Patents

Literature

189results about "Purification using alkaline earth metal compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

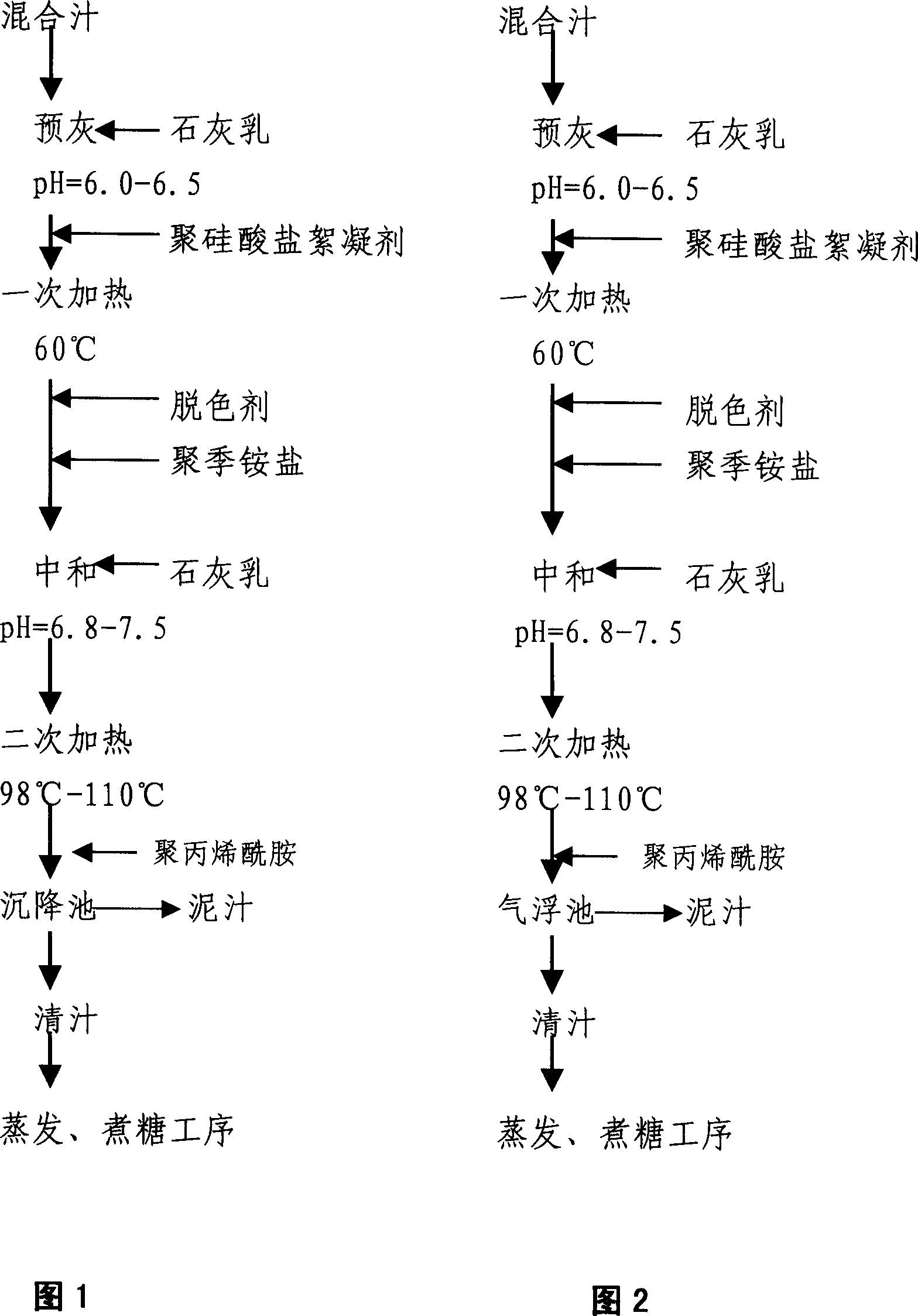

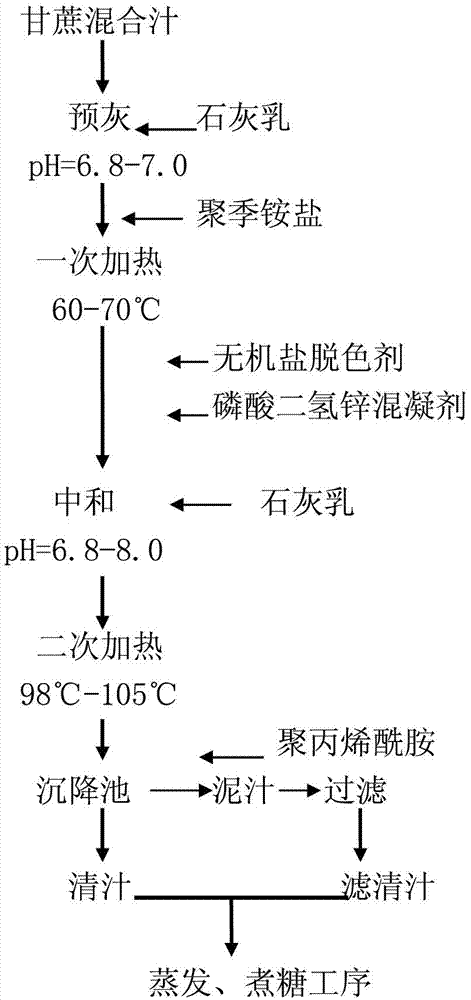

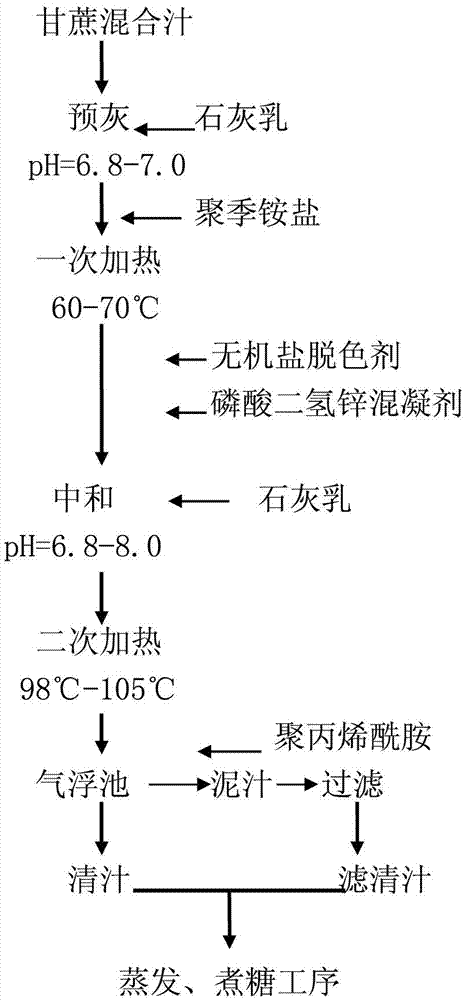

New clarification technique for refining sugar from sugar cane

InactiveCN101003842AHigh purityShort processPurification using alkaline earth metal compoundsSugar juice boiling/evaporationSulfurPhosphoric acid

This invention provides a new process for clarifying sugar produced from sugarcane. The process comprises: (1) adding inorganic decolorant, poly (quaternary ammonium salt), polysilicate coagulant and polyacrylamide into sugarcanejuice, heating, adding lime suspension to neutralize, heating, and separating clear juice and mud slurry in a precipitation pool or a flotation pool; (2) evaporating the clear juice, concentrating, boiling, crystallizing, and separating to obtain sugar product. Compared with traditional phosphoric acid / sulphurous acid process, the process has such advantages as simple process flow, light clear juice color, high sugar quality, saved phosphoric acid resources, and clean production.

