Method for producing biological feed through aerobic anaerobic coupling fermentation

A biological feed and fermentation container technology, applied in animal feed, animal feed, energy industry and other directions, can solve the problem that aerobic microorganisms such as Bacillus and yeast cannot multiply in large quantities, and cannot effectively exert the physiological functions of Bacillus and yeast. Quality control is not easy to achieve the effect of increasing animal feed intake, improving feed palatability, and improving micro-ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

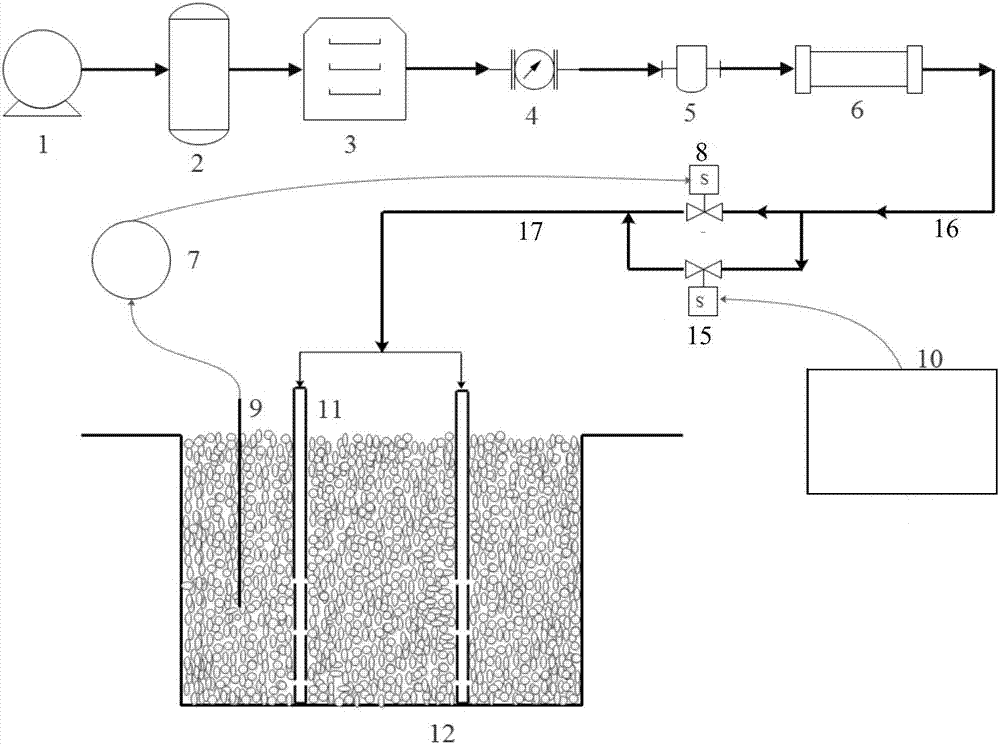

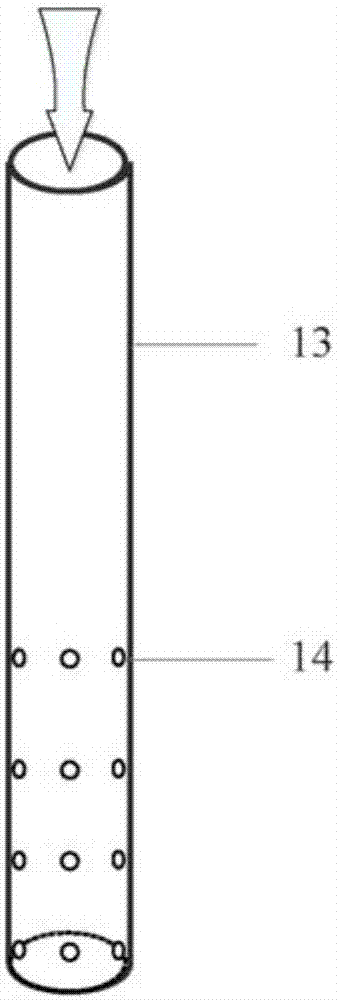

[0058] Such as figure 1 , figure 2 As shown, the present embodiment provides a ventilation and temperature control system for aerobic-anaerobic coupled fermentation of biological feed, including: compressed air device (air compressor 1, air storage tank 2 and cold dryer 3), rotor flow rate Meter 4, air filter 5, air heater 6, fermentation temperature control device (temperature control meter 7, first solenoid valve 8 and PT100 temperature sensor 9), timing ventilation control device (time controller 10 and second solenoid valve 15 ), air distributor 11 and fermentation vessel 12. The air compressor 1, the air storage tank 2 and the cold dryer 3 are connected by pressure pipes. One end of the rotameter 4 is connected to the cold dryer 3 , and the other end of the rotameter 4 is connected to the air filter 5 . The air filter 5 is connected to the air inlet of the air heater 6 through a pipeline; the air outlet of the air heater 6 is connected to one end of the first electrom...

Embodiment 2

[0068] Weigh 19 kg of fresh soybean meal and 1 kg of soybean skin, mix them evenly, and crush them through a 10-mesh sieve as a fermentation base material. The mixed strains of yeast NKY1, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus reuteri LR1 are used for fermentation. The moisture content of the base material fermentation is controlled at 40%, and 13.33 liters of mixed bacteria seed liquid for biological feed fermentation containing mixed bacteria needs to be prepared. First weigh 266.6g glucose, 40g K 2 HPO 4 and 26.7g KH 2 PO 4 Add a certain volume to clean water preheated to 30°C, stir well to dissolve. Activate the yeast and Bacillus subtilis with activation solution respectively. Then add a certain amount of saccharomyces activation solution and bacillus subtilis activation solution to the nutrient solution, so that the number of viable saccharomycetes and bacillus subtilis in the final fermentation solution reaches 2×10 respectively. 7 cfu / mL. ...

Embodiment 3

[0078] Weigh 47.5kg of fresh soybean meal and 2.5kg of soybean hulls, mix them evenly, and crush them through a 10-mesh sieve as a fermentation base material. The mixed strains of yeast NKY1, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus reuteri LR1 are used for fermentation. The moisture content of the base material fermentation is controlled at 40%, and 33.33 liters of mixed bacteria seed liquid for biological feed fermentation containing mixed bacteria needs to be prepared. First weigh 666.5g glucose, 100g K 2 HPO 4 and 66.8g KH 2 PO 4 Add a certain volume to clean water preheated to 30°C, stir well to dissolve. Activate the yeast and Bacillus subtilis with activation solution respectively. Then add a certain amount of saccharomyces activation solution and bacillus subtilis activation solution to the nutrient solution, so that the number of viable saccharomycetes and bacillus subtilis in the final fermentation solution reaches 2×10 respectively. 7 cfu / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com