Patents

Literature

71 results about "Waste Dumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A landfill site (also known as a tip, dump, rubbish dump, garbage dump or dumping ground and historically as a midden) is a site for the disposal of waste materials by burial. It is the oldest form of waste treatment (although the burial part is modern; historically, refuse was just left in piles or thrown into pits).

Composite microorganism viable bacteria preparation and preparation method and application of same

InactiveCN101538538AEfficient decompositionGrowth inhibitionFungiOrganic detergent compounding agentsBiotechnologyFeed additive

The invention discloses a composite microorganism viable bacteria preparation, which contains pediococcus, yeast and bacillus with the total bacteria count of more than 1 billion per gram. The invention also discloses a method for preparing the composite microorganism viable bacteria preparation, which comprises the following steps: performing amplification liquid culture on various strains respectively according to a conventional method in the field; mixing the materials according to a required proportion; and performing solid fermentation, drying and pulverization to obtain the composite microorganism viable bacteria preparation. The invention also discloses application of the composite microorganism viable bacteria preparation in preparing an organic waste water purifying agent and an aquaculture water body purifying agent, a deodorizer, a degreasing agent or an agent for removing pipe blockages for the hygiene of a refuse tip, a public place, an agricultural product market or a kitchen, feed additives in poultry and animal husbandry or pet culture, and preparations for controlling agricultural microorganism diseases. The composite microorganism viable bacteria preparation can effectively decompose a large amount of putrescent organic matters, inhibit the growth of harmful microorganisms and eliminate peculiar smells, and has the characteristics of high ammonia nitrogen removal rate, no generation of residual sludge, effective deodorization, low cost and the like.

Owner:SHANGHAI ECO WELL BIOSCI

Microbial deodorizing inoculant

InactiveCN104946544AGeneration and solutionSolve the stenchFungiBacteriaBacillus licheniformisBacteroides

The invention discloses a microbial deodorizing inoculant which is used in refuse sites, public toilets and livestock / poultry cultivation farms. The microbial deodorizing inoculant contains Candida utilis of which the collection number is ACCC 20060, Lactobacillus plantarum of which the collection number is ACCC 11016, lactic streptococci of which the collection number is ACCC 10653, cerevisiae fermentum of which the collection number is ACCC 21135, Streptococcus thermophilus of which the collection number is ACCC 10651, Bacillus licheniformis of which the collection number is ACCC 01870, and Bacillus natto of which the collection number is ACCC 19833. The microbial deodorizing inoculant absorbs and degrades generated malodorous gas hydrogen sulfide and ammonia gas, eliminates the malodor of the garbage and garbage leachate, inhibits the putrefaction bacteria from growth, basically prevents the malodorous gas from generation, and forms a disease-spread-free refuse piling environment capable of eliminating the malodor.

Owner:防城港市盛吉科技有限公司

Ecological restoration method of waste dump vegetation

InactiveCN102428812ASolve a lot of accumulationReduce usageHorticultureRevegetationEcological environment

An ecological restoration method of waste dump vegetation is provided, comprising the steps of leveling waste dump and sowing vegetation, wherein the specific steps are as follows: using tailings sands to fill gaps of crushed stones on the slope and plane of the waste dump; using mountain surface soil to cover the crushed stones till that the crushed stones are covered completely; irrigating the waste dump till that the mountain surface soil on surface of the waste dump is wet completely; sowing herbs on the slope of the waste dump; planting seabuckthorn in the middle of the slope; planting Robinia pseudoacacia seedlings on the lower part of the slope; planting cotton climbing plants at the root of the slope; planting Robinia pseudoacacia on the plane; and normally managing the vegetationon the other positions. The invention solves the problem that lots of the tailings are stacked, reduce usage amount of the soil and reduce engineering cost; different plants are planted on different positions of the slope of the waste dump; due to the optimal distribution method, the germination rate of the vegetation and survival rate of the seedlings are improved; the restoration effect of the waste dump vegetation is improved effectively and the ecological environment in the mine area is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

