Polythene packaging film for soymilk

A polyethylene and packaging film technology, applied in the field of plastic processing, can solve the problems of not being able to meet the needs of high-temperature cooking and sterilization, high barrier performance, and high mechanical strength, and meet the needs of high-temperature cooking and sterilization, good heat-sealing performance, and low material cost Effect

Inactive Publication Date: 2008-01-09

广西塑料研究所有限公司

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since soy milk packaging has higher requirements on the shelf life than other general liquid food packaging, this high-protein liquid food needs to be sterilized at a high temperature of 120°C to achieve a shelf life of at least two months. The operating temperature of LDPE film does not exceed 100°C. If you use this ordinary LDPE film to package soybean milk for sterilization, you can only use pasteurization (80°C). Therefore, this LDPE film cannot meet the needs of high-temperature cooking and sterilization.

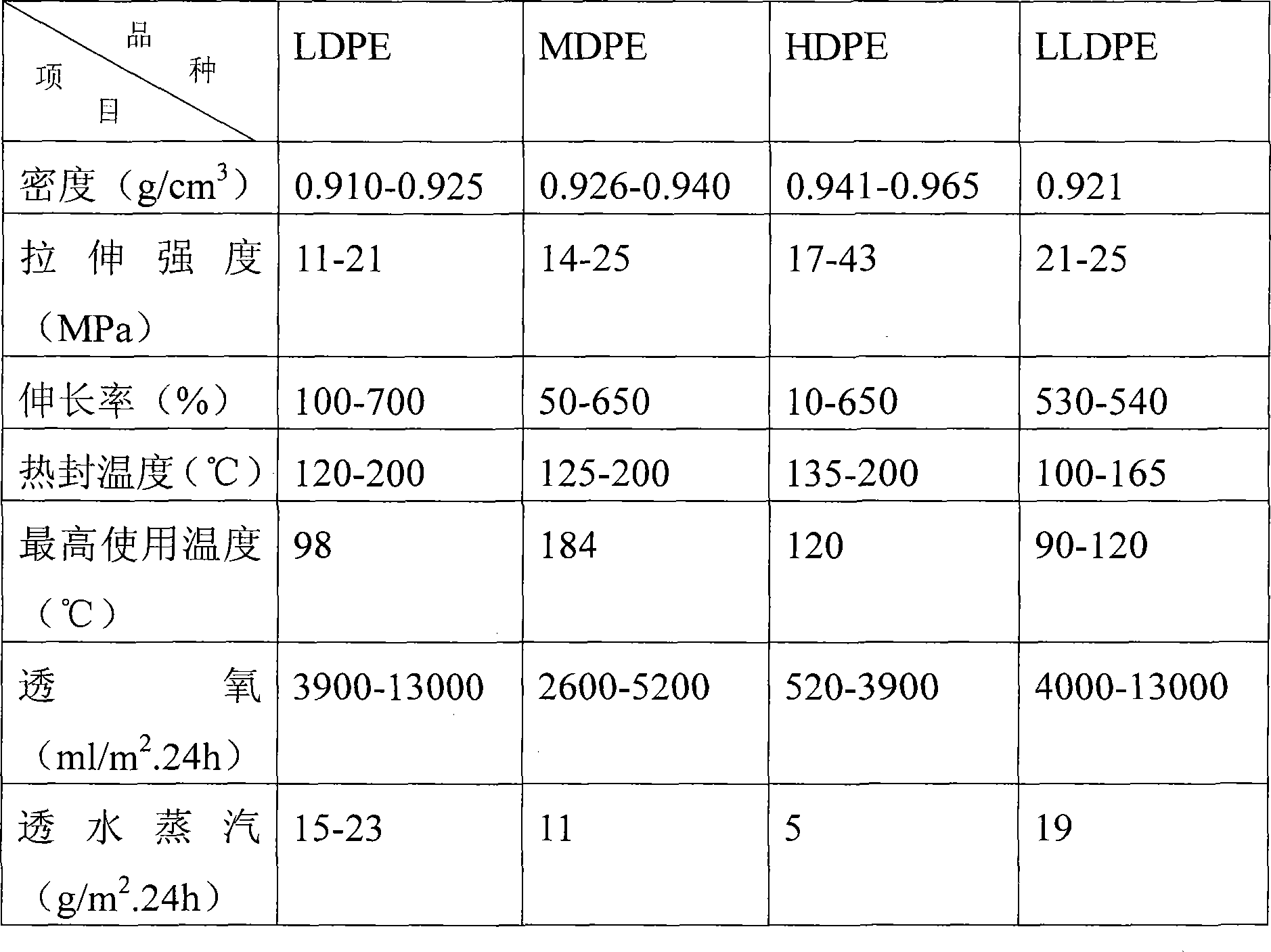

[0004] It can be seen from the above table that the maximum use temperature of high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) can reach 120°C, which can meet the temperature required for high-temperature cooking and sterilization, but when these two raw materials are used alone to make packaging films, There are also certain limitations. Due to the high mechanical strength of the HDPE film, the high barrier performance to oxygen and water vapor, the softness of the film is slightly poor, mainly due to its low sealing strength, resulting in a high proportion of film bags. Large, so it is not suitable for the production of soy milk packaging film alone

LLDPE film has high toughness, and its transparency, softness, needle resistance, and heat sealability are all good, but its mechanical strength is low, and it is easy to cause package breakage

At the same time, due to the poor processing performance of LLDPE, the melt viscosity is high during film blowing, the internal friction heat is large, the main current of the extruder is large, the head pressure is high, and the extrusion is unstable, resulting in unstable film bubbles, which increases the film thickness tolerance. , Poor plasticization of LLDPE will also make the slipperiness of the film worse. The soy milk filling machine has higher requirements on the slipperiness of the film.

Therefore, LLDPE is not suitable for the production of soy milk packaging film alone

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The following table is the specific examples and main performance indicators of the present invention, wherein the contents of each raw material in the examples are parts by mass, all made by the above-mentioned process.

[0018] material name

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A packing film of polyvinyl soymilk is prepared by taking HDPE, LLDPE and color mother material as raw materials and extruding. It's cheap, light, convenient and non-toxic. It has uniform thickness, excellent heat-sealing performance and heat resistance and no environmental pollution. It can be used for automatic soft packed canned soymilk.

Description

1. Technical field [0001] The invention belongs to the technical field of plastic processing, in particular to a high-temperature-resistant cooking and sterilization soybean milk packaging film, which is suitable for filling soybean milk in a fully automatic soft packaging machine. 2. Background technology [0002] Polyethylene resin (PE) is currently the most used resin in the flexible plastic packaging industry. It is non-toxic, tasteless, transparent, easy to process and form, and has good moisture resistance. Therefore, it is widely used in flexible plastic packaging. According to its density, polyethylene can be divided into low-density polyethylene (LDPE), medium-density polyethylene (MDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE). Different types of PE packaging films have different properties. Its main performance is shown in the table below: [0003] At present, LDPE film is widely used in the market, which is widely used fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08J5/18C08L23/06B65D85/80

Inventor 唐良华唐尧黄瑞球巫广生

Owner 广西塑料研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com