Patents

Literature

201results about How to "Reduce transport volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

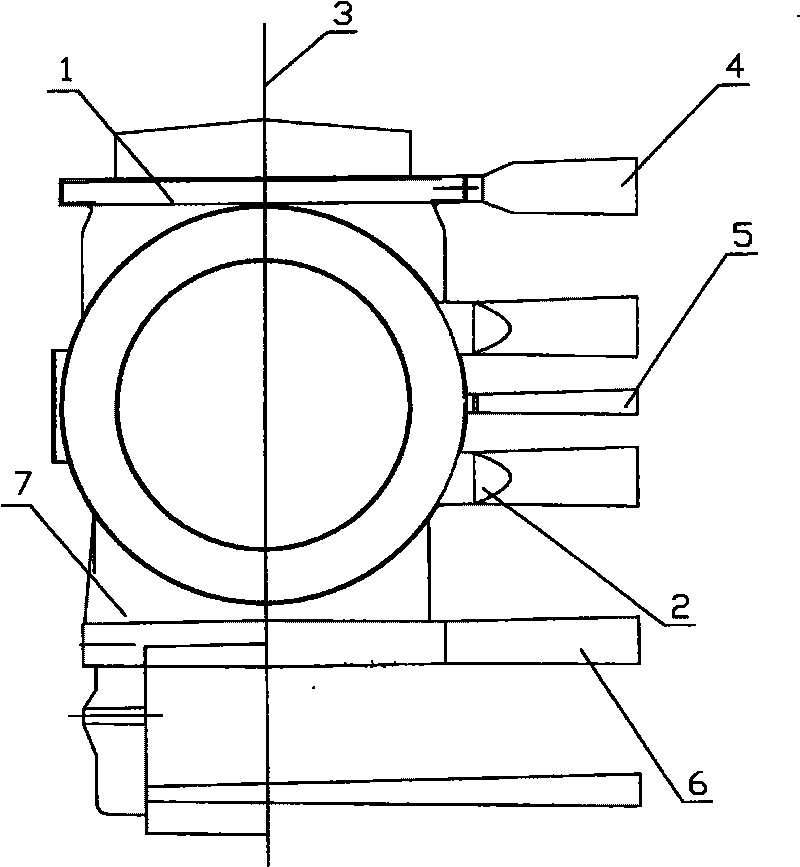

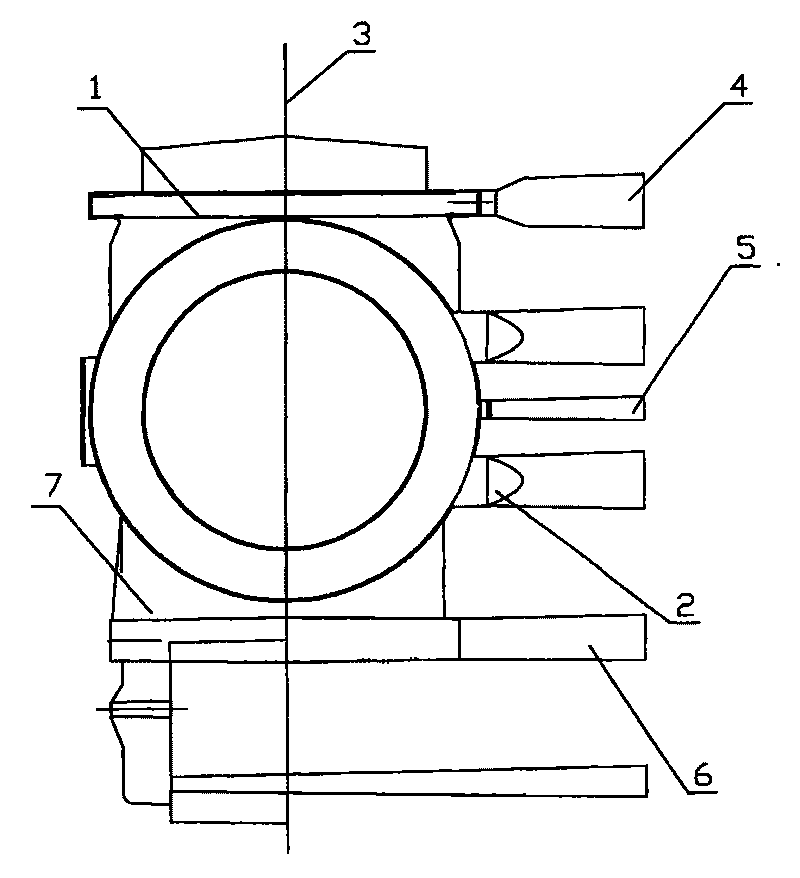

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

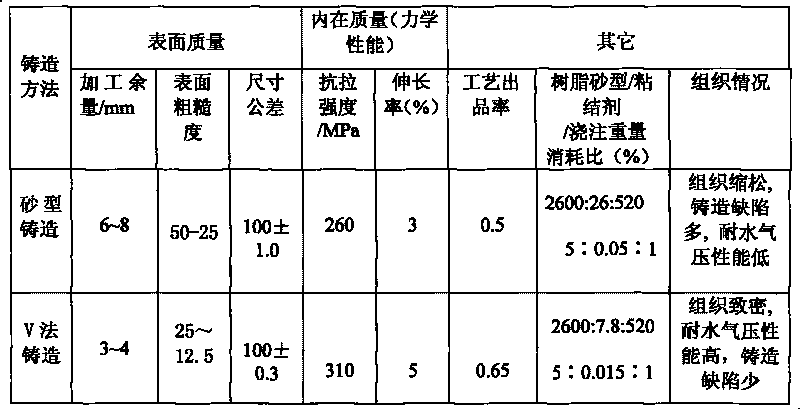

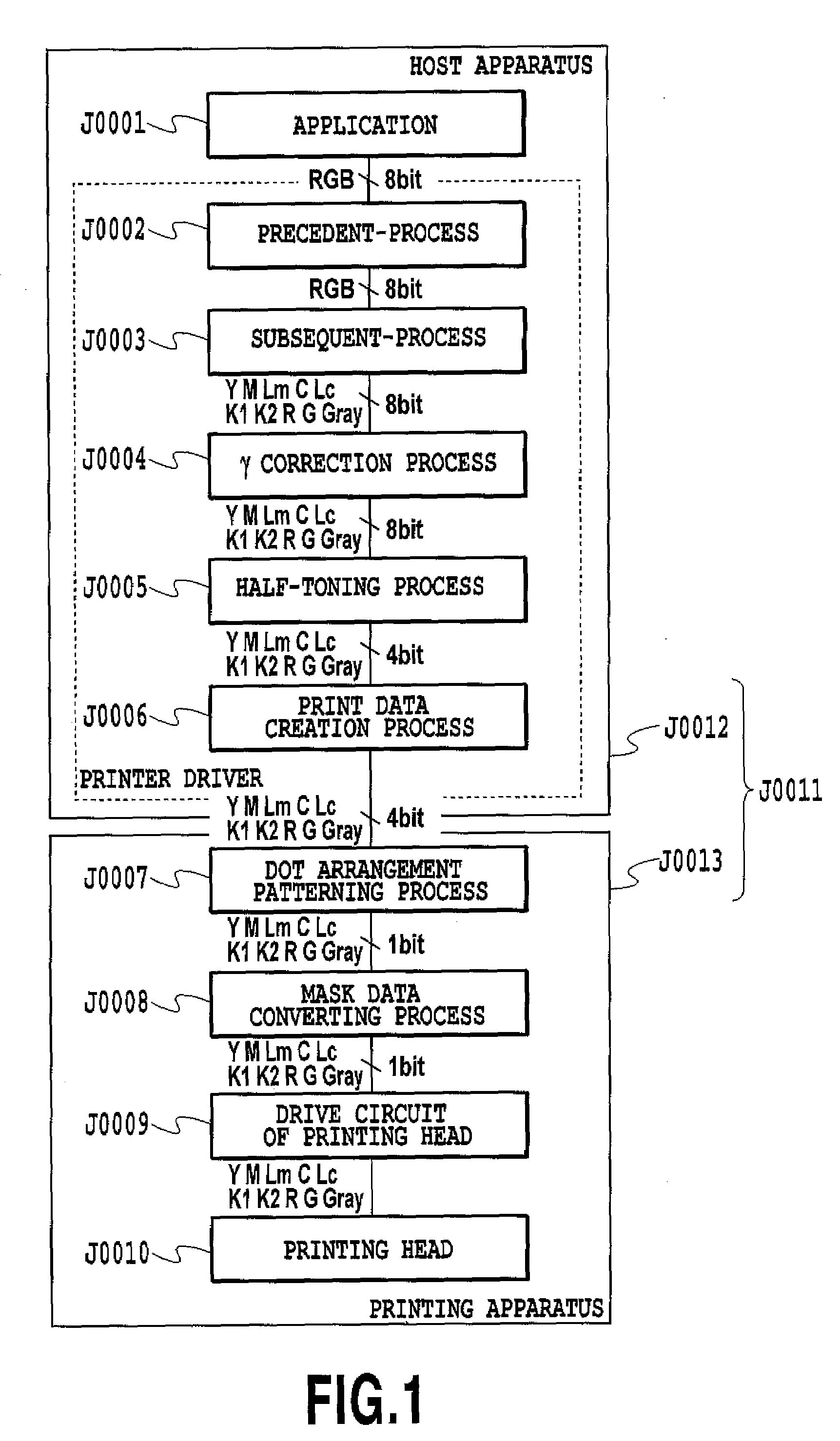

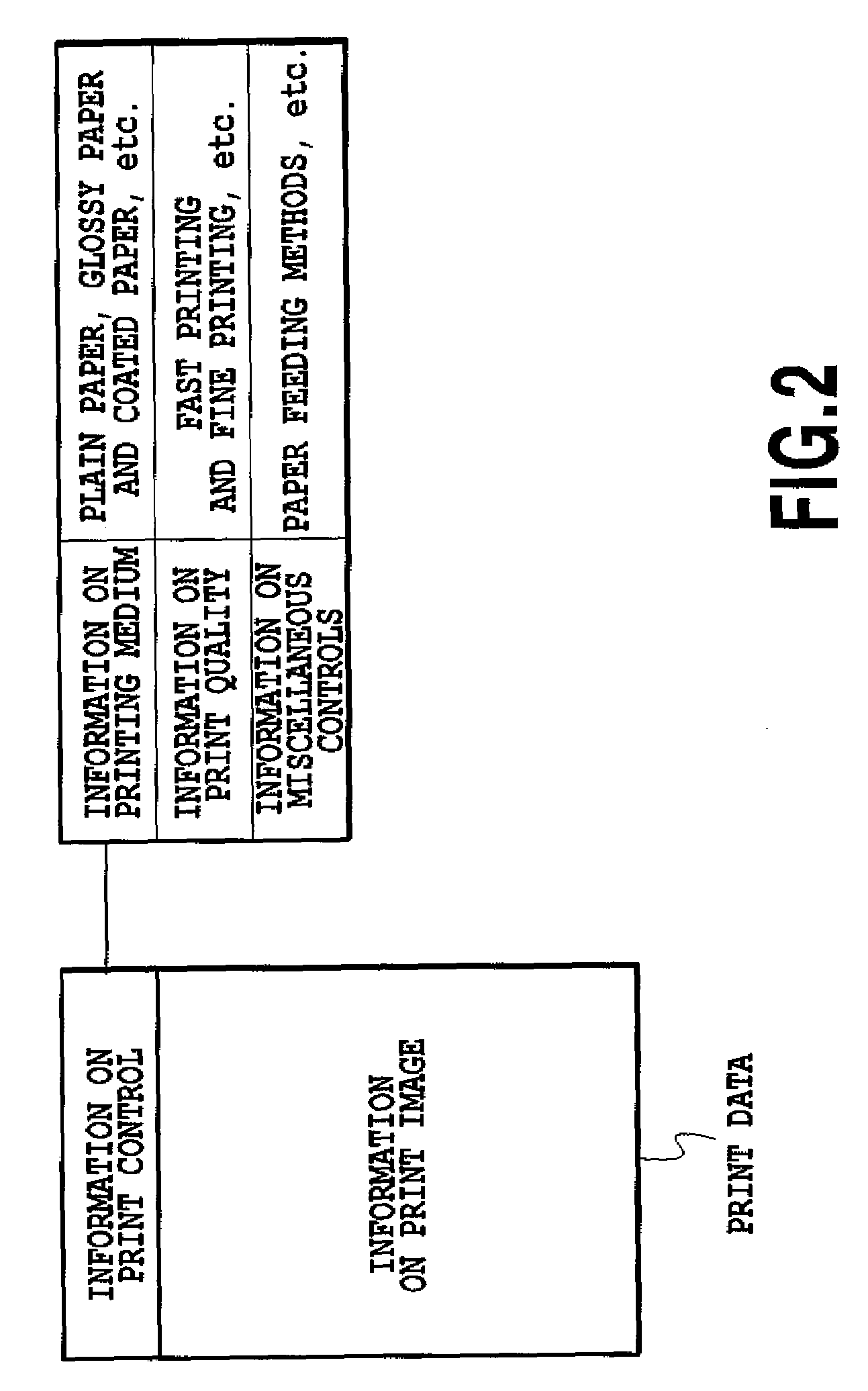

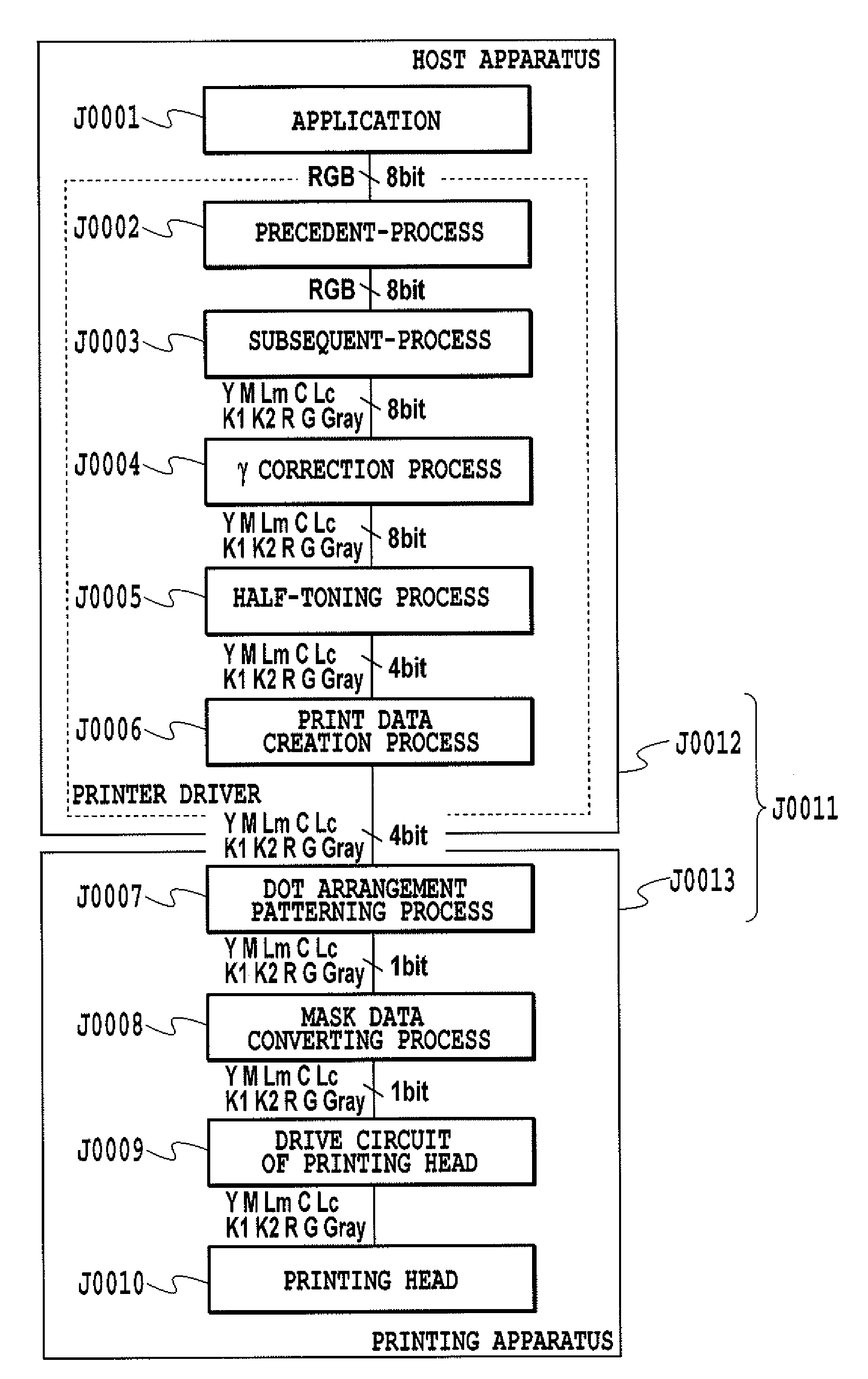

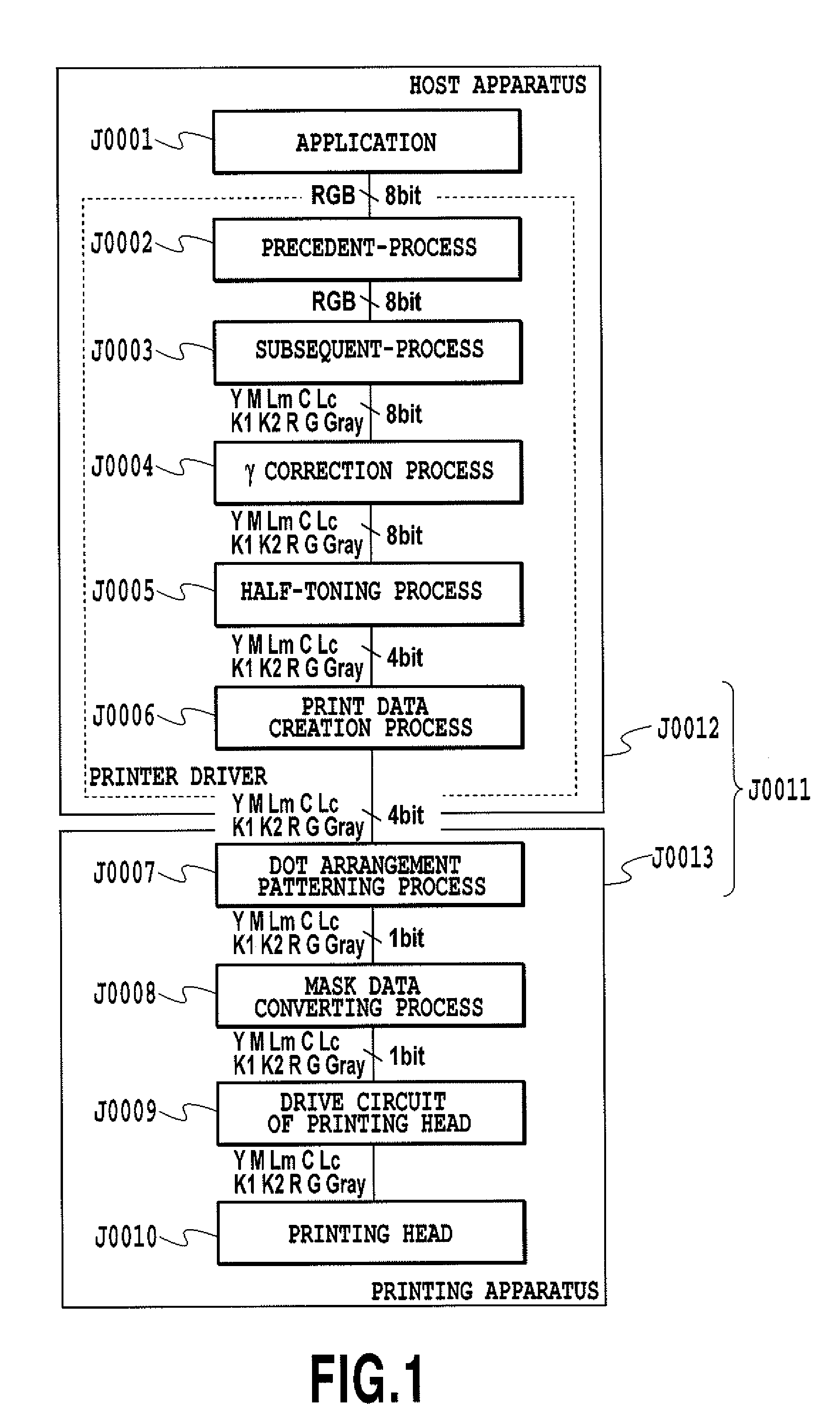

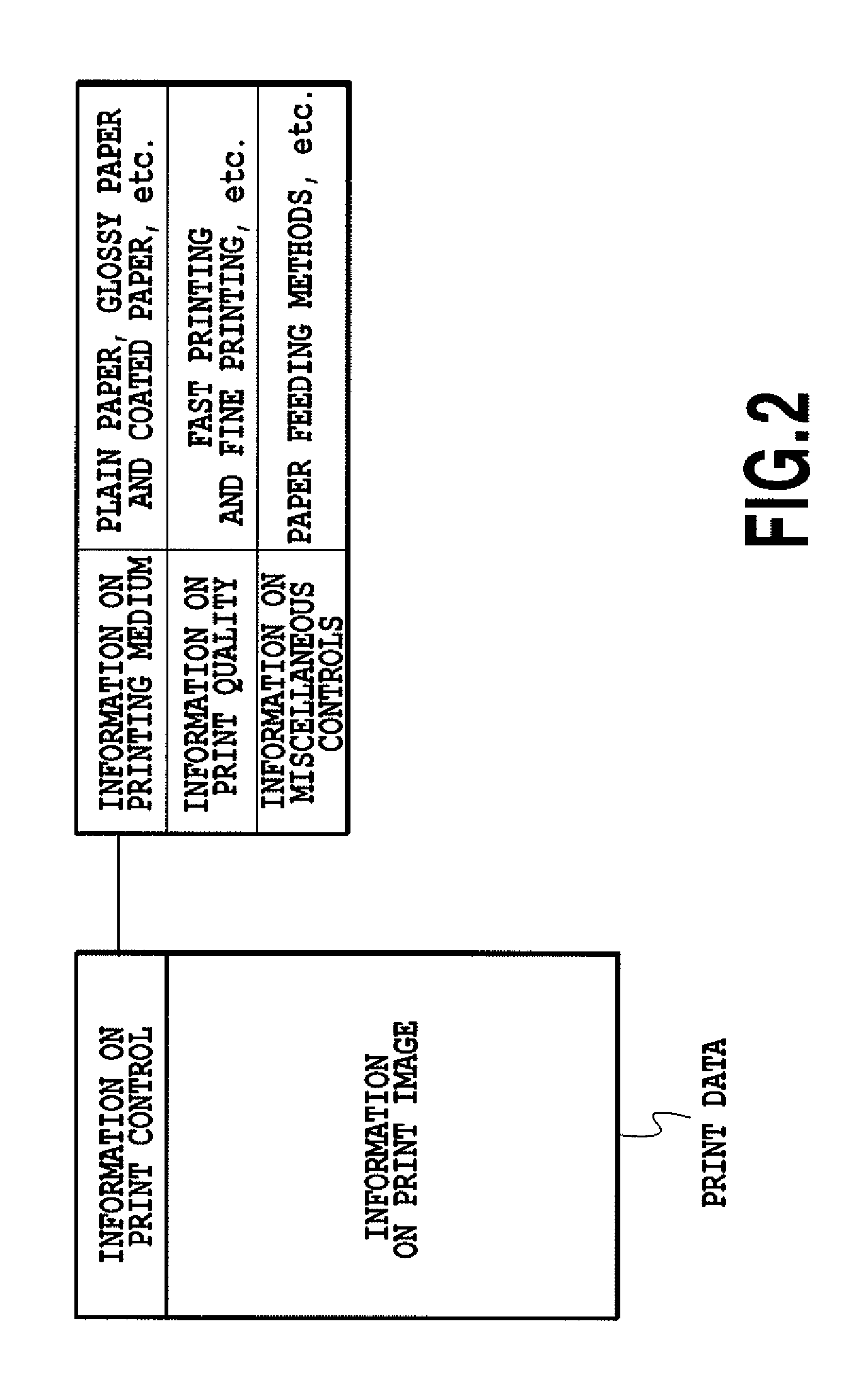

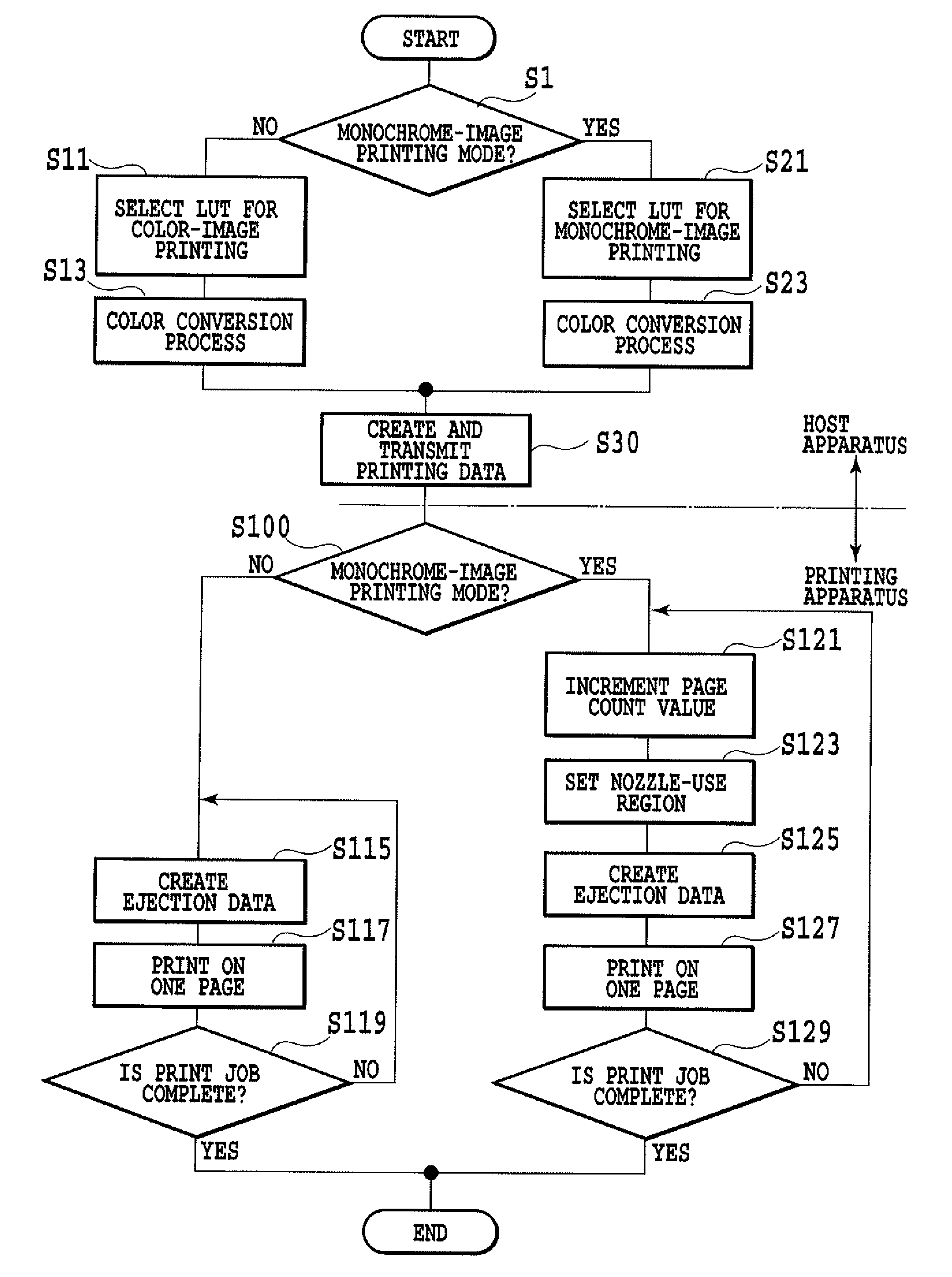

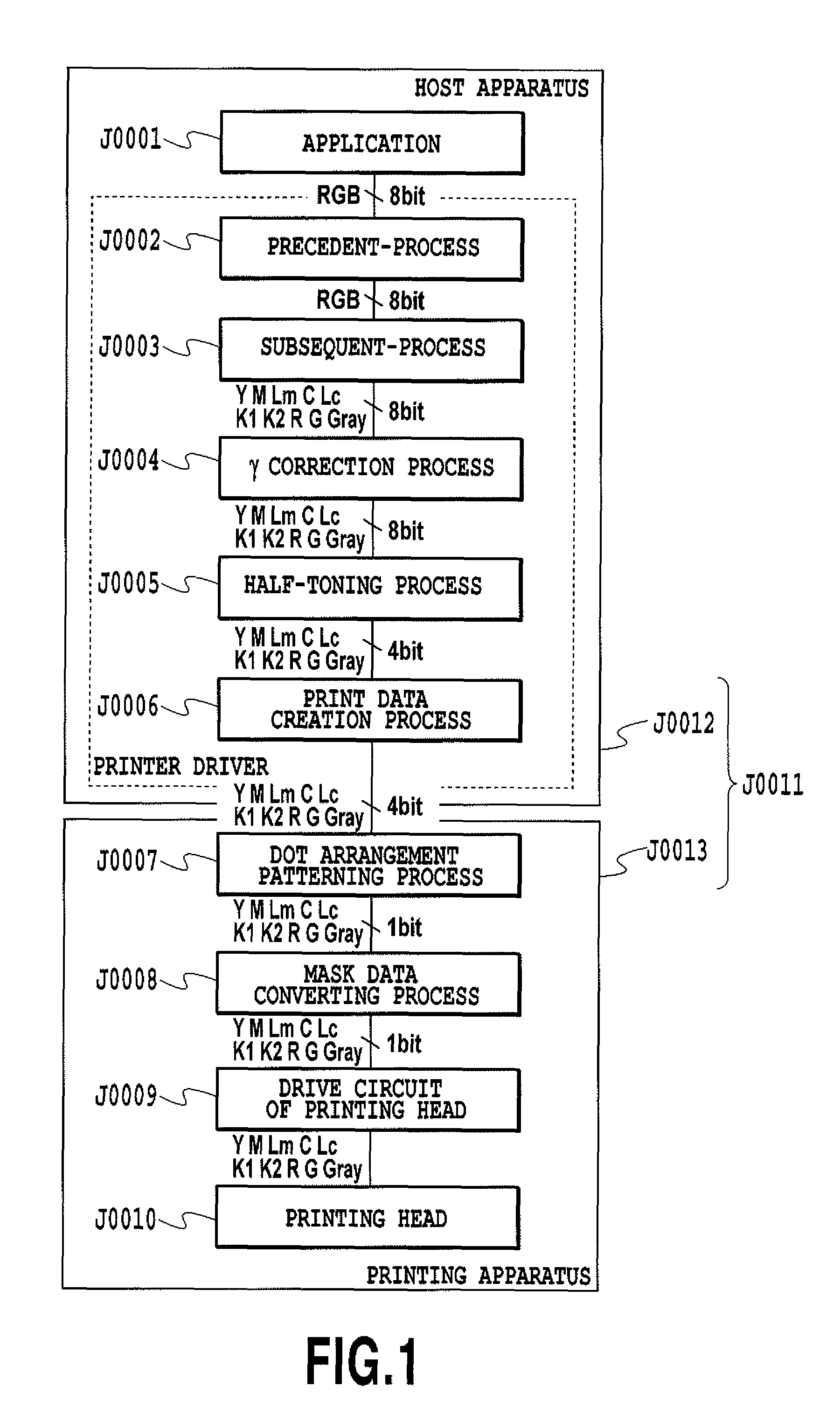

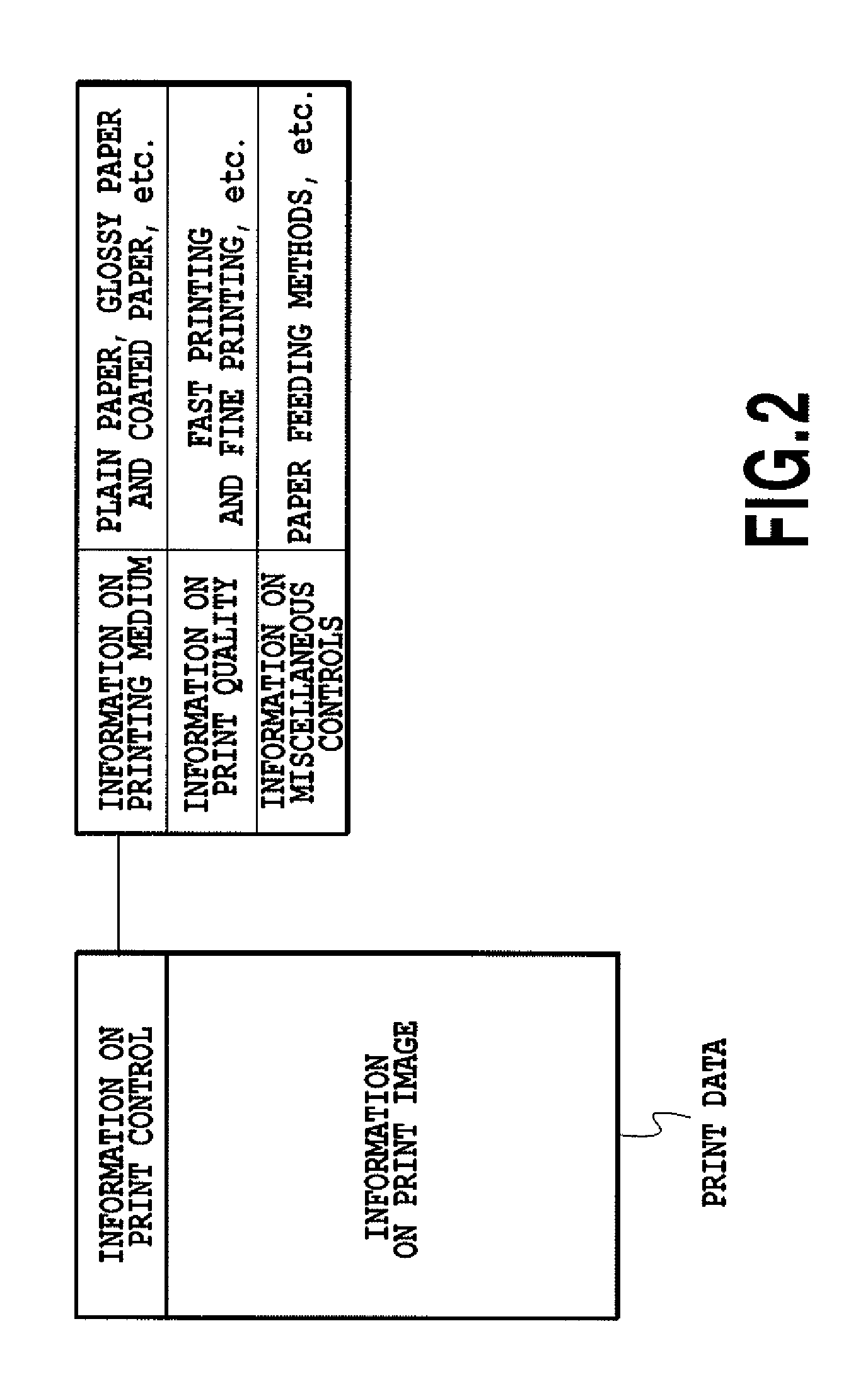

Ink jet printing apparatus and printing method

InactiveUS20070273899A1Inhibition biasInhomogeneous suppressionDigitally marking record carriersDigital computer detailsColor quantityElectrical and Electronics engineering

By suppressing deviation of dot-formation positions stemming from insufficient accuracy in conveying a printing medium due to eccentricity of a conveying roller, a printed image in which unevenness is less visible is obtained. An accumulated amount of conveyance errors is reduced by narrowing a nozzle-use range and by reducing a conveyance amount over an entire printing region according to the number of colors to be used and desired printing quality in printing an image. Moreover, the nozzles used when the nozzle-use range is narrowed are not fixed, and are switched to be used as appropriate. This prevents only certain nozzles from being used concentratedly, and allows all of the nozzles to maintain substantially the same ejection performance.

