Stabilization landfill process of fluoride

A fluoride, stable technology, applied in the field of solid waste treatment, to achieve the effect of simple landfill process and solve the problem of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

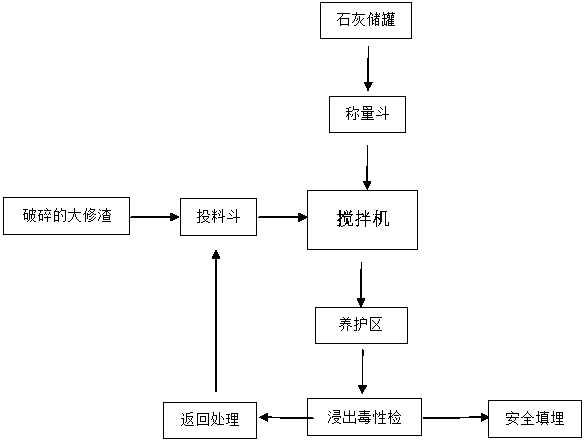

Image

Examples

Embodiment 1

[0019] A fluoride stabilization and solidification landfill process, comprising the following steps: 1) adding 30 times the amount of water to the electrolytic aluminum overhaul waste slag based on the weight of the electrolytic aluminum overhaul waste slag, soaking for 1 hour; 2) adding 2% hexahydrate Calcium chloride, stir evenly; 3) Add 0.5‰ polyaluminum chloride, stir evenly, and make a slurry; 4) Cured in the landfill conservation area for 8 days, and the solidified body formed is tested for fluoride ion by using a fluoride ion analyzer. Determination, the measured concentration of fluoride ion is 50.3 mg / L, which is lower than the standard requirement in "Hazardous Waste Identification Standard-Leach Toxicity Identification".

Embodiment 2

[0021] A landfill process for stabilizing fluoride, comprising the following steps: 1) adding 20 times the amount of water to the solid waste based on the weight of the electrolytic aluminum overhaul waste slag, and soaking for 3 hours; 2) adding 6% chlorinated hexahydrate Calcium, stir evenly; 3) Add 1.2‰ polyaluminum chloride, stir evenly, and make a slurry; 4) Curing in the landfill curing area for 14 days, the formed solidified body is measured by fluoride ion analyzer, The measured fluoride ion concentration was 43.5 mg / L, which was lower than the standard requirements in the "Identification Standards for Hazardous Wastes - Identification of Leaching Toxicity".

Embodiment 3

[0023] A fluoride stabilization and solidification landfill process, comprising the following steps: 1) Adding 25 times the amount of water to the solid waste residue based on the weight of the electrolytic aluminum overhaul waste residue, and soaking for 2 hours; 2) Adding 4% chlorinated hexahydrate Calcium, stir evenly; 3) Add 1‰ polyaluminium chloride, stir evenly, and make a slurry; 4) Cured in the landfill curing area for 10 days, and the solidified body formed is measured by fluoride ion analyzer, The measured concentration of fluoride ions was 36.7 mg / L, which was lower than the standard requirement in "Identification Standards for Hazardous Wastes - Identification of Leaching Toxicity".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com