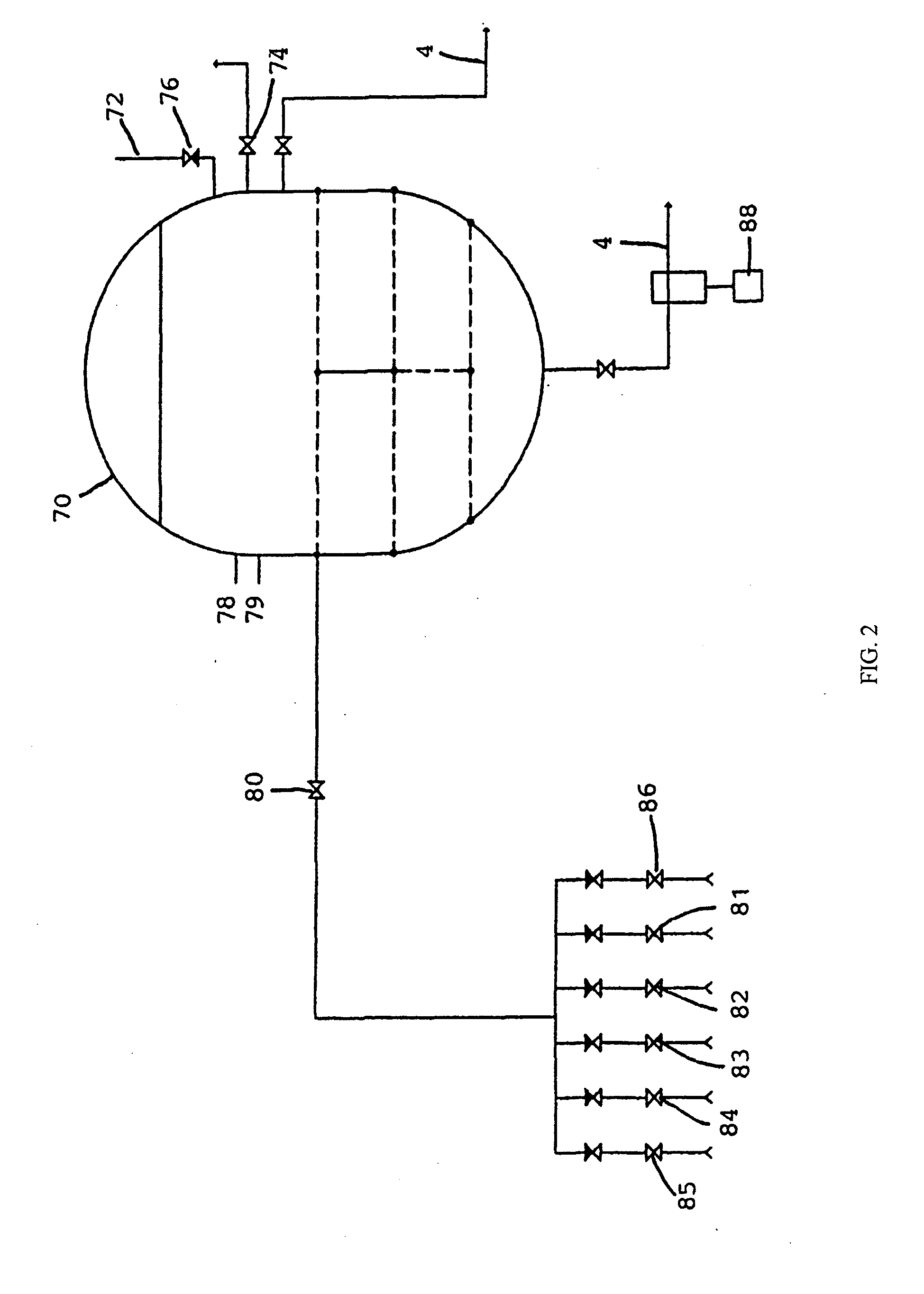

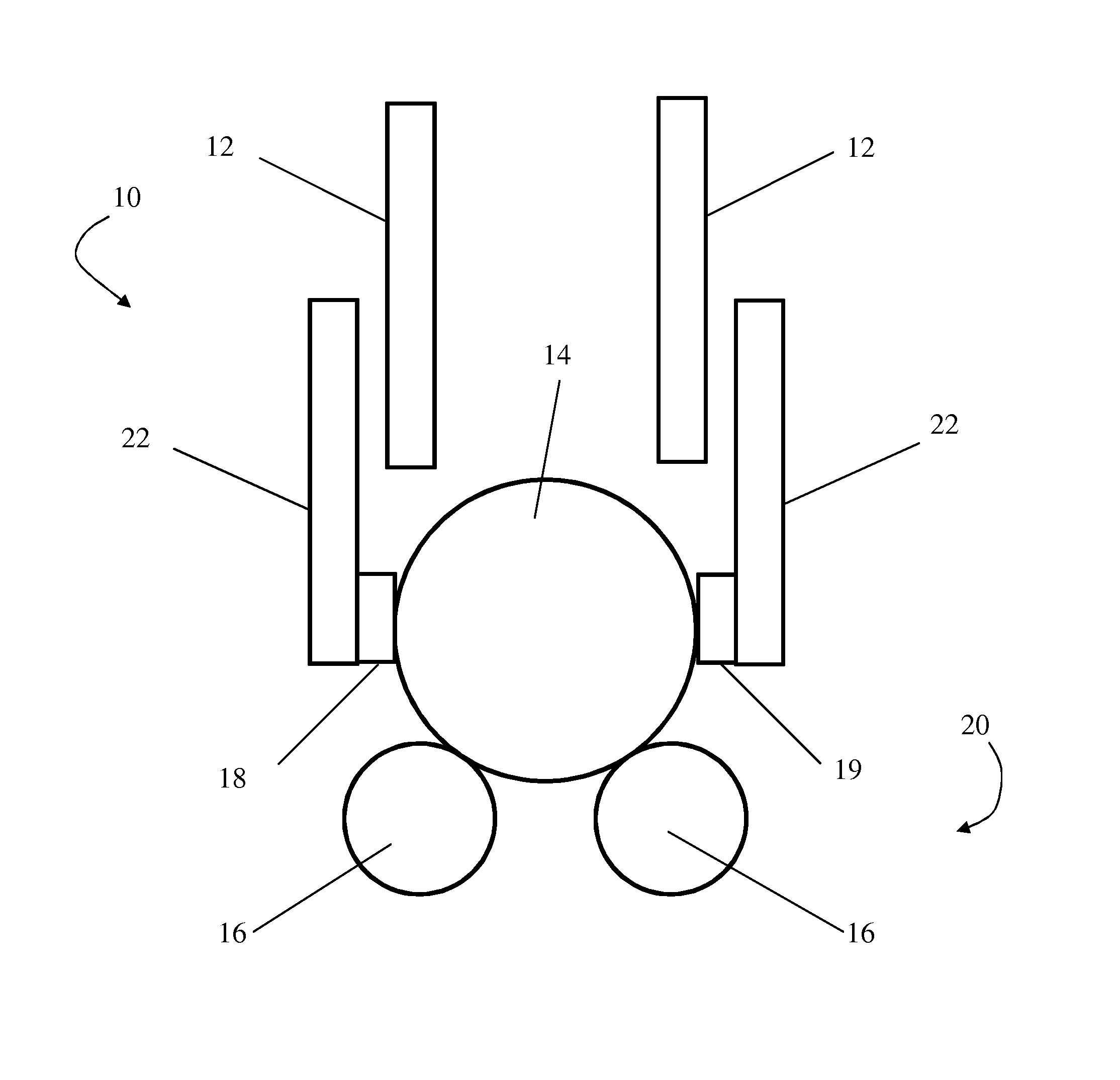

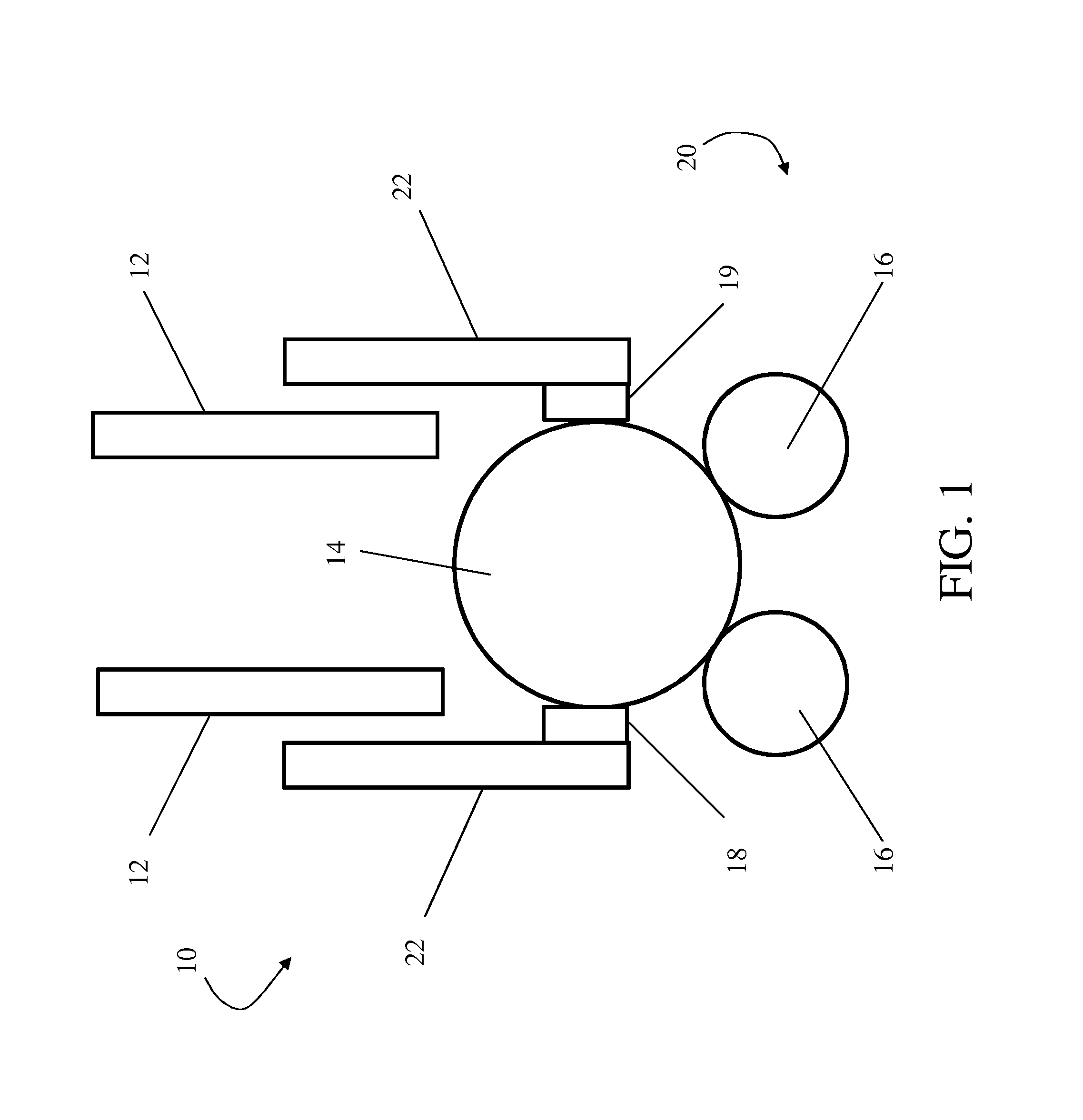

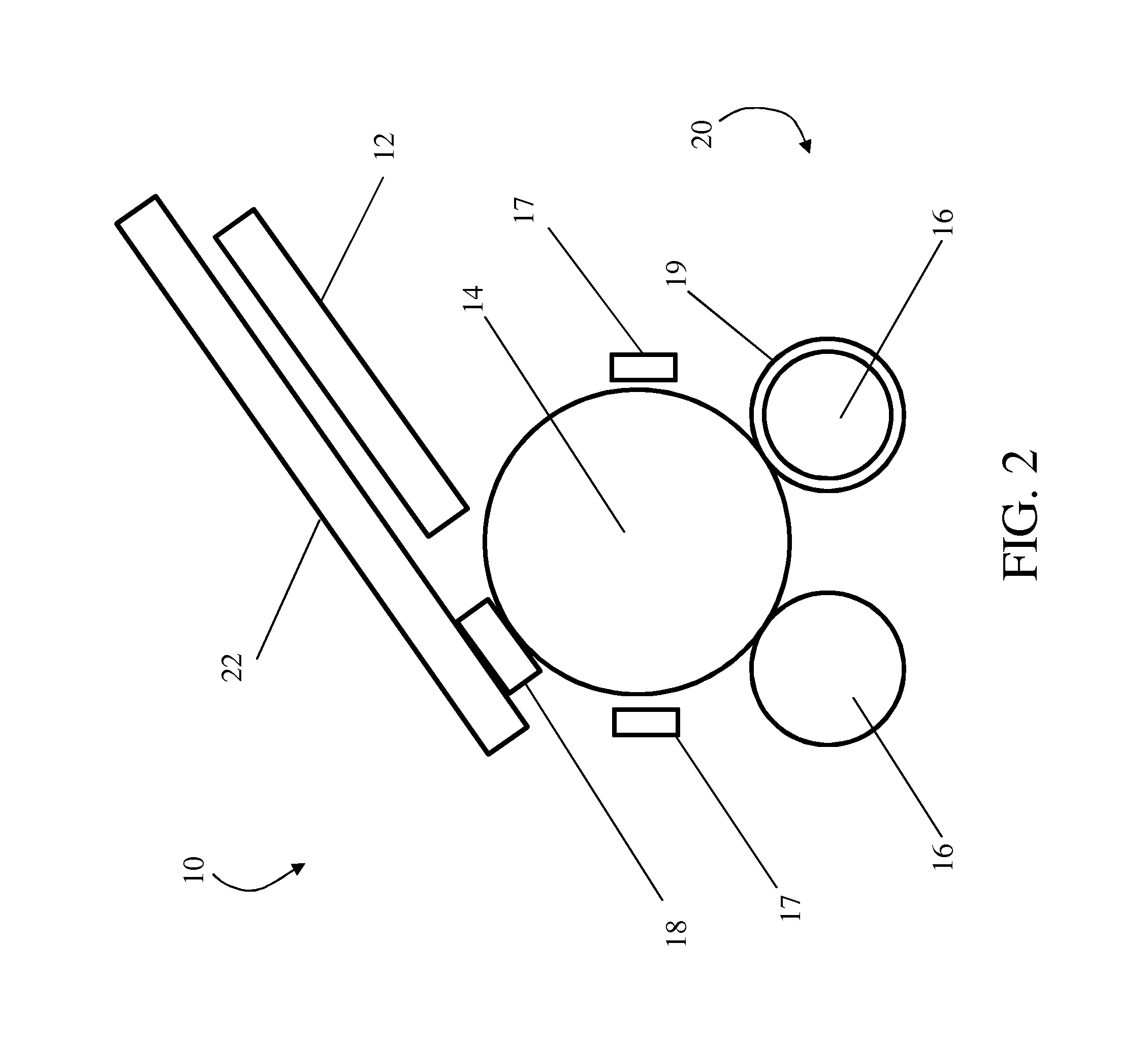

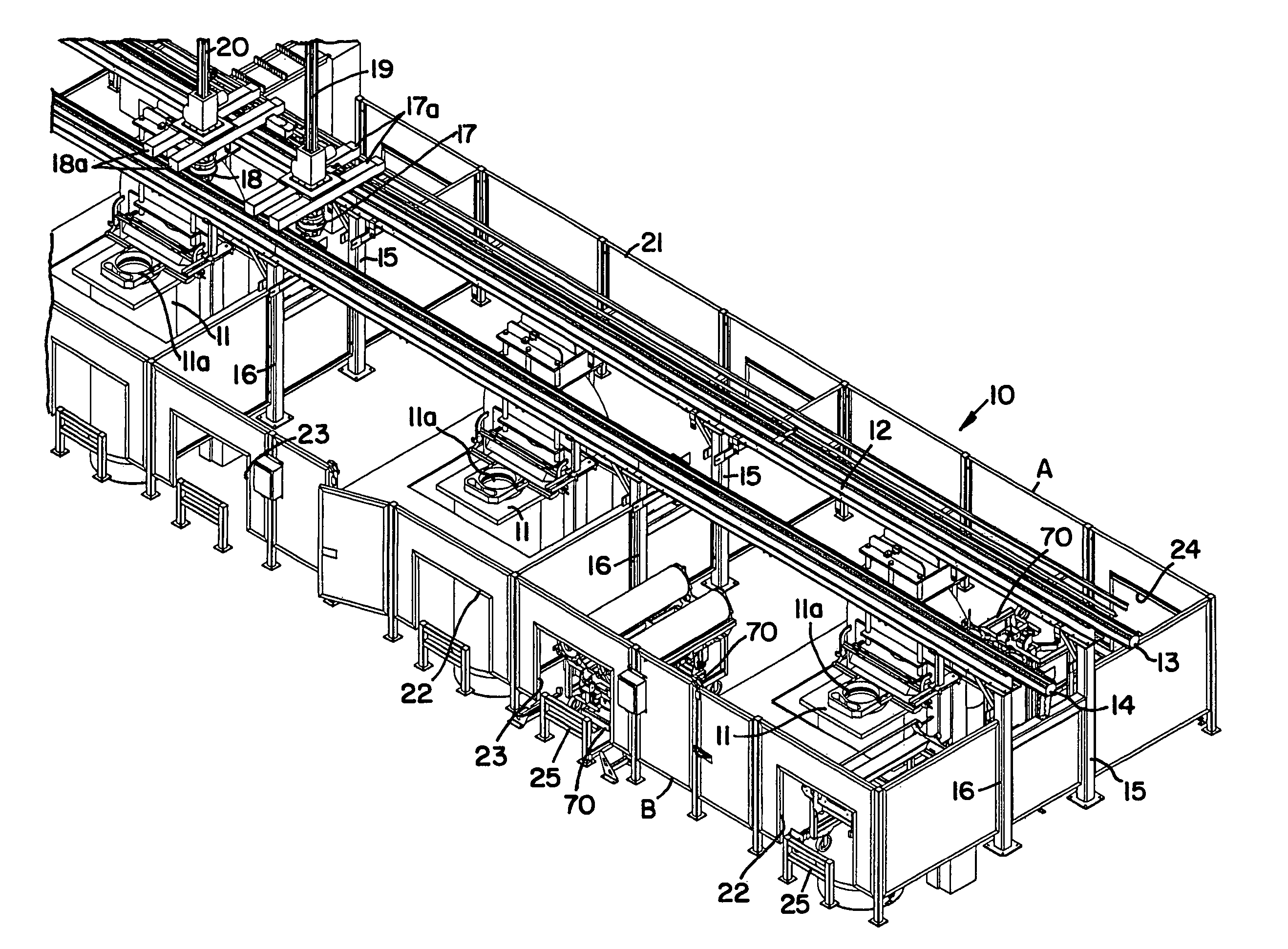

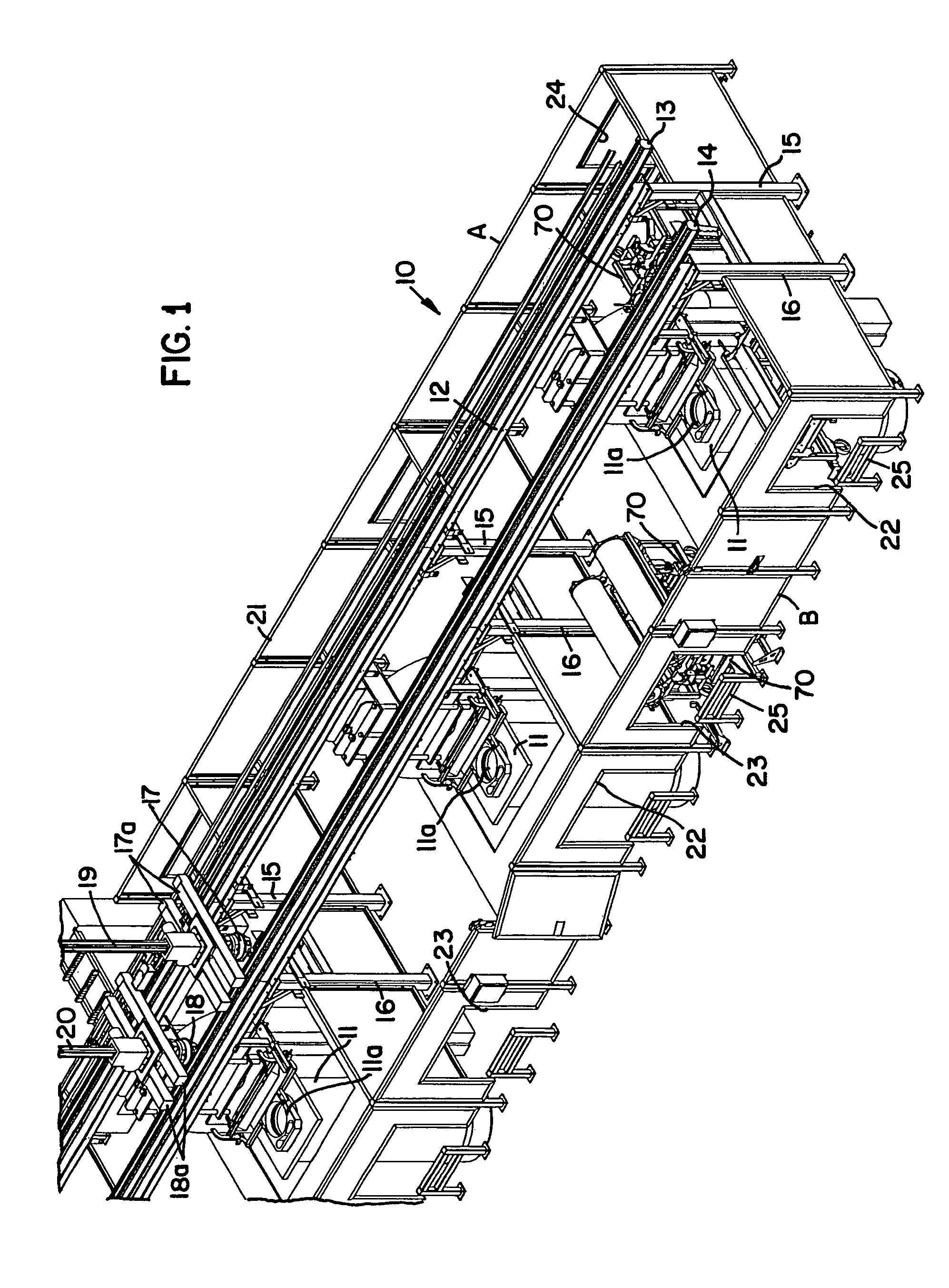

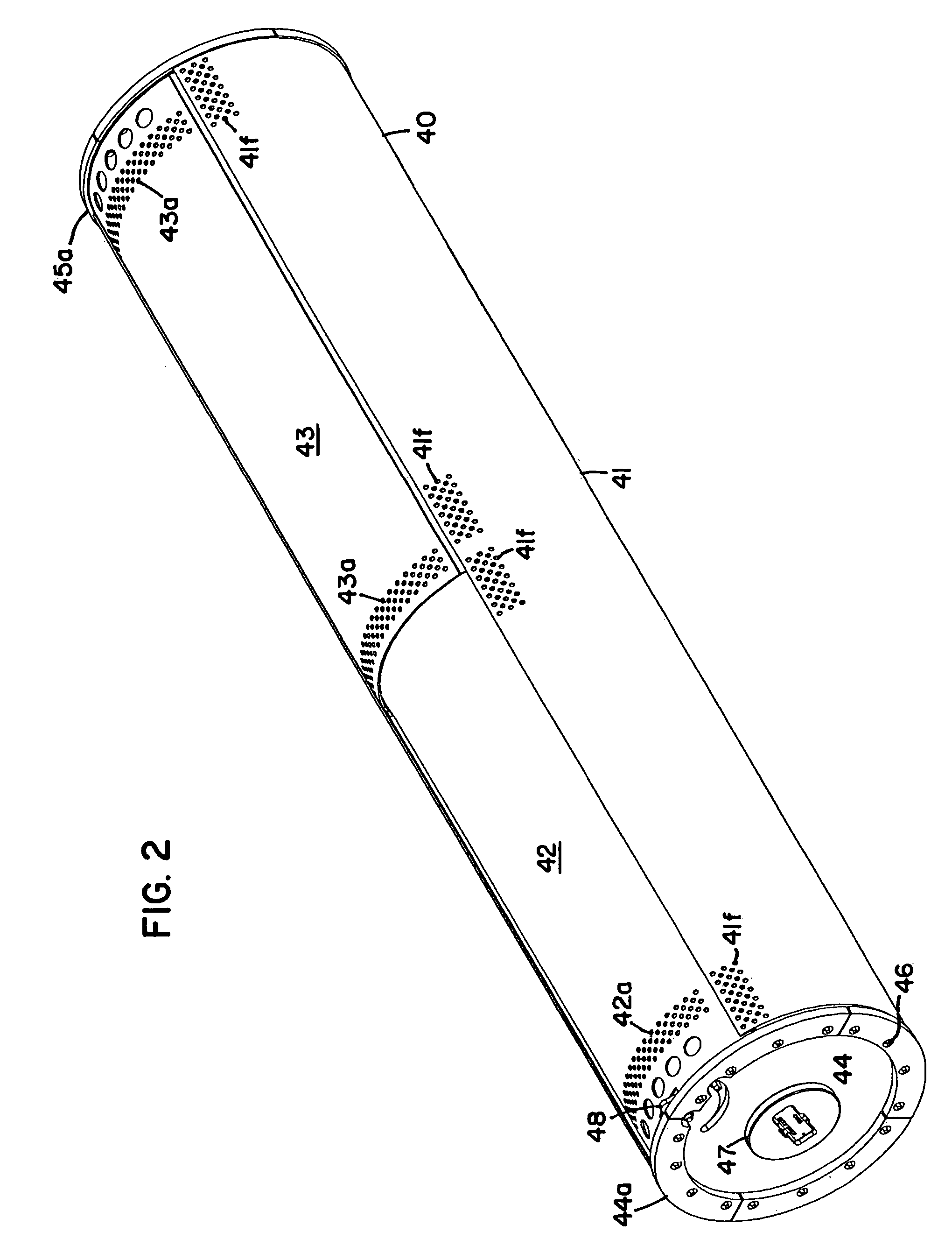

Method and apparatus for material handling for a food product using high pressure pasteurization

ActiveUS20060257552A1Great percentage of timeShorten cycle timeMilk treatmentFruits/vegetable preservation by heatingPasteurizationHigh pressure

A method and apparatus for high-pressure pasteurization utilizes a basket (40) for holding food packages (95). The basket (40) is transported on a cart (60) from a loading station (90), to the high-pressure pasteurization processing apparatus (10) and back to an unloading station (100). Two robots (17, 18) are utilized to reduce cycle time of the high-pressure pasteurization vessels (11).

Owner:HORMEL FOODS

Method for prolonging quality guarantee period of liquid eggs

ActiveCN102986828ARelieve stressReduce processing timeEggs preservation by heatingBiotechnologyMicroorganism

The invention provides a method for prolonging a quality guarantee period of liquid eggs, provides a liquid egg product with a long quality guarantee period and belongs to the technical field of egg manufacture. The invention creatively combines a high density carbon dioxide sterilization method and a super killing sterilization method, a composite antiseptic agent is added to restrain growth and breeding of remaining microorganism, quality guarantee period of liquid