Owner:CANON KK

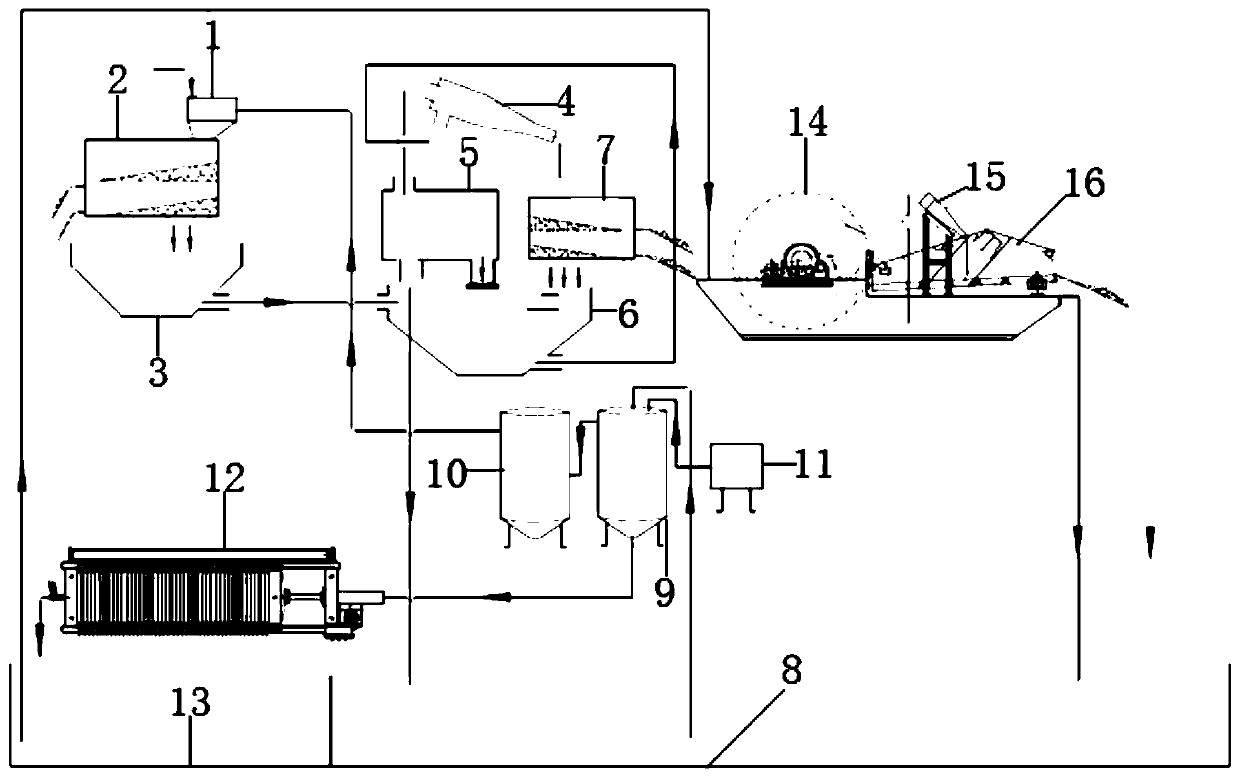

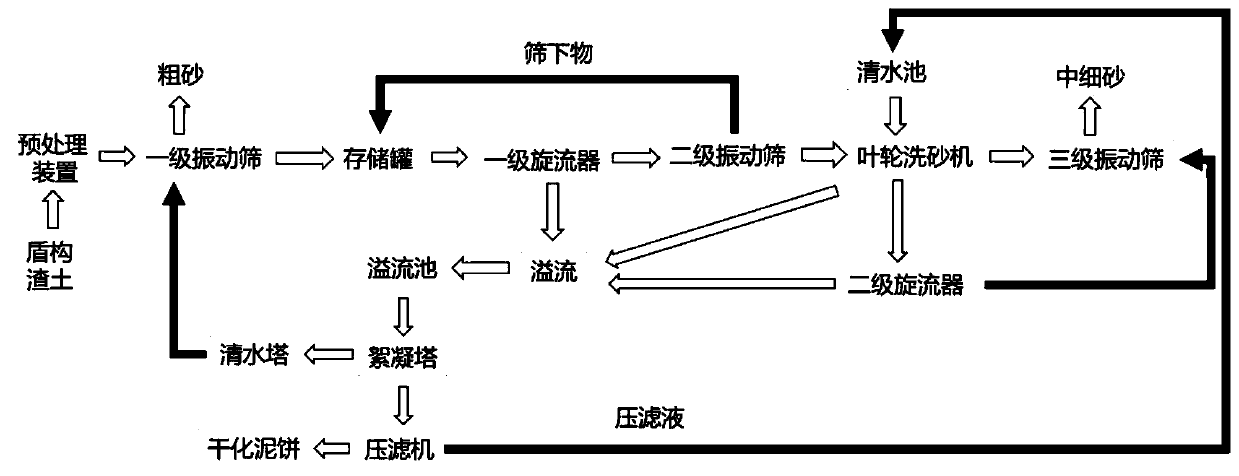

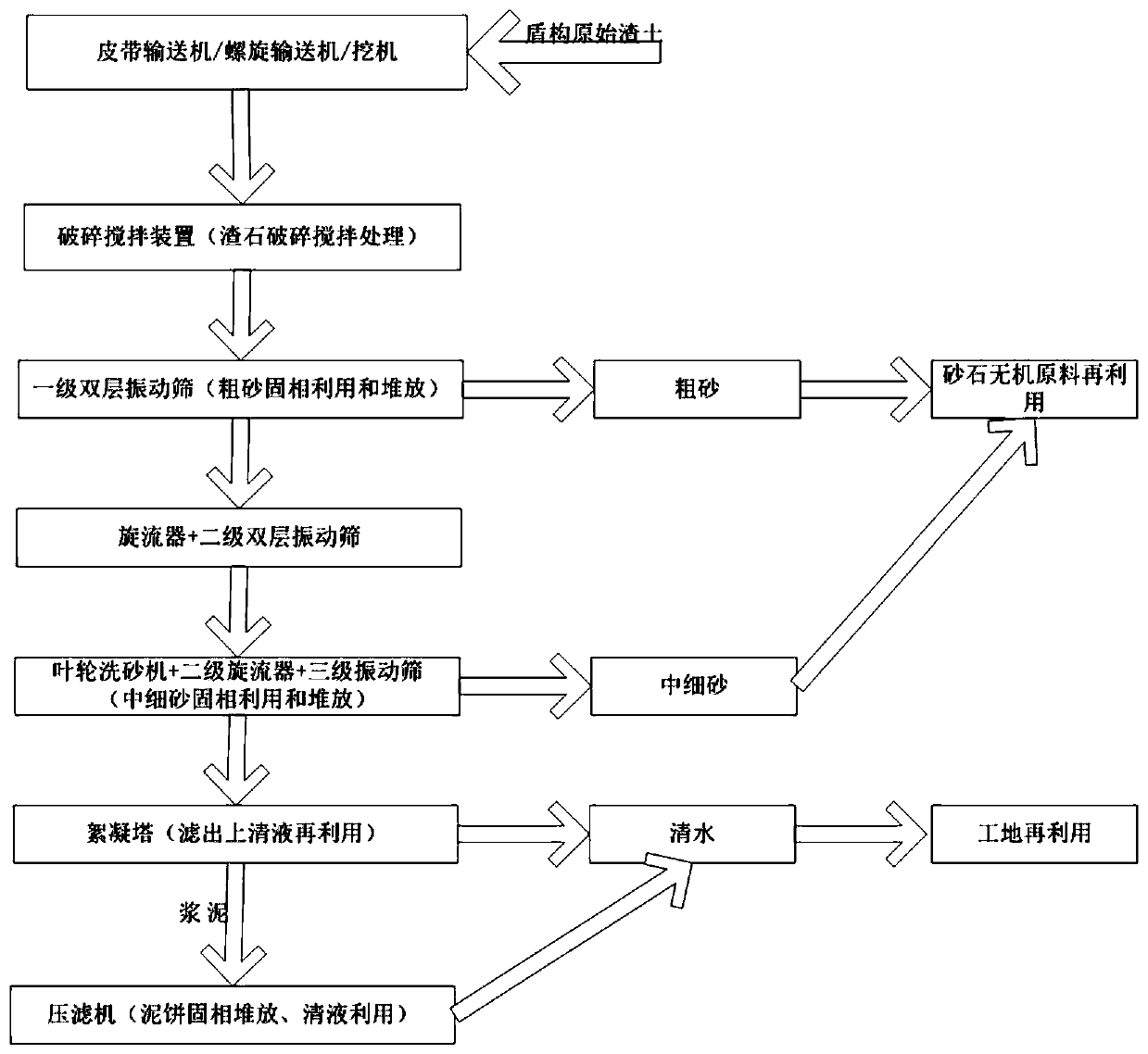

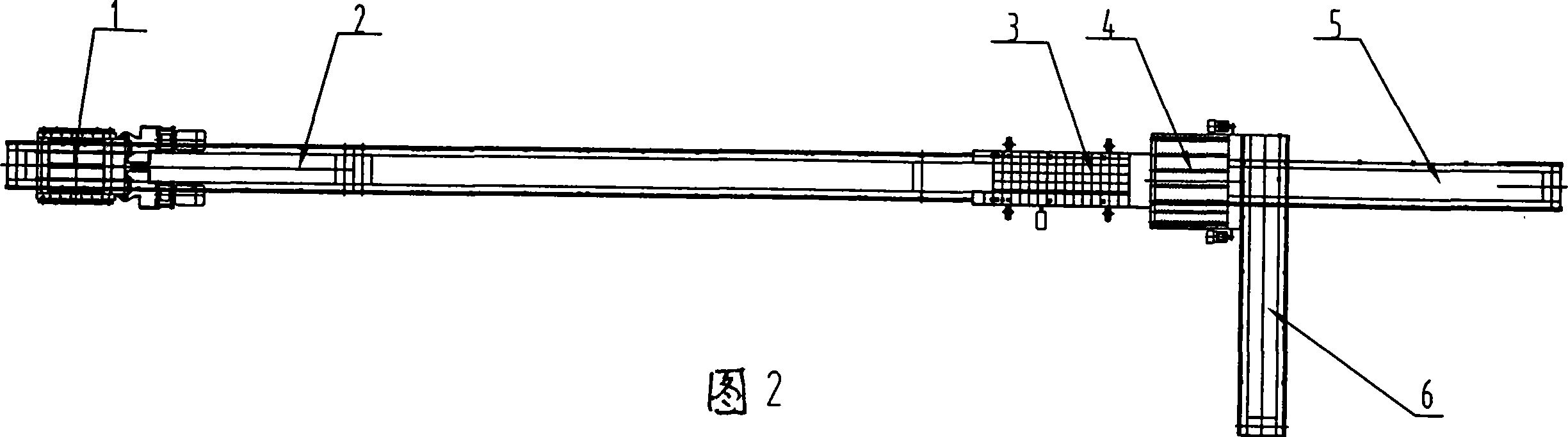

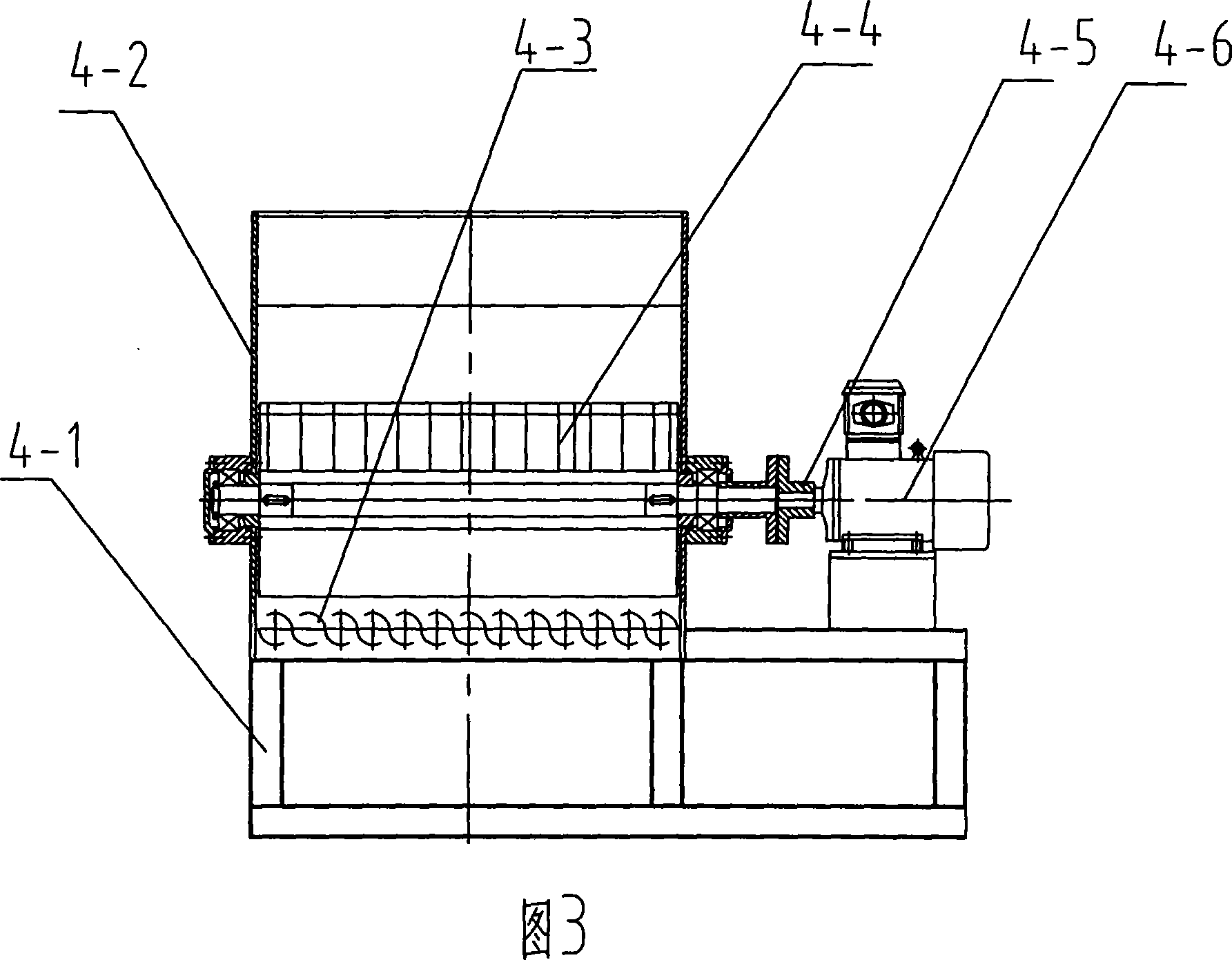

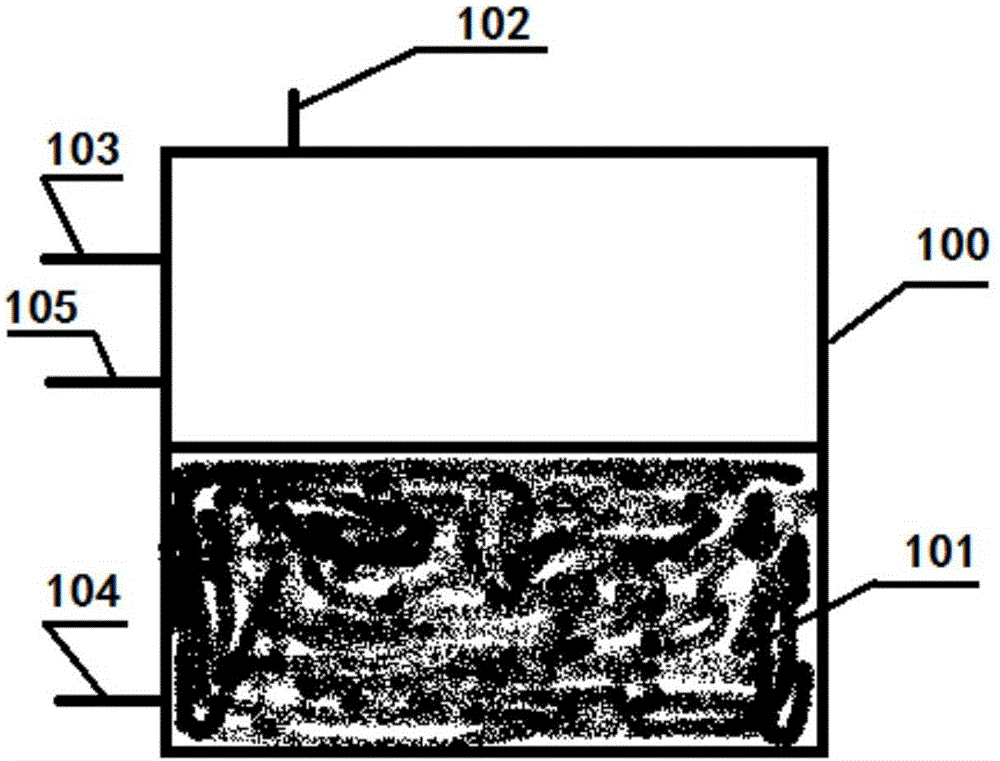

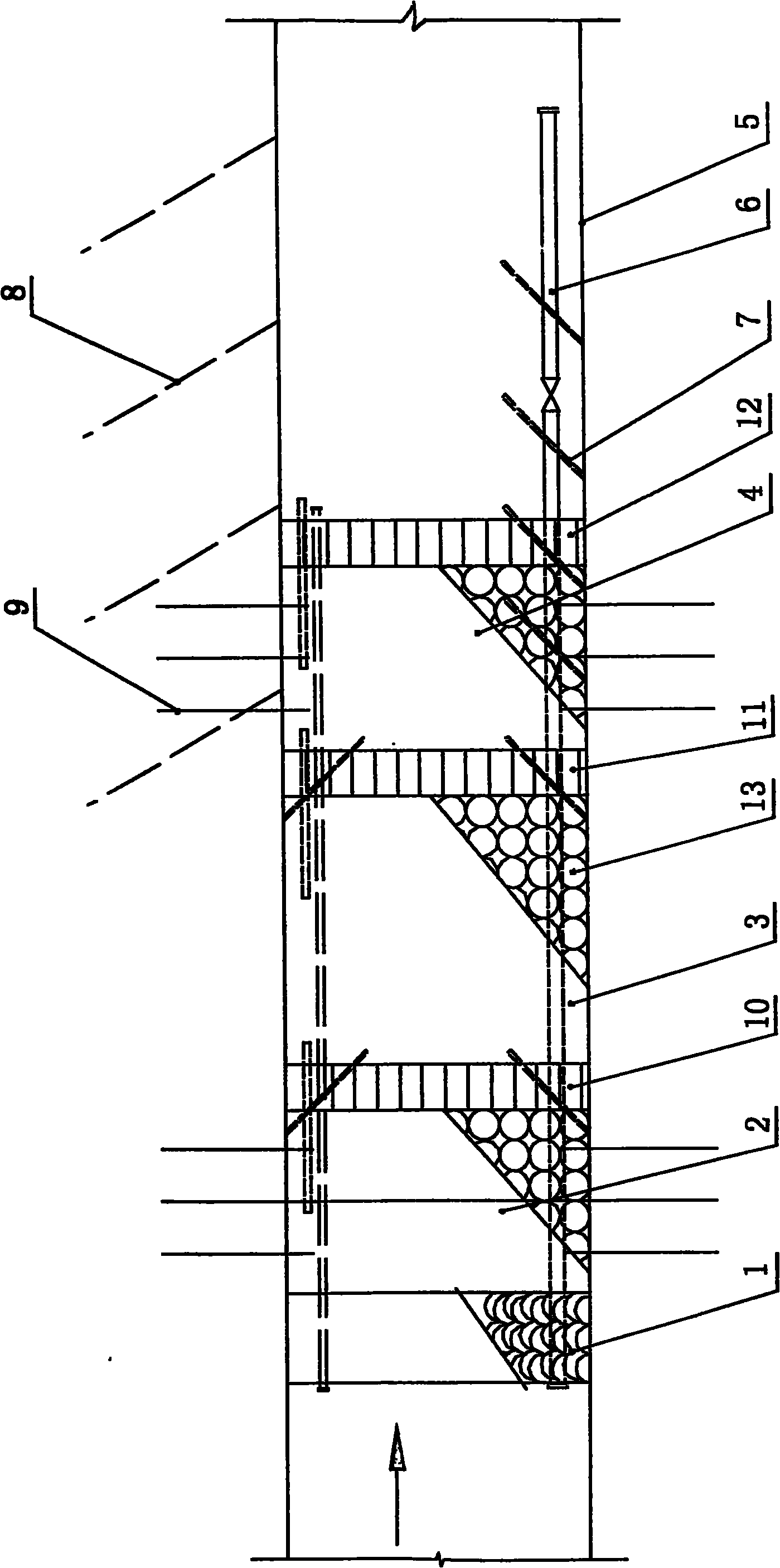

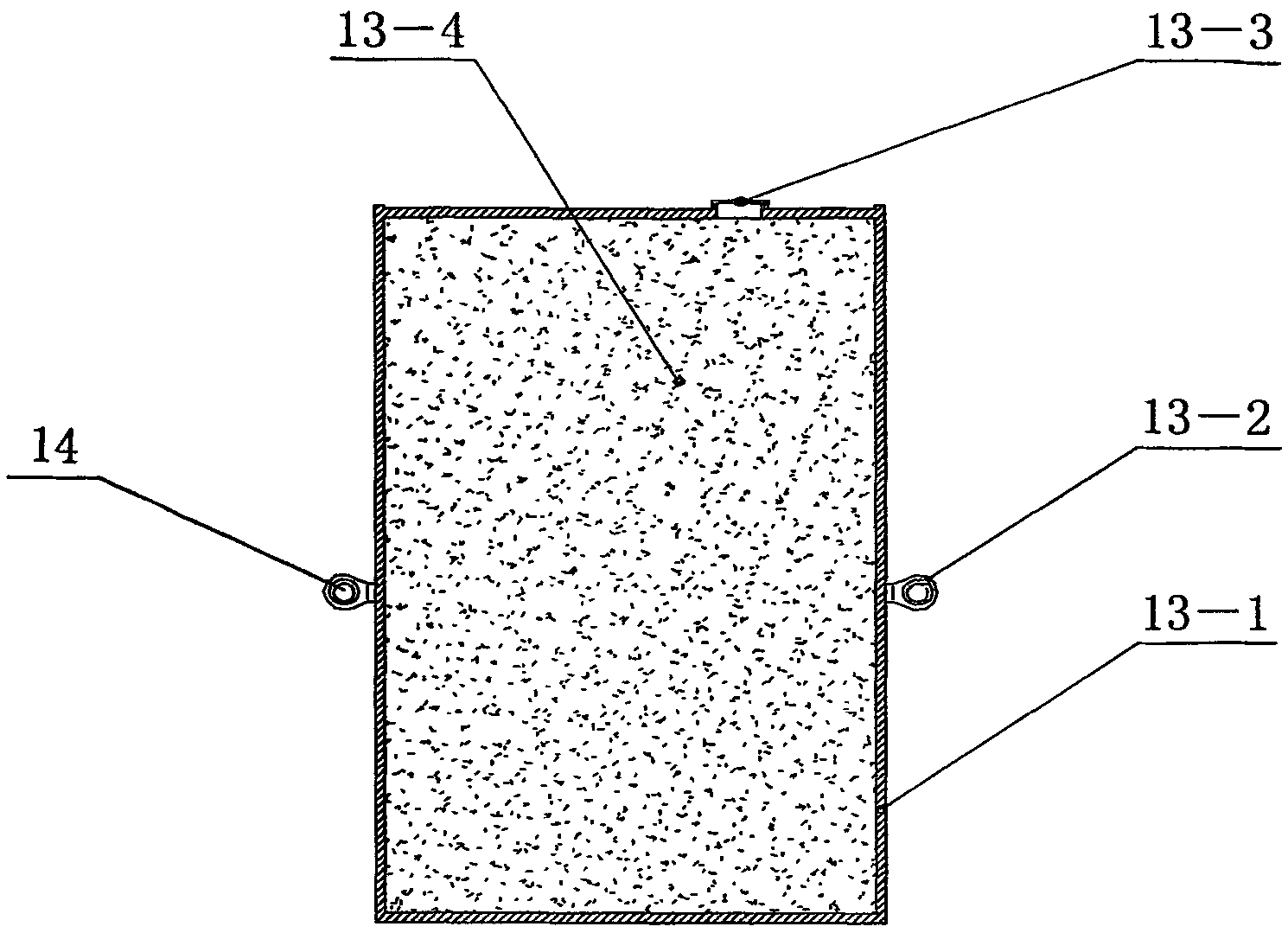

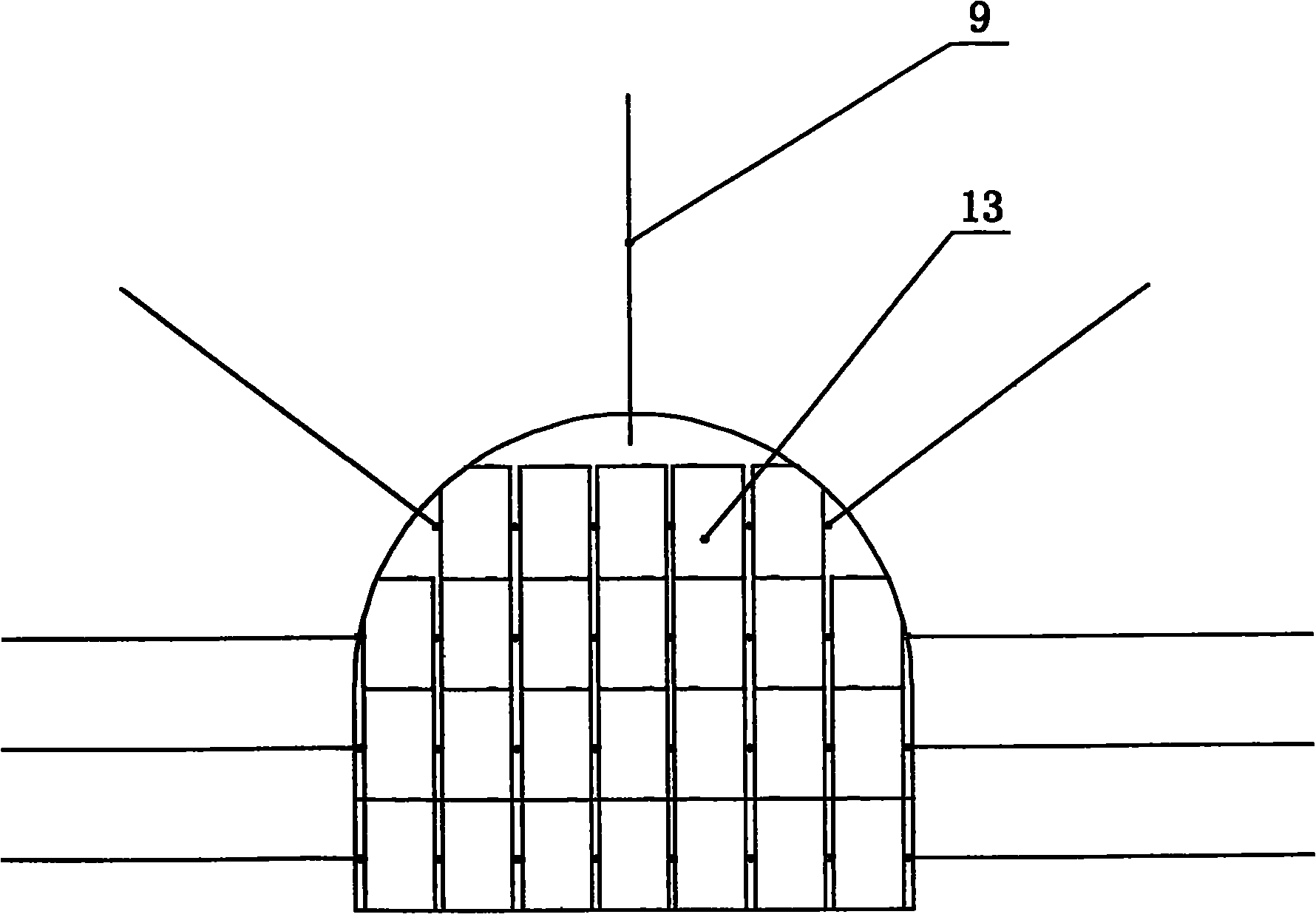

Shield construction muck treatment system and method

ActiveCN110303033AAchieve graded solid-liquid separationReduce transport volumeSievingConstruction waste recoveryEngineeringSlurry

The invention relates to the technical field of shield construction muck treatment, in particular to a shield construction muck treatment system and method. The muck generated by shield construction is crushed and stirred by a crushing and stirring device and then enters a primary-stage double-layer vibrating screen, oversize products are discharged out of the system, undersize products enter a sieve cone tank, the sieve cone tank is connected with a swirler through a pump, an intermediate tank is connected to an overflow port of the swirler, a discharge port of the intermediate tank is connected to an overflow tank through a pipeline, the slurry in the overflow tank is pumped to a flocculation tower through a pump, the flocculation tower is connected with an automatic dosing device, a flocculation medicament is pumped into the flocculation tower, the slurry in the flocculation tower is pumped to a filter press through a pump, drying mud cake treatment is carried out through the filterpress, the treated clear water flows into a clear water tank for reutilization, the dried mud cake is discharged out of the system, so that classified solid-liquid separation of different particle size components and water in the shield muck is realized, reutilization of inorganic raw materials and water resources of the shield muck is formed, and huge economic benefits are generated while the social resources are saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

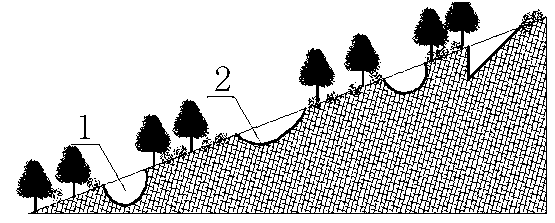

Stony desertization management method utilizing stony desertized area geographical characteristics

The invention discloses a stony desertization management method utilizing stony desertized area geographical characteristics. The stony desertization management method utilizing the stony desertized area geographical characteristics includes steps as follows that: step A, rock roves naturally formed in existing stony desertized areas are used as water storage bases, water storage units are formed by means of impermeable treatment carried out on the water storage bases; step B, shelters are covered on the water storage units; step C, artificial soil is paved and seeds are sprayed in the stony desertized areas by means of artificial planting of vegetation; step D, the shields covered on the water storage units are uncovered, so that the water storage units store rainwater on rainy days; step E, artificially planted vegetation surrounding the water storage units is irrigated through the rainwater stored by the water storage units. Accordingly, countless water storage sites are formed in the stony desertized areas after the rain. As everyone knows, the basic reason why stony desertization is difficult to manage is deficiency of water sources, stony desertization management method utilizing the stony desertized area geographical characteristics can well solves the problem of water deficiency, and provides indispensable preconditions for growth of the vegetation in later stages.