Owner:刘和清

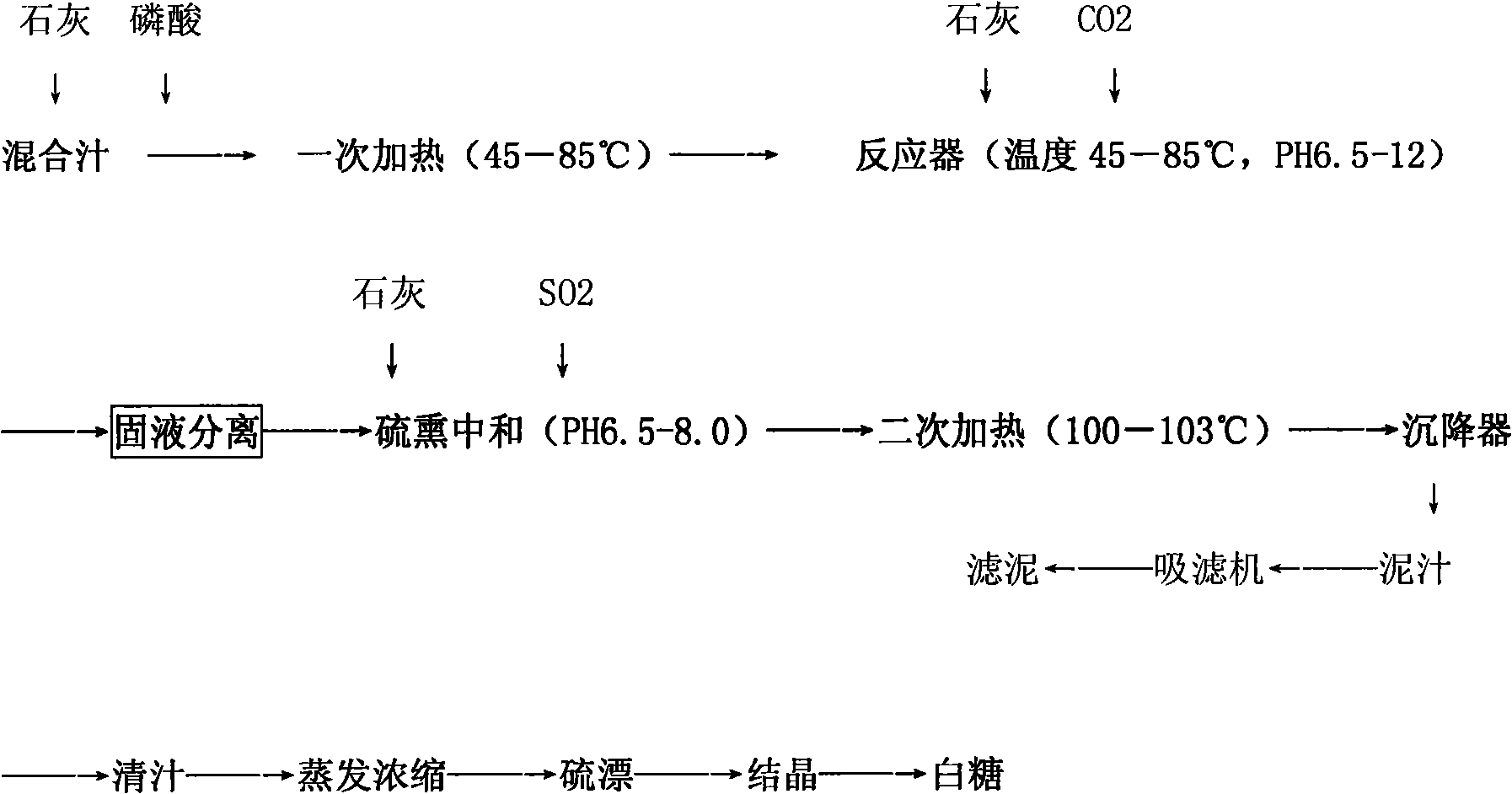

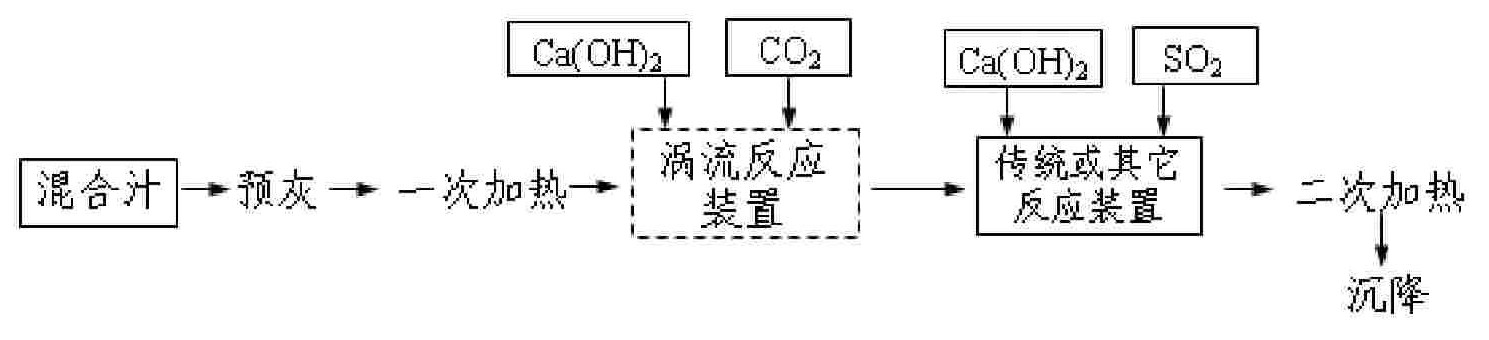

Clarification method for sugarcane juice

InactiveCN101280344AEmission reductionReduce residual sulfur dioxidePurification using alkaline earth metal compoundsSugar caneCarbonation

The invention discloses a clarification method for cane expressed juice, which is an improvement for sulfurous acid method manufacturing technique of a cane sugar factory. The cane juice is conveyed into a reactor after the first heating, and carbonation is performed through adding lime and carbon dioxide; solid-liquid separation can be performed to the carbonation cane juice to remove solid impurity, and the stoving liming neutralization treatment is performed to the obtained clear juice taking sulfur dioxide and lime as clarificant; the stoving liming neutralization treatment can be also performed to the turbid carbonation cane juice directly taking sulfur dioxide and lime as clarificant. The stoving liming neutralization cane juice is conveyed into a settler after the second heating, and the clear juice and the mud juice are separated. The clarification method has the advantages that the brenstone use level is reduced, the production cost is saved, the sulfur dioxide residual in white sugar is decreased greatly, the product quality is improved, the carbon dioxide discharge amount is reduced, the clear juice purity is increased by 1 to 1.5, the white granulated sugar color value is reduced by twenty percent, and therefore the environment problem does not exist.

Owner:南宁苏格尔科技有限公司

Process for preparing sugar from cane

InactiveCN103981290AWell mixedLow ash contentPurification using alkaline earth metal compoundsPurification by physical meansActive carbonActivated carbon

The invention discloses a process for preparing sugar from cane. The process comprises the following steps: pressing, namely horizontally pressing at first and then longitudinally pressing to obtain cane juice; filtering, namely putting the cane juice into a filter to obtain pure cane juice, and separating out cane residues; clarifying and decolorizing, namely heating the pure cane juice, adding citric acid and calcium hydroxide for mixing, adding lime milk for neutralizing, carrying out secondary heating, and adding polyacrylamide for settling separation to obtain clear juice and mud juice; filtering the mud juice to obtain filtered clear juice, combining the clear juice, and adding active carbon into the clear juice for deodorizing; performing evaporation concentration, sugar boiling and crystallization, honey separation and drying to obtain the finished sugar. The process has good filtering, clarifying and deodorizing effects, and is time-saving, labor-saving and simple to operate.

