PVC tablecloth printing process

A process and tablecloth technology, used in printing, printing machines, general parts of printing machinery, etc., can solve problems such as roll-up sticking, poor coloring, and discount on the qualified rate of printed products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

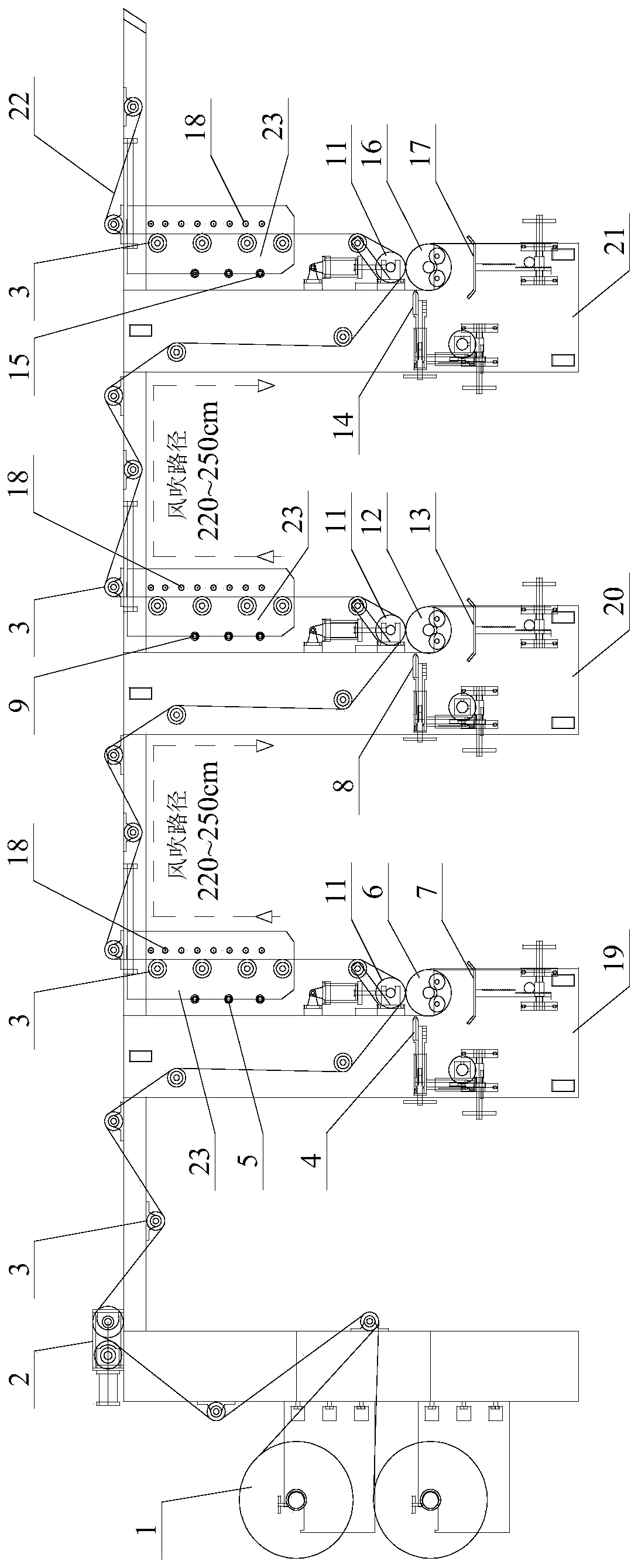

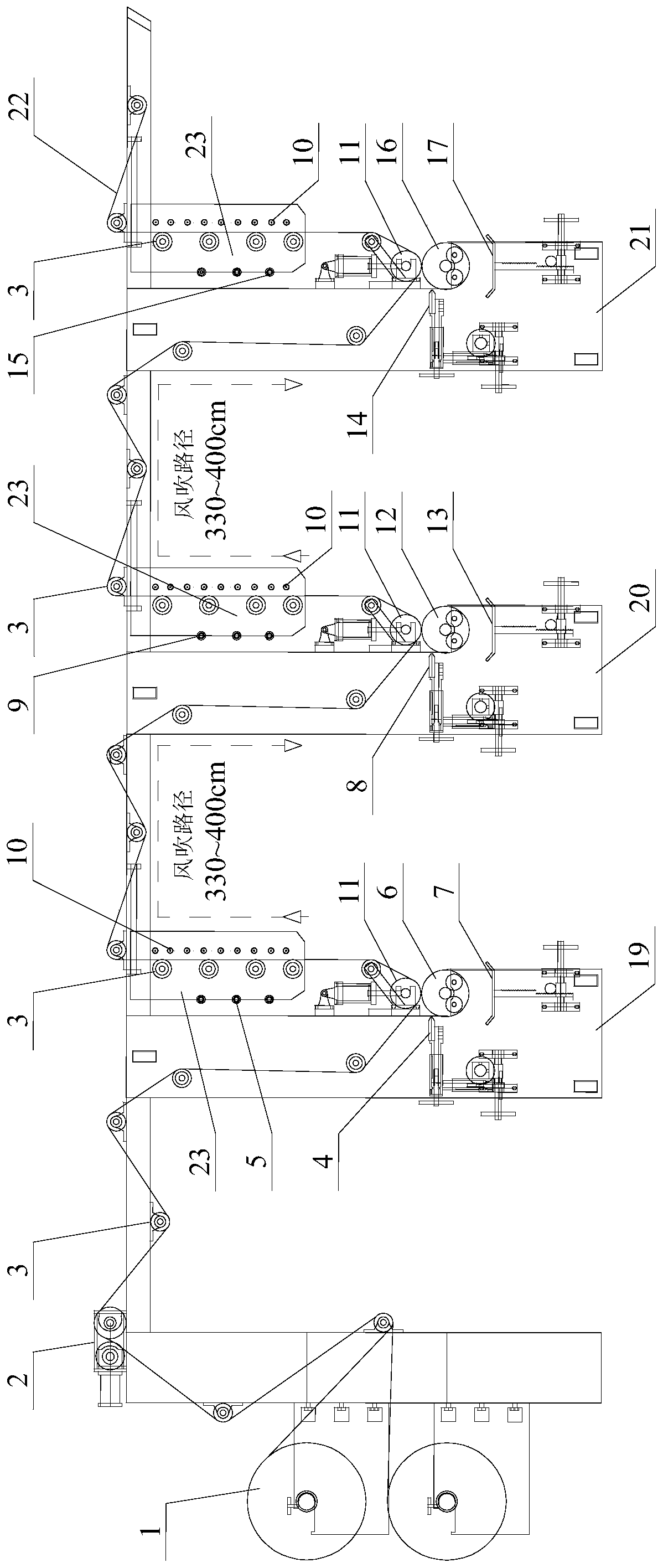

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0021] The printing process of a kind of PVC tablecloth involved in the present embodiment, the steps are as follows:

[0022] Step 1. Make a printing plate roll according to the pattern. This plate roll is gravure printing, and the engraving depth of the conventional gravure is 30 μm-50 μm. The engraving depth of the plate roll in this embodiment is 15 μm.

[0023] Step 2. Install the printing plate roller to be printed.

[0024] Step 3. Arranging the printing material (PVC film) on the machine.

[0025] Step 4: Connect the printing materials after getting on the machine, and turn on the machine.

[0026] Step 5. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com