eggs can be obviously prolonged, function property cab be kept to the maximum limit, energy consumption and production cost can be reduced, corporate economic loss can be reduced, corporate economic benefits are increased. A storage test proves that the quality guarantee period of the liquid egg product under 4 DEG C refrigeration condition can achieve 75-80 days, and a compound antiseptic special for the liquid eggs for prolonging the quality guarantee period of the liquid eggs is provided simultaneously.

Owner:迟玉杰

Devices and methods for packaging beverages

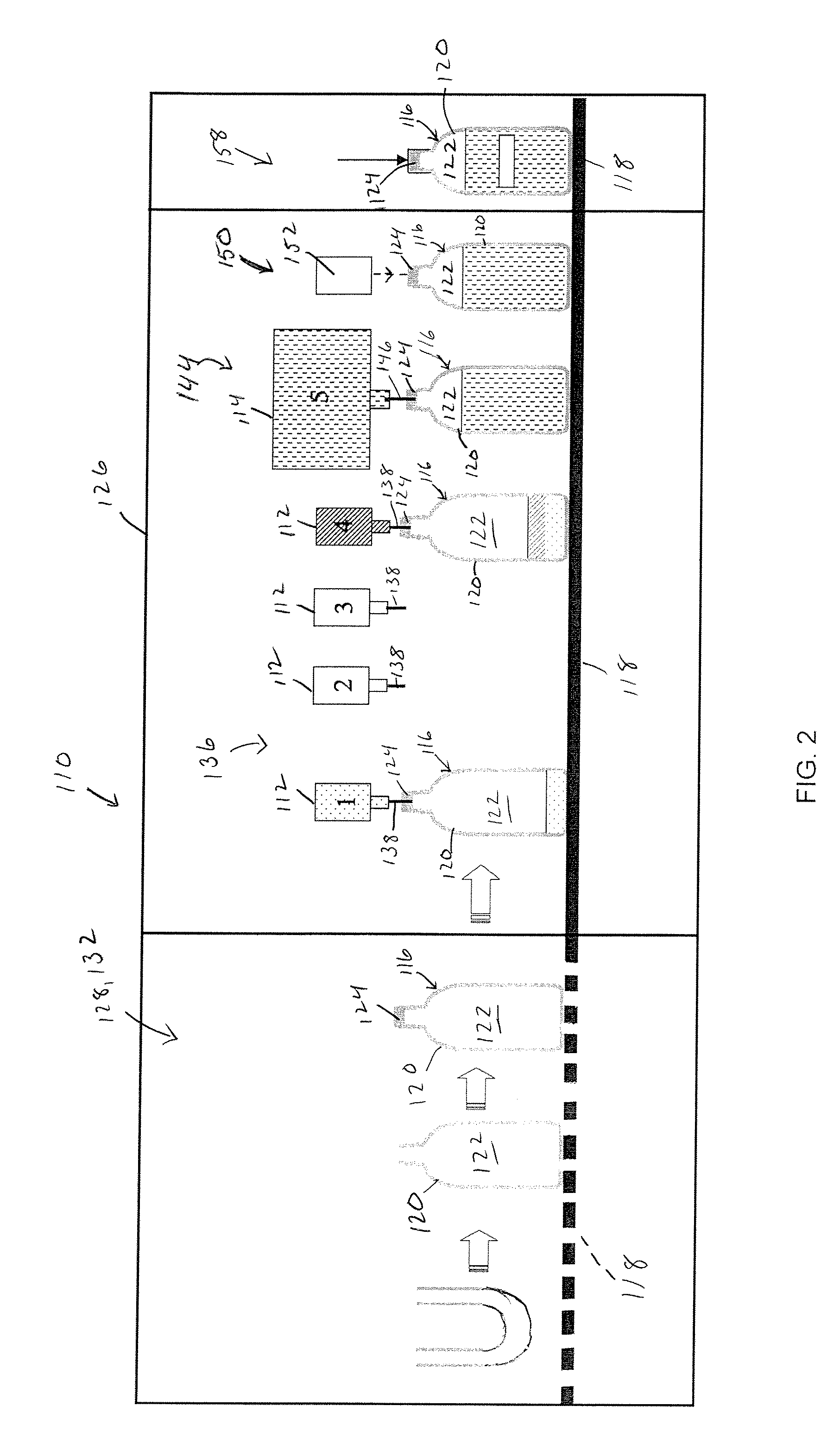

ActiveUS20080023099A1Decreasing container-to-container variationReduce buildFilling using counterpressureMixing methodsEngineering

A method for packaging a beverage comprising particulates in a liquid, the method comprising dispensing a first portion of the beverage from a first source into containers, wherein the first portion of the beverage comprises at least a majority of the particulates and a first portion of the liquid, dispensing from a counterpressure filler a second portion of the beverage from a second source into the containers, wherein the second portion of the beverage comprises a second portion of the liquid, and sealing the containers to form packaged beverages. An apparatus for packaging a beverage comprising particulates in a liquid. A method for packaging, in sequence, a first beverage comprising particulates in a liquid and a second beverage comprising a carbonated beverage. A method for packaging a beverage comprising a dairy component and a liquid.

