Low-temperature sintering technology suitable for high square resistance

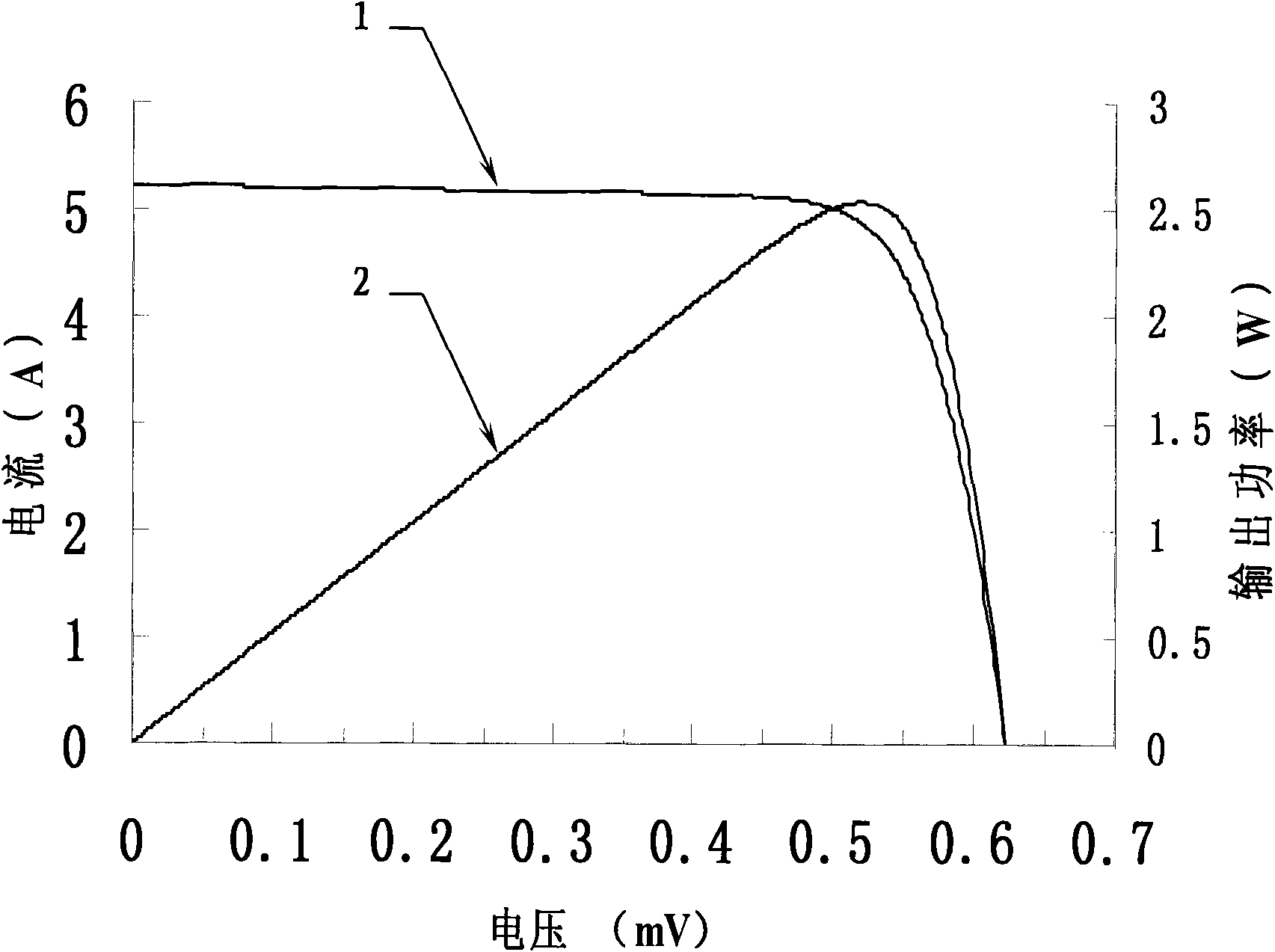

A technology of low-temperature sintering and high square resistance, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems affecting the conversion efficiency of cells, the reduction of short-circuit current and open-circuit voltage, and high contact resistance, so as to avoid the reduction of conversion efficiency , low series resistance, the effect of increasing short-circuit current and open-circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

[0015] The low-temperature sintering technology suitable for high square resistance of the present invention, its basic concept is: adjust the square resistance to be diffused to between 66-75 ohms, print the silver paste on the square resistance according to the wet weight of 0.4-0.6 grams, Then, the sheet resistance printed with silver paste is sintered through a low-temperature sintering furnace at 200-450° C. at a speed of 3000-5000 mm / min. Among them, the wet weight of 0.4-0.6 grams is the amount of silver paste printed on a silicon wafer of 148.57 square centimeters.