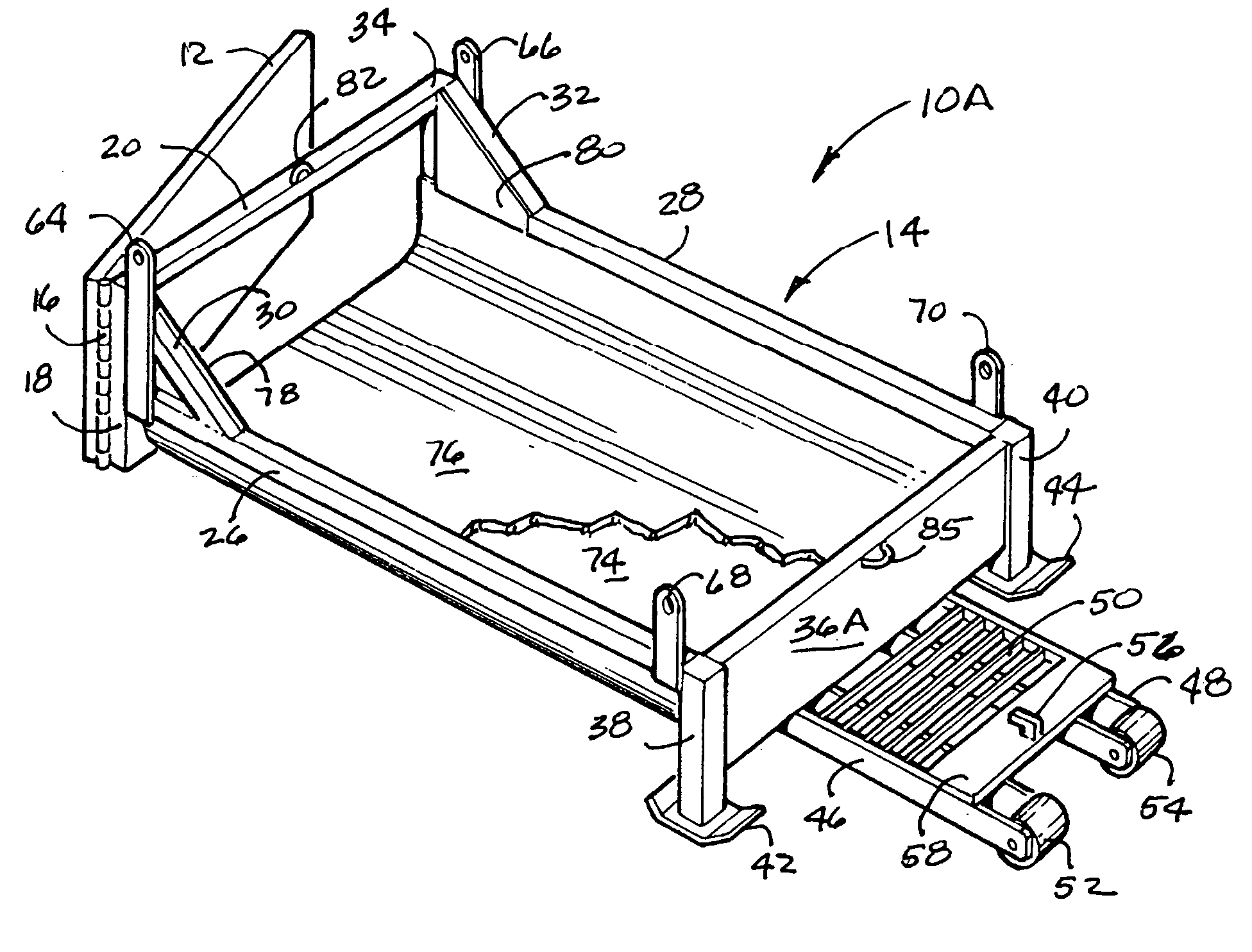

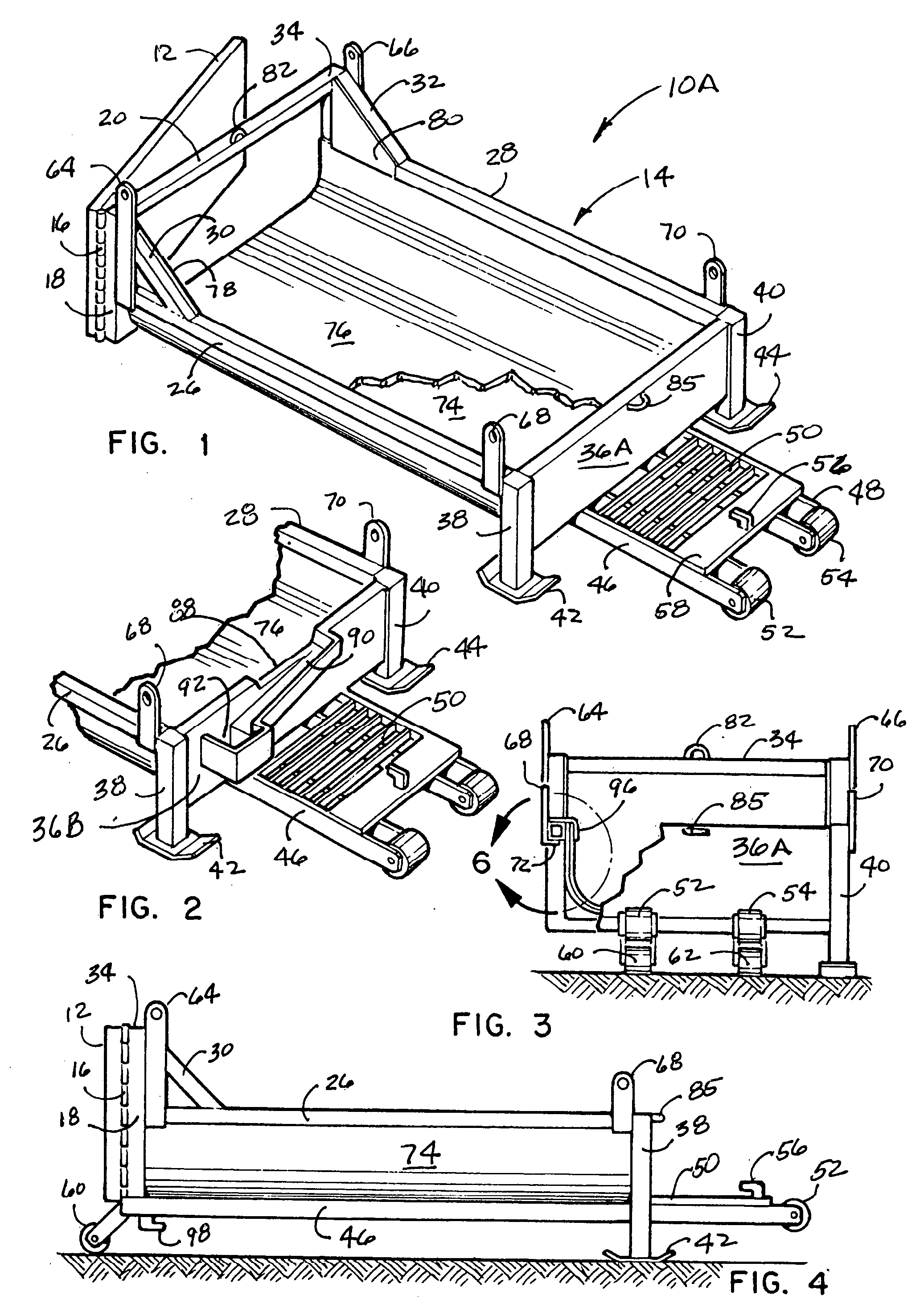

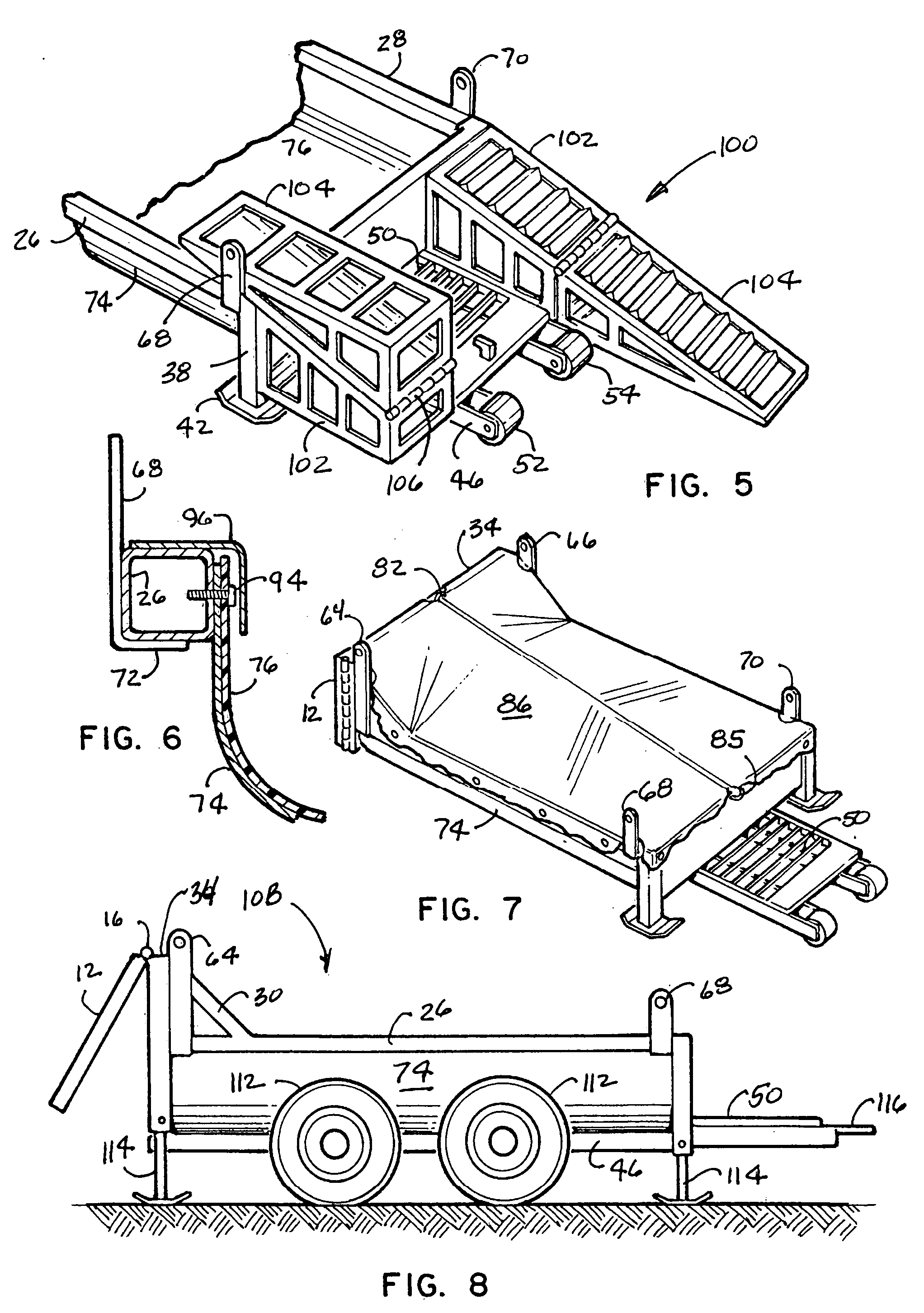

Construction residue transport system

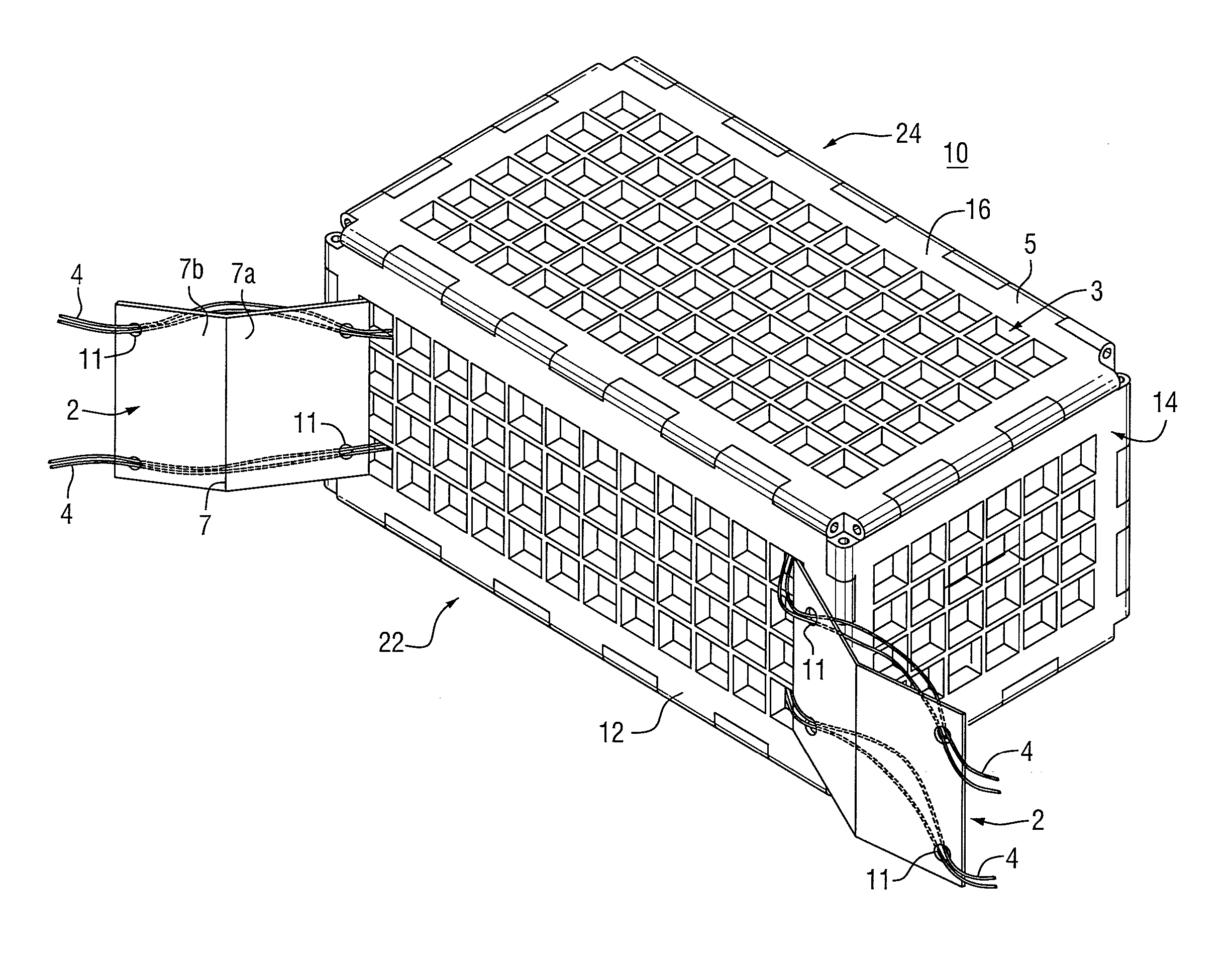

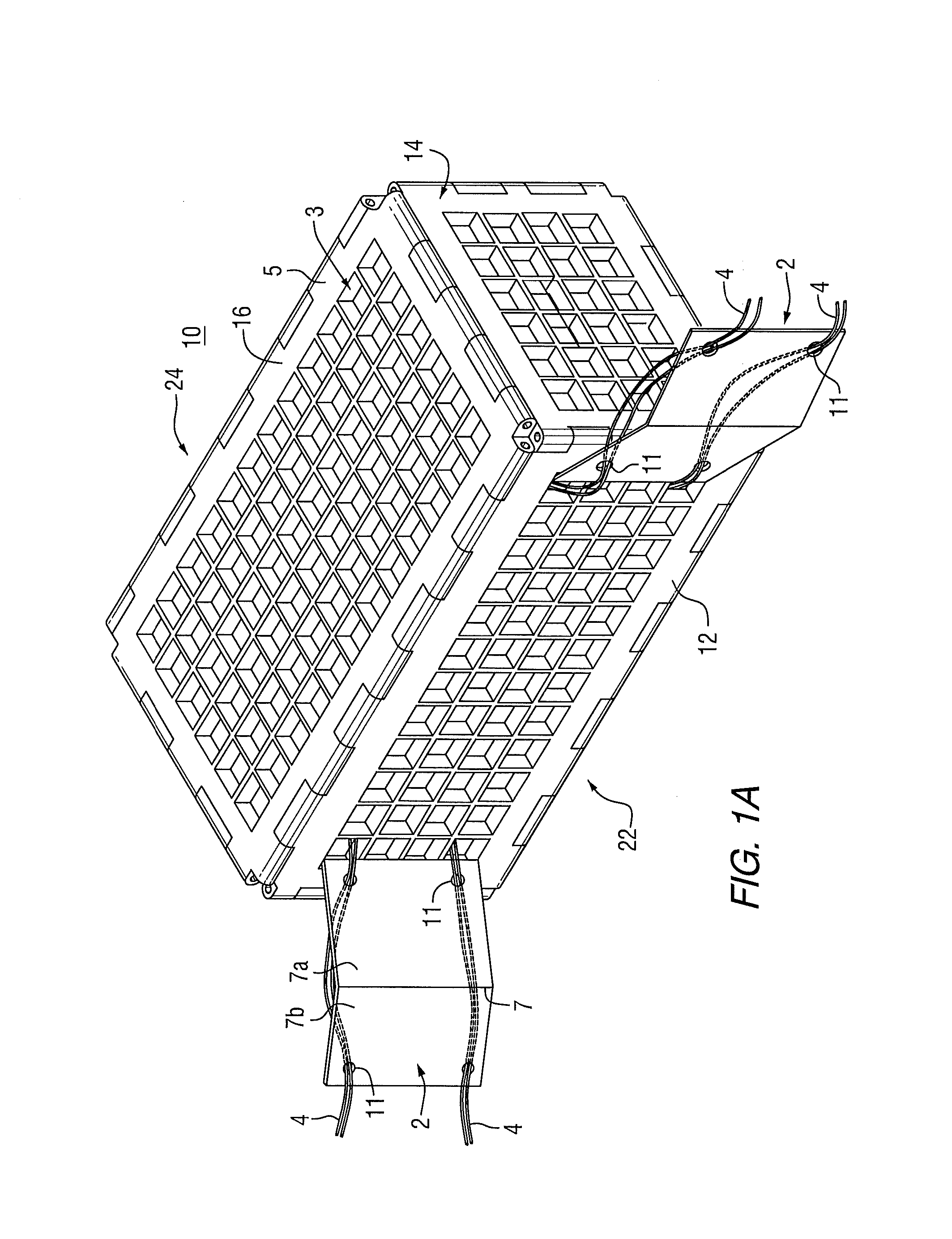

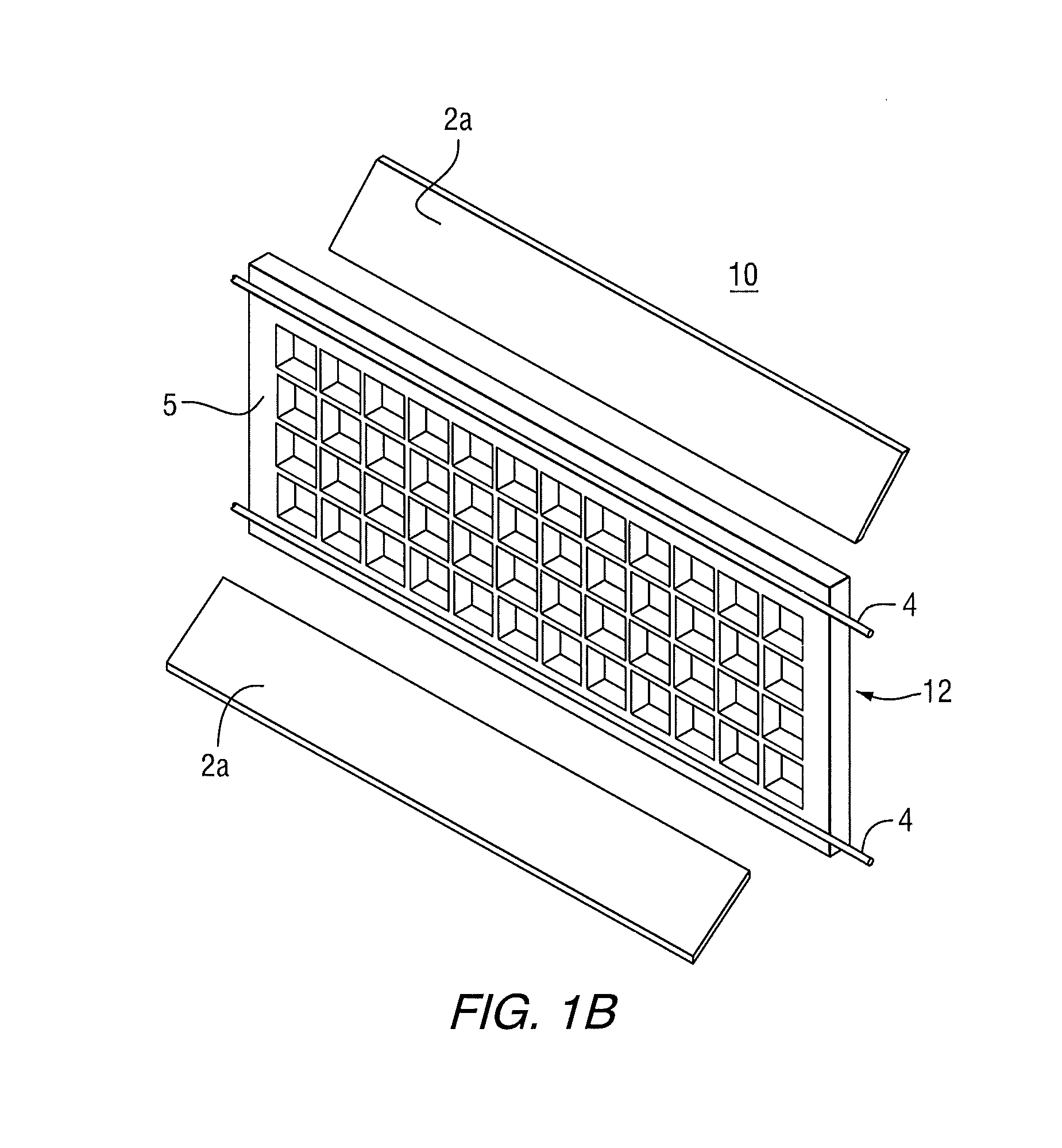

InactiveUS20050145624A1Improve sealingSmall scaleLarge containersVehicle with tipping movementTransport systemGrating

A system for the containment and removal of the residue derived from the cleaning of concrete pumps, pump hoses, concrete ready mix delivery trucks and similar materials and equipment located at construction sites, to a recycle center or dumpsite. The system may consist of a roll-off style container or a mobile trailer unit with an enlarged watertight back door or tailgate. The container will incorporate a steel non-slip grating for operators to walk on and folding ramps that can be incorporated on the sides of the grating. An alternate embodiment of the front wall will have a unique weir and gutter to direct the overflow water and scum into a filtration reservoir.