Owner:THE COCA-COLA CO

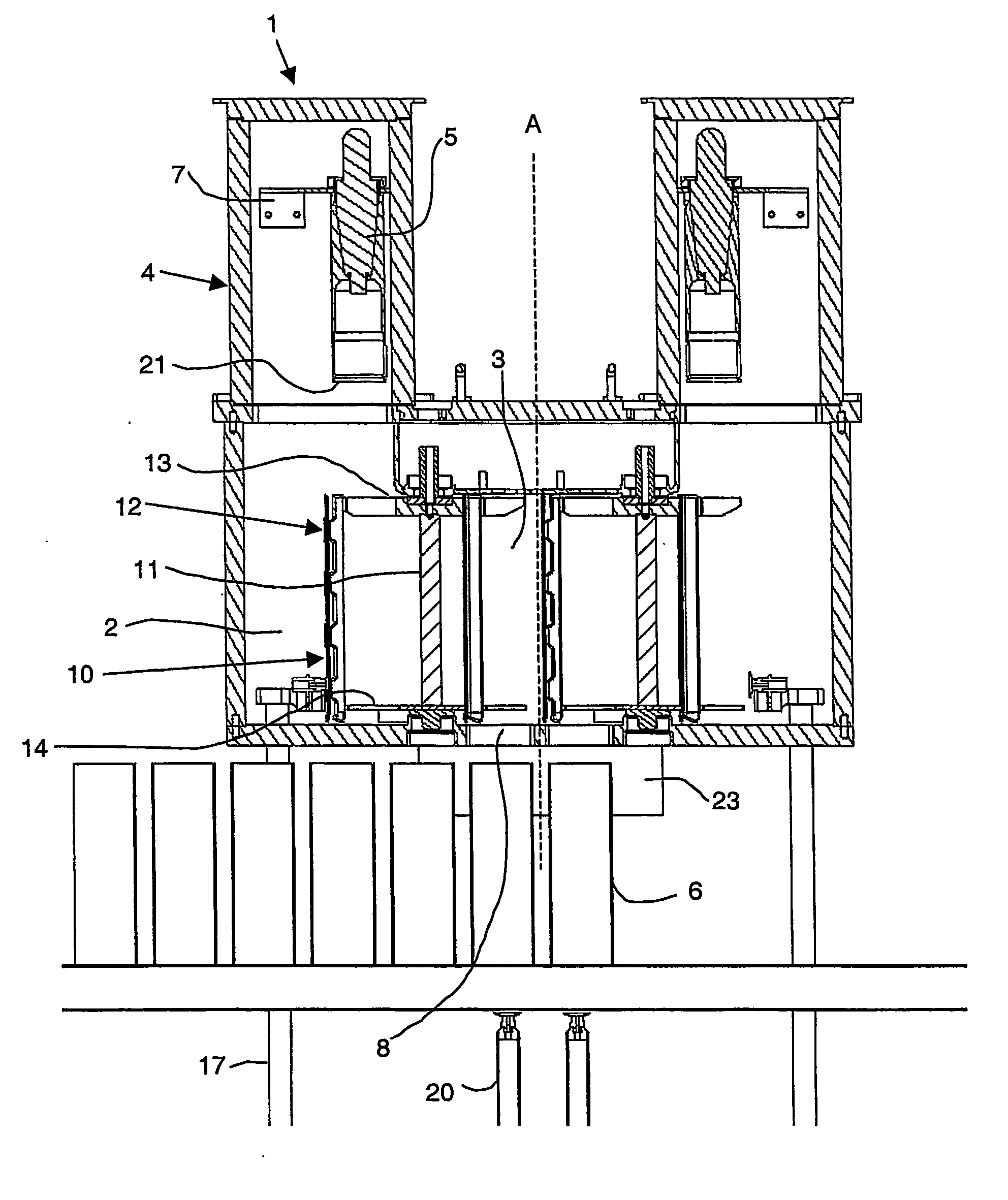

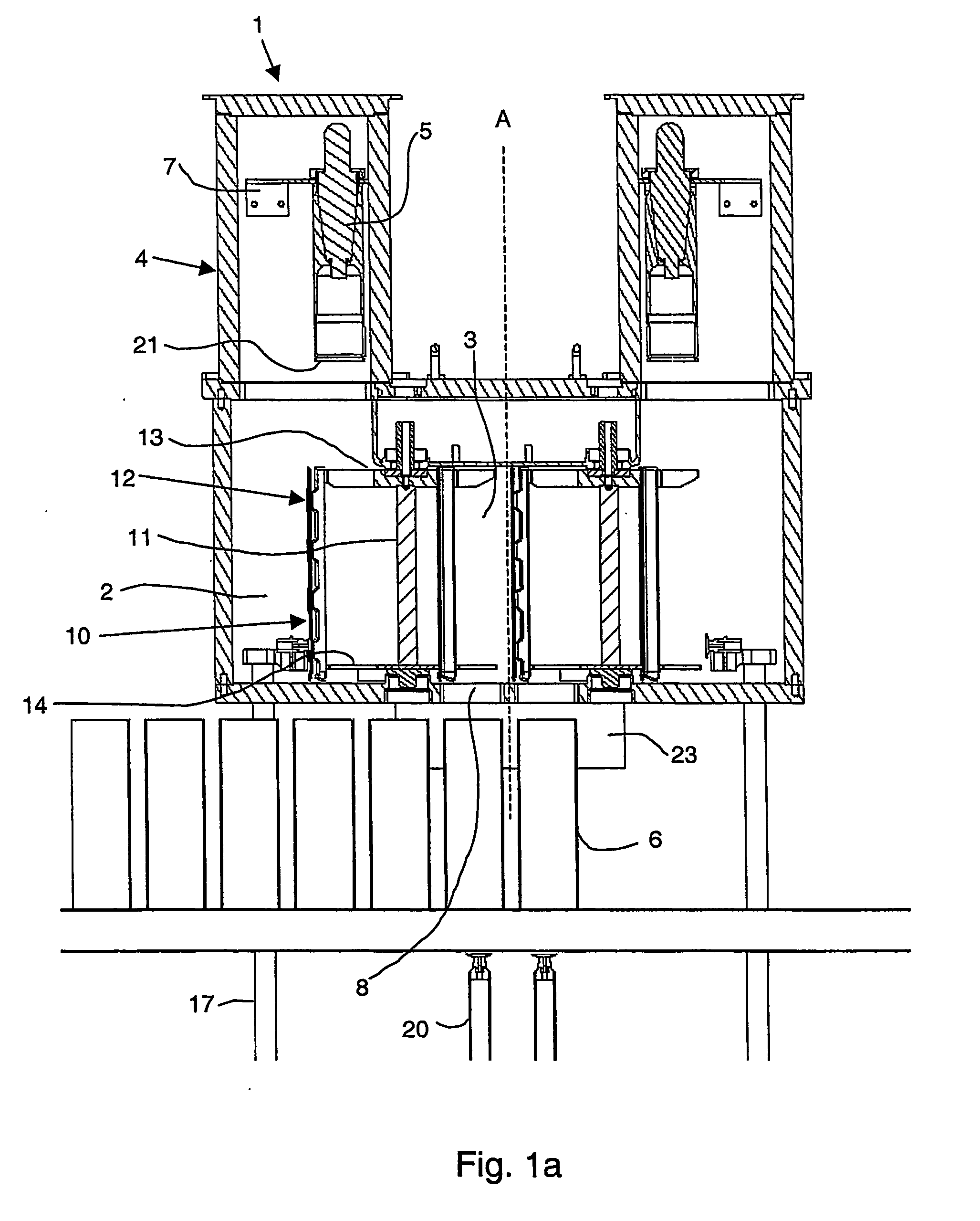

Device and method for sterilization

InactiveUS7749434B2Risk minimizationEffectively and reliably dischargedPackage sterilisationEggs preservation by heatingPackaging machineEngineering

The invention refers to a device (1) and method for sterilizing partly formed packages (6) in a packaging machine. The device (1) comprises an inner chamber (2) and an outer chamber (3), the inner chamber (2) being provided with a sterilization unit (5). Further, it comprises a carrier unit (10), comprising a separating member (11) and a package carrying member (12), which is being adapted to rotate between a first position in which the package carrying member (12) is located in the outer chamber (3), and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3), and a second position in which the carrier unit (10) has rotated a package (6) into the inner chamber (2) and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3).

Owner:TETRA LAVAL HLDG & FINANCE SA

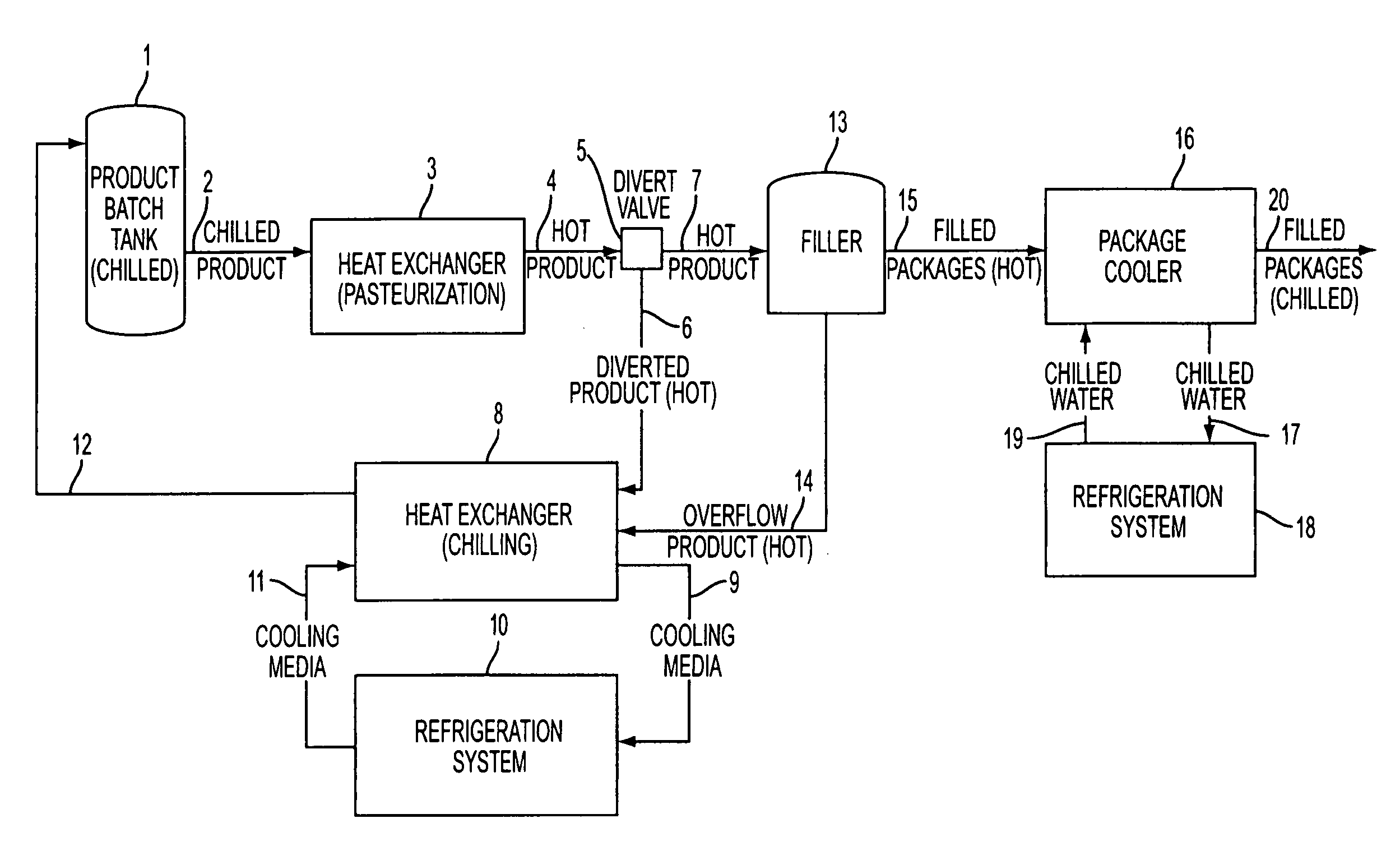

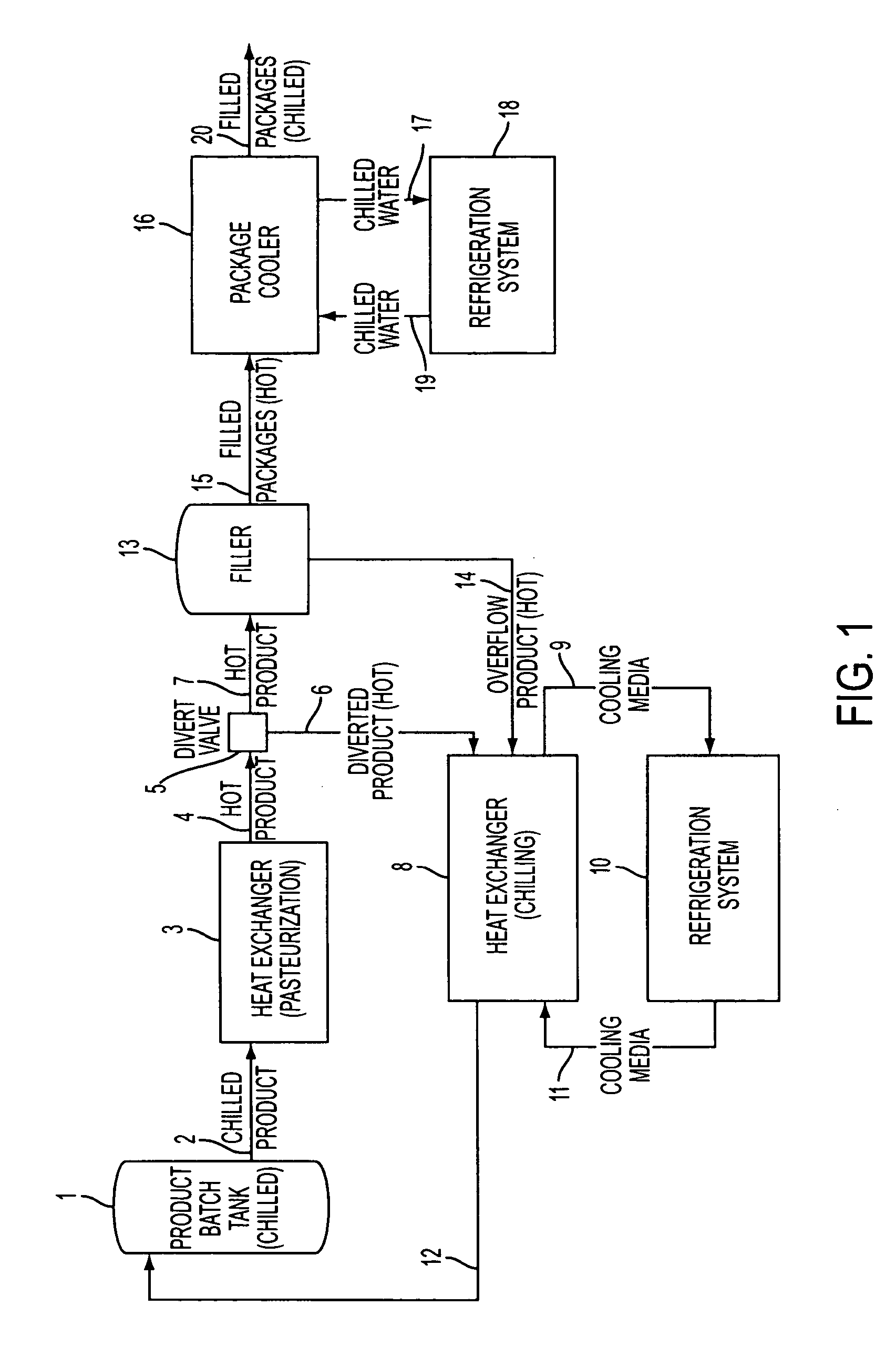

Hot fill and quick chill process for premium quality juice

InactiveUS20070184157A1Satisfies needEggs preservation by heatingPackaging protectionFruit juiceEngineering

A process for hot filling and quick chilling a premium juice, while retaining the premium qualities of the juice, by quickly chilling the juice following the hot fill process and by maintaining refrigeration of the juice through out storage and shipment of the juice. The process further includes rapidly chilling the diverted and overflow product which is being returned to the pre-chilled batch tank.

