Texturing method for solar cell

A solar cell sheet and backside technology, applied in the field of solar energy utilization, can solve the problems of reducing reflectivity, complex process, high cost, etc., and achieve the effects of reducing recombination rate, simple process, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] As mentioned in the background technology section, the texturing process in the commercial production of the prior art has reached the bottleneck stage, and it is no longer possible to reduce the reflectivity of silicon wafers to improve the utilization efficiency of solar cells. Although the laboratory can use some technical means to Modify the suede structure to reduce the reflectivity, but the research done in the laboratory requires high cost and complicated process, so it is difficult to apply it to commercial production. The inventors found that in the prior art, the reflectivity is reduced by modifying the textured structure, that is, in the prior art, only the front textured structure of the solar cell is focused on, and the reflection is reduced by modifying the textured structure of the front surface. rate, increase the short-circuit current, and ultimately improve the utilization efficiency of solar cells.

[0033] Based on this, the present invention finds a...

Embodiment 2

[0045] The method for making texture of a solar battery sheet provided by the present invention is described in detail below with a specific embodiment, and the method specifically includes:

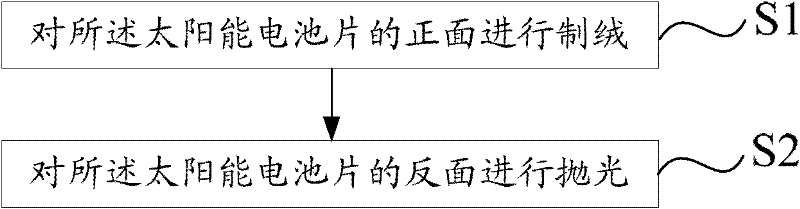

[0046] Step S1: Texturing the front side of the solar battery sheet.

[0047] Solar cells, that is, silicon wafers, are divided into monocrystalline silicon and polycrystalline silicon. In the texturing process, the texturing liquid and some process conditions used for monocrystalline silicon and polycrystalline silicon will be different. The two situations are described below.

[0048] When the solar cells are monocrystalline silicon, step S1 may further include the following steps:

[0049] Step S11: placing the front side of the solar battery sheet in the alkaline solution and the back side out of the alkaline solution.

[0050] Before this step, the single crystal silicon needs to be ultrasonically cleaned and pretreated, and then put into a texturing tank for texturing. The textur...

Embodiment 3

[0093] Provide two batches of the same P-type monocrystalline silicon samples and two batches of the same P-type polysilicon samples, the resistivity can be between 1Ω·cm~6Ω·cm, and each batch contains 10 samples. The first and second batches of samples are monocrystalline silicon, and the third and fourth batches of samples are polycrystalline silicon.

[0094] The first batch of samples is subjected to double-sided texturing according to the prior art, and the specific implementation process can be: ultrasonic cleaning and pretreatment of the first batch of samples; immersion of the first batch of samples in the alkaline solution described in Example 2 In 80°C, velvet was made for 30 minutes; after velvet making, the first batch of samples were placed in a warm water isolation tank at 45°C for the first rinsing operation; after the first rinsing operation, the first batch of samples were placed in hydrochloric acid solution Dehydration and removal of metal ions are carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com