Owner:陈人福

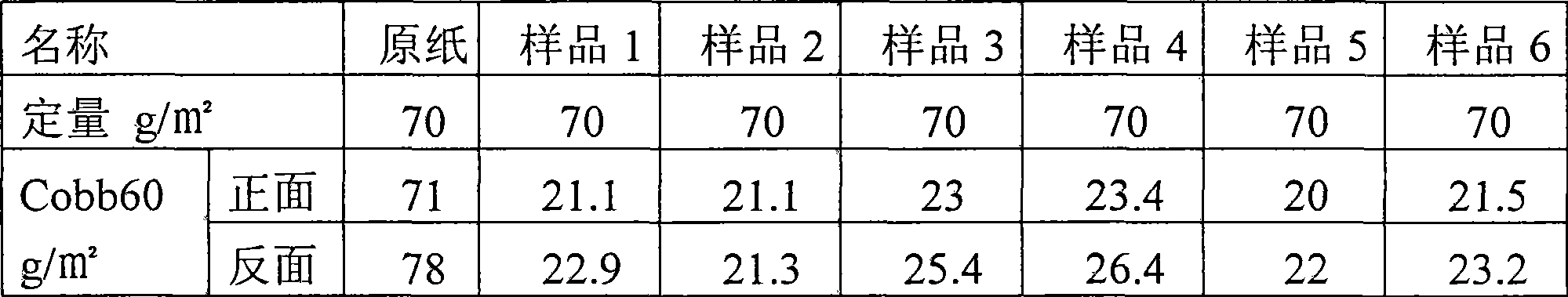

Styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and preparation method and application thereof

InactiveCN101544717AImprove water resistanceLarge particle sizeWater-repelling agents additionPaper/cardboardEmulsionOxidation-Reduction Agent

The invention discloses a styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and a preparation method and an application thereof. The preparation method comprises the following steps: adopting a seed emulsion method to synthesize core emulsion, dropping core pre-emulsified monomer solution and redox initiator into core the emulsion, controlling the dropping time, filtering the product of reaction by using a 250 mesh or 300 mesh sieve, discharging, and obtaining the microemulsion with hard core and soft core shell structure, wherein the microemulsion has a grain diameter of 20-100nm and the solid content of 40-48 percent. The surface sizing agent has the base characteristics of styrene-acrylic emulsion, good stability, core shell structure, small grain diameter, high solid content, and better gluing effect and can endow paper with better water resisting property and improve the surface property of the paper.

Owner:SOUTH CHINA UNIV OF TECH

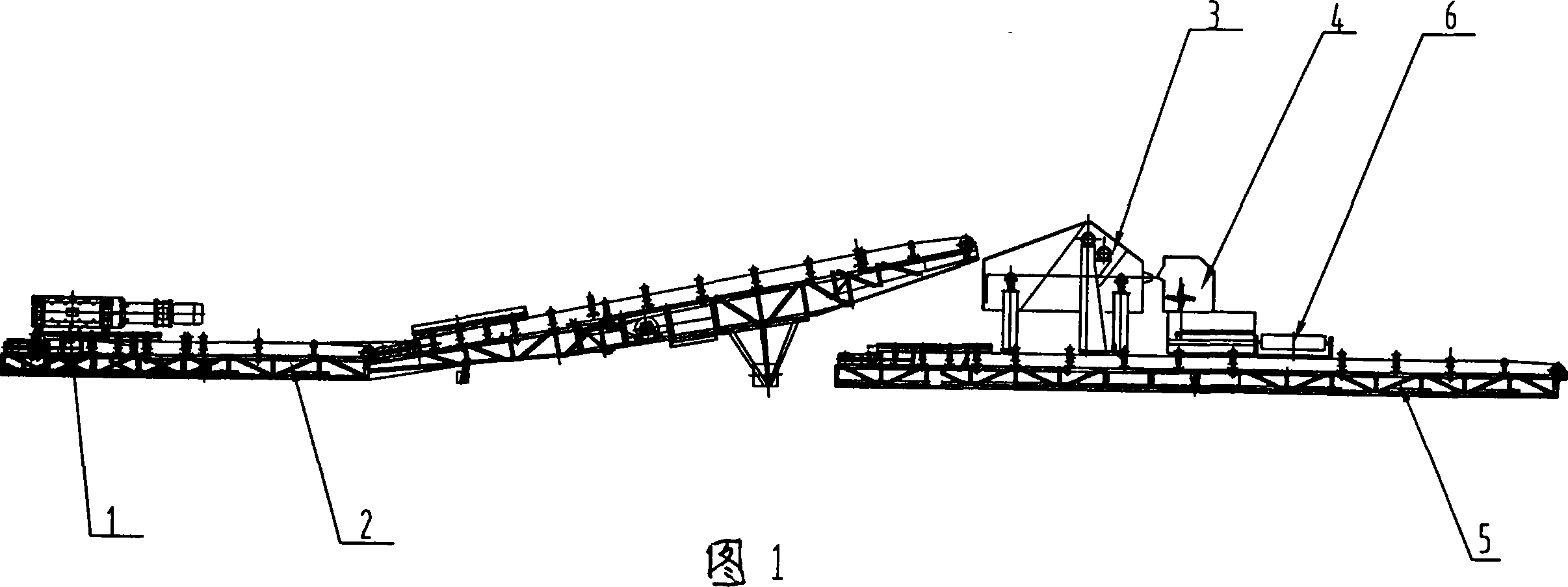

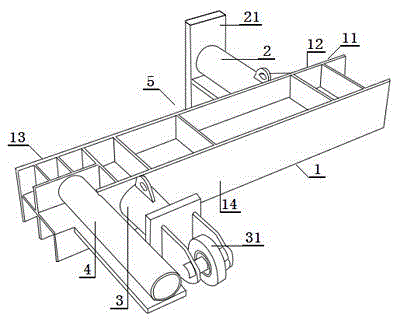

Gangue separating method and device for mine

InactiveCN101053856AReduce transport volumeSave stacking areaSievingScreeningMining engineeringCrusher

A pit coal gangue separation method and equipment adopt combination of a screening crusher, a front mounted type belt conveyer, a screening machine and a selective crushing type separating machine, a postposition type belt conveyer and a gangue transporter. The method includes the following steps: grading on the spot for coal and gangue in downhole to make the coal gangue that is smaller than 50 mm fall onto the postposition type belt conveyer for carting; entering the coal and gangue that are larger than 50 mm to the selective crushing type separating machine, breaking down the same after striking by a revolving impeller, the knocked broken coal after screened by a spiral sieve plate falling into the postposition type belt conveyer for carting; throwing out the gangue which is not knocked broken onto a backboard under a force generated while the impeller in screw rotating motion, and falling the gangue onto the gangue transporter for transport. The equipment may be directly used in downhole for the separation of coal and gangue, wherein the gangue can directly fill a gob area without being discharged from mine, thus the equipment can prevent surface subsidence, reduce environmental pollution, and save transport capacity of the gangue both in surface and underground. The invention has advantages of compact equipment, convenience for assembling and disassembling, good separation effect, and extensive practicality.

