Composite microorganism preparation for air deodorization and application of composite microorganism preparation

A technology of compound microorganisms and preparations, applied in the field of microorganisms, can solve problems such as small application range, secondary pollution of chemical substances, and failure of deodorization efficiency, and achieve the effects of improving air quality, simple production methods, and inhibiting odor-producing elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

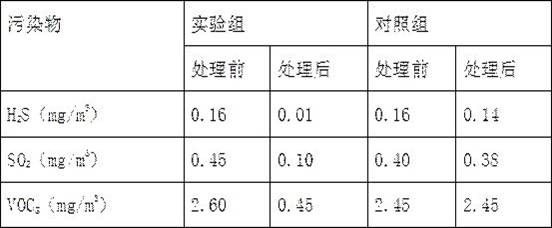

Examples

Embodiment 1

[0018] A deodorizing microbial preparation consisting of Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium, each component and its content are: 40 parts of Lactobacillus acidum, 25 parts of Streptococcus thermophilus, 450 parts of Pseudomonas putida, 10 parts of Rhodopseudomonas palustris, 15 parts of Bacillus pumilus and 20 parts of Enterococcus faecium.

[0019] The preparation method of above-mentioned deodorant microorganism preparation, comprises the steps:

[0020] 1) Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium were respectively fermented in high-density liquid, and the number of live bacteria in the fermentation broth was 200CFU the bacterial liquid;

[0021] 2) Prepare the bacterial liquid according to 40 parts of Lactobacillus acidophilus, 25 parts of Streptococcus thermophi...

Embodiment 2

[0023] A deodorizing microbial preparation, consisting of Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium, each component and its content are respectively: 48 parts of Lactobacillus acidum, 20 parts of Streptococcus thermophilus, 55 parts of Pseudomonas putida, 8 parts of Rhodopseudomonas palustris, 11 parts of Bacillus pumilus and 33 parts of Enterococcus faecium.

[0024] The preparation method of above-mentioned deodorant microorganism preparation, comprises the steps:

[0025] 1) Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium were respectively fermented in high-density liquid, and the number of viable bacteria in the fermentation broth was 200CFU the bacterial liquid;

[0026] 2) The bacterial solution was formulated according to 48 parts of Lactobacillus acidophilus, 20 parts of ...

Embodiment 3

[0028] A deodorizing microbial preparation, consisting of Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium, each component and its content are respectively: 48 parts of Lactobacillus acidum, 20 parts of Streptococcus thermophilus, 55 parts of Pseudomonas putida, 8 parts of Rhodopseudomonas palustris, 11 parts of Bacillus pumilus and 33 parts of Enterococcus faecium.

[0029] The preparation method of above-mentioned deodorant microorganism preparation, comprises the steps:

[0030] 1) Lactobacillus acidophilus, Streptococcus thermophilus, Pseudomonas putida, Rhodopseudomonas palustris, Bacillus pumilus and Enterococcus faecium were respectively fermented in high-density liquid, and the number of viable bacteria in the fermentation broth was 200CFU the bacterial liquid;

[0031] 2) The bacterial solution was formulated according to 44 parts of Lactobacillus acidophilus, 35 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com