Anti-leakage joint processing method of first filling gap of outer window of building

A joint treatment and anti-leakage technology, which is applied in the direction of frame fixing, joint fastening/covering, etc., to speed up the construction progress and reduce the effect of leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with specific examples, and the purpose is only to better understand the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

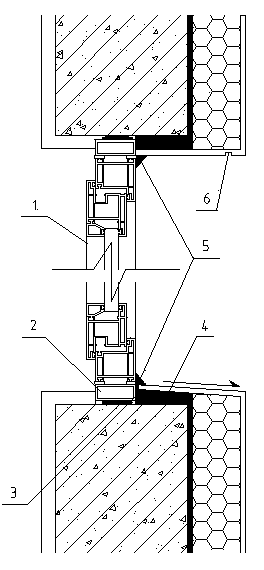

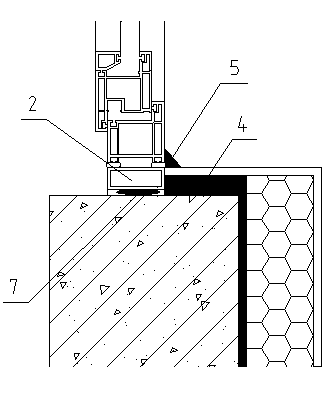

[0035] The method for dealing with leak-proof joints on the exterior windows of buildings described in this embodiment includes the following steps: find the rules by snapping the wires → determine the window position → fix the steel sub-frame → fill the gap between the sub-frame and the structural wall → paint the outside of the sub-frame with JS Waterproof coating → Plastering and closure around the auxiliary frame → Window frame installation → Pasting of external wall insulation, leaving a dripping tank → Sealing of window frame with external wall and internal wall → Acceptance.

[0036] The following combination figure 1 , figure 2 , detailing each step.

[0037] (1) Find the rules by bouncing the thread:

[0038] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com