Heat preservation pipe prefabricated by powder heat insulating materials

A technology for prefabricating thermal insulation pipes and thermal insulation materials, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve problems such as structural damage of thermal insulation materials, and achieve the effects of low comprehensive cost, reasonable structure and thin thermal insulation thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

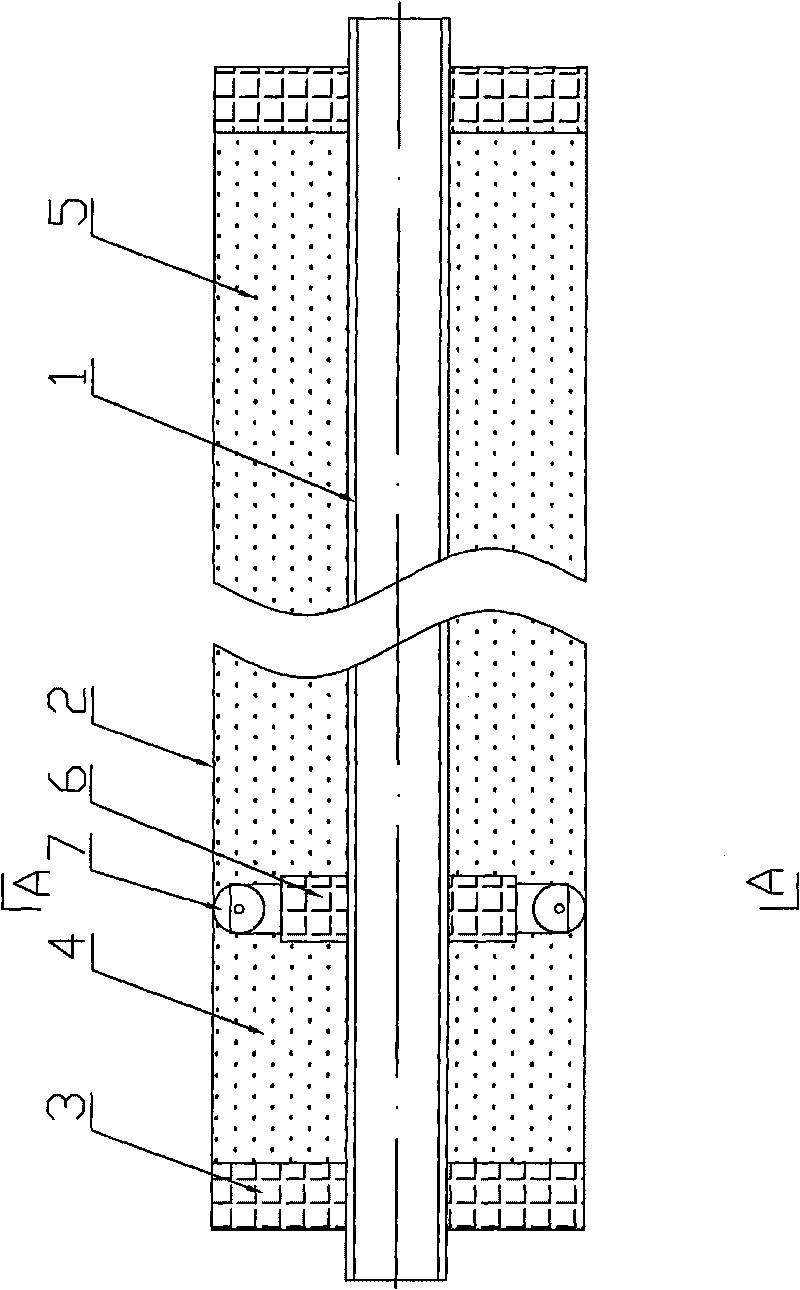

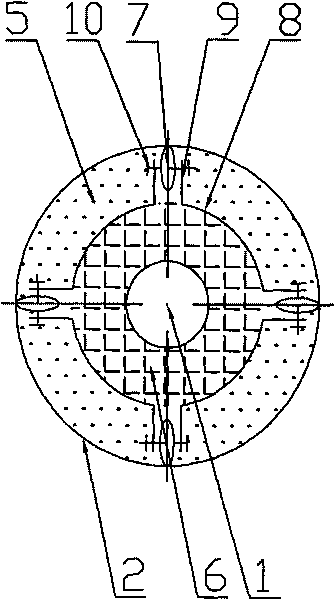

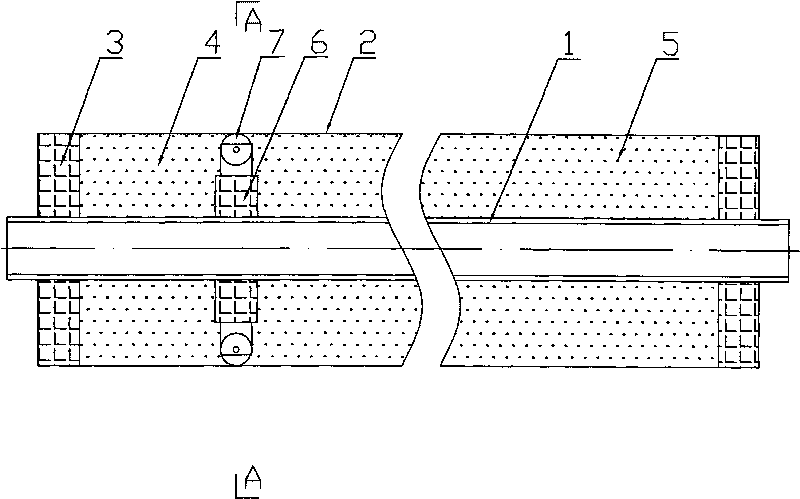

[0031]Example 1: ¢114 steel pipe is used as the working steel pipe, ¢168 steel pipe is used as the outer protective steel pipe, and there is a sliding support frame made of nano-silica aerogel as the heat-insulating liner ring 6, and both ends are also equipped with nano-silica airgel. The heat-insulating sealing plug 3 made of silica airgel, and the nano-silica airgel powder is filled in the heat-insulating chamber 4 in a natural accumulation form, so a new type of insulation pipe entity with a "tube-powder-tube" structure is made .When the 350°C heat transfer oil is transported in the working steel pipe 1, and kept for about 24 hours. Start the test and repeat the measurement many times: when the ambient temperature is about 18°C (average value), after continuously transporting the heat medium for 24 hours, the outer The average surface temperature of the protective tube 2 is about 30°C, and the average temperature of the outer protective tube 2 at the sliding support frame...

example 2

