Gas field produced wastewater reduction and harmless treatment methods

A technology for gas field produced water and treatment method, which is applied in the field of gas field produced water reduction and harmless treatment, and can solve the problems of energy consumption, high cost, inability to recover useful substances, affecting gas field development and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

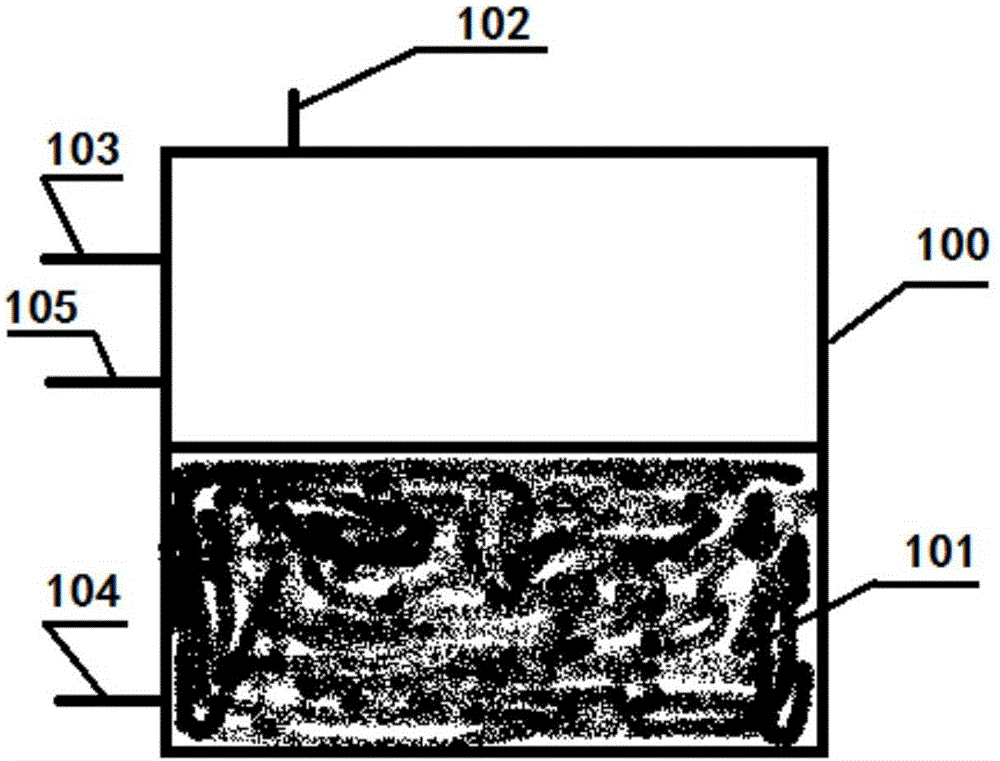

[0519] The invention relates to a gas field produced water reduction treatment method, which uses a desalination method to separate water from the gas field produced water to form concentrated gas field produced water, so as to reduce the volume of the gas field produced water and reduce the freight and treatment costs of the gas field produced water.

[0520] The desalination method should be able to effectively reduce the volume of gas field produced water, and should be able to effectively reduce the difficulty of reinjection of gas field produced water or / and effectively reduce the difficulty of further processing or comprehensive utilization of gas field produced water; There are technical methods that can determine the specific scheme, equipment and facilities, and process flow of the desalination method, can determine the proportion or percentage, physical form, water volume, and flow rate of the water separated from the produced water of the gas field, and can determine ...

Embodiment 2

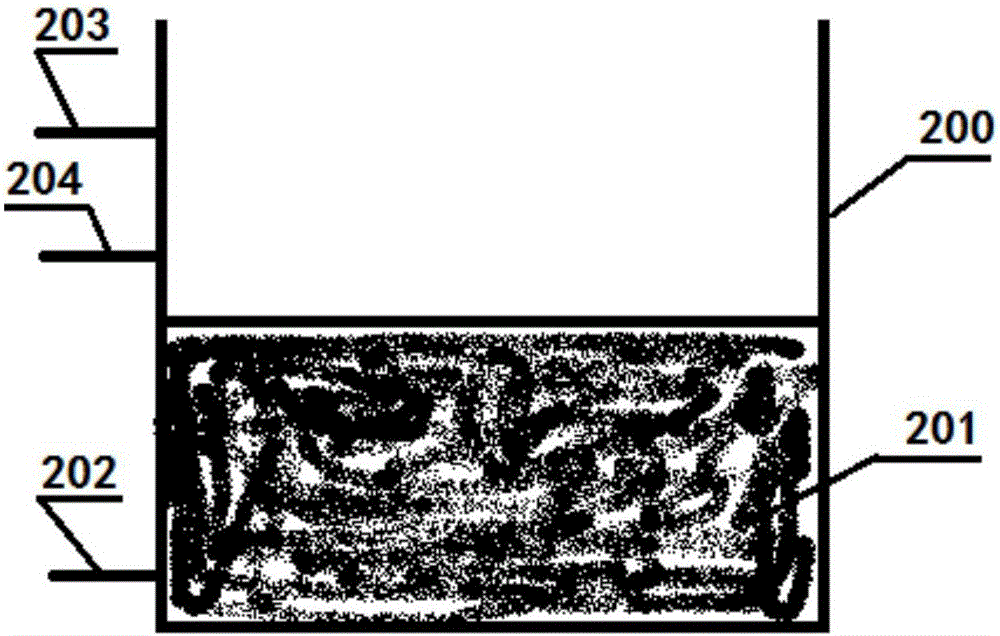

[0529] With embodiment 1, its only difference is that described desalination method adopts freezing method, freezing method such as natural freezing desalination method and artificial refrigeration freezing desalination method, high-efficiency membrane method such as polymer separation membrane method and biofilm method, Electrodialysis, such as ion exchange membrane electrodialysis and electric submerged bridge membrane, distillation, such as pressure steam distillation, forward osmosis, such as non-pressurized adsorption osmosis, semi-permeable membrane, reverse osmosis, ultrafiltration, such as Ultrafiltration membrane method and nanofiltration membrane method, microfiltration method such as microfiltration membrane method, ion exchange method such as ammonium carbonate ion exchange method, ion resin exchange method such as cation resin exchange method and hydrogen ion resin exchange method, low temperature distillation method such as low temperature Multi-effect distillatio...

Embodiment 3

[0538] With embodiment 1, its difference is only, described desalination method refers to freezing method, freezing method, efficient membrane method, electrodialysis method, distillation method, forward osmosis method, semi-permeable membrane method, reverse osmosis method, super Filtration, microfiltration, ion exchange, ion resin exchange, cryogenic distillation, solar energy, flash evaporation, membrane distillation desalination, negative pressure evaporation, adsorption desalination, dew point evaporation, spray evaporation, vacuum Any arbitrary series or / and parallel method of the freezing method, hydropower cogeneration method, and thermal film cogeneration method.

[0539] The desalination method utilizes any one of nuclear energy, solar energy, wind energy and tidal energy or any combination of two or more to provide power and / or pressure for desalination processes, devices or facilities.

[0540] Tests have shown that: with 3 sets of reverse osmosis membrane modules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com