Method for formulating and aseptically filling liquid products

a liquid product and aseptic technology, applied in the field of formulating and/or filling products, can solve the problems of adversely affecting the molecular components and structures of infant formulas and other liquid nutrition products, unusable components, and unfavorable nutritional effects,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

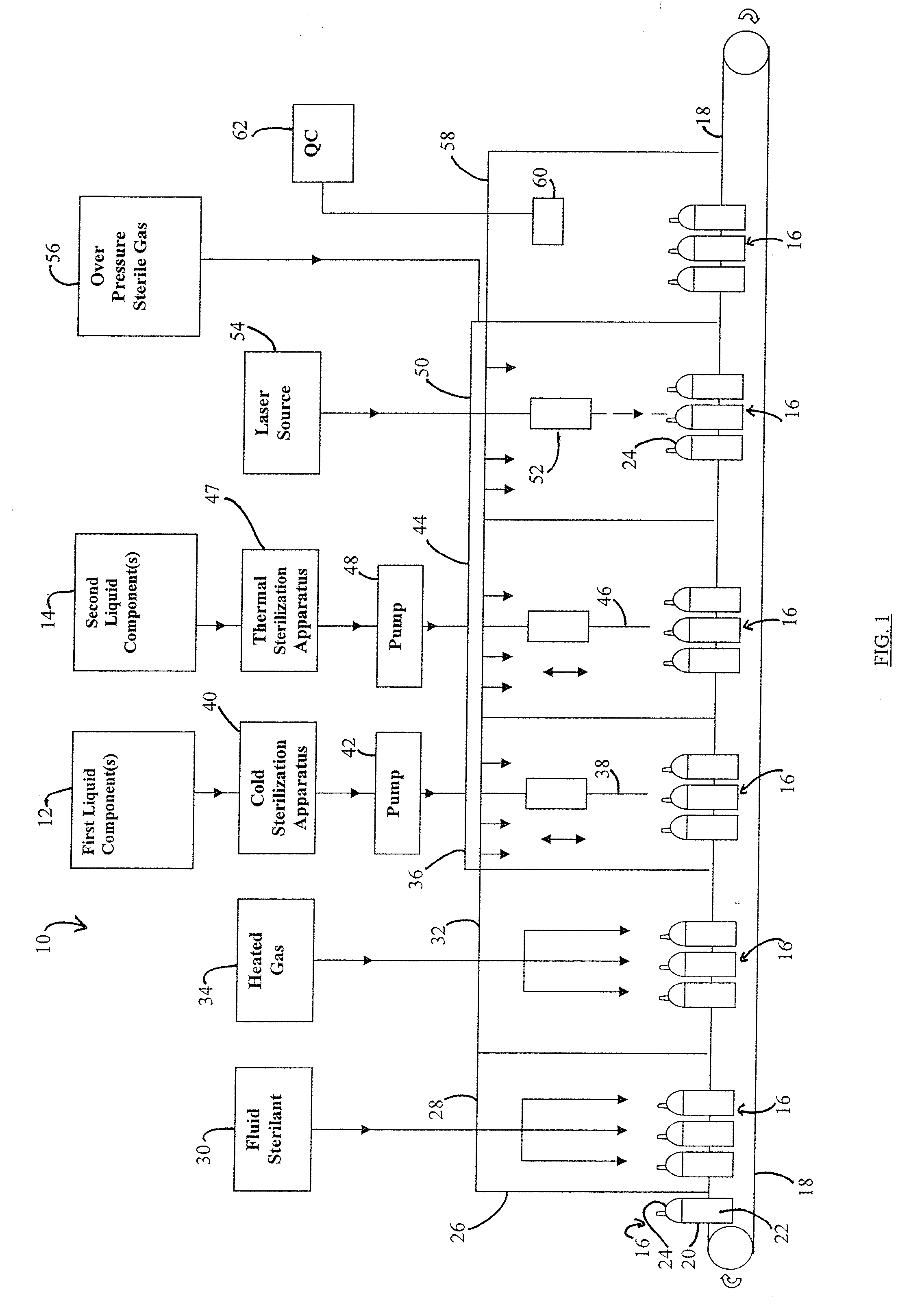

[0048]In FIG. 1, an apparatus embodying the present invention is indicated generally by the reference numeral 10. The apparatus 10 comprises a first liquid source 12 including at least one first liquid component, and a second liquid source 14 including at least one second liquid component. A plurality of containers 16 are mounted on a conveyor 18 and transported by the conveyor through the apparatus. Each container 16 includes a body 20 defining an empty, sterile storage chamber 22 therein, and a penetrable and thermally resealable portion 24 in fluid communication with the storage chamber. The apparatus 10 includes a housing 26 defining a barrier enclosure for receiving therein sealed, empty sterile containers 16 transported on the conveyor 18, sterilizing the exterior portions of the containers, aseptically filling the containers with the first and second liquid components (and other components if desired) and combining the liquid components within the storage chambers 22 of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com