Owner:MINEGAR PETER J

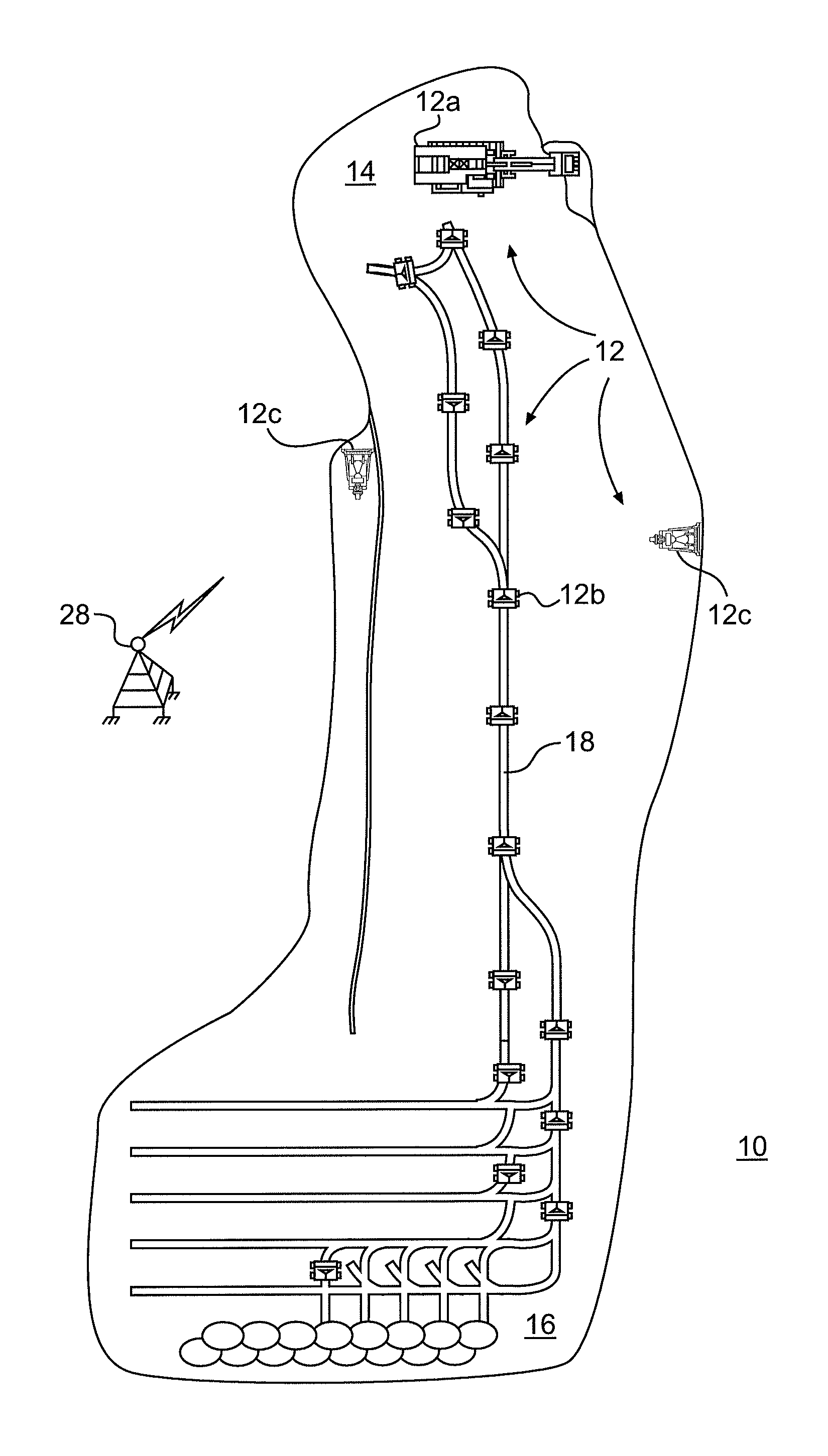

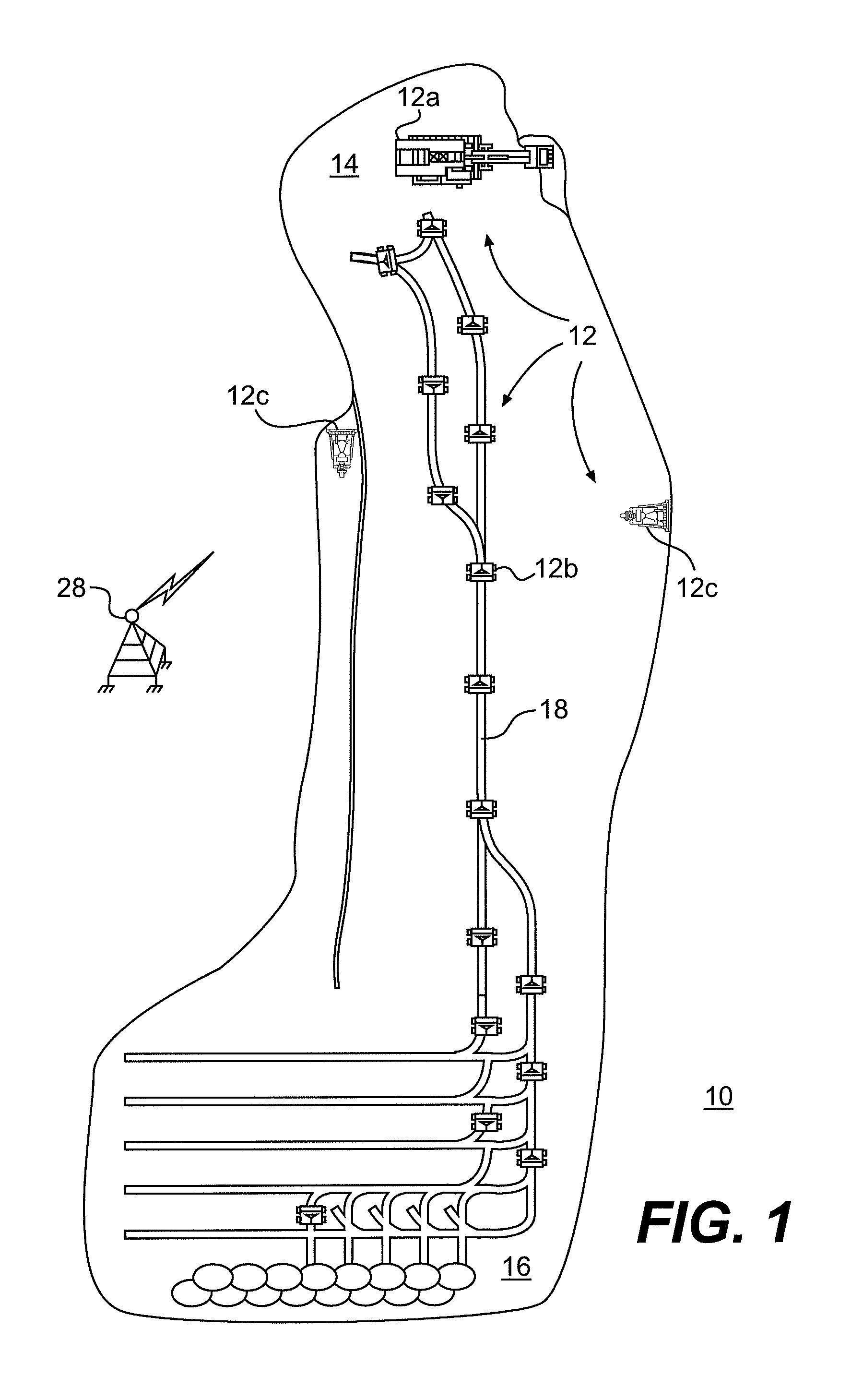

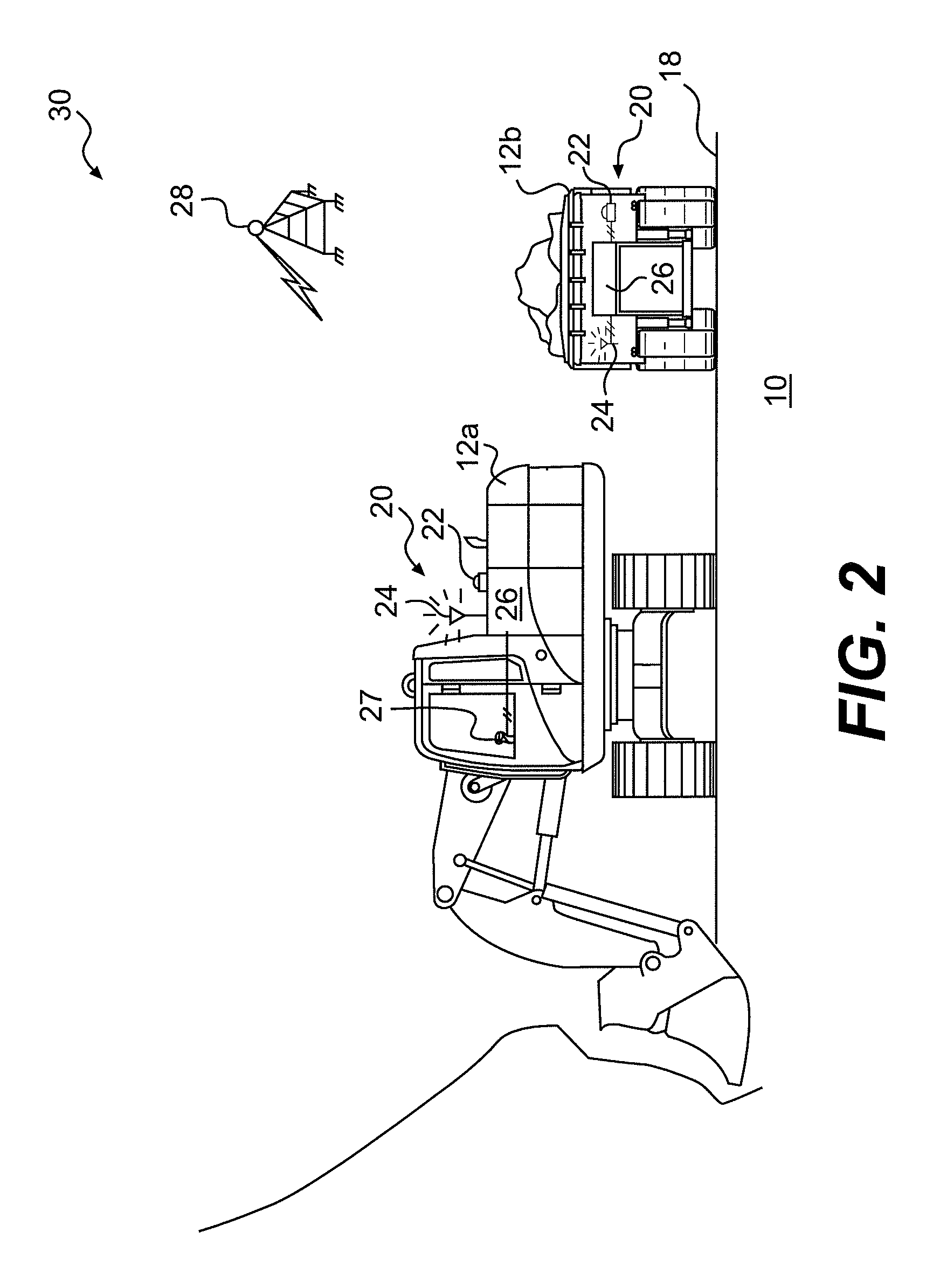

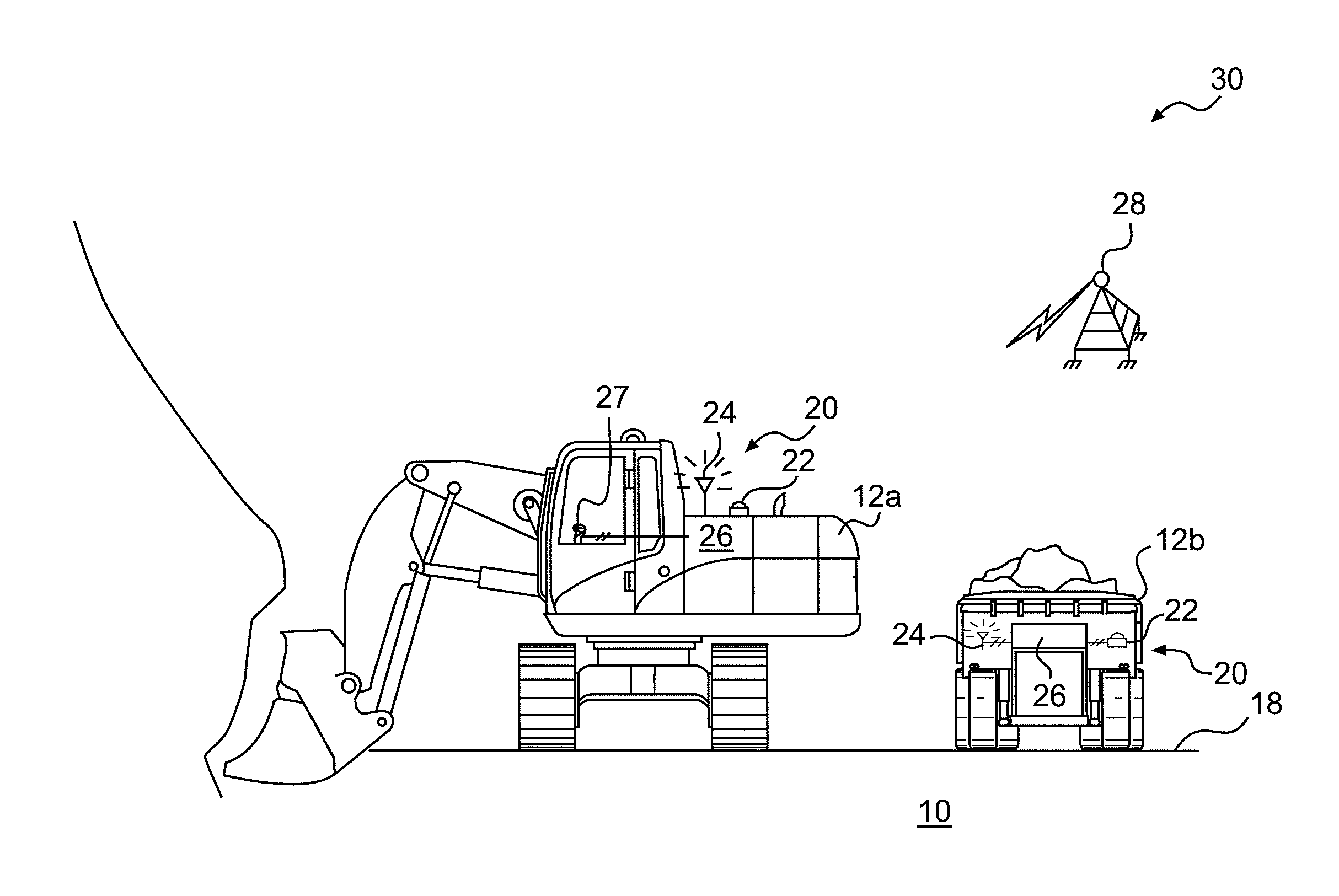

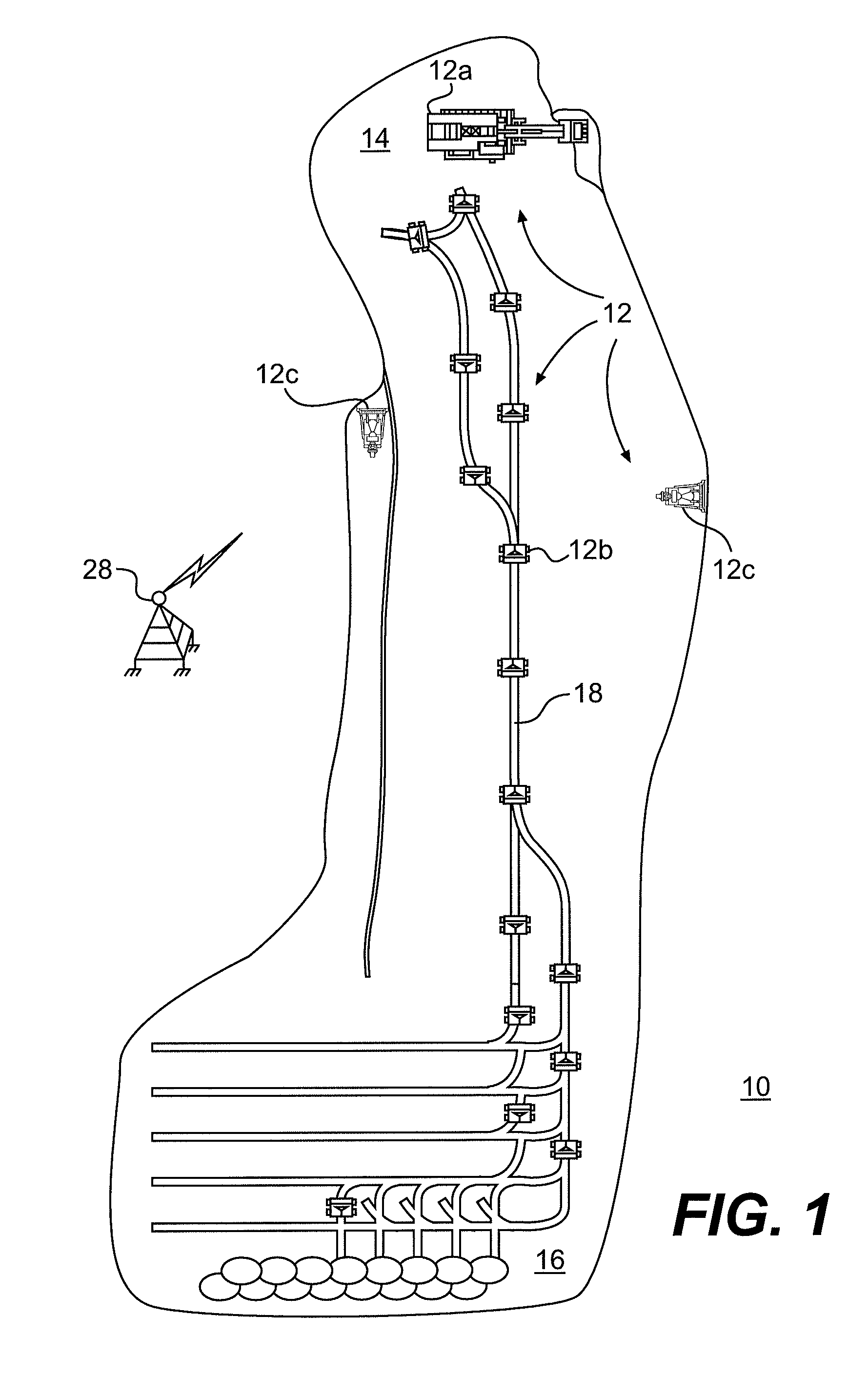

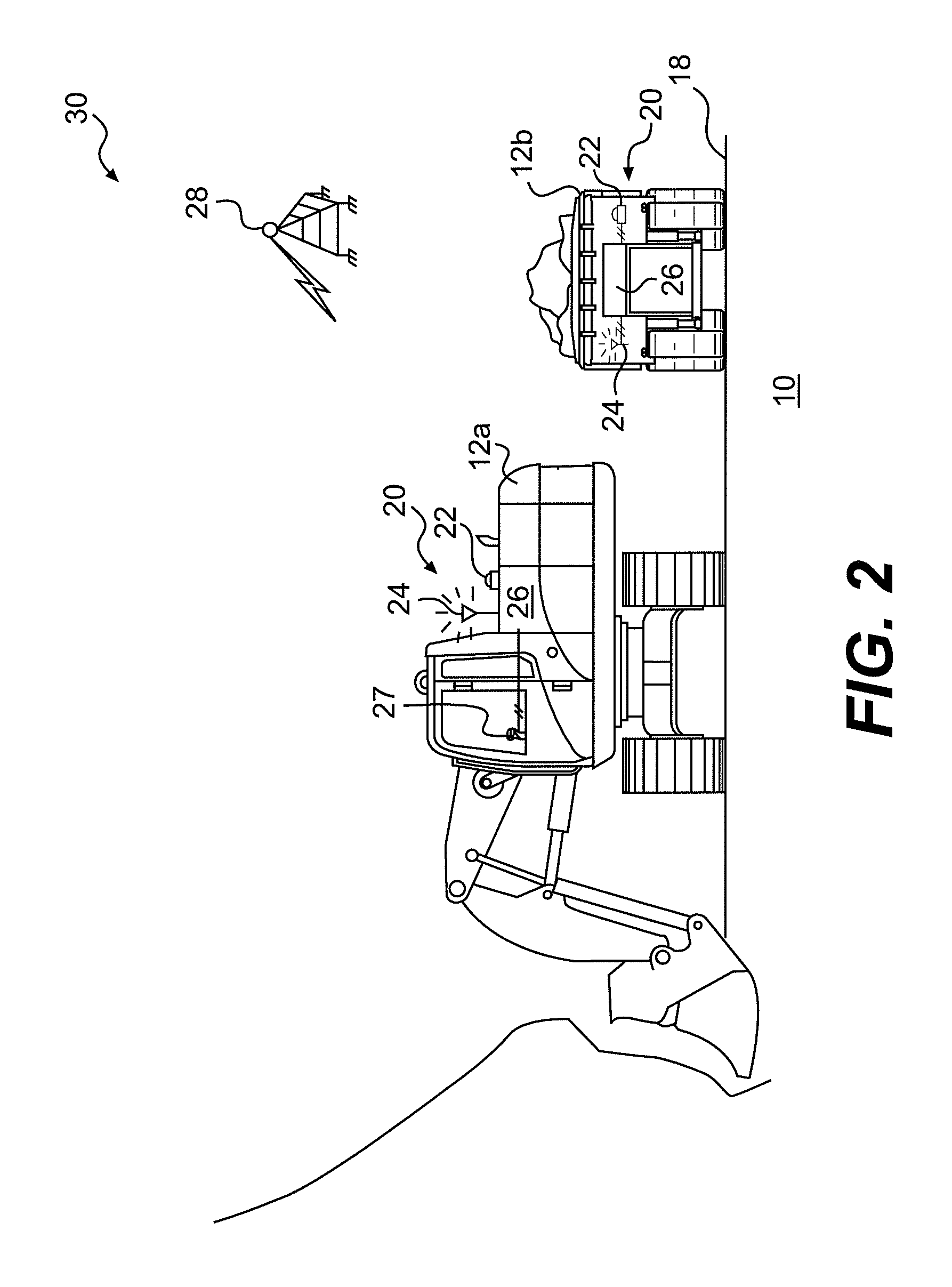

Machine control system having autonomous dump queuing

ActiveUS8983707B2Analogue computers for trafficSoil-shifting machines/dredgersMachine controlControl system

A control system for use at a dump location having a plurality of dump sites is disclosed. The control system may have a control module associated with a mobile machine and a worksite controller. The worksite controller may be configured to receive a signal from the control module indicative of the mobile machine crossing a boundary at a dump location, and assign a travel route for the mobile machine based on the signal. The travel route may include a travel segment on a common entrance row, a first single-use path from the common entrance row to a particular one of the plurality of dump sites, a second single-use path from the particular one of the plurality of dump sites to a common exit row, and a travel segment on the common exit row. The worksite controller may be further configured to communicate the travel route to the control module as the mobile machine moves toward the dump location.

Owner:CATERPILLAR INC

Method for ecological slope protection of abandoned mine waste dump

InactiveCN108018861AReduce sinkingHigh strengthExcavationsSoil-working methodsFiberEcological environment

The invention provides a method for ecological slope protection of an abandoned mine waste dump. The method comprises the steps of slope surface arrangement, base layer construction, film paving and net hanging spray-seeding. A spray-seeding matrix is mainly prepared from following raw materials including 100 parts of countryside soil, 20 parts of plant ash, 10 parts of humic acid, 8 parts of sawdust, 50 parts of drying sludge, 5 parts of cement and 2 parts of plant fibers. According to the method, bituminous concrete is paved on the slope surface, sinking of loosen soil in a side slope is weakened, and the strength of a rock-soil body of the slope surface is improved; by means of multiple layers of waterproof barriers, rainwater permeation is effectively stopped, meanwhile, a large quantity of tailings, waste stone and urban sludge can be consumed, and the region ecological environment is improved; and the engineering cost is low, and good social benefits and economic benefits are achieved.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Absorbent composition and methods thereof

InactiveCN102639229AOpen fullyOther chemical processesAbsorbent padsAluminum silicateEnvironmental engineering

An improved absorbent composition based on the natural hydrocoUoid material treated with porous aluminum silicates quickly absorbs an aqueous liquid and retains the liquid even under external pressure. The improved composition has liquid absorption and retention properties comparable to conventional SAPs, e.g., rapid, simple hydration with stable viscosity maintenance and aqueous liquid retention over wide ranges of temperatures, externally applied pressures, and salinity concentrations. This composition naturally breaks down into simple sugar molecules within several months after hydration from normal use. The released simple sugar molecules provide a great carbon source for microbes, creating an environment that promotes the breakdown of other biodegradable materials in the disposed diaper and landfills. The absorbent composition improves the performance of many aqueous liquid absorption products, such as personal hygiene products, for the absorption of significant amounts of moisture, bodily fluids or other aqueous solutions, when the composition is used as an absorbent in the products

Owner:熊海山 +3

Method for producing deodorant microbial agent

ActiveCN103463654AReduce concentrationImprove the living environmentDeodrantsBiotechnologyMicrobial agent

The invention provides a method for producing a deodorant microbial agent. The method comprises the following steps: carrying out high-density fermentation on streptococcus thermophilus, pseudomonas putida, rhodopseudomonas palustris, bacillus pumilus and enterococcus faecium, and then freezing and drying; adding a sodium citrate solution of which the concentration is 8-10% according to 1-5% of mass-volume ratio after mixing according to the ratio, so as to prepare a liquid deodorant product. The concentration of bad smells such as an ammonia gas, hydrogen sulfide and the like in the air in the places such as a toilet, a farm and a wasteyard can be effectively reduced; an odor-generating element is also restrained, so that the air quality and surroundings of people are significantly improved. The production method disclosed by the invention is simple, and adapts to most of existing fermentation technologies and equipments; large-scale popularization and application are facilitated.

Owner:QINGDAO VLAND BIOTECH GRP

Machine control system having autonomous dump queuing

ActiveUS20120136523A1Soil-shifting machines/dredgersVehicle position/course/altitude controlMachine controlControl system

A control system for use at a dump location having a plurality of dump sites is disclosed. The control system may have a control module associated with a mobile machine and a worksite controller. The worksite controller may be configured to receive a signal from the control module indicative of the mobile machine crossing a boundary at a dump location, and assign a travel route for the mobile machine based on the signal. The travel route may include a travel segment on a common entrance row, a first single-use path from the common entrance row to a particular one of the plurality of dump sites, a second single-use path from the particular one of the plurality of dump sites to a common exit row, and a travel segment on the common exit row. The worksite controller may be further configured to communicate the travel route to the control module as the mobile machine moves toward the dump location.

Owner:CATERPILLAR INC

Microorganism environment-protection waste disposal agent

InactiveCN101139220AInhibition of growth rateBlock hatchingBio-organic fraction processingSolid waste disposalMyiasisAnaerobic bacteria

The present invention discloses a treating agent for microbe environmental-protective garbage, which comprises anaerobic bacteria and facultative aerobe. The weight ratio for the anaerobic bacteria and facultative aerobe is 1: .65-1.1; because the composite fostered active bacteria preparation can decompose ammonia gas, nitrogen gas and sulfureted hydrogen and so on, the active preparation can restrict the growth speed of spoilage organisms, block the growth of the myiasis and destroy the hatch of mosquito and fly. So the present invention has the great effects to kill the mosquito and fly, deodorization, and to cure corruption. The duration is much longer; the decreasing ratio for the mosquito and fly in the refuse dump reaches up to 95 percent and the decreasing ratio for the bad smelly reaches up to 80 percent. The present invention can decrease the pollution in the refuse dump, decrease the output of the firedamp and decrease the storage volume for the garbage. Besides, the product has not any side effect and special smelly. The present invention is not dangerous to the health, without producing the garbage and bringing the second pollution. After being used with the present invention, the neighboring environment around the refuse dump can be enhanced greatly.

Owner:刘军

Microbial preparation for purifying air

ActiveCN103468619AReduce concentrationImprove the living environmentBacteriaDispersed particle separationBiotechnologyPseudomonas putida

The invention provides a microbial preparation for purifying air. By utilizing the synergic effects of streptococcus thermophilus, pseudomonas putida, rhodopseudomonas palustris, bacillus pumilus and enterococcus faecium, the microbial preparation is capable of effectively reducing concentration of stink comprising ammonia gas, hydrogen sulfide and the like in the air at toilets, culturing farms, dumps and the like, and inhibiting stink-producing elements, so that air quality and human living environment can be substantially improved. A production method provided by the invention is simple, is applicable to majority of conventional fermentation technologies and equipment, and is suitable for large-scale popularization and application.