Owner:彭华成

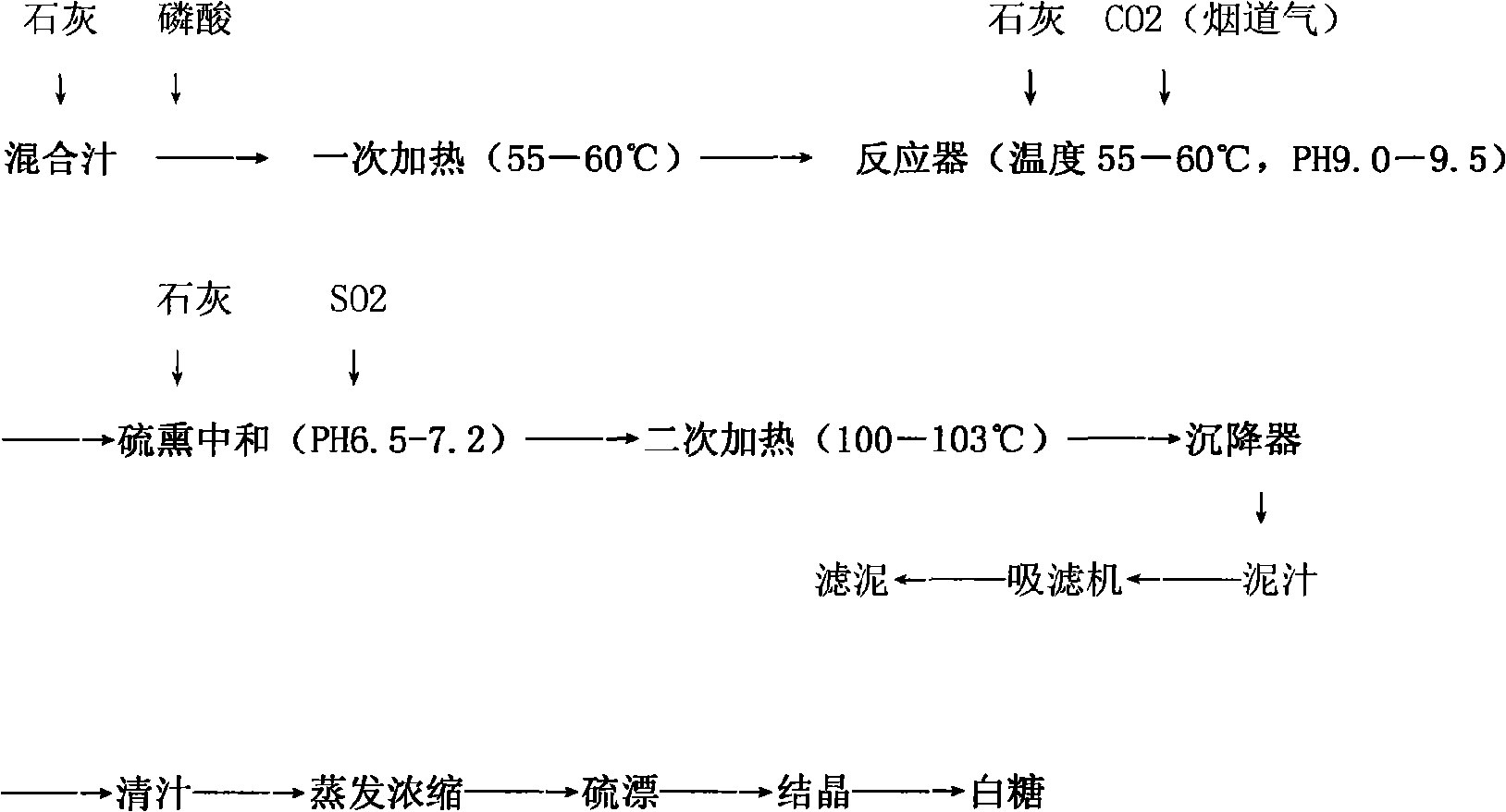

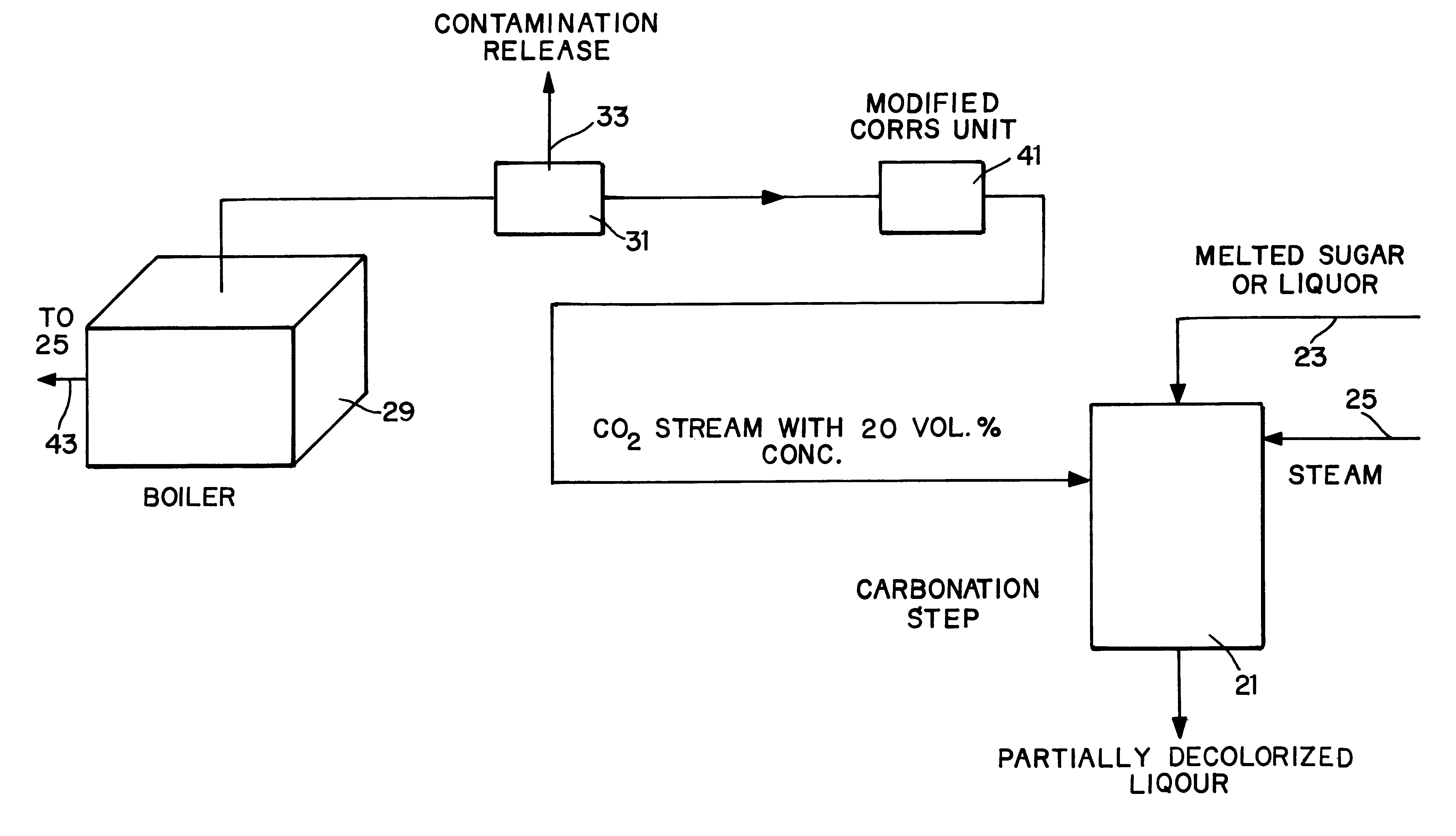

