Inside creasing

A crease line and fold line technology, applied to paper/cardboard containers, flexible coverings, containers, etc., can solve the problem of unsatisfactory auxiliary creases, and achieve easy folding, reduced folding pressure, and less wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

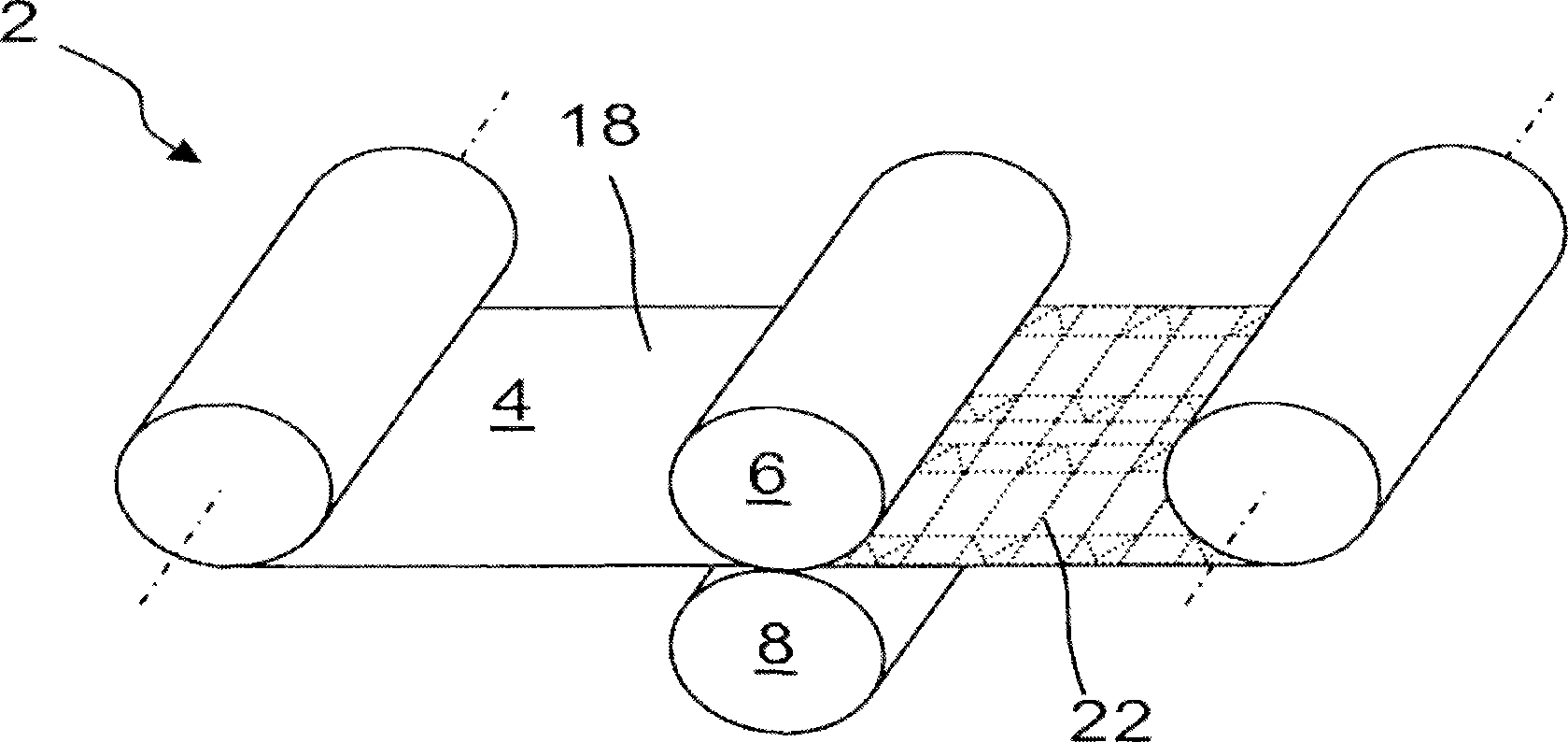

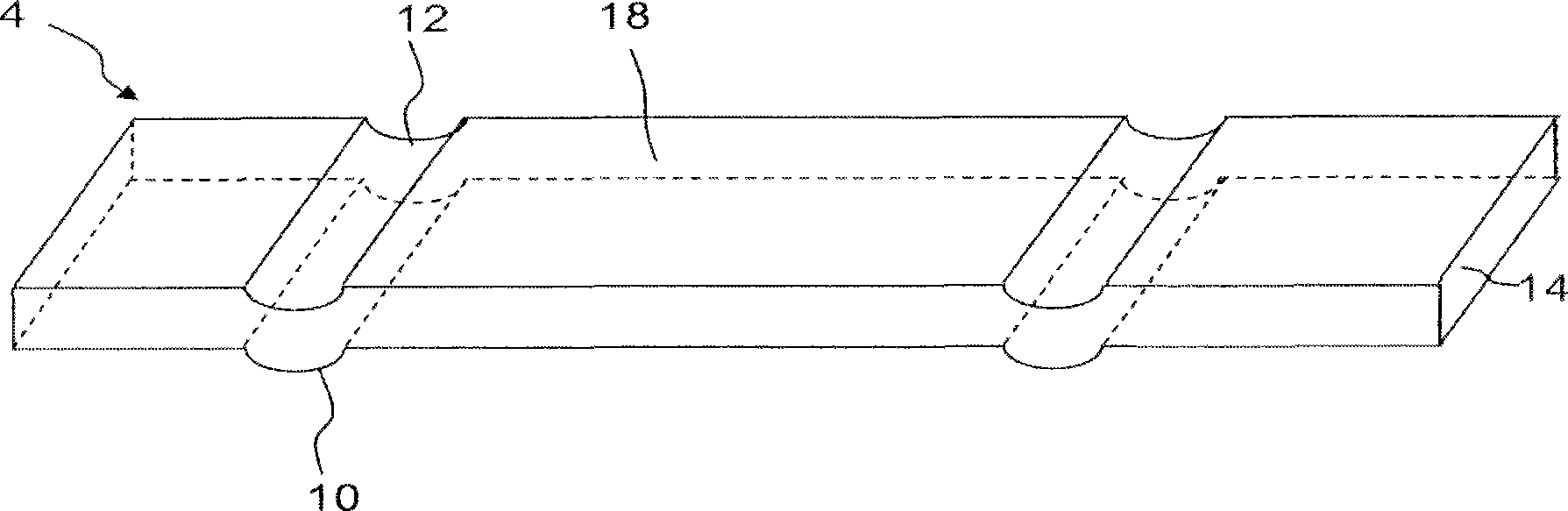

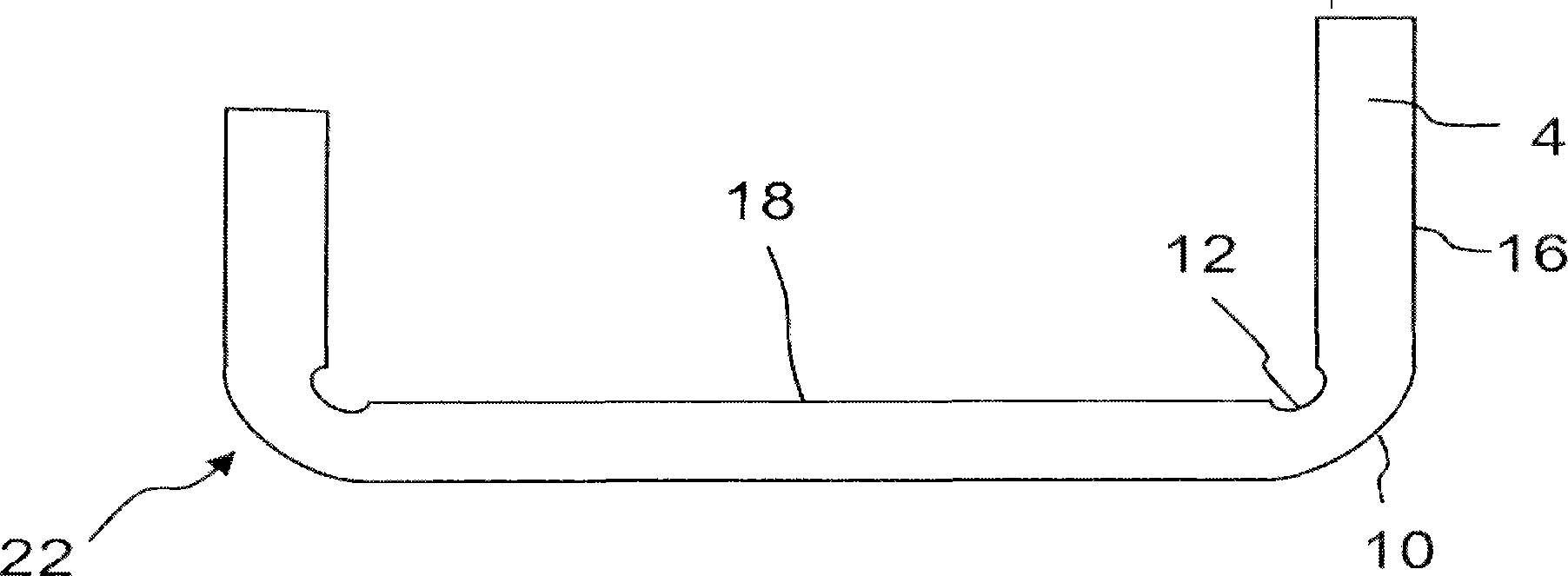

[0037] refer to figure 1 , according to one embodiment, the innovative method is carried out in a crease machine or in a crease unit 2 of a converting machine, where a paper core is printed, provided with crease lines and provided with a barrier material, thereby forming a packaging laminate 4. In the crease unit, the paper passes between two opposing crease rollers, a first roller 6 with protrusions and a second roller 8 with depressions. The protrusions and recesses are aligned so that corresponding protrusions 10 and recesses 12 are formed on the packaging laminate 4, see figure 2 . The creasing rollers 6, 8 are usually made of metal, but it should be understood that they may also be made of other materials as long as they can withstand the stresses from the creasing operation and have the necessary durability.

[0038] According to a first embodiment of the invention, a packaging laminate 4 is provided for forming a packaging container. The packaging laminate 4 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com