Owner:CITRUS WORLD

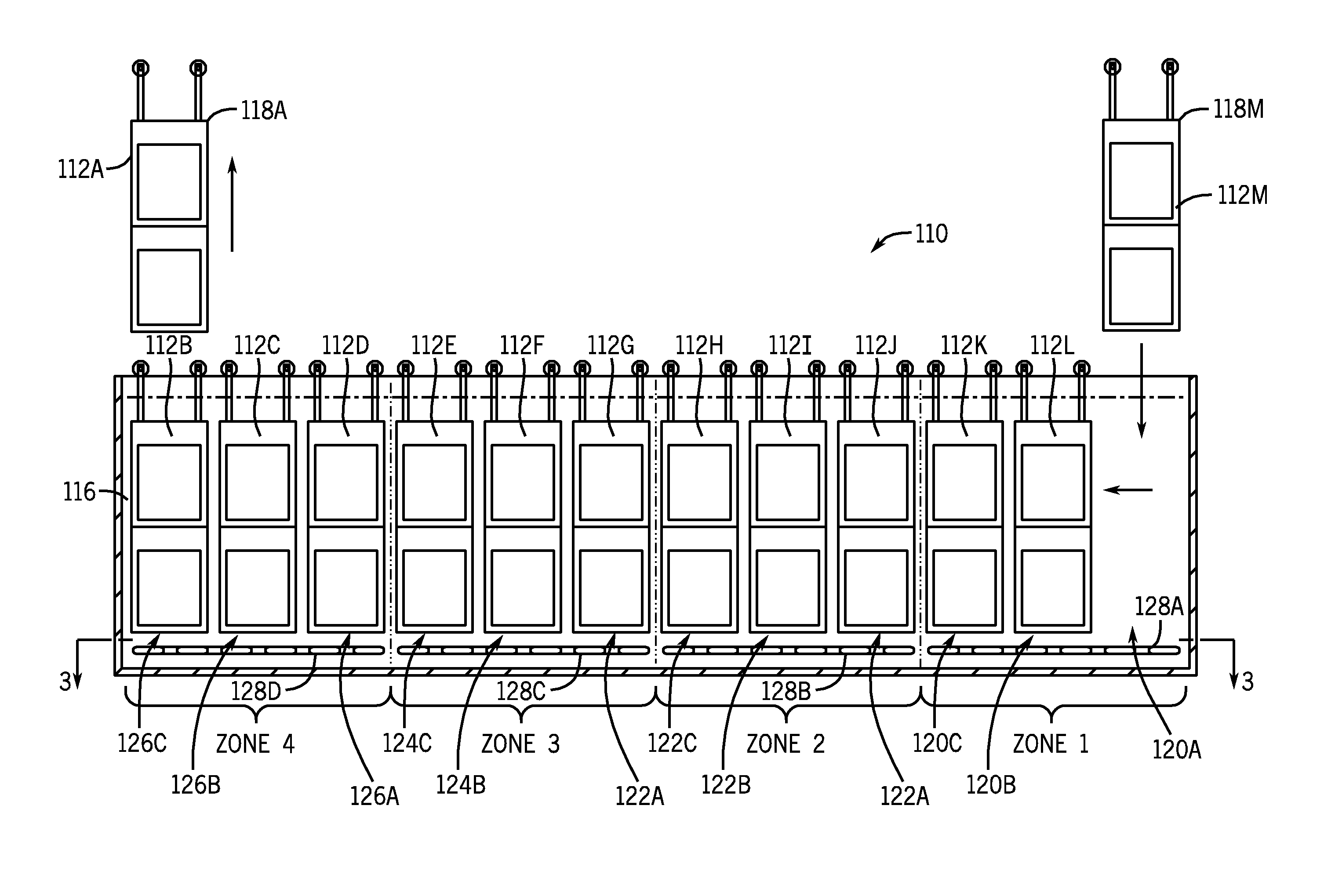

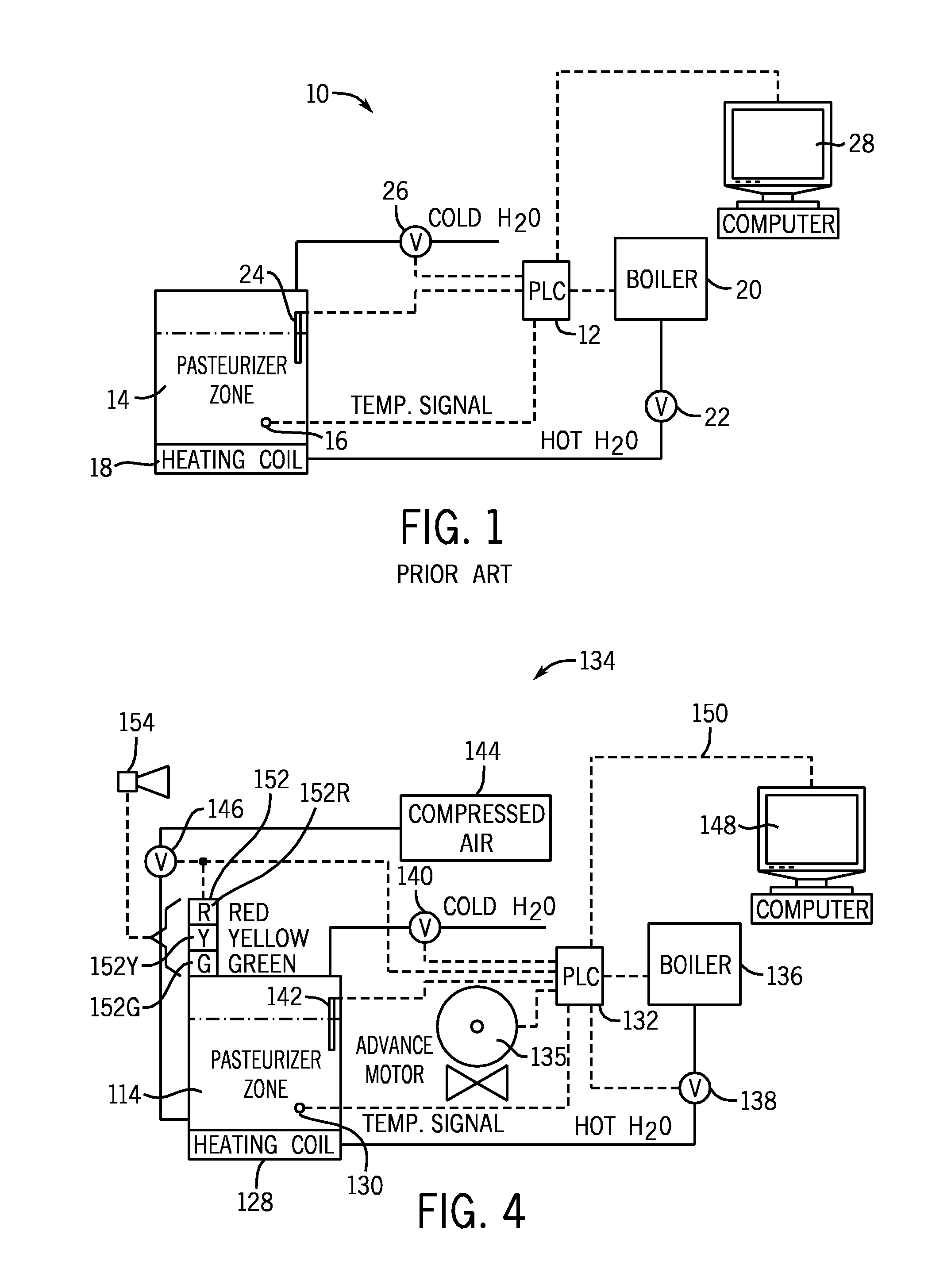

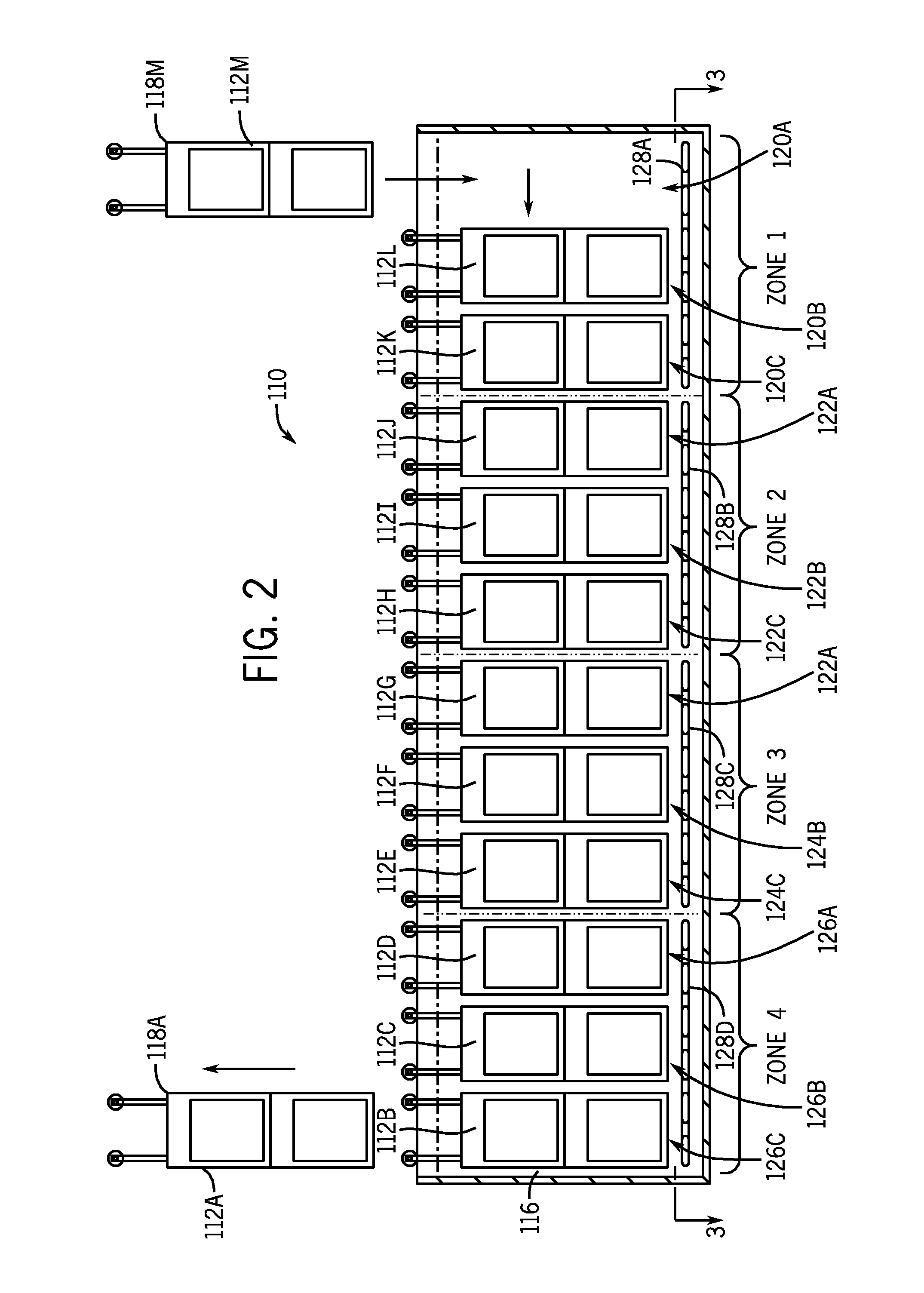

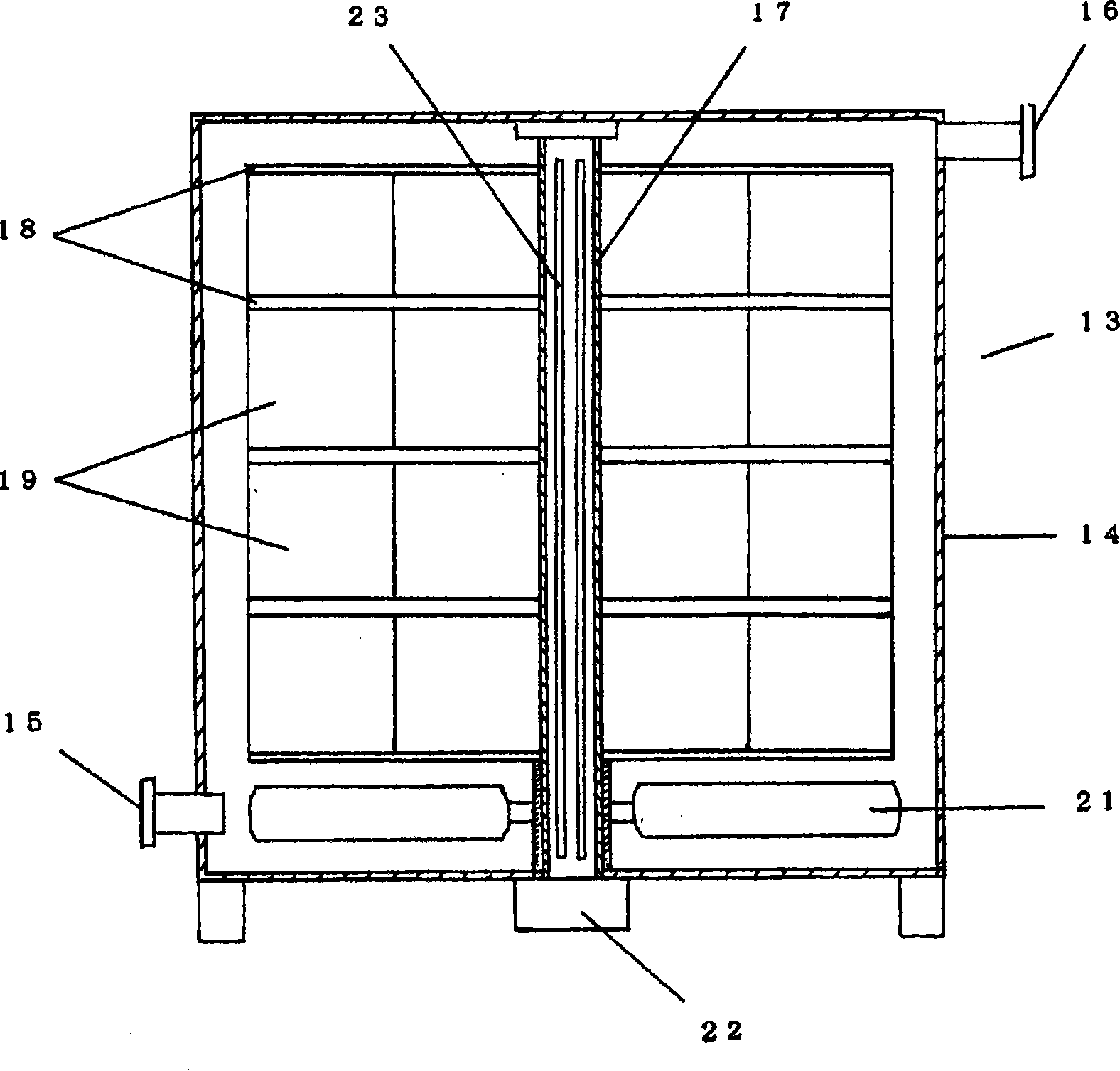

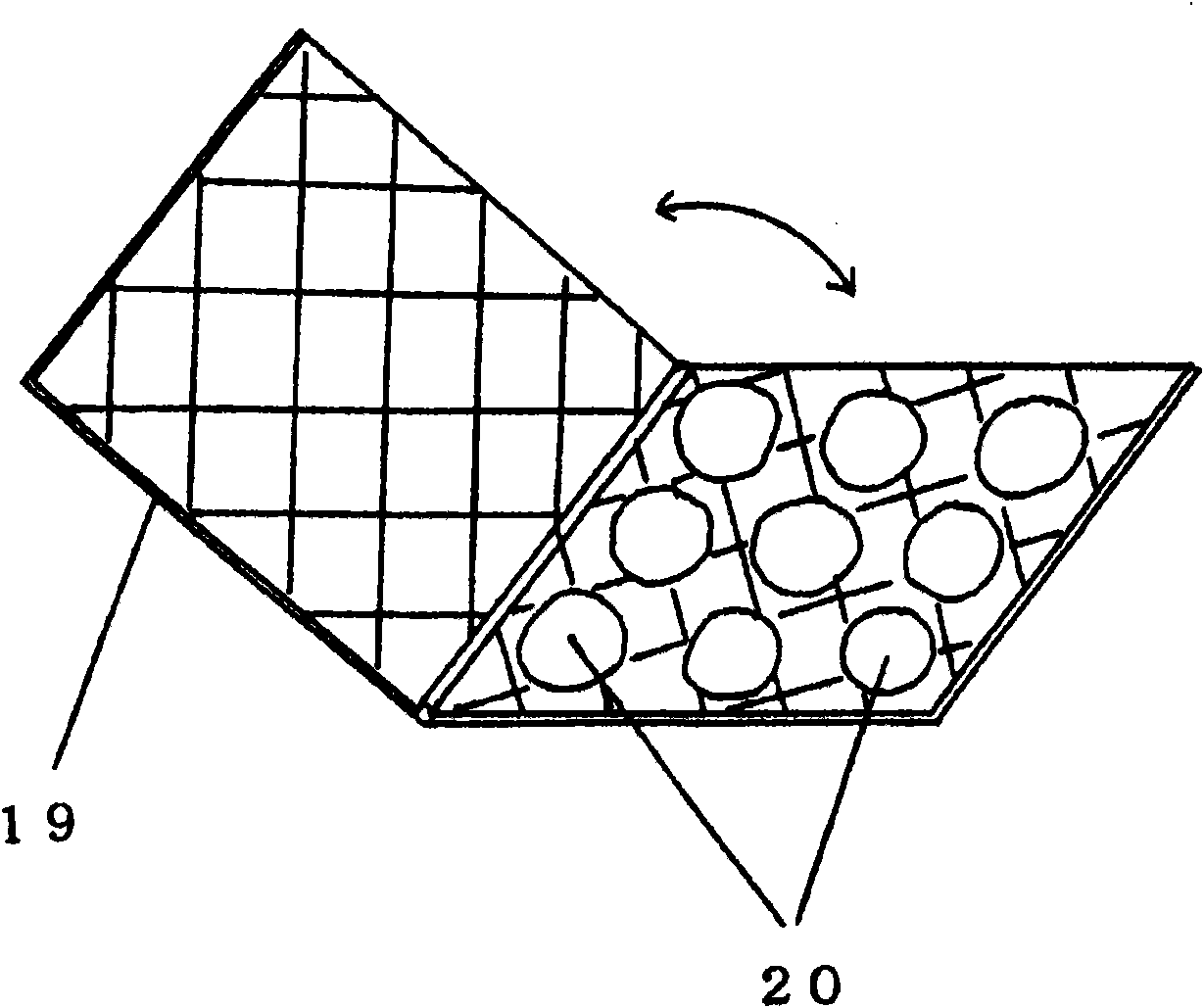

Shell Egg Pasteurization System and Method

ActiveUS20110300023A1Accelerate temperature recoveryImprove system throughputTemperatue controlEggs preservation by heatingControl systemPasteurization

A batch processing control system for a shell egg pasteurizer controls the time and temperature in which batches of shell eggs are held in a pasteurization bath in accordance with a predetermined pasteurization protocol for designated egg size and start temperature. The predetermined pasteurization protocol is preferably statistically verified to optimize batches of eggs having the designated size and start temperature. The system also includes reporting software that generates daily reports to track each respective batch and verify that the batch has been pasteurized according to the statistically verified protocol.