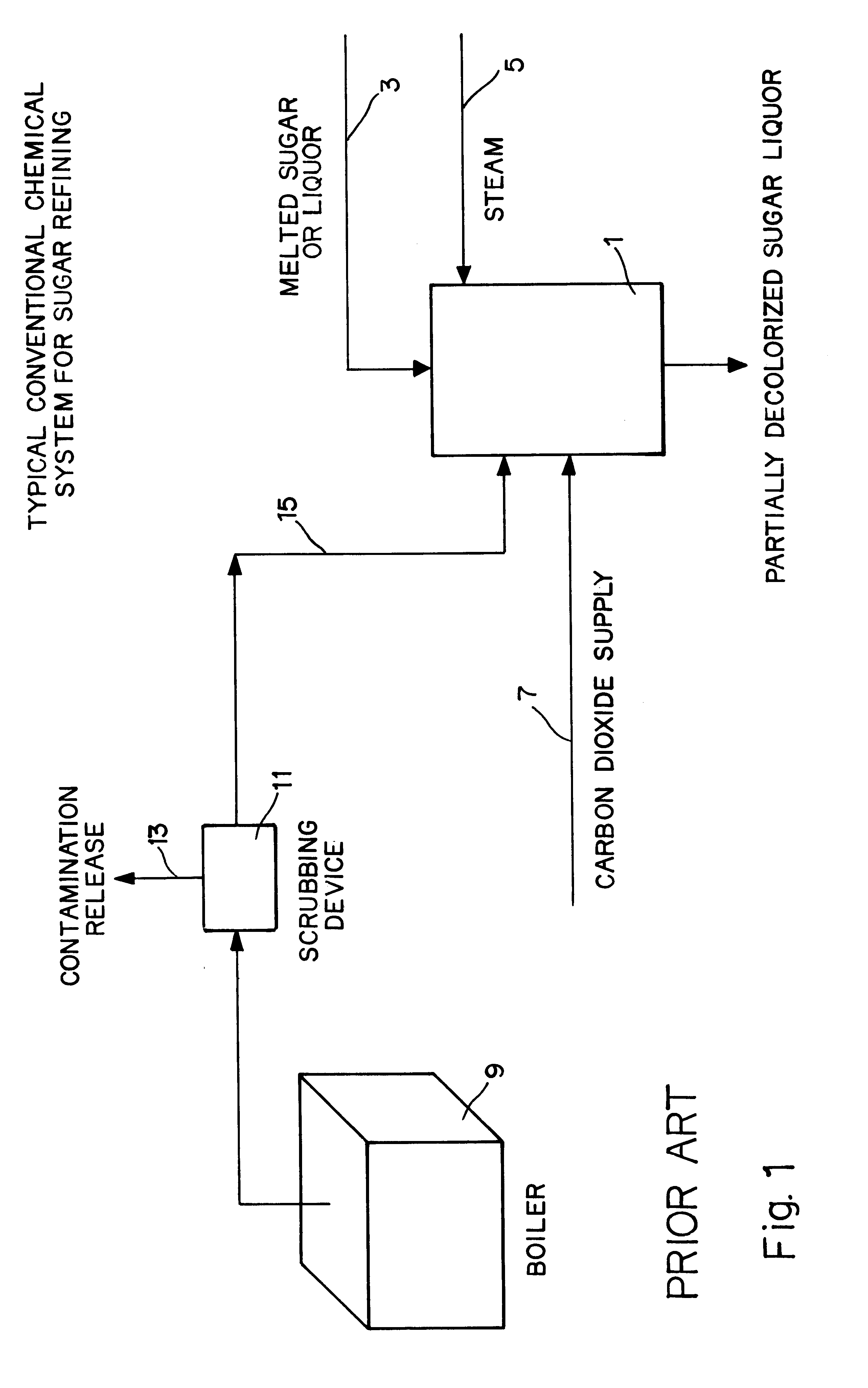

