Gangue separating method and device for mine

A coal gangue separation and mine technology, which is applied in solid separation, chemical instruments and methods, sieves, etc., can solve the problems of hidden dangers of radioactive source radiation, small sorting capacity, environmental pollution, etc., and achieves saving floor space and reducing pollution. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

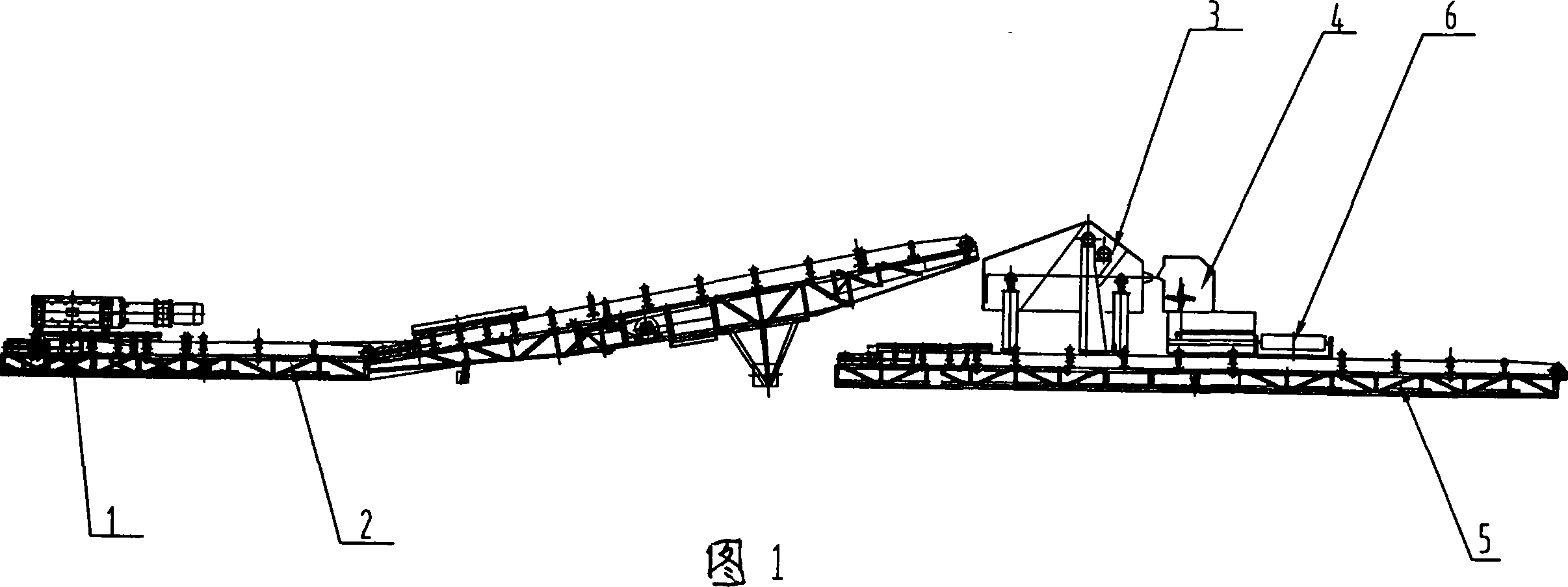

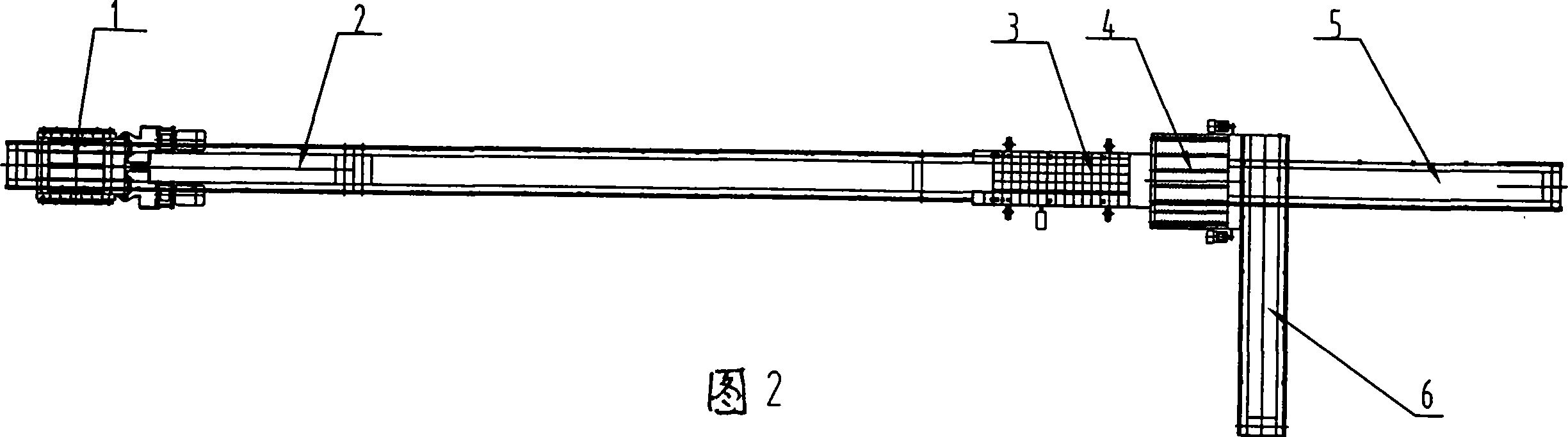

[0015] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

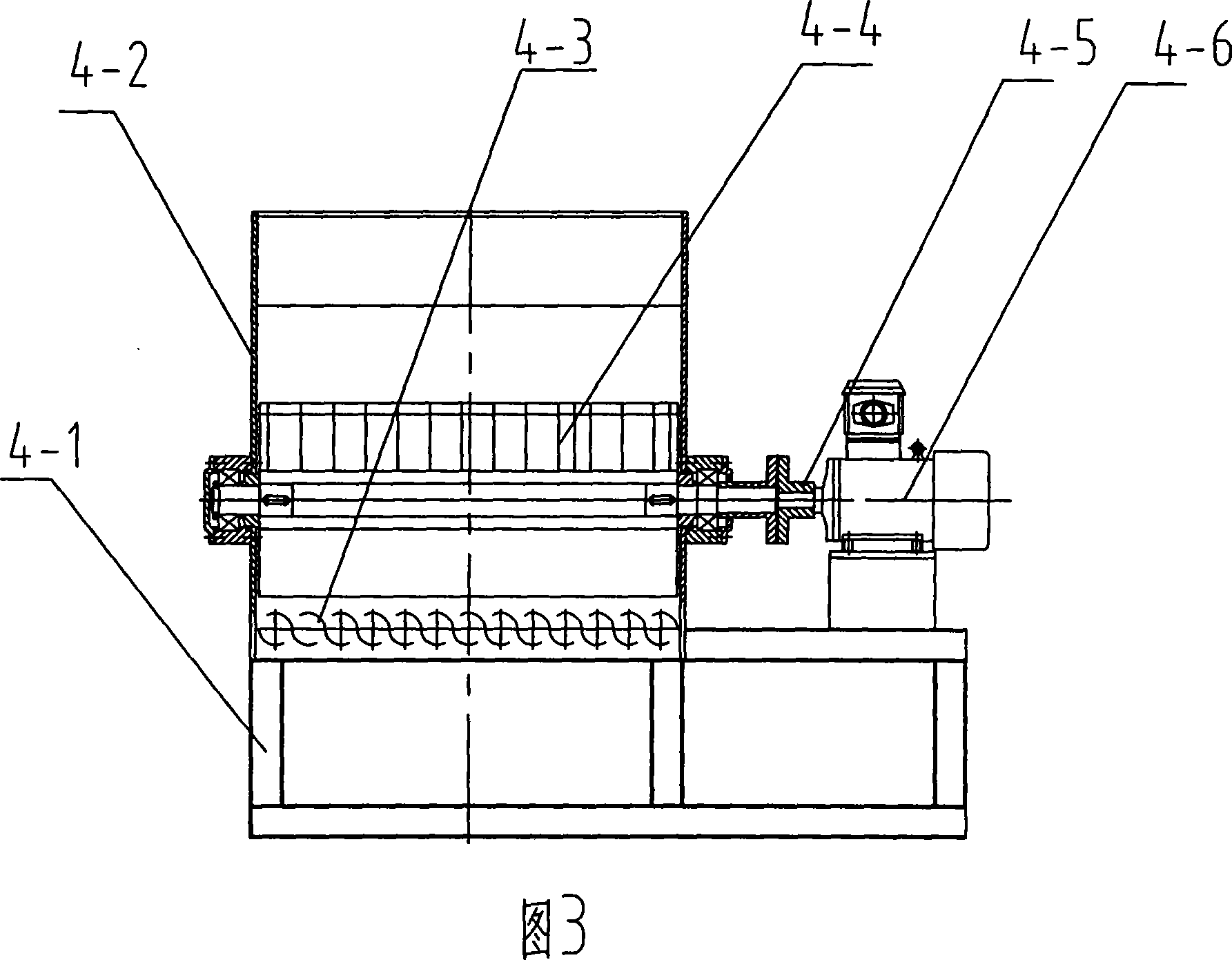

[0016] The mine coal gangue separation method of the present invention: send the mixed material of coal and gangue mined underground into the screening crusher 1 for preliminary crushing, and then send the material into the screening machine 3 through the front belt conveyor 2 for material screening , the mixed coal less than 50mm screened by the screening machine 3 falls under the screen and enters the rear belt conveyor 5 to be sent to the underground coal bunker; The rotating impeller in 4 crushes and separates the large mixed coal, and the crushed coal smaller than 50mm falls into the rear-mounted belt conveyor 5 through the spiral sieve plate of the crushing separator 4 and is sent to the underground coal bunker , the unbroken gangue is thrown to the tailgate under the force of the spiral rotation of the middle impeller, and falls into the gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com