Owner:NAT PASTEURIZED EGGS

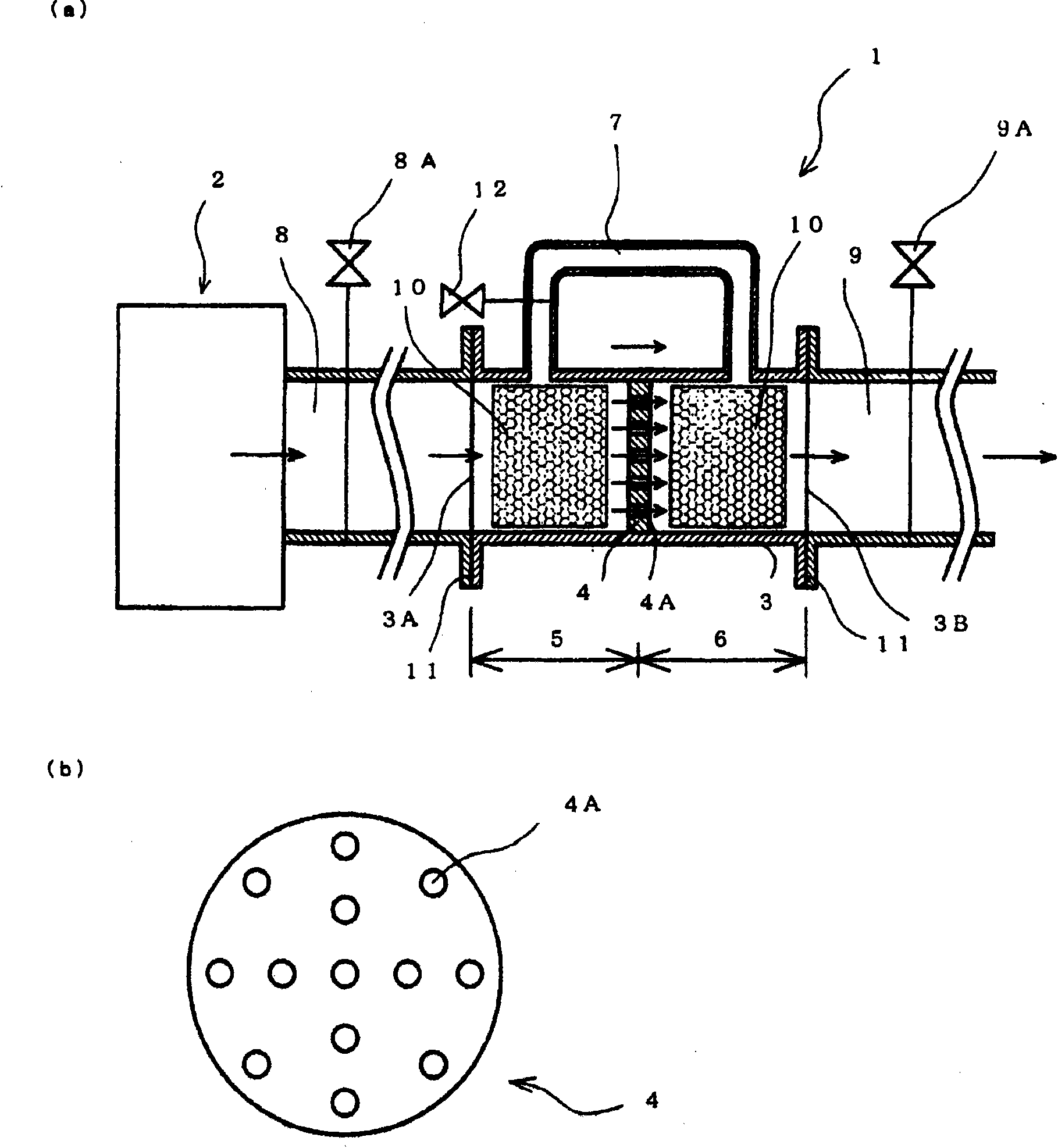

Overheated compressed hot air stream producing method and device, object processed by overheated compressed hot air stream, processing method, and processing apparatus

InactiveCN101910748ADry evenlyEven drying effectLiquid fuel feeder/distributionDrying solid materials with heatWater qualityEngineering

A method and device for producing a minus-ion air similar to a heated compressed hot air stream, electromagnetic waves in the far-infrared and submilimeter region (hereinafter referred to as ''terahertz wave'') by regulating the discharge pressure and the discharge temperature. The device is excellent in versatility, small in size, and low in cost. An object processed by using the method and device, a processing method, and a processing apparatus are also provided. Air is sent from a blower or an air compressor (2) through an air pipe (8) to a heated compressed air regulator (vessel (3)). The air sealed in the heated compressed airregulator (1) regulated under a predetermined discharge pressure (for example, 30 kPa to 150 kPa) and at a temperature (40 DEG C to 250 DEG C) is passed through a through hole (4A) of a circular plate (4) to produce a heated compressed air. In the produced hot air stream, a resonance electromagnetic wave resonating with the natural frequency of the water molecule is generated by a terahertz wave and a generated thermal shock wave, thereby the hydrogen bond of the water molecules in the air is cut, and electrons are released from hydrogen atoms, thus also producing a minus-ion air stream. A processed object, a processing method, and a processing apparatus are so constituted that the produced hot air stream is used for drying, production of a functional water by exposing water to the hot air stream, production of an aqueous fuel, beauty / health appliances, air / water quality improvement devices, combustion efficiency enhancement devices for internal combustion engines, and so forth.

