Patents

Literature

333 results about "First Fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for dispensing a vapor phase reactant to a reaction chamber and related methods

ActiveUS20190093221A1Well formedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingFirst FillCompound (substance)

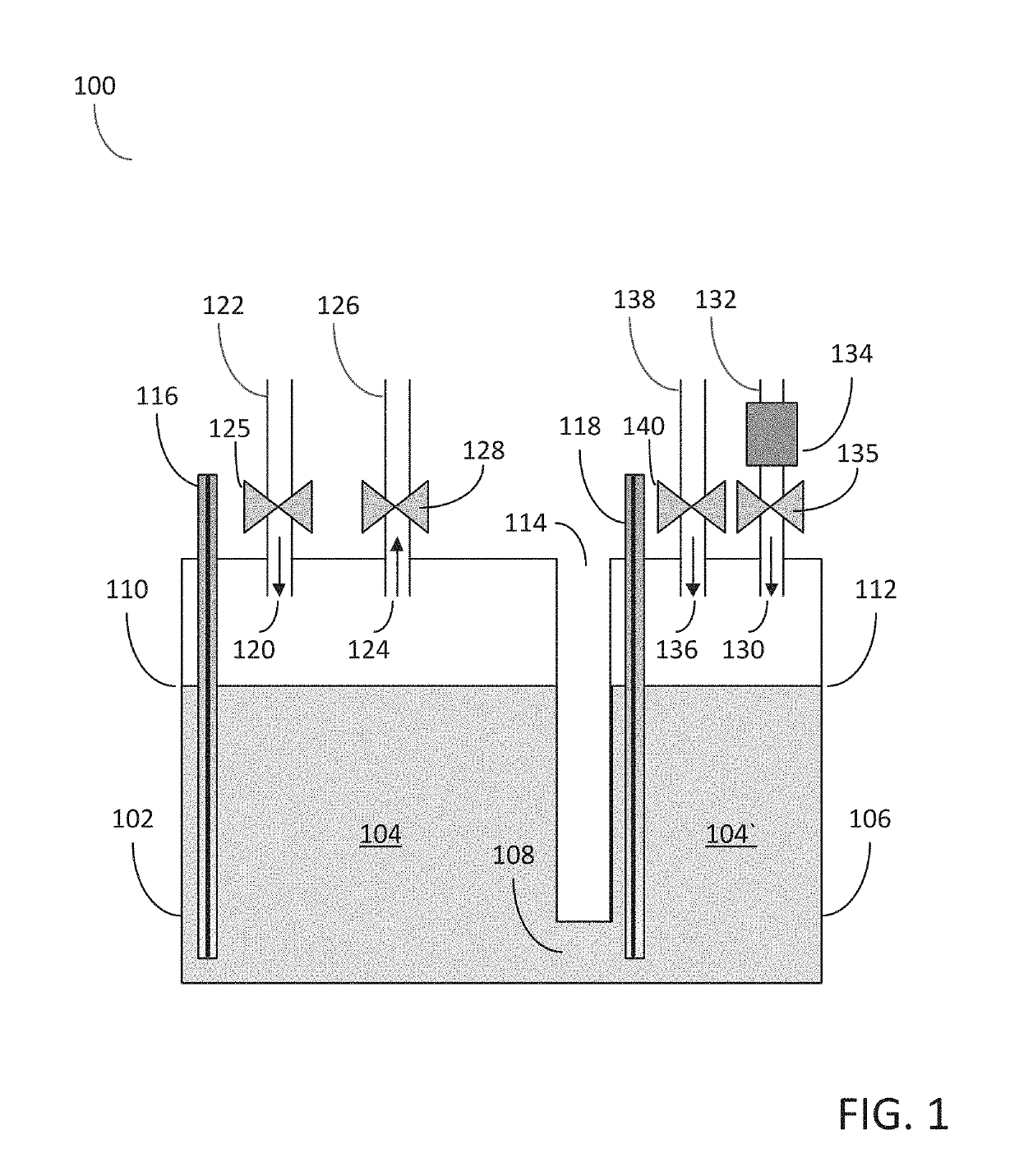

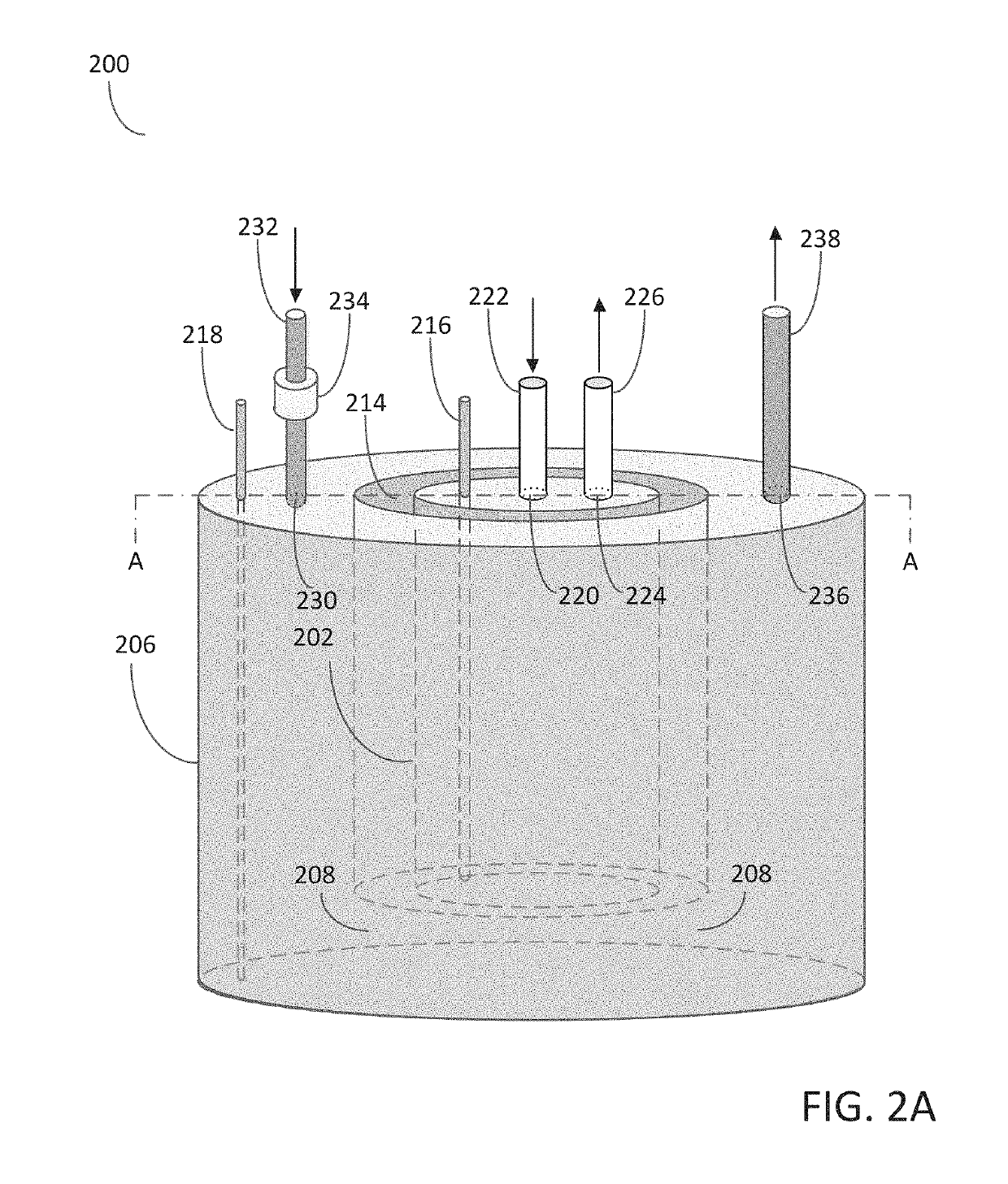

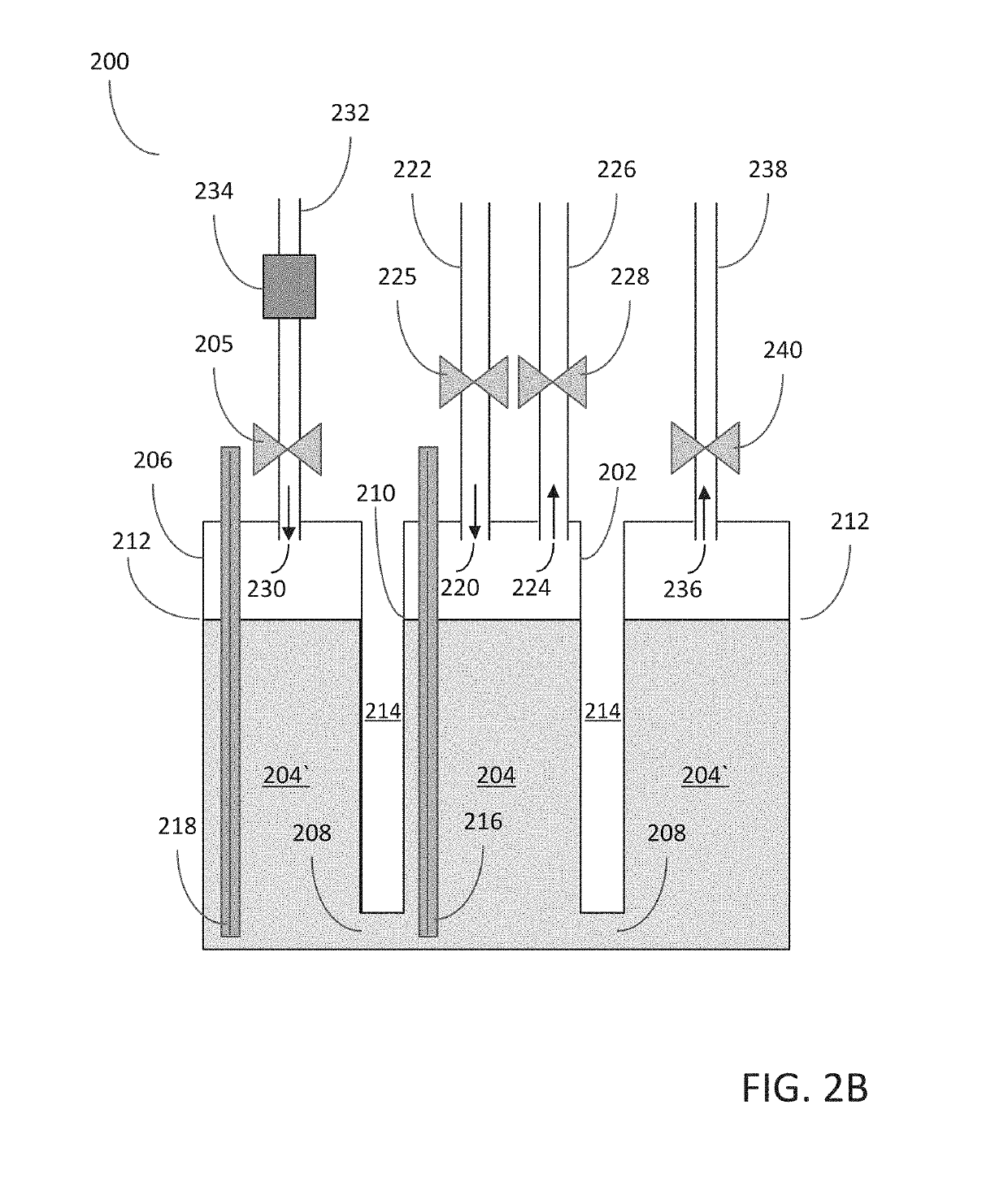

An apparatus for dispensing a vapor phase reactant to a reaction chamber is disclosed. The apparatus may include: a first chamber configured for holding a source chemical with a first fill level; and a second chamber configured for holding the source chemical with a second fill level and in fluid communication with the first chamber via a fluid channel below the first and second fill levels. The apparatus may also include: a second chamber inlet opening in fluid communication with a pressurizing gas feed provided with a flow controller configured for controlling a flow of a pressurizing gas in the second chamber to control the first fill level in the first chamber. Methods for dispensing a vapor phase reactant are also provided.

Owner:ASM IP HLDG BV

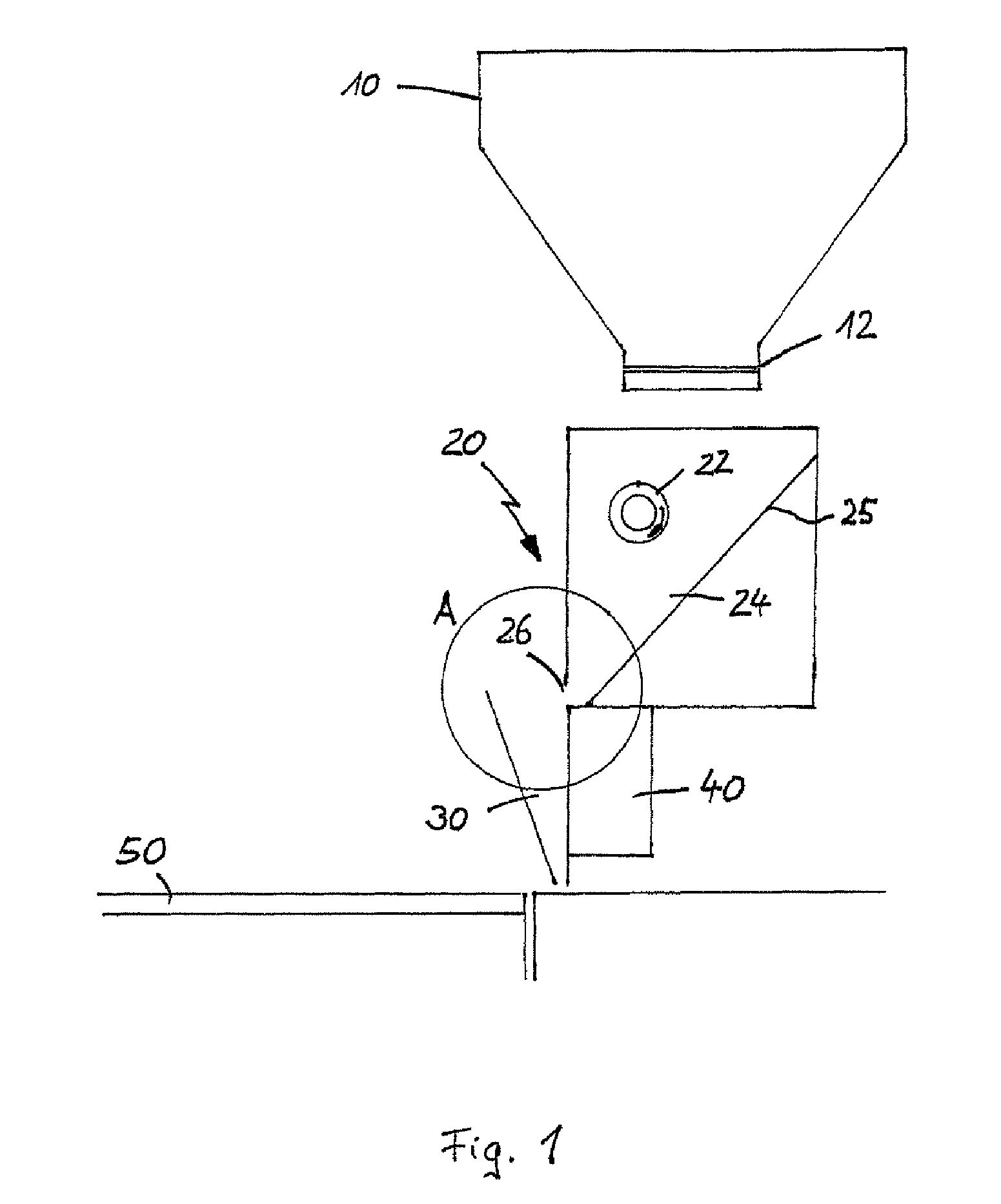

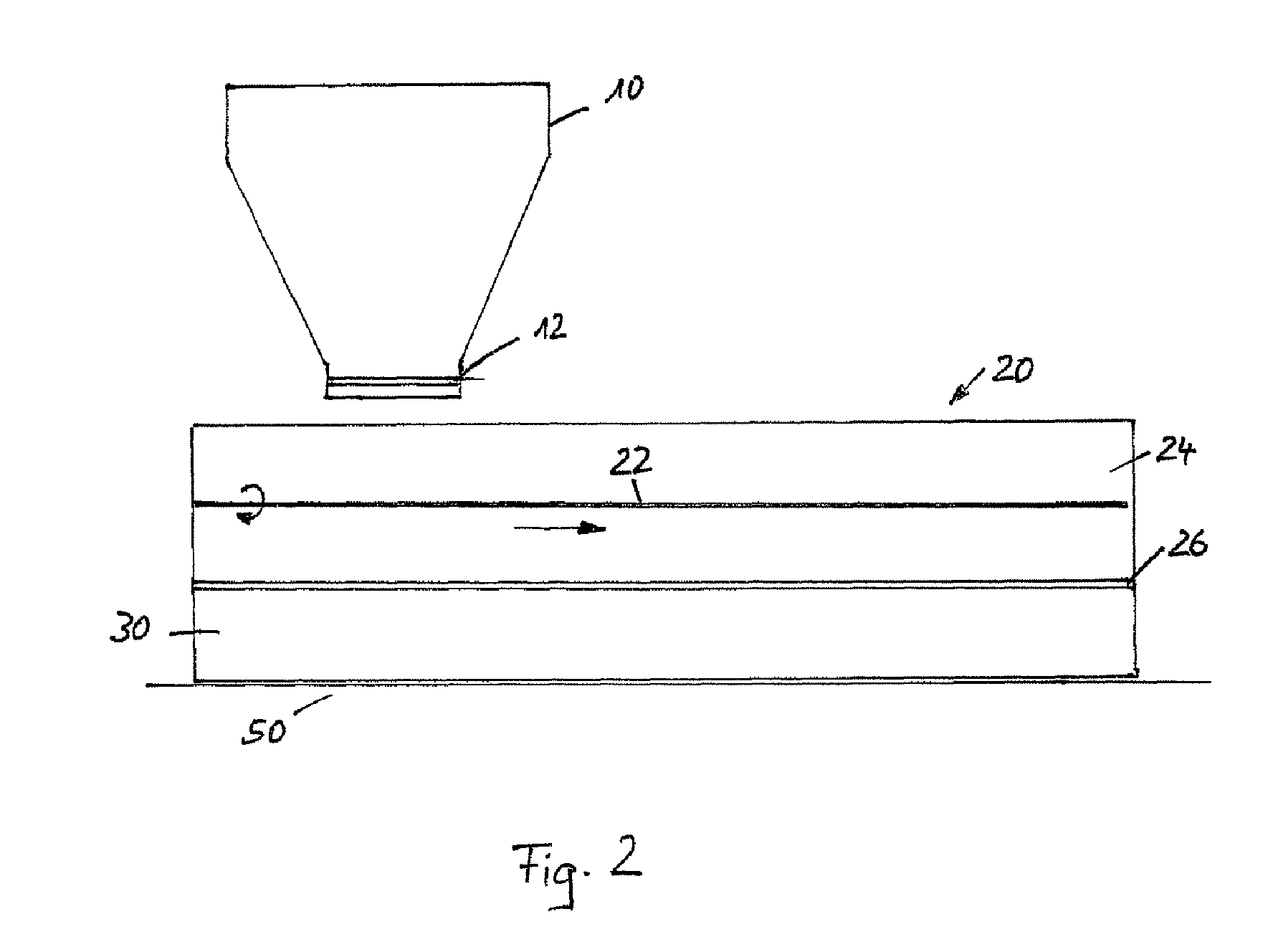

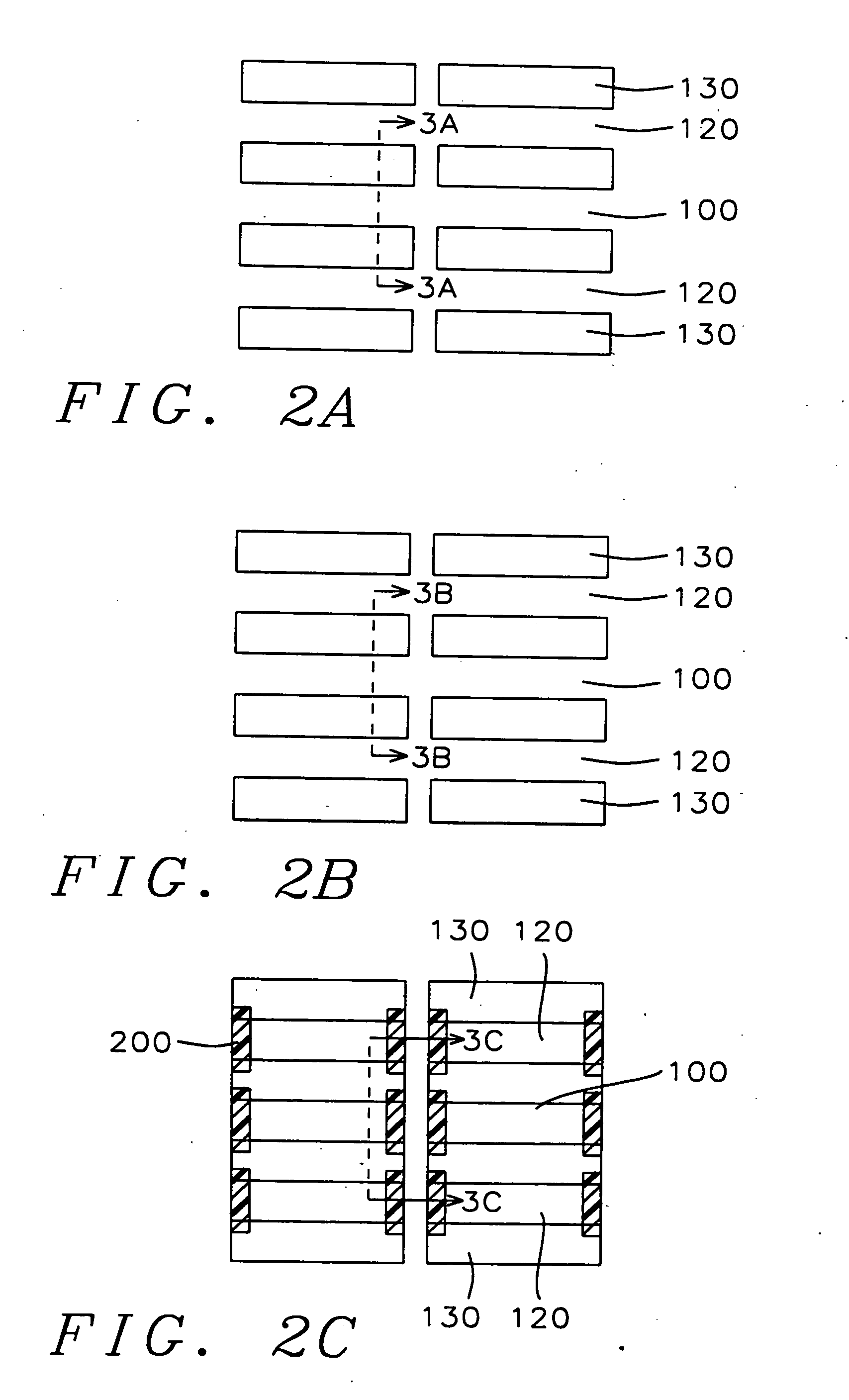

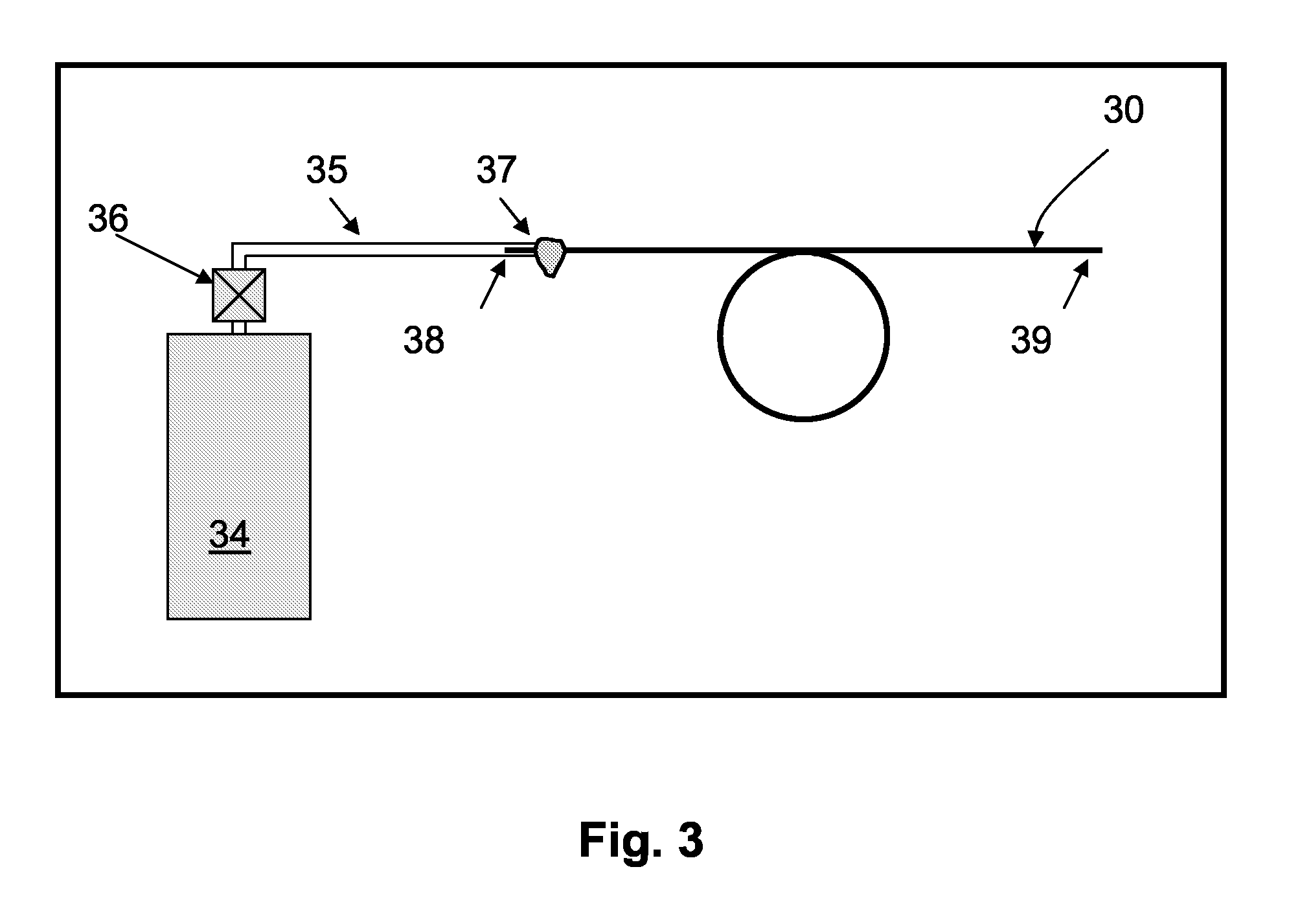

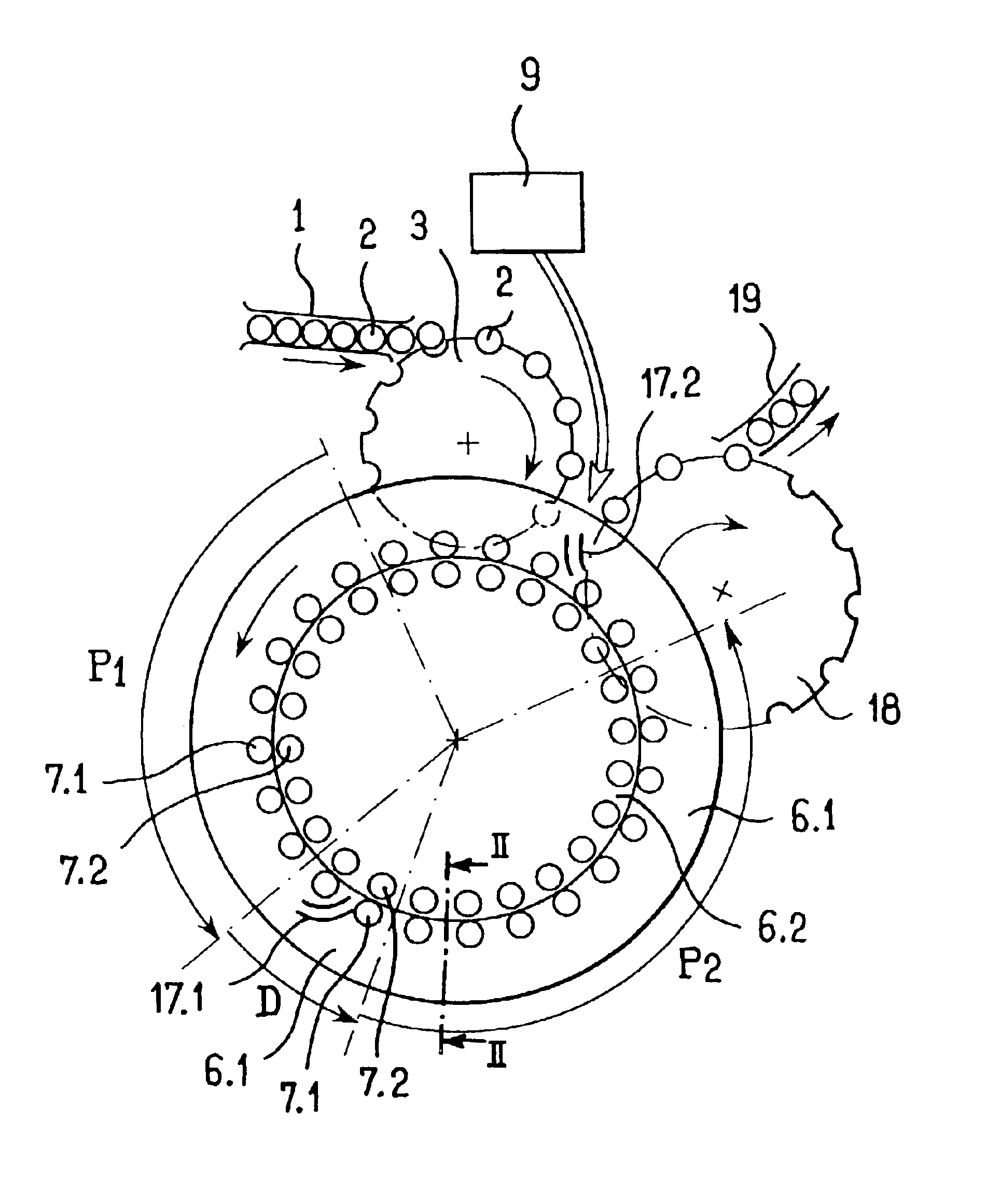

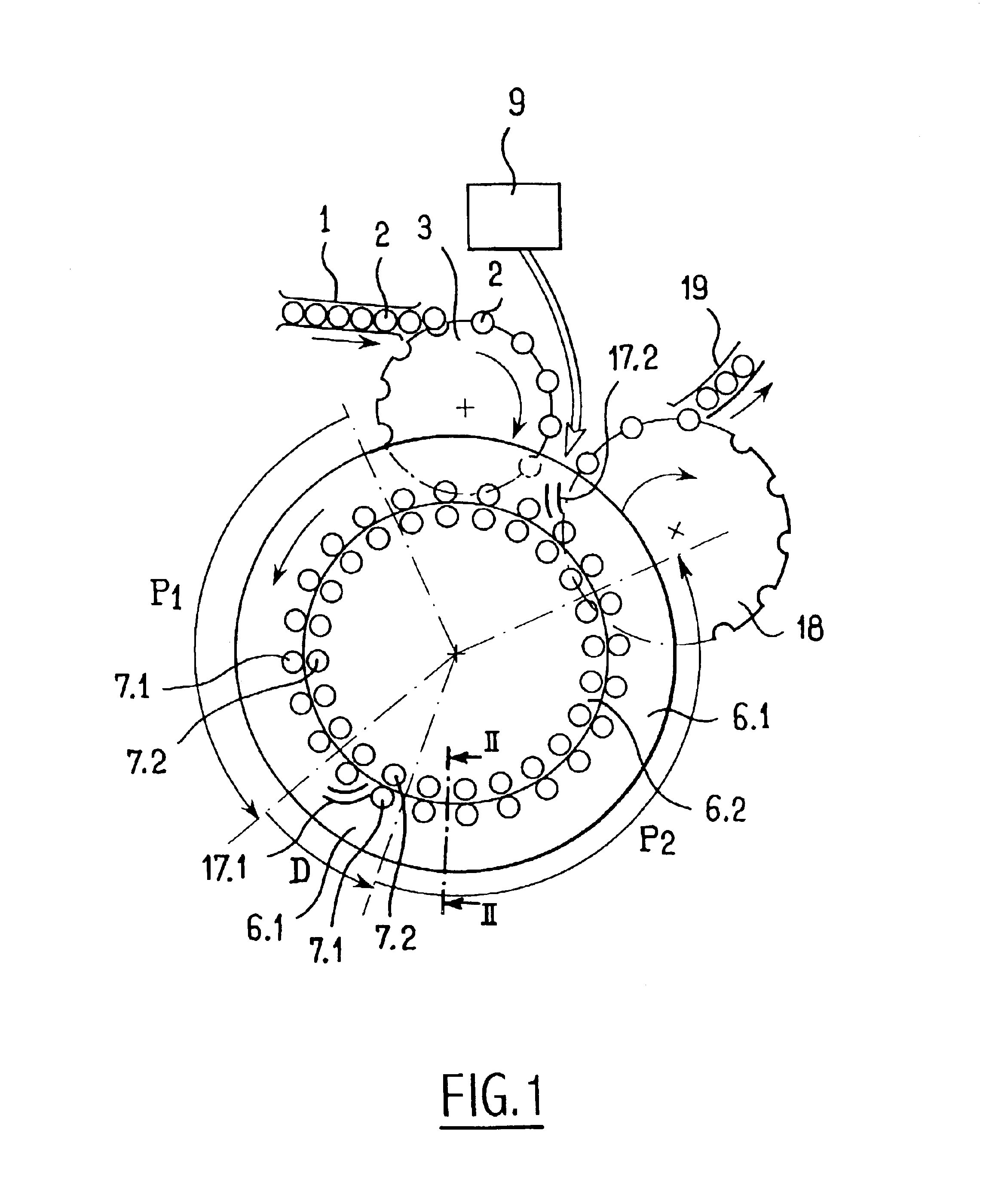

Method of, and apparatus for, applying flowable material across a surface

ActiveUS7799253B2Reduce volume of containerReduce in quantityAdditive manufacturing apparatusLiquid surface applicatorsFirst FillEngineering

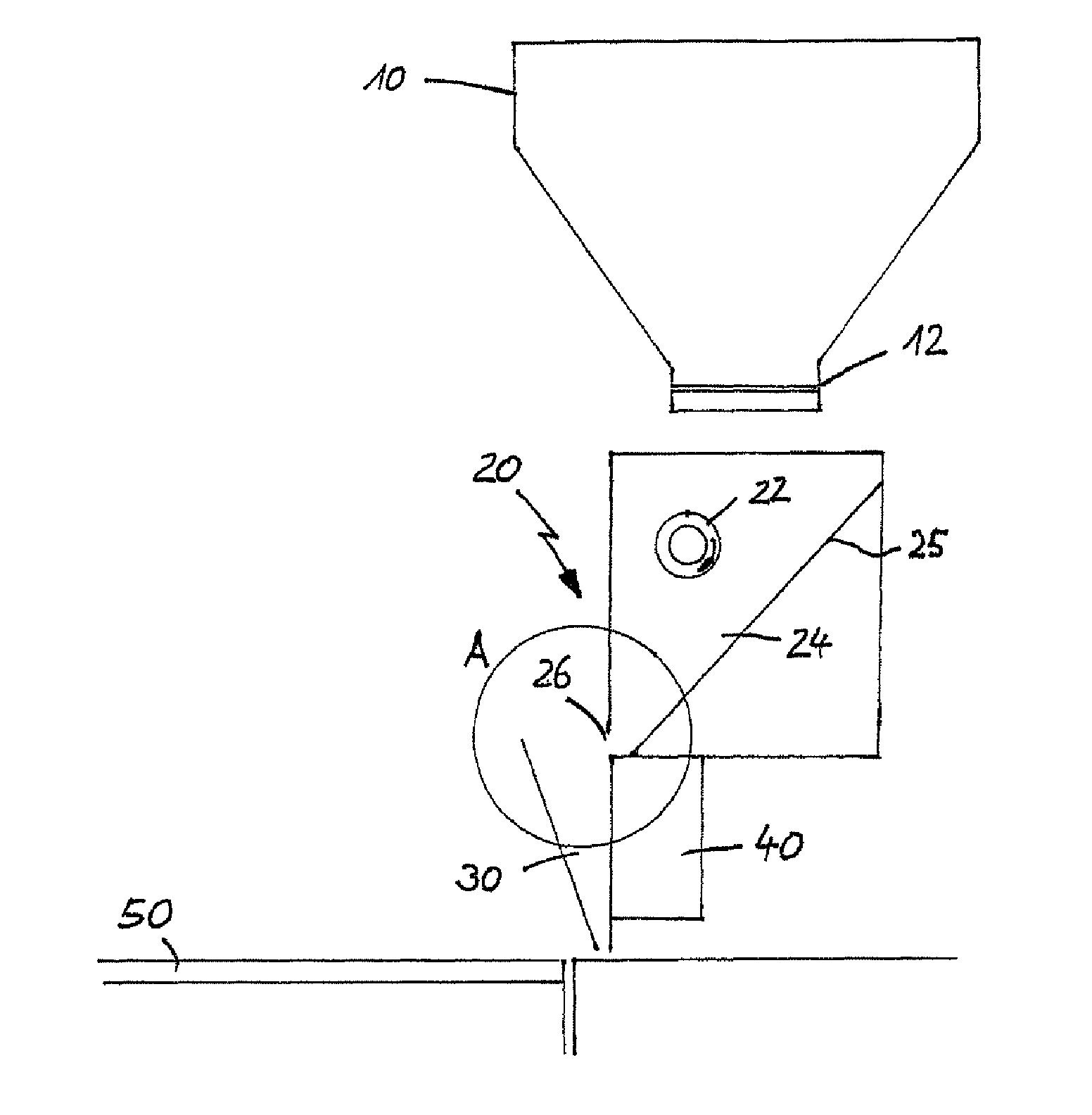

The invention relates to a method and a device for applying for a flowable material, especially a particulate material, in individual superimposed layers across a support (50), the flowable material being first filled from a stationary feed station (10) into a storage container (24) of an application device. In the application device (30), which travels back and forth across the support, the flowable material is distributed inside the storage container across the entire length of the device and is then metered through a slot into a metering shaft in such a manner that the filling level in the metering shaft remains constant during application of the flowable material from the metering shaft onto the support.