Owner:CHINA UNIV OF MINING & TECH

Synchronous grouting material used for tunnel and preparation method thereof

InactiveCN101928122AUnchangedImprove technical effectSolid waste managementCarboxymethyl celluloseHigh energy

The invention discloses a synchronous grouting material used for a tunnel and a preparation method thereof. The grouting material is the grout which is prepared by taking sediment grout as a main raw material, wherein the sediment grout comprises 30 to 65 percent of clay and fine sand totally and the weight ratio of soil to sand in the sediment grout is 0.1-0.18:1; and adding 80 to 120 kg of cement, 300 to 450 kg of coal ash, 200 to 500 kg of water or mud water and 3 to 10 kg of sodium carboxymethyl cellulose into per cubic meter of the sediment grout, wherein the grout density is between 1.85 and 2.05 g / cm<3> and the grout consistency is between 10.5 and 12 cm. In the preparation method, sediment and the mud water generated in a construction process are adopted as grouting materials, so that the sediment and the mud water can be changed into treasure from waste; and therefore, the preparation method has the characteristics of great reduction of the dosage of high-energy consumption cement, capability of working inside and outside tunnels, and convenient construction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

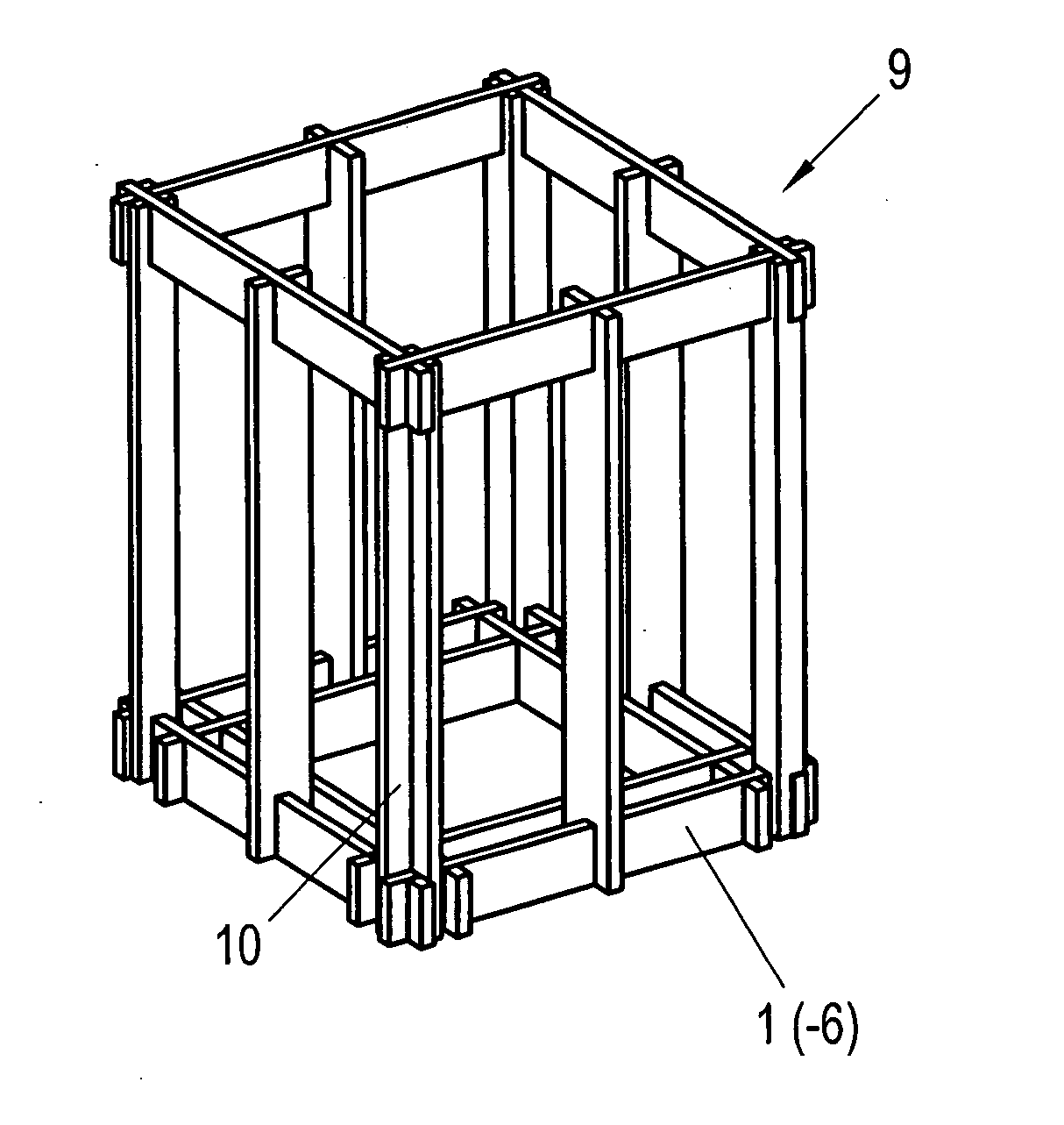

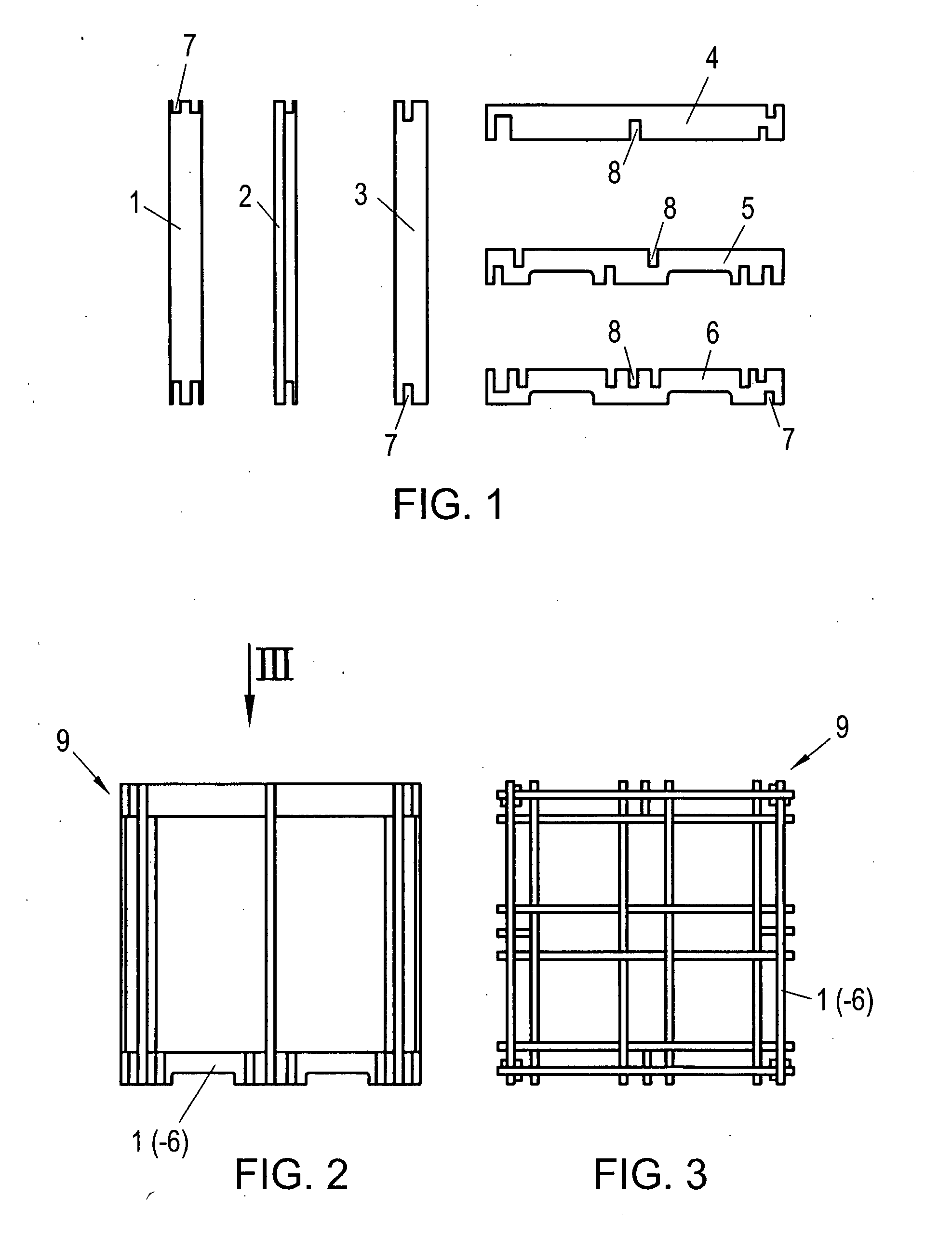

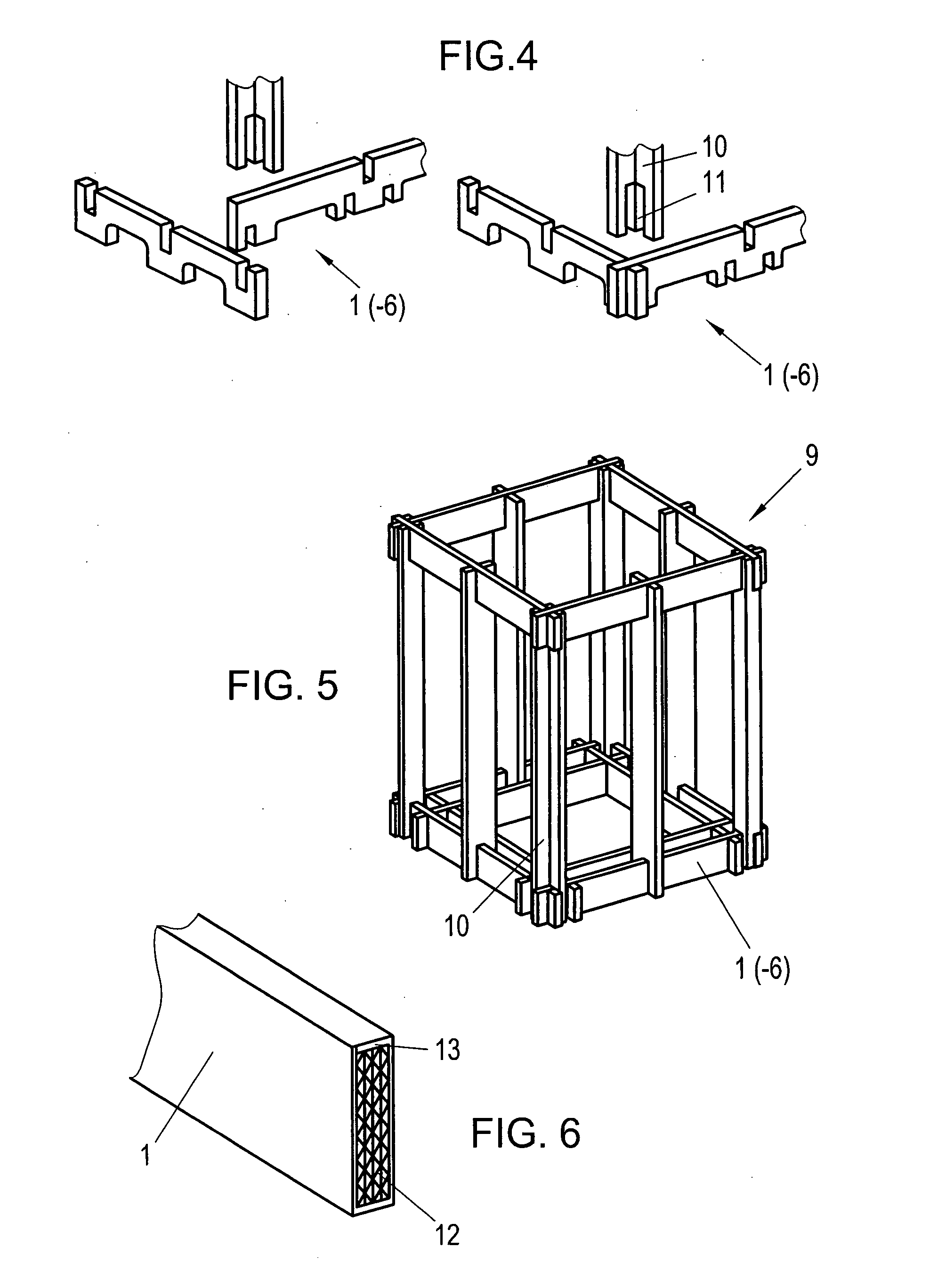

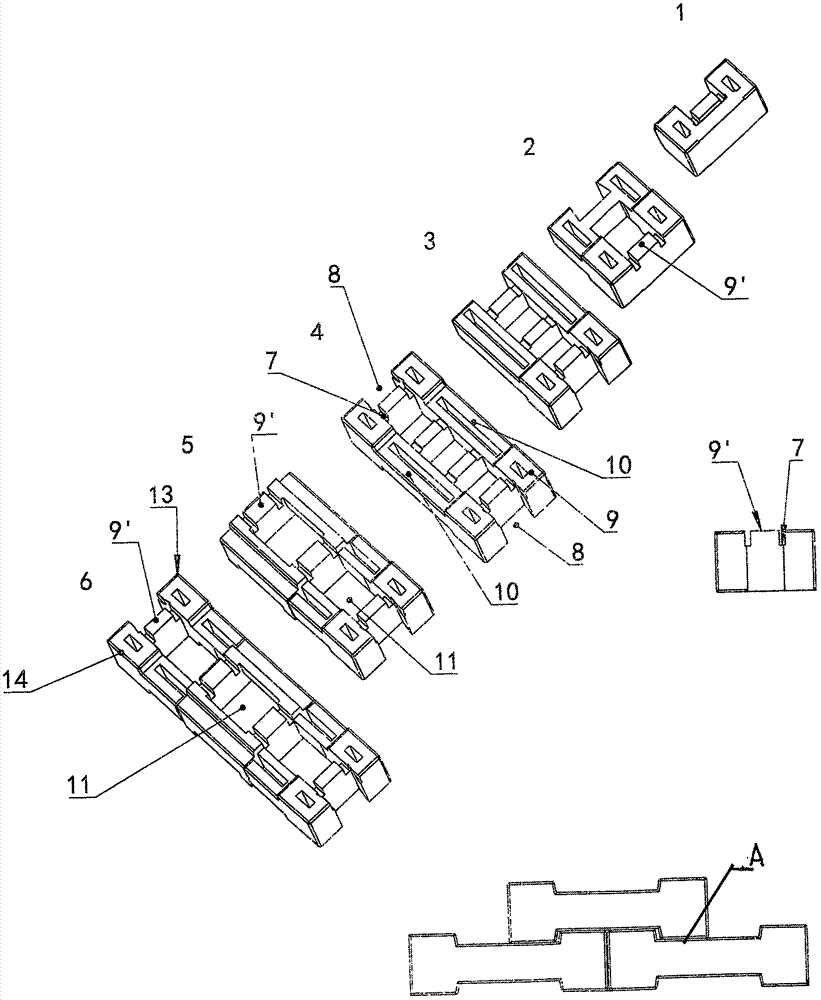

Three-dimensional frame structure or support structure for transporting and/or storing and object and method for the production thereof

The invention relates to a three-dimensional frame structure or support structure (9) for transporting and / or storing at least one object, which has a multitude of support elements (1-6, 10), which are or can be joined to one another and extend at least along the outer edges of the frame structure or support structure (9) while defining it. The invention provides that each support element (1-6, 10) is made of a multilayered composite of tightly packed sheets or boards (12) made of a corrugated paper or cardboard material, particularly corrugated board. The invention also relates to a method for easily and rapidly producing a three-dimensional frame structure or support structure of the aforementioned type.

Owner:UNIPAL INT LTD CO

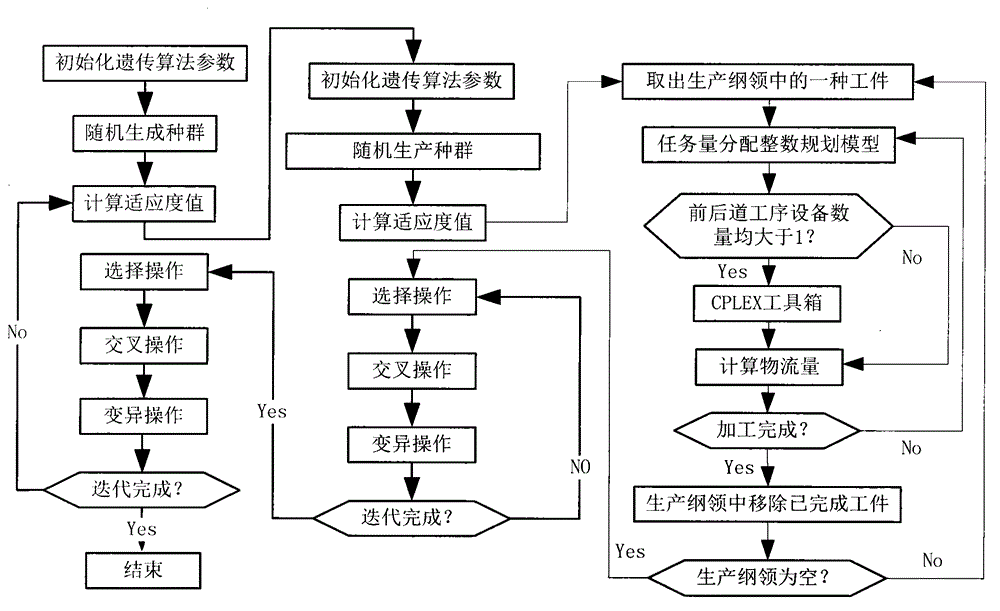

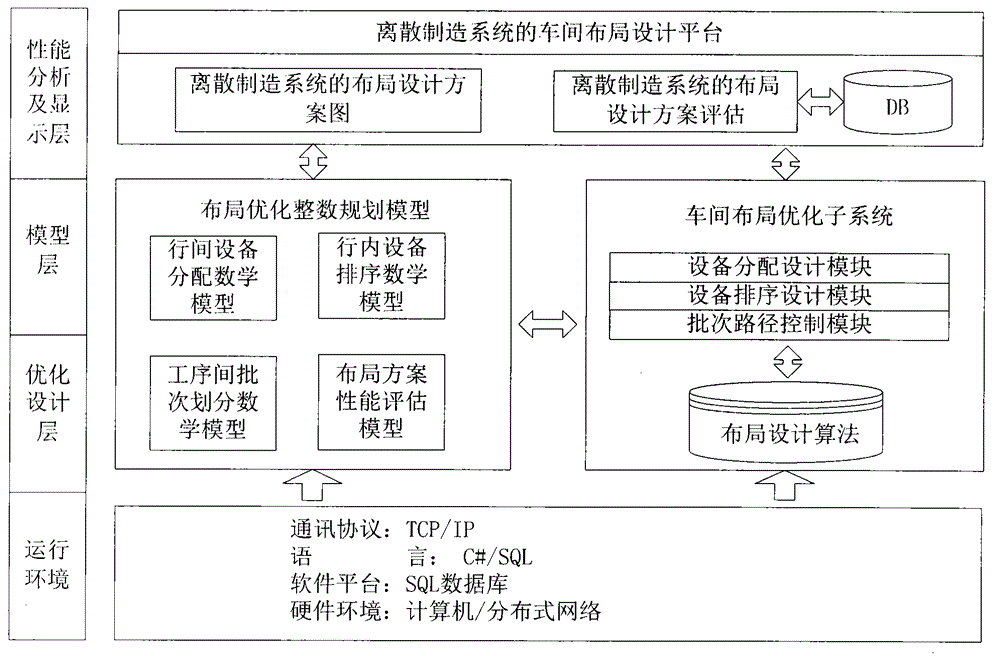

Workshop layout method of discrete manufacturing system

InactiveCN104808627AGuaranteed global searchImprove solution efficiencyTotal factory controlProgramme total factory controlLogistics managementComputer module

The invention discloses a workshop layout method of a discrete manufacturing system. The workshop layout method comprises the specific steps: a system UI layer is used for recording workshop equipment and production information to a layout design platform; a model establishing layer is arranged; an inter-row equipment distribution mathematic model, an in-row equipment sorting mathematic model, an inter-procedure batch division mathematic model and a layout scheme performance estimation model are established respectively according to the recorded workshop information; a workshop layout optimization subsystem is arranged; a workshop layout design result estimation and display module is arranged. A user sends a layout design scheme to a server through module permission and workshop management staffs execute optimized results. The workshop layout method has the advantages that the defects that the workshop layout overall performance is reduced, caused by the fact that common layout optimization only considers block layout of a machining station, are avoided. Meanwhile, the optimal distribution of task amounts of an equipment workshop is considered under the condition that a plurality of sets of equipment of front and rear procedures are utilized, and the logistics transportation amount is further reduced by utilizing third-grade optimization.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Gas field produced wastewater reduction and harmless treatment methods

InactiveCN106395926ASolve harmless disposalReduce volumeWaste water treatment from quariesGeneral water supply conservationEconomic benefitsWastewater

The invention discloses gas field produced wastewater reduction and harmless treatment methods. According to the methods, water is separated from gas field produced wastewater with a desalting process, concentrated gas field produced water is formed, and the volume of the gas field produced water is reduced; meanwhile, the invention also discloses a further concentrated gas field produced wastewater harmless treatment method. With the adoption of the treatment method, defects in existing gas field produced wastewater treatment methods are overcome, the problem of harmless treatment on the gas field produced wastewater can be effectively solved, the problem of pollution environment caused by the gas field produced wastewater can be effectively solved, gas production aids and useful substances in the gas field produced wastewater can be effectively recovered, the cost and the energy consumption for recovery of the gas production aids and useful substances from the gas field produced wastewater can be greatly reduced, and the transportation volume, the transportation cost and the treatment energy consumption and expense of the gas field produced wastewater can be greatly reduced; the method has the advantages of being easy to implement, safe, reliable, wide in application, easy to popularize and the like; the economic benefit and the environmental protection benefit are remarkable.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

Method of preparing ceria by mixed precipitant

A method of preparing ceria by a mixed precipitant mainly comprises the steps of enabling a mixed solution of ammonium bicarbonate and ammonia as the precipitant to perform combined action with inoculating crystals, precipitating rare earth ions in a rare earth chloride solution to obtain a mixture with primary alkali type cerous carbonate and subsidiary cerous carbonate and cerium hydroxide, and further firing to prepare a rare earth ceria product. The prepared ceria accords with industry standards; reaction conditions of the method are mild; energy consumption during preparing process is obviously reduced, and the cost is low; meanwhile, the carbon dioxide emission is greatly reduced, and obvious social benefit and environmental benefit are achieved.