Owner:SUZUYAELECTRIC SERVICE

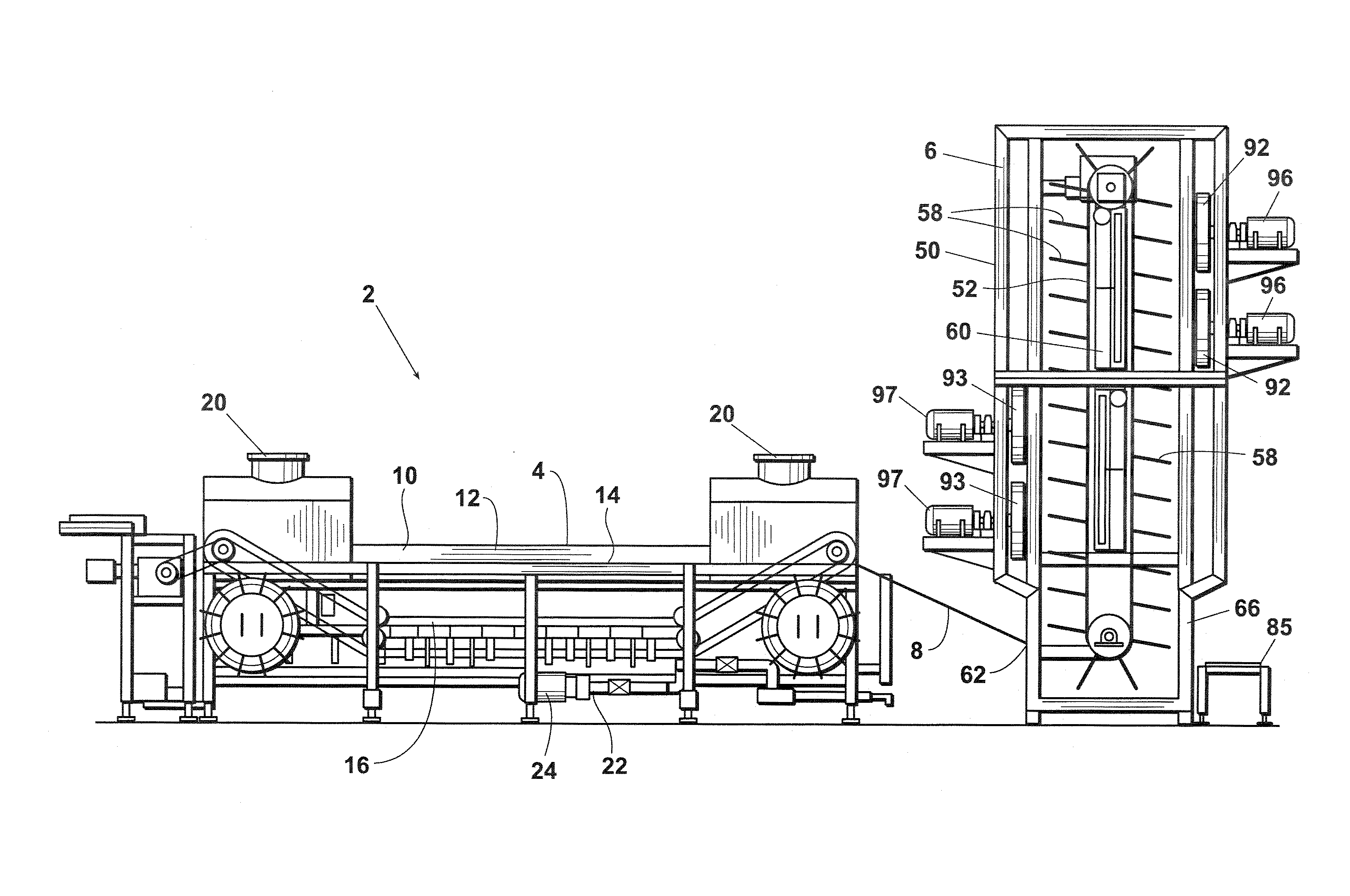

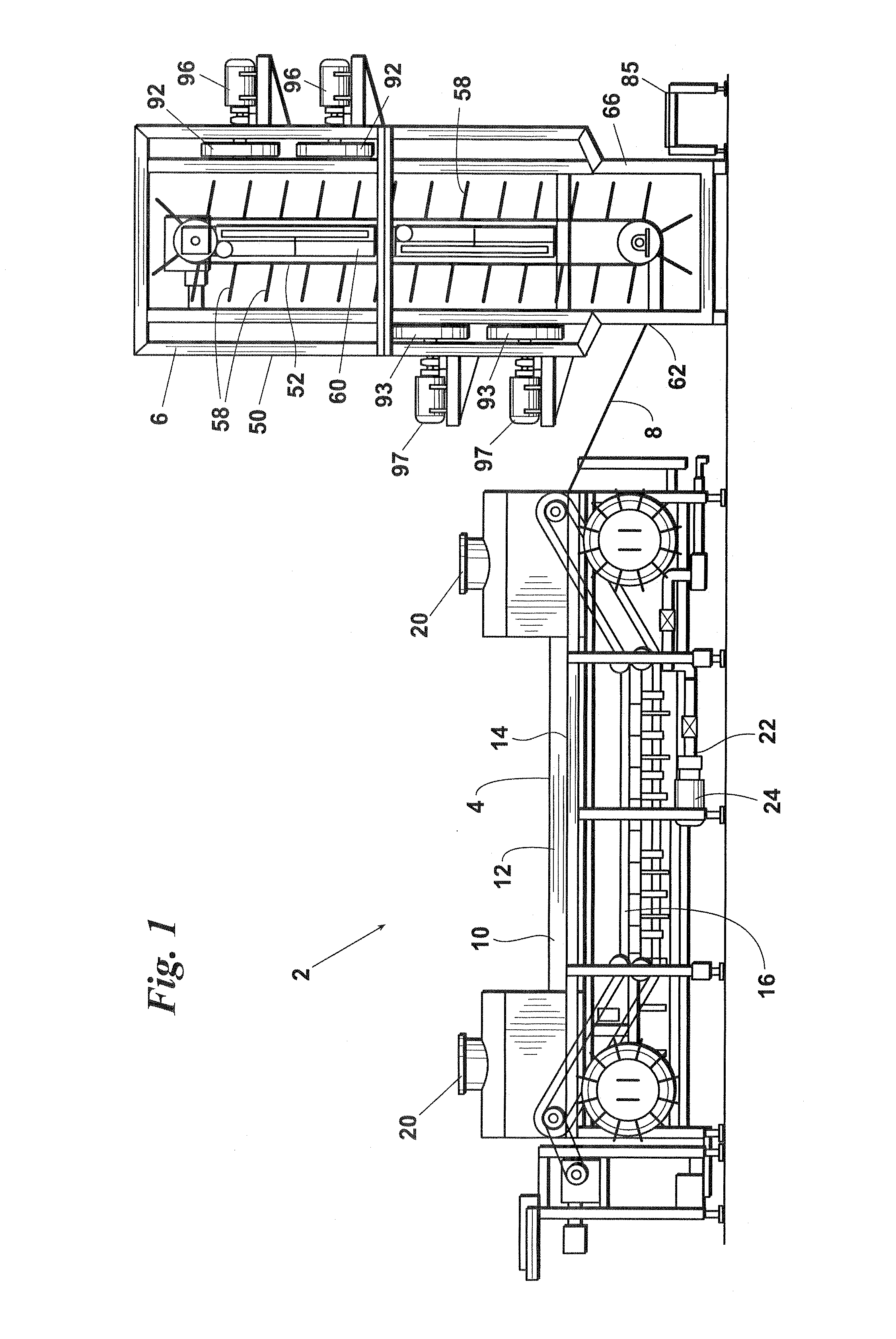

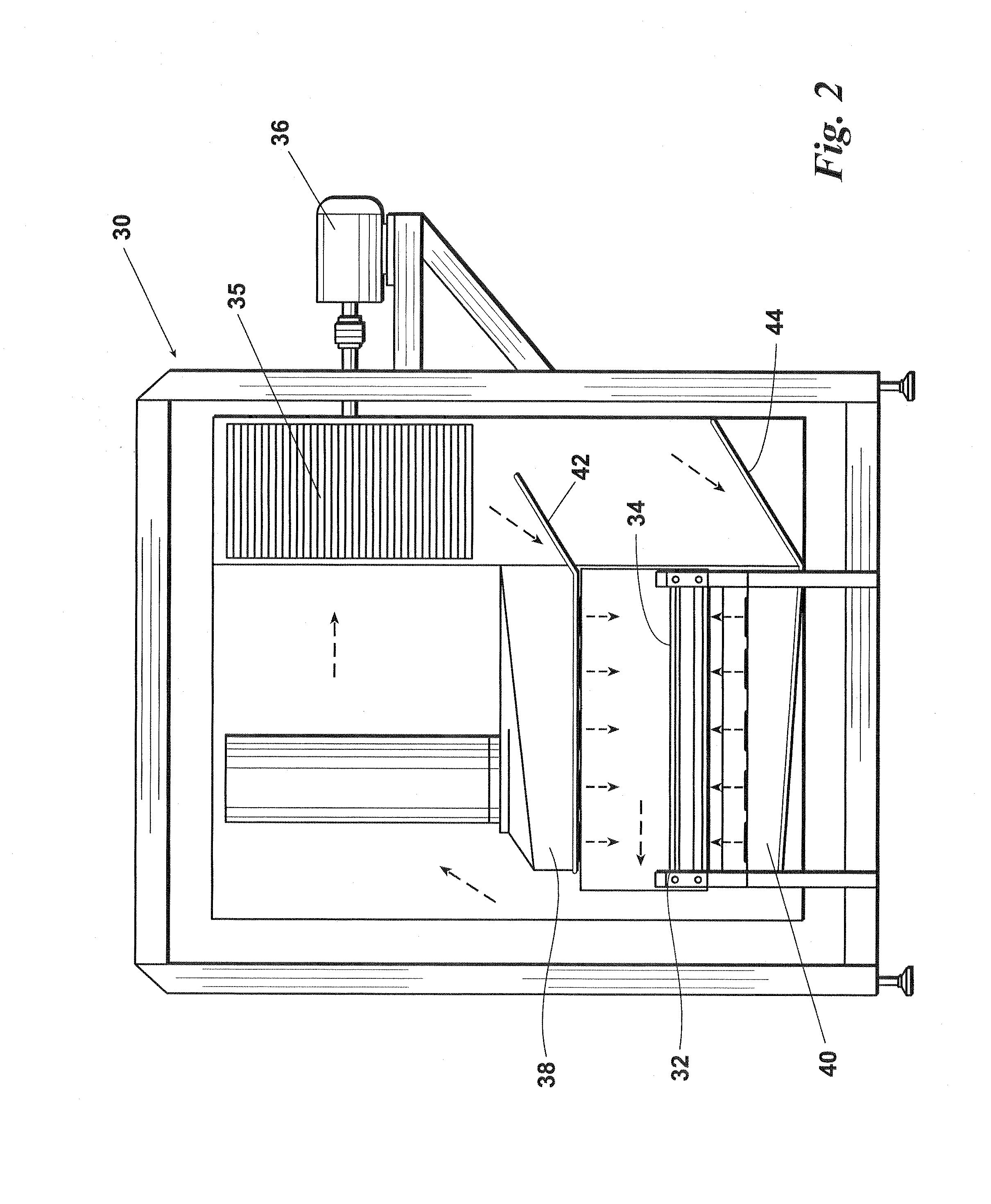

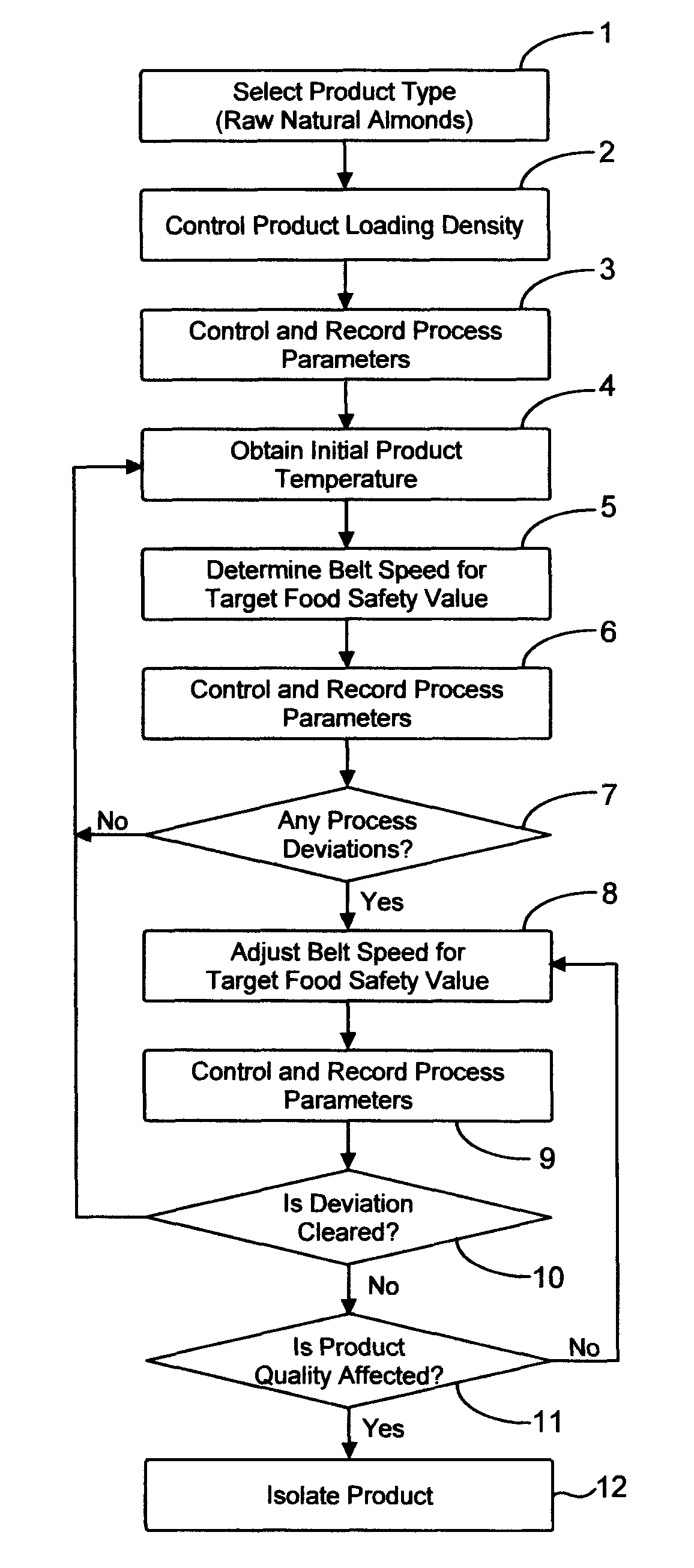

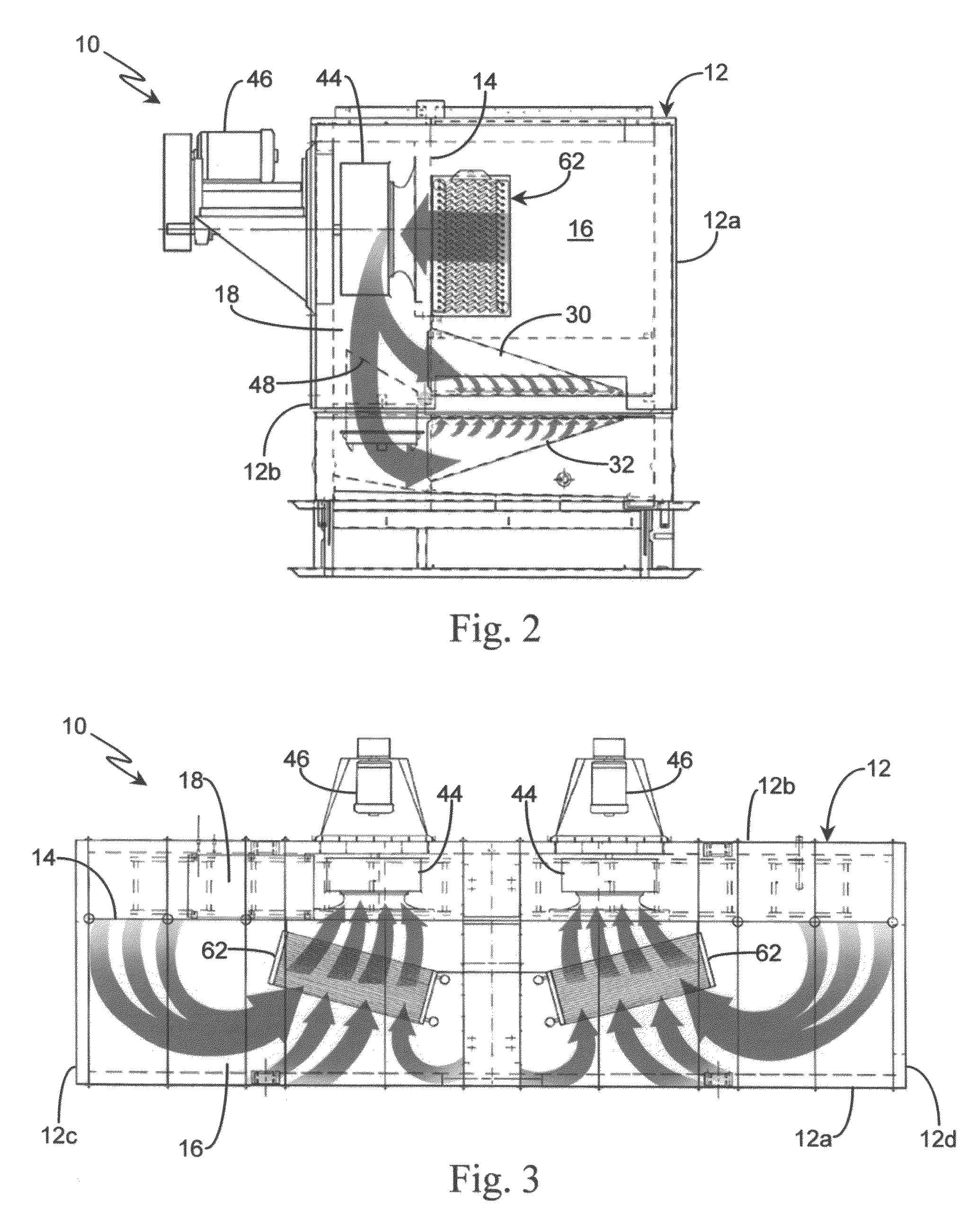

Dry food pasteurization apparatus and method

ActiveUS8707861B2Consistent rateIncrease volumeEggs preservation by heatingSteam cooking vesselsPasteurizationEngineering

An apparatus for pasteurizing a dry food product comprises an impingement chamber, a conveyor for conveying the dry food product through the impingement chamber; a heater and water supply assembly for generating heated, moist air, and a fan for circulating the heated, moist air through the impingement chamber and onto the dry food product. In operation, the moisture in the heated, moist air condenses on the surface of the dry food product and produces a heat of condensation which heats the surface of the dry food product. Moreover, this heat of condensation is sufficient to kill a percentage of any pathogenic microorganisms which may be present on the surface of the dry food product.

Owner:JOHN BEAN TECH CORP

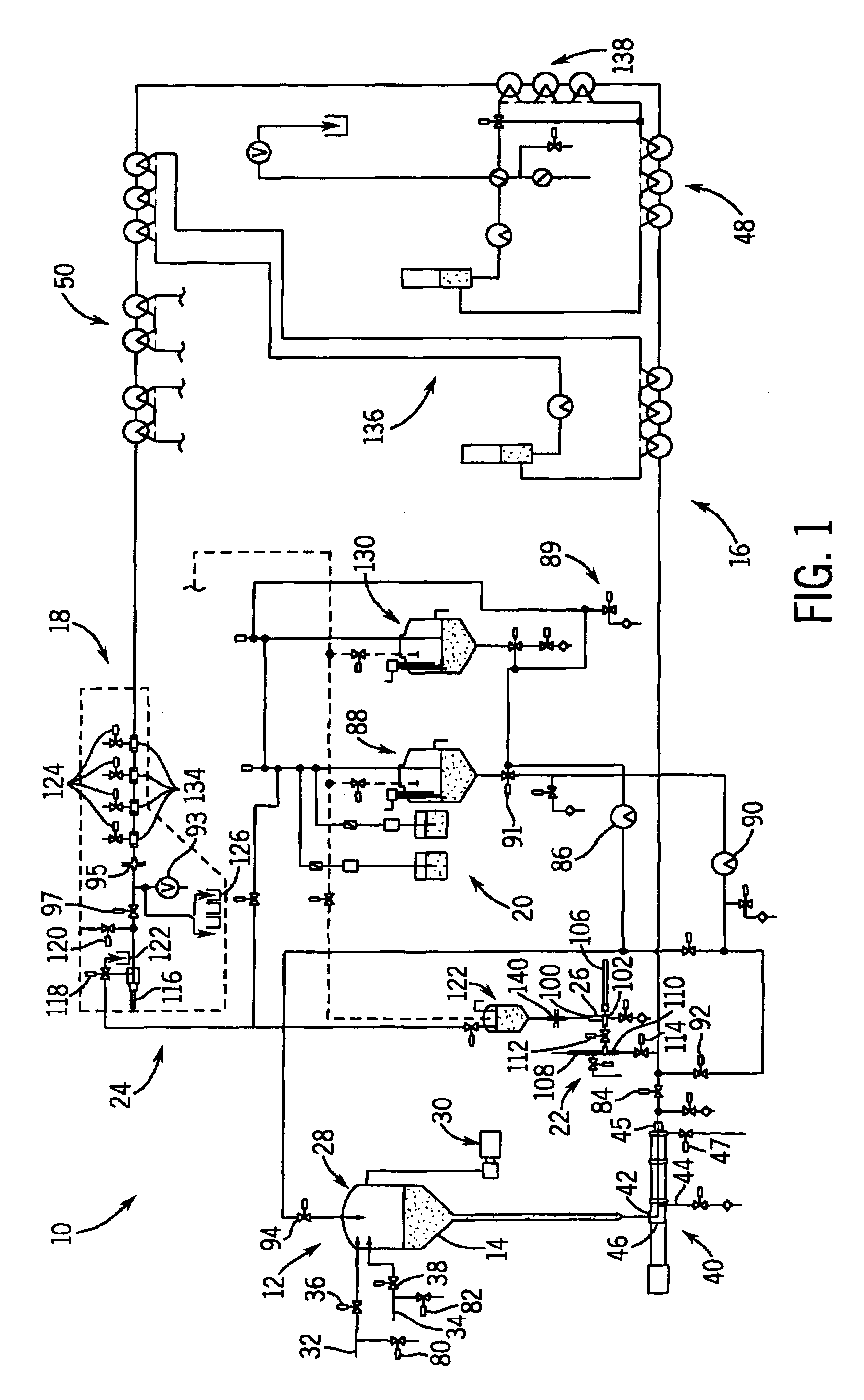

Aseptic processing system for fruit filling

ActiveUS7368139B1Eliminate downtimeHollow article cleaningPackage sterilisationCleaning stationEngineering

An apparatus for aseptic processing of a viscous food product includes a product tank configured to hold the viscous food product. A first pump is configured to pump the viscous food product from the product tank through a heat exchanger at a given rate. A cleaning station including a cleaning pump configured to pump a flushing fluid through the product tank. A second pump is configured to pump a flushing fluid through the heat exchanger at the same rate as the first pump, while the cleaning pump is pumping the flushing fluid through the product tank and first pump.