Owner:SHANGHAI KDN BIOTECH

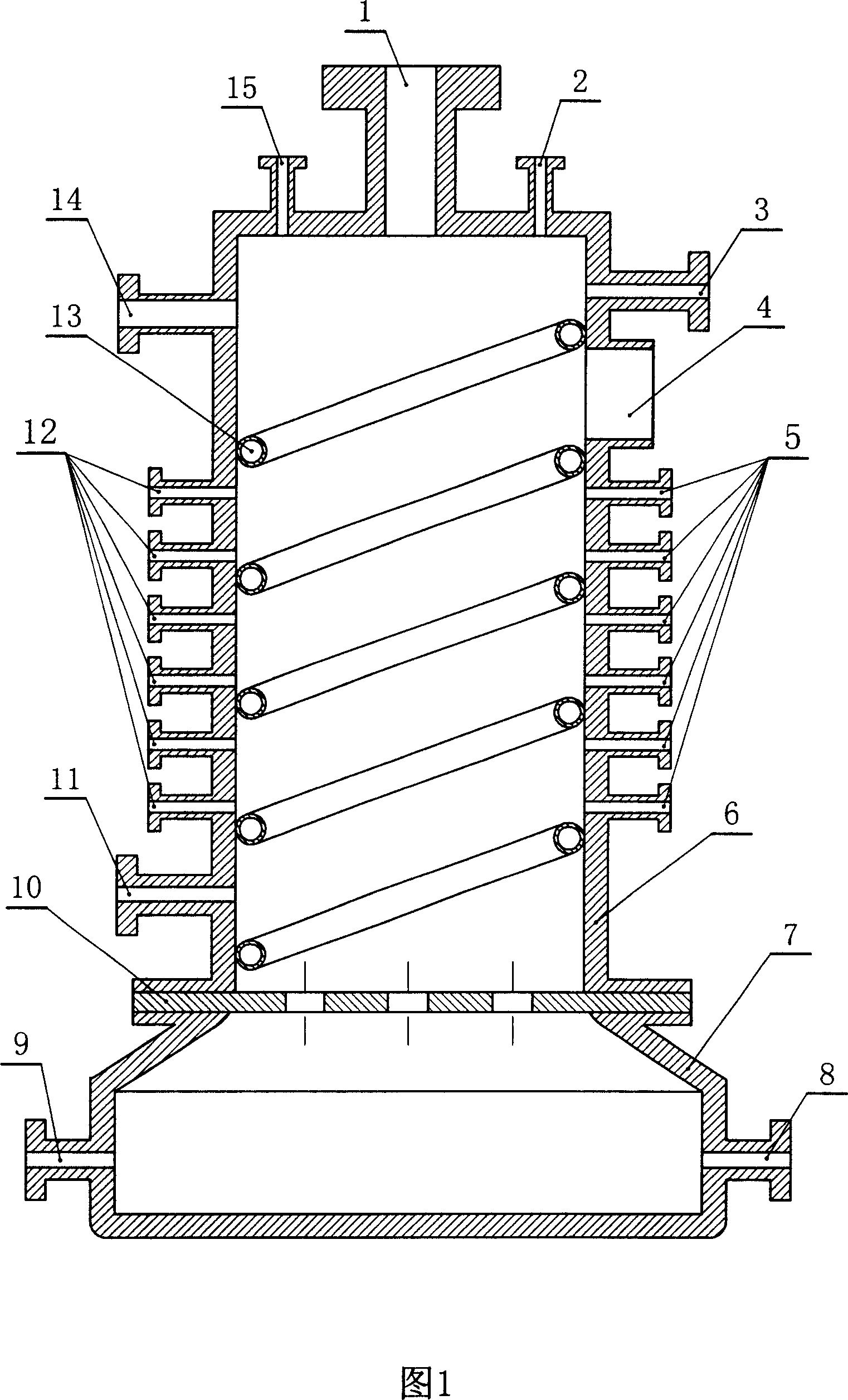

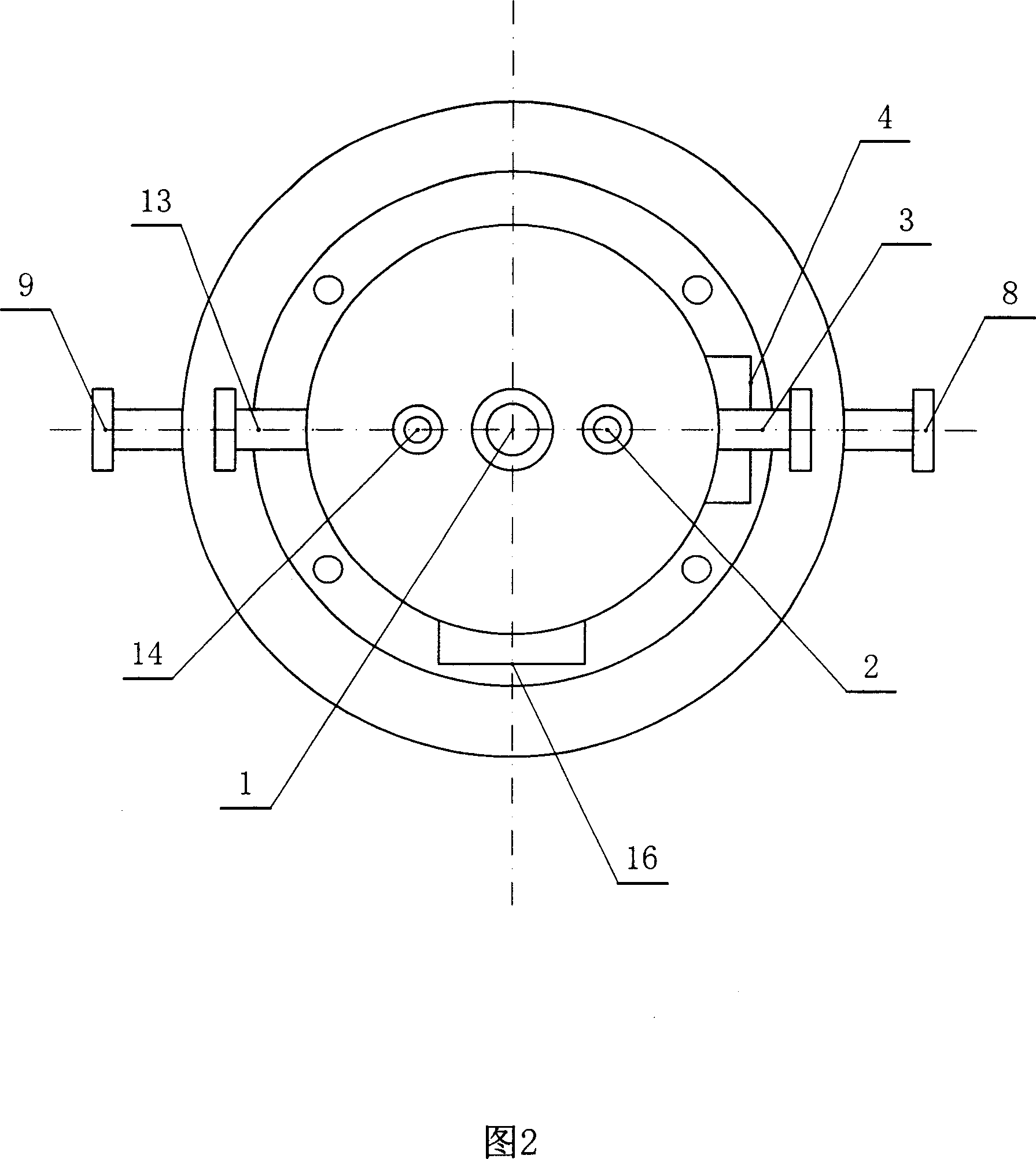

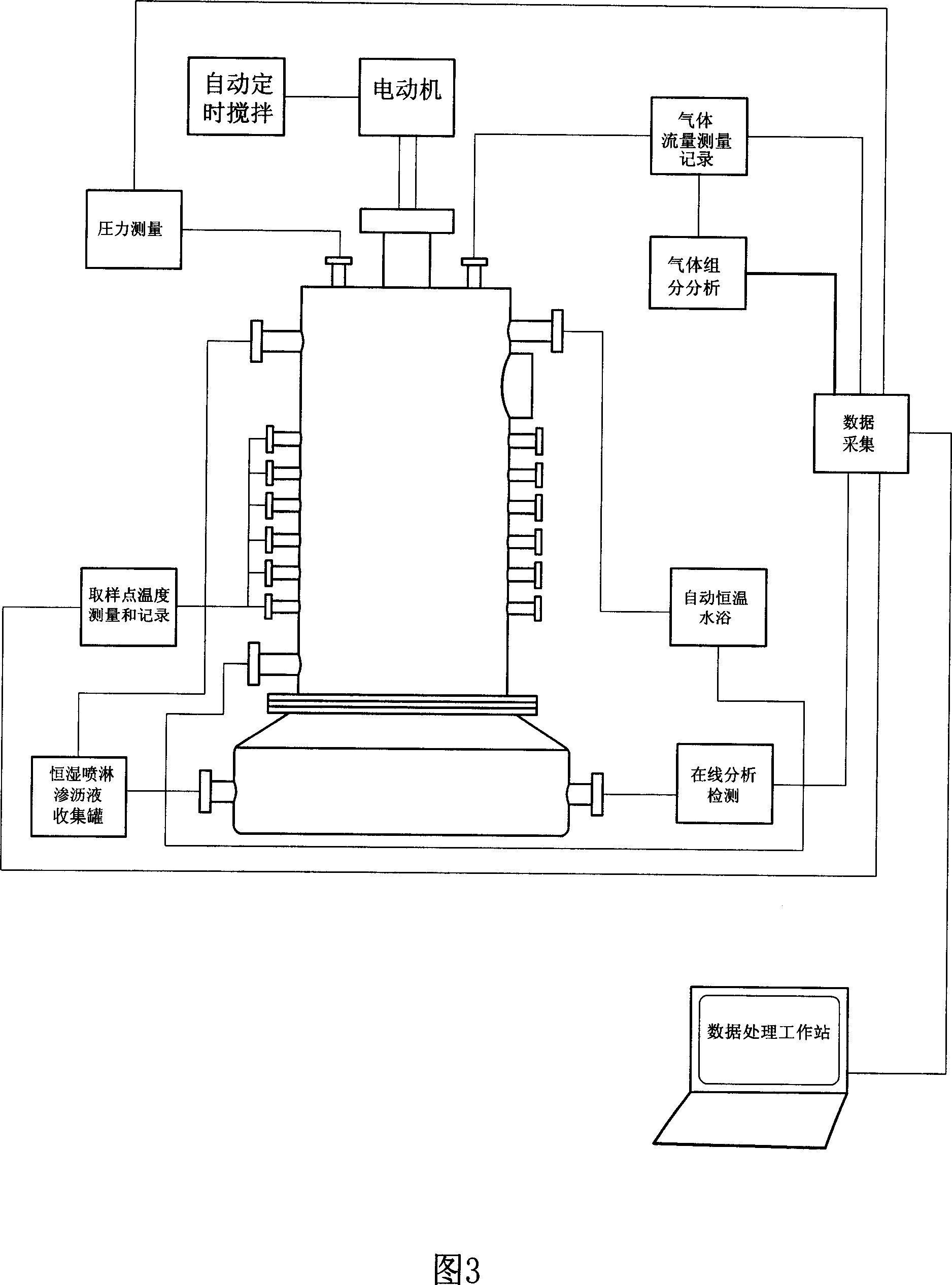

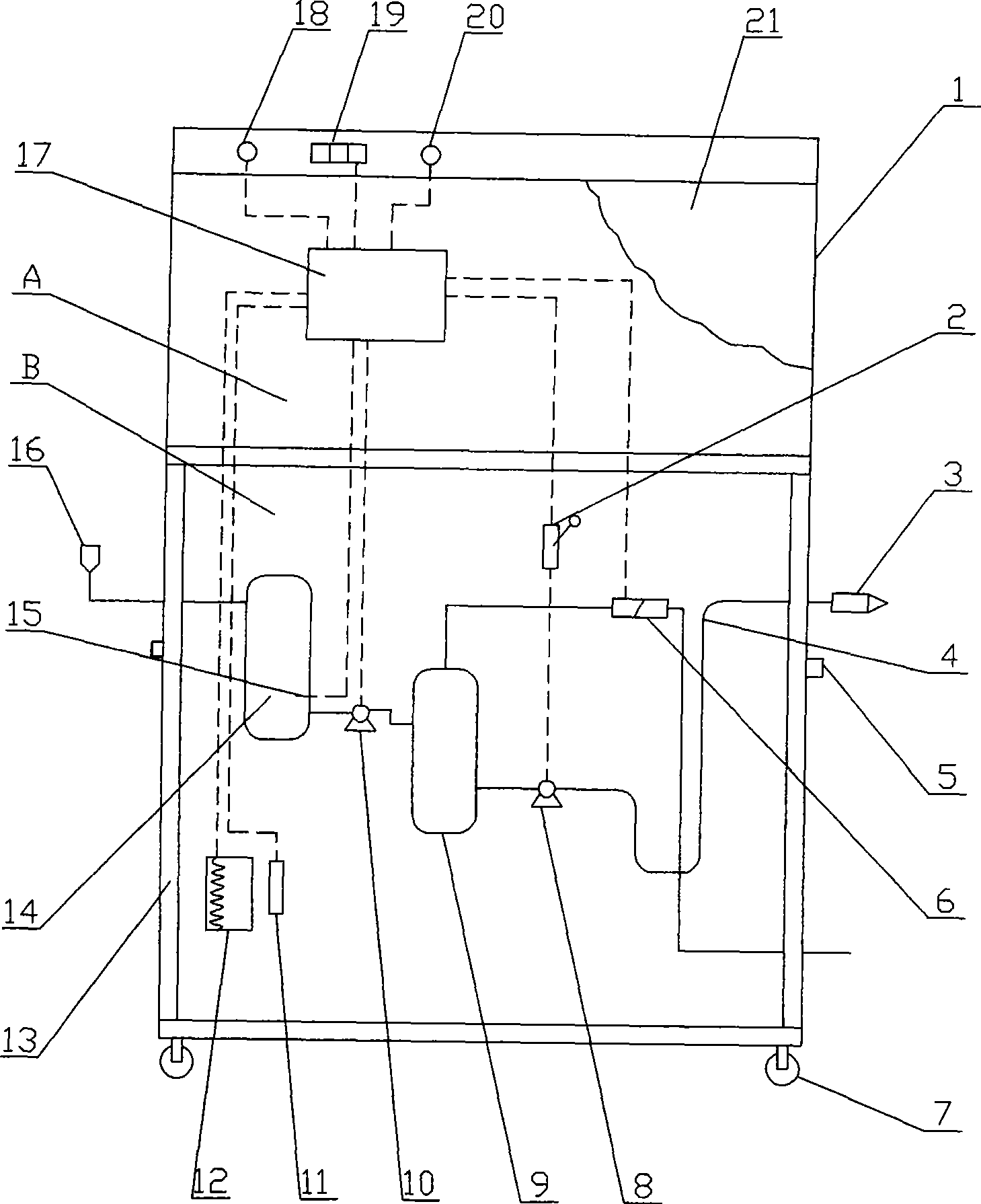

Anerobic type biological reactor

InactiveCN1995318ABioreactor/fermenter combinationsBiological substance pretreatmentsWarm waterLitter

The invention discloses an anaerobic biological reacting tank, which comprises the following parts: ferment tank, bleeding liquid collecting tank to fix ferment tank, baffle between ferment tank and bleeding liquid collecting tank, through-out hole on the baffle, wherein the bleeding liquid sampling sample and constant humidity sprinkling outlet are opened on the lateral wall of bleeding liquid collecting tank; the ferment sampling hole and temperature gauging hole are opened on the middle part of lateral wall of ferment tank; the constant warm water outlet, discharge are opened on the lateral wall of ferment tank bottom; the constant warm water inlet, charge and constant humidity sprinkling inlet are set on the ferment tank; the top wall of ferment tank possesses timely stirring sleeve, flow gauging interface, pressure measuring interface; the coiler is set in the ferment tank.

