Method for fermenting and drying straw laying hen fodder

A technology of laying hen feed and straw, which is applied in the field of fermentation and drying of straw laying hen feed, to achieve the effects of promoting the reproduction of different straw degrading microorganisms, increasing the spraying area, and improving the nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

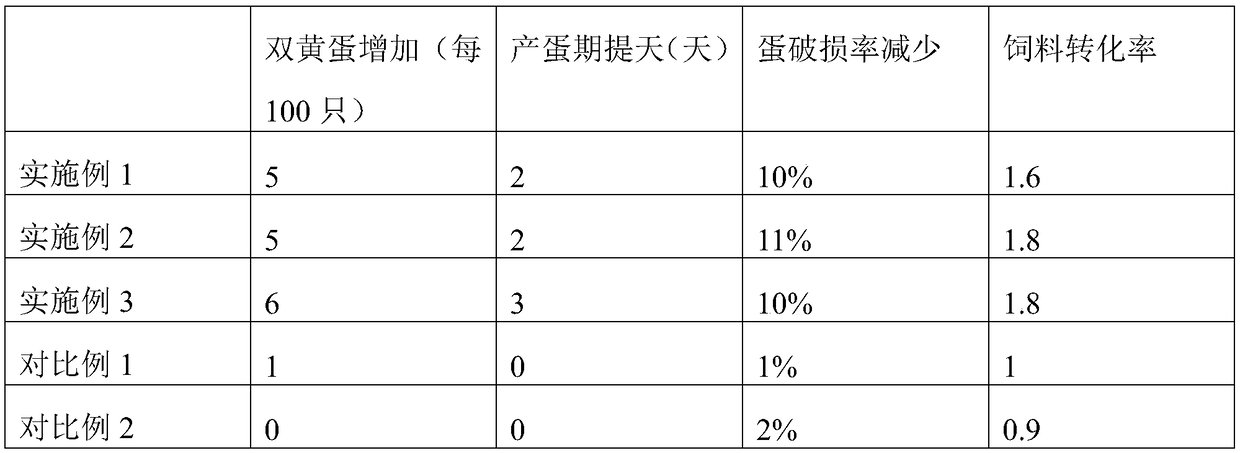

Examples

Embodiment 1

[0037] This embodiment provides a method for making straw fermented laying hen feed, the steps include

[0038] 1) Select 50 parts of corn stalks, 30 parts of sorghum stalks and 20 parts of soybean stalks in parts by weight;

[0039] 2) Separately pulverize corn stalks, sorghum stalks and soybean stalks to obtain corn stalk powder, sorghum stalk powder and soybean stalk powder, wherein the corn stalk powder has a mesh size of 100 mesh, the sorghum straw powder has a mesh size of 200 mesh, and the soybean straw powder has a mesh size of 100 mesh. 150 mesh;

[0040] 3) Put corn straw powder, sorghum straw powder and soybean straw powder into different soaking pools for hot water soaking, the temperature of hot water is 60°C for 1 hour;

[0041] 4) Cook the soaked corn stalk powder, sorghum stalk powder and soybean stalk powder respectively, put the corn stalk powder into a first cooking tank, inject a sodium sulfite solution with a concentration of 20% into the first cooking ta...

Embodiment 2

[0057] This embodiment provides a method for making straw fermented laying hen feed, the steps include

[0058] 1) Select 80 parts of corn stalks, 40 parts of sorghum stalks and 30 parts of soybean stalks in parts by weight;

[0059] 2) Separately pulverize corn stalks, sorghum stalks and soybean stalks to obtain corn stalk powder, sorghum stalk powder and soybean stalk powder, wherein the corn stalk powder has a mesh size of 200 mesh, the sorghum straw powder has a mesh size of 300 mesh, and the soybean straw powder has a mesh size of 300 mesh. 300 mesh;

[0060] 3) Put corn straw powder, sorghum straw powder and soybean straw powder into different soaking tanks for hot water soaking, the temperature of hot water is 70°C for 2 hours;

[0061] 4) Cook the soaked corn stalk powder, sorghum stalk powder and soybean stalk powder respectively, put the corn stalk powder into a first cooking pot, inject a sodium sulfite solution with a concentration of 25% into the first cooking po...

Embodiment 3

[0077] This embodiment provides a method for making straw fermented laying hen feed, the steps include

[0078] 1) Select 60 parts of corn stalks, 35 parts of sorghum stalks and 25 parts of soybean stalks in parts by weight;

[0079] 2) Separately pulverize corn stalks, sorghum stalks and soybean stalks to obtain corn stalk powder, sorghum stalk powder and soybean stalk powder, wherein the corn stalk powder has a mesh size of 150 mesh, the sorghum straw powder has a mesh size of 250 mesh, and the soybean straw powder has a mesh size of 150 mesh. 200 mesh;

[0080] 3) Put corn straw powder, sorghum straw powder and soybean straw powder into different soaking tanks for hot water soaking, the temperature of hot water is 65°C for 1.5 hours;

[0081] 4) Cook the soaked corn stalk powder, sorghum stalk powder and soybean stalk powder respectively, put the corn stalk powder into a first cooking pot, inject a sodium sulfite solution with a concentration of 22% into the first cooking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com