Owner:EXONE

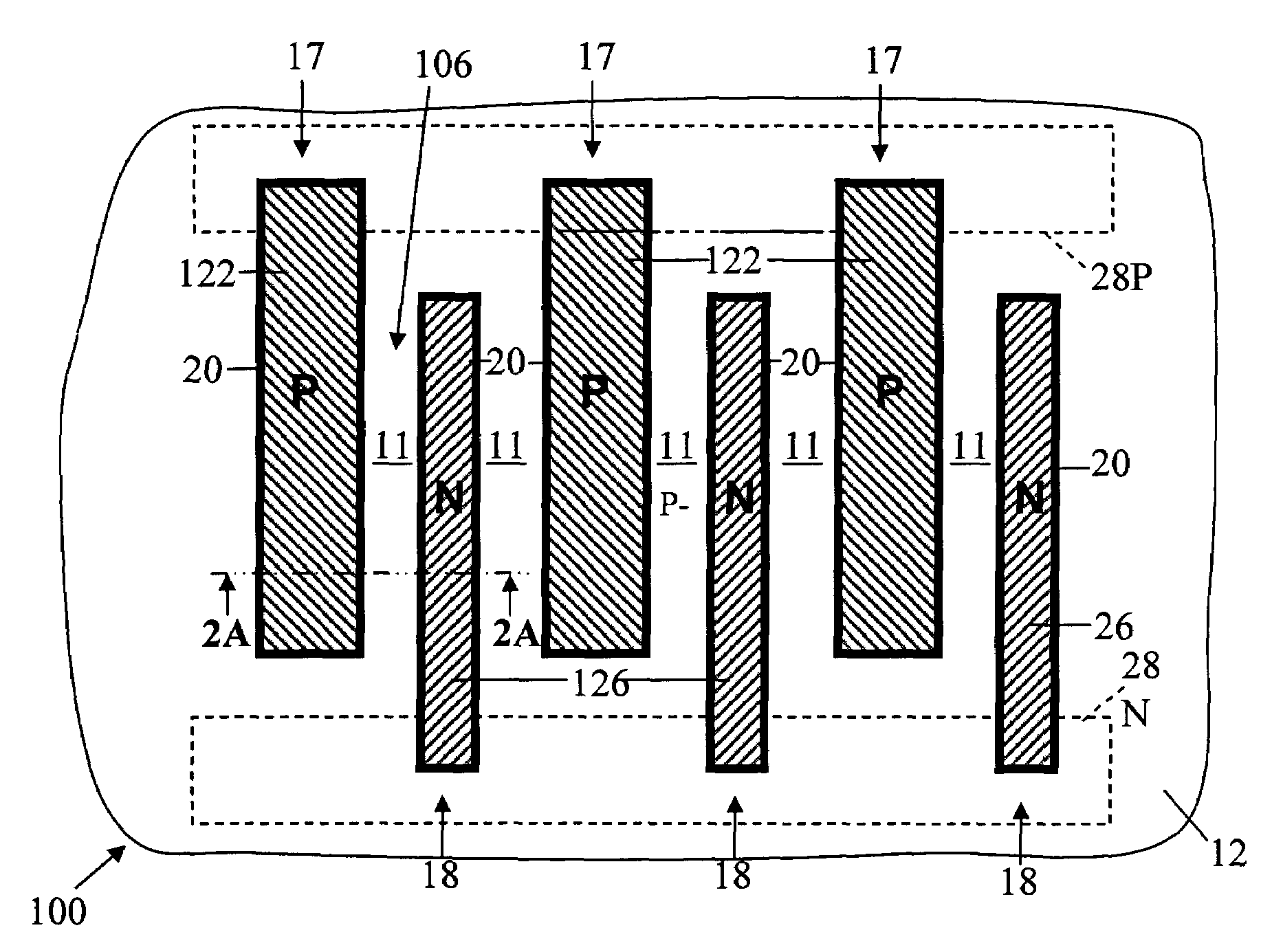

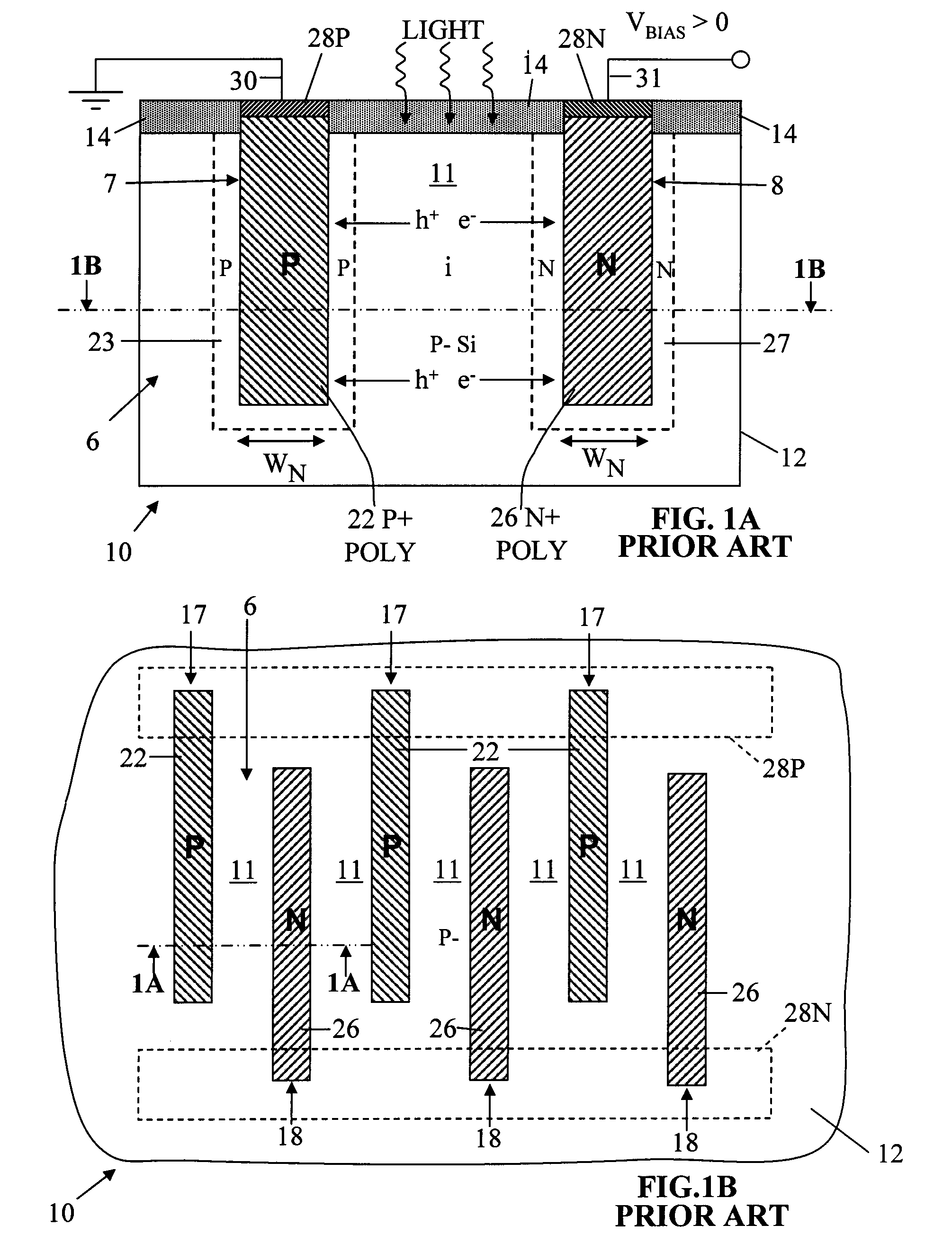

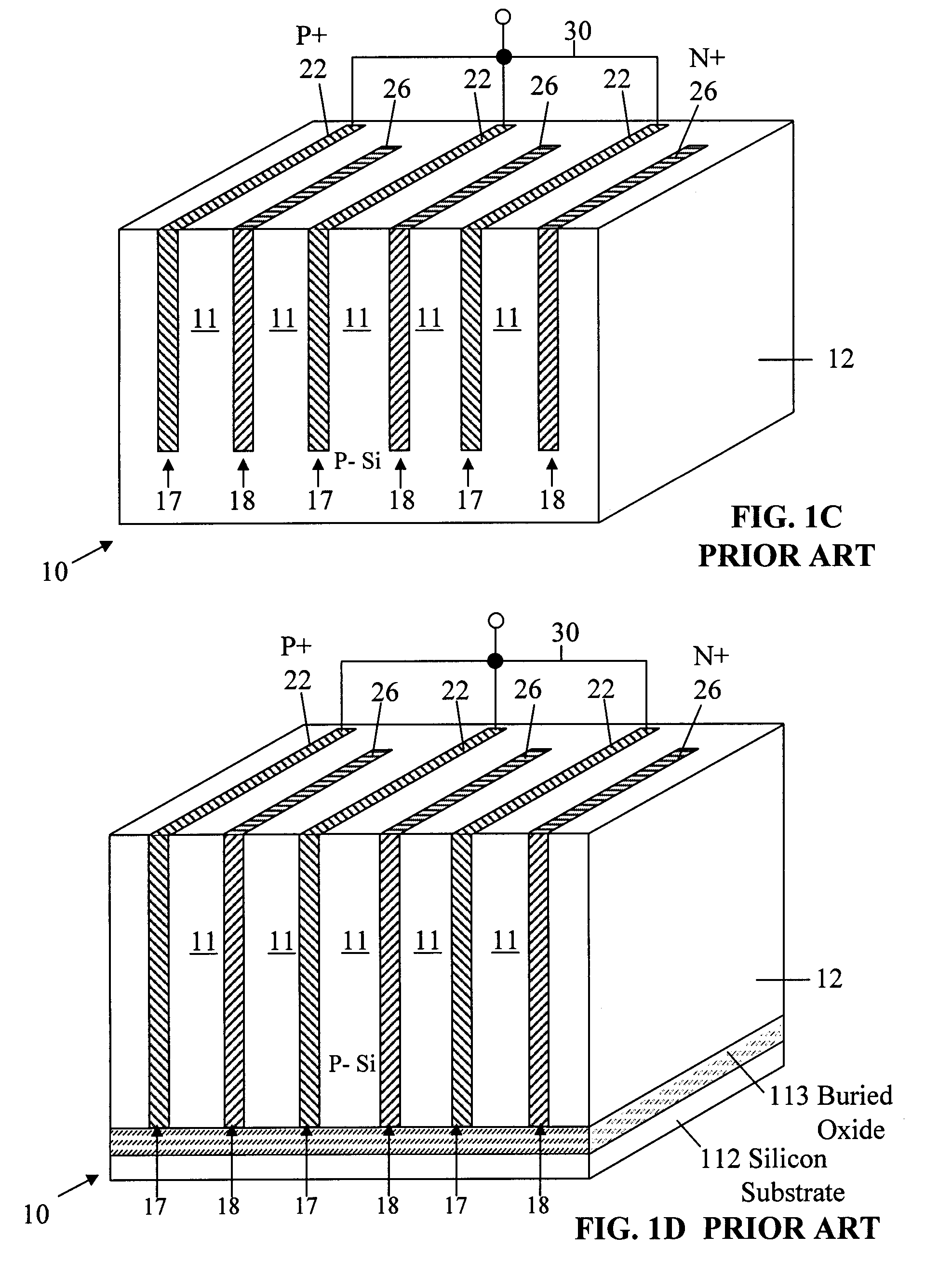

Trench optical device

A semiconductor device is formed in on a semiconductor substrate starting with a first step, which is to form a wide trench and a narrow trench in the substrate. Then form a first electrode in the narrow trench by depositing a first fill material of a first conductivity type over the device to fill the wide trench partially and to fill the narrow trench completely. Etch back the first fill material until completion of removal thereof from the wide trench. Form a second electrode in the wide trench by filling the wide trench with a second fill material of an opposite conductivity type. Anneal to drive dopant both from the first fill material of the first electrode into a first outdiffusion region in the substrate about the periphery of the narrow trench and from the second fill material of the second electrode into a second outdiffusion region in the substrate about the periphery of the wide trench.

Owner:GLOBALFOUNDRIES US INC

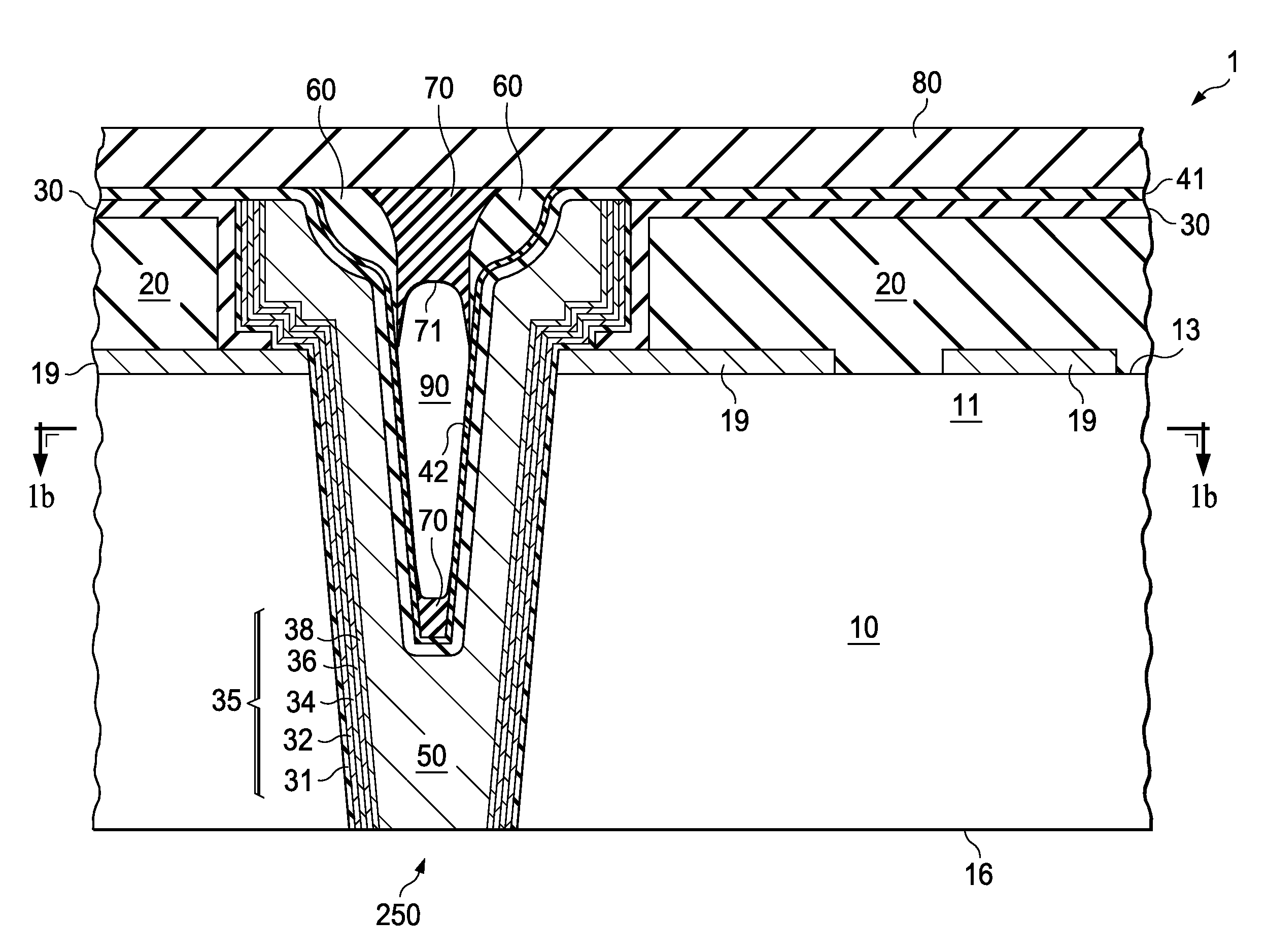

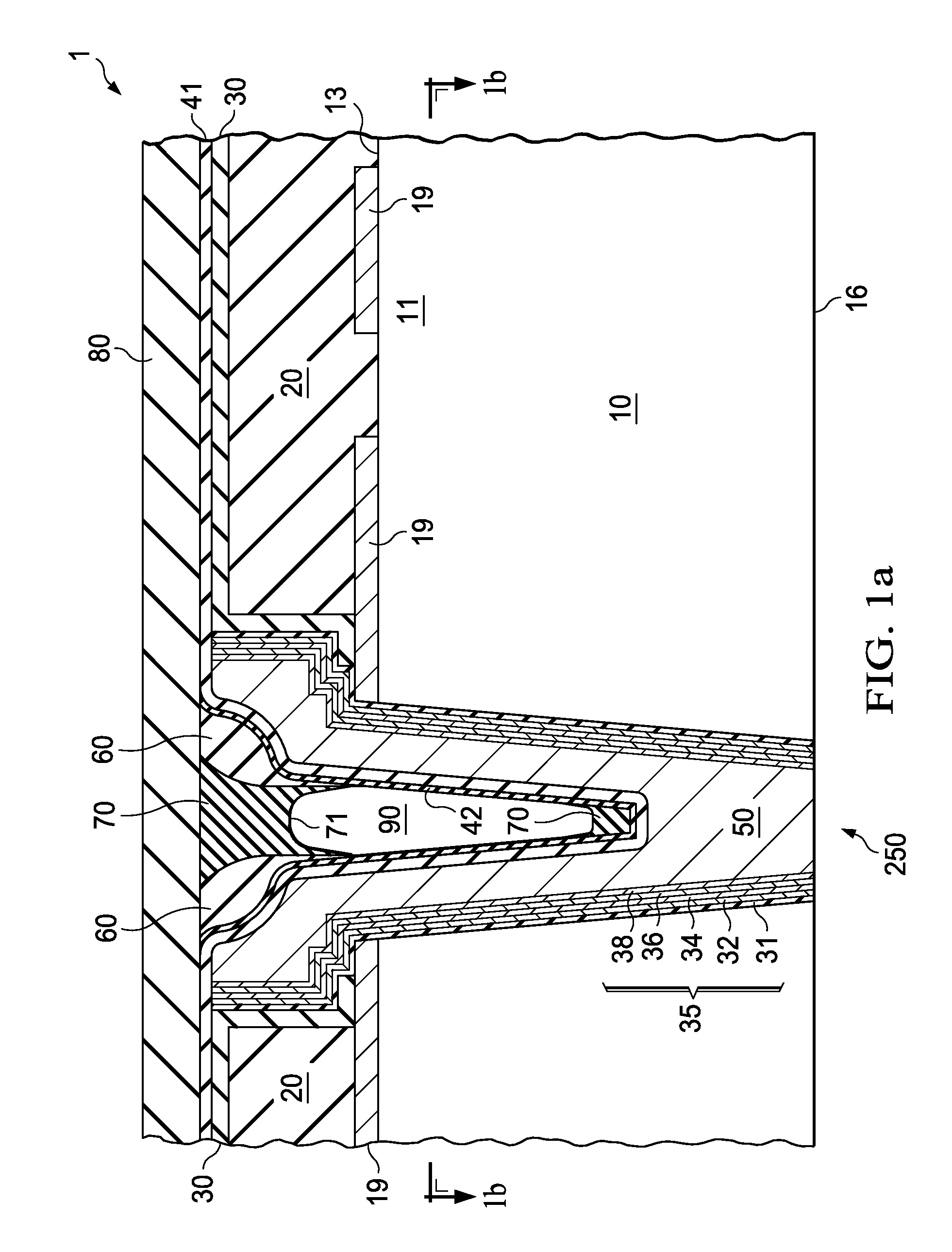

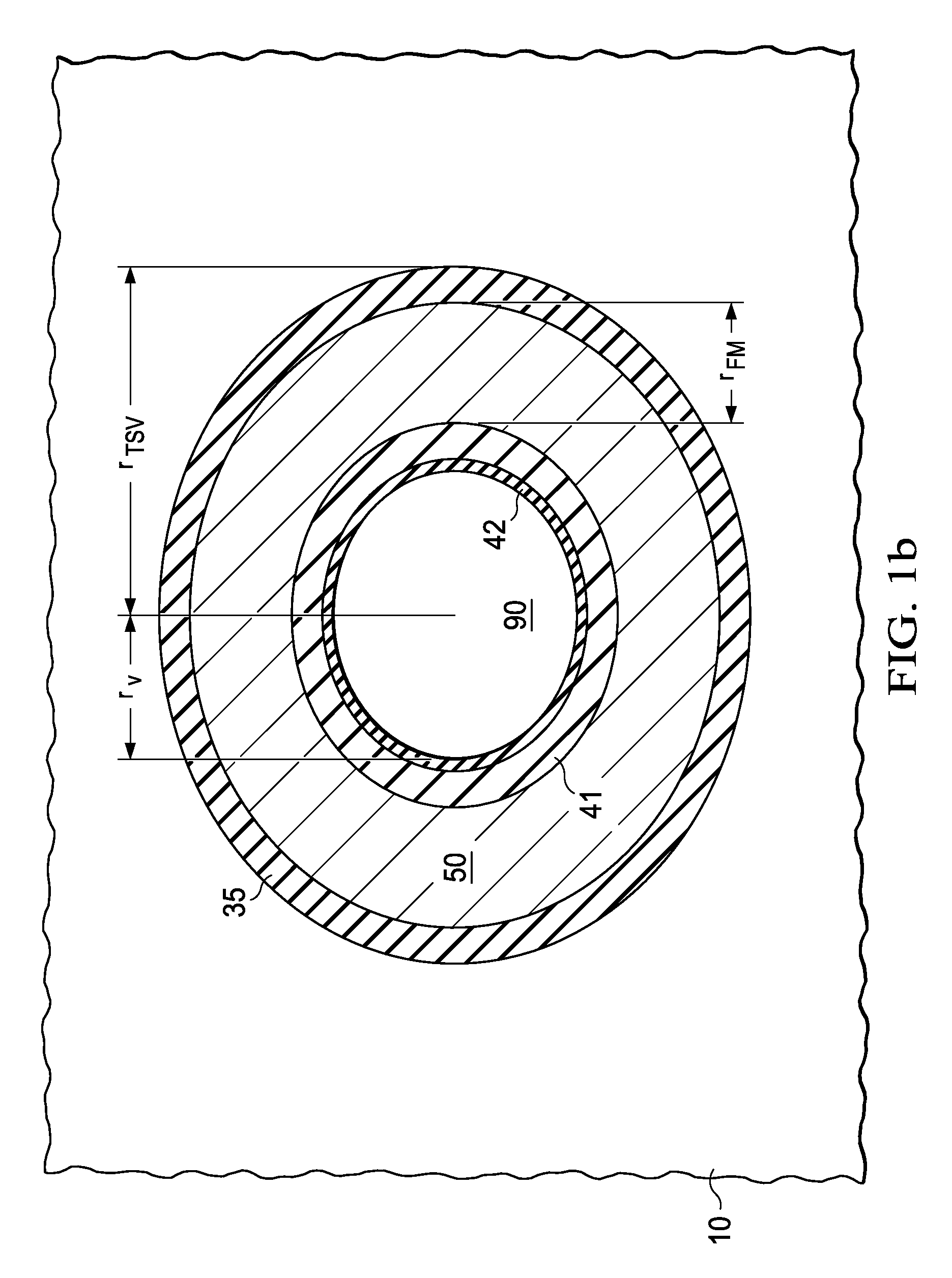

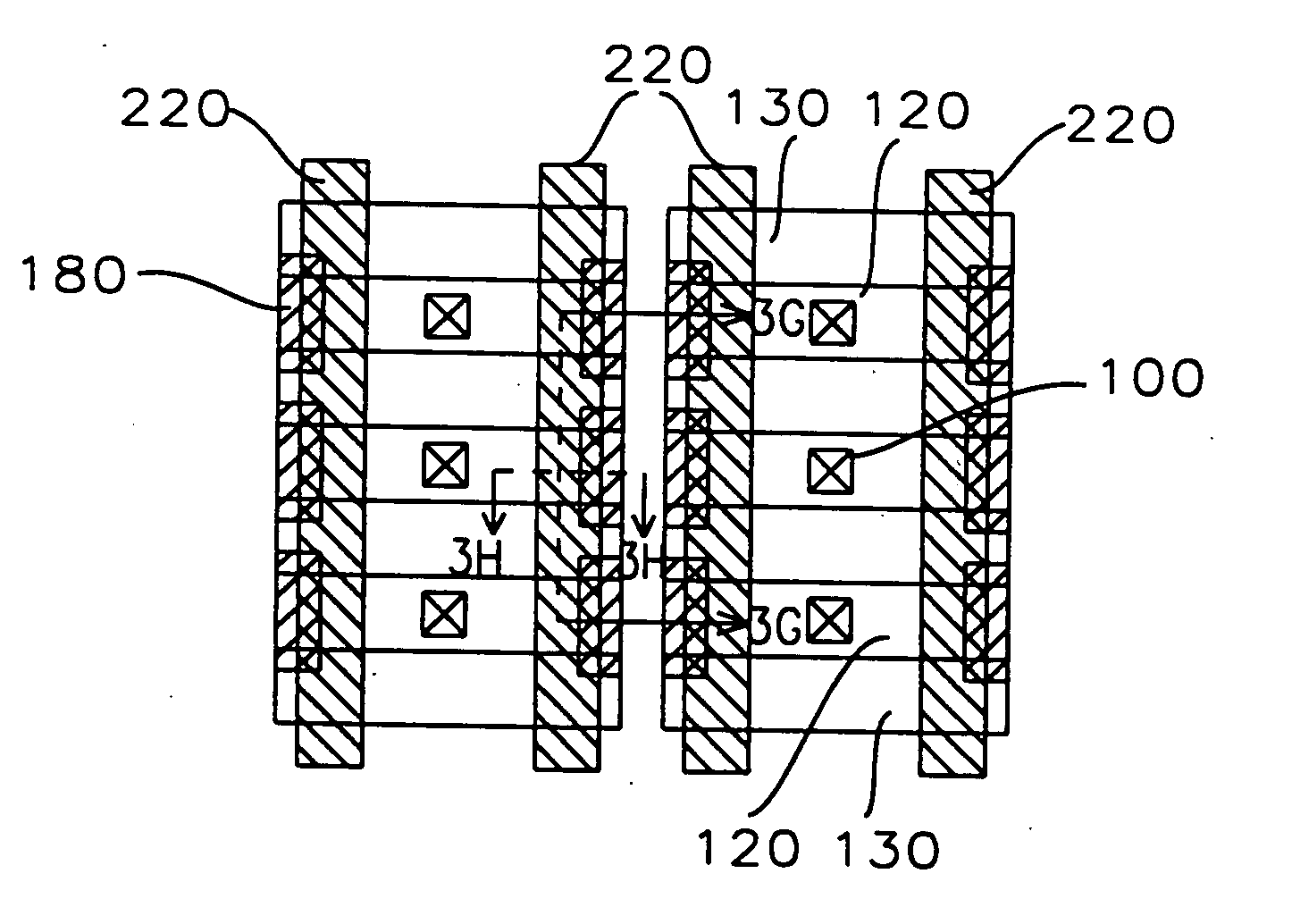

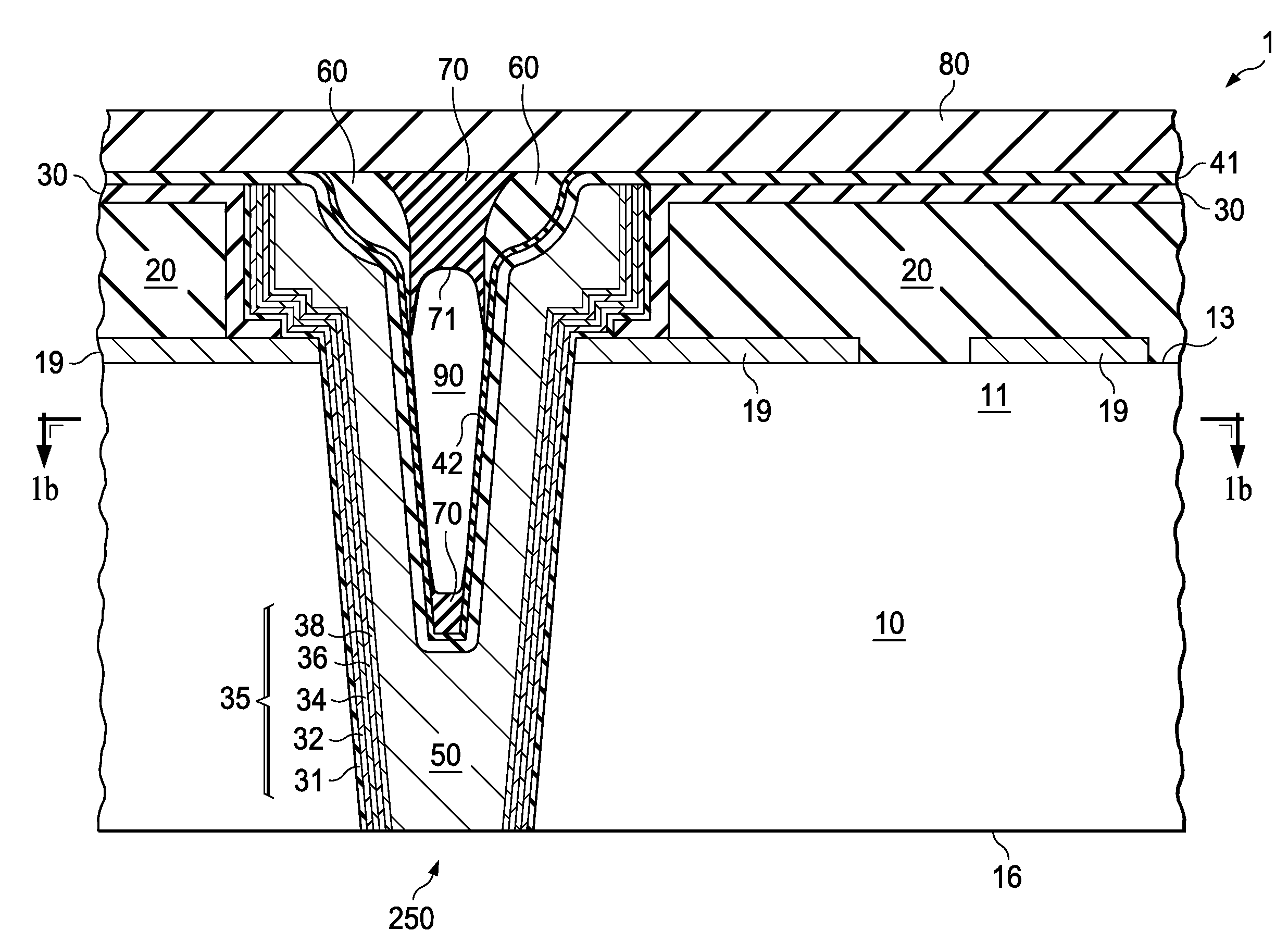

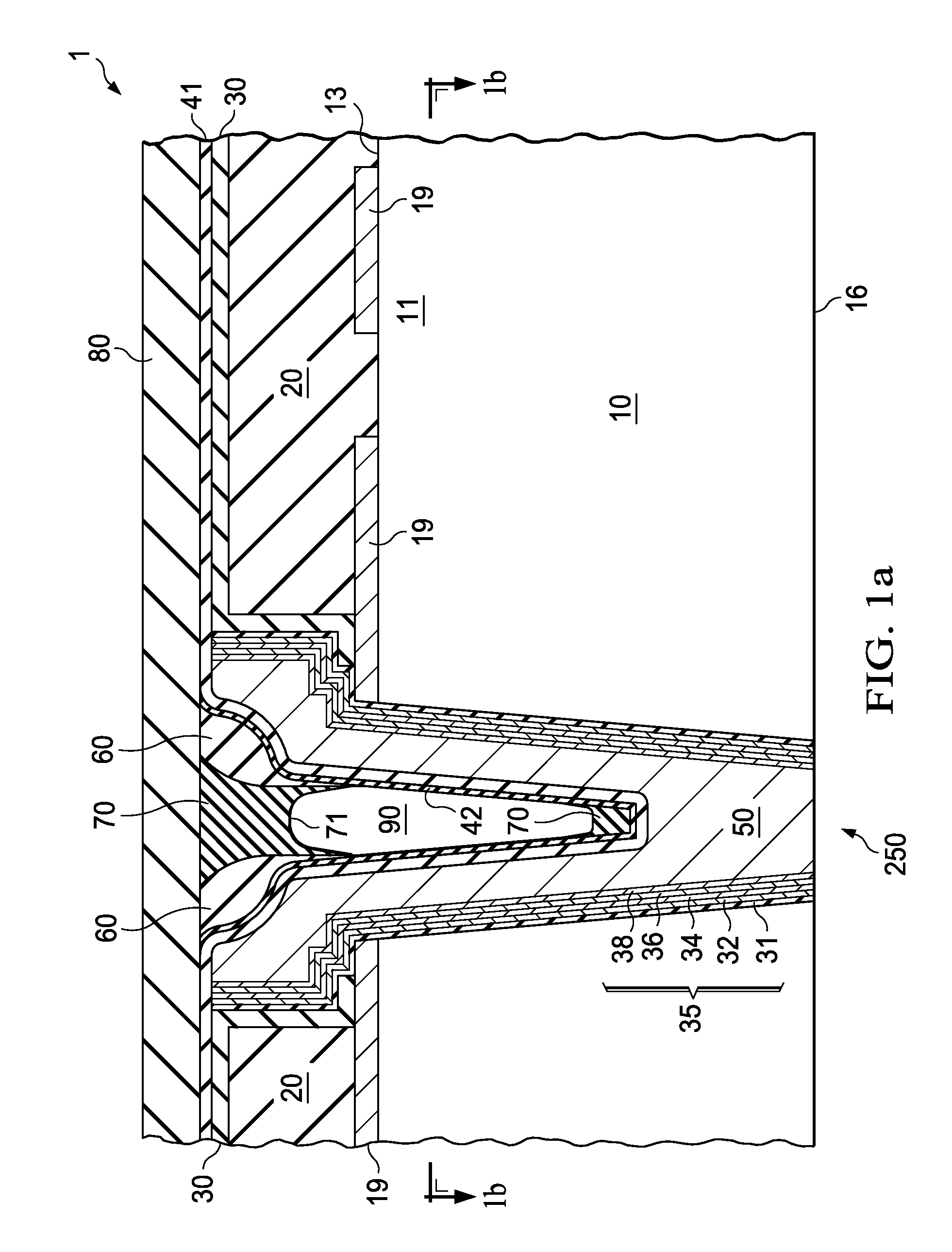

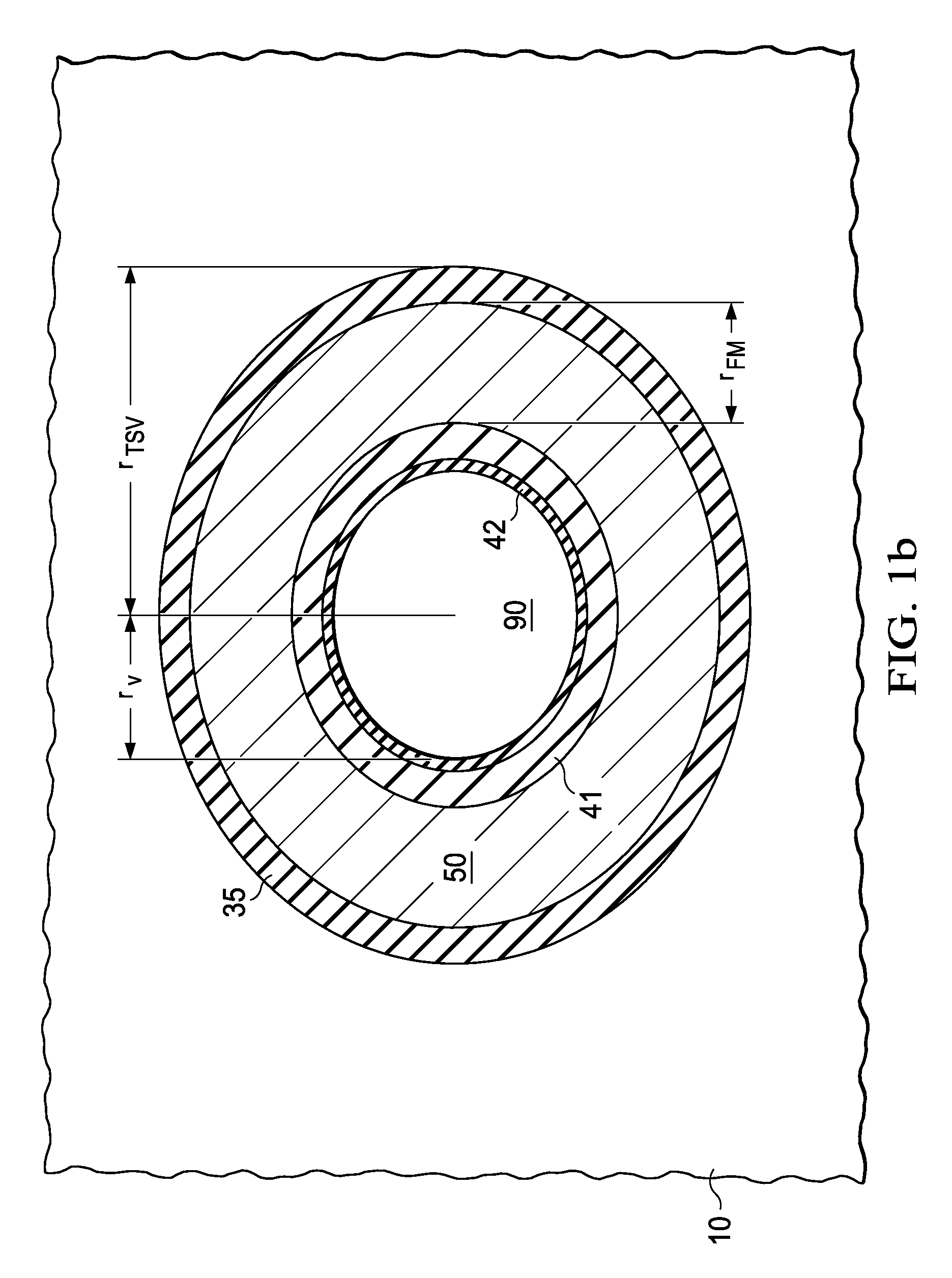

Through Substrate Via Semiconductor Components

ActiveUS20090302480A1Semiconductor/solid-state device detailsSolid-state devicesFirst FillFilling materials

A structure and method of forming through substrate vias in forming semiconductor components are described. In one embodiment, the invention describes a method of forming a through substrate via by partially filling an opening with a fill material, and forming a first insulating layer over the first fill material thereby forming a gap over the opening. The method further includes forming a second insulating layer to close the gap thereby forming an enclosed cavity within the opening.