Owner:徐伟

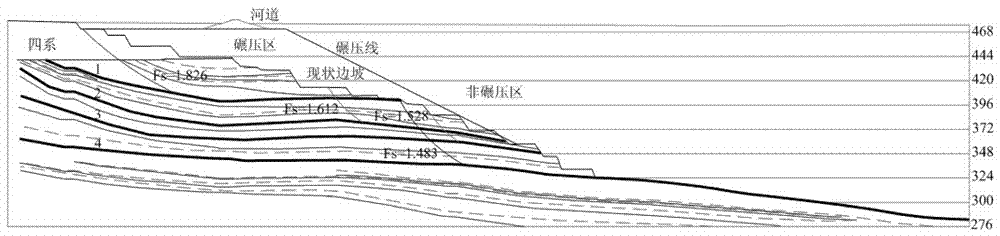

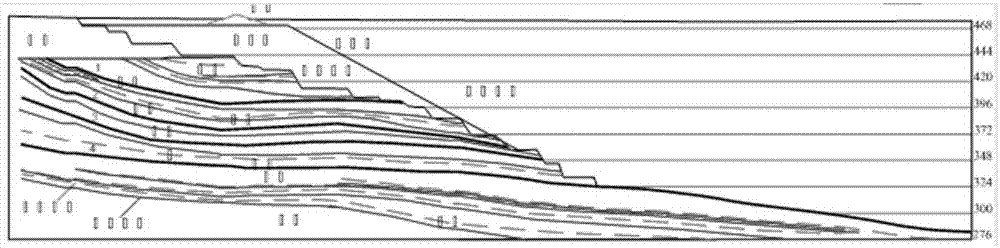

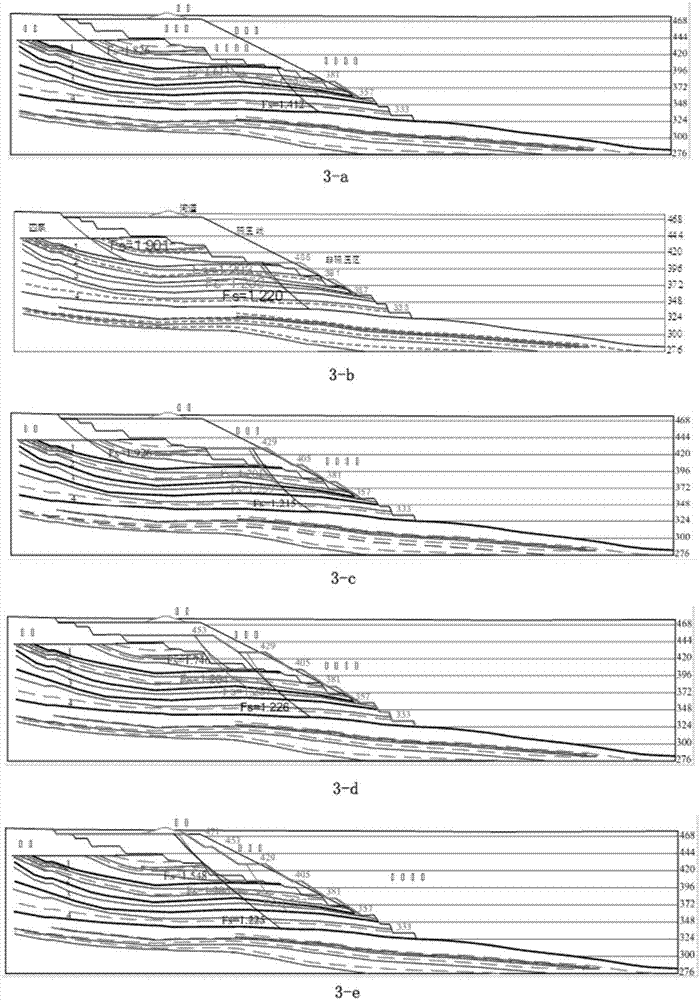

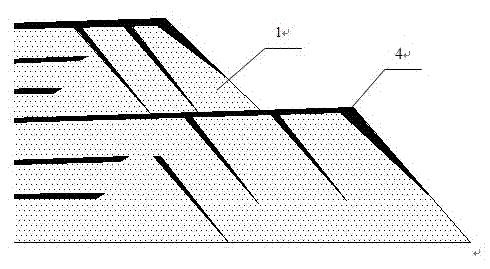

Waste dump presser foot wall hanging concurrent construction method in open pit coal mine

ActiveCN107503750AIncrease capacityShort construction periodUnderground miningSurface miningStability coefficientCoal

The invention provides a waste dump presser foot wall hanging concurrent construction method in an open pit coal mine. The construction method comprises the following steps: (1) performing stability evaluation on a stope bounded slope of the open pit coal mine, and executing a step (2) if the stability coefficient is greater than a safety storage coefficient K of the inner waste dump, otherwise executing a step (3); (2) performing wall hanging dumping, and sequentially determining the optimal flat plate width of each wall hanging dumping step from bottom to top; and (3) sequentially performing presser foot dumping from bottom to top, performing stability evaluation on a stope-inner waste dump composite slope II when the primary presser foot dumping step is completed, and returning to the step (2) when the stability coefficient Fsn of the composite slope II is greater than the safety storage coefficient K of the inner waste dump, otherwise performing the previous level of presser foot dumping step until the final disposal position designed by the open pit coal mine is reached, and forming an inner waste dump presser foot form; and (4) performing continuous dumping according to the waste dump flat plate width of the open pit coal mine.

Owner:扎鲁特旗扎哈淖尔煤业有限公司

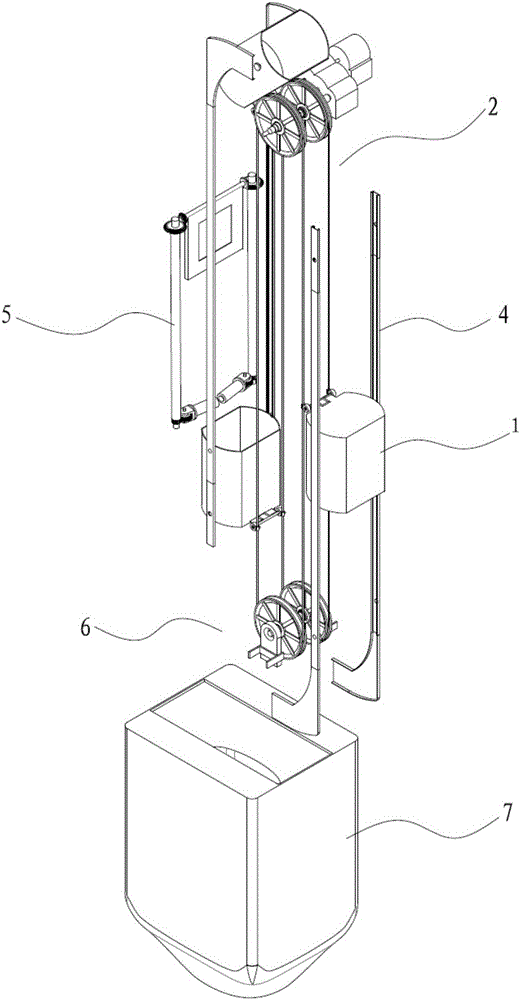

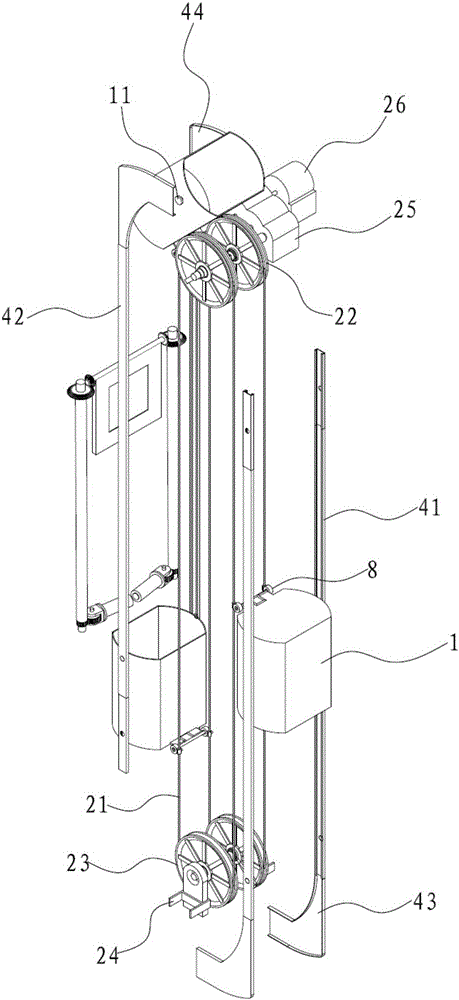

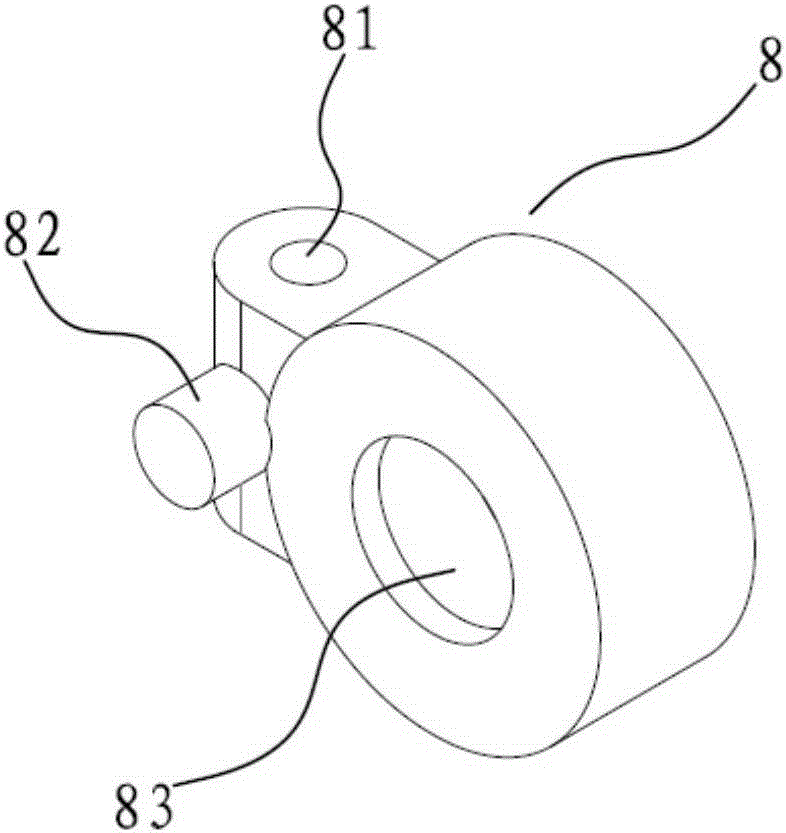

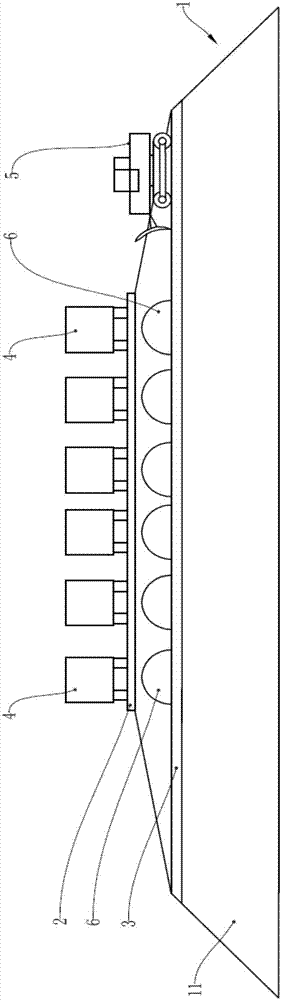

Self-cleaning waste conveying system for energy recovery

ActiveCN105217229ASolve shipping problemsReduce manpower consumptionConveyorsWaste collection and transferEnergy recoveryHigh rise

The invention discloses a self-cleaning waste conveying system for energy recovery. The self-cleaning waste conveying system for energy recovery comprises a lifting mechanism, limiting rails, instant stopping mechanisms and a waste storage bin. The lifting mechanism is used for conveying dustbins up and down in a circulating mode and comprises an annular conveying piece. A plurality of connecting bases are arranged on the annular conveying piece at intervals. The dustbins are connected to the connecting bases in a rotary mode respectively. The limiting rails are installed at the two sides of the lifting conveying mechanism and used for keeping the rising and falling movement postures of the dustbins. A waste dumping position having a non-limiting rail function is arranged close to the bottom of the lifting mechanism. The instant stopping mechanisms are arranged on all storeys and used for controlling the dustbins to stop instantly at waste throwing-in openings. The waste storage bin is arranged below the lifting mechanism and used for storing waste dumped from the dustbins in an mode. The self-cleaning waste conveying system is suitable for lifting and conveying waste of all storeys of a high-rise building; power consumption for conveying waste through an elevator is reduced, energy is saved, and emission is reduced; manpower consumption of waste disposal is reduced, and management cost is reduced.

Owner:ZHEJIANG UNIV

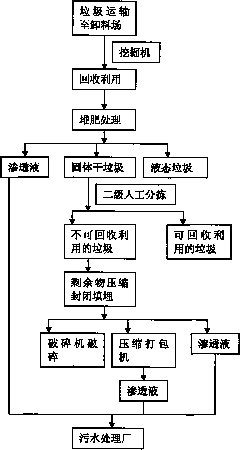

Garbage sorting compressing environmental processing technology

InactiveCN101823071AReduce investmentHazard reductionWaste processingSolid waste disposalSocial benefitsLitter

The invention provides a garbage sorting compressing environmental processing technology. Comprehensive sorting treatment is carried out on garbage, garbage is sequentially subject to four stages of recycling, composting, residue compression sealing landfill and penetrating liquid treatment, then a plurality of processes of sorting, bag-breaking screening, compression packaging and winding packaging are carried out on the garbage, density volume reduction is adopted to realize simplification of garbage treatment, the garbage is daily treated, storage capacity is effectively reduced, and the existing landfill time is prolonged for more than seven years. The invention has reasonable design, simple construction member, strong practicability and convenient and easy operation, no large-scale dump site is required to be established, the existing dump site landfill storage capacity can be directly utilized to carry out sorting, compression and sealing on garbage, funding is reduced, and the penetrating liquid produced by garbage is purified, harmfulness of various harmful substances can be reduced to minimum, no secondary pollution to the environment is produced, and the technology has obvious social benefit and economic benefit.

Owner:广东昕旺环保科技发展有限公司

Modular systems and methods for collecting and containing oil spills

InactiveUS8557121B1Reduce and minimize effect of spreadingFluid flow is minimizedGeneral water supply conservationSolid sorbent liquid separationOil spillWaste Dumps

A system and method for capturing ecologically harmful substances in the nature of hydrocarbons from the surface of a body of water or from the ground adjacent a landfill or waste dump or from a shoreline of a body of water into which residual waste fluids from an adjacent ground leakage is passed. The system and method including a plurality of modular traps. The traps having a side, end, top and bottom panels constructed of a material that allows fluid flow therethrough.

Owner:UGOLYN VICTOR +1

Environmental purification device

InactiveCN101422626AAvoid damageImprove safety and reliabilityAtomized substancesChemicalsControl roomEngineering

The invention discloses an environment purifying device which belongs to the category of environmental protection equipment. The device is a tank type structure; the interior of the tank body is divided into a controlling chamber and an executive chamber which are mutually separated; a controlling part is arranged in the controlling chamber; and a liquid medicine delivery part, a heater and a temperature measuring device are arranged in the executive chamber. The further improvement is as follows: a nozzle and a telescopic flexible pipe are connected, a liquid level detector is arranged in a stock solution tank, an insulating layer is arranged on the internal wall of the executive chamber, a handle is arranged at the external side of the tank body and a rolling wheel is arranged at the bottom of the tank body. The invention can be used in dumps, livestock and poultry raising and slaughter houses and other special places to carry out treatments of deodorization, disinfection, sterilization and fly killing by spraying the liquid medicine, and the environment purifying device has the outstanding advantages of good safe reliability, normal work at low temperatures, convenient transportation and moving, flexible manoeuvrability and wide application range.

Owner:朱吉根

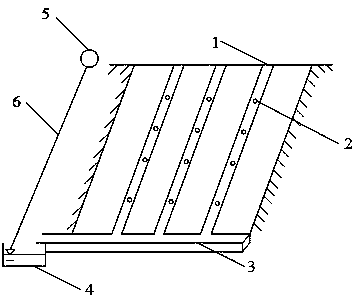

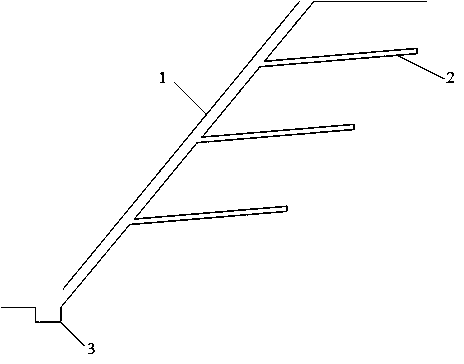

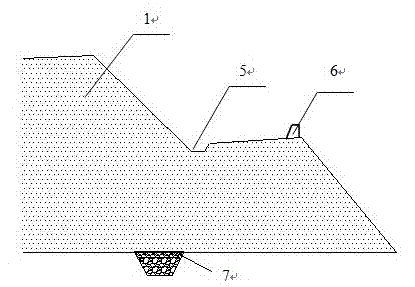

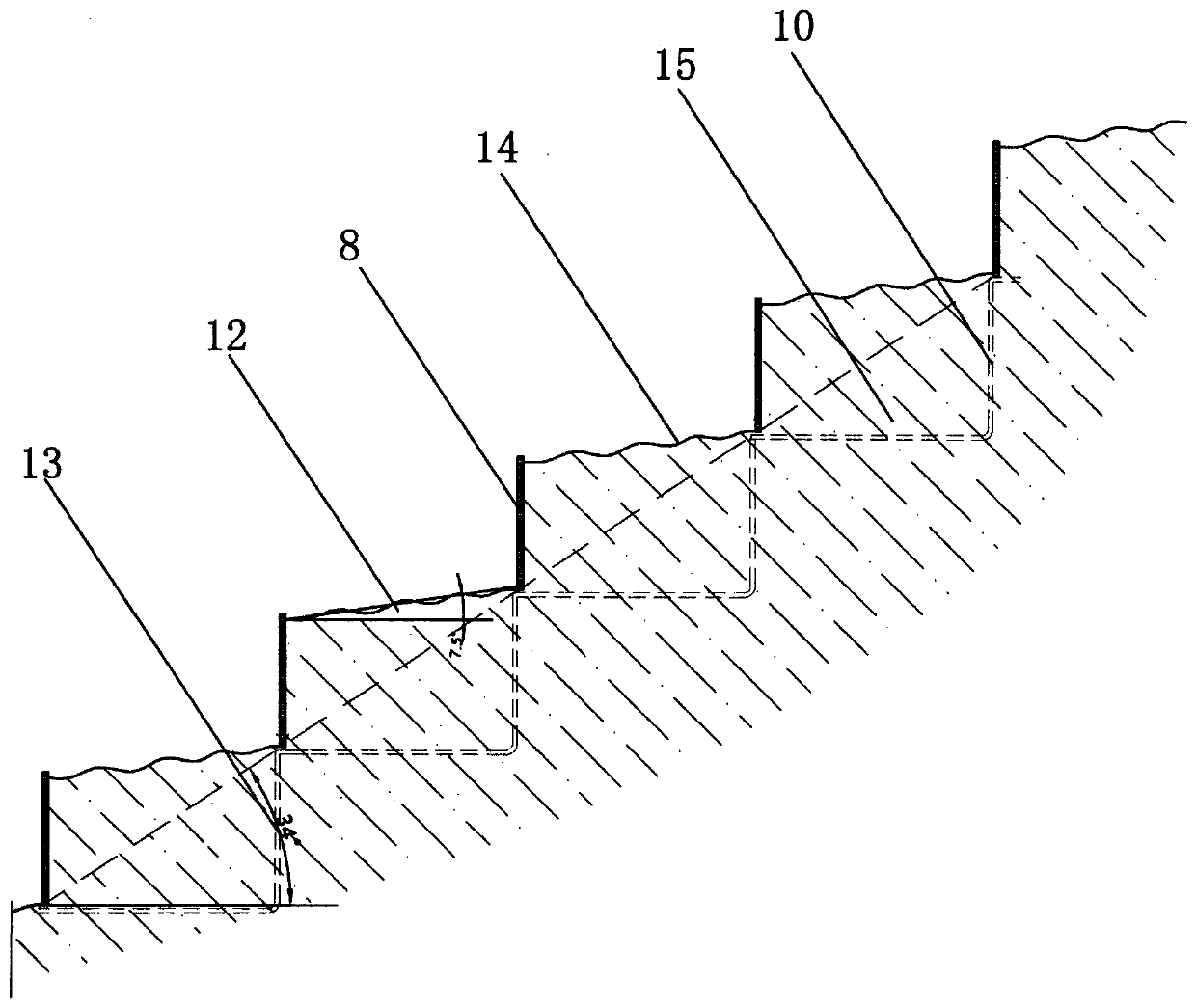

Mine waste dump slope water drainage system and construction method thereof

PendingCN109356180AAvoid water damagePrevent landslidesHuman health protectionSewerage structuresVegetationWater storage