[0016] As a further improvement and supplement to the above-mentioned technical solution, the present invention also includes the following additional technical features, so as to be adopted during implementation:

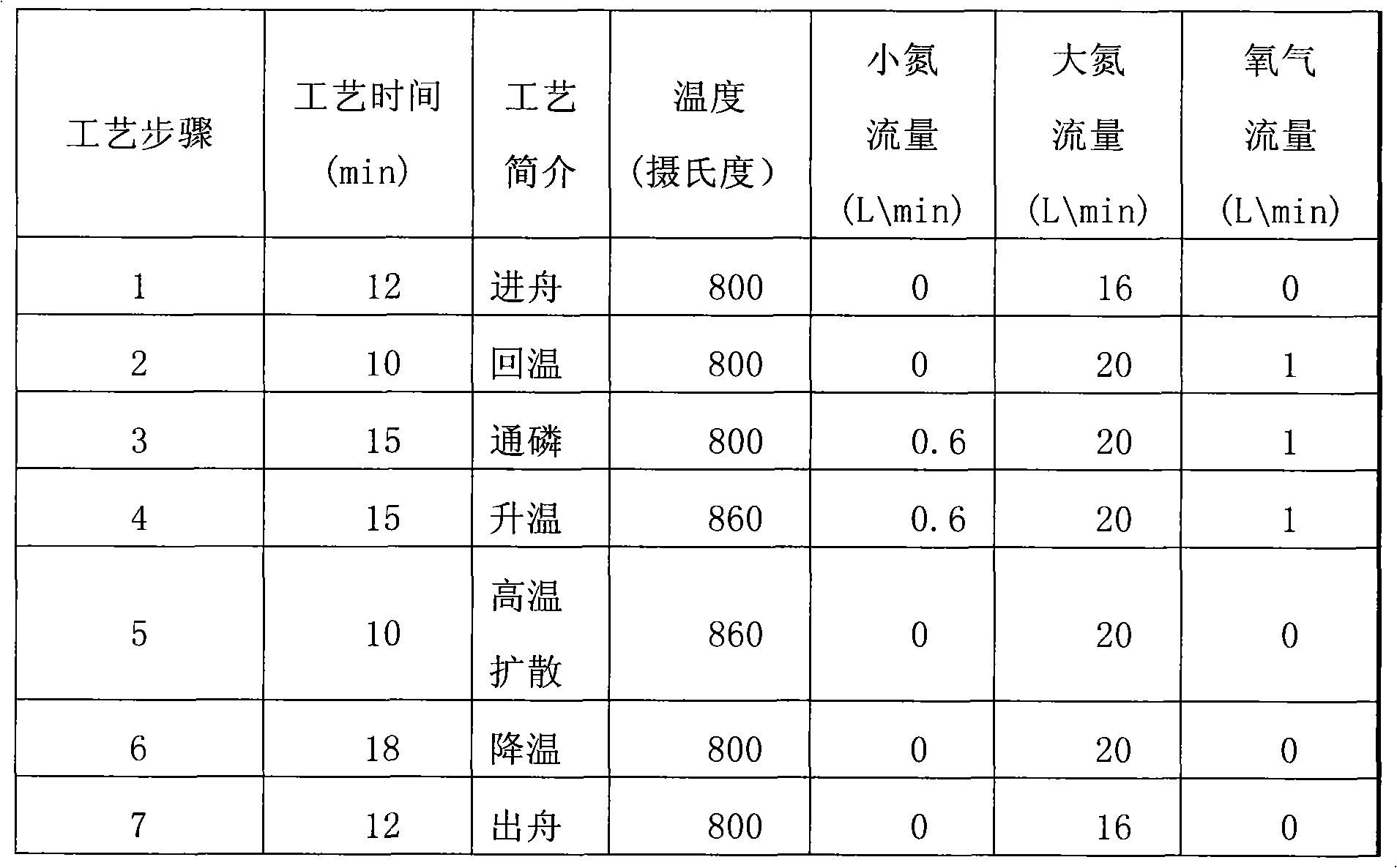

[0017] The low temperature sintering furnace is divided into 10 continuous temperature zones, the 1st to 3rd temperature zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com