Owner:YANSHAN UNIV

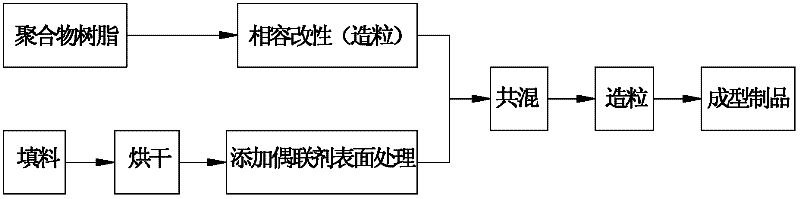

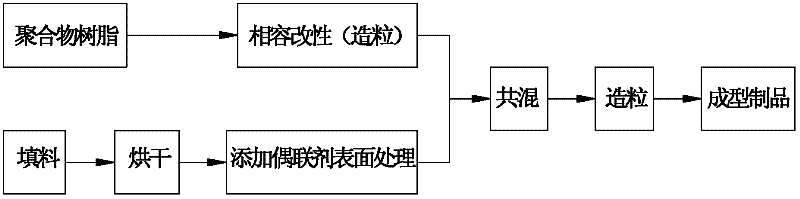

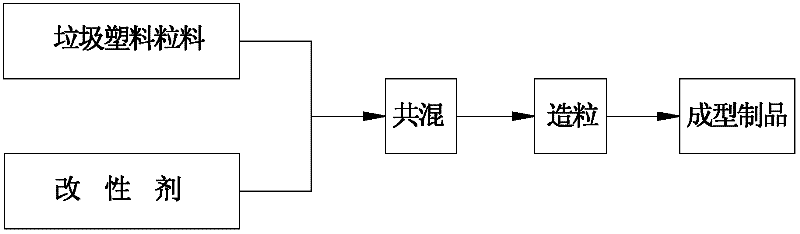

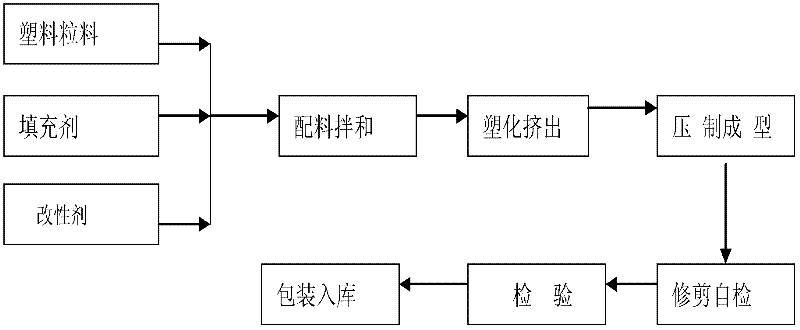

A method for recycling waste plastics

InactiveCN102268190AThe process method is simpleReduce environmental pollutionClimate change adaptationHeat proofingPelletizingReinforced concrete

The invention relates to a recycling method of garbage plastic, and mainly solves the technical problems of high cost and large environmental pollution existing in the traditional technology methods. The technical schemes comprises the following steps: firstly directly granulating the recycled garbage plastic, then adding a modifier with compatibility and coupling performance and filler and mixing, then carrying out alloy modification, and then processing into plastic pellets to produce buried drainage combined pipelines for municipal building, combined core molds or mold shells for building structures, or wall heat-insulation inner molds. Through the recycling method provided by the invention, garbage plastic can be recycled, and the process method is relatively simple and generates little environmental pollution. The treated recycled plastic including garbage plastic can be used to manufacture in-situ cast reinforced concrete core molds or manufacture industrial and building articles, daily necessities and the like, and can also be used to manufacture production raw materials such as granulation materials.

Owner:阳文皇

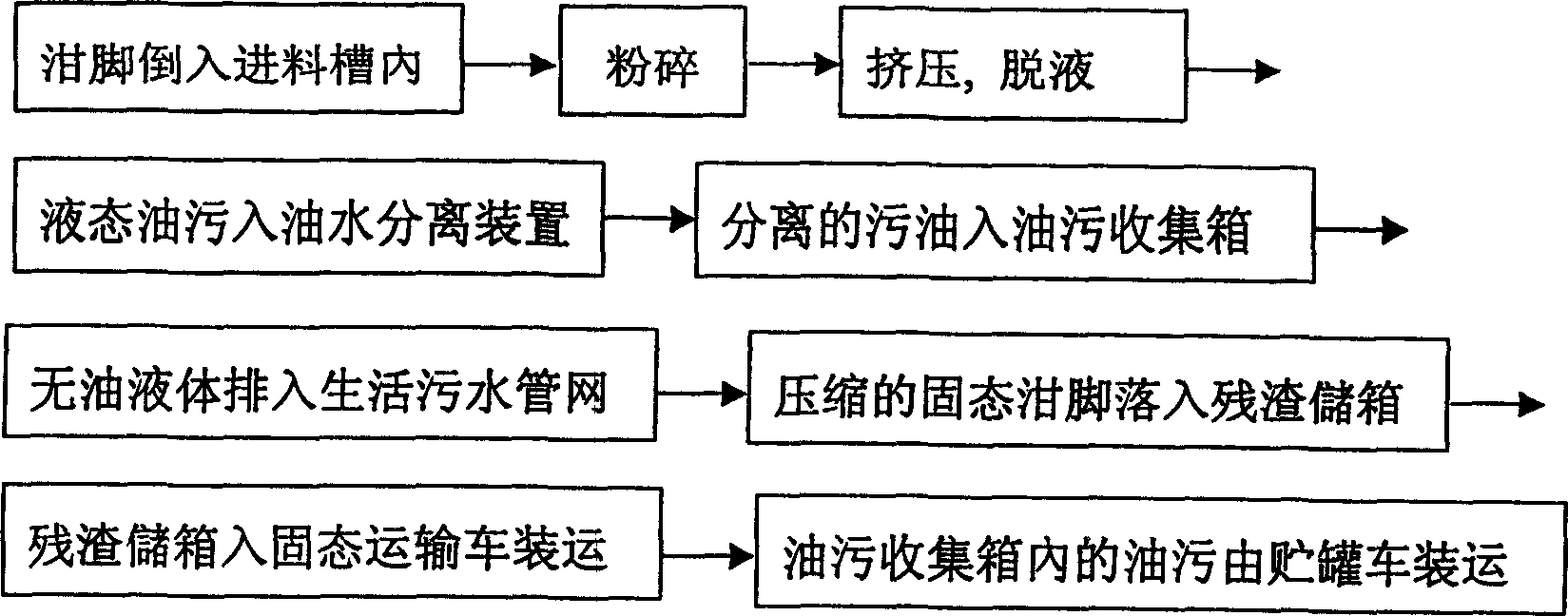

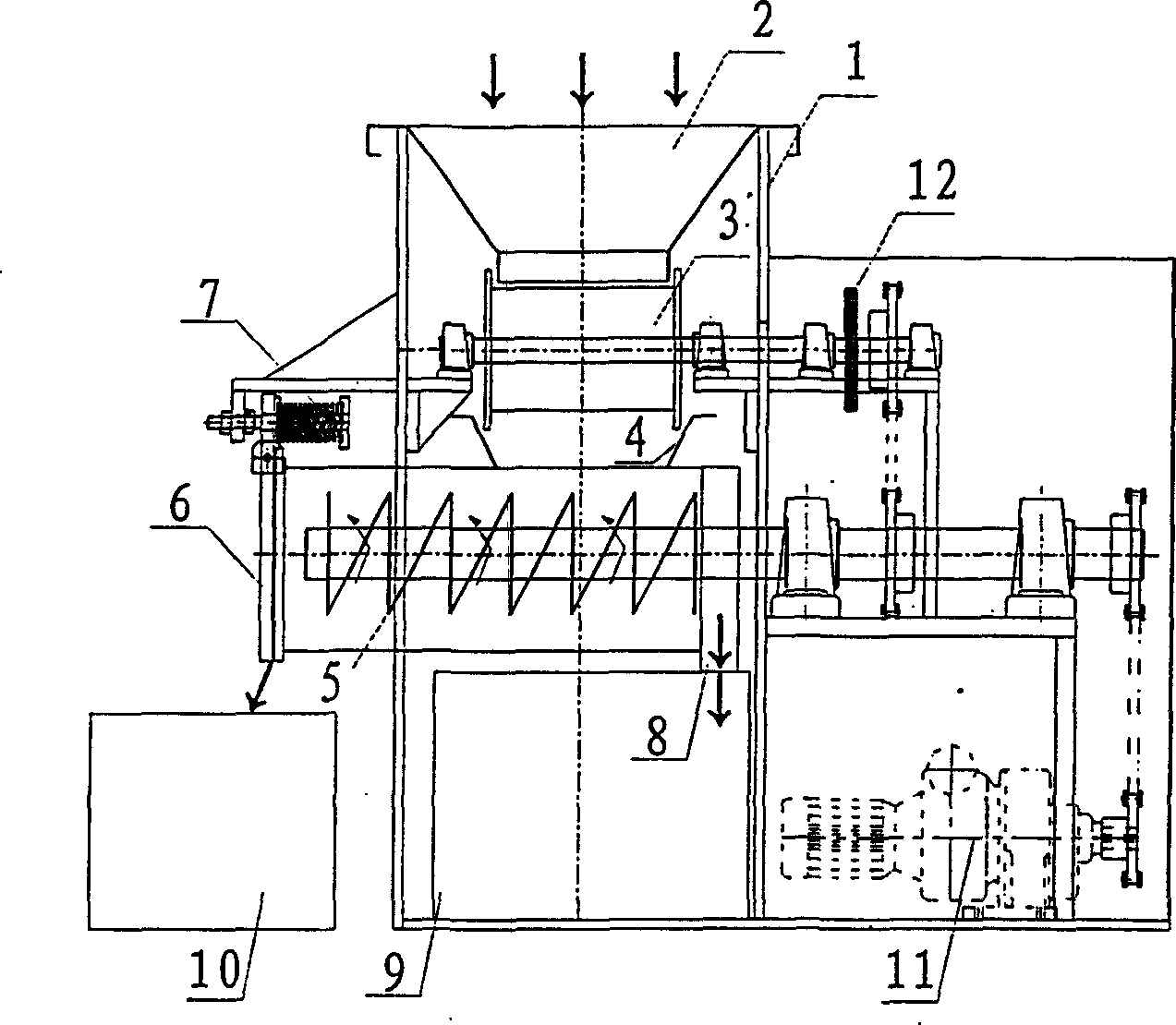

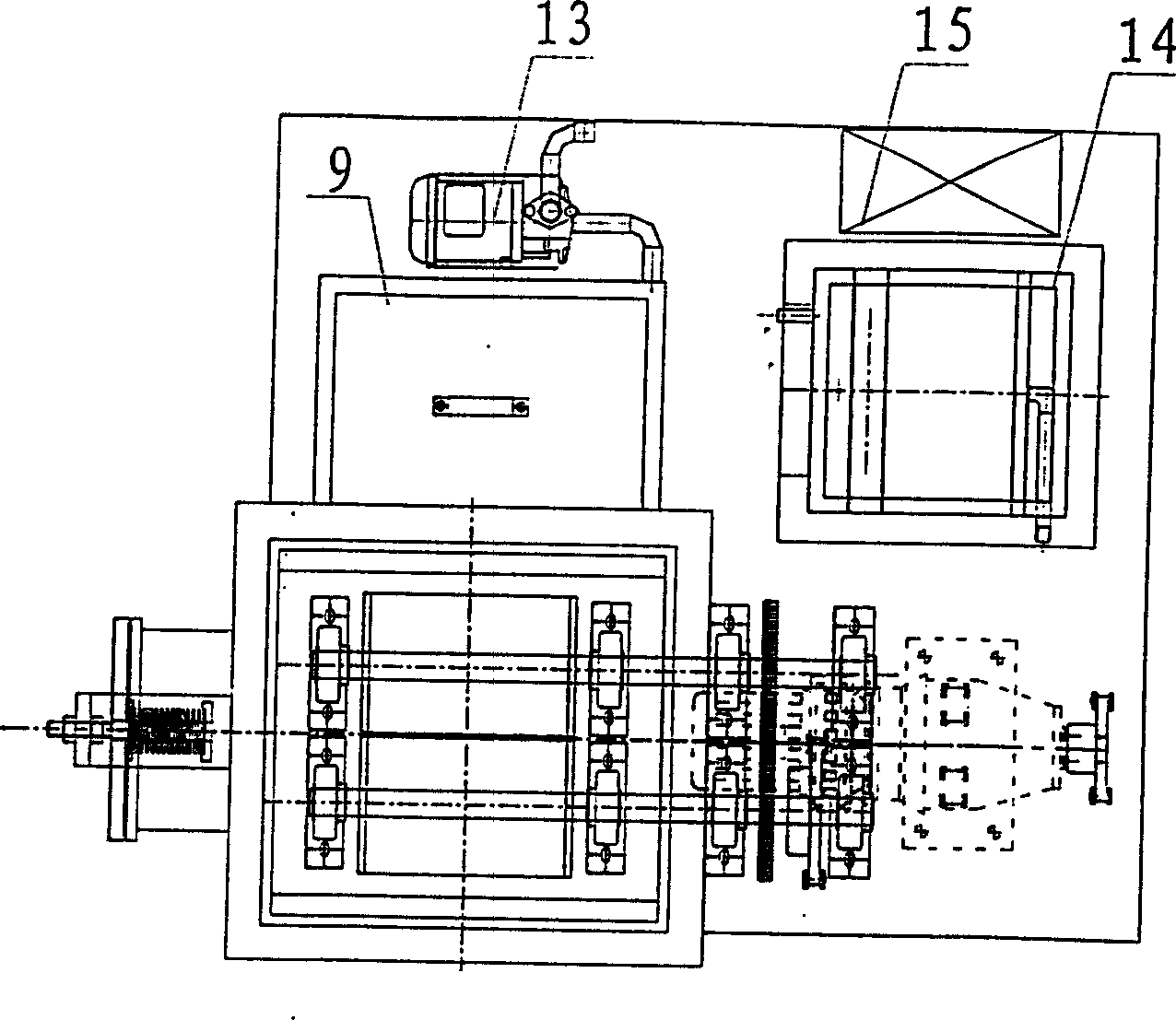

Pretreatment method and treating machine for hogwash refuse of kitchen

InactiveCN1879980AReduce transport volumeAvoid pollutionSolid waste disposalElectricityPretreatment method

The invention relates to a pretreatment of kitchen garbage waste, and relative processor, wherein it is characterized in that: said method separates the solid and liquid matters, which uses breaking, compressing, removing liquid removing oil, and dewatering; the oil is collected into oil collect tank; the non-oil liquid is fed into the life sewage tube network; the compressed solid garbage is fed into the slag storage tank to be stored in solid carrier; the oil is carried via storage carrier. The invention comprises two meshed rolling tooth wheels, whose meshed center is under the feeding groove and under the broken guide groove; and it comprises a compress baffle plate, an oil-water separator and an oil collecting tank. The invention has small volume, less electricity consumption and simple operation.

Owner:钟建成

Sugar production process using boiler flue gas as clarificant

InactiveCN1654682AGood purification effectLess investment in equipmentPurification using alkaline earth metal compoundsLime productionChemistryFlue gas

The present invention is sugar refining process with boiler fume as the clarifier, and the sugar refining process includes the steps of extracting crude sugar liquid, purifying crude sugar liquid and producing high quality sugar. During purifying crude sugar liquid, calcium oxide or regenerated filtering mud are added, and boiler fume with CO2 content of 6-17 is introduced for reaction with calcium oxide or regenerated calcium oxide to produce calcium carbonate adsorbing non-sugar impurity in the sugar liquid, with the volume ratio between boiler fume and crude sugar liquid being 100-300, and the mass ratio between boiler fume and calcium oxide or regenerated filtering mud being 5-30. The present invention has high sugar liquid purifying effect, sugar liquid purity raised by 2-13 %, reduced lime consumption, reduced CO2 exhaust of boiler, and raised economic utility and environment utility.

Owner:SOUTH CHINA UNIV OF TECH

Ink jet printing apparatus and printing method

InactiveUS20070273720A1Inhibition biasLow accuracyOther printing apparatusVolumetric Mass DensityEngineering

By suppressing deviation of dot-formation positions stemming from insufficient accuracy in conveying a printing medium due to eccentricity of a conveying roller, a printed image in which unevenness is less visible is obtained. An accumulated amount of conveyance errors is decreased by narrowing a nozzle-use range and reducing a conveyance amount over an entire printing region according to a mode used for printing an image in which the coverage of a printing medium is low due to a small number of ink colors to be used, for example, a mode used for printing a monochrome image by using a black ink dominantly in all of the density regions.

