A method for recycling waste plastics

A technology of plastics and garbage, which is applied to the preparation of building components on site, building components, climate change adaptation, etc., to achieve the effect of less environmental pollution and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

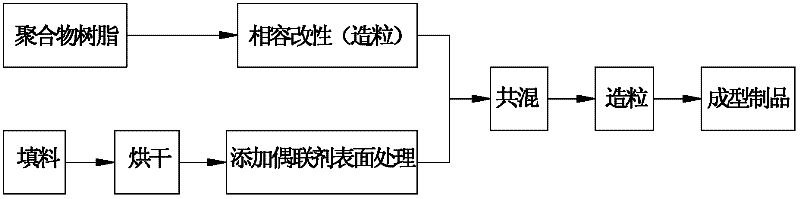

Method used

Image

Examples

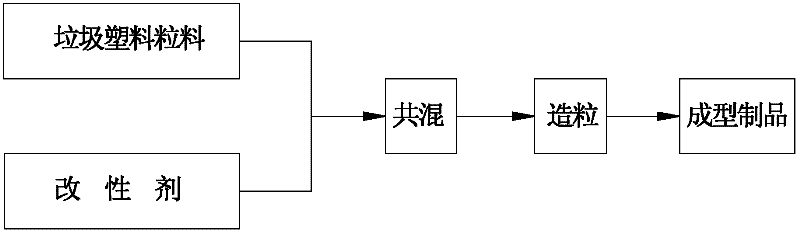

Embodiment 1

[0018] Embodiment 1, the present invention modifies garbage plastics by developing a modifier with compatibility and coupling, and then produces construction products. The principle is: the types of plastics contained in garbage plastics are basically thermoplastics such as PE, PP, ABS, EVA, etc., and there are also very small amounts of PVC, PET, etc.; Grafting plant fibers such as polar monomers and maleic anhydride on the molecular chains of permanent polyolefin resins, ethylene acrylic acid copolymers are used as polymer compatible modifiers, and the modifiers can be acrylate copolymers, Any one of maleic anhydride-modified polyolefin resin, ethylene acrylic acid copolymer grafted with polar monomers, or grafted plant fibers such as maleic anhydride, or two or two of them Any combination of the above substances. When the modifier is added, the weight ratio of the garbage plastic pellets to the modifier is 100: (1-2). By adding the above-mentioned modifiers, the main chai...

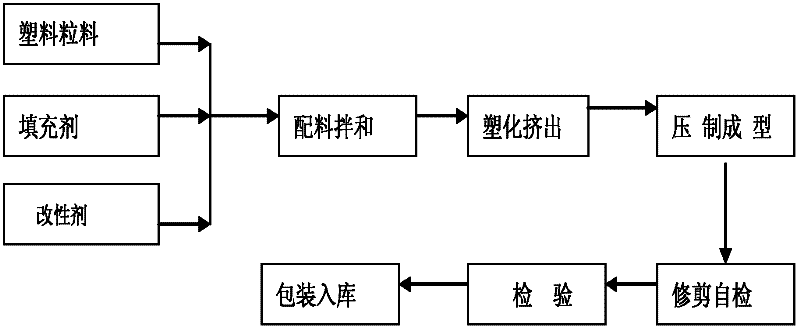

Embodiment 2

[0019] Example 2, first directly granulate recycled garbage plastics, then add modifiers with compatibility and coupling properties and fillers to mix and carry out alloy modification. When modifiers are added, garbage plastic pellets and modified The weight ratio of the agent is 100: (1-2), and the filler can be any one of rice husk, bran powder, or wood powder, or any combination of any two or more of them, modified The weight ratio of the final plastic pellets to the filler is 100: (25-35). Because the main component of the filler is cellulose, the present invention uses organic fibers such as rice husk, bran powder, and wood powder as fillers to physically modify waste plastics, and adopts green and environmentally friendly raw materials to produce a brand new green and environmentally friendly plastic. wood material. It is then made into plastic pellets to produce buried drainage composite pipes for municipal construction, composite core molds or mold shells for building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com