Process for processing glass fibre drawing sewerage

A treatment process, glass fiber technology, applied in the field of glass fiber drawing sewage treatment process, can solve the problems of serious environmental pollution, incomplete treatment process, etc., and achieve the effect of reducing COD value, low cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Taking the treatment of 5 tons of sewage as an example, first dissolve 15 kg of sodium hydroxide in 120 kg of industrial soft water and stir for 30 minutes, then dissolve 0.6 kg of anionic polyacrylamide in 100 kg of industrial soft water, and stir for 30 minutes. Pour sodium hydroxide solution, pay attention to dispersion, then pour 15kg of aluminum chloride, stir for 20 minutes, then pour 12kg of ferrous sulfate, pour it in evenly, pour slowly, continue stirring for a while, then slowly Pour the anionic polyacrylamide solution and stir until flocculent suspension appears.

[0018] After 1-2 days, the water stratified. The flocculent suspended matter was taken out and bagged, filtered and bagged and dumped into the garbage dump as garbage. The clean water continued to be used as water for mopping.

Embodiment 2

[0020] Taking the treatment of 10 tons of sewage as an example, first dissolve 30 kg of sodium hydroxide in 240 kg of industrial soft water and stir for 35 minutes, then dissolve 1.2 kg of anionic polyacrylamide in 200 kg of industrial soft water, and stir for 45 minutes. Pour sodium hydroxide solution, pay attention to dispersion, then pour 30kg aluminum chloride, stir for 30 minutes, then pour 24kg ferrous sulfate, pour it in evenly, pour slowly, continue stirring for a while, then slowly Pour the anionic polyacrylamide solution and stir until flocculent suspension appears.

[0021] After 1-2 days, the water stratified. The flocculent suspended matter was taken out and bagged, filtered and bagged and dumped into the garbage dump as garbage. The clean water continued to be used as water for mopping.

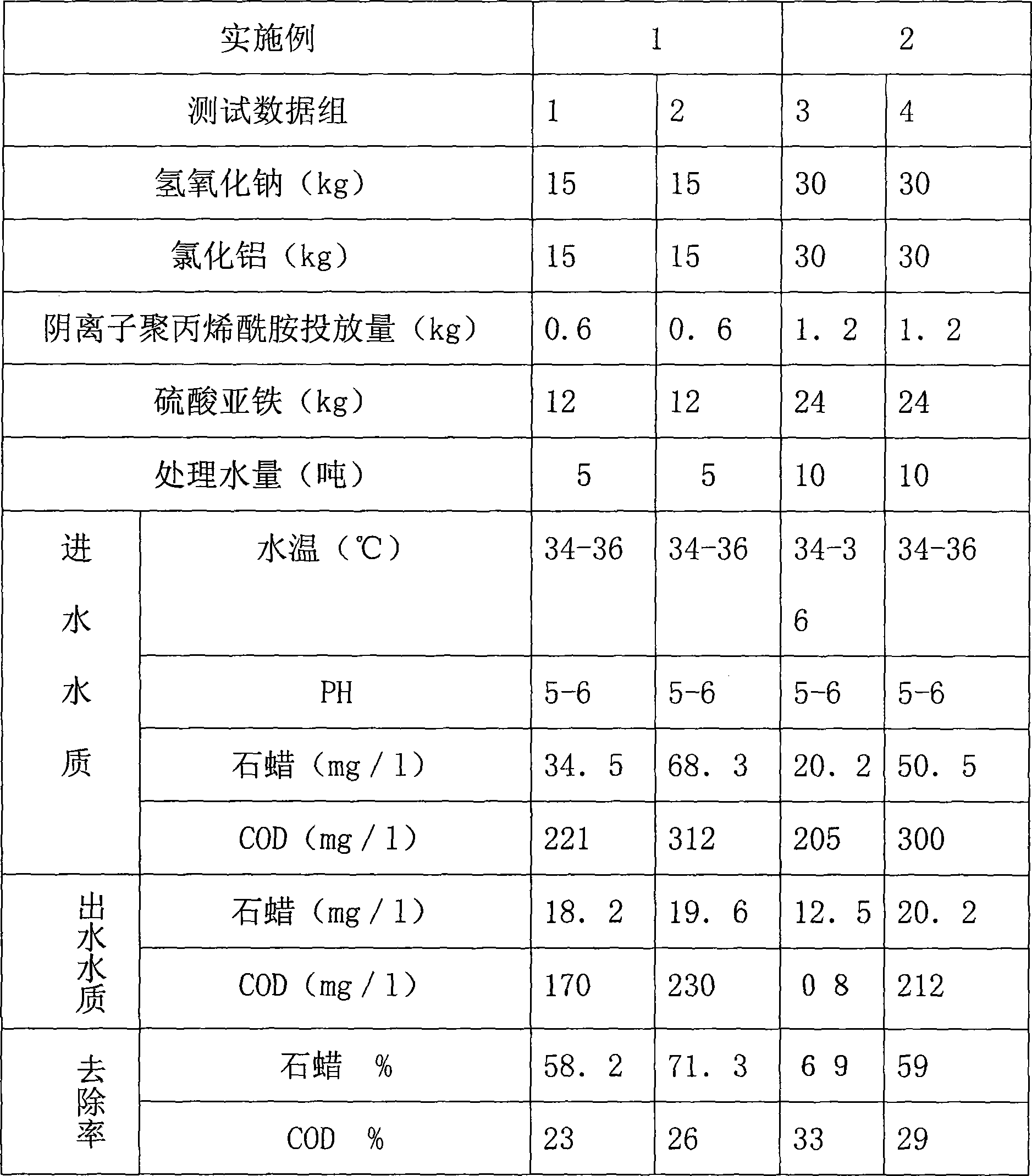

[0022] Table 1 shows the sewage treatment effects of Example 1 and Example 2:

[0023]

[0024] It can be seen from the experimental data that the treatment effect of paraffin wax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com