Thermostable polystyrene packing composition and preparing method

A molding method, yogurt technology, applied in packaging, wrapping paper, packaged food, etc., to achieve the effect of improving elongation at break and notch impact, improving compatibility, and excellent modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

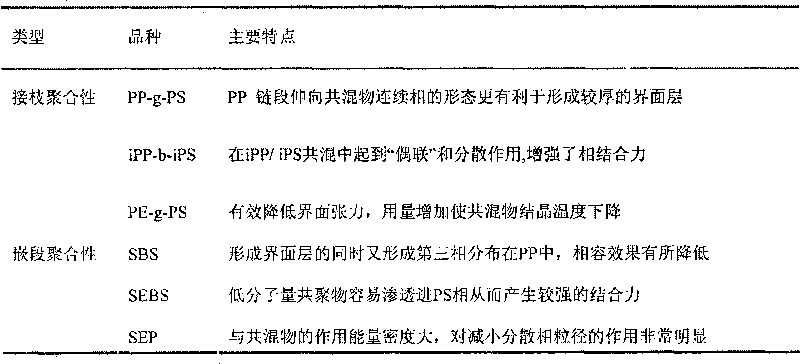

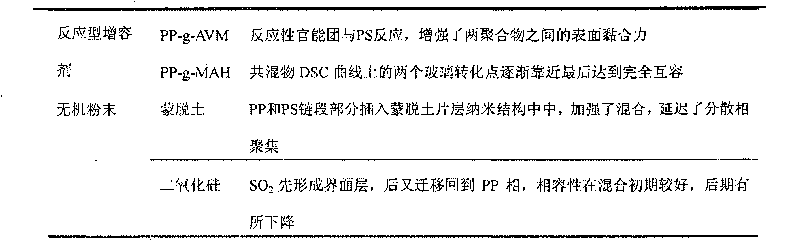

Method used

Image

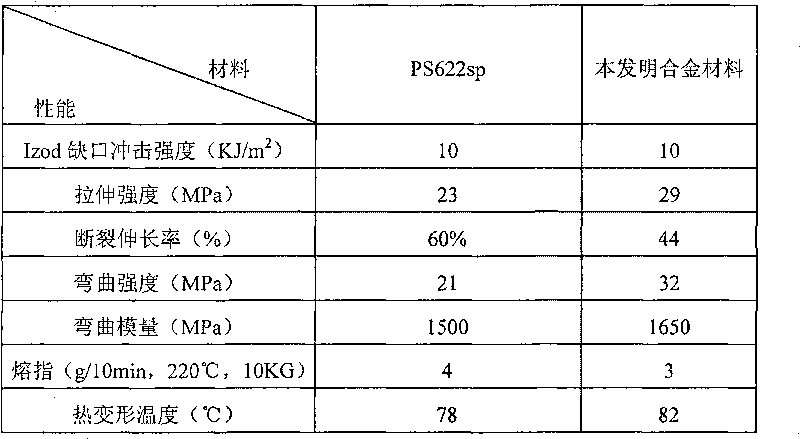

Examples

Embodiment 1

[0025] 20% by weight of HIPS, 40% of GPPS, 15% of PP, 10% of compatibilizer, 10% of inorganic powder (pre-treated with coupling agent), and by their total weight 0.5% antioxidant is first put into a high-speed mixer with a speed of about 1000rpm and mixed for 3 minutes, and then put into a twin-screw extruder. The temperature is controlled at 200℃~215℃, and the screw speed is 450 rpm. It is obtained by extrusion and granulation.

Embodiment 2

[0027] 28% by weight of HIPS, 32% of GPPS, 12.5% of PP, 5% of compatibilizer, 8% of inorganic powder (pre-treated with coupling agent), and 0.5% by weight of their total % antioxidant is first put into a high-speed mixer with a rotation speed of about 1000rpm and mixed for 3 minutes, and then put into a twin-screw extruder, extruded under the conditions of a processing temperature of 200-215°C and a screw speed of 450 rpm. Grains are obtained.

Embodiment 3

[0029] 28% by weight HIPS, 32% GPPS, 20% PP, 5% compatibilizer, 8% inorganic powder (pre-treated with coupling agent), and 0.5% by weight % antioxidant is first put into a high-speed mixer with a rotation speed of about 1000rpm and mixed for 3 minutes, and then put into a twin-screw extruder, extruded under the conditions of a processing temperature of 200-215°C and a screw speed of 450 rpm. Grains are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com