An application method of treated oil-based rock debris in an inorganic stable road base

A road base, inorganic stable technology, applied in the direction of roads, roads, sustainable waste treatment, etc., can solve problems such as easy cracks, high cost of rigid base materials, and damage to road surface structures, so as to reduce the amount of cement and solve the problem of harmless The effect of dealing with problems and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As the best implementation mode of the present invention, the present invention discloses a method for applying treated oil-based cuttings to inorganic stabilized road base, the steps are as follows:

[0027] (1) Using LRET technology and thermal analysis technology to process oil-based cuttings. The toxicity, flammability, corrosiveness, reactivity and acute toxicity of the leachate after treatment are all qualified and ready for use;

[0028] (2) Before the construction of the base layer, a comprehensive inspection of the base layer should be carried out. The surface of the base layer should be flat and solid, and it should have a specified road arch. Phenomenon;

[0029] (3) The mixture shall be fully mixed according to the content of gravel at 52%, sand at 12%, cement at 3-5%, and oil-based cuttings at 31-33%.

[0030] (4) Layer-by-layer filling: layer-by-layer compaction, the thickness of layered loose paving is less than 30cm, and the full-width and full-width f...

Embodiment 2

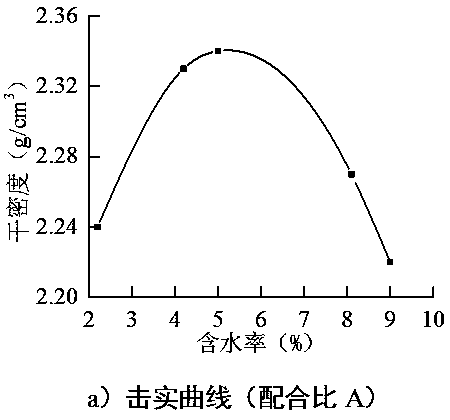

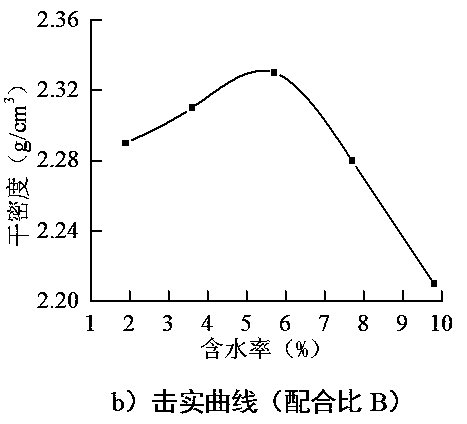

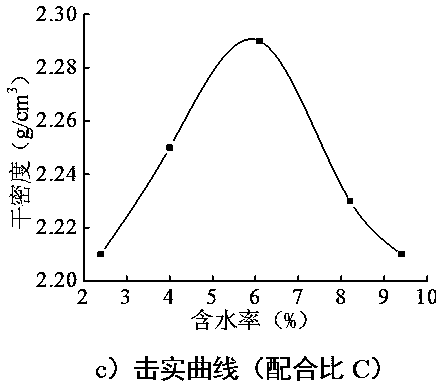

[0032] Refer to the attached Figure 1-3, this embodiment is a verification example, and the cost of cement-stabilized gravel materials mainly comes from the purchase and transportation costs of cement, gravel and sand. The mining of aggregates not only consumes manpower, material resources, and financial resources, but also has a certain impact on the ecological environment. In recent years, various places have attached great importance to environmental protection and restricted the mining of sand and gravel, which has also caused the continuous rise of raw material prices and increased construction costs. As a kind of industrial solid waste, oil-based cuttings can replace some sand and be used in inorganic binders, which will not only increase the treatment of oil-based cuttings, but also reduce construction costs. Different proportions of raw materials are blended to make the pavement structure meet the design requirements in terms of strength, which is technically reliabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com