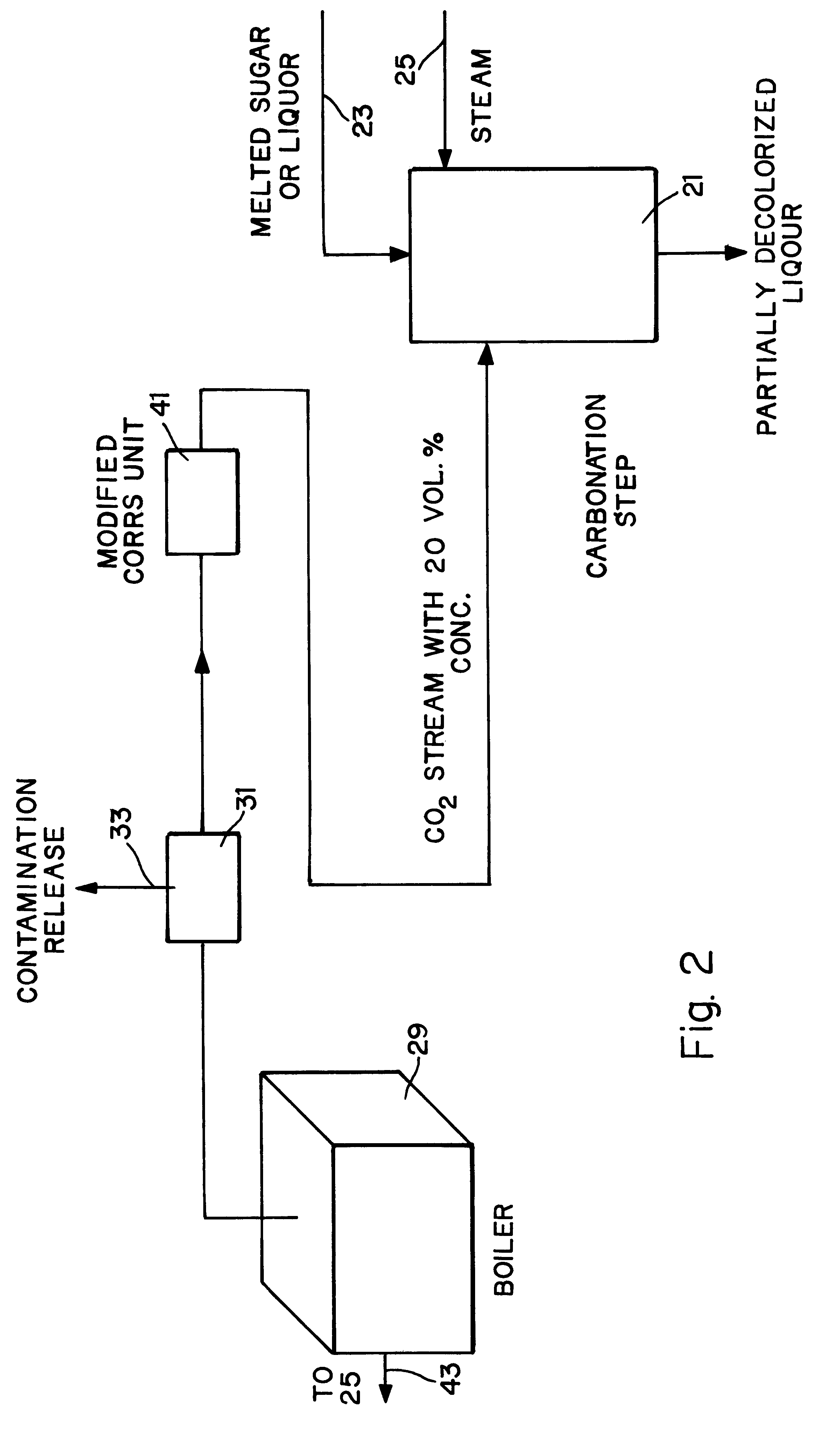

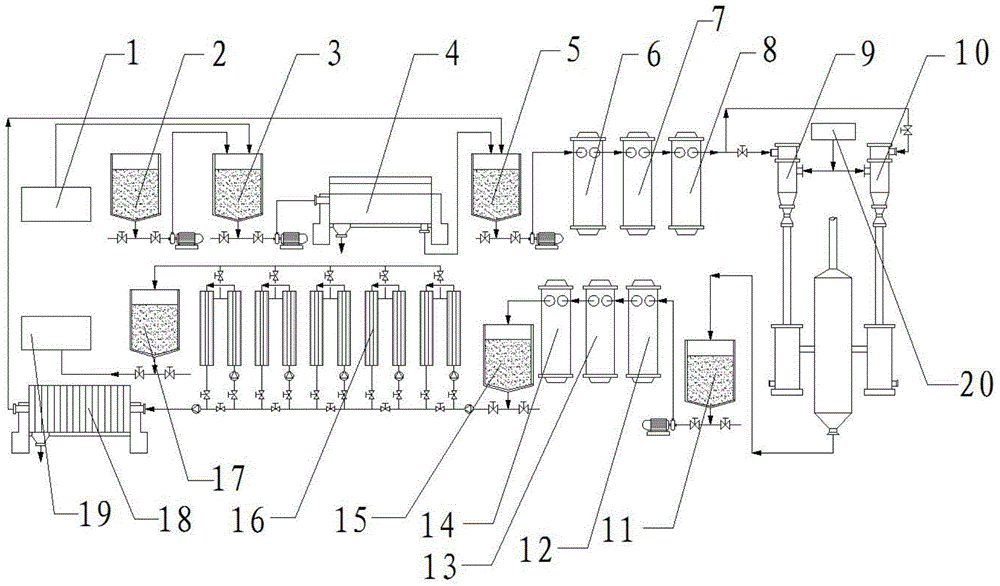

