Deviation integral elevation steel corridor carrying method and lateral limiting device thereof

A technology of overall upgrading and steel corridors, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as construction, achieve the effects of ensuring construction quality, reducing the amount of high-altitude operations, and broadening market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

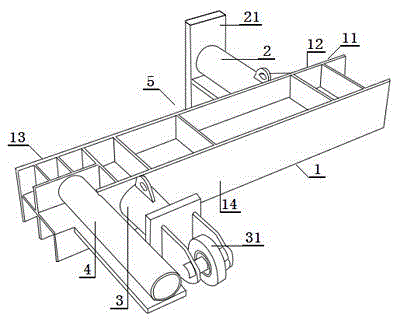

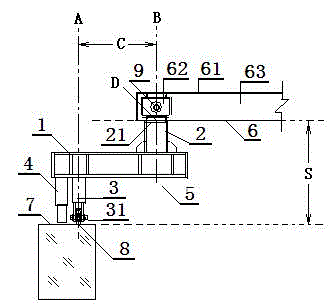

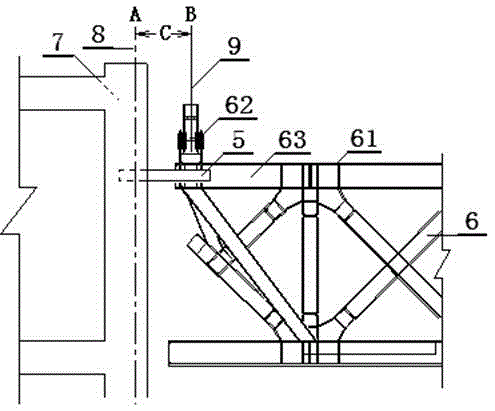

[0022] exist figure 1 , figure 2 and image 3 Among them, the method and the lateral limiting device of the present invention for partial overall lifting of steel corridors are realized in the following way: through the outermost side of the existing steel corridor 6 composed of several steel trusses and several steel frames A welding setting is added on the upper chord 63 on the outer side of the lug 62 of a steel truss 61. The upper limit supports the steel corridor 6 in the front, rear, left and right directions and deviates from the position below the orthographic projection of the steel corridor to avoid the steel connection. The corridor is provided with a lateral limiting device 5 for hanging and lifting the obstacles between the ground floors below the orthographic projection, so that the steel corridor 6 can deviate from the obstacle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com