Owner:INFINEON TECH AG

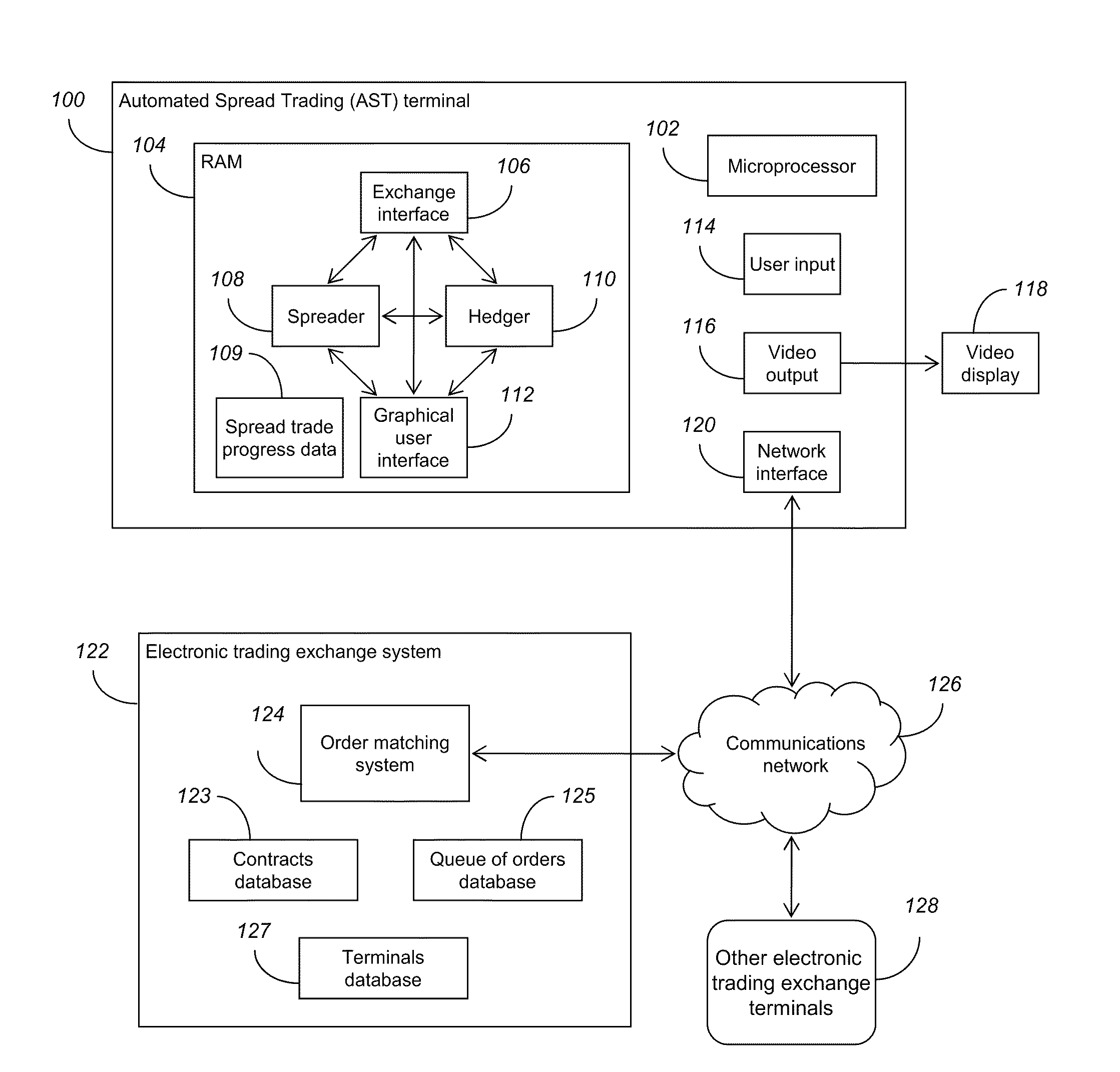

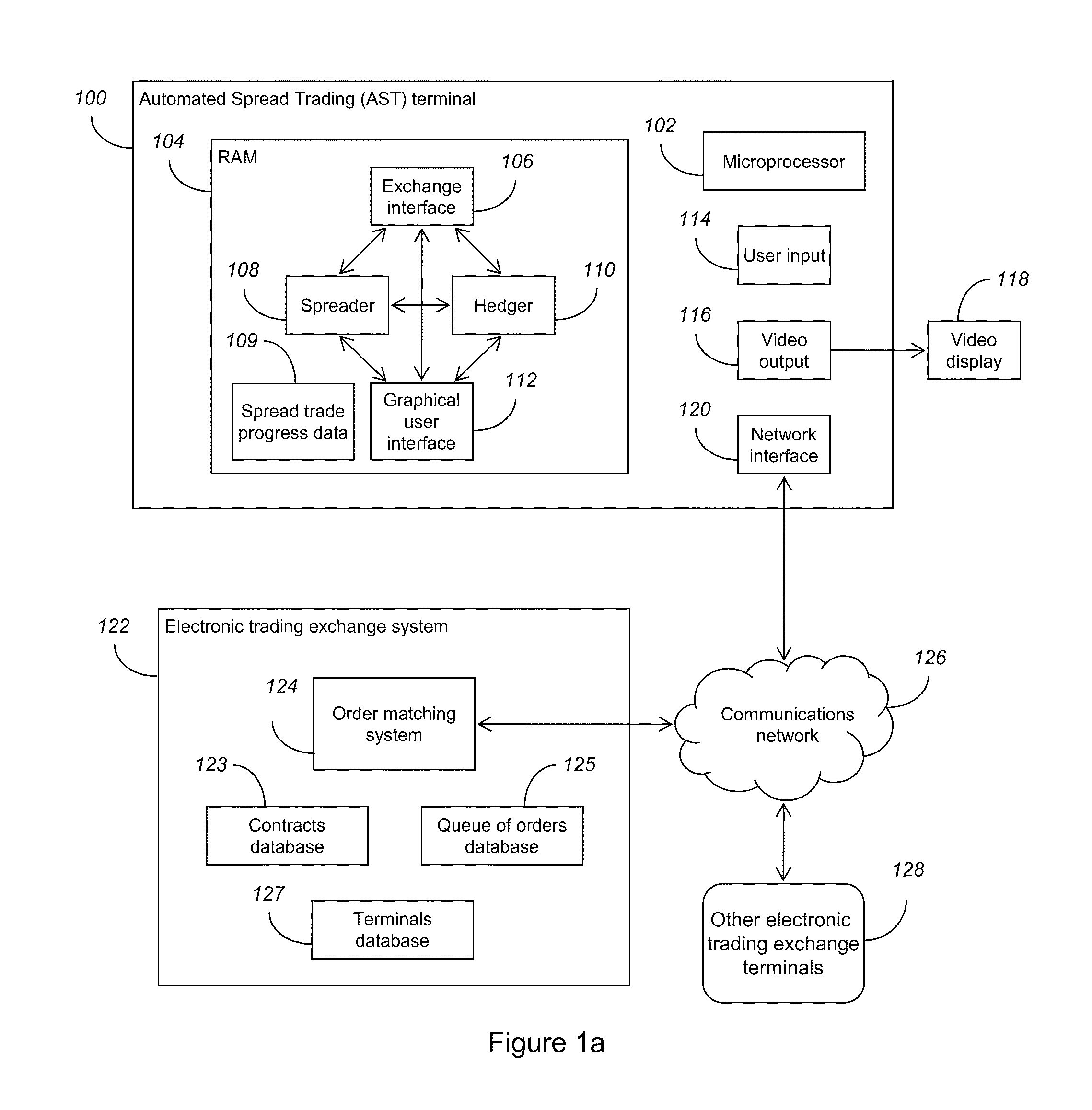

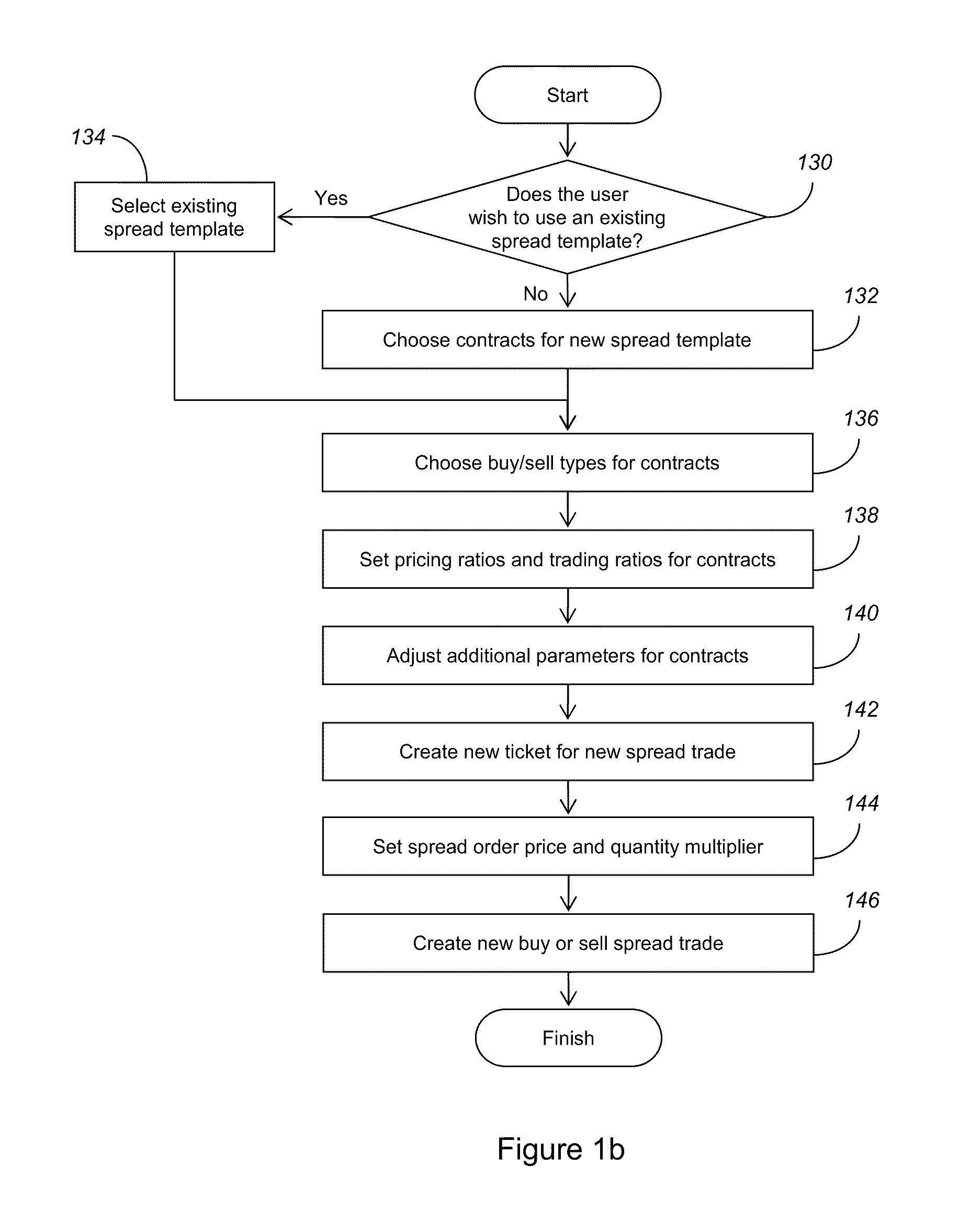

Automated spread trading system

An automated spread trading terminal receives from a user a selection of a spread trade indicative of a set of trading contracts and transmits to an electronic trading exchange a first set of messages including an order message relating to the user selection such that an initial set of more working orders are rendered operative. The terminal receives from the electronic trading exchange a first fill confirmation message confirming at least partial completion of a first working order, and in response transmits to the electronic trading exchanges both second and third sets of messages such that a completing set of working orders are rendered operative and additional working orders corresponding to the trading contracts are rendered operative, the third set of messages being transmitted before the set of working orders is completed.

Owner:LEE DARREN

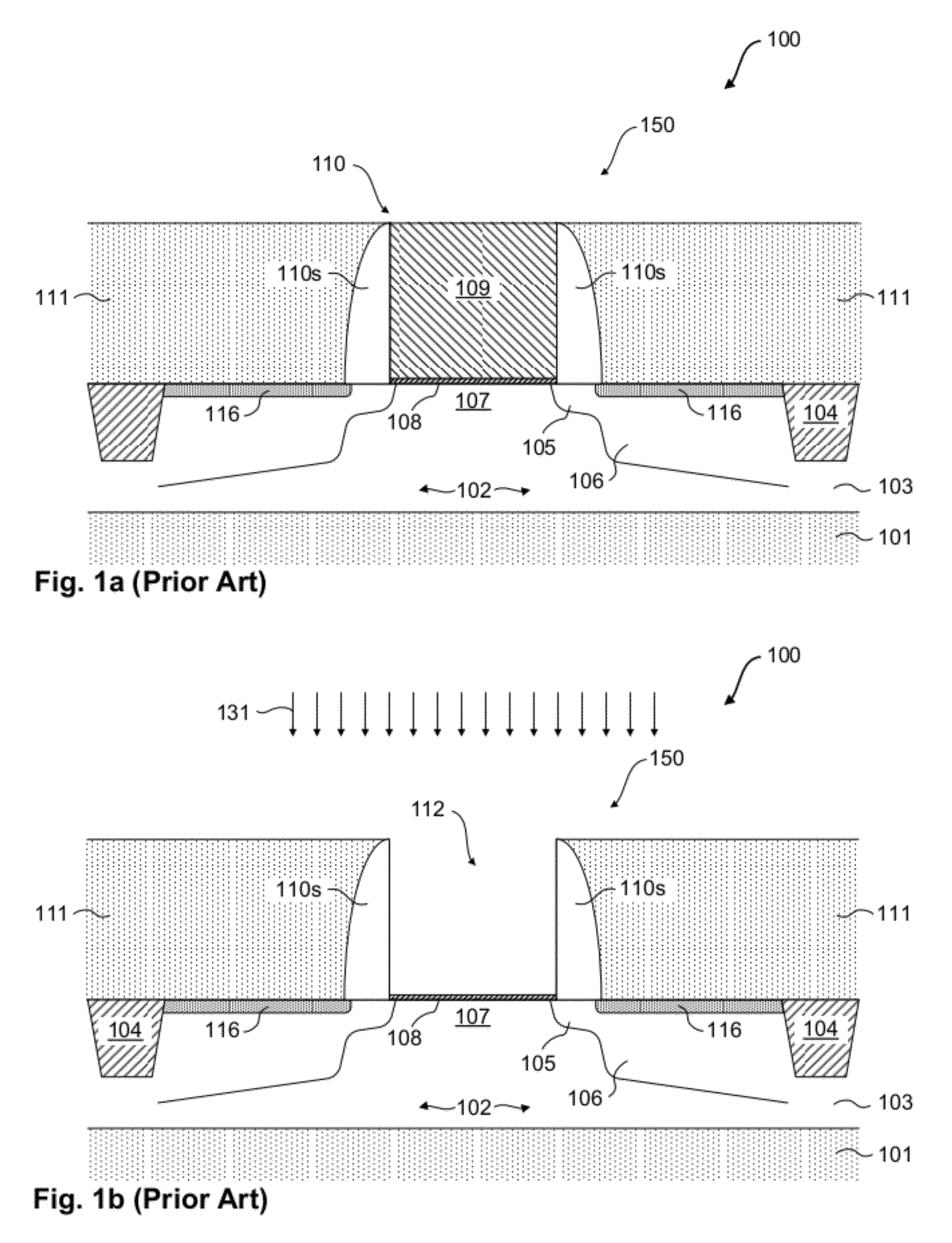

Filling Narrow Openings Using Ion Beam Etch

ActiveUS20120217590A1Well formedTransistorSemiconductor/solid-state device manufacturingFirst FillFilling materials

Generally, the subject matter disclosed herein relates to modern sophisticated semiconductor devices and methods for forming the same, wherein a multilayer metal fill may be used to fill narrow openings formed in an interlayer dielectric layer. One illustrative method disclosed herein includes forming an opening in a dielectric material layer of a semiconductor device formed above a semiconductor substrate, the opening having sidewalls and a bottom surface. The method also includes forming a first layer of first fill material above the semiconductor device by forming the first layer inside the opening and at least above the sidewalls and the bottom surface of the opening. Furthermore, the method includes performing a first angled etching process to at least partially remove the first layer of first fill material from above the semiconductor device by at least partially removing a first portion of the first layer proximate an inlet of the opening without removing a second portion of the first layer proximate the bottom of said opening, and forming a second layer of second fill material above the semiconductor device by forming the second layer inside the opening and above the first layer.