The invention provides a mine waste dump slope water drainage system. The mine waste dump slope water drainage system comprises a torrent tank, water seepage pipes, a water drainage tank, a water storage pool, a water pump and a pipeline; the water seepage pipes are buried in the oblique upper direction of the slope surface, and water outlet pipe ports of the water seepage pipes are arranged in the torrent tank and are parallel to the bottom of the torrent tank; the torrent tank is built from top to bottom along the slope surface, and the bottom end of the torrent tank is connected with the water drainage tank; the tail end of the water drainage tank is connected with the water storage pool; and the water pump is connected with the water storage pool through the pipeline. According to themine waste dump slope water drainage system, reinforced cement prefabricated round pipes are adopted as the water seepage pipes and buried in the slope surface, therefore, seepage water in the slope surface can be quickly drained, and water damaging and landsliding of the slope are avoided; meanwhile, the drained water is stored by the water storage pool and used for irrigating vegetation on the slope surface in drought days, and therefore the water resource utilization rate is increased; in addition, water outlets of the water seepage pipes are buried in the torrent tank, and therefore the condition that effluent water of the water seepage pipes generates secondary scouring to the slope surface is avoided; and furthermore, the reinforced cement prefabricated round pipes are buried in theslope surface to achieve the effect of anchor rods, the slope surface can be fixed, and slope surface sliding can be prevented.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

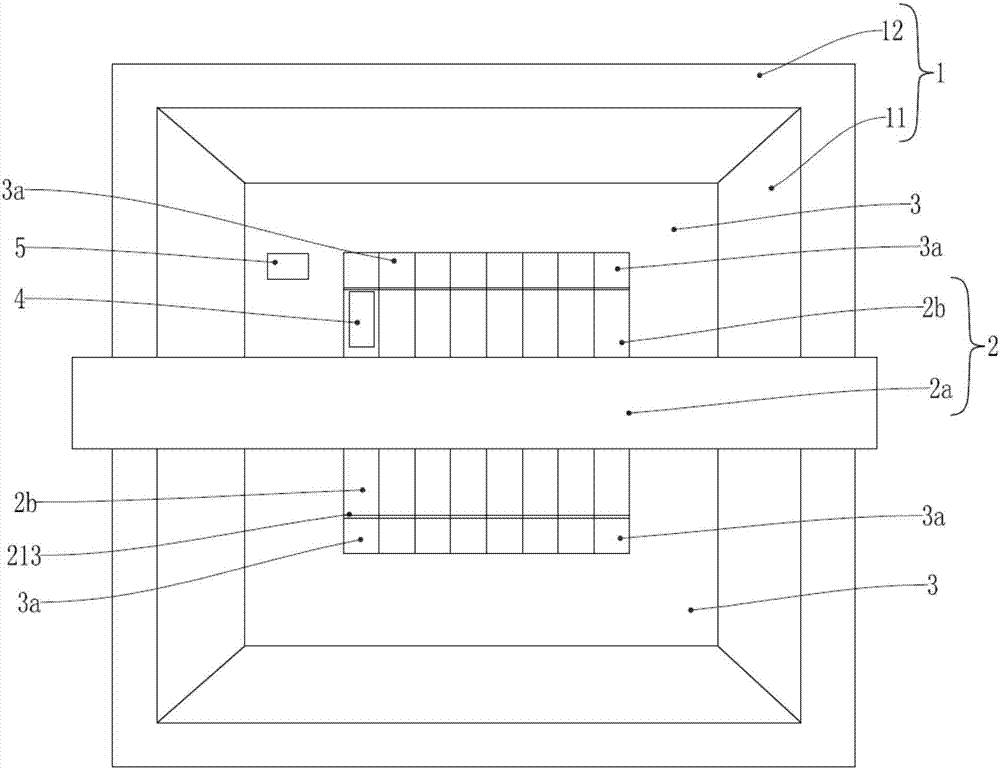

Garbage dump platform for subarea unloading and application method and building method thereof

InactiveCN107262488AReduce entry and exit timeReduce areaSolid waste disposalTemporary pavingsLandslideTruck

The invention discloses a garbage dump platform for subarea unloading and an application method and a building method thereof. The garbage dump platform comprises a garbage basal body, an unloading platform and a push carrying platform; the unloading platform is arranged at the top of the garbage basal body; the push carrying platform is arranged on the garbage basal body, and surrounds the edge of the unloading platform; and the push carrying platform is arranged under the unloading platform. A garbage truck and a bulldozer are not operated on the same plane, and are not disturbed to prevent road snatching or road occupation, so that the operation safety coefficient is improved; the construction time is shortened; the area of the exposed surface of the garbage basal body is reduced; and the seepage landslide risk is reduced. The area of the platform is reduced to greatly reduce unnecessary driving travel of the garbage truck and the bulldozer, so that the landfill field transfer speed is accelerated, and the bulldozer operation pushing distance is reduced.

Owner:GUANGZHOU HUANTOU ENVIRONMENTAL SERVICES CO LTD

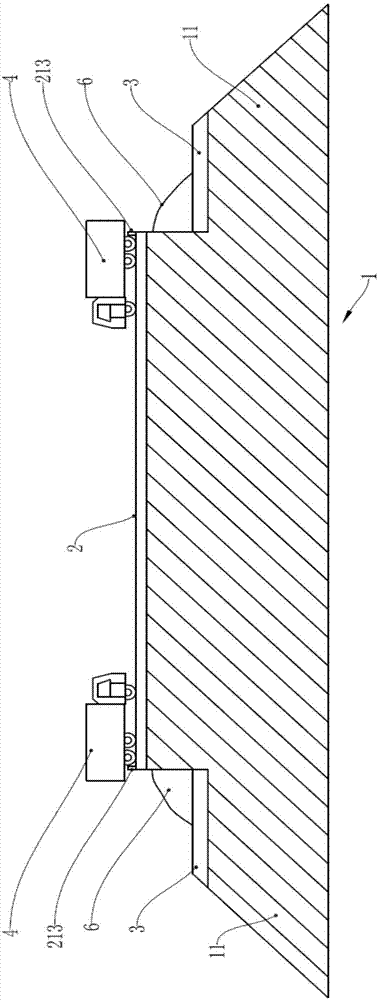

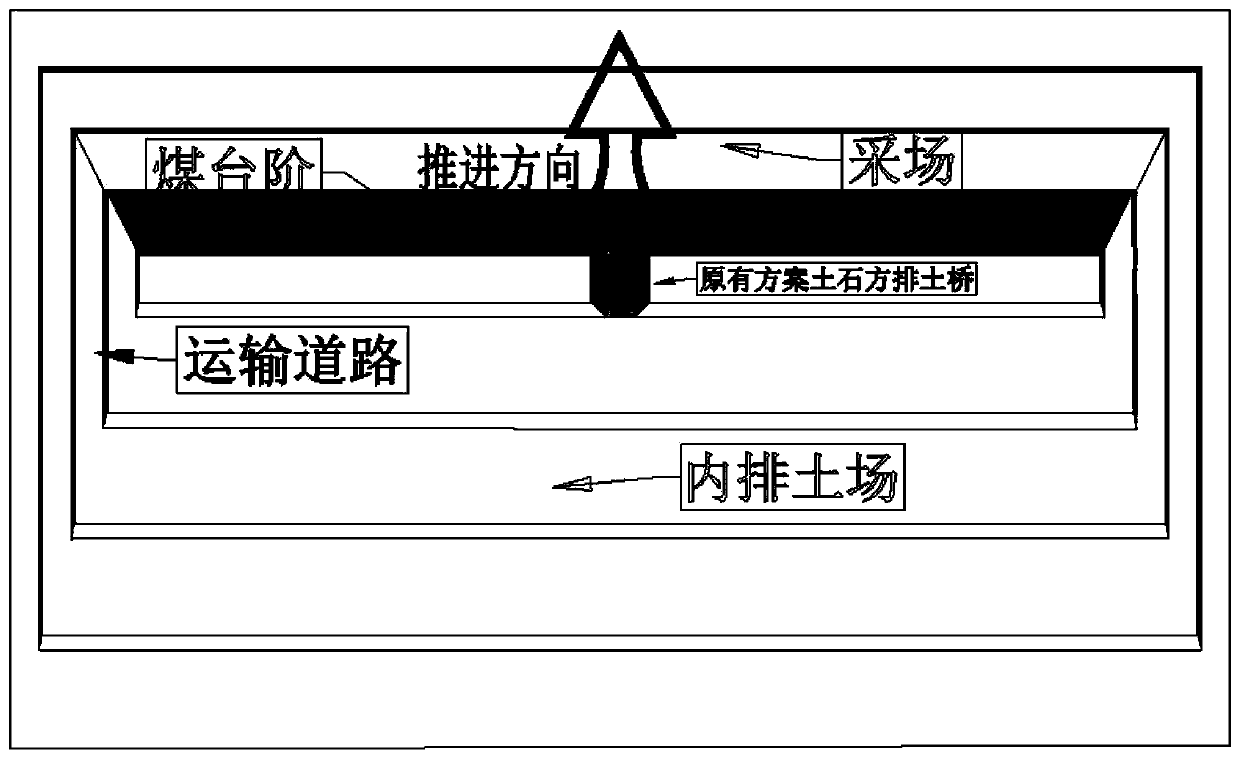

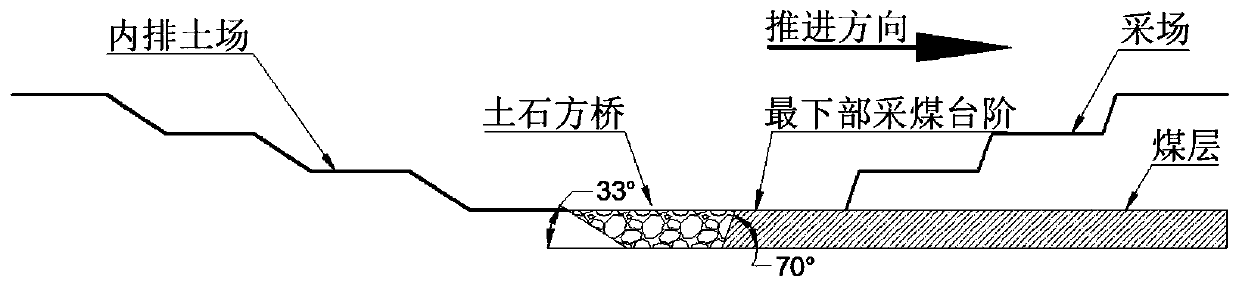

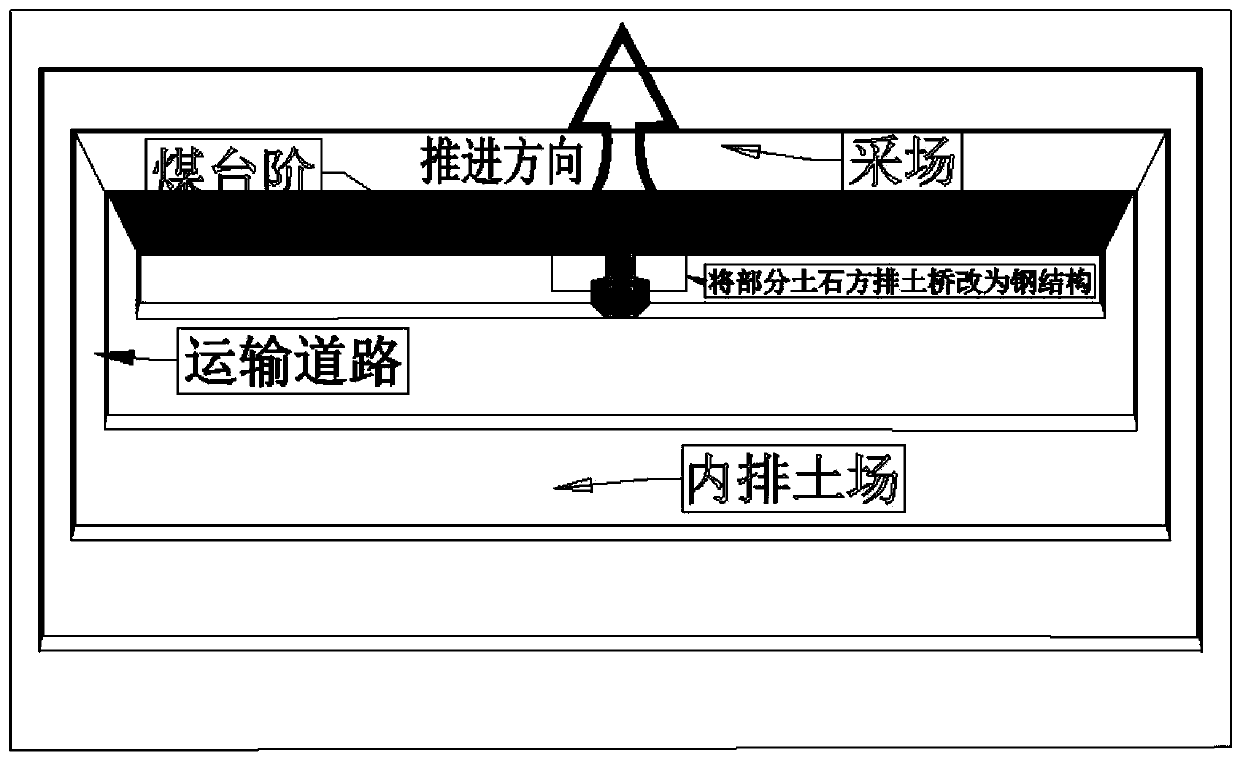

Self-moving vehicular bridge for connecting open-pit mine stope and inner waste dump

ActiveCN110331651ASave secondary stripping costsImprove securityTravelling bridgesHydraulic cylinderWaste Dumps

The invention relates to a self-moving vehicular bridge for connecting an open-pit mine stope and an inner waste dump, and belongs to the technical field of self-moving vehicular bridges. The bridge comprises a main bridge floor top plate, a main bridge floor side plate, a lifting platform, a side protecting plate, first hydraulic cylinders, supporting hydraulic cylinders, a stope side folding bridge floor, a stope side folding hydraulic cylinder, a waste dump side first folding bridge floor, a waste dump side folding hydraulic cylinder, a waste dump side second folding bridge floor, a stope first side face guard, a stope second side face guard, a third hydraulic cylinder, a waste dump first side face guard, a waste dump second side face guard, a waste dump third side face guard, a fourthhydraulic cylinder, a fifth hydraulic cylinder, a track walking mechanism and a cab, a part, which is originally formed by piling up loose earth rock, of a steel structure is changed into a whole self-moving steel structure, and secondary stripping does not need to be carried out on the part of the steel structure during coal pressing under a subsequent mining structure. Due to the fact that the vehicular bridge needs to be moved and erected repeatedly, the secondary stripping cost is greatly saved.

Owner:LIAONING TECHNICAL UNIVERSITY

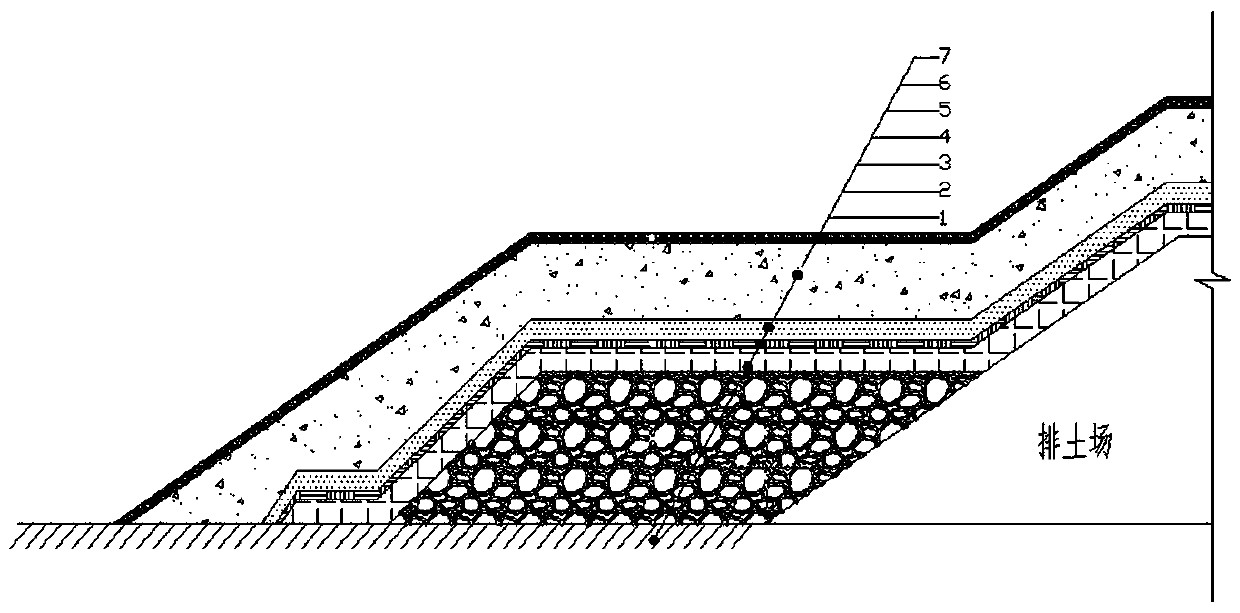

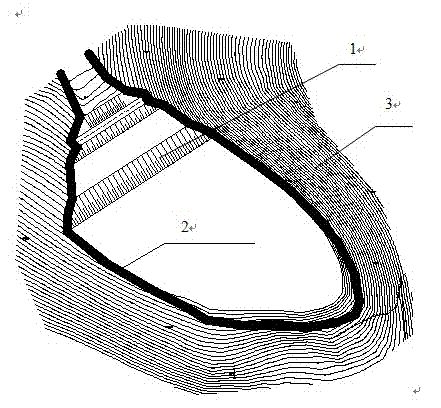

Comprehensive waste dump water controlling method applicable to soft foundations

ActiveCN103046536AReduce catchment areaPrevent infiltrationSoil drainageProtective foundationLandslideDebris flow