Owner:CANON KK

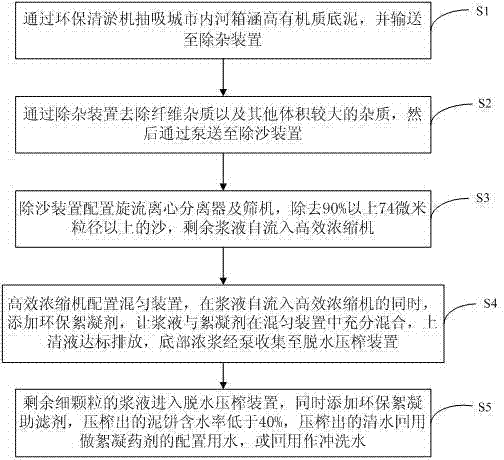

Dredging and classified dewatering treatment method and system for sludge in urban river box culvert

InactiveCN104724893AReduce transport volumeReduce transportation energy consumptionSludge treatment by de-watering/drying/thickeningStream regulationFlocculationSludge

The invention discloses a dredging and classified dewatering treatment method and system for sludge in an urban river box culvert. The method comprises the following steps: sucking high-organic matter bottom mud in the urban river box culvert through an environment-friendly silt remover, and conveying to an impurity removal device; removing impurities through the impurity removal device; pumping to a sand removal device; configuring a cyclone centrifugal separator and a screening machine by the sand removal device; removing over 90% of sand of which the particle diameters are greater than 74 microns; flowing the residual slurry into an efficient thickener; configuring a blending device by the efficient thickener; adding an environment-friendly flocculating agent when the slurry flows into the efficient thickener; fully mixing the slurry with the flocculating agent in the blending device, and discharging the supernatant up to the standard; collecting the bottom dense slurry into a dewatering and squeezing device through the pump; and entering the residual slurry of fine particles into the dewatering and squeezing device, and simultaneously adding an environment-friendly flocculation filter aid, wherein the moisture content of the squeezed mud cake is smaller than 40%; and the squeezed clear water is recycled as water for preparing a flocculating agent or recycled as rinse water.

Owner:SAFECLEEN TECH

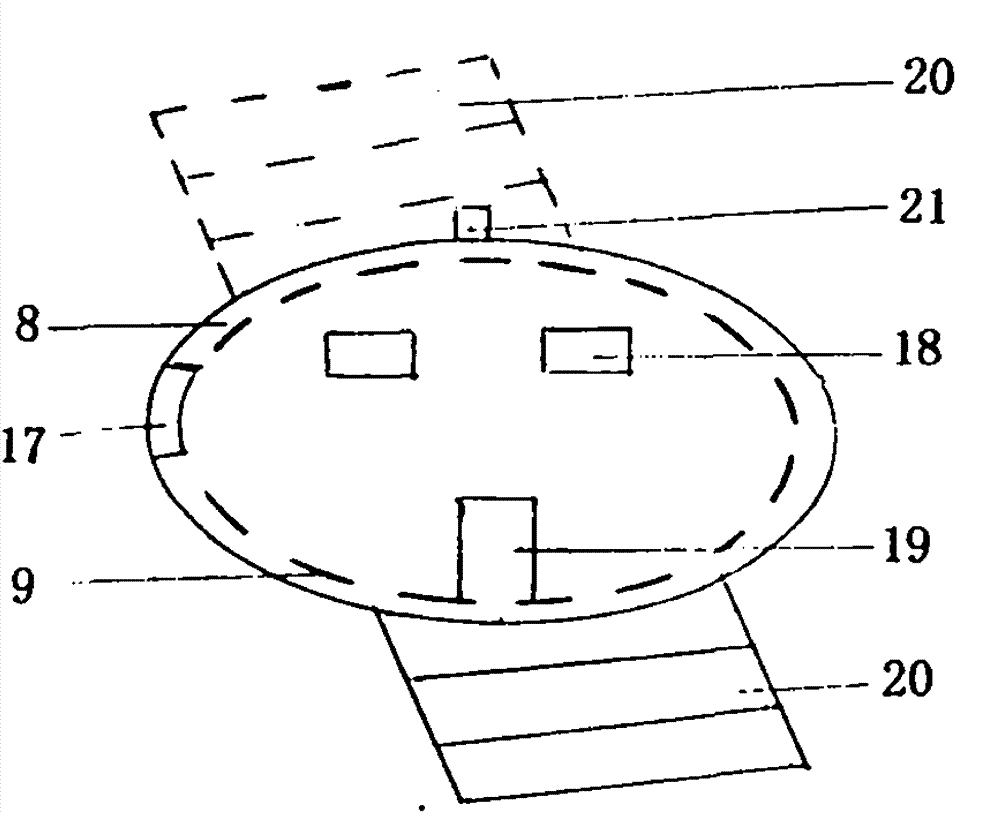

Jet-propelled vertical-lift air bag aircraft

InactiveCN103786863AImprove securityEase traffic congestionRigid airshipsJet engineElectric machinery

The invention discloses a jet-propelled vertical-lift air bag aircraft. The aircraft is characterized in that an inflaming-retarding, heat-insulating and tearing-resistant air bag interlayer which is not fully expanded is used as a jet-propelled aircraft body or one or two inflaming-retarding, heat-insulating and tearing-resistant air bag interlayers which are not fully expanded are arranged on the outer surface of a rigid device body of the aircraft or the inner surface and the outer surface of the rigid device body of the aircraft. An automatic parachute is arranged on the jet-propelled aircraft body. An exhaust nozzle of a jet engine of the aircraft and a parallel-connection pipe of the exhaust nozzle are provided with jetting systems and a terminal jetting device of each system is a vector device. Or, a base of the jet engine is fixed to a rotation shaft of a motor 1 and then a base of the motor 1 is fixed to a rotation shaft of a motor 2. The jetting direction of the engine is perpendicular to rotation axes of the two rotors. The two motors are controlled by two inverted inching switches respectively. Each wing is arranged to be a folding wing and urban and countryside transportation can be greatly changed by means of the aircraft.

Owner:李彦征

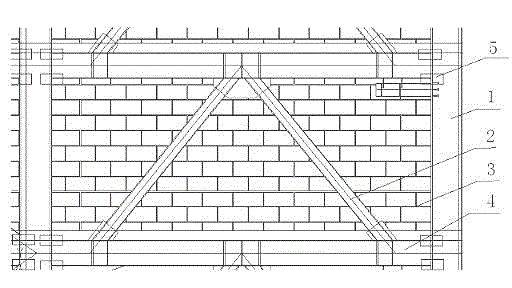

Method for fabricating house through members assembled by interlocking combined building blocks

ActiveCN107060071AReduce the risk of manpower working at heightsEasy to implement finelyWallsEngineeringHigh rise

The invention relates to a method for fabricating a house through members assembled by interlocking combined building blocks. The combined building blocks with different thicknesses, different interlocking types and functional block shapes are assembled to be the independent members such as inner-outer-wall equal thickness and unequal thickness hollow or solid square, L-shaped, T-shaped and cross structural column window beams, door beams, cantilevering beams, ring beams, wallboards and floors, and the independent members are fabricated to be the house meeting the current standard quality requirements. The products are not only suitable for small scattered living house man-made buildings, but also suitable for whole mechanical low-rise, multi-rise and high-rise full-fabricated buildings, the effect of improving seismic performance of the house is achieved, the aerial working safety risk under layer-by-layer erecting is avoided, lots of formworks are saved, the building construction speed is increased, and compared with all other domestic and oversea current building structure systems, the products have the more significant cost performance advantage.

Owner:段志祥

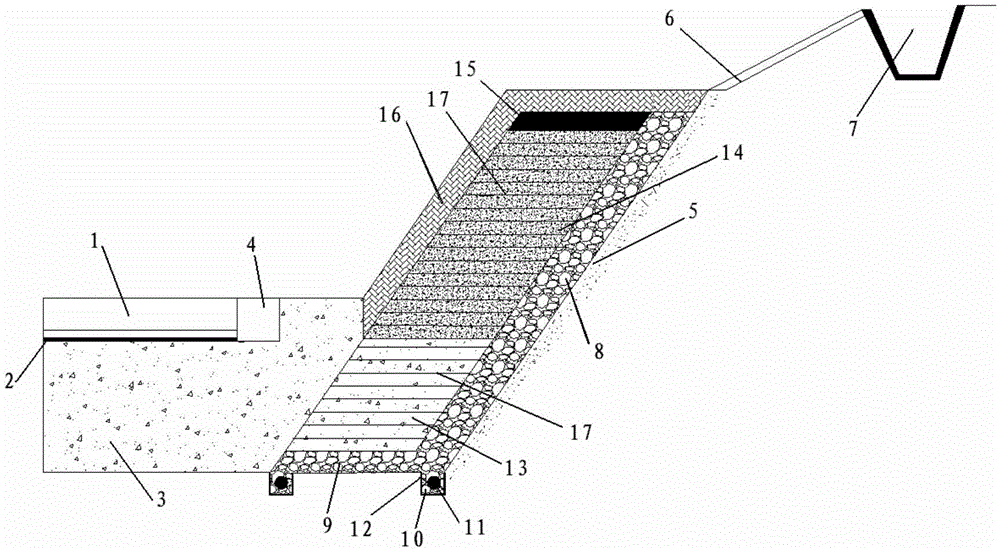

Expansive soil cutting structure and construction method thereof

InactiveCN105569058ARealize moisturizing and anti-seepageReduce hygroscopic swellingPaving gutters/kerbsClimate change adaptationWater dischargeChipseal

The invention discloses an expansive soil cutting structure. The expansive soil cutting structure comprises a pavement, waterproof geotextile and a roadbed which are in sequential arrangement from top to bottom, wherein a side slope provided with an intercepting ditch on the top is arranged on the side surface of the roadbed; anti-seeping geotextile is arranged between the side slope and the intercepting ditch; the slope surface of the side slope is provided with a side slope water seeping layer; a basic water seeping layer, a gravel soil layer, an expensive soil layer and a non-expensive clay layer are arranged between the side slope water seeping layer and the roadbed; the bottom of the basic water seeping layer is provided with at least one seeping ditch; a two-cloth one-film sealing layer and a water discharge pipe with holes are arranged in the seeping ditch; and a geogrid is arranged in the gravel soil layer and the expensive soil layer. A construction method comprises the following steps of performing side slope overexcavation; digging the bottom foundation of the basic water seeping layer; digging the seeping ditch; laying the two-cloth one-film sealing layer, and distributing the water discharge pipe; filling and building a basic water seeping layer and the side slope water seeping layer; filling and building the gravel soil layer and the expensive soil layer; trimming the slope surface of the side slope, and laying the planting soil layer; and arranging the intercepting ditch and the anti-seeping geotextile. The expansive soil cutting structure and the construction method well solves the road repair problems in an expansive soil region, and great popularization values are realized.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

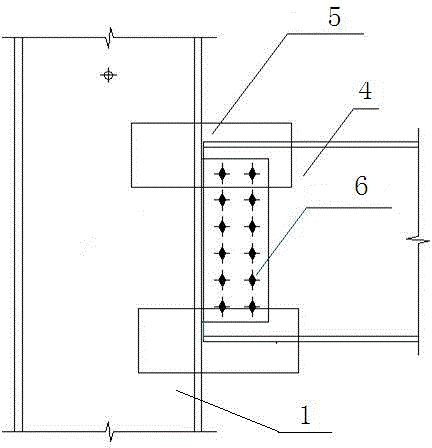

Multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness

InactiveCN104481170AReduce labor intensityReduce transport volumeHeat proofingSound proofingThermal insulationEngineering

The invention relates to a multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness. According to a structural scheme of rectangular steel tube concrete pillars, a steel framework beam and a steel support adopted by the invention, an outer wall, a separating wall, a core tube wall and a firewall are arranged in the steel structure framework, and indoor partitioning walls are arranged in rooms; floors and stairs are arranged between each layer of the steel framework beams. The multi-storey and high-rise steel structure house integrated system with equal-thickness pillars and walls is characterized in that the width of the pillars is 180mm-200mm, an inner partition plate and a transverse partition plate are not arranged inside each pillar, and the width of an outer ring beam combined with each pillar is limited to be within 200mm; inner beams of the steel structure house adopt small steel beams; after fireproof paint and a screeding layer are sprayed, the beam width is controlled to be within the width of the partition walls, the wall plates adopt composite wall plates with good thermal insulation performance and good fireproof soundproof performance, and using area of a house is increased according to the thicknesses of the walls. The multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness has the advantages of reasonable layout, low cost, high prefabricating efficiency, good anti-seismic performance and capacity of increasing the using area of the house.

Owner:HANG XIAO STEEL STRUCTURE (INNER MONGOLIA) CO LTD

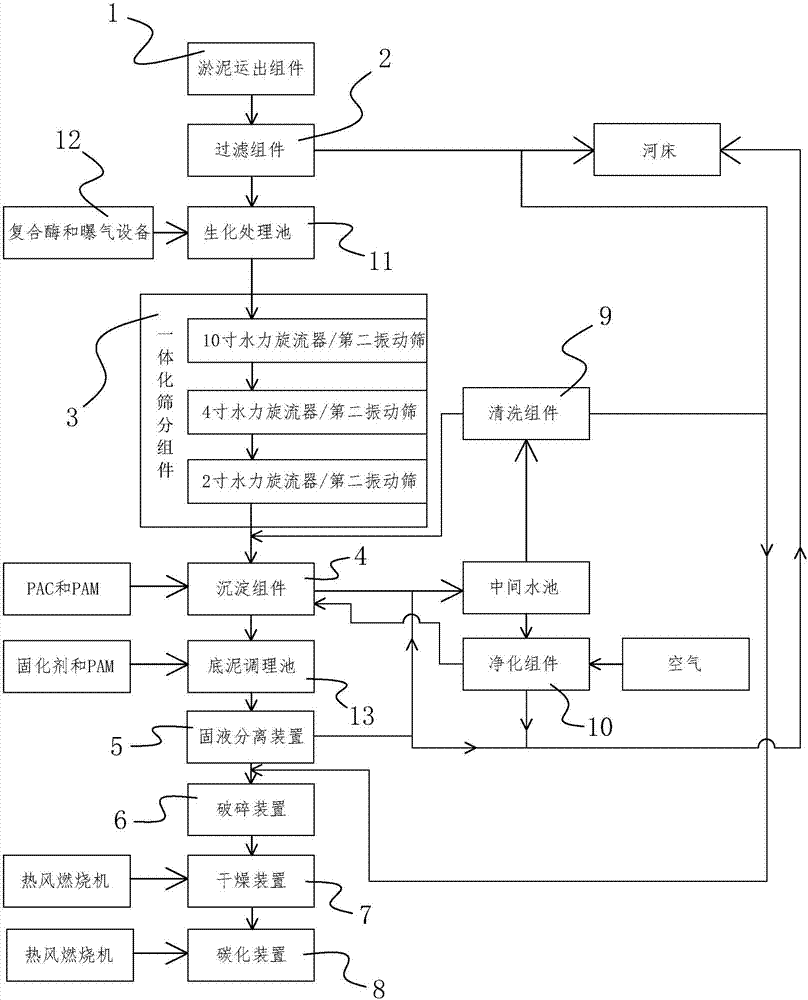

River and lake sludge harmless treatment system and method

InactiveCN107265800APrevent leakagePrevent over miningSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSmall footprint

The invention discloses a river and lake sludge harmless treatment system. The system comprises a sludge carting component, a filtering component for separating impurities from sludge, an integrated screening component for separating powder particles from sludge, a sedimentation component for precipitating bottom mud from sludge, a solid-liquid separator for bottom mud dehydration, a crushing device for crushing clinker after dehydration, a drying device for drying the crushed clinker and a carbonation device for converting the dried clinker into carbonized sludge. The river and lake sludge harmless treatment system is easy to operate, needs short sludge treatment time and has a small occupied land area.

Owner:江门市三清环境技术工程有限公司

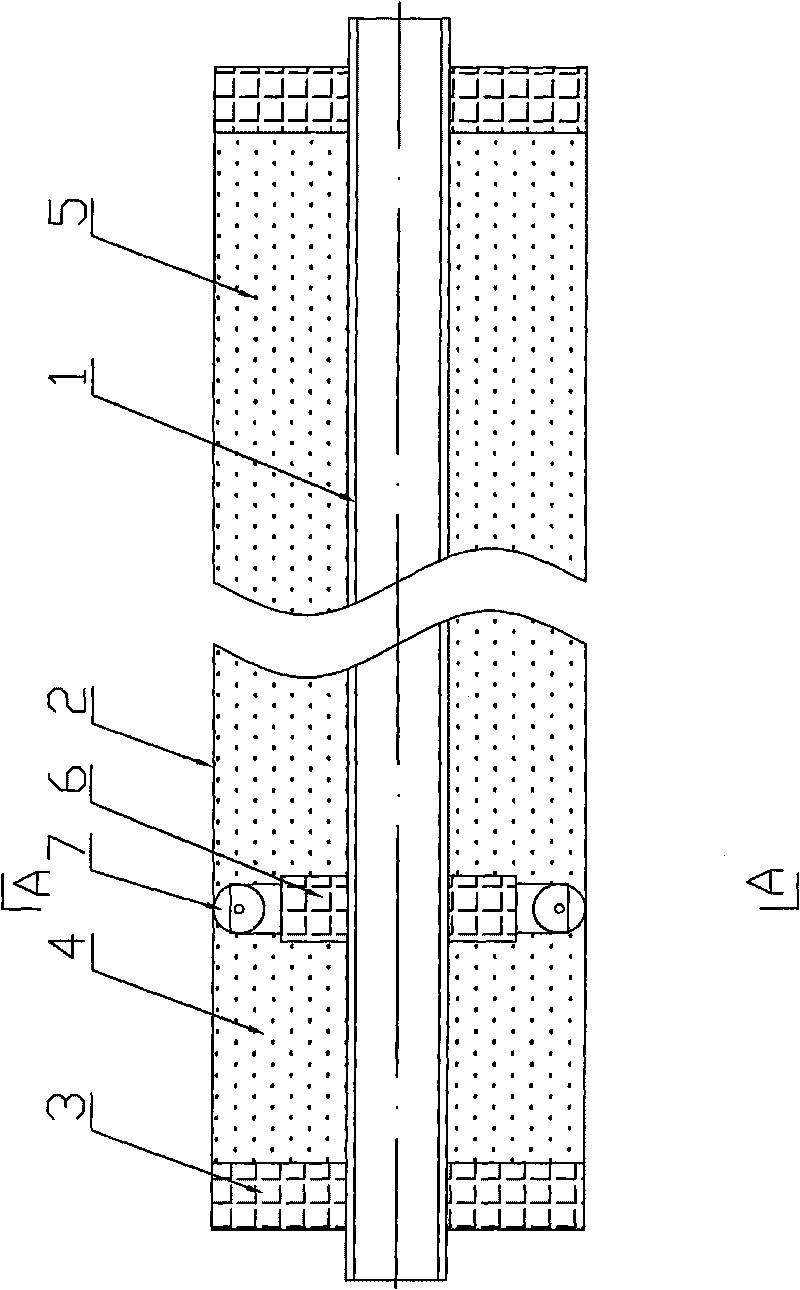

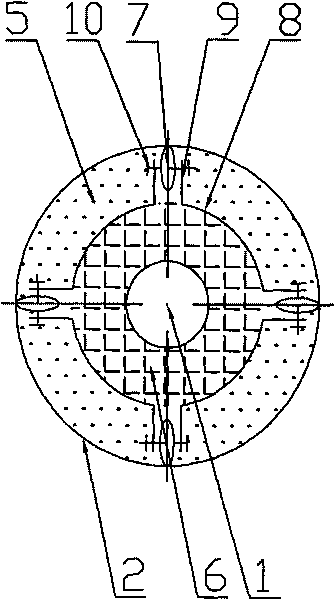

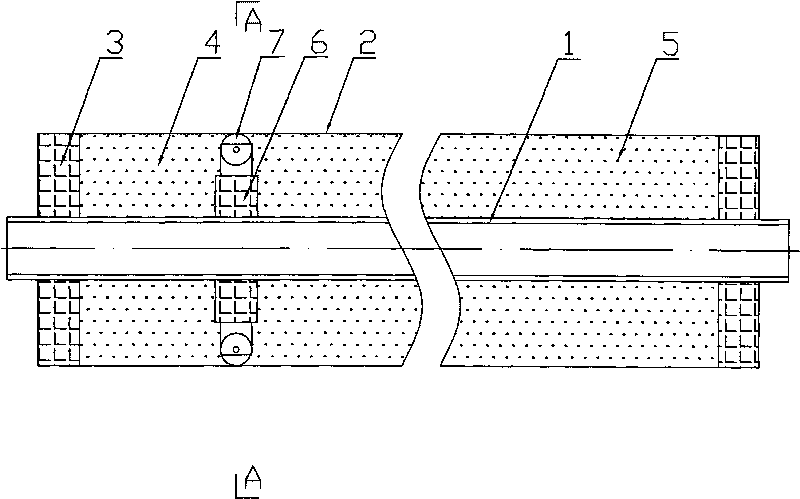

Heat preservation pipe prefabricated by powder heat insulating materials

InactiveCN101706031ACompact and reasonable structureSmall structureThermal insulationPipe protection by thermal insulationHeat transmissionTransfer procedure

The invention discloses a heat preservation pipe prefabricated by powder heat insulating materials, comprising a working steel pipe and an external protective pipe. The external protective pipe is arranged at the outer side of the working steel pipe, and heat insulating drain plugs are arranged at two ends between the working steel pipe and the external protective pipe. The structure of the invention is reasonable and compact, powder materials are adopted for the heat insulating materials, the heat insulating structure cannot be destroyed, and the heat insulating performance cannot be influenced when the volume of a cavity formed between the working steel pipe and the external protective pipe changes, thereby a series of problems caused by the expansion because of heat and the contraction because of cold that are generated by temperature change during a heat transmission process are solved. The powder materials have lower coefficient of heat conductivity at the higher temperature, thereby energy-saving effect is obvious; because a supporting device is arranged in the cavity filled with the powder heat insulating materials, the heat insulating effect is good, and heat bridges are completely stopped; the heat preservation materials with the lowest coefficient of heat conductivity are used by the heat insulating materials, a heat isolating cushion ring and the heat insulating drain plugs, so that the integral heat preservation thickness of the heat preservation pipe is thin, the structure of the external protective pipe correspondingly becomes smaller, the quantity of installation and conveying is reduced, and the comprehensive manufacturing cost is low.