Owner:IBM CORP +1

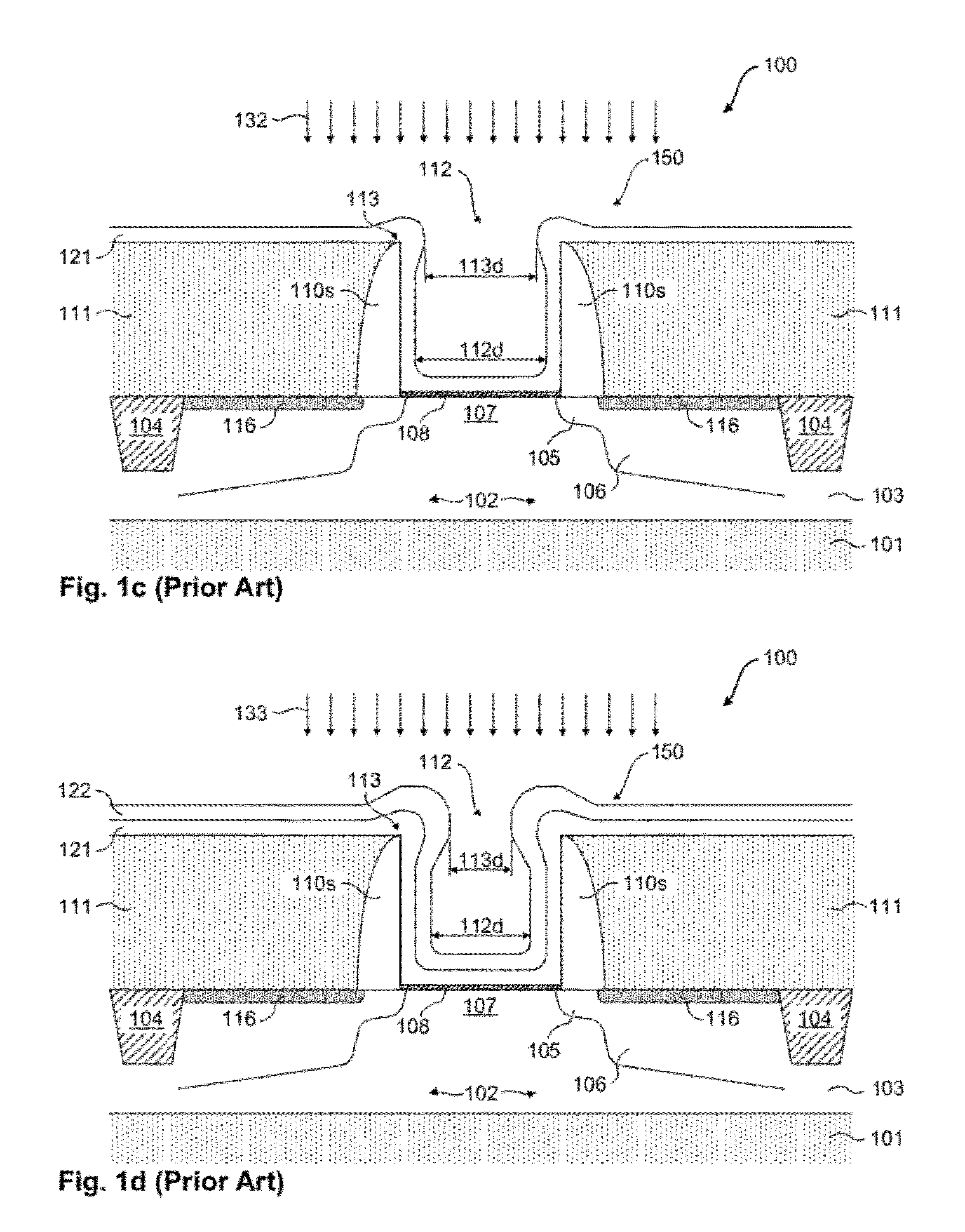

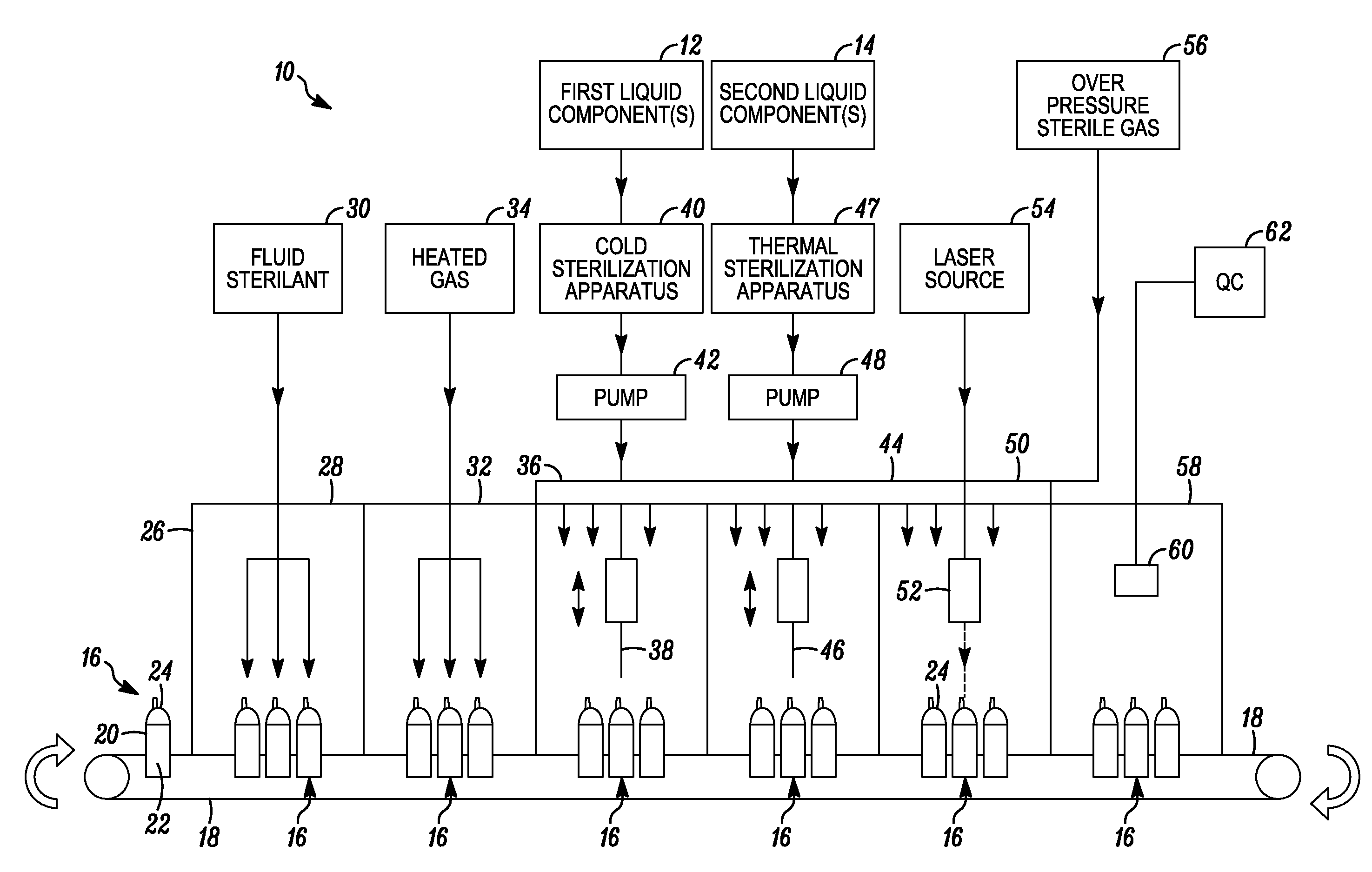

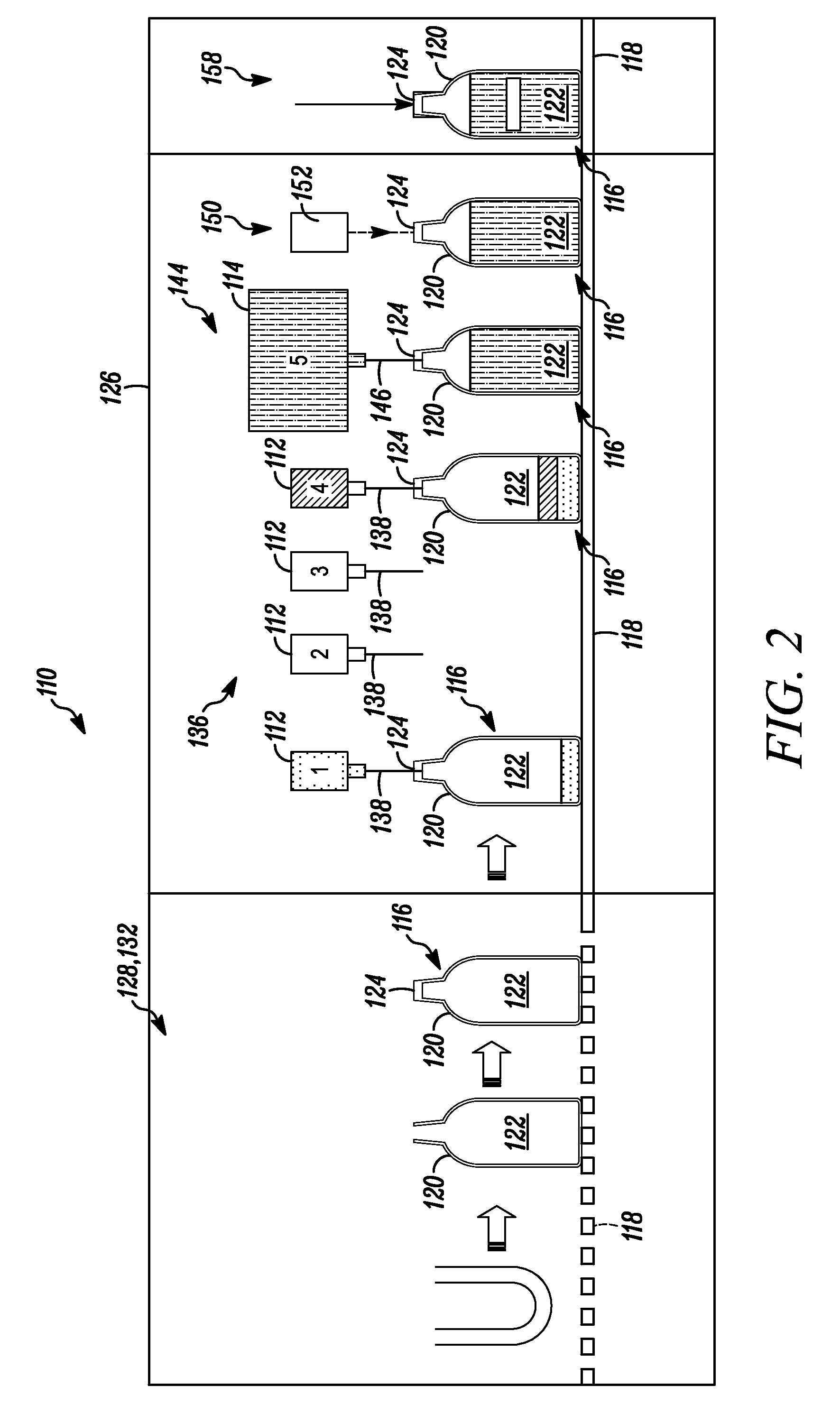

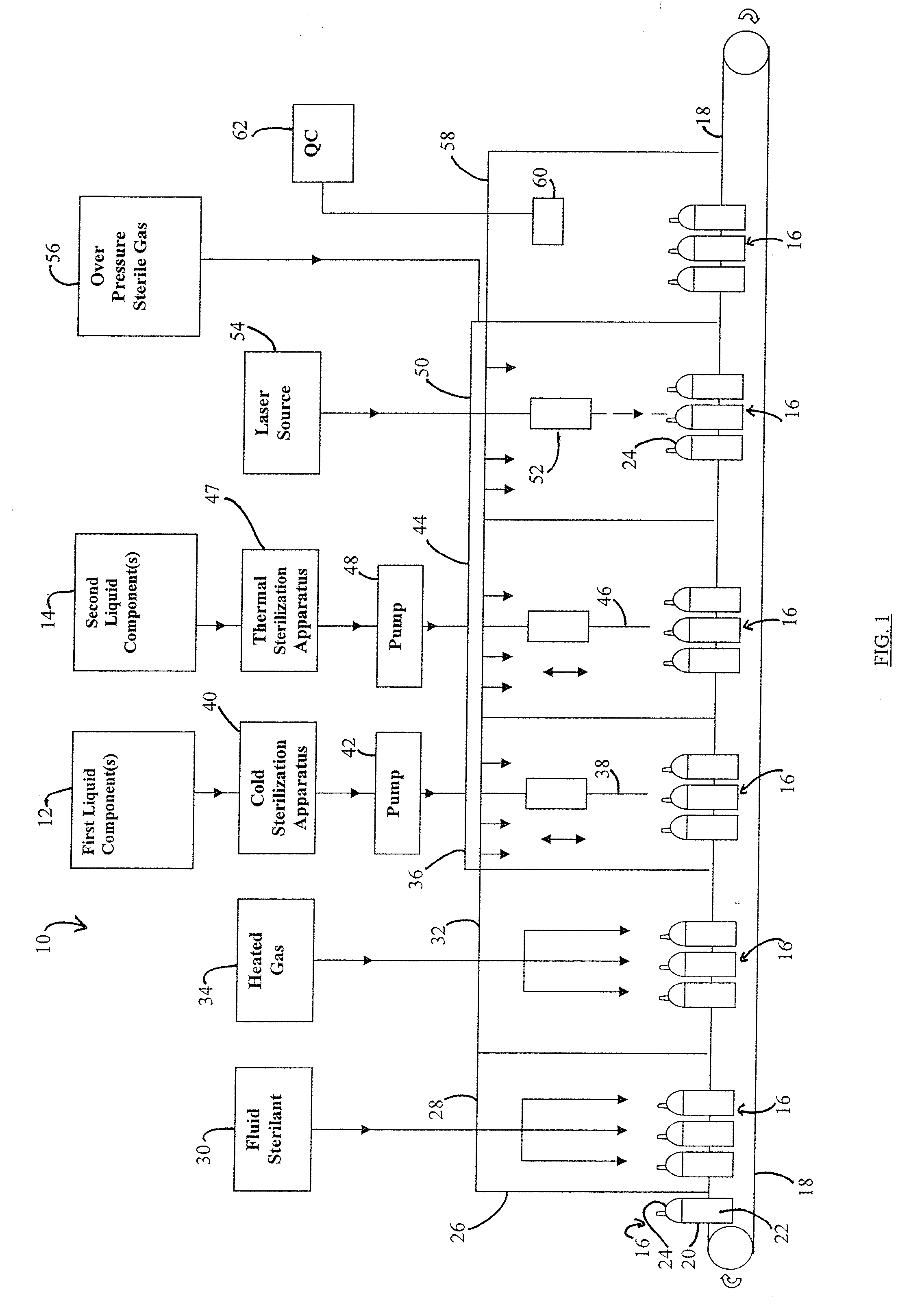

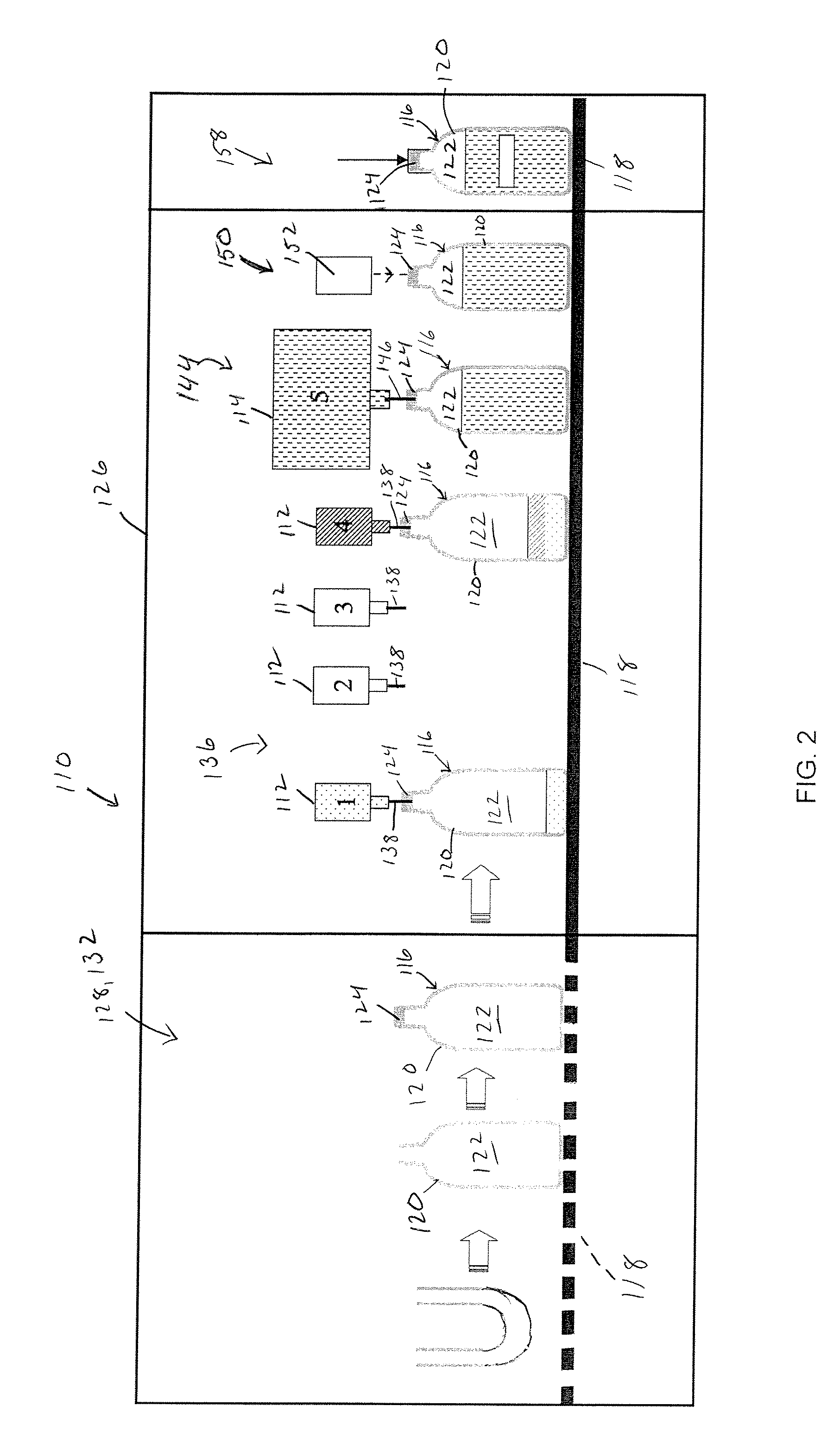

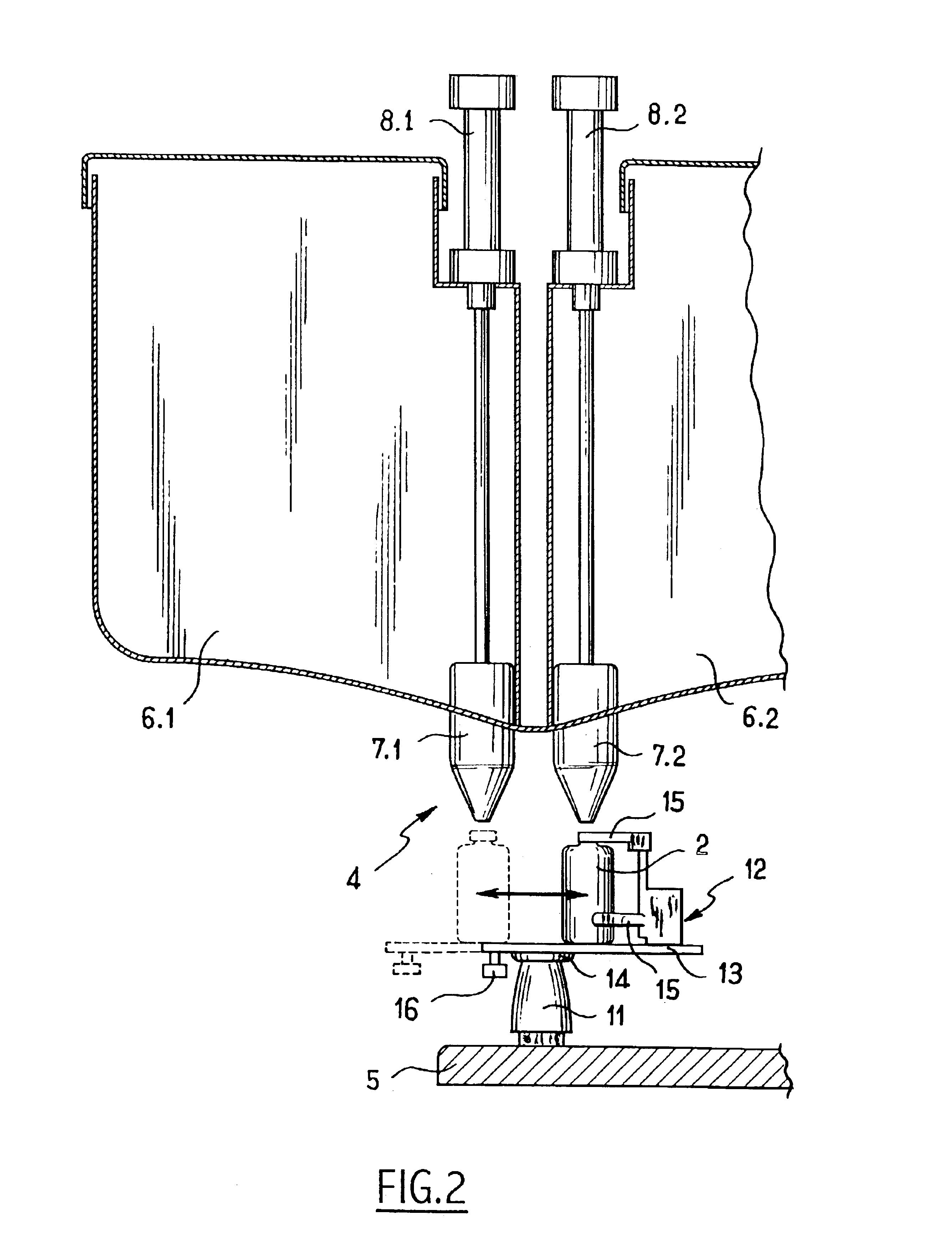

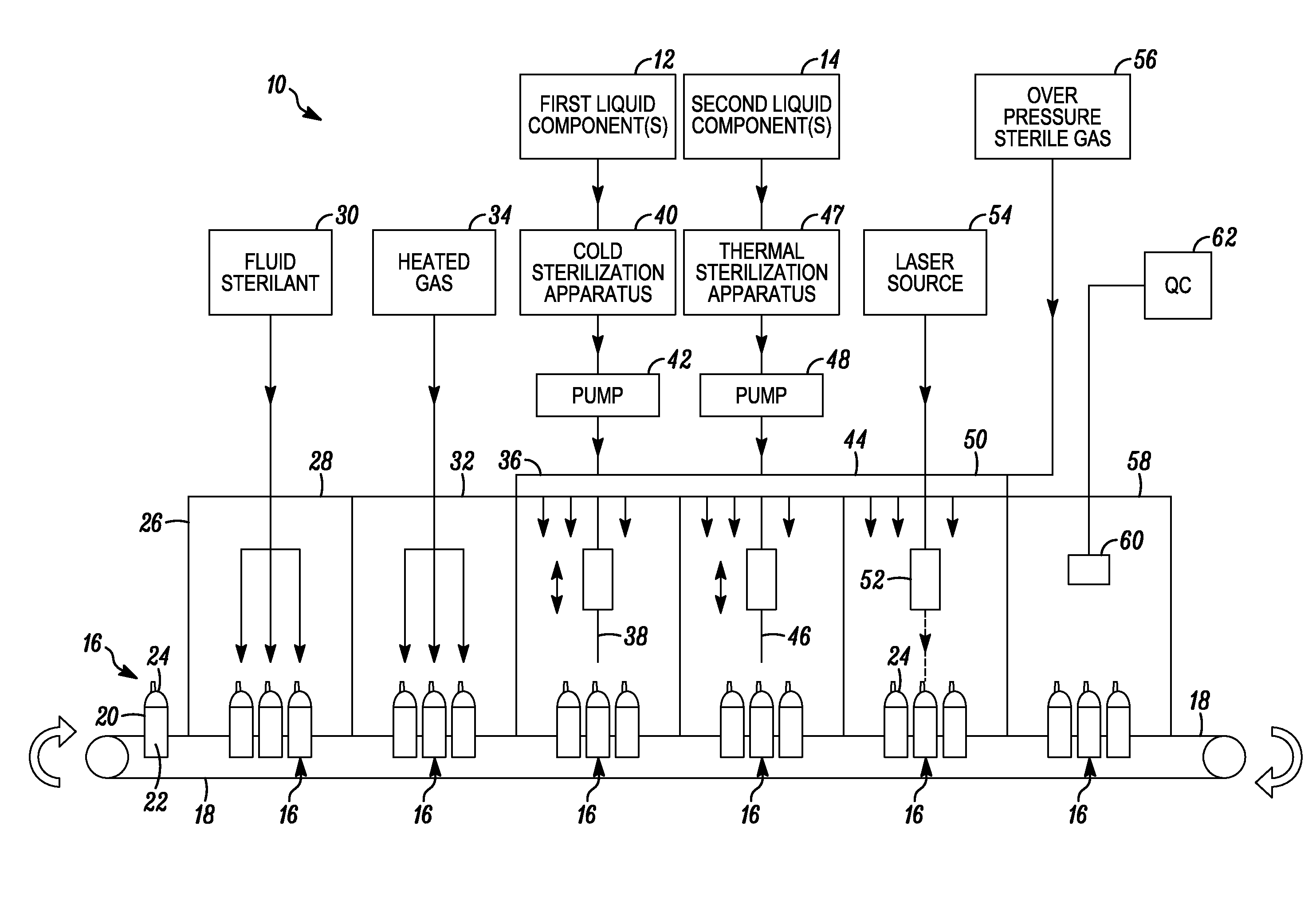

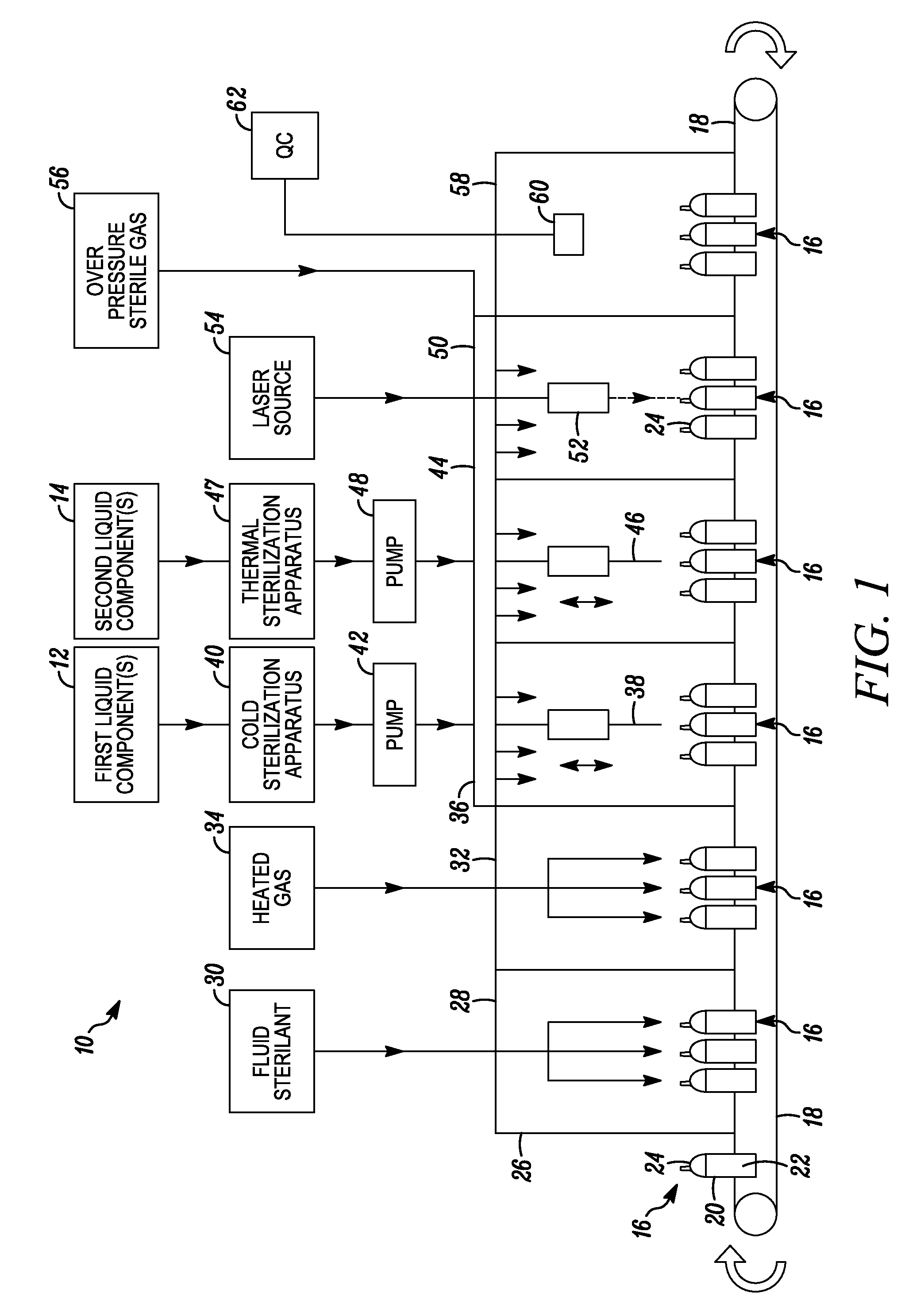

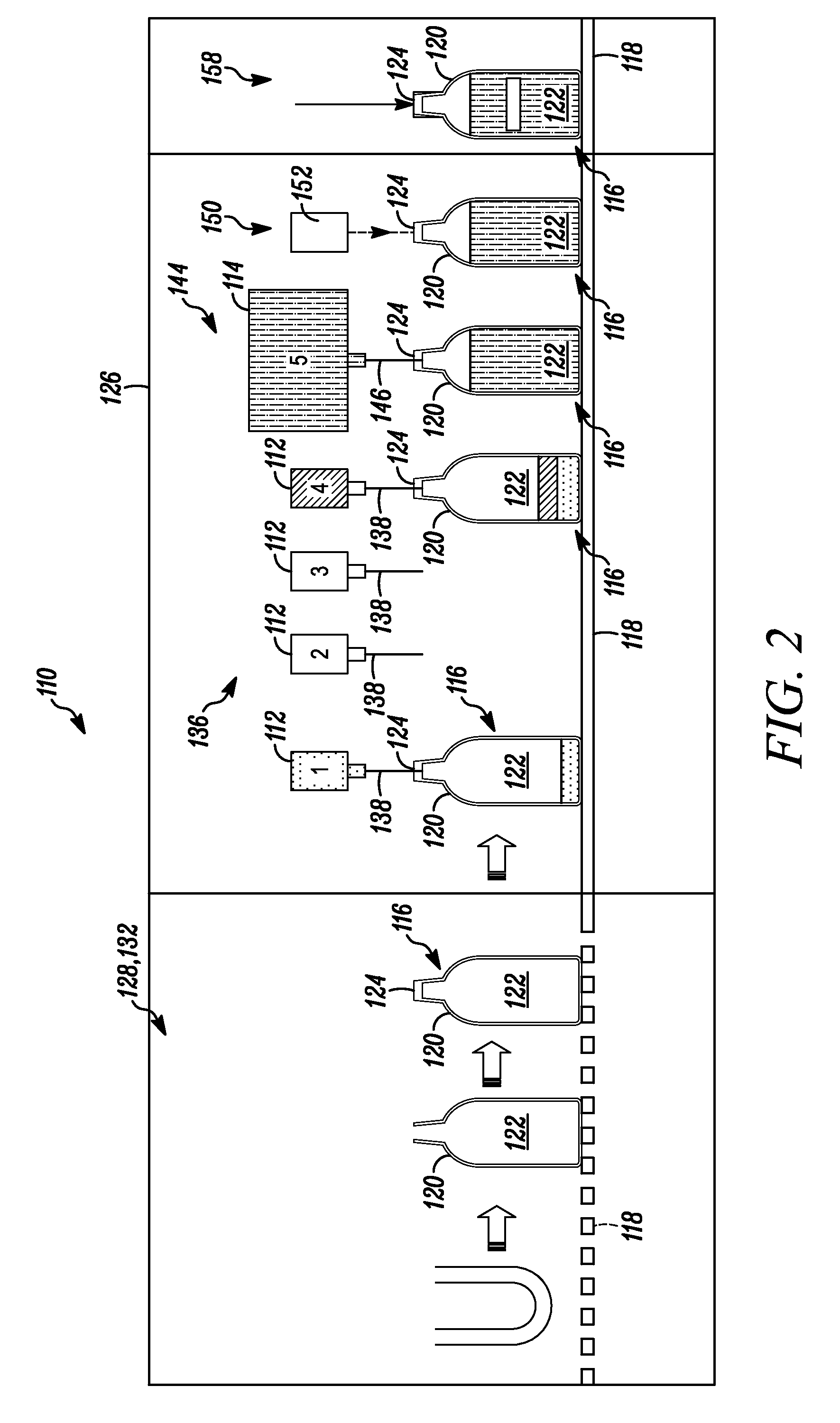

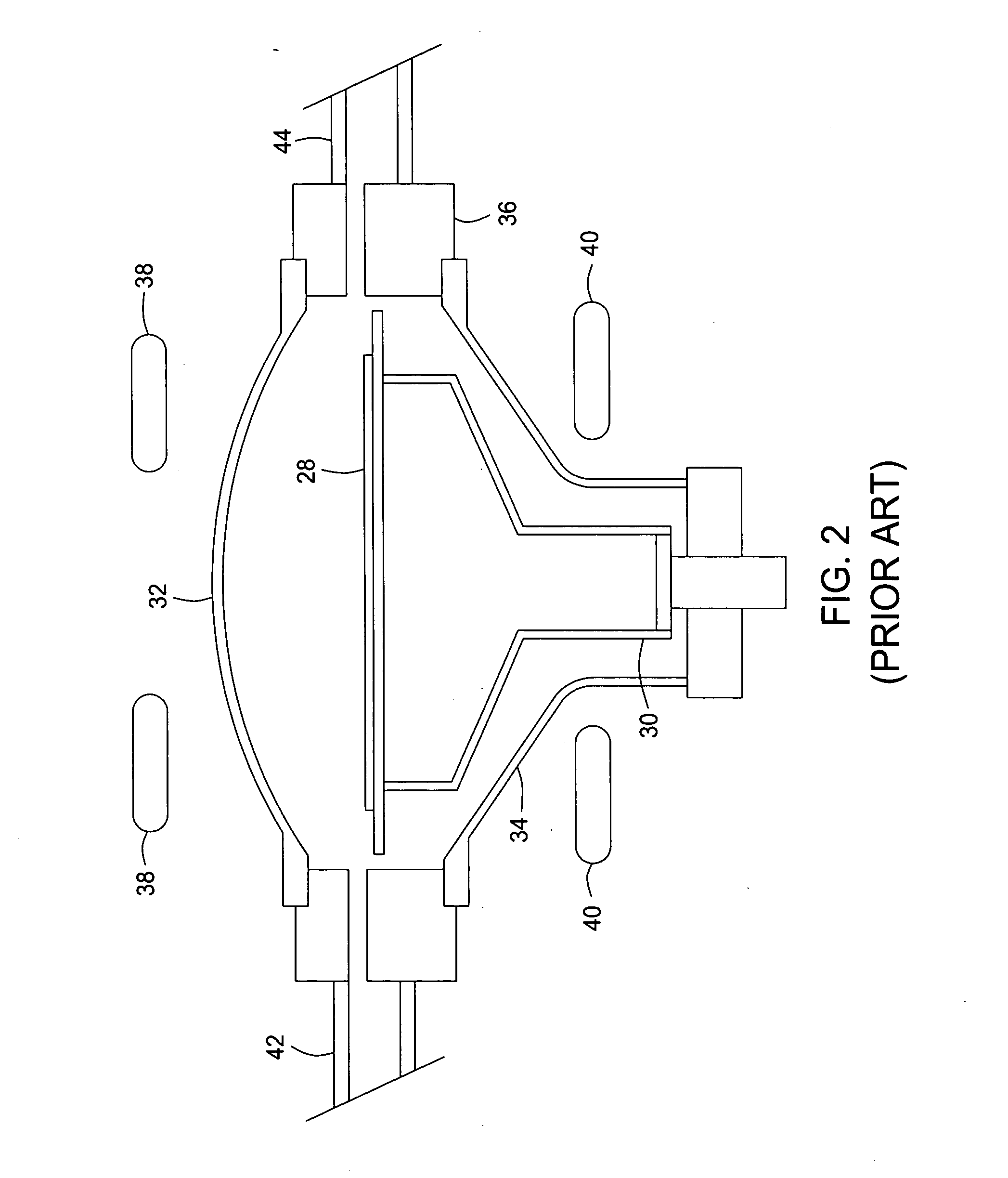

Apparatus for formulating and aseptically filling liquid products

InactiveUS20090094940A1Readily apparentFood preservationPackage sterilisationLiquid productFirst Fill

An apparatus and method are provided for formulating and aseptically filling liquid products. A first liquid source includes at least one first liquid component; a second liquid source includes at least one second liquid component; and a container includes a body defining an empty, sterile storage chamber therein that is sealed with respect to ambient atmosphere. The container is introduced into a sterile filling chamber. A first filling member coupled in fluid communication with the first liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the first liquid component is aseptically introduced through the first filling member and into the storage chamber. A second filling member coupled in fluid communication with the second liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the second liquid component is aseptically introduced through the second filling member and into the storage chamber and, in turn, the first and second liquid components are combined into a liquid product formulation within the sterile chamber of the container. The first and second filling members are withdrawn from fluid communication with the storage chamber of the container located within the sterile filling chamber, and the filled storage chamber is sealed with respect to ambient atmosphere to hermetically seal the liquid product formulation within the storage chamber of the container.

Owner:MEDINSTILL DEV

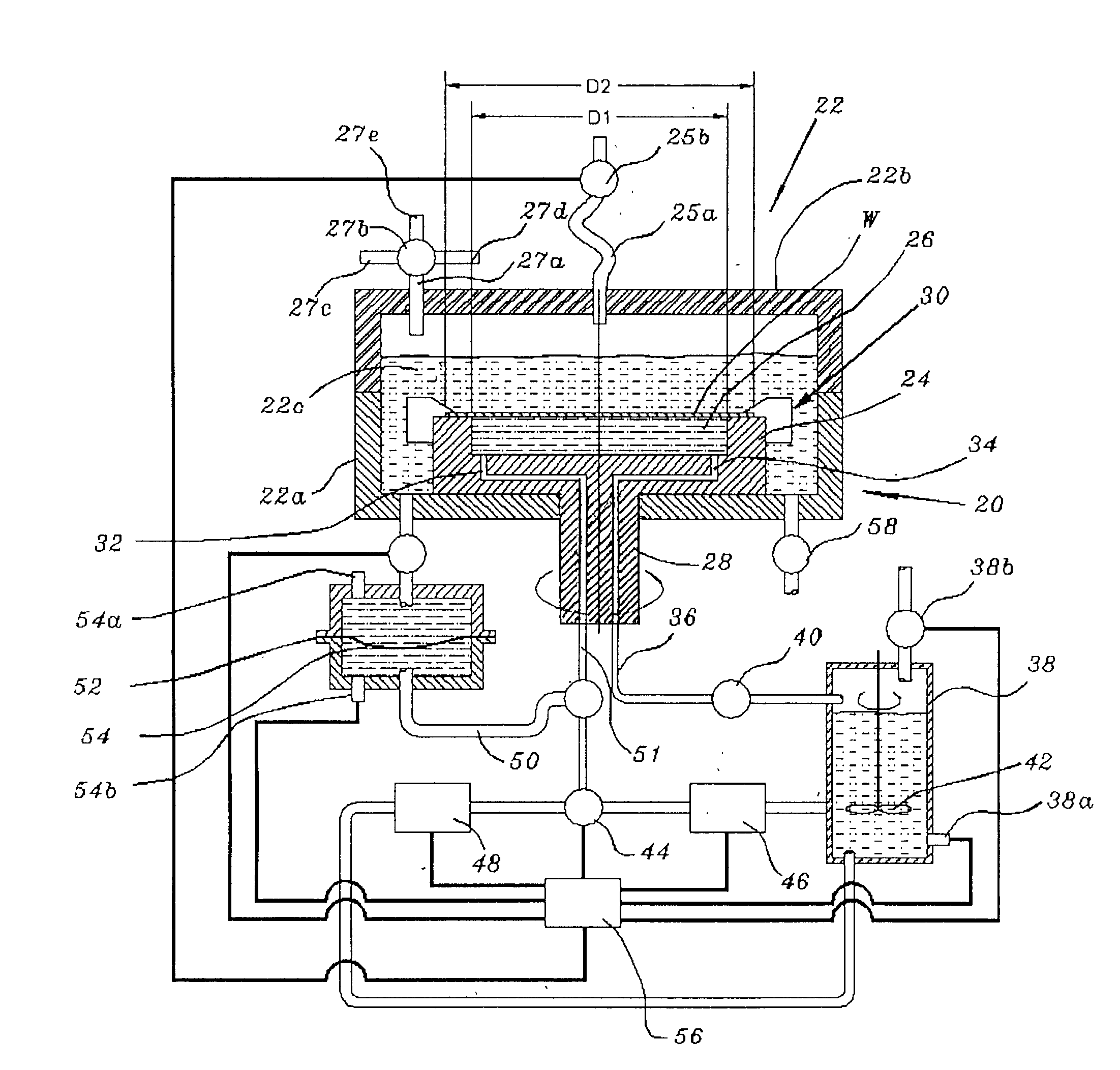

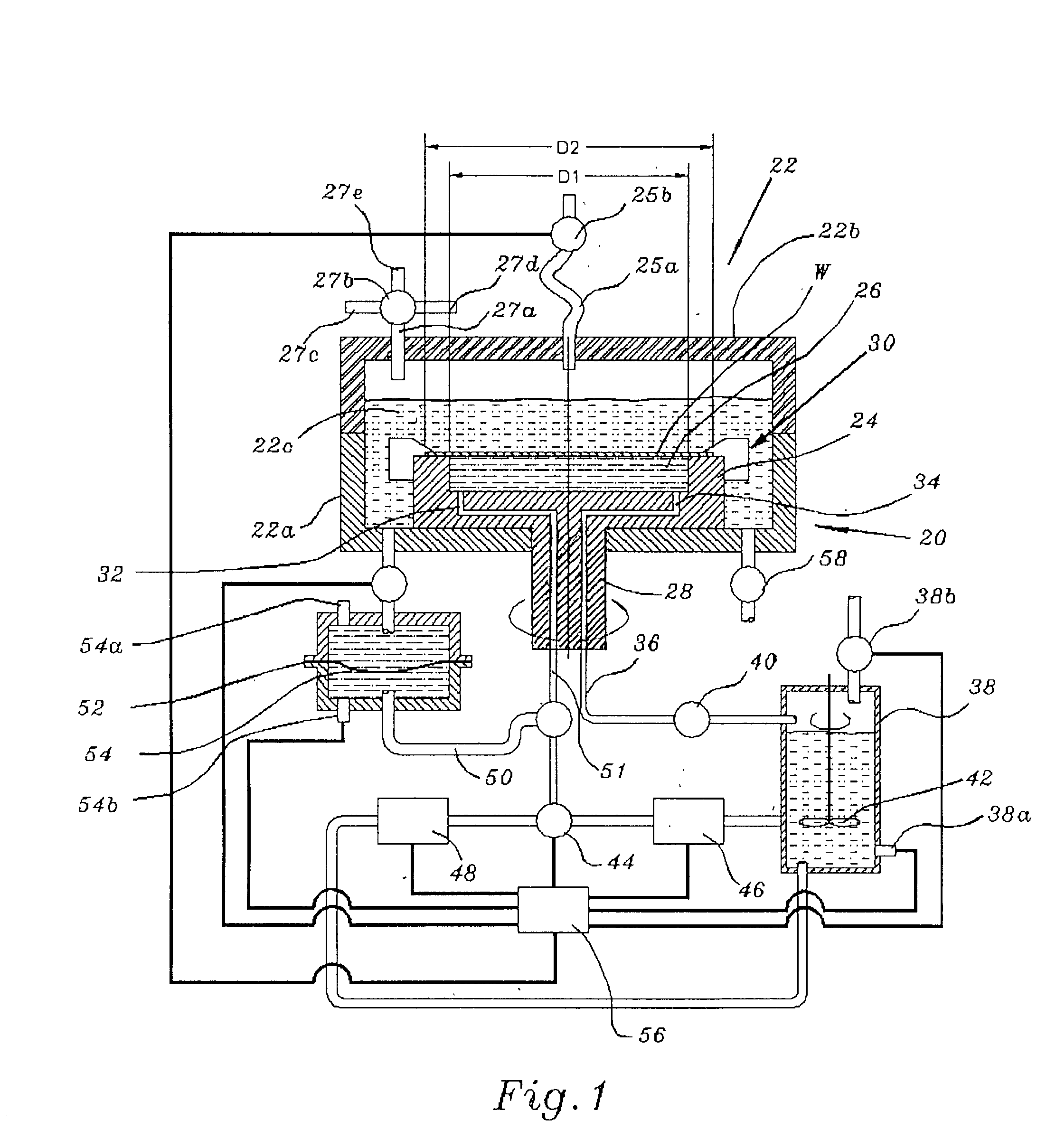

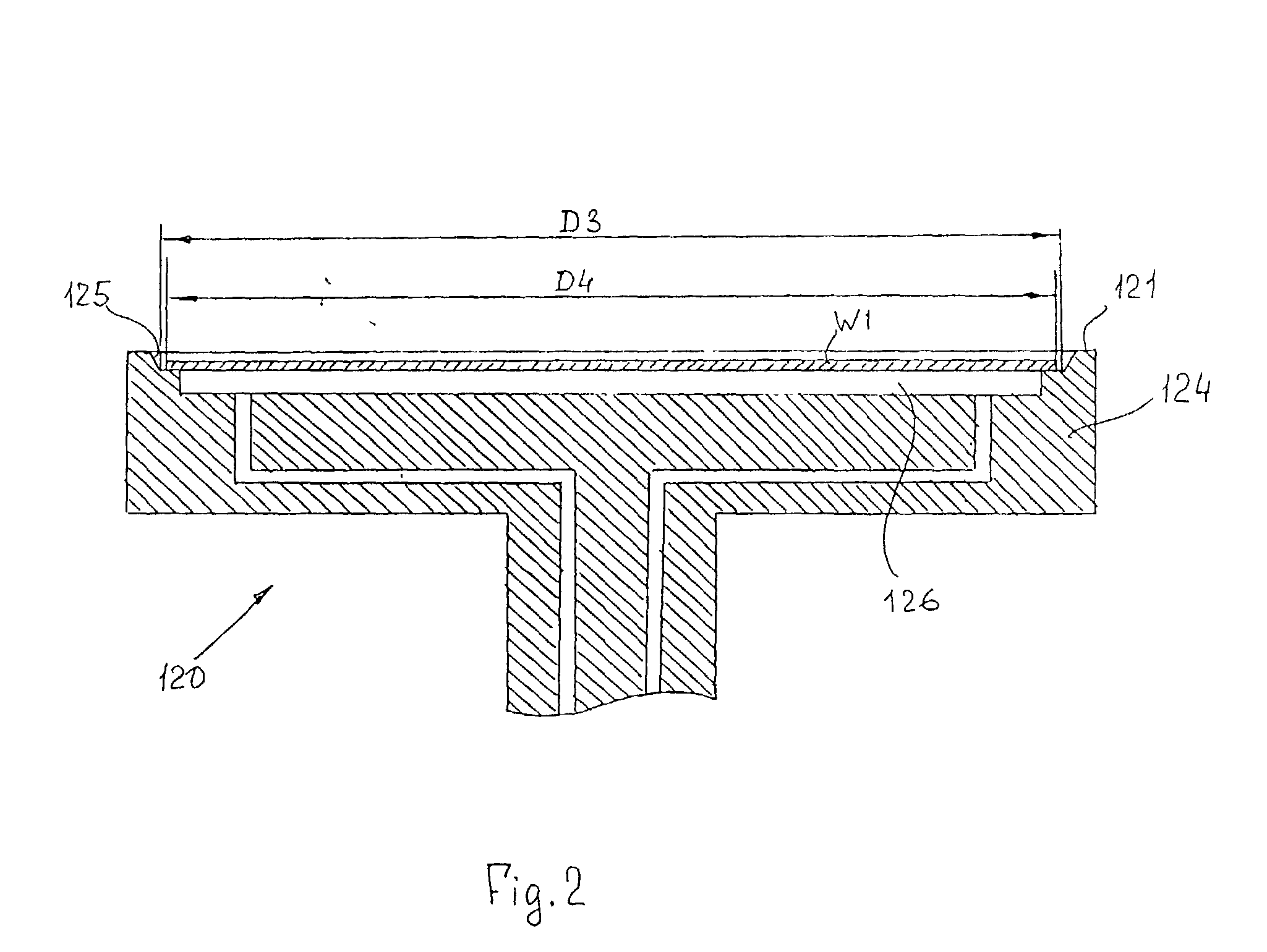

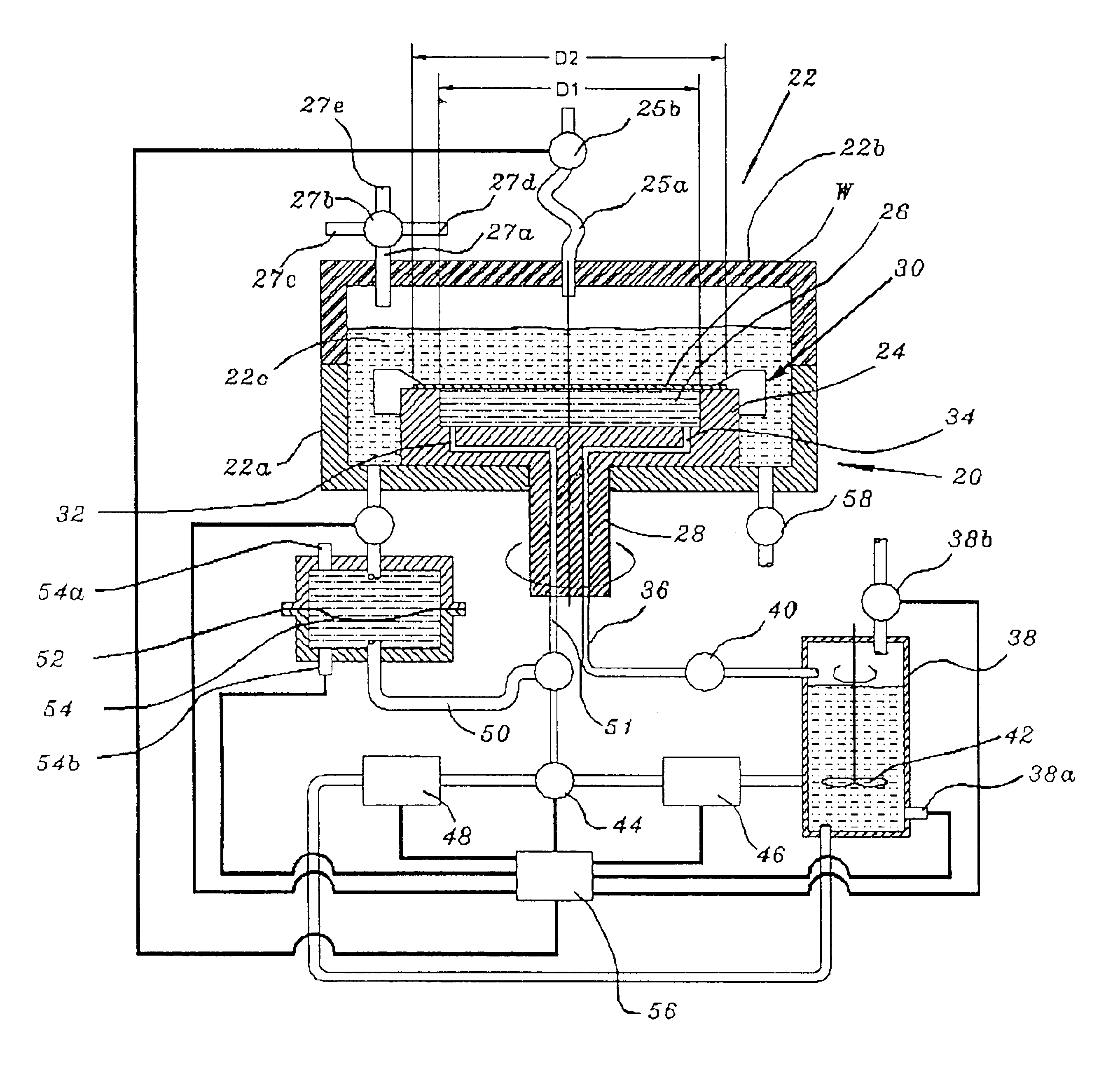

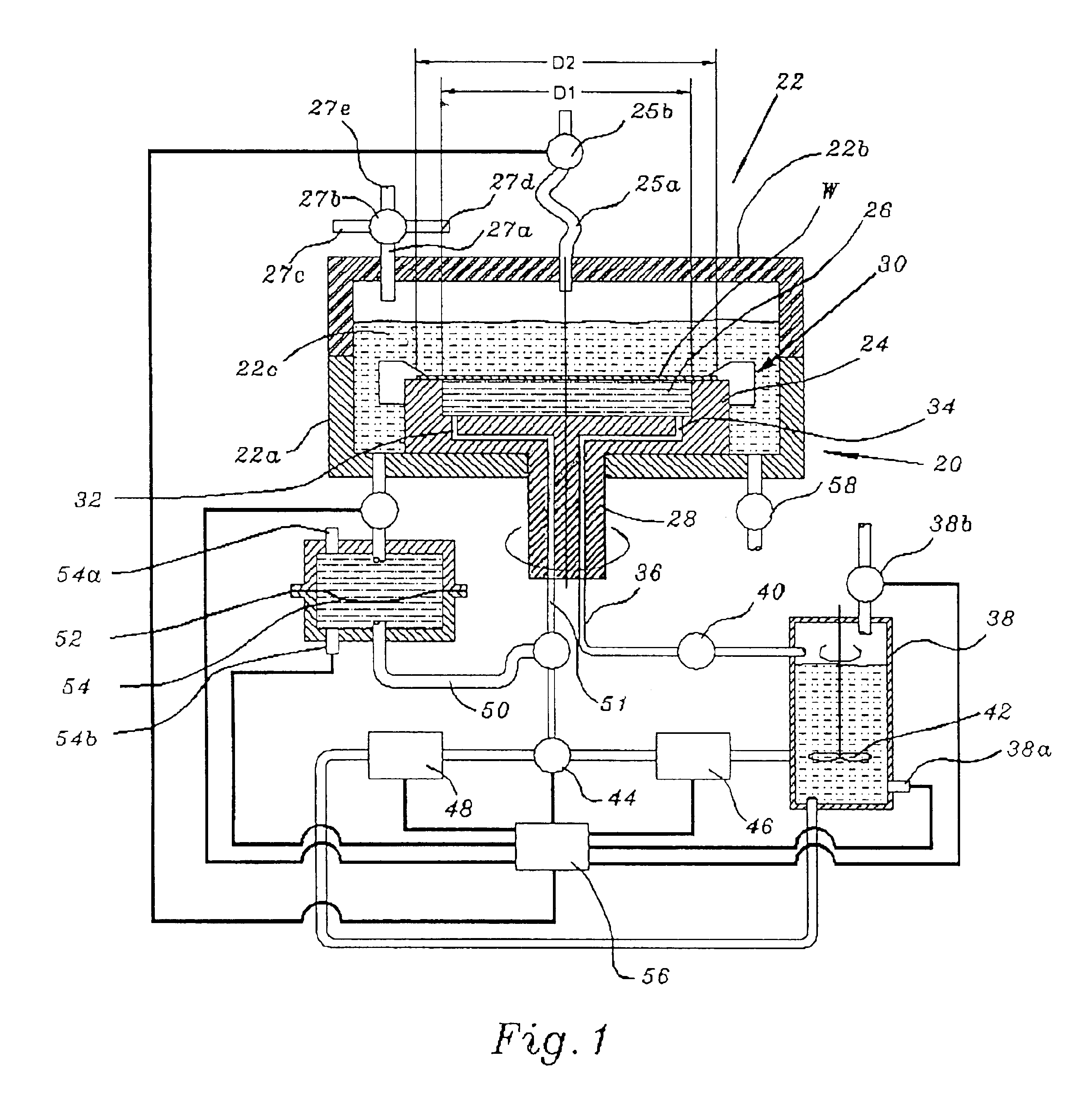

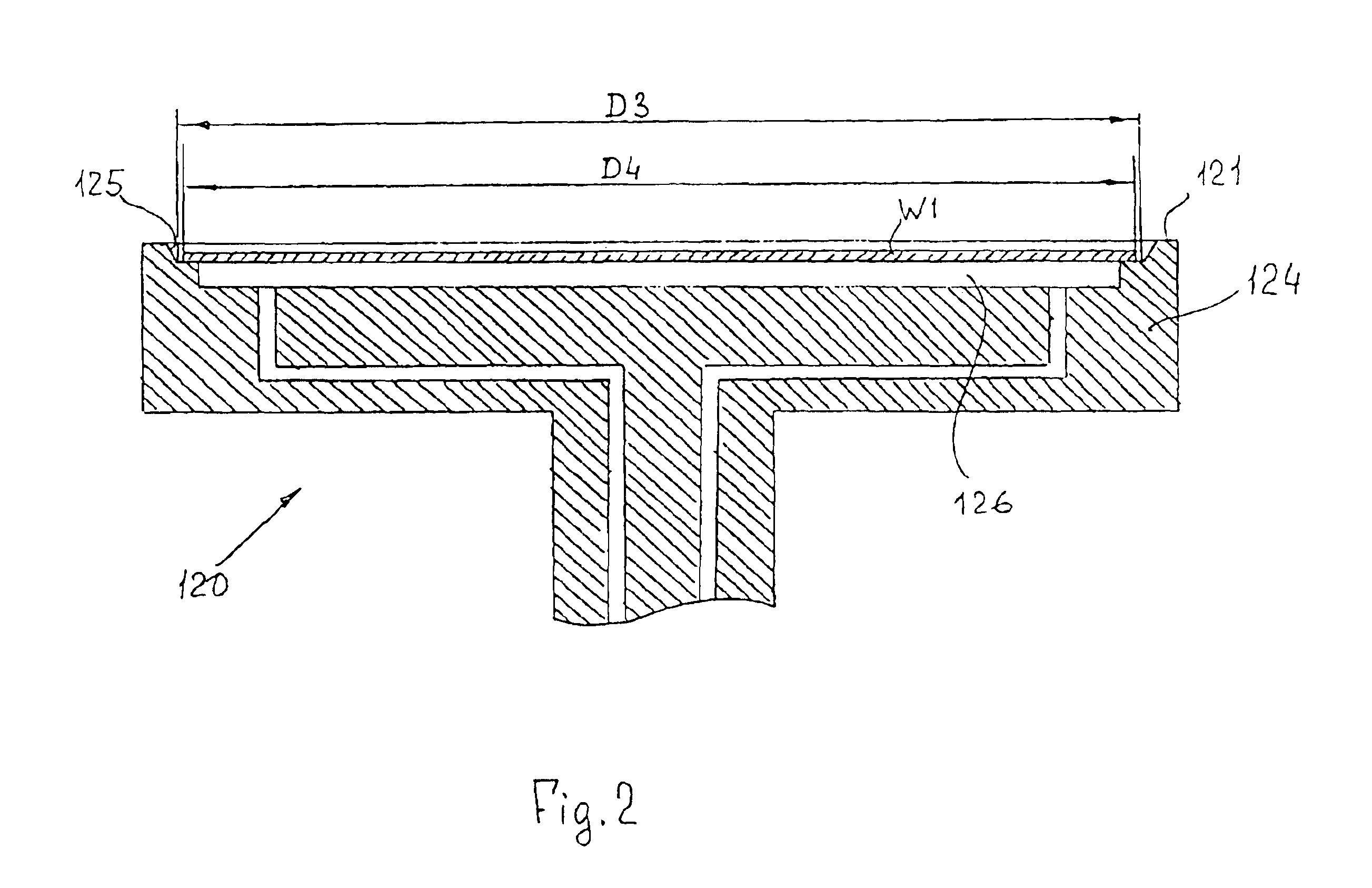

Temperature-controlled substrate holder for processing in fluids

InactiveUS20040084143A1Quick changeLiquid surface applicatorsDrying gas arrangementsTemperature controlFirst Fill

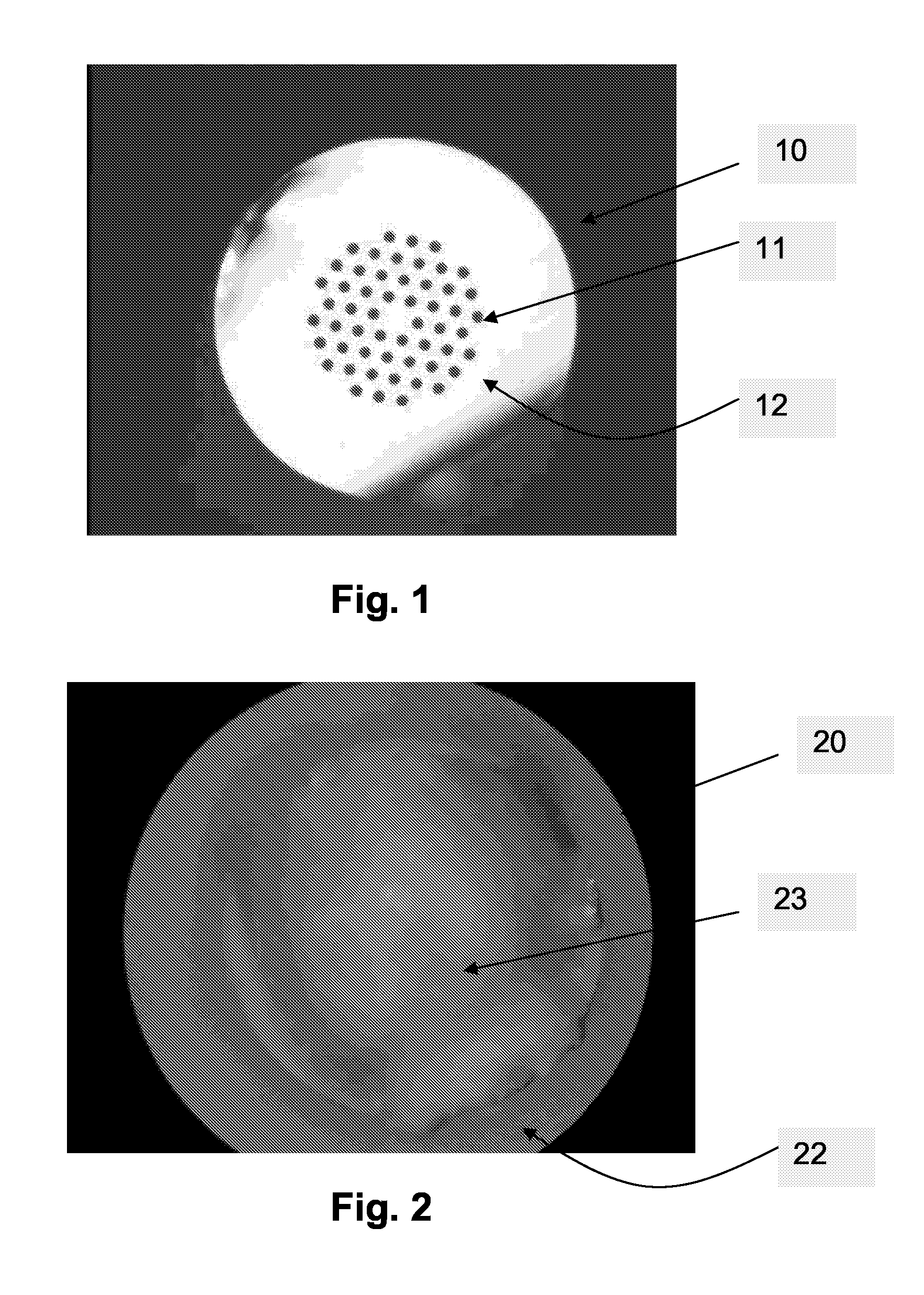

A substrate holder has a disk-like body with a central recess having diameter smaller than the diameter of the substrate placed onto the upper surface of the holder. The substrate can be clamped in place by the clamps of the edge-grip mechanism or placed into a seat without the use of clamps. In both cases, the substrate forms a partial wall that confines the heating / cooling recess or chamber. The aforementioned recess is filled with a cooling or heating liquid (depending on the mode of metal deposition) selectively supplied from a liquid heating or cooling system. In order to ensure in the working chamber above the substrate a pressure slightly higher than the pressure in the cooling / heating recess, the working chamber is first filled with the working solution under the atmospheric pressure, and then the recess is filled with a heating or cooling liquid with simultaneous increase of pressure in the working chamber to a level slightly exceeding the pressure in the recess. The substrate holder of the invention provides direct heat / cool-exchange between the heating / cooling medium and the substrate and allows instantaneous change of temperature of the heating / cooling liquid.

