Gypsum-based pre-mixed mortar and preparation method thereof

A technology of ready-mixed mortar and production method, which is applied in the field of building materials, can solve problems such as reduced construction requirements, achieve the effects of reduced construction requirements, overcome easy cracking, and good fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

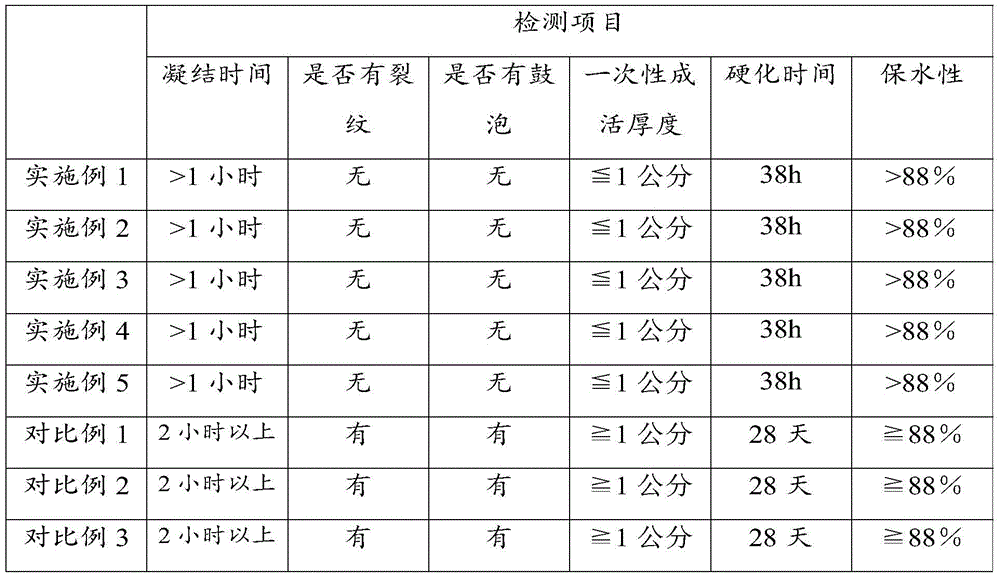

Examples

Embodiment 1

[0043] 450 kg of sulfur hemihydrate gypsum, 550 kg of heavy calcium, 53330.5 kg, 0.2 kg of redispersible latex powder, 0.2 kg of foaming agent, and 1 kg of gypsum retarder.

[0044] After the above components are fully mixed, the gypsum-based ready-mixed mortar is obtained.

Embodiment 2

[0046] 500 kg of sulfur hemihydrate gypsum, 600 kg of cinder, 53331.5 kg, 0.5 kg of neutral redispersible latex powder, 1 kg of sodium lauryl sulfate, and 10 kg of citric acid.

[0047] After the above components are fully mixed, the gypsum-based ready-mixed mortar is obtained.

Embodiment 3

[0049] 470 kg of sulfur hemihydrate gypsum, 580 kg of zeolite powder, 53331.2 kg, 0.7 kg of flexible redispersible latex powder, 0.7 kg of sodium dodecylsulfonate, and 6 kg of sodium citrate.

[0050] After the above components are fully mixed, the gypsum-based ready-mixed mortar is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com