The invention discloses a comprehensive waste dump water controlling method applicable to soft foundations. The method comprises building a flood intercepting trench on the mountain slope on the upper portion of a waste dump (1); paving clay on each platform of the waste dump (1) to form impermeable layers, building platforms of the waste dump (1) into 2% to 3% of adverse slopes, building a drainage ditch (5) at the slope toe on a platform of the waste dump (1), and building floor retaining walls (6) outside the waste dump platforms; and excavating blind drainage ditches (7) in the soft foundation of a waste dump, wherein the space among the blind drainage ditches (7) is between 20m and 40m. According to the comprehensive waste dump water controlling method, comprehensive water control measures of interception, prevention, drainage and dredging are utilized together, and the platform impermeable layers are used for preventing rainwater from permeating downwards; and the floor retaining walls (6) and the adverse slopes can prevent rainwater from washing the slope and guide water into the drainage ditch (5) on the inner side of the platform; and the drainage blind ditches (7) are arranged in the soft foundation, so that underground water in soft rock foundations can be drained, drainage in the waste dump can be promoted, the problem of water damage of waste dumps can be solved effectively, and landslide and debris flow of waste dumps are prevented.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

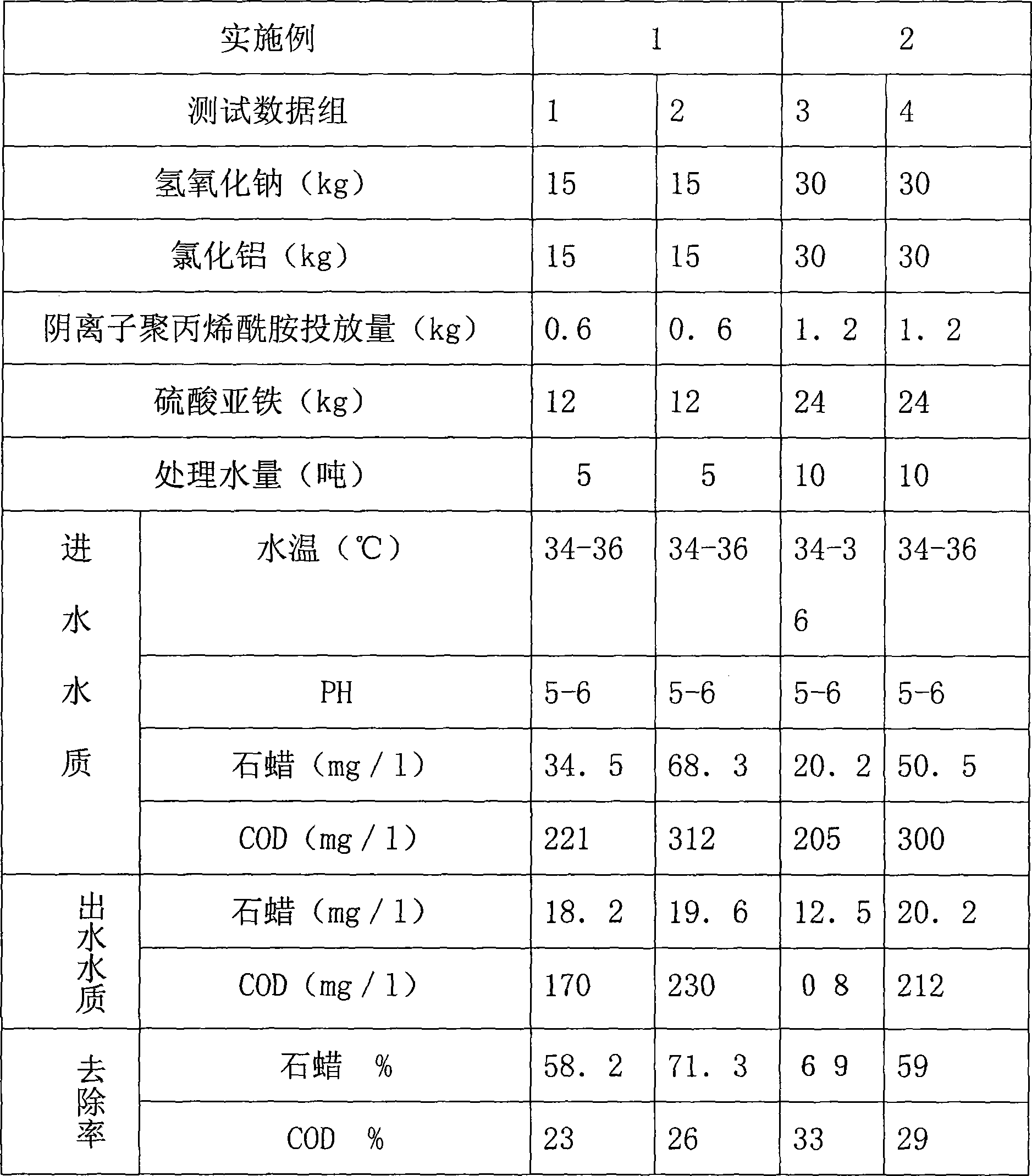

Process for processing glass fibre drawing sewerage

InactiveCN101376534AEliminate paraffinEliminate odorWater/sewage treatment by flocculation/precipitationGlass fiberChloride

The invention discloses a treatment technology of glass fiber wire drawing waste water. Sodium hydroxide and anionic polyacrylamide are respectively dissolved in a mount of water first and then are stirred for a period of time; the waste water in a sewage reservoir is stirred, a sodium hydroxide solution is slowly poured in first, and then aluminum chloride and ferrisulphas are poured in turn; after the mixed solution is stirred for a period of time, an anionic polyacrylamide solution is slowly poured in, and the stirring is continued until flocculent suspended substances appear; after the mixed solution is placed for 1 to 2 days, the waste water presents layered phenomenon, the flocculent suspended substances are fished out and processed through drainage, and then are poured into a refuse dump as trash; and the remaining water is used as the water for cleaning floor. The treatment technology eliminates paraffin, acidoid and odour in the glass fiber wire drawing waste water, reduces the COD value, has low cost, and is convenient for the treatment of glass fiber waste water.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

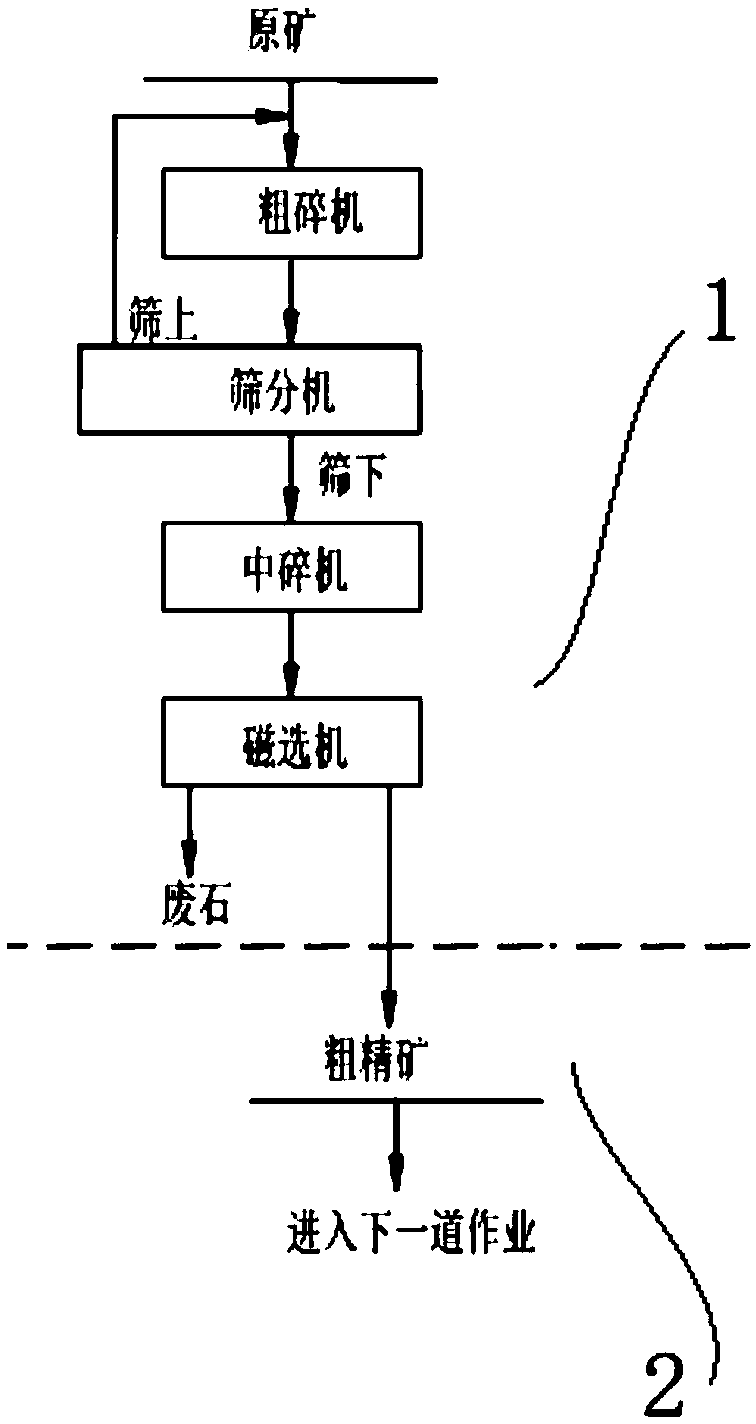

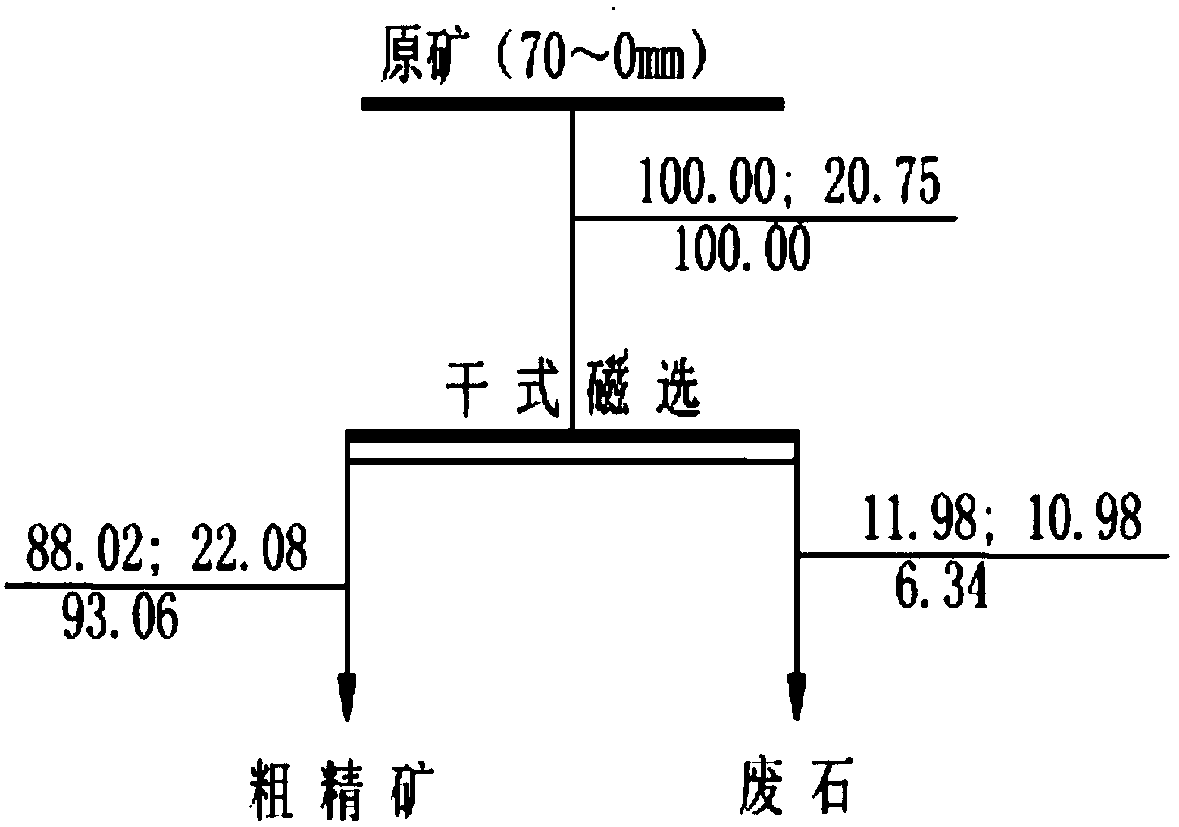

Beneficiation production system of lean magnetite

ActiveCN109351447AReduce transport volumeReduce shipping costsMagnetic separationGrain treatmentsOperational costsIronstone

The invention discloses a beneficiation production system of lean magnetite, and belongs to the technical field of beneficiation. The beneficiation process comprises the steps of coarse crushing, middle crushing, magnetic separation and transfer; and a middle crushing device is arranged in front of an ore mining field, the coarse crushing, the middle crushing and the dry type magnetic separation work are directly carried out on the ore mining field, the purpose of early throwing and early discarding of the tailing waste rock is achieved, the grade of rough concentrate is improved, and the oretransportation amount is reduced, the ore transportation cost is reduced, the service life of a belt and a funnel lining plate of the magnetic separator is prolonged, so that the operation cost of a mine is effectively reduced. The production system comprises a coarse crusher, a screening machine, a middle crusher, a magnetic separator, an adhesive tape conveyor I and an adhesive tape conveyor IIwhich are sequentially arranged in an ore mining field according to a production line, wherein the adhesive tape conveyor I is used for transporting the tailing waste rock which is subject to the magnetic separation to a waste dump, and the adhesive tape conveyor II is used for conveying coarse concentrate which is subject to the magnetic separation to a subsequent process. The area of mining ironore is expanded, the system is especially worthy of popularization and application for our country mineral facts taking the lean iron ore as a main body.

Owner:马钢集团设计研究院有限责任公司

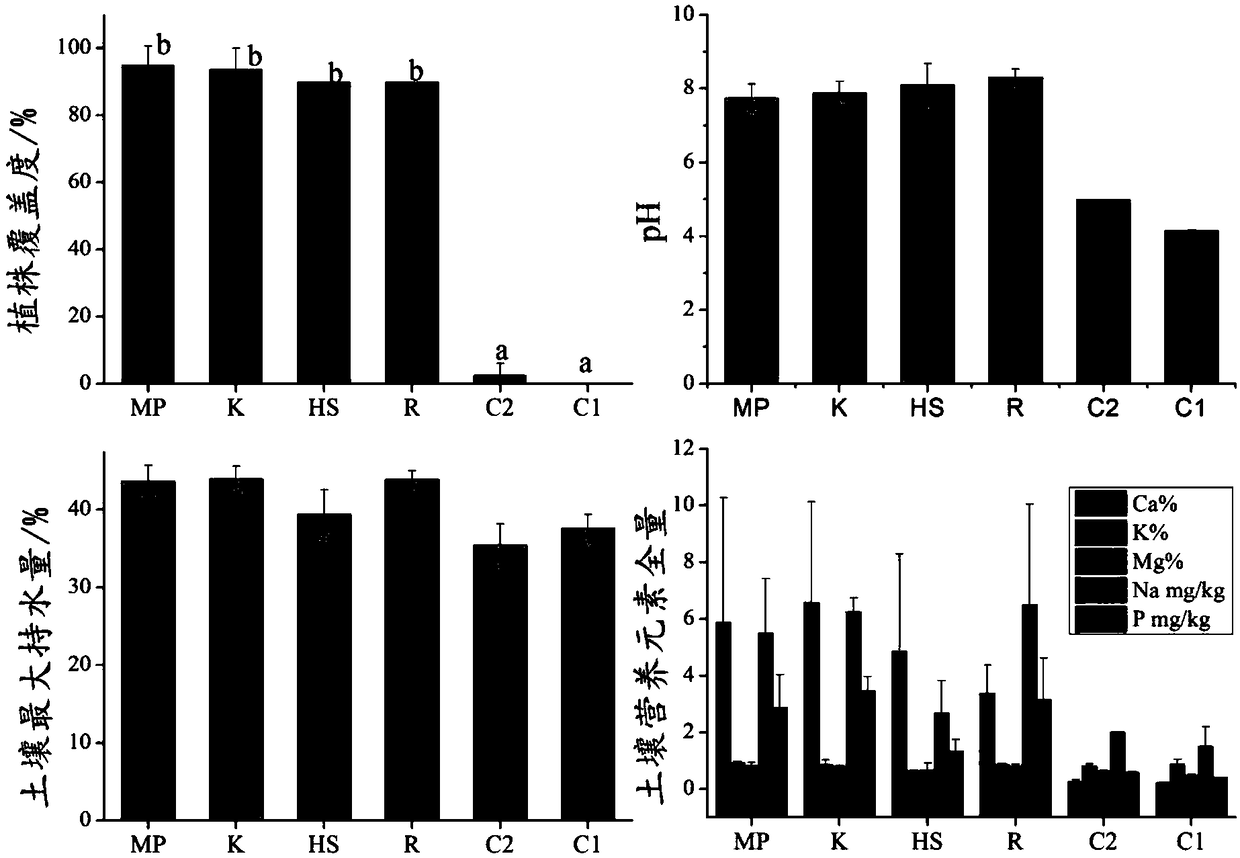

Method for stabilizing waste-dump heavy metal of polymetallic mine with biochar-manure compounded ameliorant and plant isolating layer

The invention discloses a method for stabilizing waste-dump heavy metal of polymetallic mine with biochar-manure compounded ameliorant and plant isolating layer. Through the research and development of the ameliorant and the screening of vegetation planting modes, the improved and stable effects of a soil conditioner are combined, and the compact isolating layer is formed by leguminosae seeds, commercial herbal seeds, Chinese silvergrass and eucalypts, and therefore the oxidation of the heavy metal (such as Pb, Zn, Cu, Cd) is effectively inhibited, the releasing of heavy metal and H+ ions is also inhibited, the loss of the heavy metals at the waste-dump is reduced.

Owner:SUN YAT SEN UNIV

Manufacturing method of composite regenerated coal and its use

InactiveCN1948445AReduce the burden onReduce occupancySolid fuelsWaste based fuelEngineeringPulverized fuel ash

A production method of Composite and renewable coal and its usage, solving that people always forsake coal cinder as waste in the present technology. The inadequacy of this is: while wasting a lot of energy which can be second used, also increasing quantity of rubbish, increasing quantity of transportation. Increase the burden of dumping grounds, occupy valuable land. Its characteristic is that coke is extracted from coal cinder and coal ash, then matched with run-off-the-mine, charcoal powder, yellow soil, calcined lime, calcium dioxide, soil nitre and kalium permanganicum according to appreciable proportion to be mixed uniformly, forming coal is produced and it can be used. Its good quality is: utilization of waste material. while saving a lot of energy which can be second used, also decreasing quantity of rubbish, decreasing quantity of transportation. Decrease the burden of dumping grounds and land occupying. Its fixed carbon is more than no smoke broken run-off-the-mine which is the kind of Zero number. The cost is low. Coal ash can directly put in soil after burned, improving soil. Social effects, social effects, environment effects are significant. It can be used to produce forming coal for burning.