Owner:LAM RES CORP

Method for formulating and aseptically filling liquid products

InactiveUS20090098250A1Readily apparentMilk preparationFruit and vegetables preservationFirst FillLiquid product

An apparatus and method are provided for formulating and aseptically filling liquid products. A first liquid source includes at least one first liquid component; a second liquid source includes at least one second liquid component; and a container includes a body defining an empty, sterile storage chamber therein that is sealed with respect to ambient atmosphere. The container is introduced into a sterile filling chamber. A first filling member coupled in fluid communication with the first liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the first liquid component is aseptically introduced through the first filling member and into the storage chamber. A second filling member coupled in fluid communication with the second liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the second liquid component is aseptically introduced through the second filling member and into the storage chamber and, in turn, the first and second liquid components are combined into a liquid product formulation within the sterile chamber of the container. The first and second filling members are withdrawn from fluid communication with the storage chamber of the container located within the sterile filling chamber, and the filled storage chamber is sealed with respect to ambient atmosphere to hermetically seal the liquid product formulation within the storage chamber of the container.

Owner:MEDINSTILL DEV

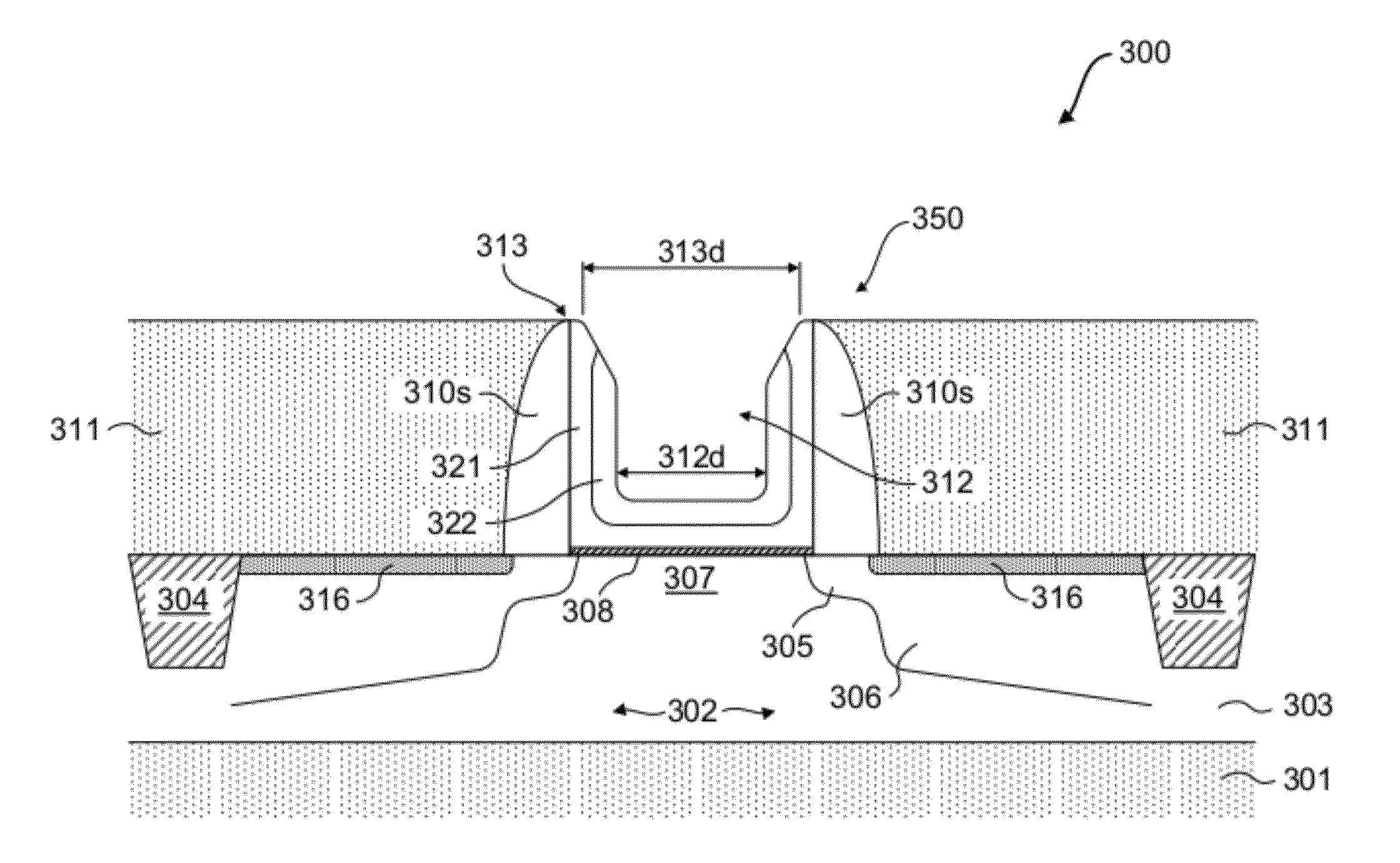

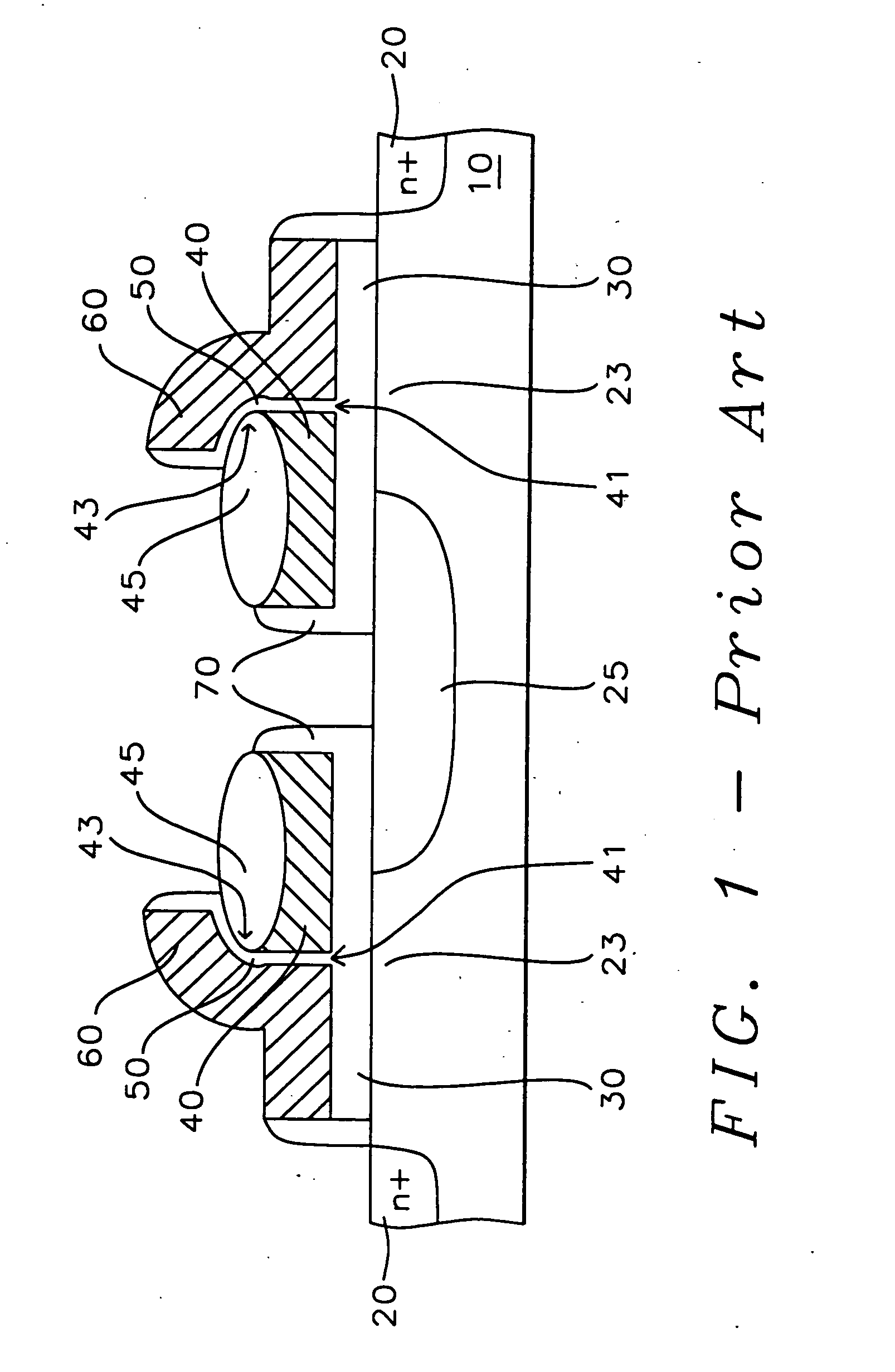

Method to increase coupling ratio of source to floating gate in split-gate flash

InactiveUS20050207264A1Improve the coupling ratioIncrease lateral couplingTransistorSolid-state devicesFirst FillCoupling ratio

A split-gate flash memory cell having a three-dimensional source capable of three-dimensional coupling with the floating gate of the cell, as well as a method of forming the same are provided. This is accomplished by first forming an isolation trench, lining it with a conformal oxide, then filling with an isolation oxide and then etching the latter to form a three-dimensional coupling region in the upper portion of the trench. A floating gate is next formed by first filling the three-dimensional region of the trench with polysilicon and etching it. The control gate is formed over the floating gate with an intervening inter-poly oxide. The floating gate forms legs extending into the three-dimensional coupling region of the trench thereby providing a three-dimensional coupling with the source which also assumes a three-dimensional region. The leg or the side-wall of the floating gate forming the third dimension provides the extra area through which coupling between the source and the floating gate is increased. In this manner, a higher coupling ratio is achieved without an increase in the cell size while at the same time alleviating the punchthrough and junction break-down of source region by sharing gate voltage along the side-wall.

Owner:TAIWAN SEMICON MFG CO LTD

Through substrate via semiconductor components

ActiveUS7772123B2Semiconductor/solid-state device detailsSolid-state devicesFirst FillFilling materials

A structure and method of forming through substrate vias in forming semiconductor components are described. In one embodiment, the invention describes a method of forming the through substrate via by filling an opening with a first fill material and depositing a first insulating layer over the first fill material, the first insulating layer not being deposited on sidewalls of the fill material in the opening, wherein sidewalls of the first insulating layer form a gap over the opening. The method further includes forming a void by sealing the opening using a second insulating layer.

Owner:INFINEON TECH AG

Temperature-controlled substrate holder for processing in fluids

InactiveUS6908512B2Quick changeLiquid surface applicatorsDrying gas arrangementsTemperature controlFirst Fill

A substrate holder has a disk-like body with a central recess having diameter smaller than the diameter of the substrate placed onto the upper surface of the holder. The substrate can be clamped in place by the clamps of the edge-grip mechanism or placed into a seat without the use of clamps. In both cases, the substrate forms a partial wall that confines the heating / cooling recess or chamber. The aforementioned recess is filled with a cooling or heating liquid (depending on the mode of metal deposition) selectively supplied from a liquid heating or cooling system. In order to ensure in the working chamber above the substrate a pressure slightly higher than the pressure in the cooling / heating recess, the working chamber is first filled with the working solution under the atmospheric pressure, and then the recess is filled with a heating or cooling liquid with simultaneous increase of pressure in the working chamber to a level slightly exceeding the pressure in the recess. The substrate holder of the invention provides direct heat / cool-exchange between the heating / cooling medium and the substrate and allows instantaneous change of temperature of the heating / cooling liquid.

Owner:LAM RES CORP

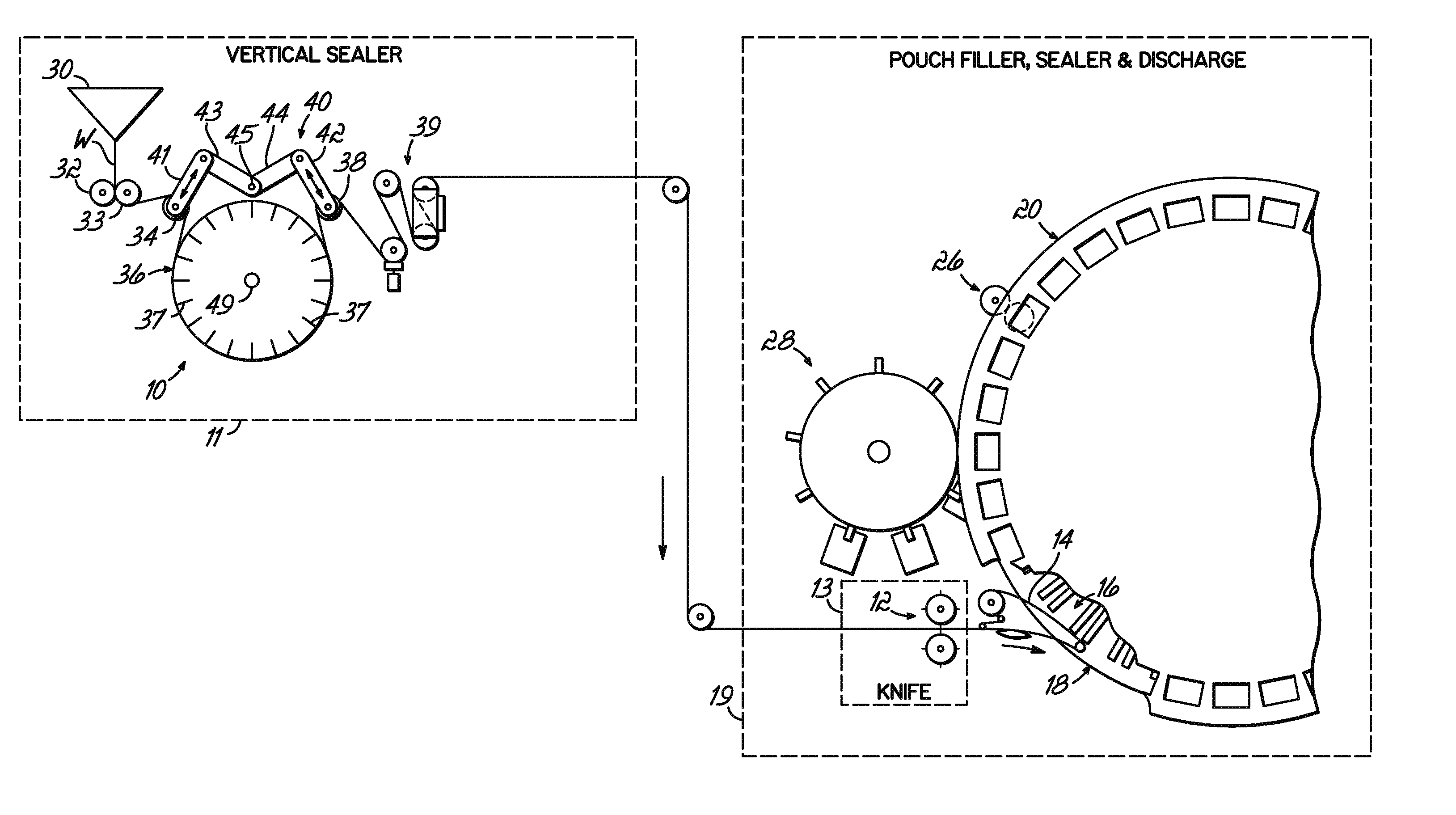

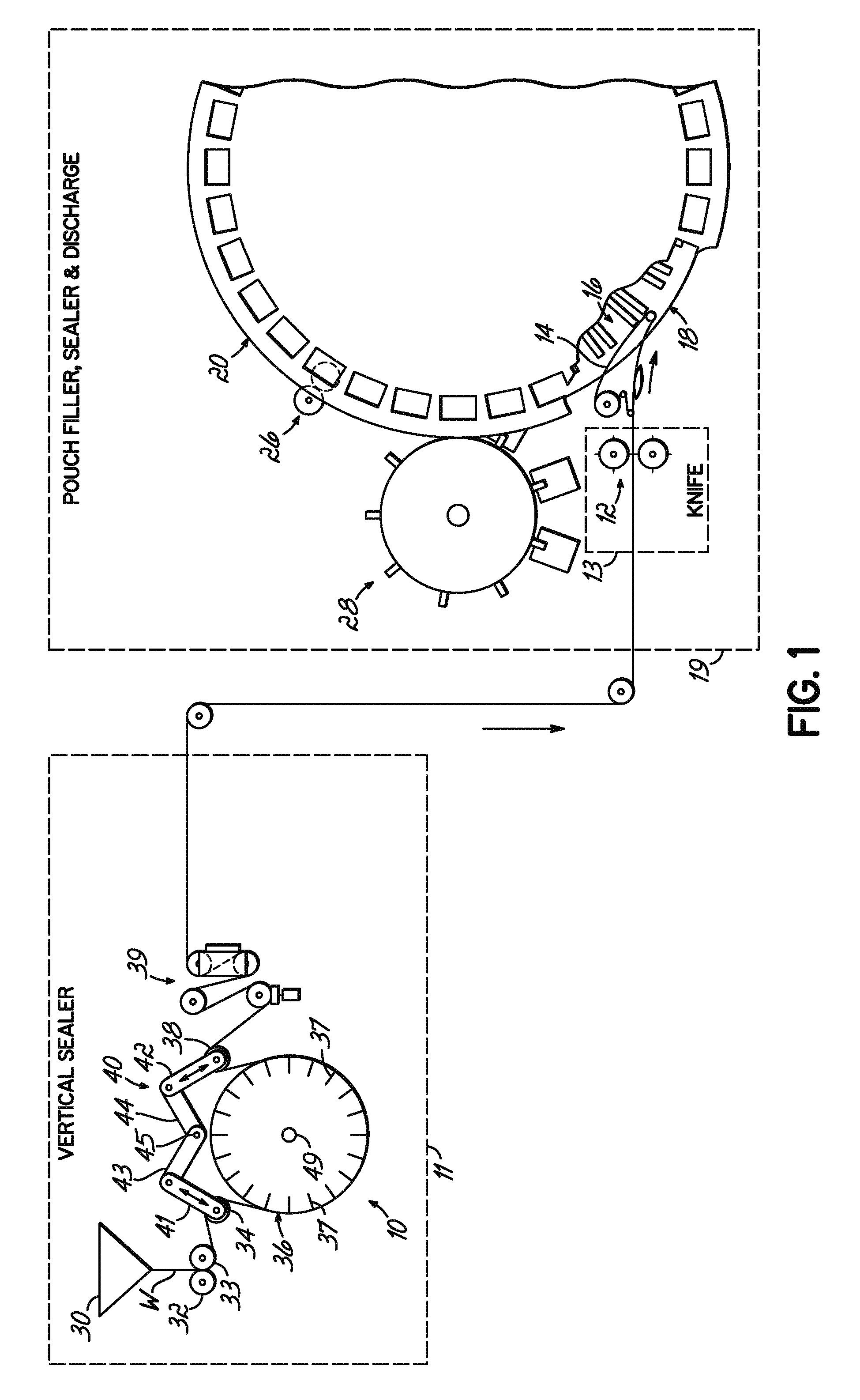

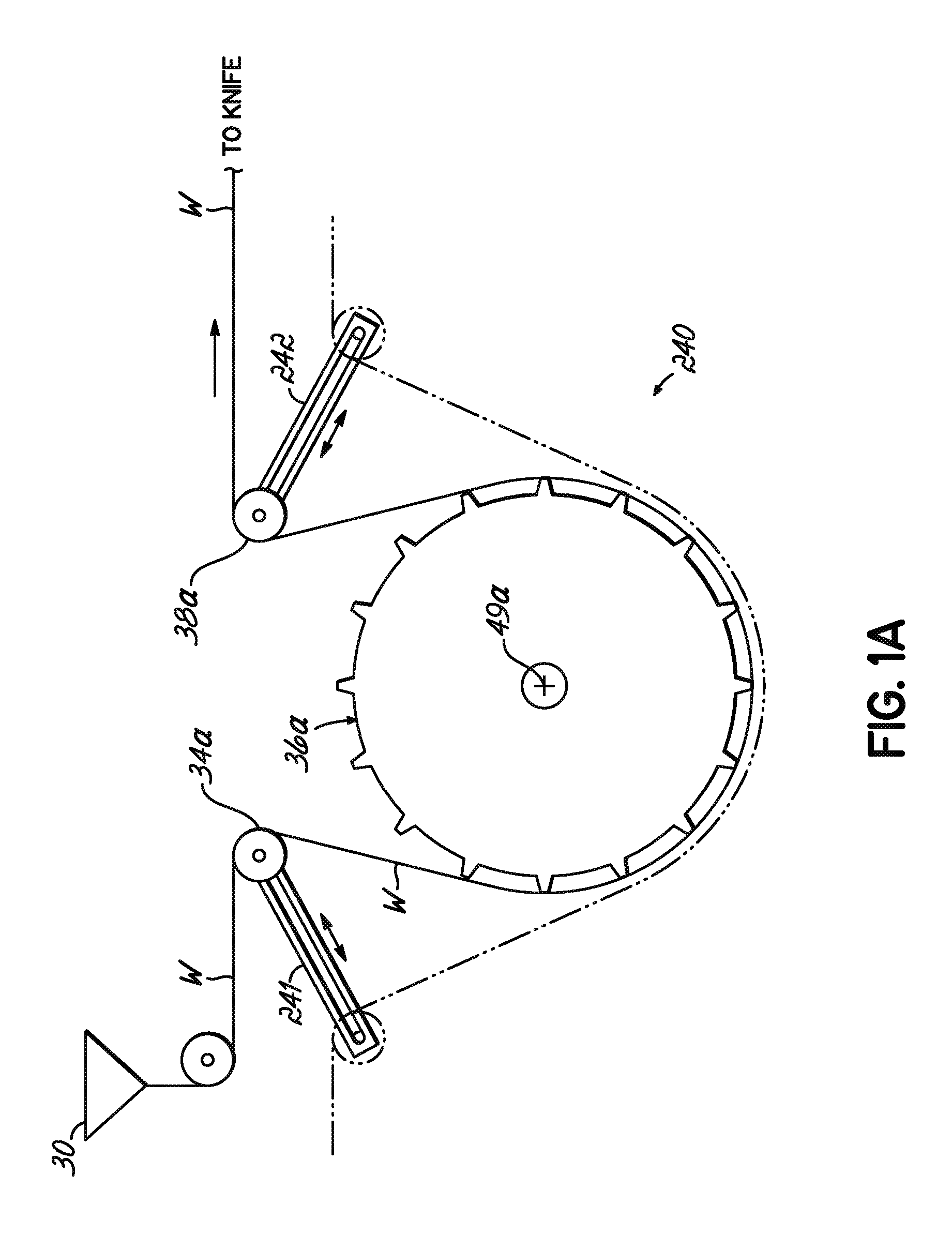

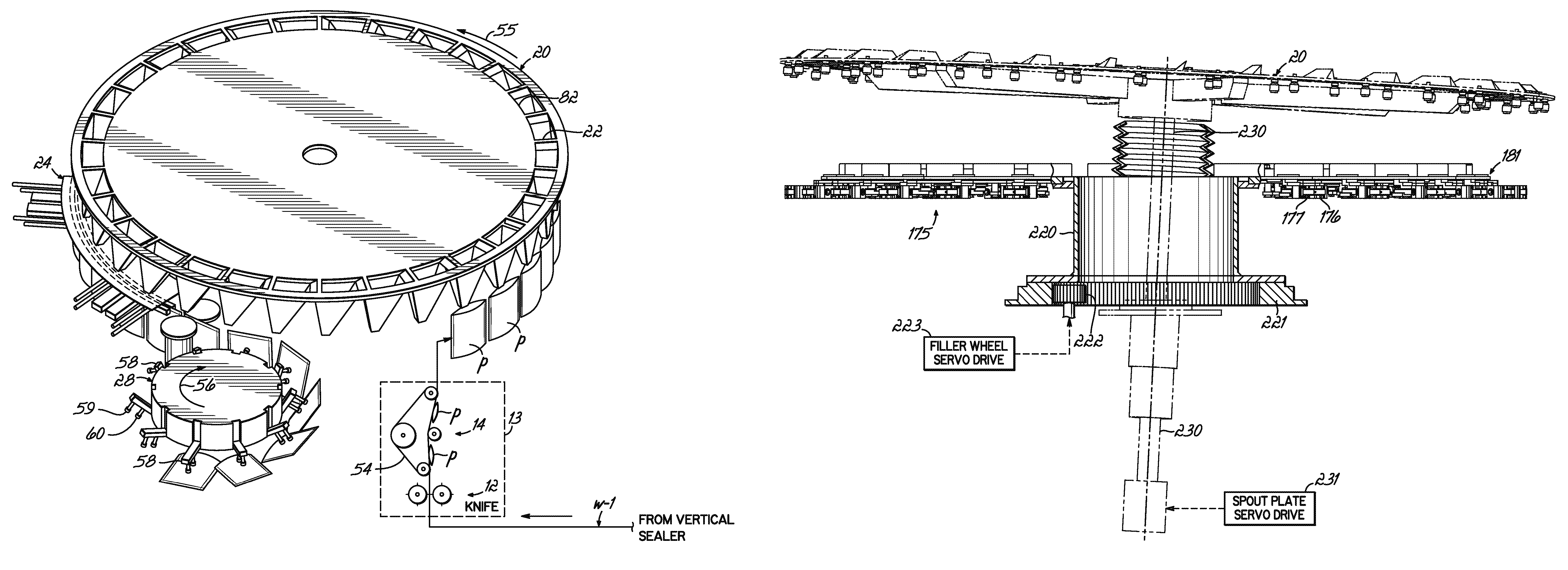

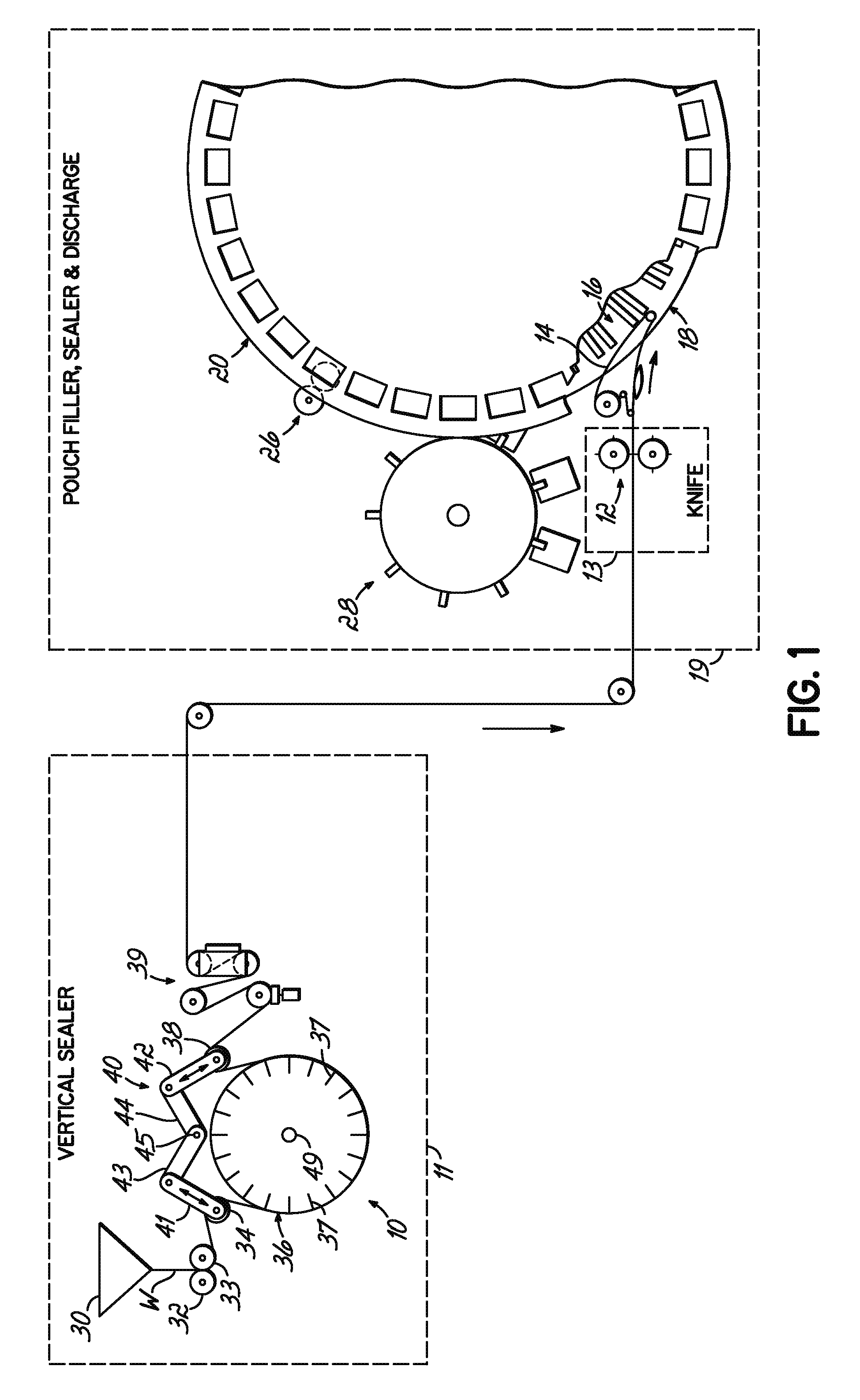

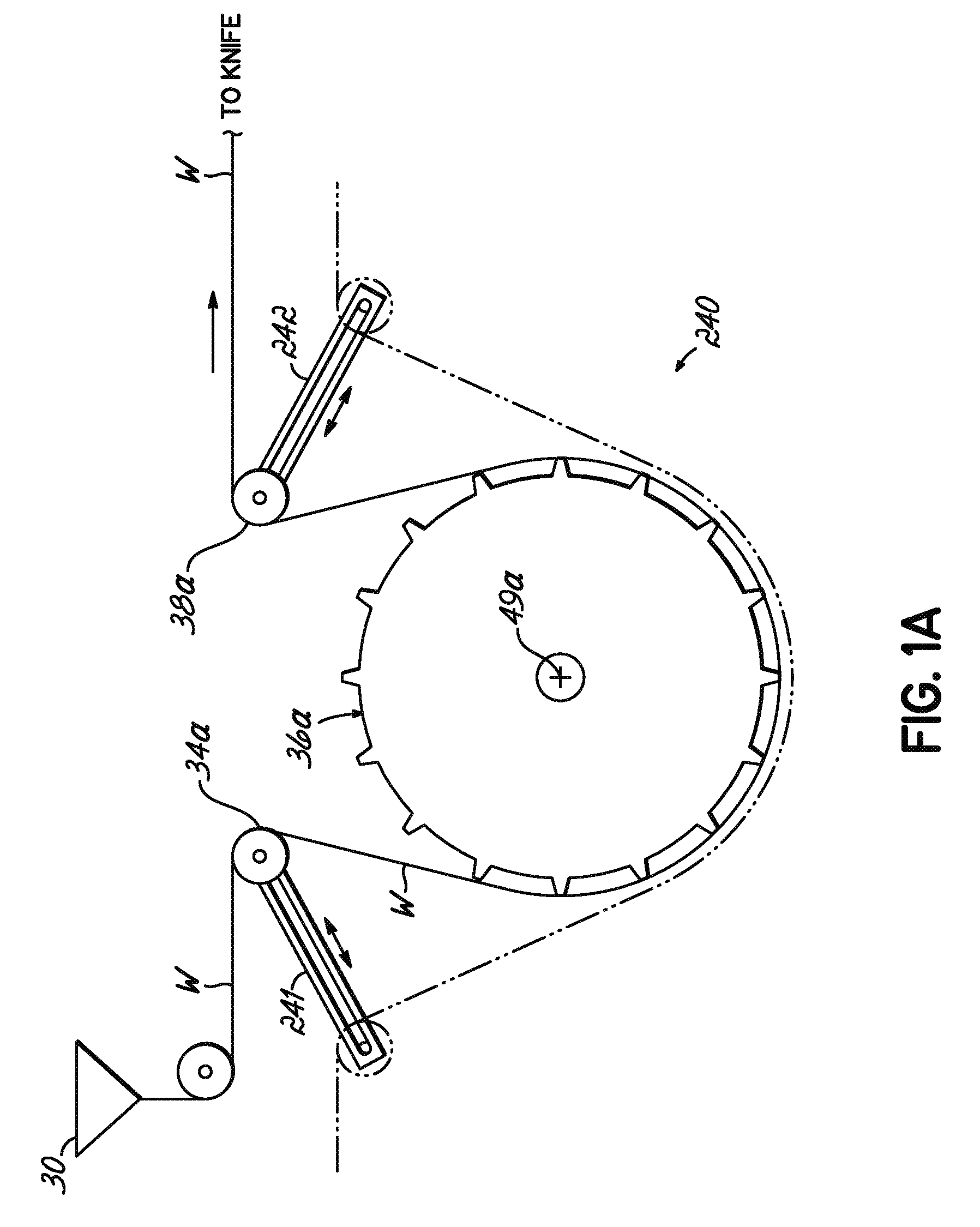

Adjustable pouch forming, filling and sealing apparatus and methods

ActiveUS20070180794A1Eliminate weightRemove complexityBoxes/cartons making machineryBox making operationsFirst FillEngineering

An adjustable pouch machine comprises a vertical sealer module forms transverse seals between two plies of a pouch web to partially define a plurality of pouches. Rollers selectively tension and relax the web on the vertically oriented wheel, allowing them to drop away from heated lands on emergency and cycle stops. A filler wheel has a plurality of adjustable gripper units mounted directly thereon for transporting independent separate pouches cut from the pouch web. An adjustable knife is selectively provided with changeable knife hub sets to handle a variety of pouch sizes where a filler wheel alternately first fills and seals pouches in a train. Gear linkage accommodates variation in distance between hubs of different sets. Various embodiments, apparatus and methods are described.

