Multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness

An integrated system and steel structure technology, applied in residential buildings, building components, building structures, etc., can solve problems affecting the site environment, difficulty in grouting site control, unreasonable structural layout, etc., to reduce road transportation volume, The effect of reducing the labor intensity of workers and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

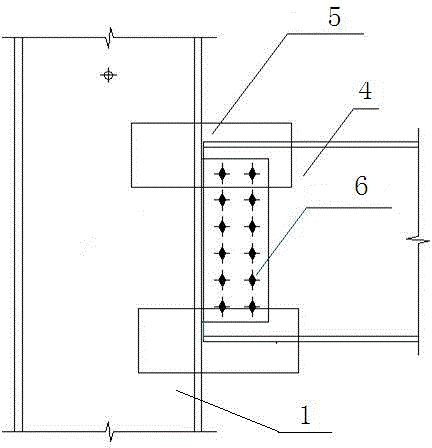

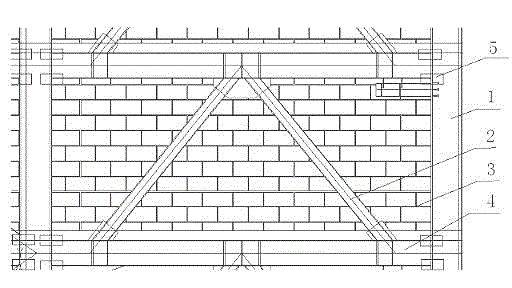

[0013] With reference to the accompanying drawings, the multi-high-rise steel structure residential integrated system with pillars and walls of the same thickness according to the present invention adopts a structural scheme of rectangular steel pipe concrete pillars-steel frame beams-steel supports, and sets exterior walls and household walls in the steel structure frame. , core wall and firewall, indoor partition walls are set in the room, and floor slabs are set between steel frame beams on each floor. The characteristics are: the width of the columns is 180-200 mm, and there are no internal partitions and transverse partitions inside the columns The beam width of the outer ring combined with the column is limited to within 200mm. After brushing the fireproof coating and the smoothing layer outside the fireproof coating, the total width is less than or equal to 0.24~0.28m, which increases the usable area, especially the following The usable area of 1 / 2 floor; the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com