Owner:BRONNERT HERVE X

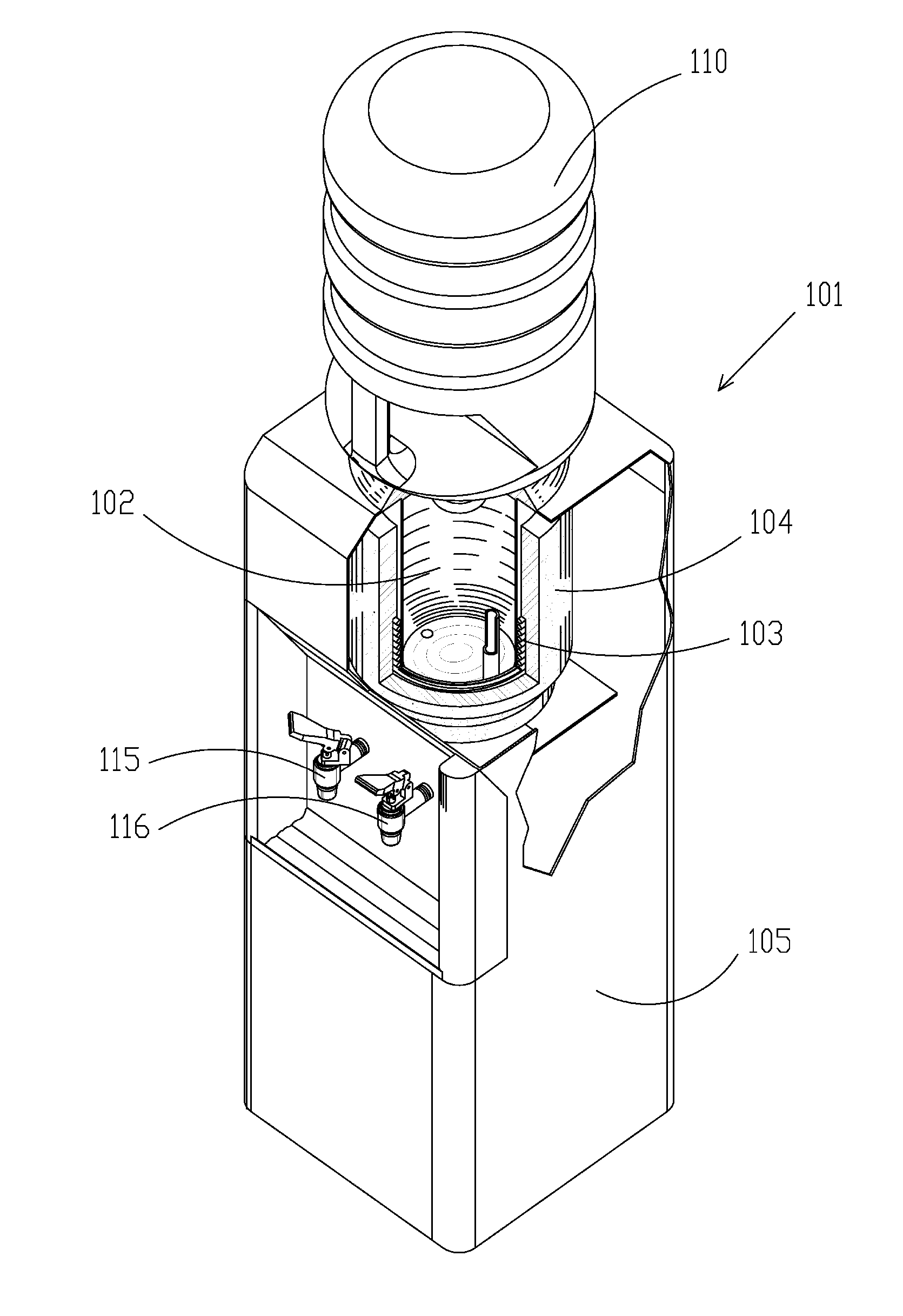

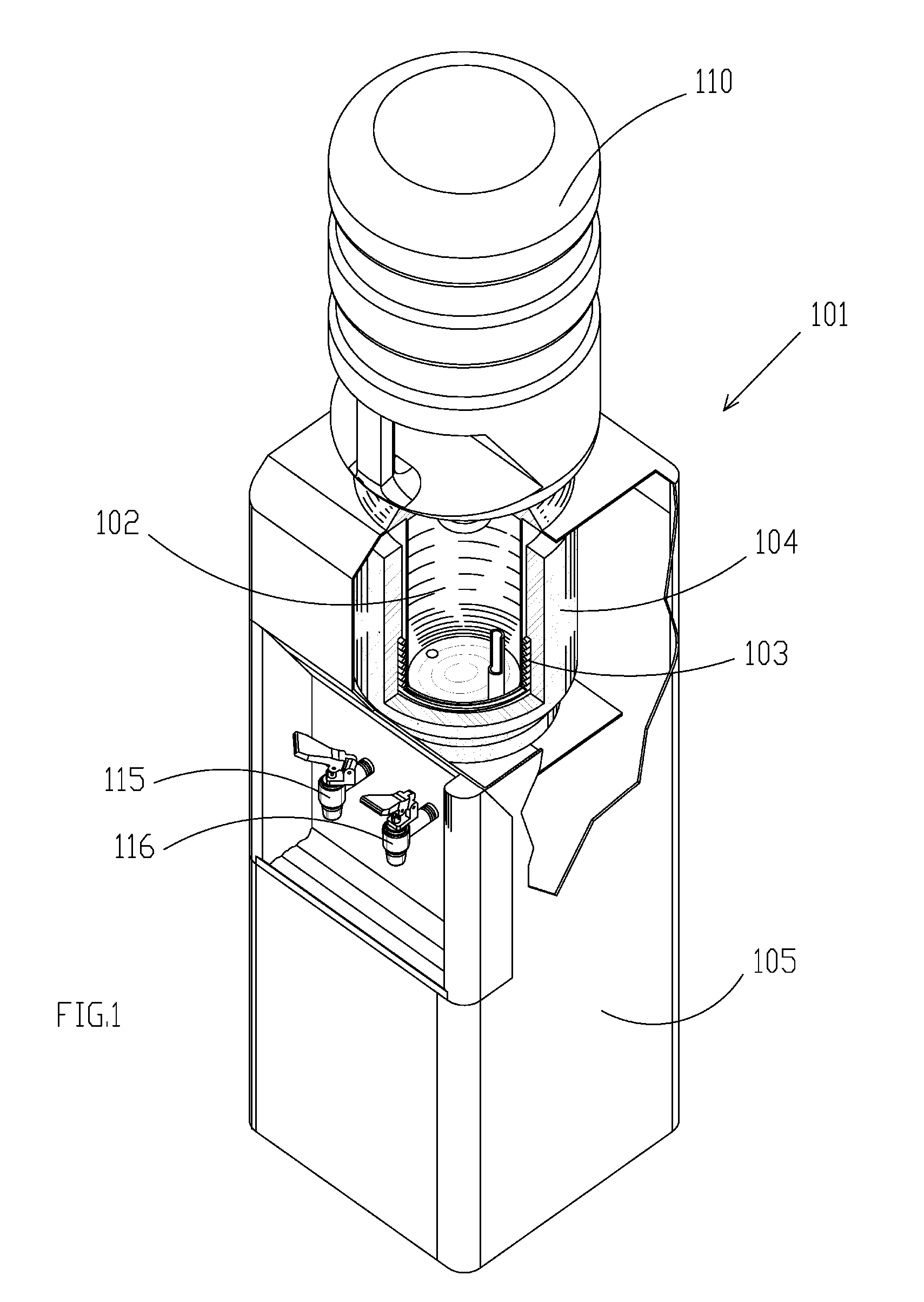

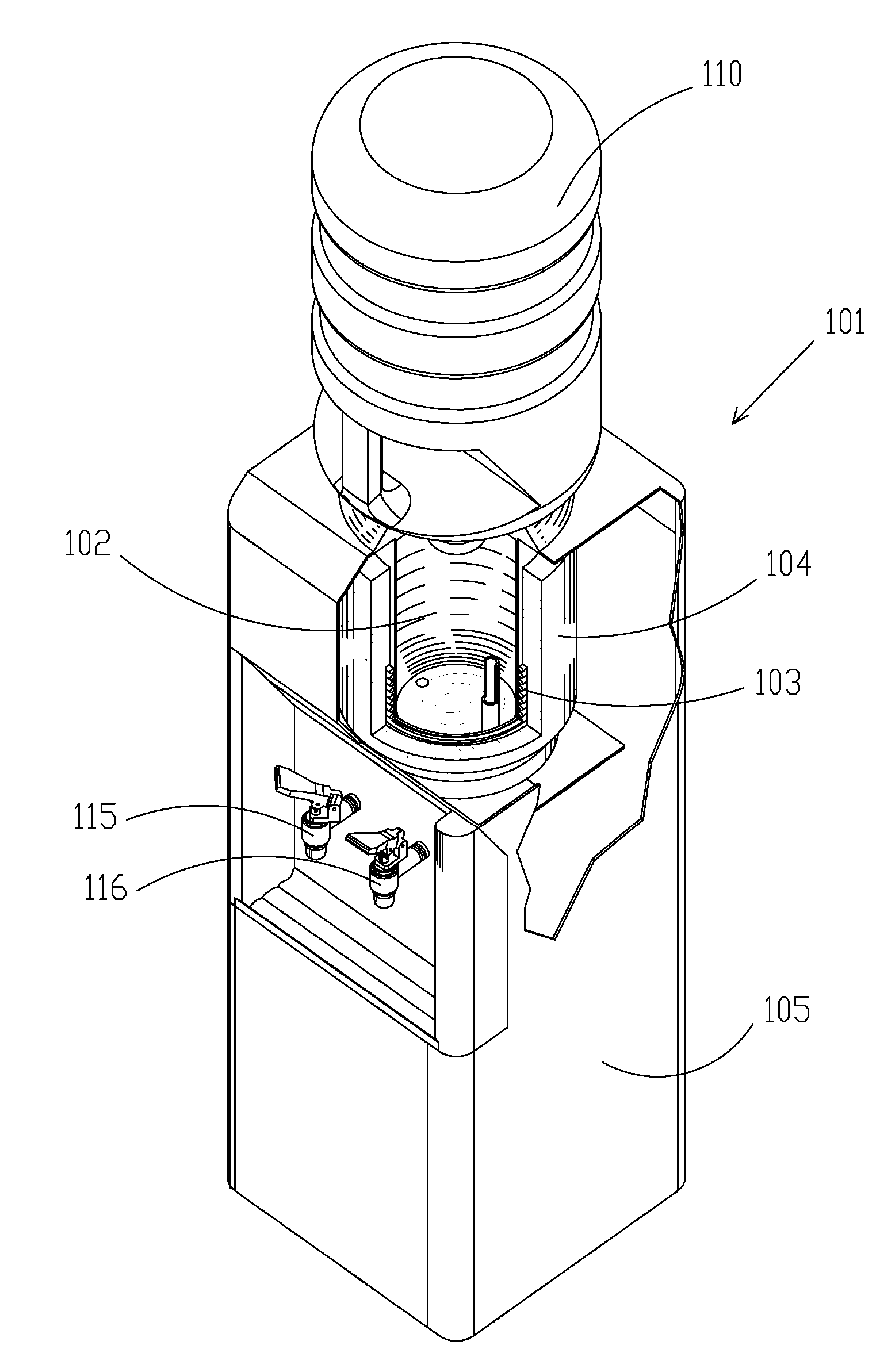

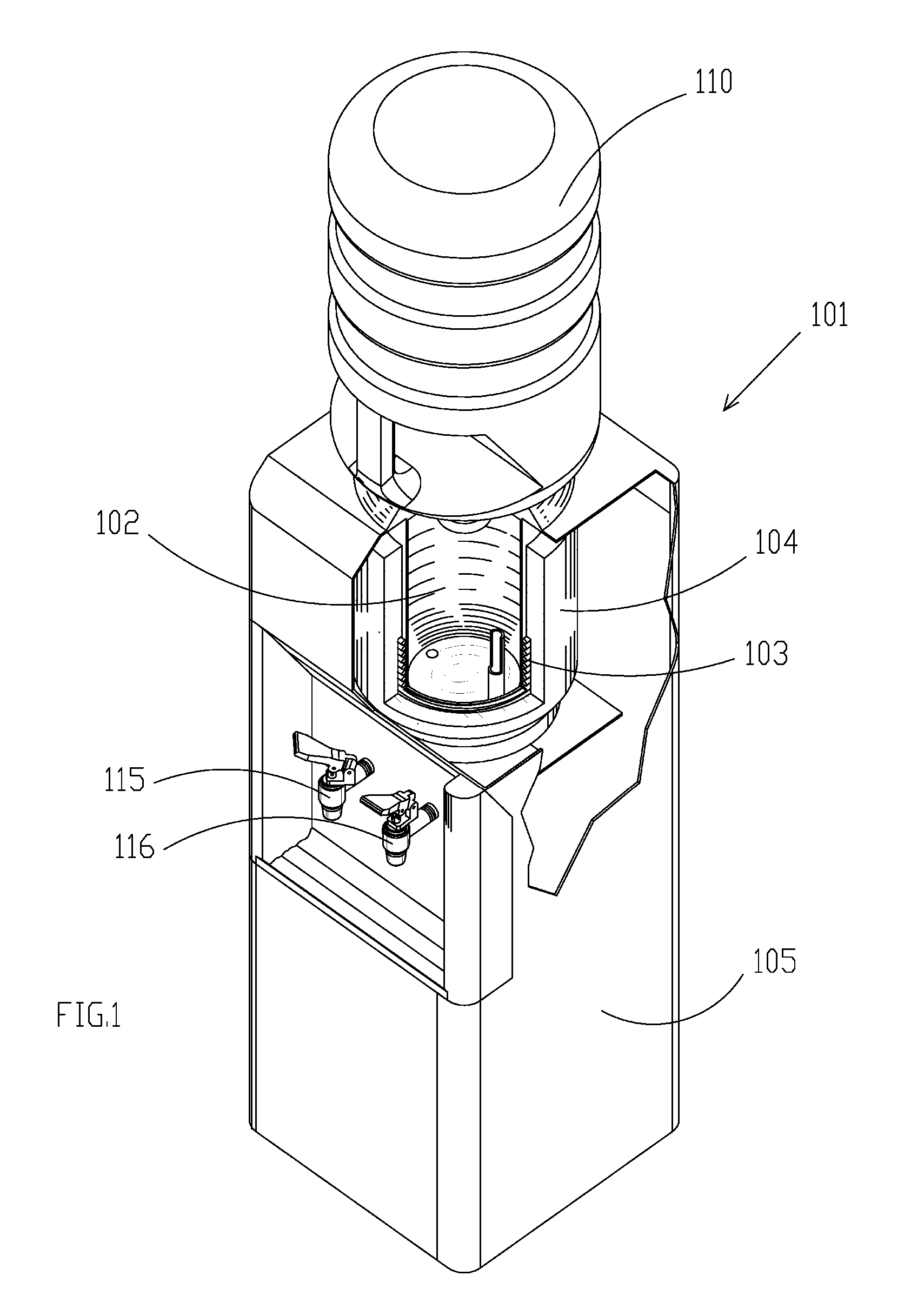

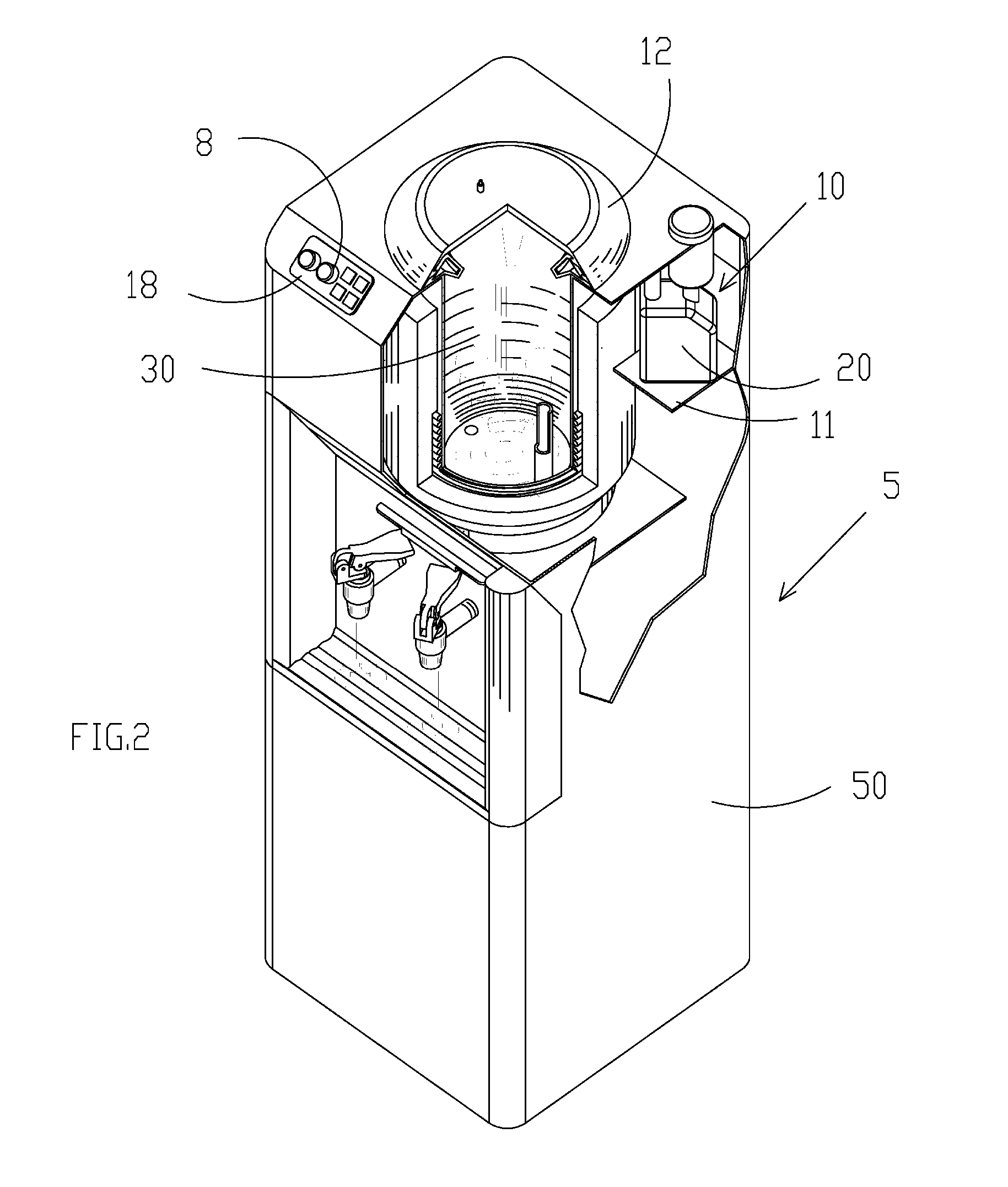

Apparatus and Method for Steam Disinfection of Liquid Dispensing Machine

InactiveUS20070084351A1Facilitate easy refilling thereofImprove completenessThermal drillingInsulationFluid compartmentsEngineering

A method and apparatus using steam to sterilize liquid dispensers. This is achieved by injecting steam into a drained dispenser machine equipped with a cover having a safety valve that matches the top of the dispenser to provide sealing. The steam is generated by a steam generator physically integrated with the new liquid dispenser machine. The steam circulates through the fluid compartment of the liquid dispenser and continues through its conduits and exits at the taps which are held open by a stepped boss. The sanitizing period can be adjusted and controlled. After sterilizing the machine, the cap of the dispenser is removed and its taps are released in order to return the machine back to its normal operation.

