Workshop layout method of discrete manufacturing system

A layout method and technology for manufacturing systems, applied in general control systems, control/regulation systems, program control, etc., can solve the problem of unsatisfactory global optimization capability and calculation time performance, low search efficiency of genetic algorithm, slow convergence speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

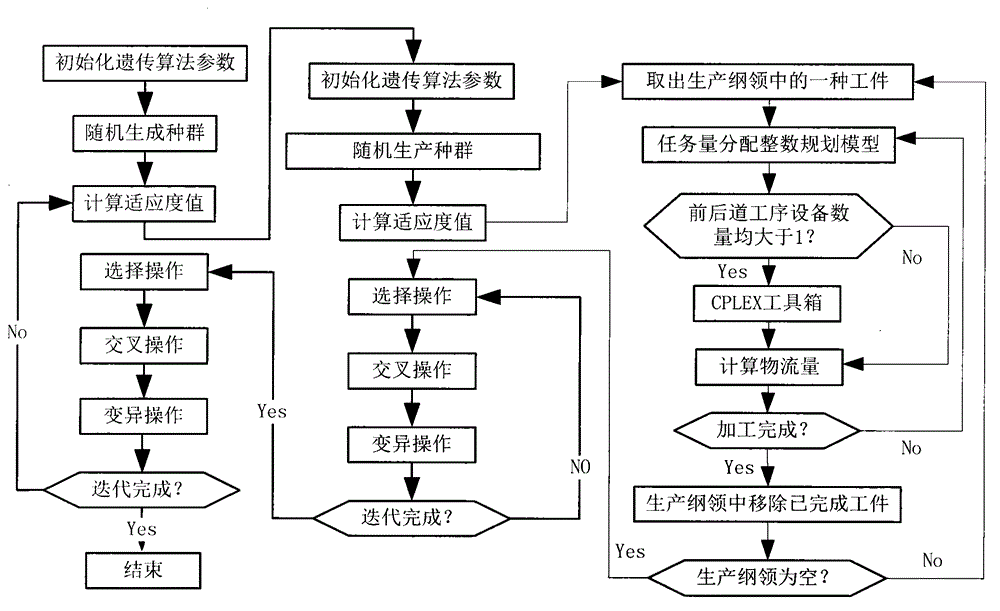

[0067] Specific examples figure 1 , figure 2 Shown, the realization steps of the present invention are as follows:

[0068] A. The UI layer of the system is used to input workshop equipment and production information to the layout design platform;

[0069] For example, workshop equipment and production information are shown in Tables 1, 2, and 3 respectively:

[0070] Table 1 Information table of workshop equipment

[0071] device ID

[0072] Table 2 Product order information table

[0073] product number

[0074] 5

[0075] Table 3 Product process information table

[0076]

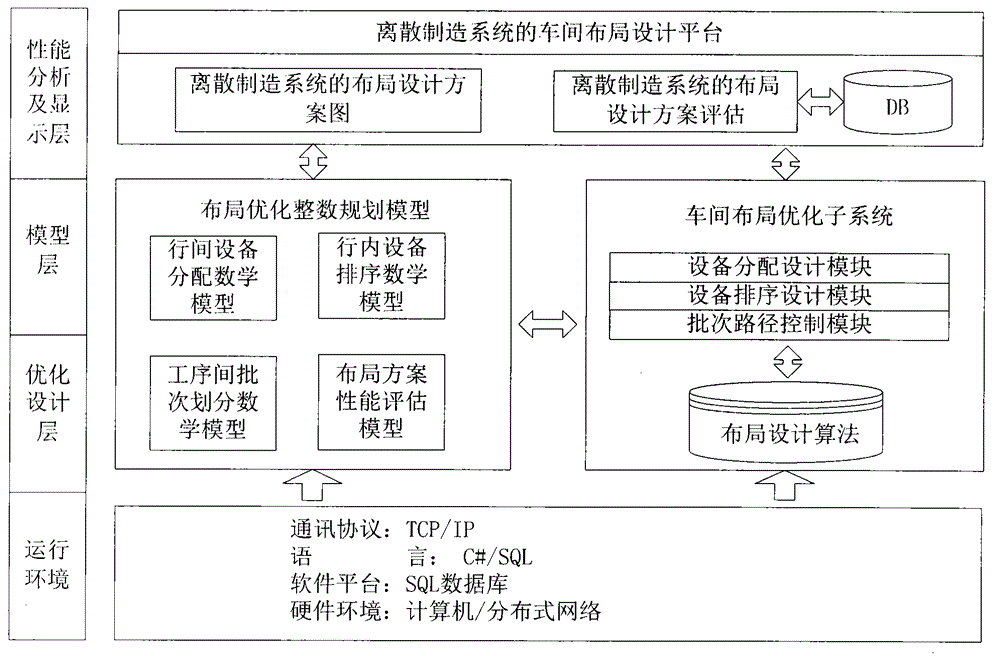

[0077] B. Model building layer. According to the entered workshop information, build the mathematical model of inter-row equipment allocation, the mathematical model of intra-row equipment sorting, the mathematical model of batch division between processes, and the performance evaluation model of layout schemes;

[0078] C. Workshop layout optimization subsystem. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com