Waste dump presser foot wall hanging concurrent construction method in open pit coal mine

An open-pit coal mine and internal dumping technology, which is applied in earth square drilling, surface mining, underground mining, etc., can solve problems such as lagging construction of internal dumping sites, loss of internal drainage space, and deterioration of initial economic benefits of open-pit mines, and achieves shortened The effect of construction cycle and capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

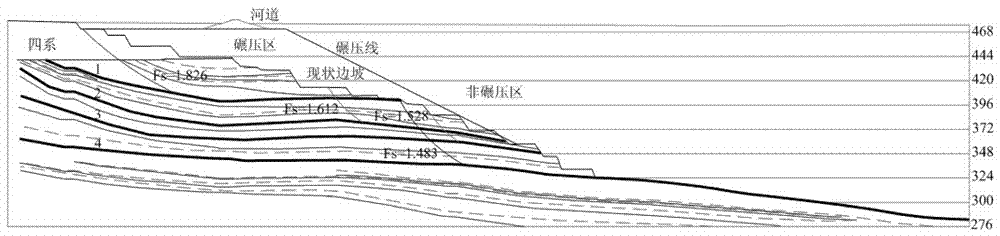

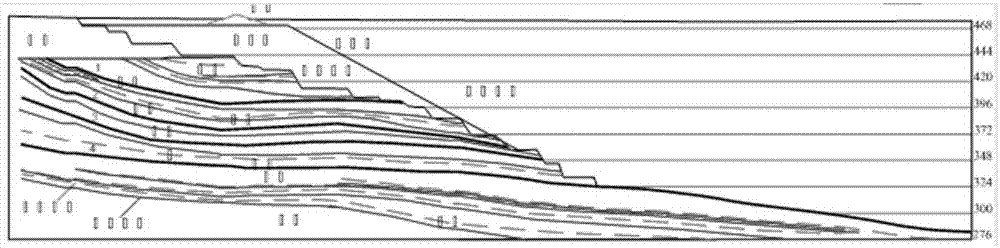

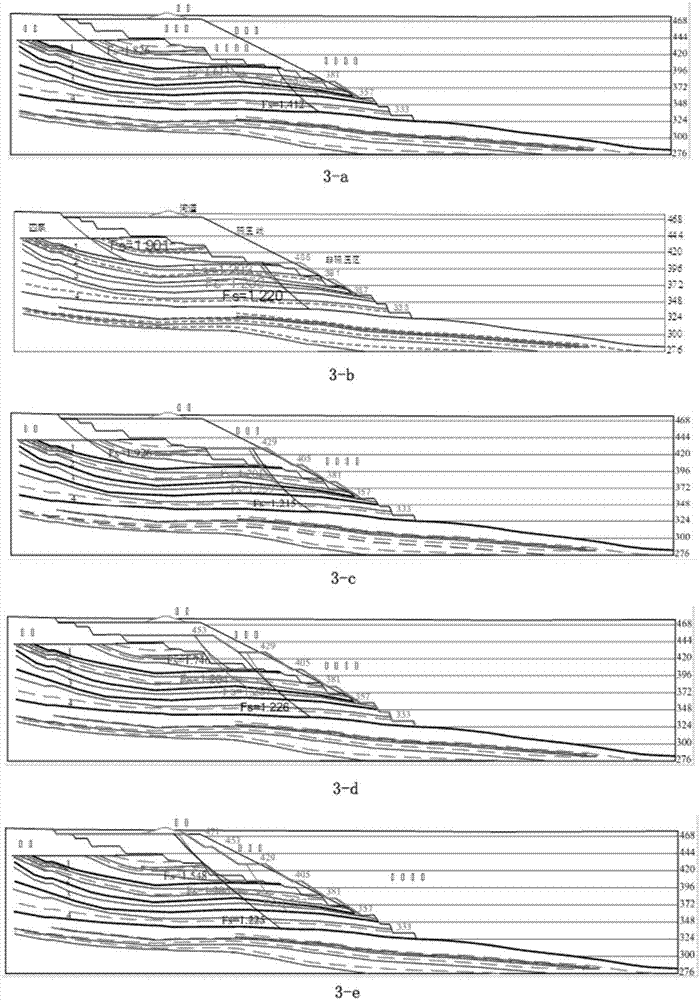

[0019] The open-pit mine plans to build a river channel on the inner dump. In order to control the settlement of the river channel, a certain section of the inner dump must be rolled in layers during the dumping process to form a rolled area and a non-rolled area. The stripping objects in this mining area are mainly Quaternary, Tertiary and Jurassic. The Quaternary strata are mainly composed of gravel, round gravel, and mud gravel, and the mud gravel is partially cemented; the Tertiary is mainly composed of fine sandstone, siltstone, and mud conglomerate; the Jurassic is mainly composed of sandstone, glutenite, siltstone and coal seam composition. The stope-to-boundary slope is part of the basement of the internal dump, and there are four weak carbonaceous mudstone layers (named 1, 2, 3, and 4 from top to bottom) inside it, which are prone to bedding landslides. The design final disposal elevation of the inner dump is +471m, the section height is 24m, the width of the flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com