Owner:R A JONES

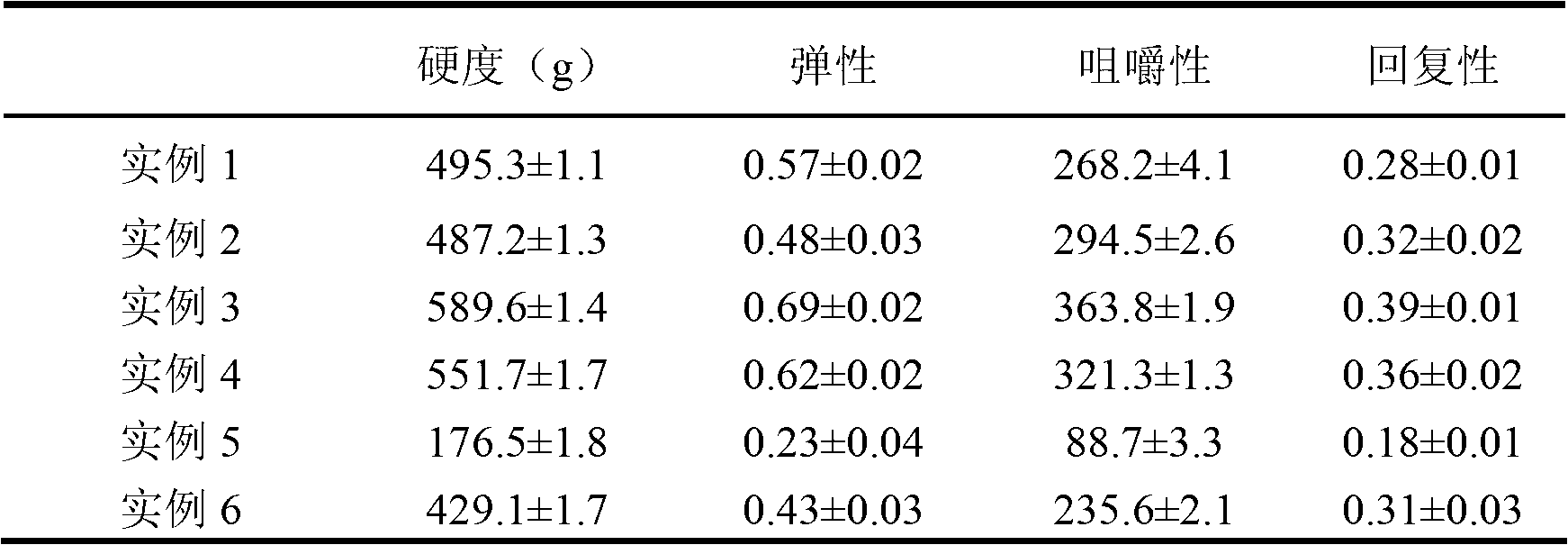

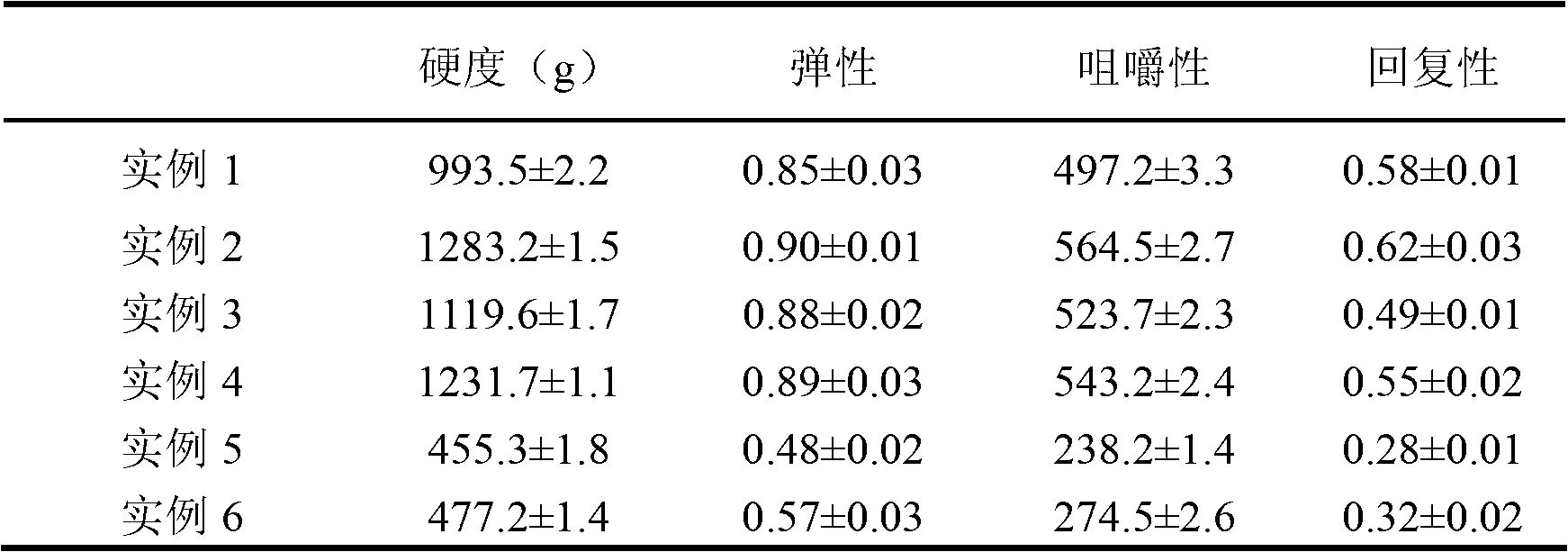

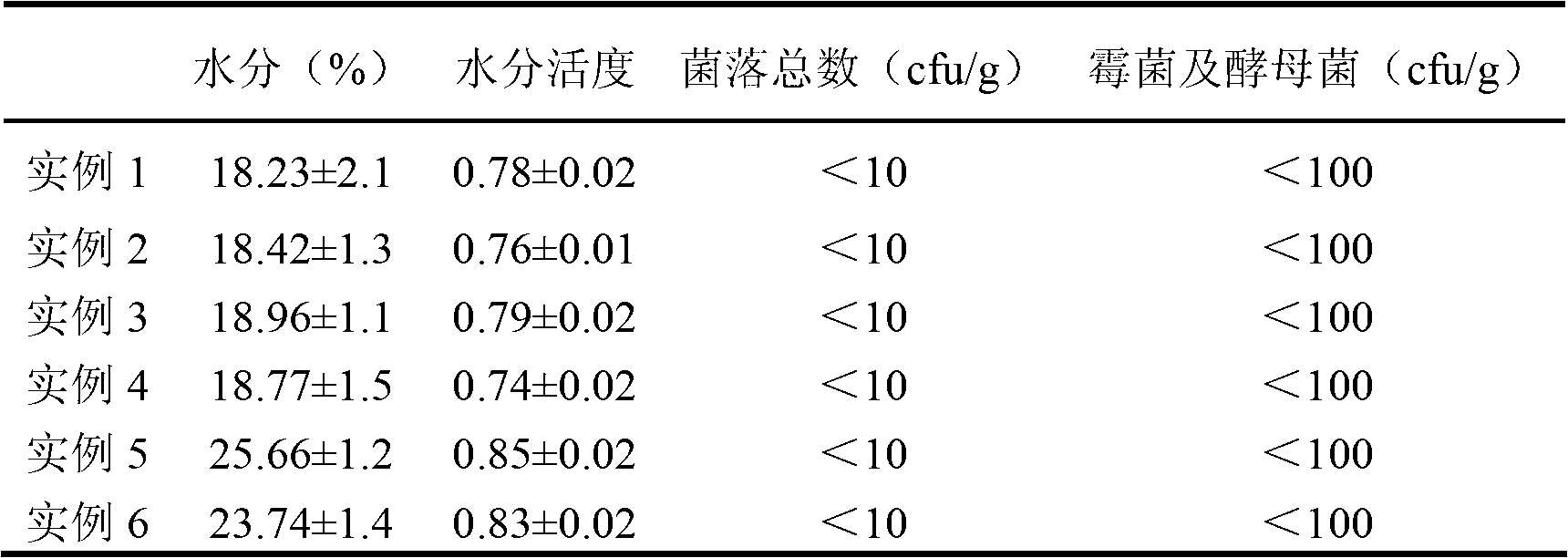

High-temperature self-gelation and baking-resistant cake stuffing pre-mix powder and preparation and application thereof

The invention discloses high-temperature self-gelation and baking-resistant cake stuffing pre-mix powder and preparation and application thereof. The cake stuffing pre-mix powder comprises the following components: 40-50 percent pre-gelatinized starch, 12-15 percent methyl cellulose, 1-12 percent xanthan gum, 20-25 percent sorbitol powder, 8-15 percent powdered sugar and 3-5 percent corn starch. The cake stuffing is in a half-solidification state and has a certain viscosity when being stirred with the pre-mix powder; the situation that a feeding head leaks due to the good liquidity of paste is avoided when the paste is filled in a paste filling machine; meanwhile, the viscosity degree can meet the requirements of normal extrusion of the paste filling machine, and the normal production efficiency is not affected; during the baking, the half-solidification stuffing paste can be automatically solidified into a solid state, the overflowing boiling phenomena of the stuffing can be reduced,a cavity can not be formed in the cake, and the organization and appearance of the cake can not be affected; and the water in the baked stuffing can not transfer to the cake embryo, so that the watercontent in the cake embryo can not increase to affect the guarantee period of the cake. According to the invention, the cake paste is first filled in the cake stuffing, and then the high-temperature baking step is carried out, so that the guarantee period risks of the cake are greatly reduced.

Owner:广州合诚实业有限公司

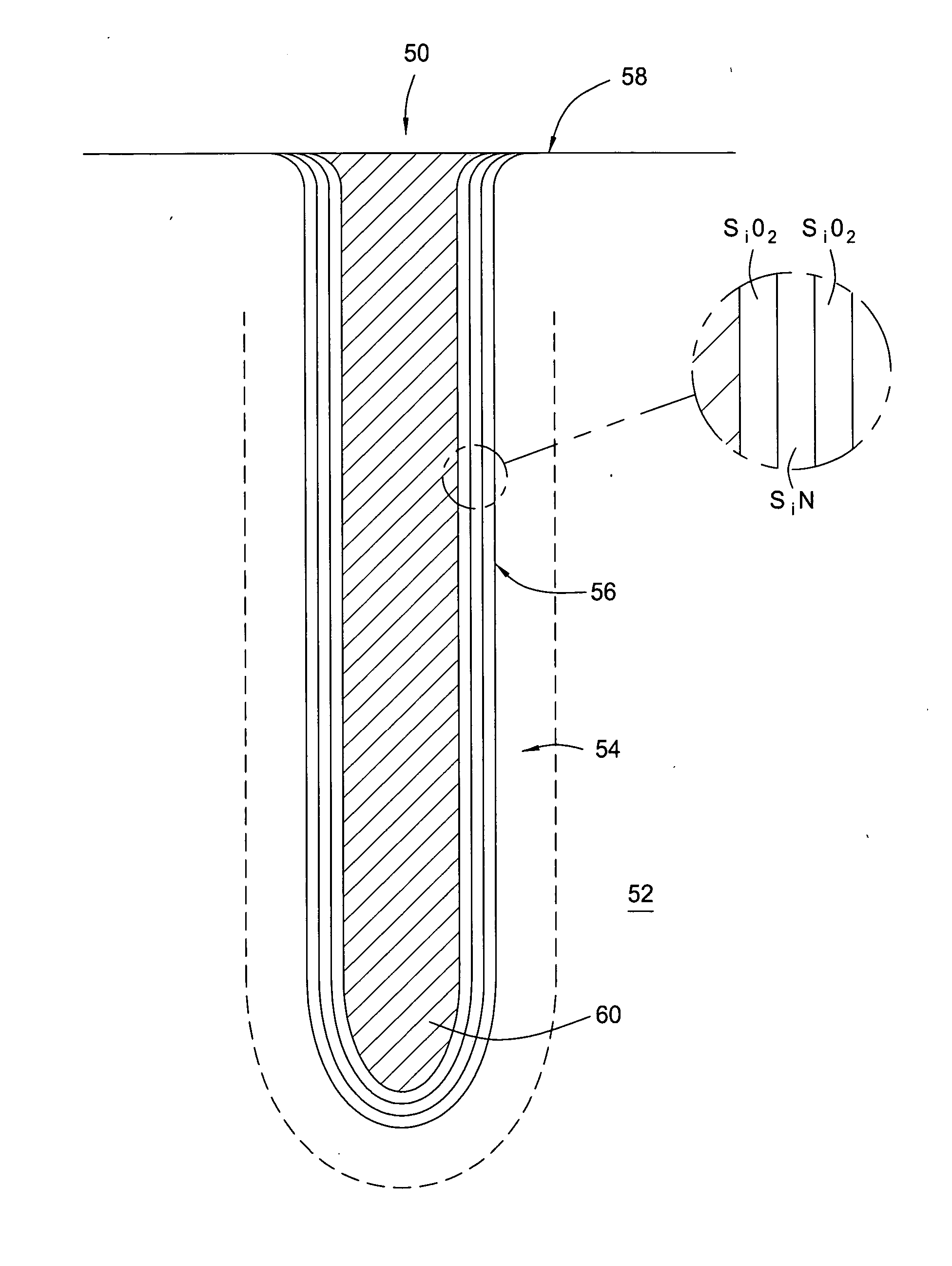

Method of inducing refractive index structures in a micro-structured fiber, a micro-structured fiber and an article

InactiveUS7792408B2Inhibition formationPrevents in-diffusion of waterLaser using scattering effectsOptical fibre with graded refractive index core/claddingGratingRefractive index

Refractive index modifications such as e.g. Fiber Bragg gratings in micro-structured Fiber are according to an aspect of the invention fabricated by first filling and / or purging the holes of the micro-structured fiber with inert gas or by evacuation and, optionally subsequently scaling the ends. Alternatively, the ends of the micro-structured fiber may be sealed without a preceding purging or evacuation of the holes. In this way hydrogen or deuterium present in the holes after photosensitizing loading will not react with atmospheric oxygen to form water. Water formed this way would otherwise seriously impair the grating formation process. Bragg gratings and other refractive index structures can thus be fabricated with high quality and predictable specifications in micro-structured fiber. Sealing the fiber ends also prevents in-diffusion of moisture. The invention may e.g. find application in connection with fiber optical sensors, high-power fiber lasers, etc.

Owner:NKT PHOTONICS

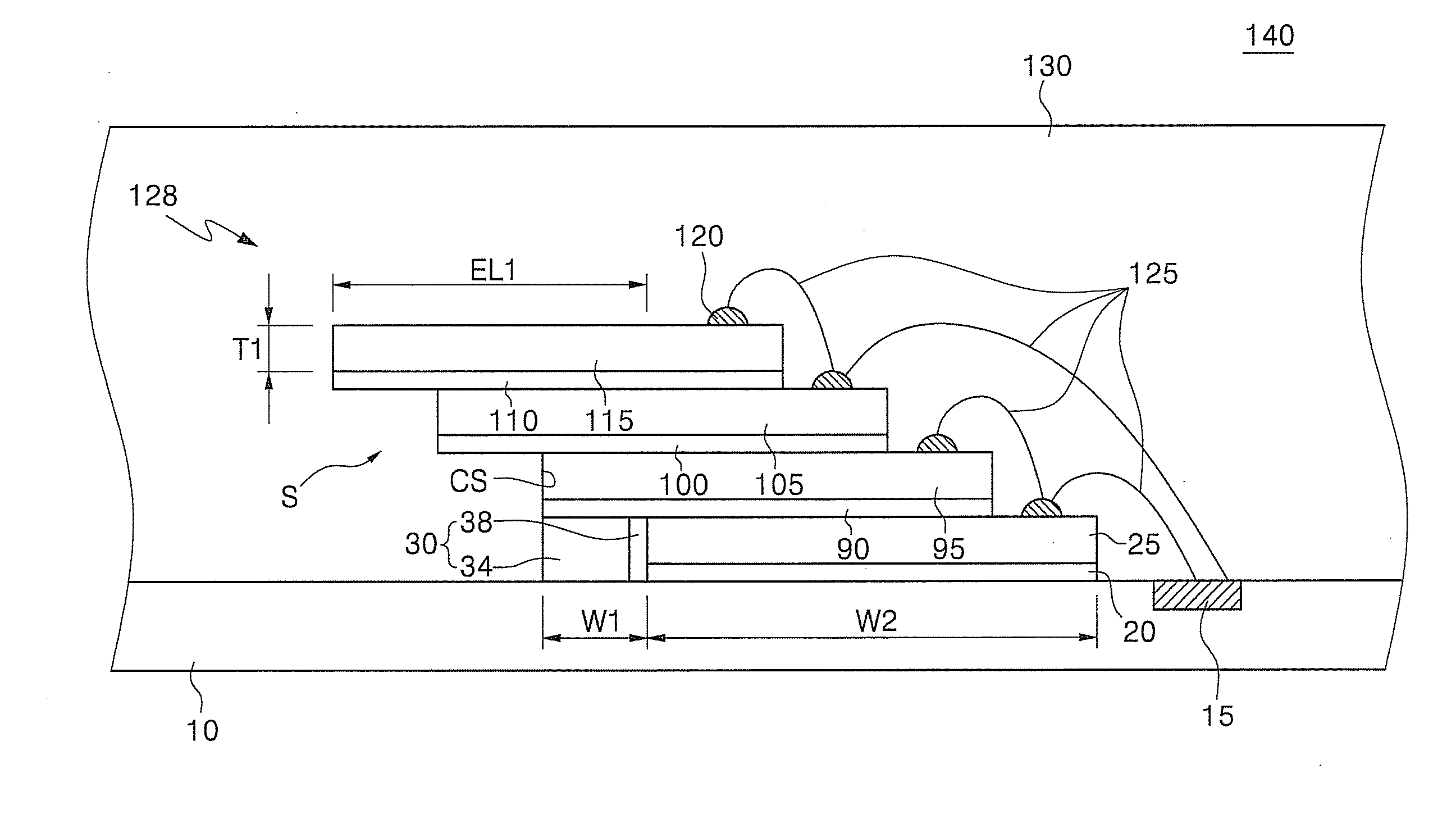

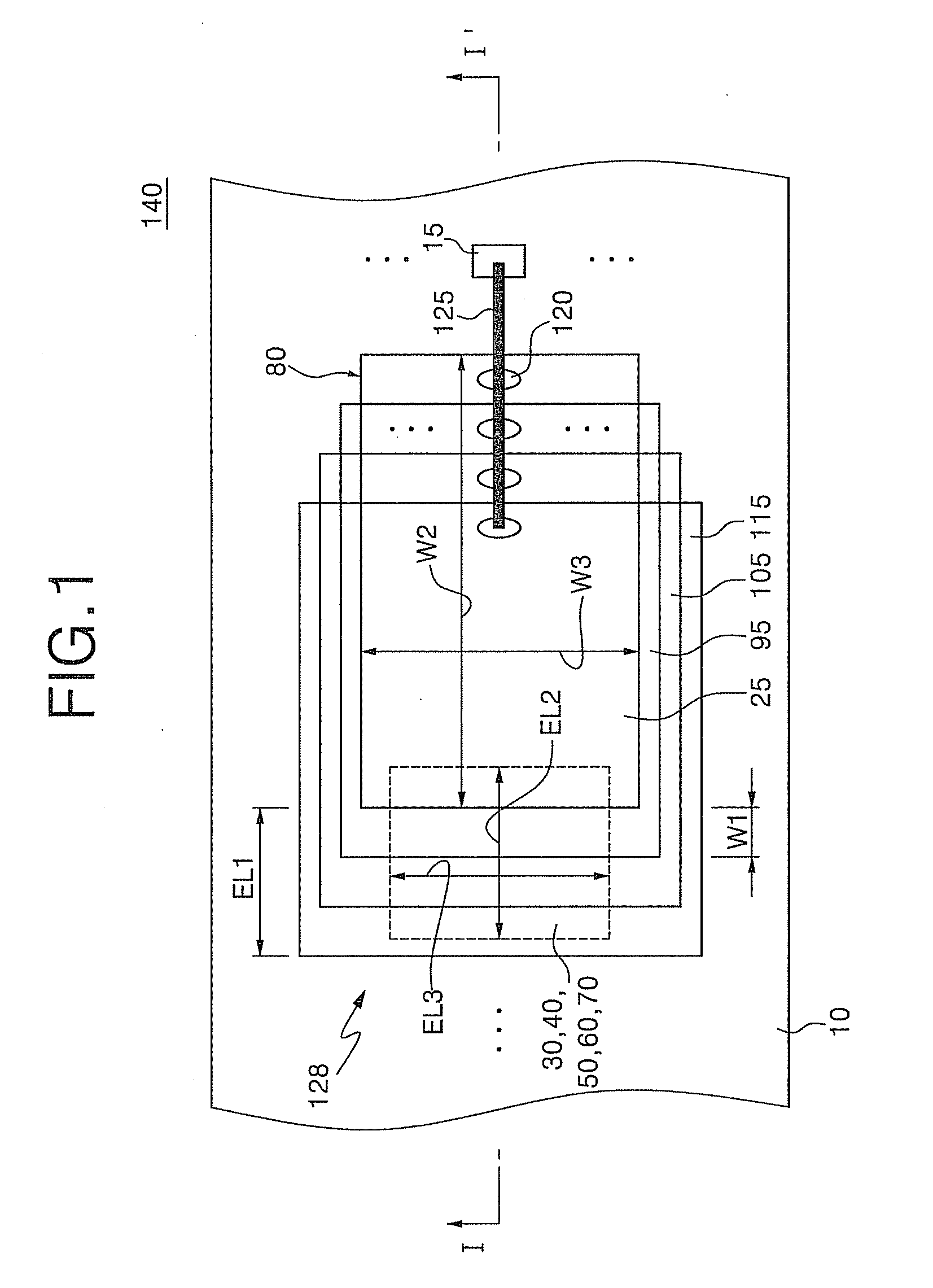

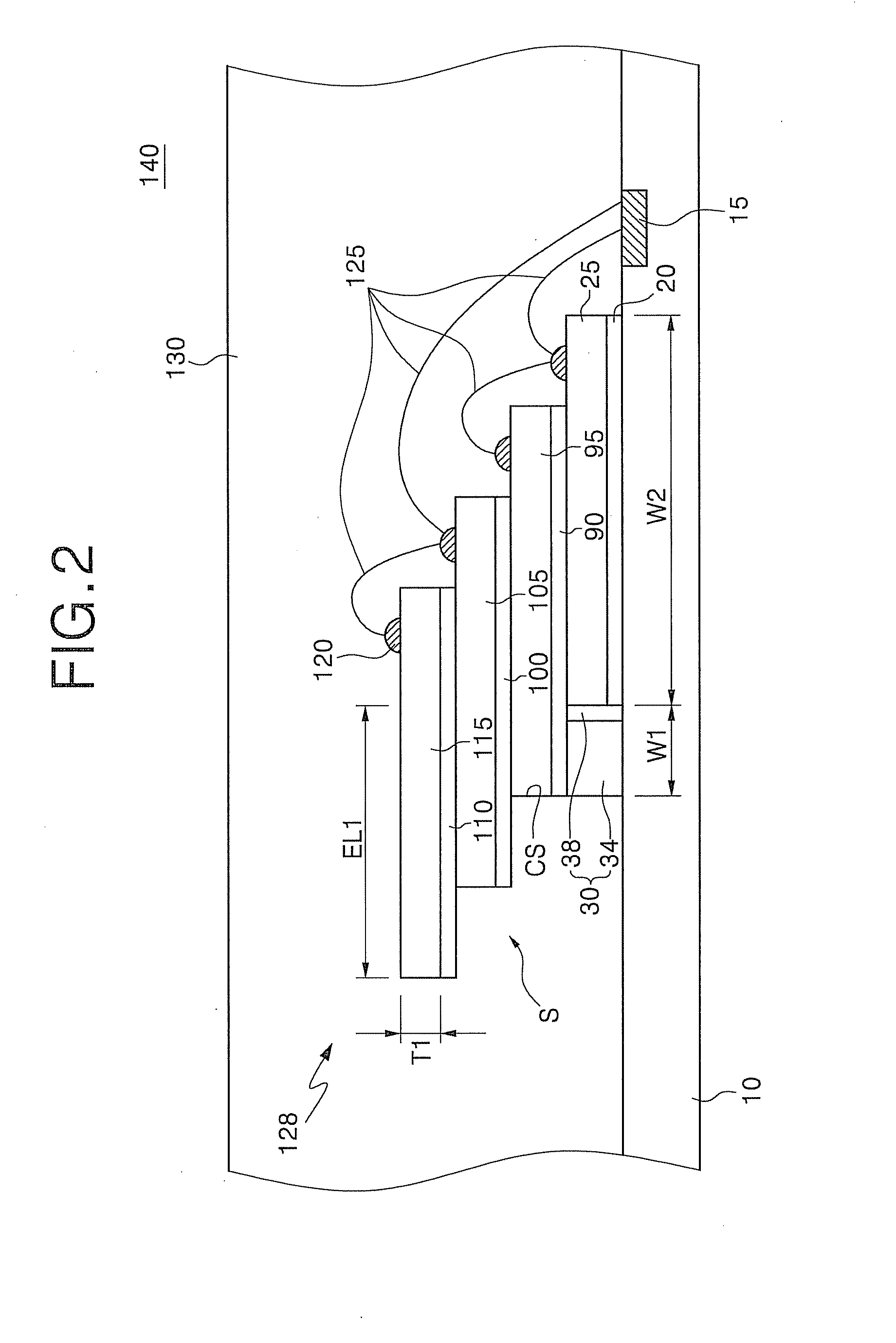

Semiconductor package, semiconductor package structure including the semiconductor package, and mobile phone including the semiconductor package structure

ActiveUS20110079890A1Fully filledSemiconductor/solid-state device detailsSolid-state devicesFirst FillSemiconductor chip

Provided is a semiconductor package. The semiconductor package may include a first semiconductor package having first semiconductor chips sequentially stacked on a substrate. In example embodiments, the first semiconductor chips may have a cascaded arrangement in which first sides and second sides of the semiconductor chips define cascade patterns. The cascaded arrangement may extend in a first direction to define a space between the first sides of the first semiconductor chips and the substrate. The semiconductor package may also include at least one first connection wiring at the second sides of the semiconductor chips, the at least one first connection wiring being configured to electrically connect the substrate with the first semiconductor chips. In addition, the semiconductor package may further include a first filling auxiliary structure adjacent to the first sides of the first semiconductor chips.

Owner:SAMSUNG ELECTRONICS CO LTD

Installation for filling receptacles with varying product compositions

InactiveUS6772806B2Reduce size and costMinimize timeLiquid fillingSolid materialFirst FillRelative displacement

An installation for filling receptacles comprises a rotary platform supporting a first filling station comprising a first feed vessel having first filling nozzles connected thereto, and at least one second filling station comprising a second feed vessel having second filling nozzles connected thereto, the second filling nozzles being adjacent to the first filling nozzles and the installation further comprising displacement members for imparting relative displacement between the receptacles and the filling nozzles.

Owner:SERAC GROUP

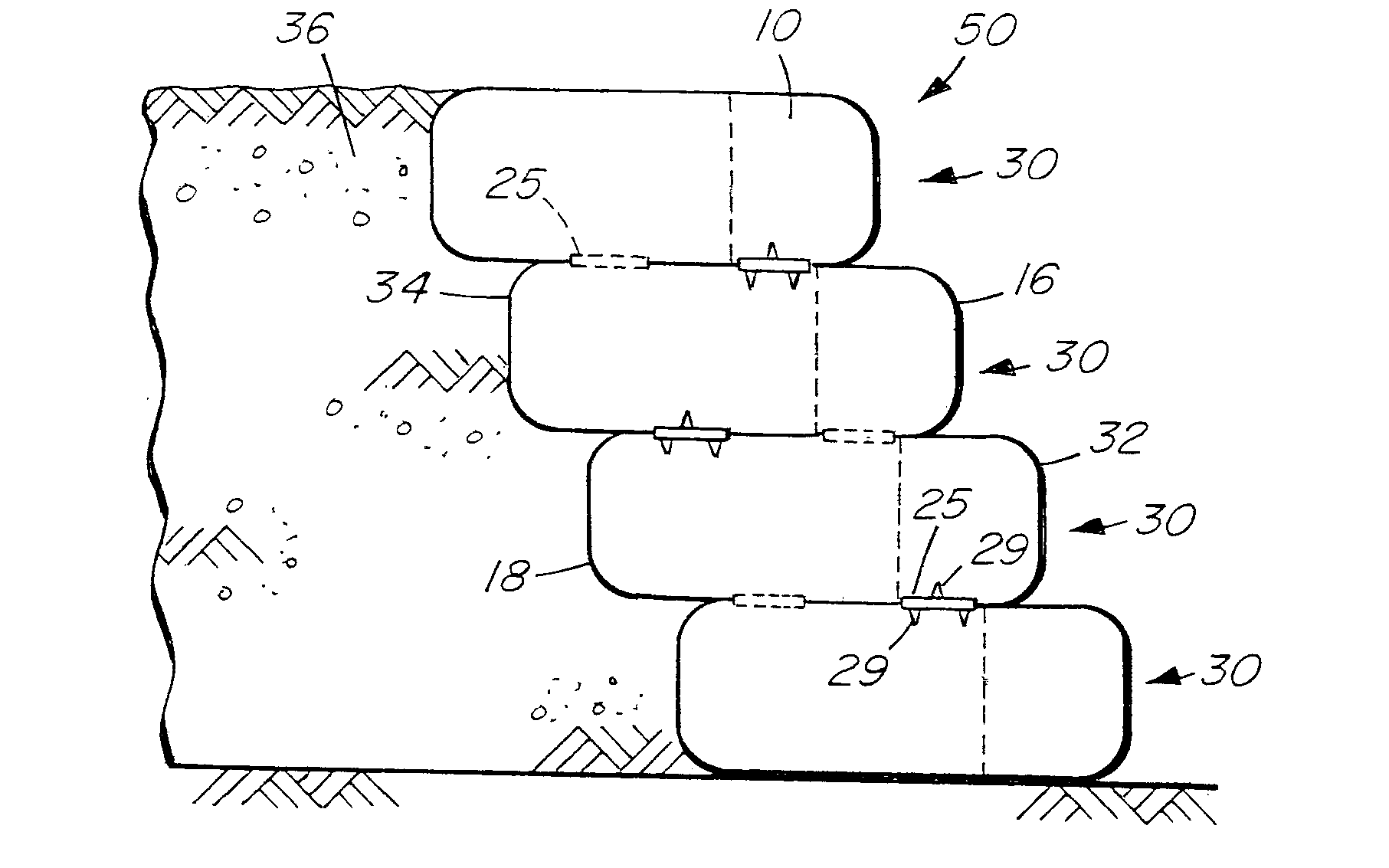

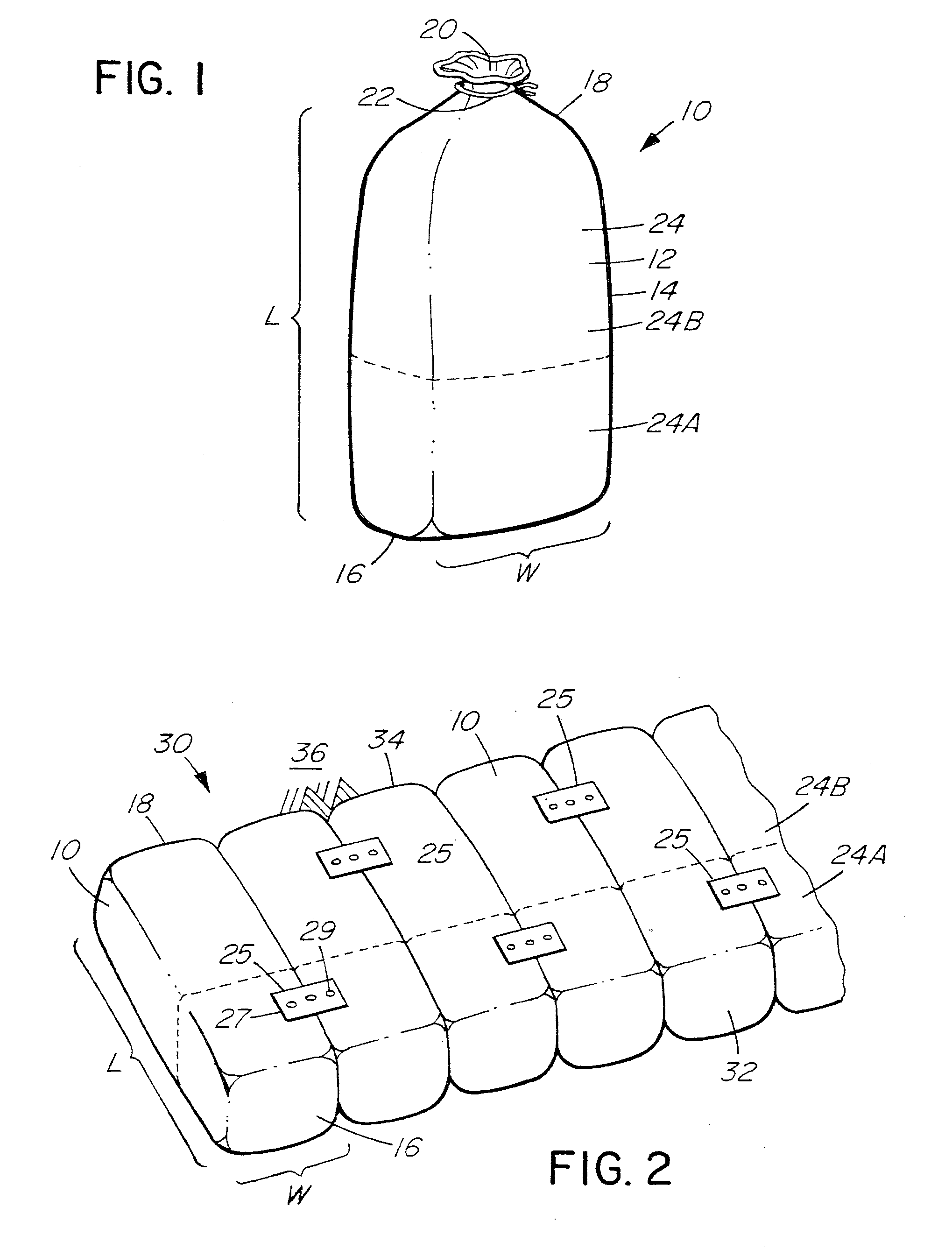

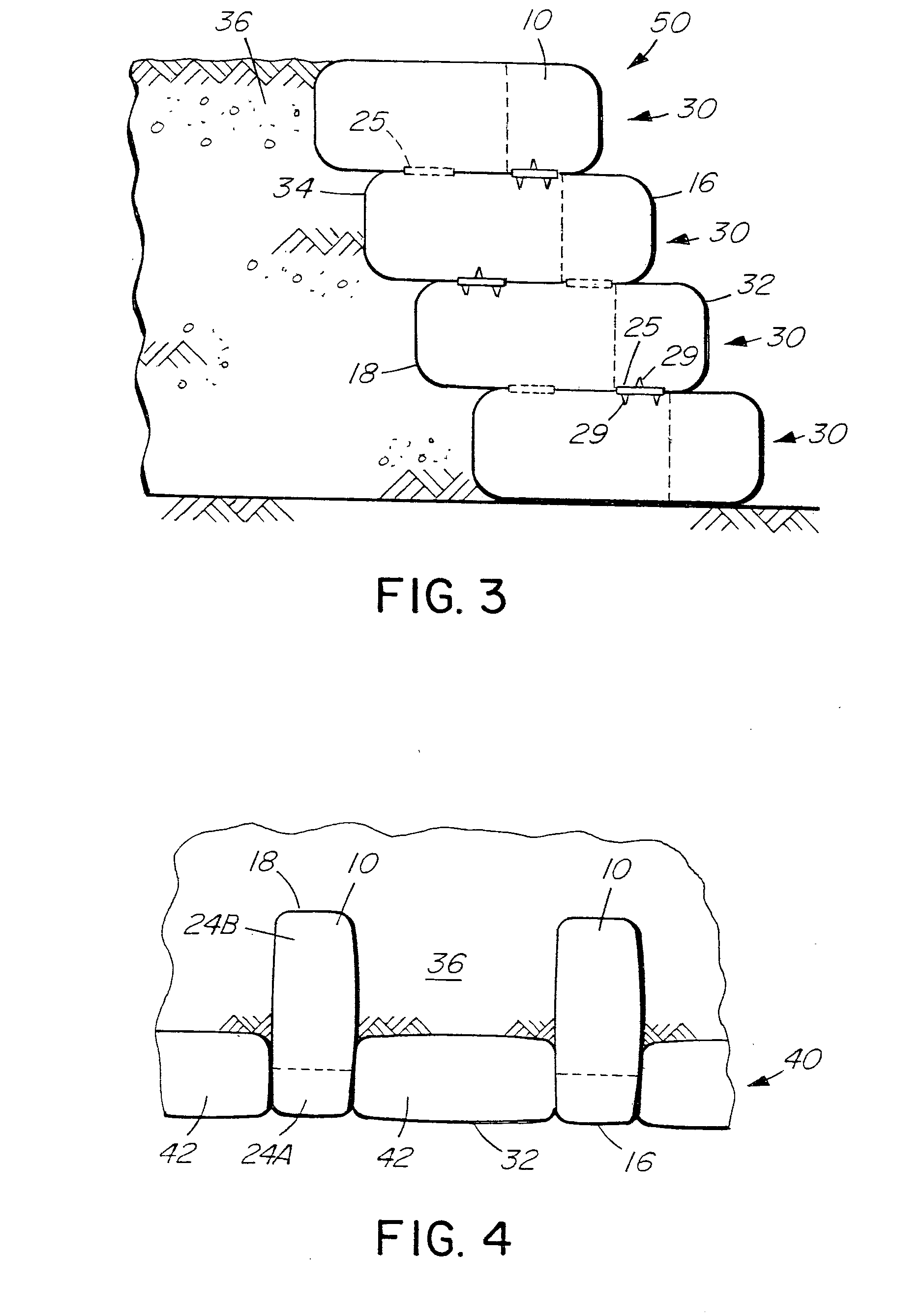

Sandbag retaining walls adapted for plant growth

The sandbag for use in constructing retaining walls having a vegetation-covered wall face. The sandbag contains soil mixed with seeds as a first fill material at one end of the bag, and the remainder of the bag is filled with a cheaper fill material such as sand or gravel. The sandbags are arranged in a sandbag wall such that the ends of the bags having the soil and seed mixture forms at least part of the outer face of the wall.

Owner:DELTALOK +1

Adjustable pouch forming, filling and sealing apparatus and methods

ActiveUS7954307B2Robust structureWider widthBoxes/cartons making machineryBox making operationsFirst FillMechanical engineering

An adjustable pouch machine comprises a vertical sealer module forms transverse seals between two plies of a pouch web to partially define a plurality of pouches. Rollers selectively tension and relax the web on the vertically oriented wheel, allowing them to drop away from heated lands on emergency and cycle stops. A filler wheel has a plurality of adjustable gripper units mounted directly thereon for transporting independent separate pouches cut from the pouch web. An adjustable knife is selectively provided with changeable knife hub sets to handle a variety of pouch sizes where a filler wheel alternately first fills and seals pouches in a train. Gear linkage accommodates variation in distance between hubs of different sets. Various embodiments, apparatus and methods are described.