Owner:余诚容

Novel maggot killing tablet

The invention discloses a novel larvicide block agent, which is characterized in that the block body is molded by mixing clay, sawdust, slow release material and floating material according to a certain ratio. The content of the effective constituent is 25 percent; 25 percent of dichlorvos larvicide block agent is formed by absorbing 80 percent of dichlorvos cream on the block after baking the effective constituent; the manufacturing technique is mixing and pressing clay and sawdust into a block, baking, absorbing, packaging, and warehousing the block after inspection. Compared with traditional flyheaded larvicide, the invention has advantages of saving time and labor, no need of any equipment, convenience and efficiency, and is suitable to be applied to a dry pail latrine in a village, and environmental treatment of a dump.

Owner:SHANXI YANGQUAN SHUANGQUAN CHEM FACTORY

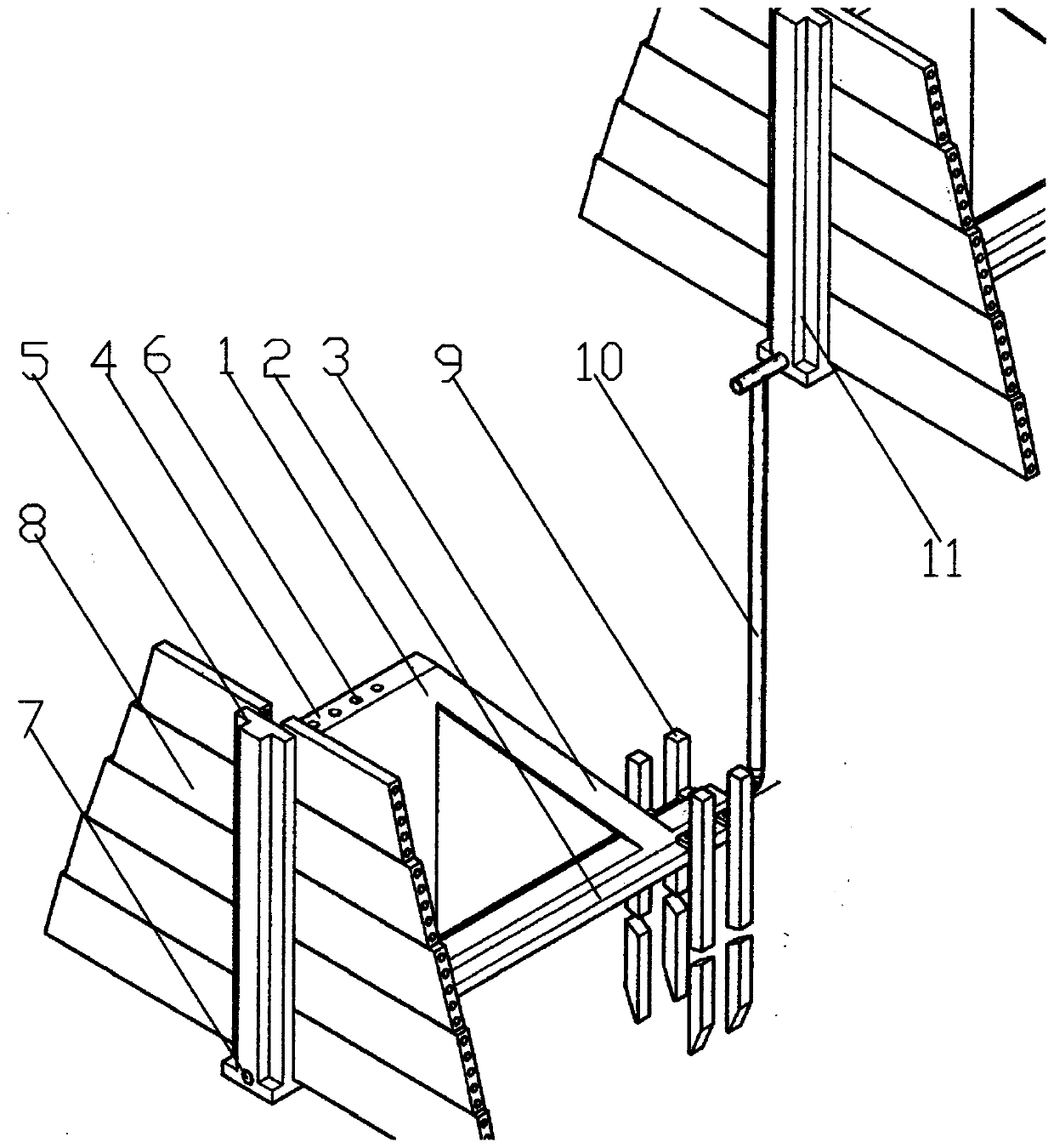

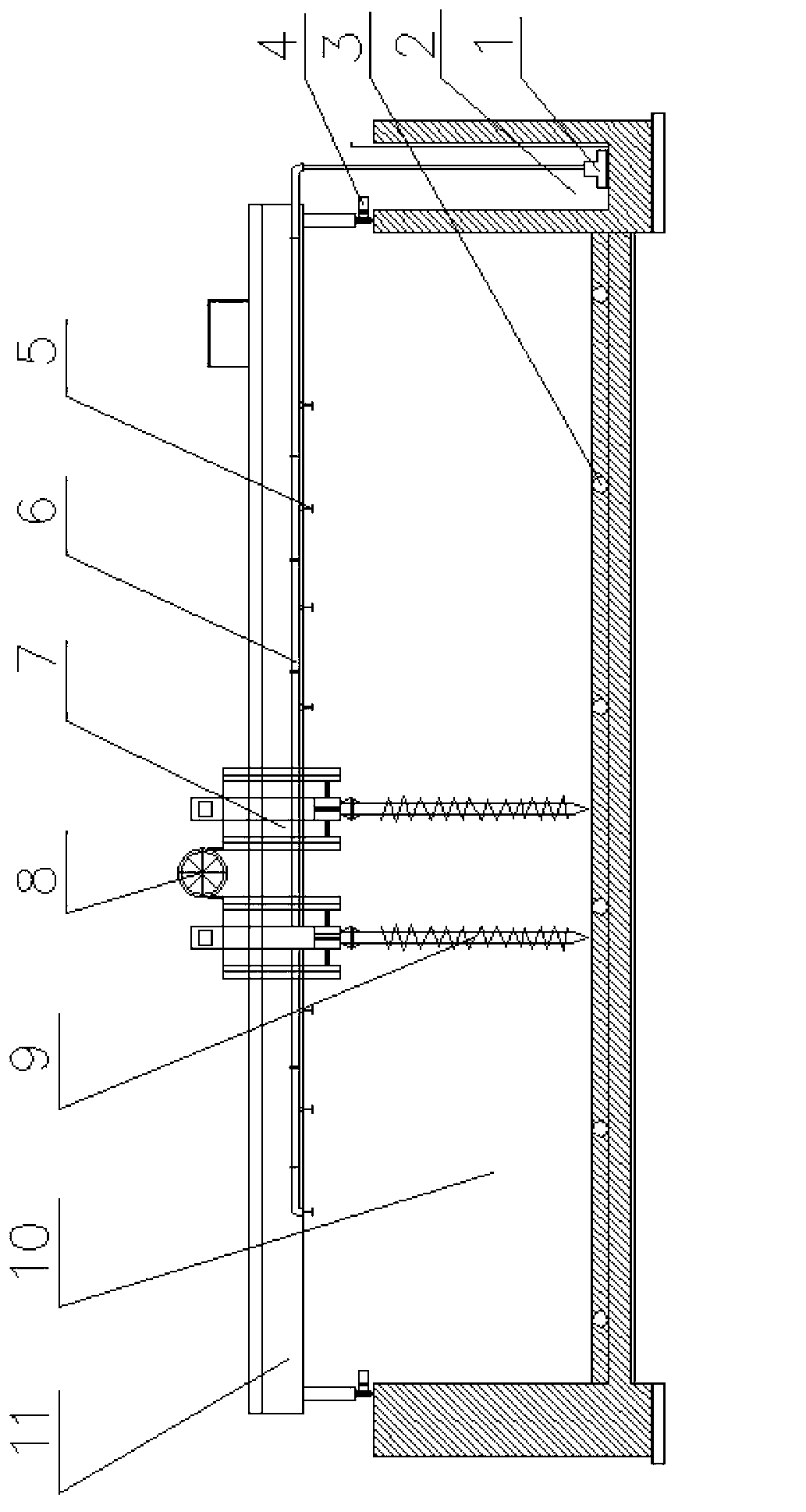

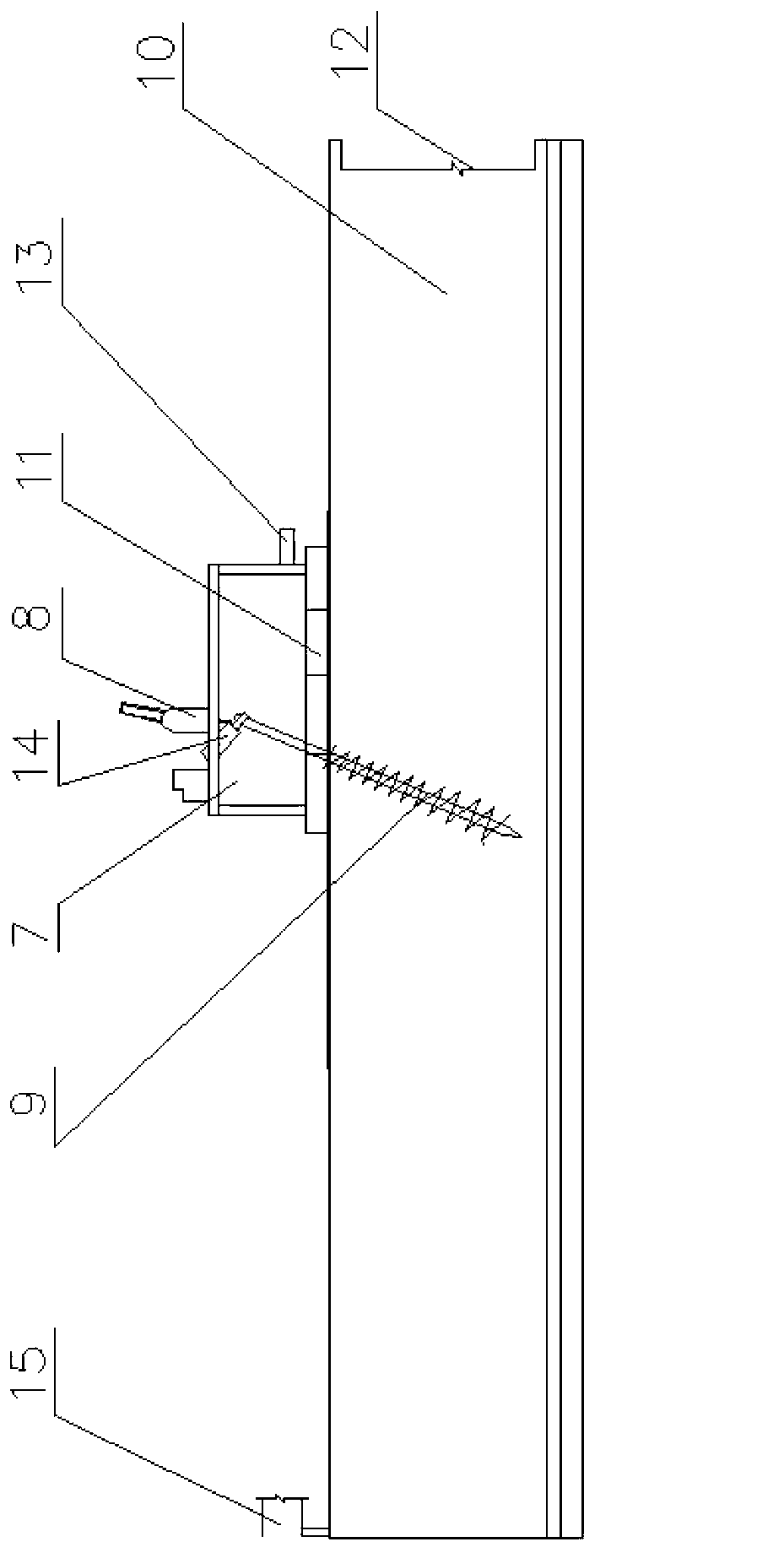

Quick assembling component type protective system of waste dump edge slope

The invention discloses a quick assembling component type protective system of a waste dump edge slope. The edge slope construction characteristics of the protective system are that vertical slope lowsteps plus layered horizontal large platform, the problem that the inclined slope of a conventional waste dump in the overlooking range is solved; and the edge slope protective system is characterized in that sand is blocked, water is drained, muddy water is changed to clear water, the whole is broken into parts, obvious modes are replaced by hidden modes, and water and soil loss of the waste dump is eliminated thoroughly; the edge protection is characterized in that a 100% soil blocking protective plate is obtained through a slope with inclined degree larger than 10 degrees, and thus slope permanent stability is guaranteed; and the characteristics of slope ecological restoration is that 100% edge slope greening is achieved in 3-6 months.

Owner:GUANGDONG ANYUAN MINING TECH SERVICE

Manure treatment system

InactiveCN103073167ASimple structureEasy and flexible operationClimate change adaptationExcrement fertilisersHuman wasteLiquid manure

The invention discloses a manure treatment system, which is characterized in that a beam is arranged above a corridor-like manure treatment pond, wherein a stirring device is mounted on the beam; the stirring device is provided with an underneath type spiral stirring rod; a radial oil cylinder is mounted on the upper end of the spiral stirring rod; a blower and a transverse engine are mounted on the stirring device; a manure pipe is arranged on one side of the beam; multiple manure nozzles are arranged on the manure pipe; a longitudinal sliding mechanism is mounted between both sides of the beam and the side wall of the manure treatment pond; a liquid manure groove is arranged in one side of the manure treatment pond; a manure pump is mounted in the manure groove; the manure pump is communicated with the manure pipe on the beam; and a blast pipe is mounted at the bottom of the manure treatment pond. The manure treatment system solves the problems of incompleteness in fermentation and environmental pollution when the manure is treated by performing aerobic fermentation with anaerobic biogas or filled strains, and is widely used for treating animal wastes of a farm and treating human wastes and organic substances in the urban garbage dump.

Owner:青岛派如环境科技有限公司

Composite microorganism preparation for air deodorization and application of composite microorganism preparation

InactiveCN111909865AQuality improvementImprove the living environmentGas treatmentBacteriaBiotechnologyPseudomonas putida

The invention discloses a microorganism preparation for air deodorization and an application of the microorganism preparation. Through synergistic reaction of lactobacillus acidophilus, streptococcusthermophilus, pseudomonas putida, rhodopseudomonas palustris, bacillus pumilus and enterococcus faecium, propagation of germs can be effectively restrained. The concentration of odor comprising ammonia gas, hydrogen sulfide and the like in air of places of toilets, farms, waste yards and the like is reduced, odor production elements are inhibited, and therefore, the air quality and the living environment of people are remarkably improved. The production method provided by the invention is simple, is suitable for most existing fermentation processes and equipment, and is beneficial for large-scale promotion and application.

Owner:薛松晓

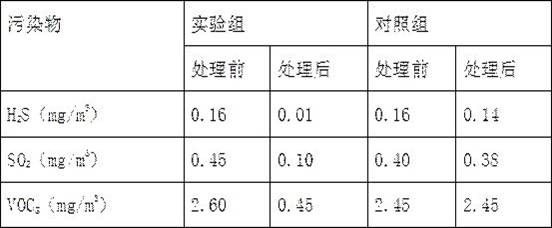

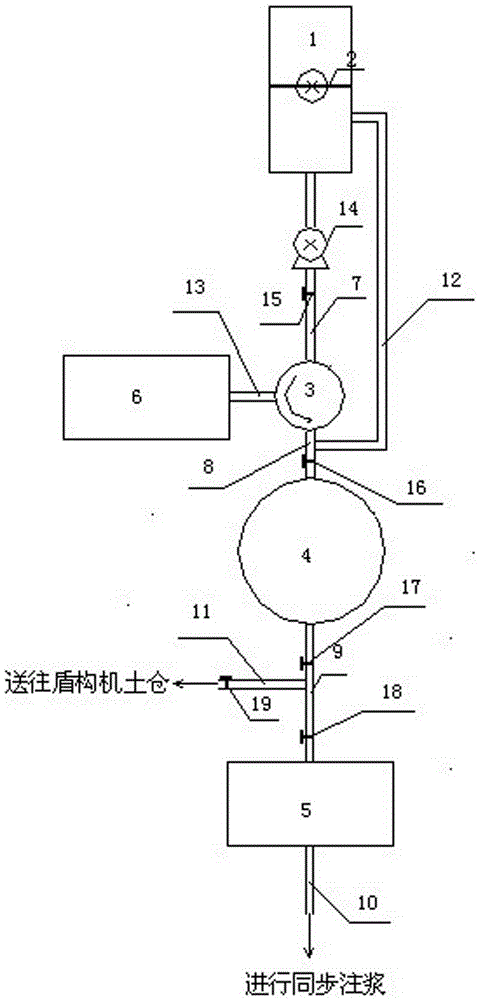

Method for Shield Tunneling Construction of Shield Tunneling Slag Purification, Recovery and Reuse System

ActiveCN103437786BReduce processing costsReduce consumptionUnderground chambersTunnel liningSludgeSlurry

The invention discloses a shield sludge cleansing / recycling / reusing system and method. The system comprises a slurry mixing pool (1), a mixer (2), a cyclone desander (3), a slurry storage tank (4), a mortar mixing station (5), a waste dump (6) and a pipeline. The shield sludge cleansing / recycling / reusing system and method have the advantages that the sludge generated in shield construction is cleansed and recycled so as to be reused as the raw material of shield synchronous grouting, so that the problems of large sludge waste amount and pollution on environment in the shield construction in the past and the problem of large consumption amount of raw materials such as shield synchronous grouting bentonite are solved, and therefore, the utilization amount of the bentonite is saved, the pollution on the environment caused by the waste sludge is reduced and the shield construction cost is also decreased. The system and the method provided by the invention further are characterized in that slurry prepared according to the slurry preparation ratio according to the invention is used for synchronous grouting in the mortar mixing station, the performance and the quality of grouting are the same with the performance and the quality of grouting by using the bentonite slurry, and the requirements of the shield construction can be met.

Owner:CHINA CONSTR COMM ENG GRP UNITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com