Owner:CHANG CHUNG +4

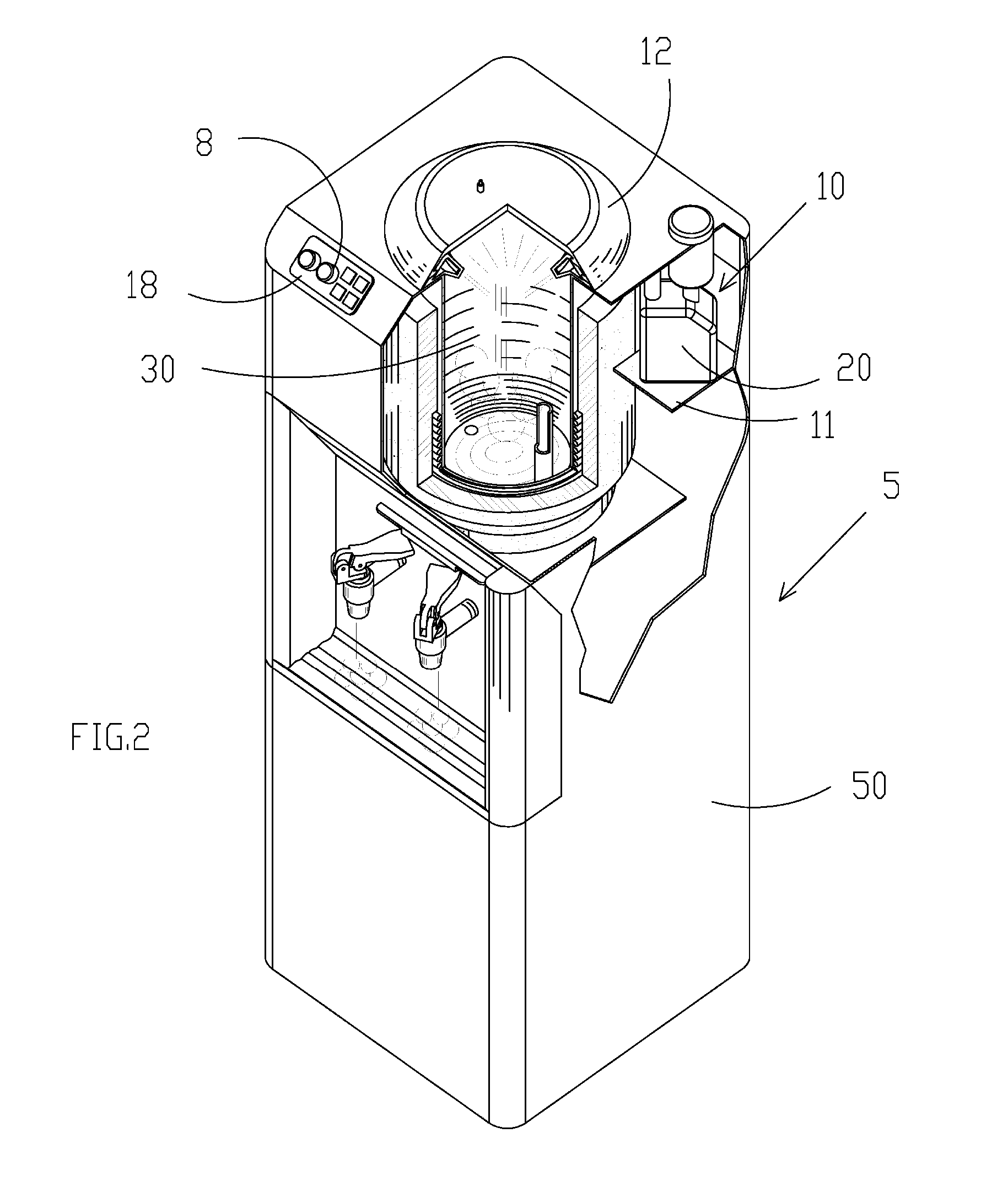

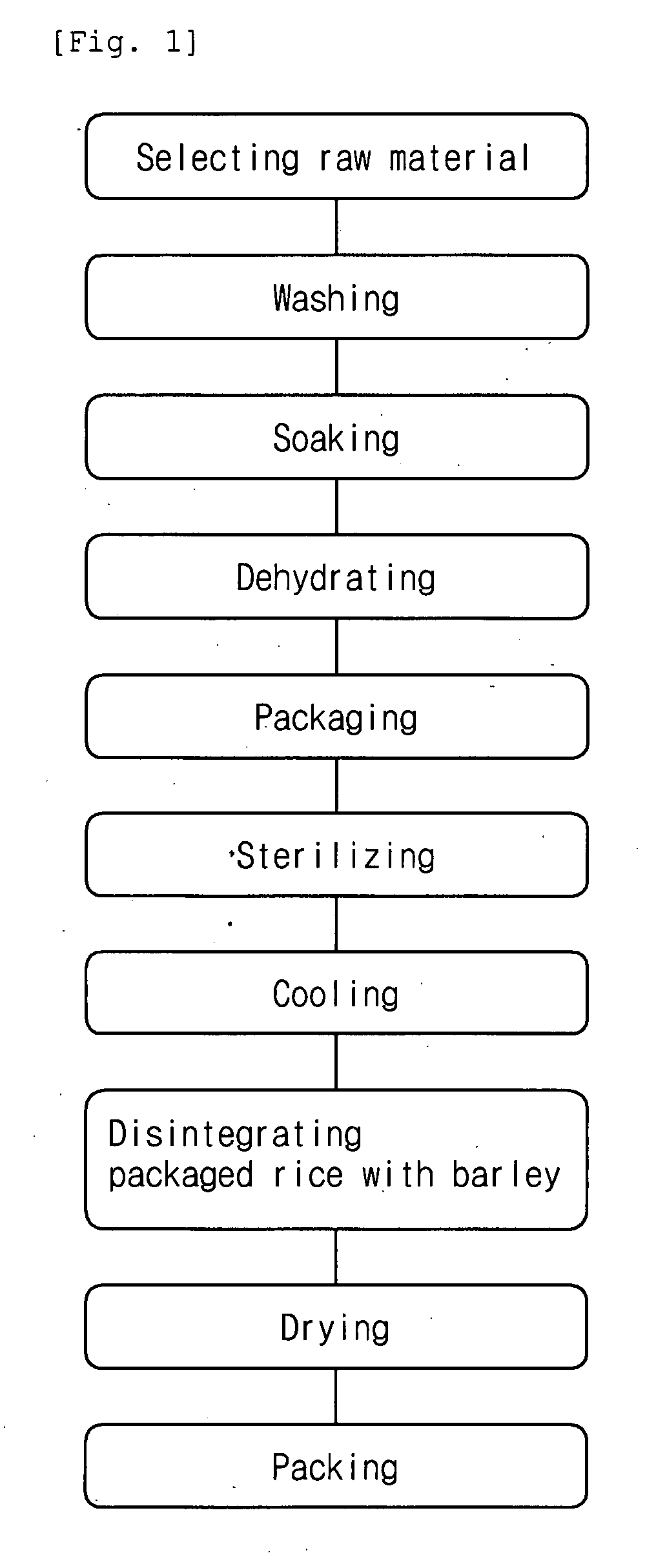

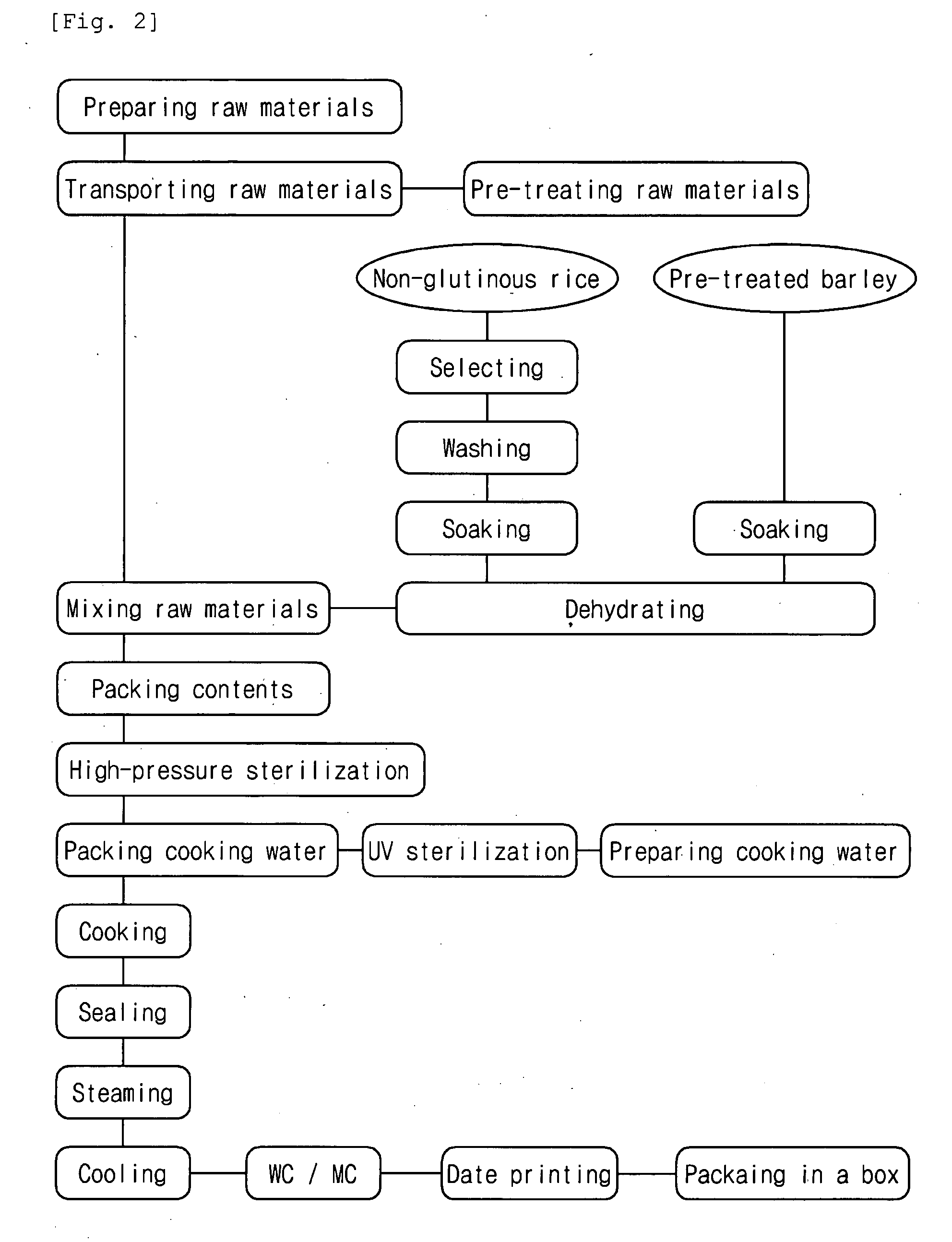

Preparation method of cooked rice with barley in aseptic packing system

ActiveUS20090004361A1Great tasteAdd flavorFruits/vegetable preservation by heatingSeed preservation by heatingMicroorganismRice dishes

The present invention relates to a method for preparing cooked rice with barley in an aseptic packing process, comprising mixing barley, which had been sterilization-treated and then dried, with non-glutinous rice. The method for preparing cooked rice with barley in an aseptic packing system according to the present invention is characterized in that by using barley that has been first gelatinized and then retrogradated, the cooked rice with barley has a reduced initial level of microorganisms in the barley, leading to excellent stability against microorganisms, a long storage life, of 6 months or longer at ambient temperature, excellent appearance, pleasant flavor, and soft, flexible, and sticky texture.

Owner:CJ CHEILJEDANG CORP

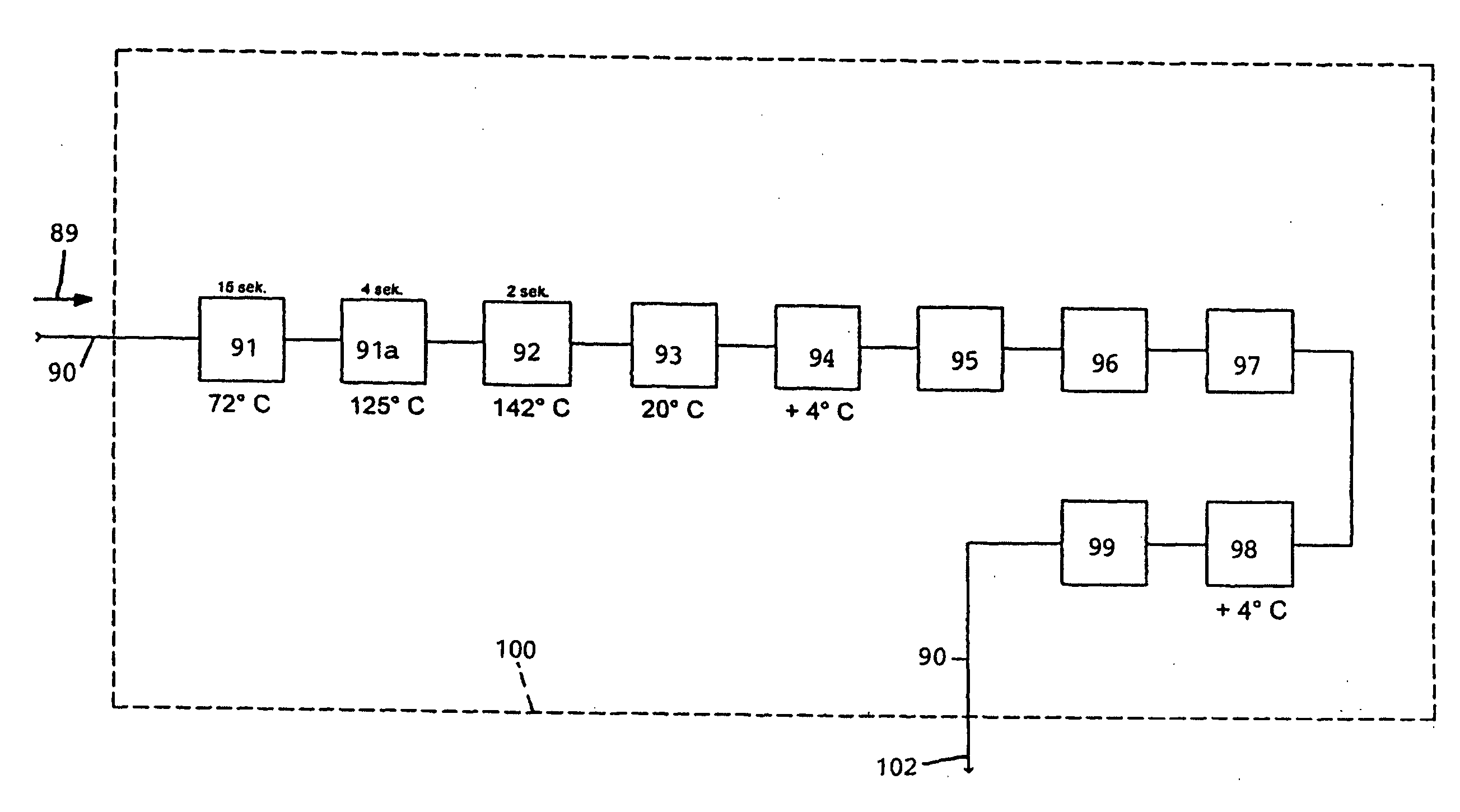

Method and device for treating eggs in shells

InactiveUS20120258218A1Preventing alterationInhibition of denaturationEggs preservation by coatingMilk preservationMicroorganismPasteurization

The invention relates to a method and a device, by which eggs in shells are subjected to heat treatment using a liquid or gaseous or vaporous medium, wherein pasteurization is carried out at a temperature in a range from 70 to 75° C. The object of the invention is to destroy or temporarily render dormant harmful microorganisms that can be destroyed at low heat, and further harmful microorganisms and viruses that cannot be destroyed at low heat, wherein altering of the eggs and / or denaturation of the proteins thereof should be prevented. It is proposed to subject the eggs, prior to pasteurization, to a preheating step at a temperature of substantially 60° C., followed by shock-like cooling to 4° to 5° C., and to carry out pasteurization for a duration of between 12 to 18 seconds.

Owner:KOBIL SYST

Apparatus and method for steam disinfection of liquid dispensing machine

InactiveUS7895938B2Facilitate easy refilling thereofImprove completenessThermal drillingInsulationFluid compartmentsEngineering

A method and apparatus using steam to sterilize liquid dispensers. This is achieved by injecting steam into a drained dispenser machine equipped with a cover having a safety valve that matches the top of the dispenser to provide sealing. The steam is generated by a steam generator physically integrated with the new liquid dispenser machine. The steam circulates through the fluid compartment of the liquid dispenser and continues through its conduits and exits at the taps which are held open by a stepped boss. The sanitizing period can be adjusted and controlled. After sterilizing the machine, the cap of the dispenser is removed and its taps are released in order to return the machine back to its normal operation.

Owner:CHANG CHUNG +4

Method and apparatus for pasteurizing shell eggs using radio frequency heating

Radio frequency (RF) energy is used to quickly heat the yolk portion of a shell egg. An anode and corresponding cathode are applied to each individual egg. As the egg is selectively and systematically rotated, RF energy and a stream of cooling fluid (preferably water) are simultaneously applied to the egg. This initiates pasteurization of the egg yolk while maintaining a low temperature in the heat-sensitive albumen (egg white) thus preventing denaturation of the albumen. Immediately after the RF yolk heating process, the egg is placed in a hot water bath designed to rapidly pasteurize the albumen as well as to minimize heat loss from the yolk and pasteurize any portion of the yolk that is not already pasteurized through the RF yolk heating process.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

Method and apparatus for material handling for a food product using high pressure pasteurization

ActiveUS7722912B2UtilizedOptimize timingMeat/fish preservation by heatingMilk treatmentEngineeringPasteurization

A method and apparatus for high-pressure pasteurization utilizes a basket (40) for holding food packages (95). The basket (40) is transported on a cart (60) from a loading station (90), to the high-pressure pasteurization processing apparatus (10) and back to an unloading station (100). Two robots (17, 18) are utilized to reduce cycle time of the high-pressure pasteurization vessels (11).

Owner:HORMEL FOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com