Method for filling level measurement

A technology of level measurement and total quantity, applied in volume measurement instruments/methods, liquid level indicators for physical variable measurement, measurement capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

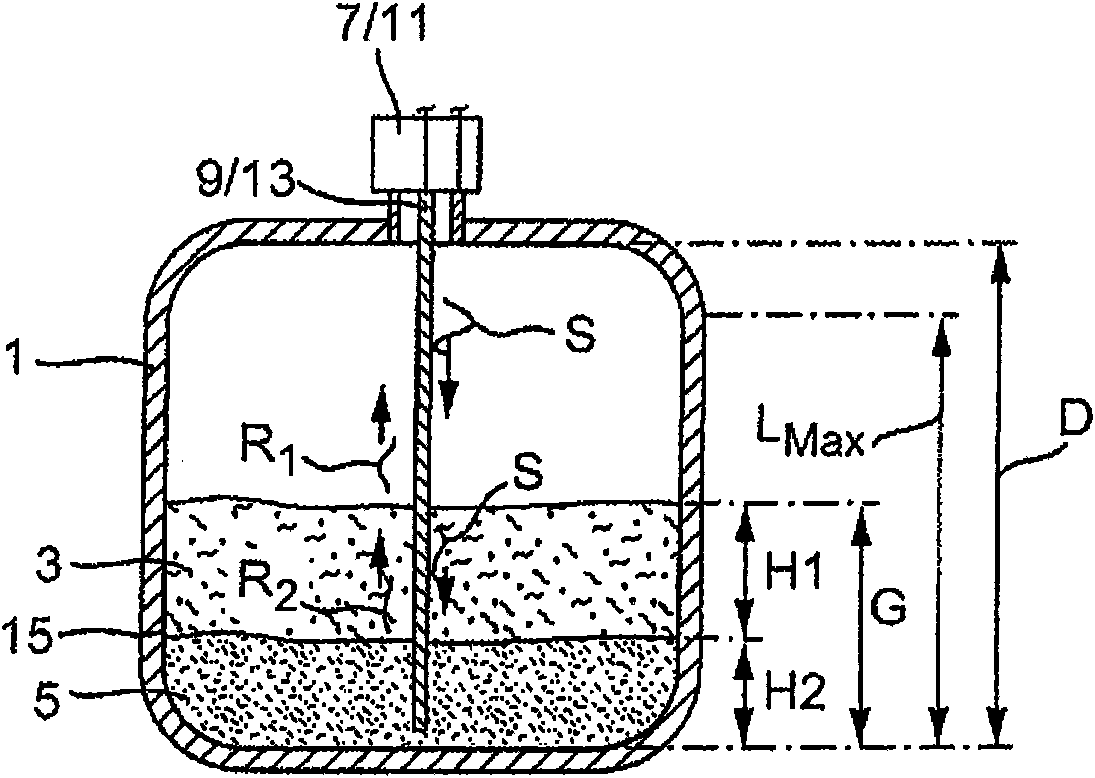

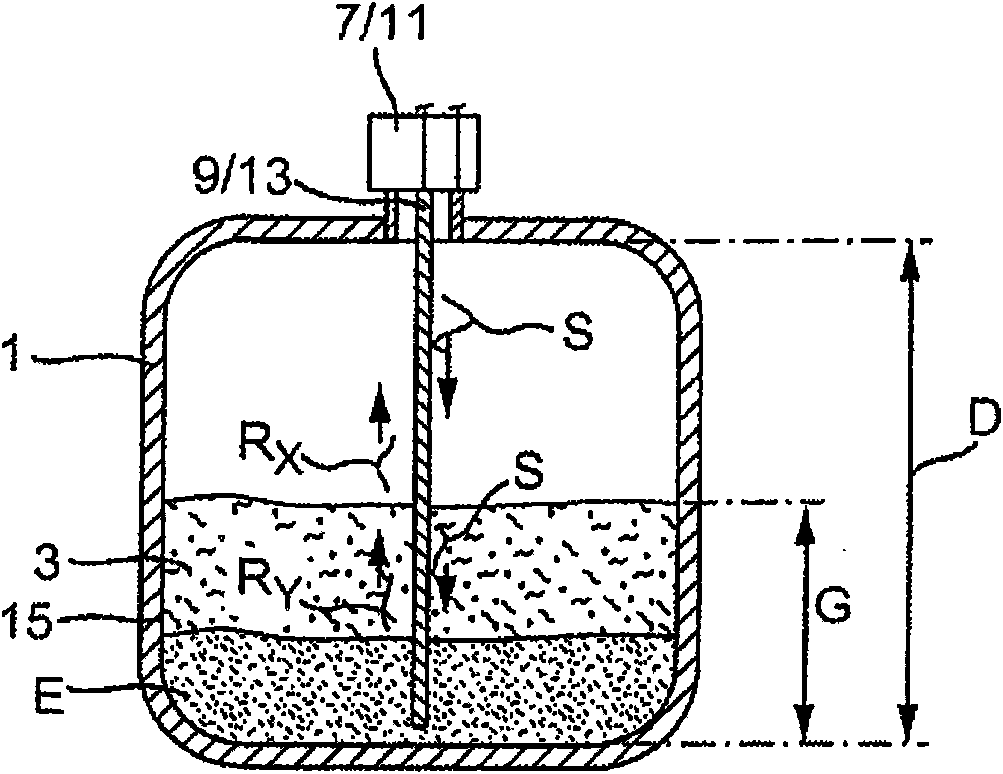

[0062] figure 1 A schematic diagram of a measurement system to which the method for level measurement of the present invention is applied is shown. It comprises a container 1 in which an unknown quantity of a first filling substance 3 and / or an unknown quantity of a second filling substance 5 can be located. If two different filling substances 3 , 5 are present, it is assumed here that the first filling substance 3 has a lower specific gravity than the second filling substance 5 . In addition, the filling substances 3, 5 have different dielectric constants.

[0063] figure 1 A filling state is shown in which the two filling substances 3 , 5 are at rest in the container 1 . The first filling substance 3 forms an upper layer with a filling height H1 in the container 1 , and the second filling substance 5 forms a lower layer below it with a filling height H2 . The first filling substance 3 is, for example, oil, and the second filling substance 5 is water. Above the first fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com