[0032] Example 2: As described in Example 1, Example 2 uses a pipe-in-pipe device with the same structure and specifications, and fills the large-pore-volume silica powder in the heat-insulating cavity 4 to obtain the "tube-powder-tube" insulation Tube. According to the same method as Example 1, the average surface temperature of the outer protective tube 2 of the insulation pipe is about 35° C., and the average surface temperature of the outer protective tube 1 at the sliding support frame is about 40° C. When the temperature of the heat transfer oil conveyed in the working steel pipe 1 is repeatedly at normal temperature (15°C--20°C) or 350°C alternately, the structure of the overall heat preservation pipe remains unchanged, there is no heat leakage or heat dissipation of the bare pipe, and the outer protection of the heat preservation pipe There is no abnormality in the external temperature and internal insulation layer of tube 2, and the operation is good.

example 3

[0033] Example 3. As described in Example 2, Example 3 uses ¢273 steel pipe as the working steel pipe 1, and ¢400 rigid polyvinyl chloride double-wall corrugated pipe as the outer protective pipe 2, with a sliding support frame inside and two ends. Adiabatic sealing plug 3 made of nano-silica aerogel. The thermal insulation chamber 4 is filled with large pore volume inorganic powder material to make the thermal insulation layer 5, which is in a natural accumulation state and has a thickness of about 42 mm, which is a thermal insulation tube with a "steel-plastic" "tube-powder-tube" structure. At an ambient temperature of about 15°C to 20°C, heat flow is introduced into the working steel pipe 1, and the temperature continues to rise, and the external temperature is stabilized at several temperature points for 6 hours to test the external temperature. Whether the structure is damaged, the test data is as follows:

[0034] Heat flow temperature in working steel pipe

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com