Owner:董勖 +1

Method for quickly constructing water gate wall

ActiveCN102121388AFast constructionStrength hasUnderground chambersTunnel liningBarrel ShapedEngineering

The invention discloses a method for quickly constructing a water gate wall, which comprises five steps of constructing a temporary water barrier, constructing an entity temporary water battier, constructing a filling section, constructing a main water gate wall and constructing an external tunnel of the main water gate wall. Barrel-shaped building blocks are used as the aggregate, water can be got at the construction site, and only barrel bodies and little coacervated single-liquid material are needed to be transported, so that the labor intensity and the transportation volume are both greatly reduced, the construction speed is improved, and plenty of time is saved for rescue construction; the coacervated single-liquid grouting material reacts in the presence of water to generate gel, and the generated gel has certain strength and steady performance, is not decomposable and corrosion resistant, and cannot absorb water; two sides of each barrel body are provided with iron hoops, and the iron hoops of neighboring barrel bodies are fixed through bolts to form a net structure; the barrel bodies are connected with anchor rods on the two sides, the top and the bottom plate of the tunnel, so that the water gate wall can resist the impact of water pressure, the construction quality is effectively ensured, and fast construction for constructing the water gate wall is implemented.

Owner:HEBEI TONGCHENG MINING TECH

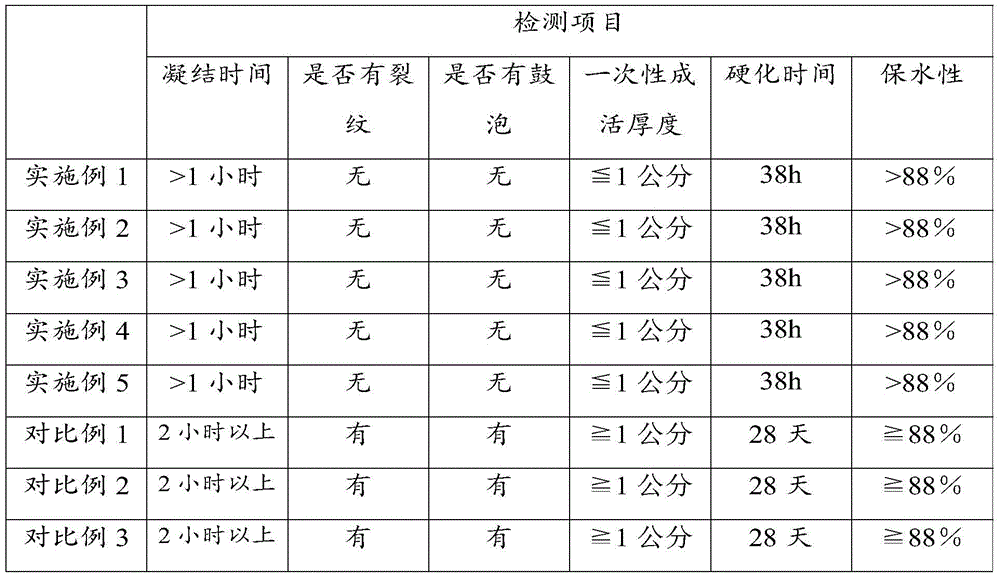

Gypsum-based pre-mixed mortar and preparation method thereof

The invention provides a gypsum-based ready-mixed mortar and a preparation method thereof. The ready-mixed mortar comprises 450-500 parts of hemihydrate gypsum, 550-600 parts of aggregate, 0.7-1.5 parts of compound modification additive, 0.2-1.0 part of foaming agent and 1-10 parts of setting retarder. The preparation method includes the following steps: mixing hemihydrate gypsum, aggregate, compound modification additive, foaming agent and retarder to obtain ready-mixed mortar. The gypsum-based ready-mixed mortar has strong adhesion to the substrate, which overcomes the shortcomings of easy cracking and hollowing in the use of traditional cement-based ready-mixed mortar; the one-time survival thickness is 4mm-2cm, which is smooth to the wall surface The requirements for the degree of strength are not high, and the construction requirements are greatly reduced; the hardening is fast, which can speed up the construction progress; the cost is low, and at the same time, it also has the advantages of good fire resistance, automatic temperature adjustment function, and light weight.

Owner:GUIZHOU TENGFENG TECH CO LTD

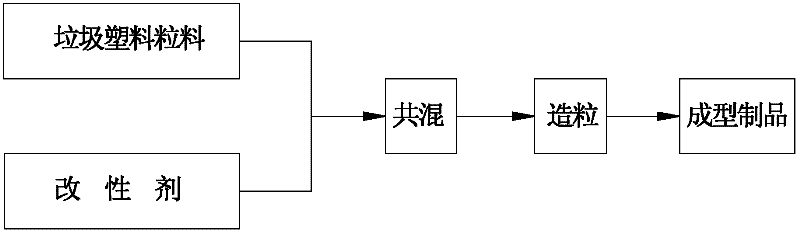

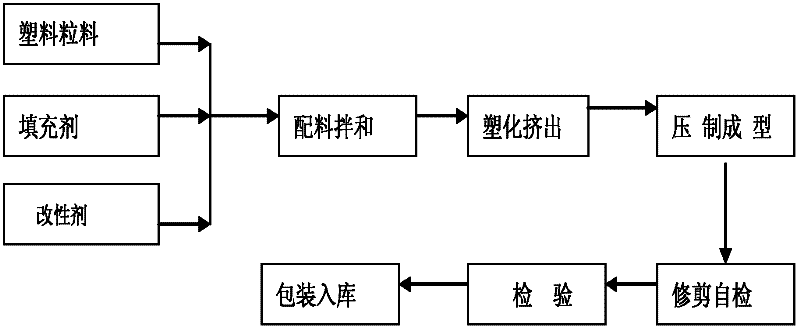

Method for recycling garbage plastics and special equipment

The invention discloses a method for recycling garbage plastics and special equipment, belonging to a method for recycling garbage plastics and mainly solving the technical problems of high water consumption, high operating cost and higher pollution to the environment and the like in the traditional water separation process. The method is characterized by comprising procedures of separation for plastics and impurities, air drying for plastics, granulation, modification of plastics and re-granulation. The method specifically comprises the following steps of: firstly, conveying the raw materials of the garbage plastics into a crushing apparatus, and crushing into sheet-like materials; secondly, conveying the crushed garbage plastic sheets into a wind separator, spirally propelling plastic sheet materials and impurities therein along with the hot air flow, generating vibration during the propelling, completely separating the plastics from the impurities and falling on different positions due to density difference between the plastics and the impurities, picking out the plastic sheet materials and removing impurities; simultaneously, accelerating vaporization of moisture in the action of hot wind, sending the dried and clean plastic sheet materials subjected to the air separation to a granulation device and making into reusable particles; and finally, adding a modifier with compatible and coupling property to the garbage plastic particles, mixing and then making into plastic particle materials for producing products. According to the invention, the garbage plastics can be recycled, and the method is relatively simple and the pollution to the environment is little. The treated recycled plastics comprise garbage plastics capable of being used for manufacturing of cast-in-place reinforced concrete core moulds and raw production materials such as granulation materials and the like, or manufacturing industry, building and articles for daily life and the like.

Owner:阳文皇

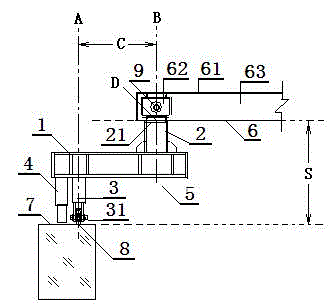

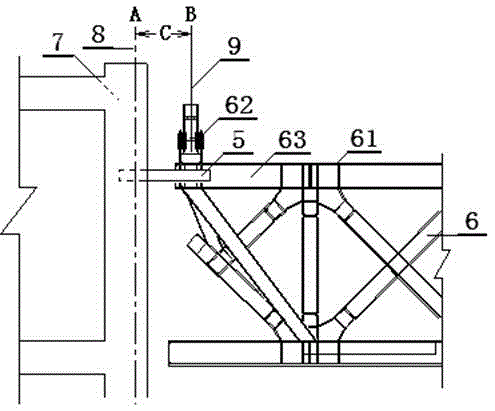

Deviation integral elevation steel corridor carrying method and lateral limiting device thereof

ActiveCN103603496AReduce transport volumeImprove work efficiencyBuilding material handlingOperabilityBuilding construction

The invention relates to a deviation integral elevation steel corridor carrying method and a lateral limiting device thereof. According to the method, an upper chord of the outer sides of lifting lugs of the two ends of an existing steel corridor is closely provided with the lateral limiting device which is composed of a force transmitting steel beam and front and rear support rods on the front and rear side surfaces of the steel beam and has front and rear as well as left and right limiting functions and a function of supporting the steel corridor to deflect from below an orthographic projection of the set position of the steel corridor, so that steel corridors can be combined and assembled on the ground on the limiting position of the lateral limiting device, a hanging mechanism can hoist in a low level slant manner, barriers below the orthographic projections of the set positions of the steel corridors are avoided, and the corridors can integrally perpendicularly rise in a deviation manner. The deviation integral elevation steel corridor carrying method and the lateral limiting device thereof provided by the invention have the advantages that the problem that normal construction is influenced by building barriers below the orthographic projections of the set positions of the steel corridors is solved, the high altitude operation capacity and the transport capacity of dispersing materials are reduced, the construction is convenient, the operational efficiency is high, the construction cost is low, the construction quality is guaranteed, and the production is safe. The deviation integral elevation steel corridor carrying method is an innovation of the construction process for vertically lifting a steel structure piece in a wide span and has high practicability and operability.

Owner:JIANGSU TONGZHOU FOURTH CONSTR GROUP +1

Ink jet printing apparatus and printing method

By suppressing deviation of dot-formation positions stemming from insufficient accuracy in conveying a printing medium due to eccentricity of a conveying roller, a printed image in which unevenness is less visible is obtained. An accumulated amount of conveyance errors is decreased by narrowing a nozzle-use range and reducing a conveyance amount over an entire printing region according to a mode used for printing an image in which the coverage of a printing medium is low due to a small number of ink colors to be used, for example, a mode used for printing a monochrome image by using a black ink dominantly in all of the density regions.

Owner:CANON KK

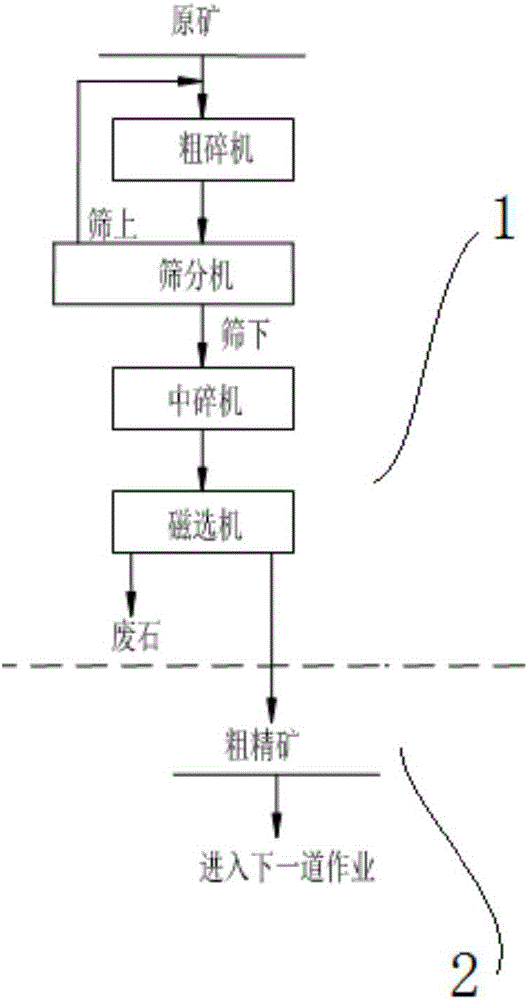

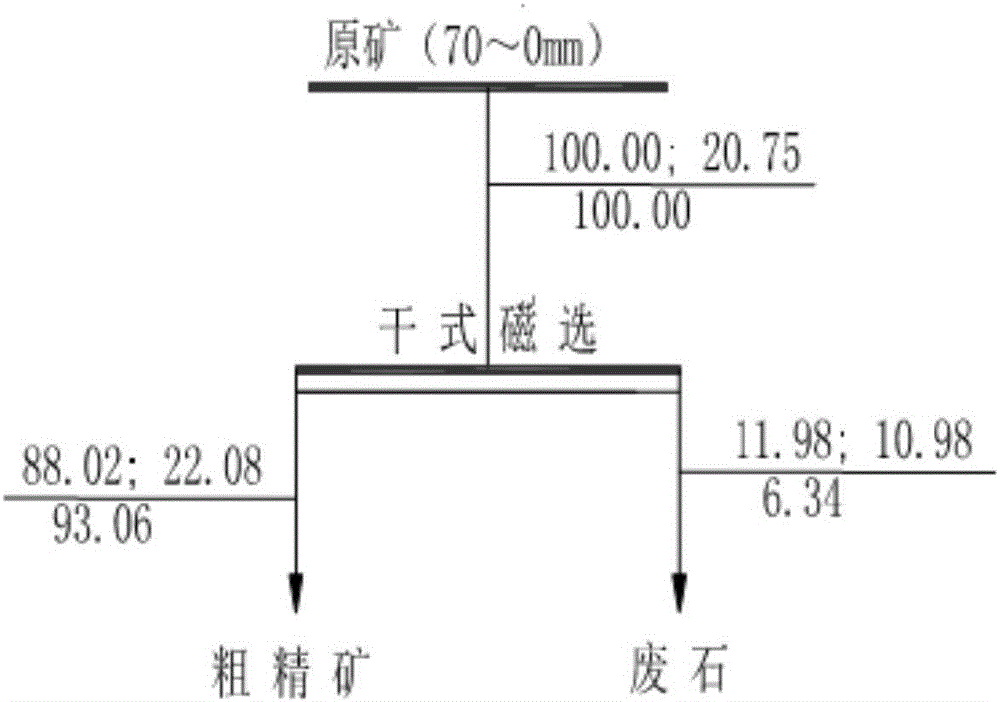

Beneficiation process of lean magnetite ores and production system thereof

ActiveCN106111297AImprove gradeReduce ore transportationMagnetic separationGrain treatmentsMagnetic separatorIronstone

The invention discloses a beneficiation process of lean magnetite ores and a production system thereof, and belongs to the technical field of beneficiation. The beneficiation process comprises the following steps: coarse crushing, intermediate crushing, magnetic separation and transferring. An intermediate crushing device is placed at the front of an ore stope, coarse crushing, intermediate crushing and dry magnetic separation are directly carried out on the stope, the purpose of 'early throwing and discarding' tailings and waste rock is achieved, the grade of rough concentrates is improved, the conveyance amount of the ores is reduced, the conveyance cost of the ores is also reduced, the service lives of a belt and a funnel lining plate of a magnetic separator are prolonged, and therefore, the operation cost of a mine is reduced effectively. The production system comprises a coarse crusher, a screening machine, an intermediate crusher, the magnetic separator, a belt conveyor I and a belt conveyor II, wherein the coarse crusher, the screening machine, the intermediate crusher and the magnetic separator are successively arrayed according to a production line in the ore stope; the belt conveyor I conveys the tailings and the waste rock to a dumping site after the tailings and the waste rock are separated magnetically; and the belt conveyor II conveys magnetically separated rough concentrates to a follow-up process. An iron ore extraction region is expanded, and for the actual situation that lean iron ores are main iron ores in China, the beneficiation process of the lean magnetite ores and the production system thereof are particularly worthy of being popularized and used.

Owner:马钢集团设计研究院有限责任公司

Foundation construction of precast concrete pipes

InactiveCN1712643AReduce transport volumeReduce workloadFoundation engineeringEngineeringPrecast concrete

Owner:胡彦彬

Gas field sewage harmless treatment method

InactiveCN105523596ASolve harmless disposalSolve the pollution of the environmentWaste water treatment from quariesGeneral water supply conservationSocial benefitsSewage treatment

The invention discloses a gas field sewage harmless treatment method comprising the following steps: water content in the gas field sewage is evaporated with a ventilation method, such that gas field sewage is turned harmless. With the method, defects of existing gas field sewage treatment methods are overcome; a gas field sewage harmless treatment problem can be effectively solved; a gas field sewage environment pollution problem can be effectively solved; gas production auxiliary agents and useful substances in the gas field sewage can be effectively recycled; cost and energy consumption for recycling the gas production auxiliary agents and useful substances in the gas field sewage can be greatly reduced; and gas field sewage transportation volume, transportation cost, treatment energy consumption and treatment cost can be greatly reduced. The method is safe and reliable, and has the advantages of easy implementation, wide application, easy popularization and the like. The method provides significant economic and social benefits.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com