Owner:R A JONES

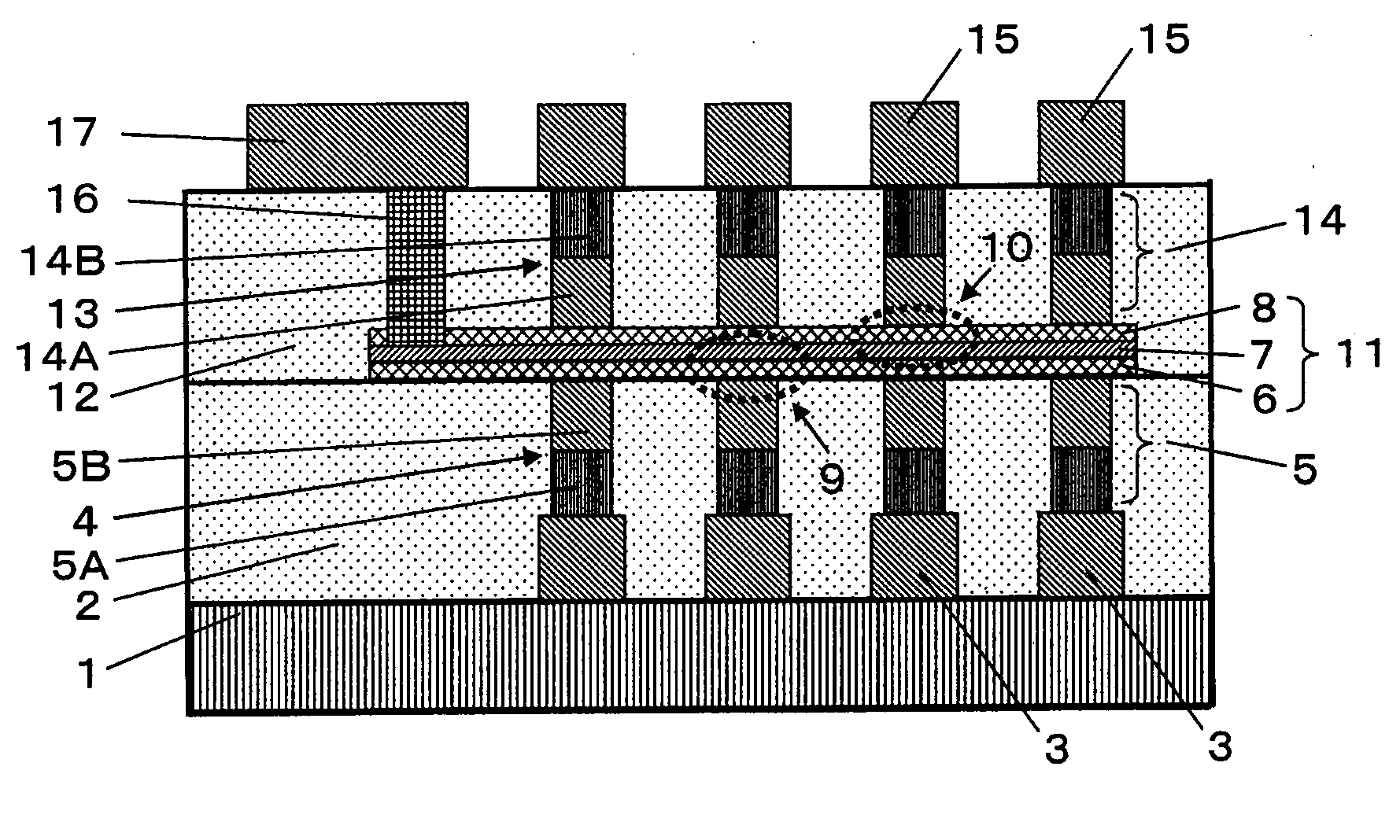

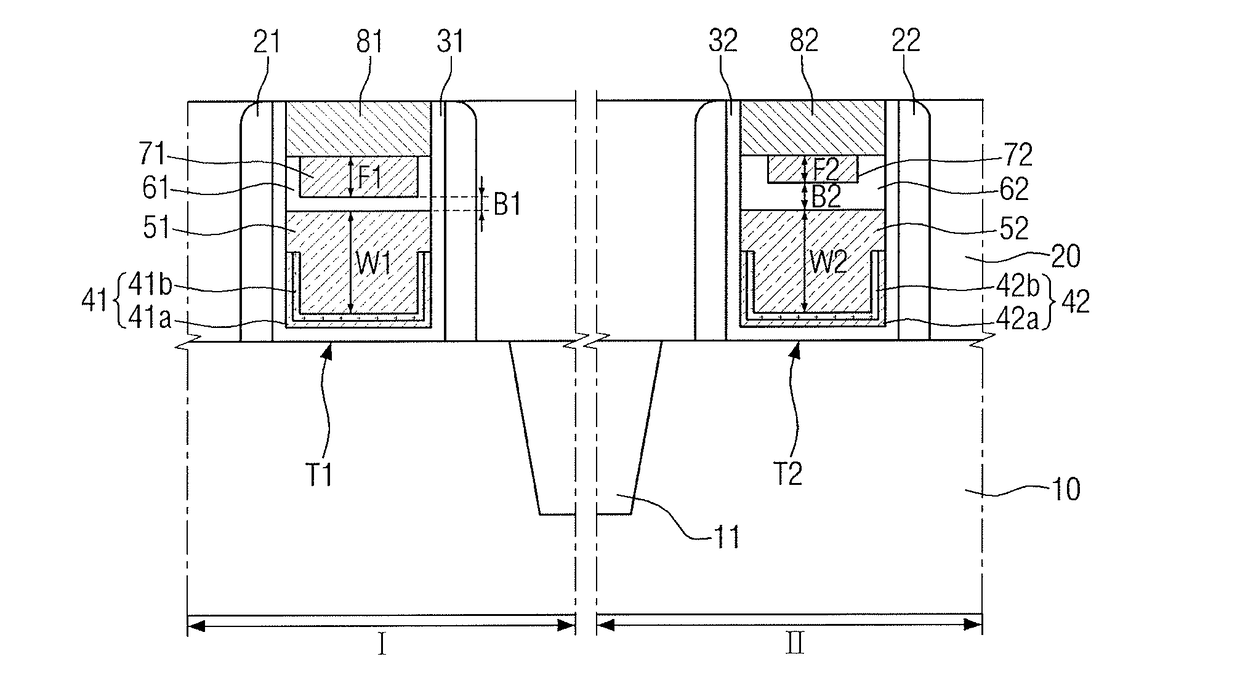

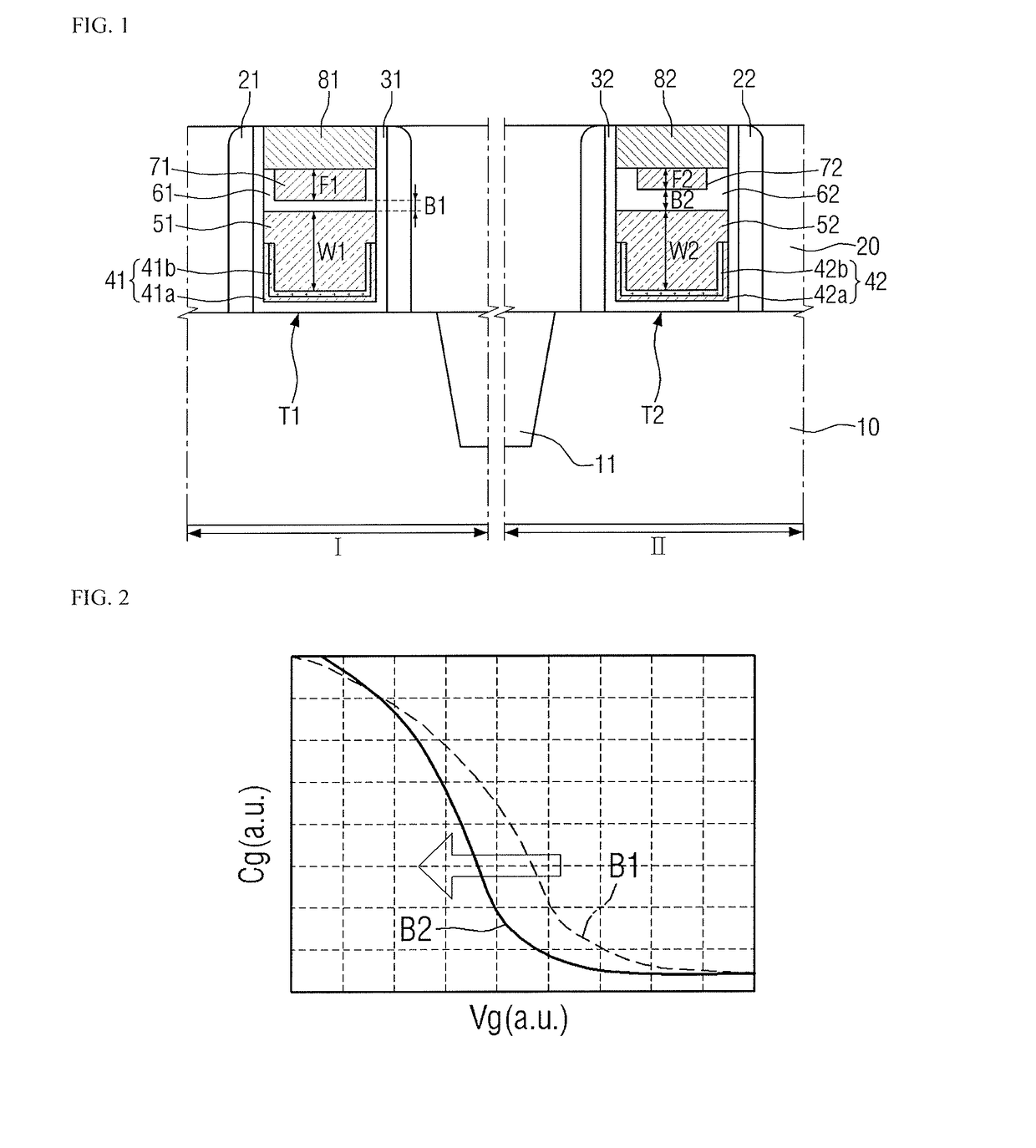

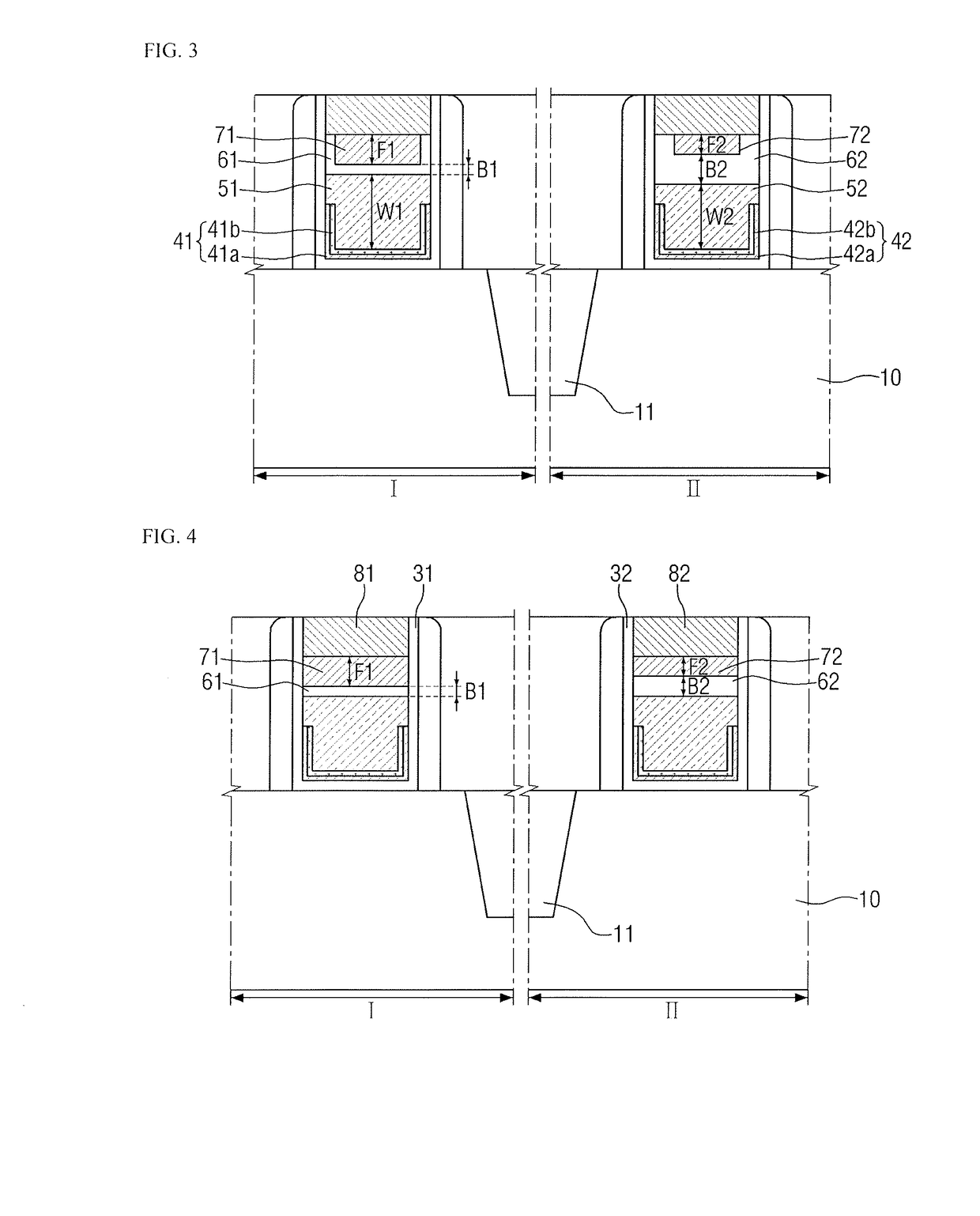

Nonvolatile memory device and manufacturing method thereof

ActiveUS20100264393A1Low costEasy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingFirst FillNon-volatile memory

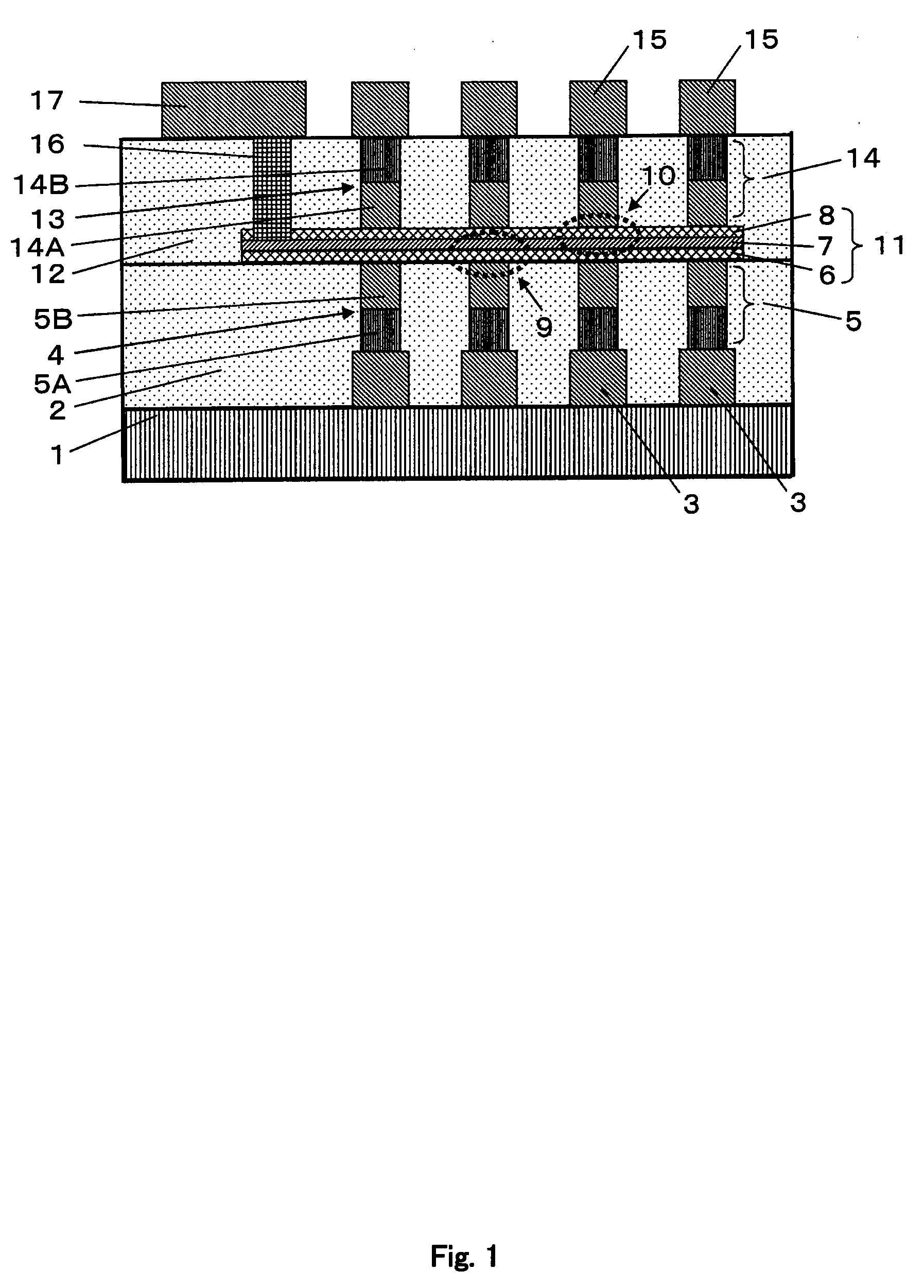

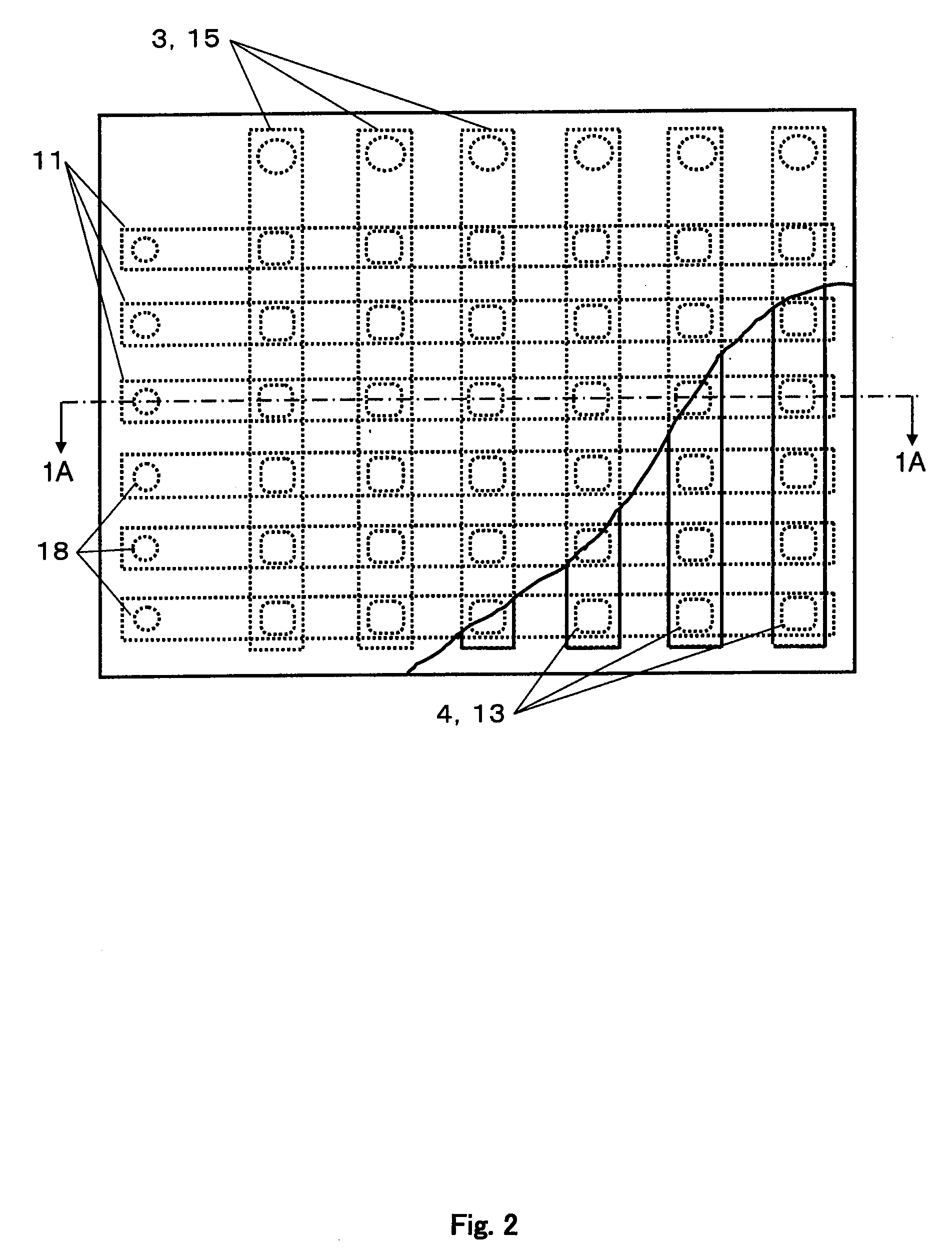

A nonvolatile memory device of the present invention comprises a substrate (1), first wires (3), first filling constituents (5) filled into first through-holes (4), respectively, second wires (11) which cross the first wires (3) perpendicularly to the first wires (3), respectively, each of the second wires (11) including a plurality of layers including a resistance variable layer (6) of each of first resistance variable elements, a conductive layer (7) and a resistance variable layer (8) of each of second resistance variable elements which are stacked together in this order, second filling constituents (14) filled into second through-holes (13), respectively, and third wires (15), and the conductive layer (7) of the second wires (11) serves as the electrodes of the first resistance variable elements (9) and the electrodes of the second resistance variable elements (10).

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

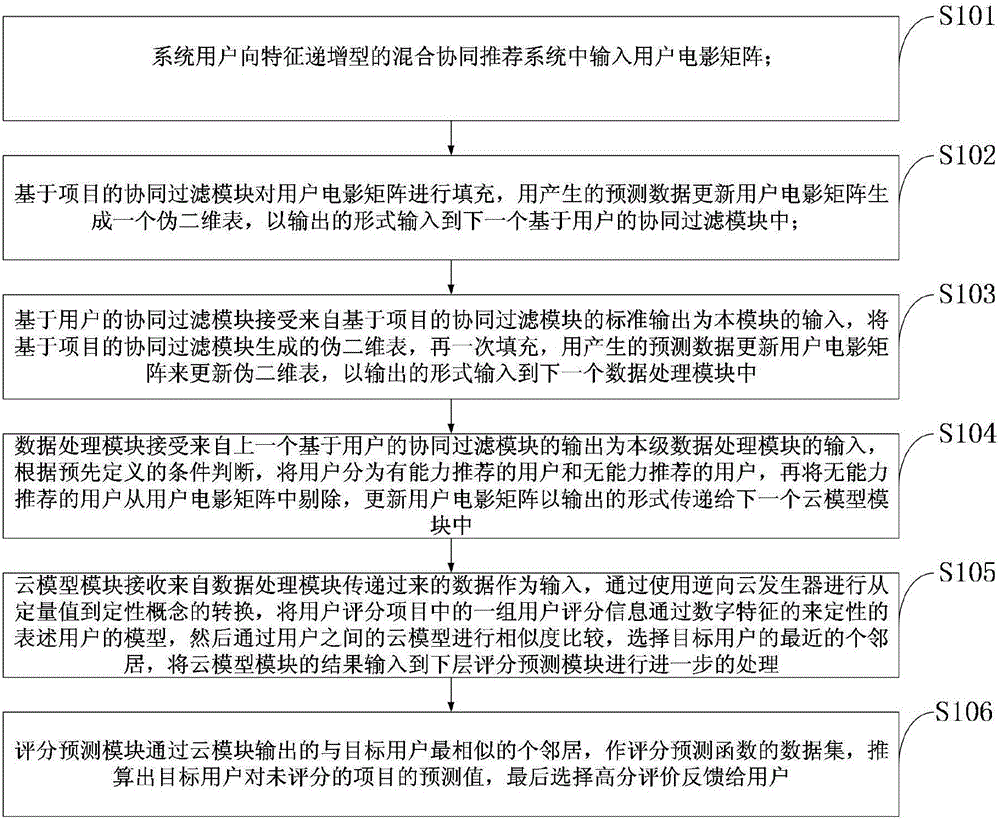

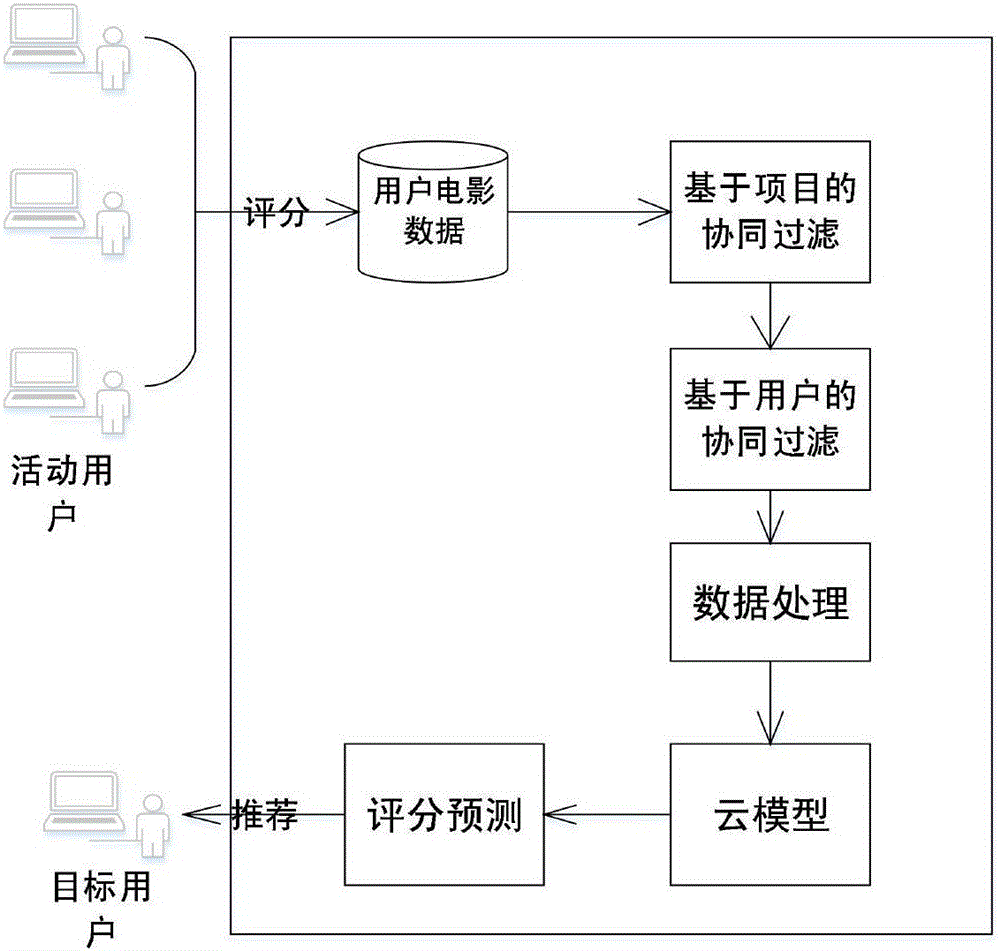

Personalized film recommendation method and system based on feature augmentation

InactiveCN105868334ASolve the sparse problemImprove recommendation qualitySpecial data processing applicationsFirst FillPersonalization

The invention discloses a personalized film recommendation method and system based on feature augmentation. The necessity and feasibility that the personalized recommendation system is transferred to a cloud calculation platform are discoursed by analyzing the problems brought by mass data to the existing personalized recommendation system, and by combining a mixed recommendation model adopting feature augmentation, the method comprises the steps that an original extremely-sparse user item rating matrix is filled for the first time through a collaborative filtering algorithm based on items to generate a pseudo two-dimensional table, then the pseudo two-dimensional table is further filled through a collaborative filtering algorithm based on the user, and lastly the defects of strict object attribute matching are avoided through conversion of quantitative knowledge and qualitative knowledge of a cloud module. According to the method, all rating data of the user is fully utilized, the calculation efficiency is greatly improved and calculation speed is greatly increased through parallel calculation of cloud calculation, therefore, the better experience is provided for the user, and the advantages of an enterprise in competition are achieved.

Owner:YUNNAN UNIVERSITY OF FINANCE AND ECONOMICS

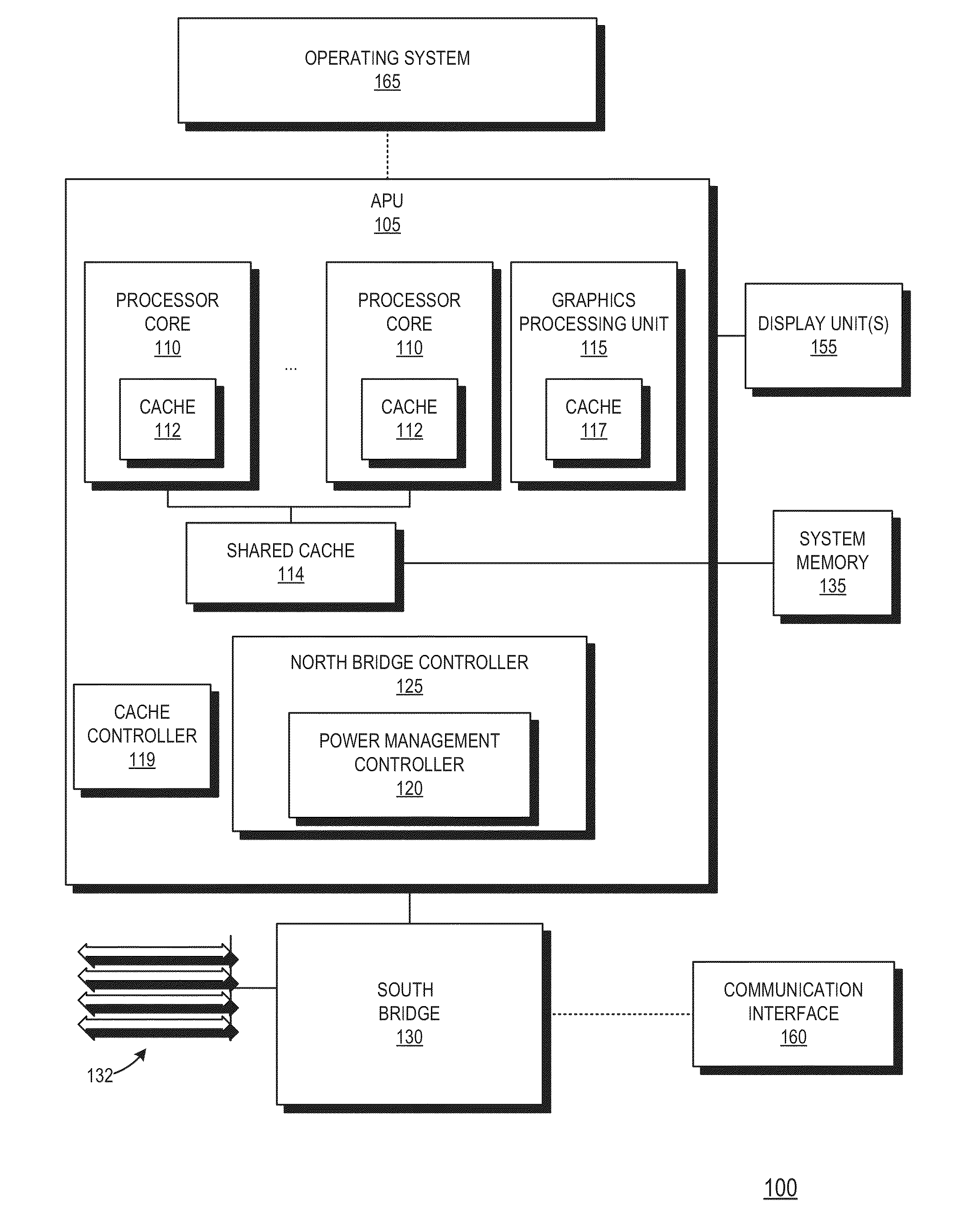

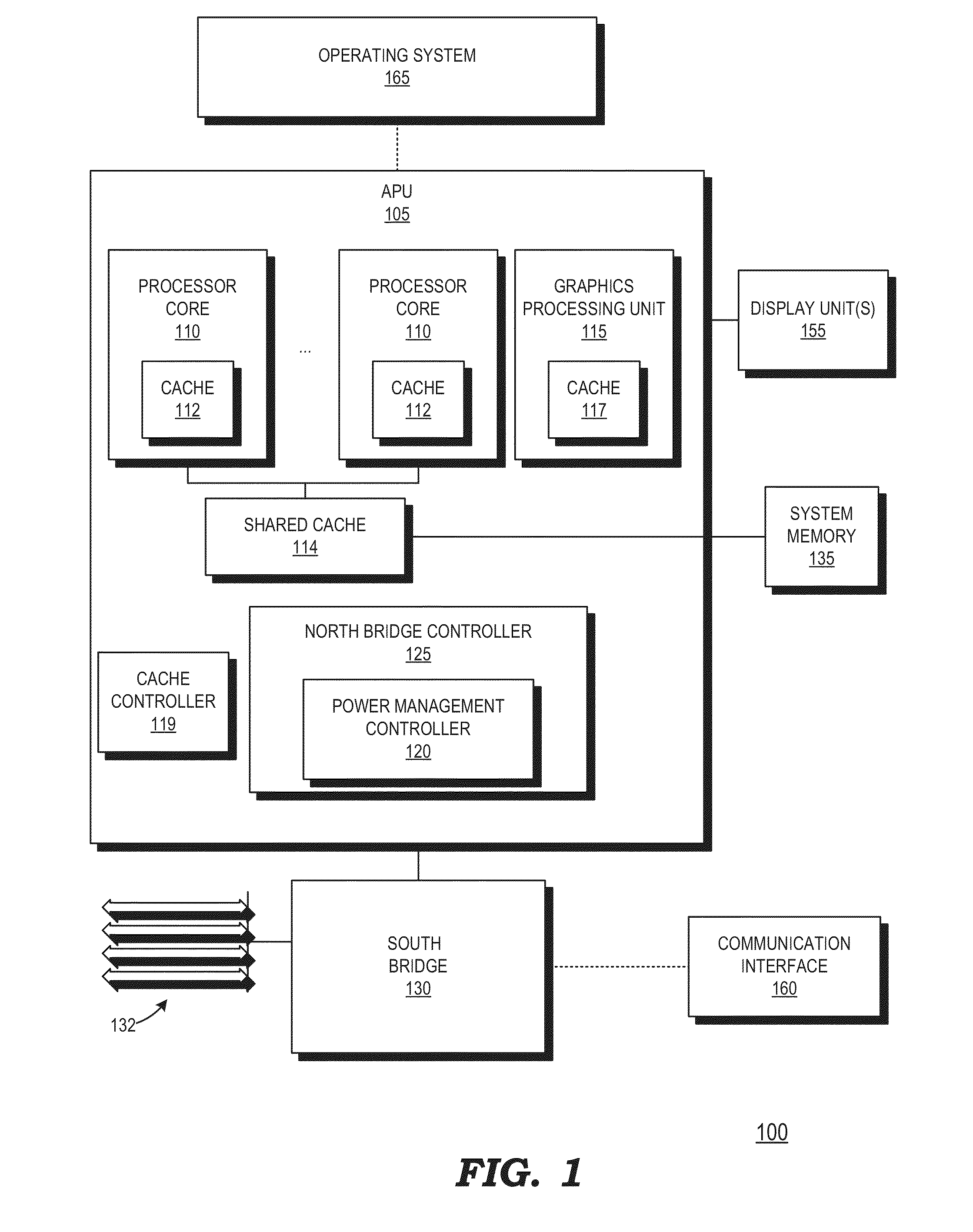

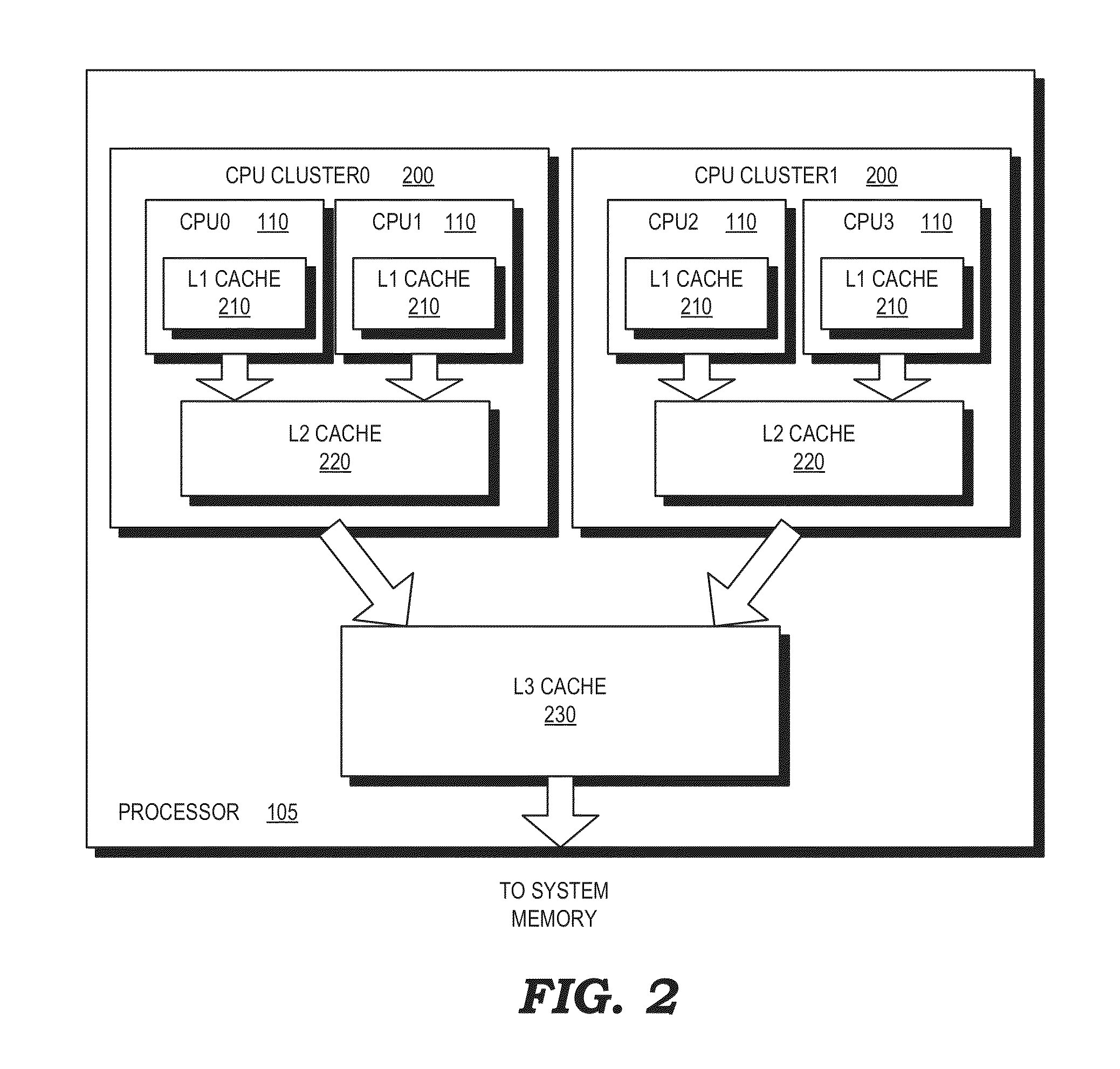

Method and apparatus for storing a processor architectural state in cache memory

ActiveUS20150081980A1Memory adressing/allocation/relocationNon-redundant fault processingFirst FillParallel computing

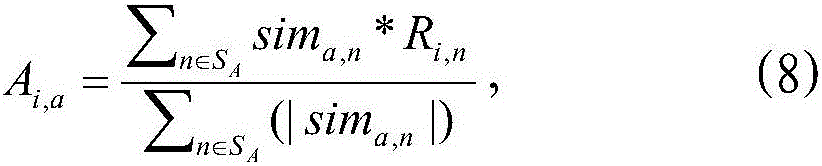

A method includes storing architectural state data associated with a processing unit in a cache memory using an allocate without fill mode. A system includes a processing unit, a cache memory, and a cache controller. The cache controller is to receive architectural state data associated with the processing unit and store at least a first portion of the architectural state data in the cache memory using a first fill mode responsive to a first value of a fill mode flag and store at least a second portion of the architectural state data in the cache memory using a second fill mode responsive to a second value of a fill mode flag, wherein the first fill mode differs from the second fill mode with respect to whether previous values of the architectural state data are retrieved prior to storing the first or second portions in the cache memory.

Owner:ADVANCED MICRO DEVICES INC

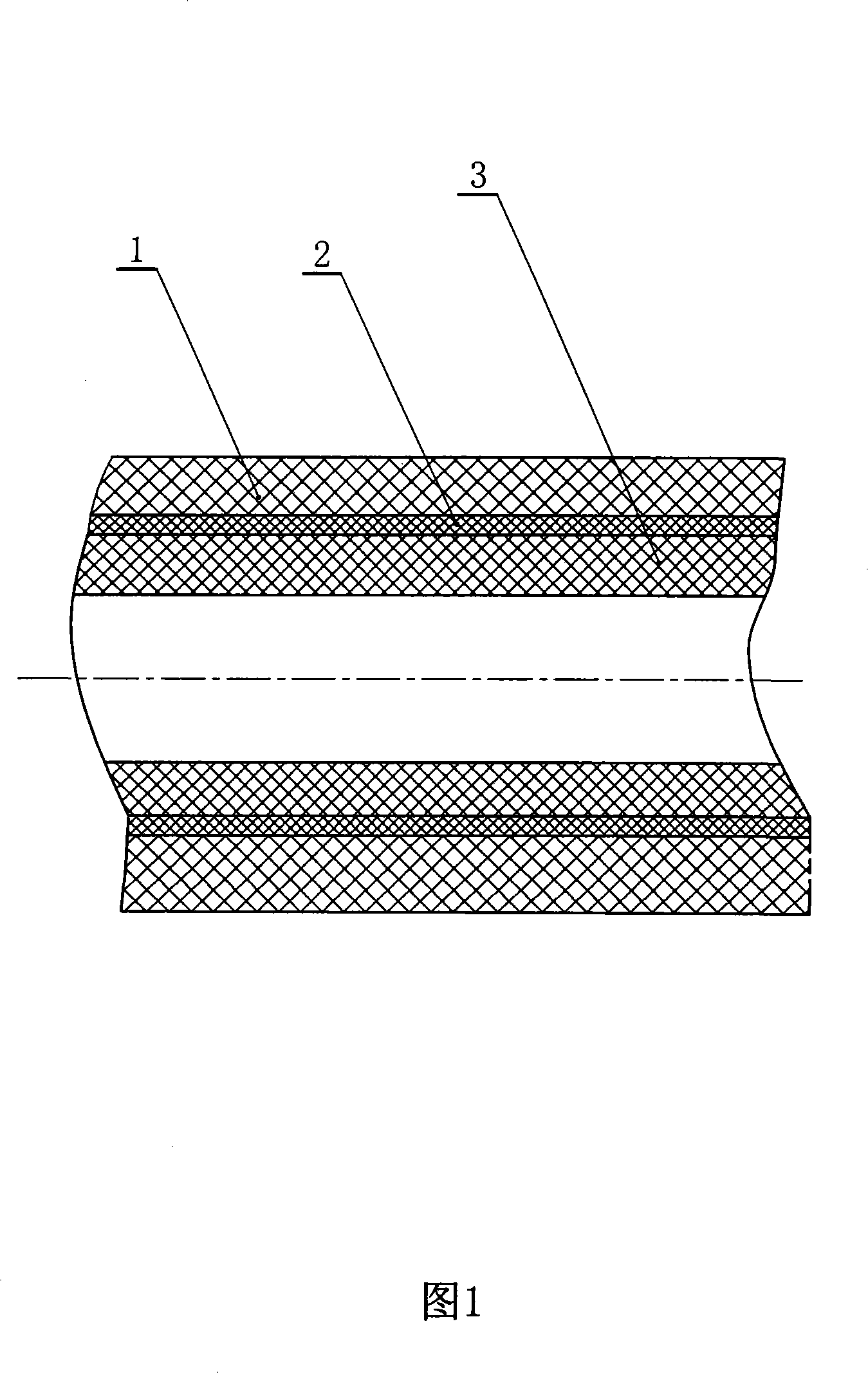

Water hose and manufacture method therefor

A kind of fire control water band it includes a rubber plastic pipe, a tubular skeleton and a coat; the manufacturing method of fire control water band is that: a. the longitude and the latitude line interlace to form the tubular skeleton; b. mix the material of making the rubber plastic pipe as following: polyvinyl chloride, stearic acid cadmium, butyl rubber, di-n-fatty oil, sterric acid calcium zinc, light calcium carbonate powder, barium stearate; c. heat the mixed rubber plastic pipe material then rack the heated rubber plastic pipe material into the rubber plastic pipe after that the rubber plastic pipe becomes coiling after cooling; d. make the coiling rubber plastic pipe gumming and the gumming layer at the outside wall of rubber plastic pipe is the coat and then make the rubber plastic pipe after gumming through into the tubular skeleton then curing it. At the time of curing first fill air into the rubber plastic pipe let the rubber plastic pipe coincidence with the tubular skeleton then fill water vapor into the rubber plastic pipe and then dry it at last pack it into production; the invention has low cost and high productive efficiency.

Owner:山东省枣庄市消防水带厂

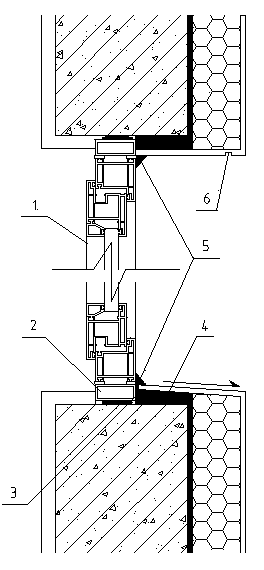

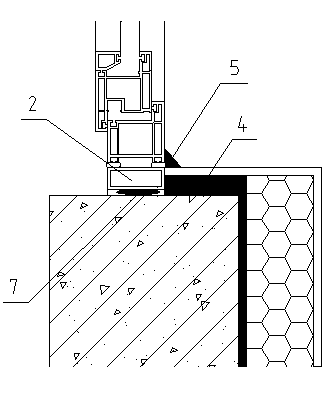

Anti-leakage joint processing method of first filling gap of outer window of building

ActiveCN103967386AReduce leakageImprove construction progressFrame fasteningJoints tightening/coveringFirst FillSteel frame

The invention relates to construction process of first filling a gap of an outer window of a building, in particular to an anti-leakage joint processing method of first filling the gap of the outer window of the building. The method comprises the following steps: aligning a snap line, determining the window position, fixing an auxiliary steel frame, filling a seam of the auxiliary steel frame and a structural wall body, coating the outer side of the auxiliary steel frame with JS waterproof paint, filling the gap in the periphery of the auxiliary steel frame through plastering, installing a window frame, conducting outer wall insulation adhesion and reserving a water dropping groove, sealing the window frame, the inner wall and the outer wall with sealant and conducting acceptance inspection. On the premise that internal decoration and external decoration are conducted at the same time and the construction progress is greatly accelerated, the leakage problem caused by the fact that a gap of an outer window of the building is first filled is effectively solved.

Owner:二十二冶集团第一建设有限公司

Apparatus for formulating and aseptically filling liquid products

An apparatus and method are provided for formulating and aseptically filling liquid products. A first liquid source includes at least one first liquid component; a second liquid source includes at least one second liquid component; and a container includes a body defining an empty, sterile storage chamber therein that is sealed with respect to ambient atmosphere. The container is introduced into a sterile filling chamber. A first filling member coupled in fluid communication with the first liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the first liquid component is aseptically introduced through the first filling member and into the storage chamber. A second filling member coupled in fluid communication with the second liquid source is placed in fluid communication with the storage chamber of the container located in the sterile filling chamber, and the second liquid component is aseptically introduced through the second filling member and into the storage chamber and, in turn, the first and second liquid components are combined into a liquid product formulation within the sterile chamber of the container. The first and second filling members are withdrawn from fluid communication with the storage chamber of the container located within the sterile filling chamber, and the filled storage chamber is sealed with respect to ambient atmosphere to hermetically seal the liquid product formulation within the storage chamber of the container.

Owner:MEDINSTILL DEV

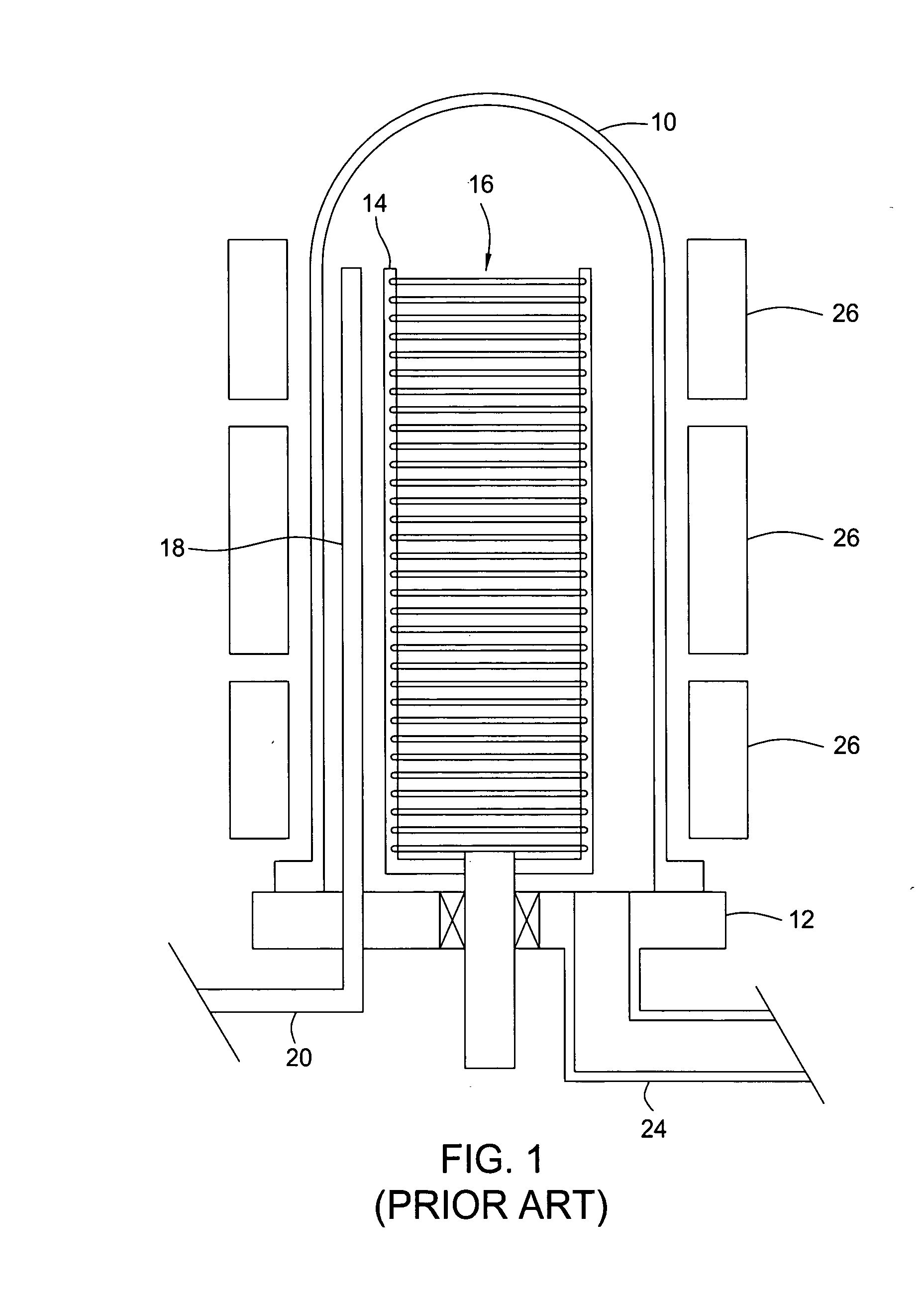

Process sequence for doped silicon fill of deep trenches

InactiveUS20060128139A1Increase deposition rateShort staySolid-state devicesSemiconductor/solid-state device manufacturingDopantFirst Fill

A method for void free filling with in-situ doped amorphous silicon of a deep trench structure is provided in which a first fill is carried out in at a temperature, pressure and dopant to silane ratio such that film deposition occurs from the bottom of the trench upwards. By way of this first fill, step coverages well in excess 100% are achieved. In the second fill step, deposition is carried out under changed conditions so as to reduce the impact of dopant on deposition rate, whereby trench fill is completed at a deposition rate which exceeds the deposition rate of the first fill. In an application of this method to the formation of deep trench capacitor structures, the intermediate steps further including the capping of the void free filled trench with a thick layer of amorphous silicon, planarization of the wafer thereafter, followed by a thermal anneal to re-distribute the dopant within the filled trench. Thereafter, additional steps can be performed to complete the formation of the capacitor structure.

Owner:APPLIED MATERIALS INC

Semiconductor device and method for fabricating the same

A semiconductor device includes a first trench and a second trench, a liner pattern along a portion of side surfaces and along bottom surfaces of the first and the second trenches, respectively, a work function metal in the first and the second trenches and on the liner pattern, respectively, a first barrier metal in the first trench and on the work function metal, and having a first thickness, a second barrier metal in the second trench and on the work function metal, and having a second thickness thicker than the first thickness, and a first fill metal on the first barrier metal.

Owner:SAMSUNG ELECTRONICS CO LTD

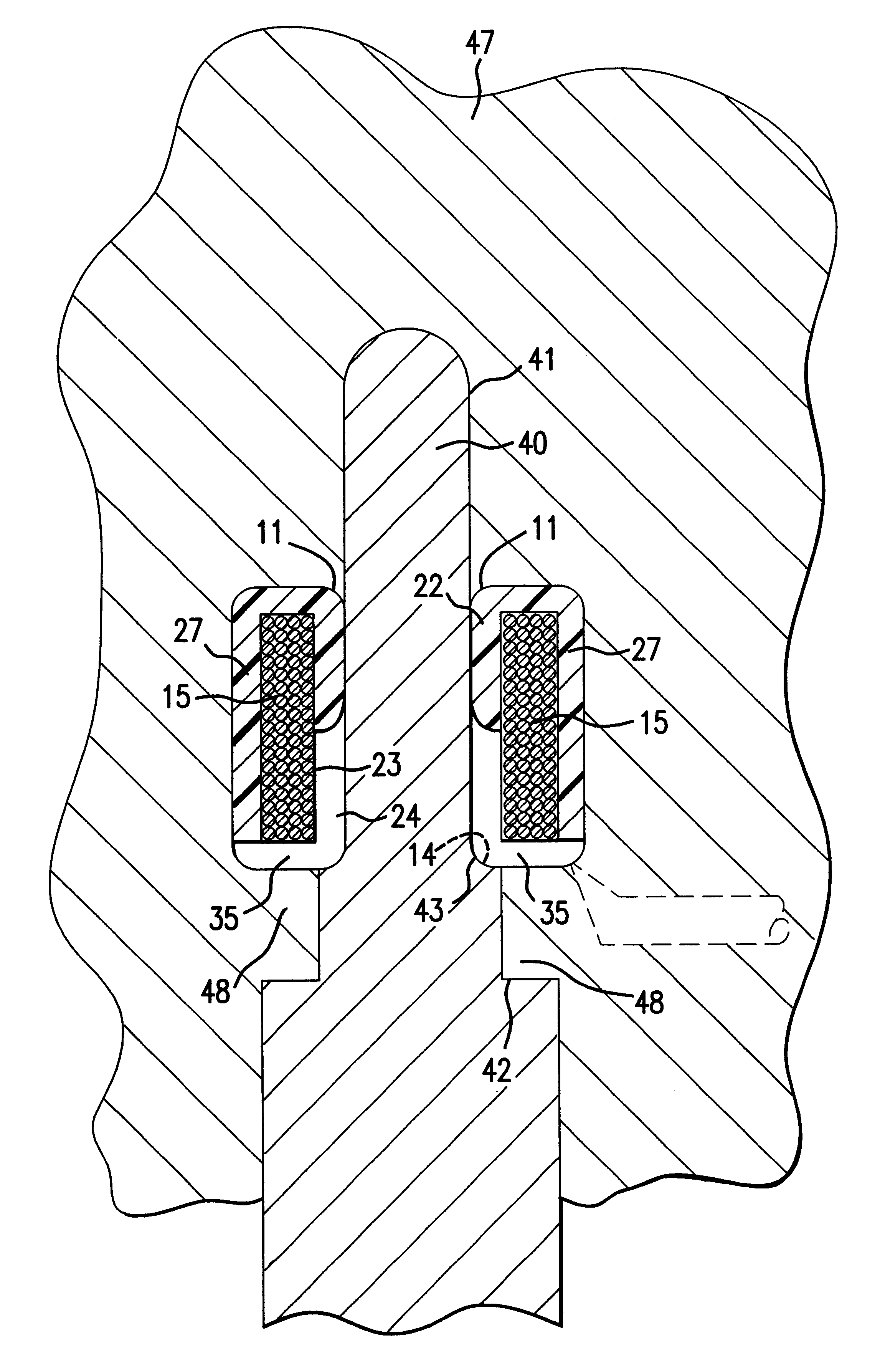

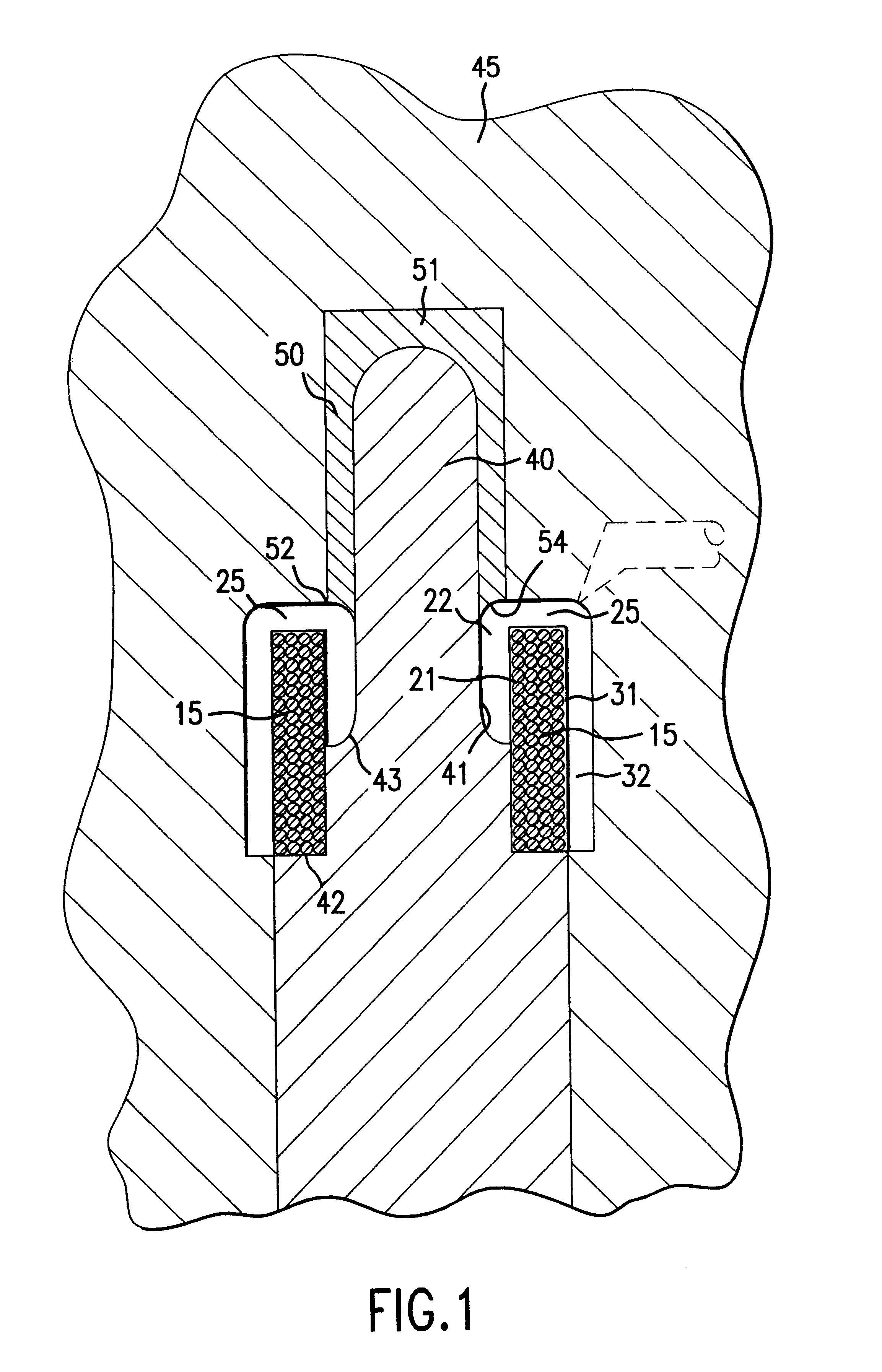

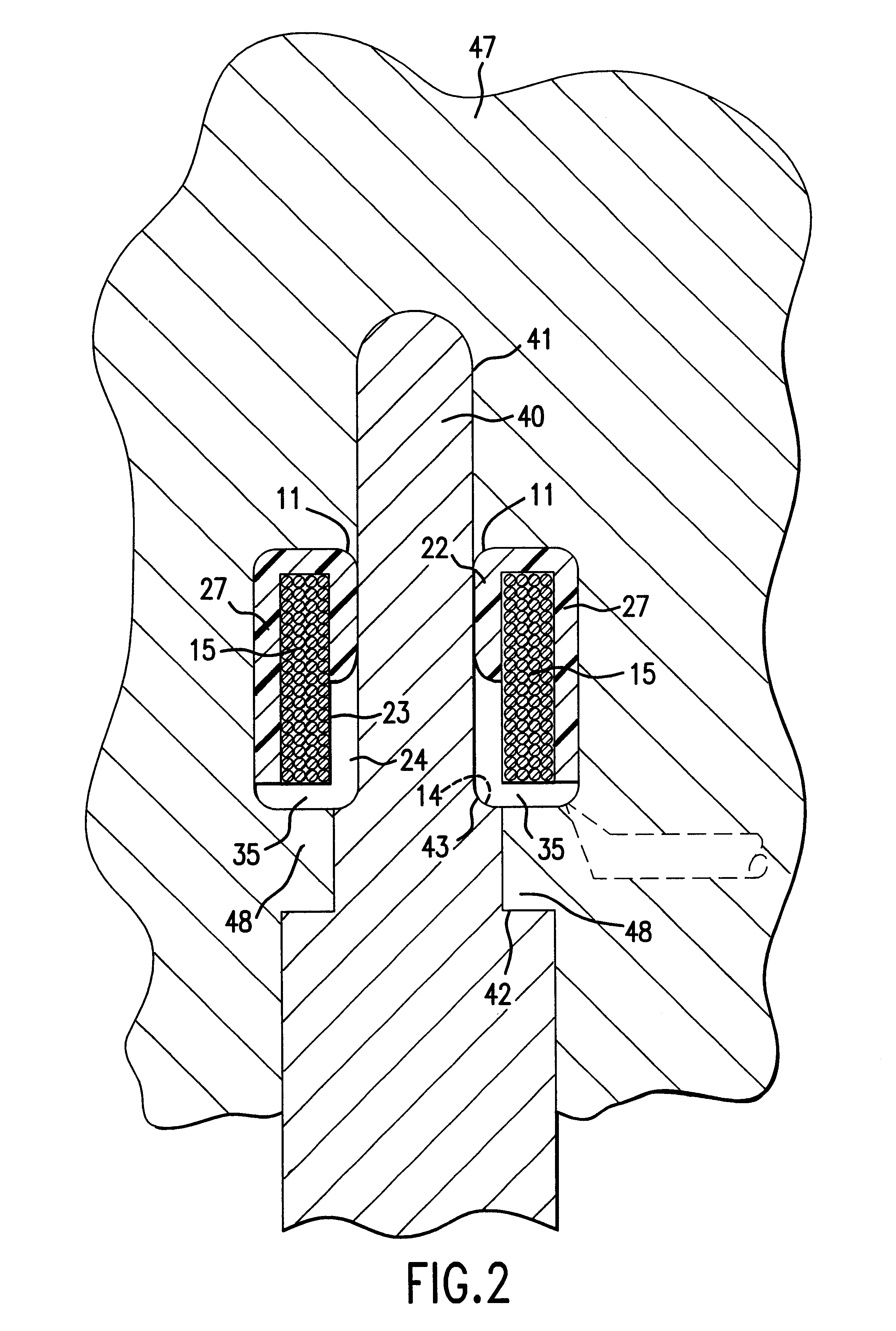

Method and apparatus for encapsulating a ring-shaped member

A method and apparatus for encapsulating a ring-shaped member, such as a wound coil of wire, a wound metal ribbon, or a metal composite material. The ring-shaped member is mounted upon a mandrel. The mandrel and the mounted ring-shaped member are positioned in a first mold. A thermoplastic material is injection molded peripherally about a first inner void between the mandrel and the ring-shaped member and a first outer void between the first mold and the ring-shaped member. The mandrel is moved with respect to the ring-shaped member. The mandrel and the re-mounted ring-shaped member are positioned in a second mold. The thermoplastic material is injection molded into a second inner void between the mandrel and the ring-shaped member and within a second outer void between the second mold and the ring-shaped member. The second fill of the thermoplastic material joins with the first fill to fully encapsulate the ring-shaped member. The encapsulated ring-shaped member can then be annealed or heat treated to stress relieve any undesired stress or tension within the ring-shaped member.

Owner:PANZER TOOL WORKS +1

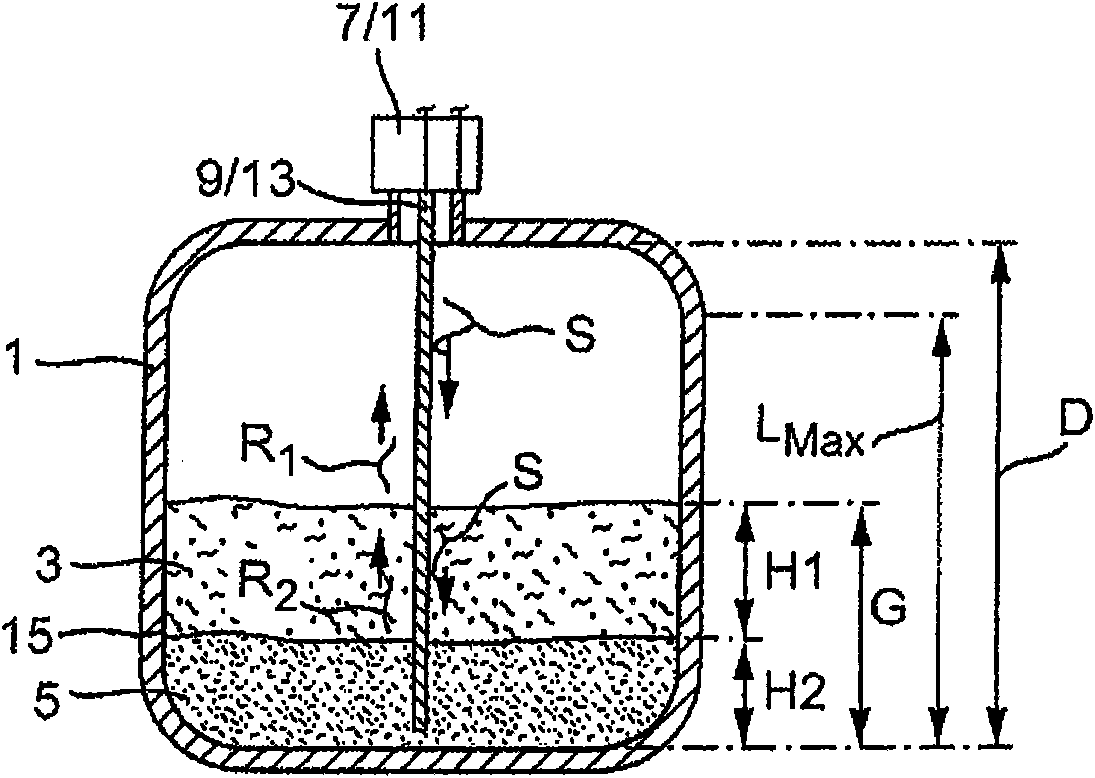

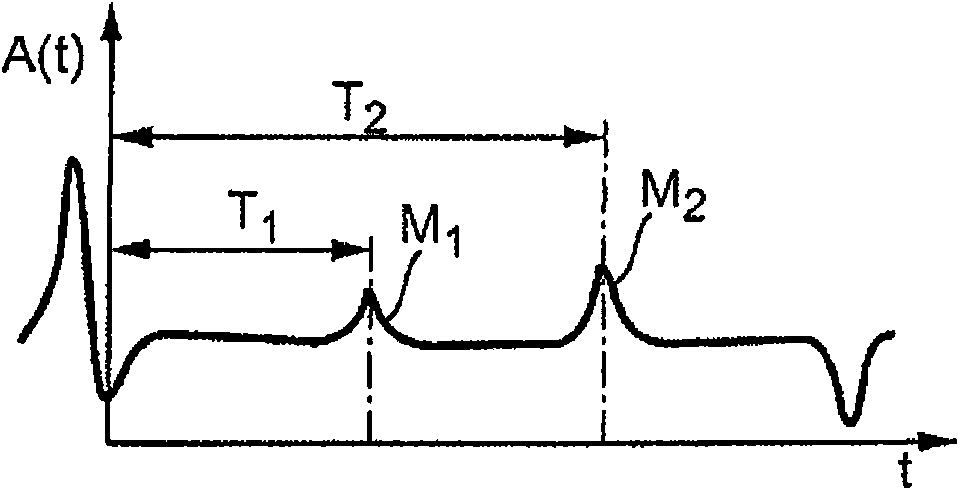

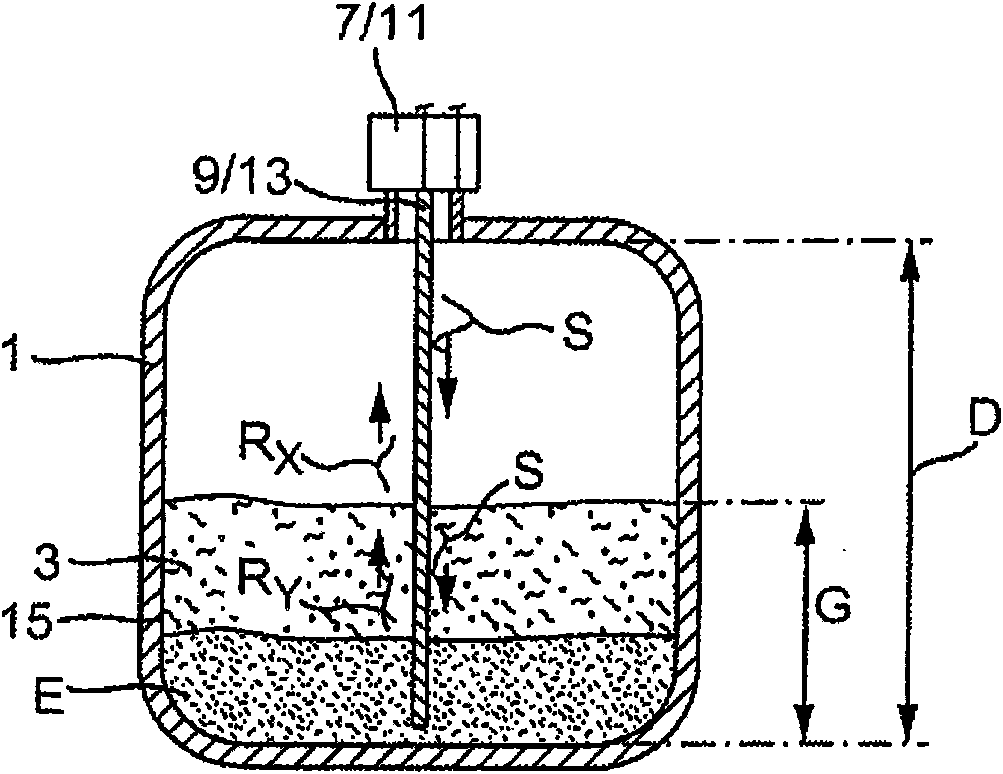

Method for filling level measurement

ActiveCN101896797AProvided correctlyVolume measurement apparatus/methodsMachines/enginesCapacitanceFirst Fill

A method for filling level measurement is disclosed, using which, in a container (1), in which a first and / or a second filling product (3, 5) can be located, for each filling product (3, 5) contained in the container (1), a rest location can be determined, which corresponds to the location which the filling product surface of the particular filling product (3, 5) assumes because of the quantity of the first filling product (3) which is contained in the container (1) and the quantity of the second filling product (5) which is contained in the container (1), if the total quantity of each filling product (3, 5) in the container (1) forms a single layer containing only this filling product (3, 5), wherein said first filling product (3) has a lower specific weight than said second filling product (5), and said two filling products (3, 5) have different dielectric constants (e), wherein an electromagnetic signal (S) is transmitted into said container (1), a reflection occurs on at least one media boundary generated by said filling products (3, 5) contained in said container (1), wherein a component (Rx, Ry) of said signal (S) is reflected, and for each reflected component (Rx, Ry), a run time (Tx, Ty), which is a function of the location of the media boundary triggering the reflection, is measured, which said component (Rx, Ry) of the signal (S) requires for the route to this media boundary and back, a capacitance (C), which is a function of the quantities of the filling products (3, 5) located in the container (1), is measured between a capacitive probe (13) and a reference electrode (15), and the rest location of said filling product surface is determined for each filling product (3, 5), which is, contained in the container (1), on the basis of the measured capacitance (C) and the measured runtimes (Tx, Ty).

Owner:EHNDRESS KHAUZER GMBKH KO KG

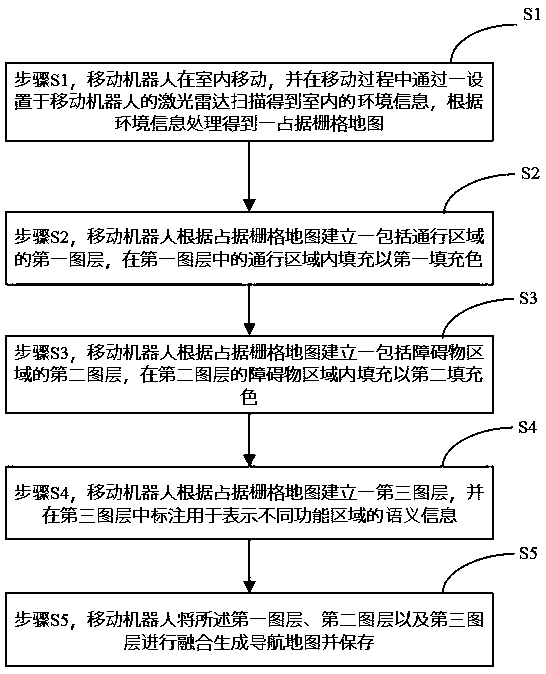

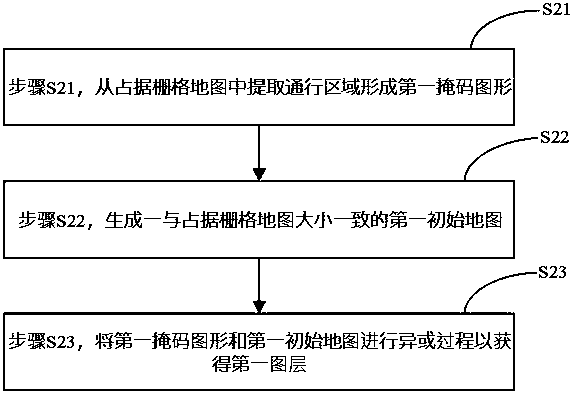

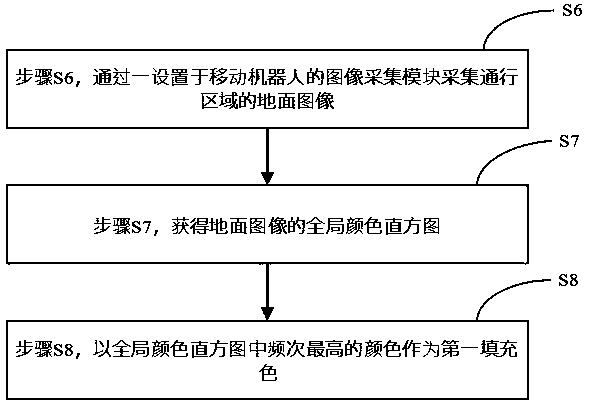

Method for constructing navigation map

ActiveCN108303101AEasy to getInformativeInstruments for road network navigationFirst FillRobot control

The invention discloses a method for constructing a navigation map, and belongs to the technical field of robot control. The method comprises the steps of step S1, obtaining an indoor occupied grid map; step S2, establishing a first layer including a passage area, and filling the passage region with a first fill color; step S3, establishing a second layer including an obstacle region, and fillingthe obstacle region with a second fill color; step S4, establishing a third layer, and marking semantic information in the third layer; step S5, merging the first layer, the second layer and the thirdlayer to generate the navigation map. The method has the advantages that the method can obtain the navigation map simply and quickly, distinguishes each area by different colors, and can quickly recognize different obstacles in the navigation map according to the different colors, and the navigation map is added with the semantic information to increase the readability of the navigation map.

Owner:FLYINGWINGS INTELLIGENT ROBOT TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com