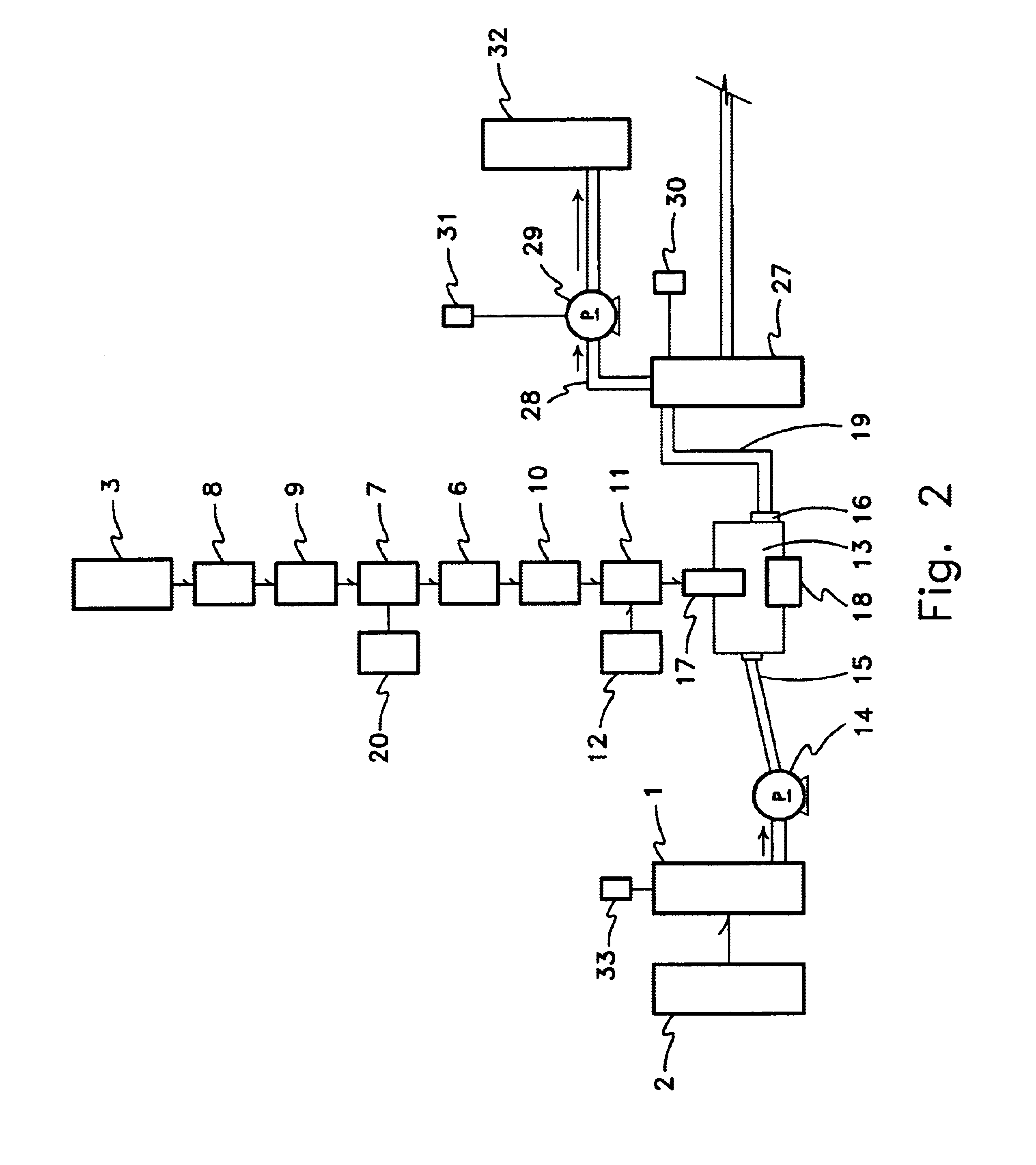

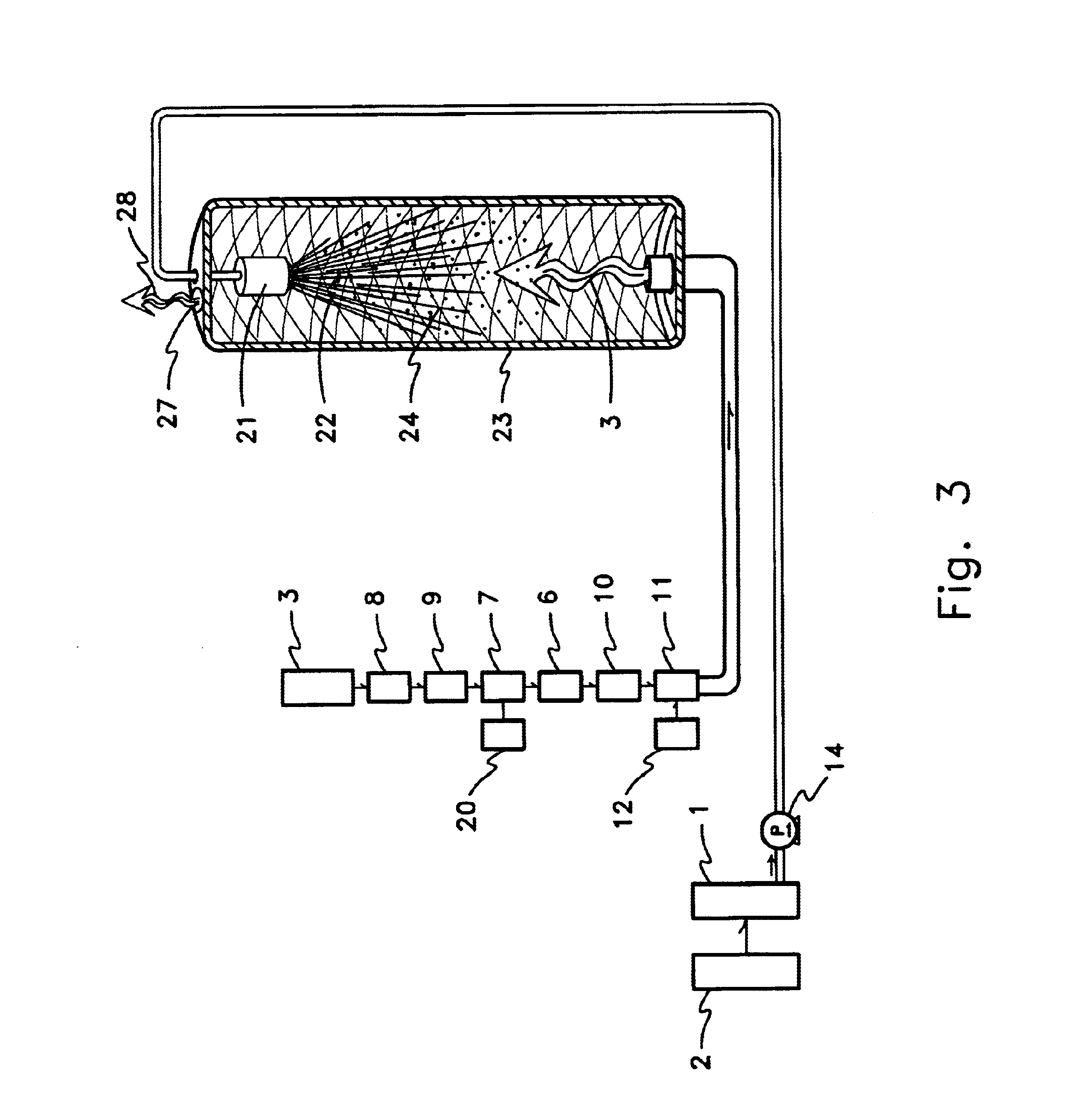

System and method for refining sugar

InactiveUS6176935B1Speed up the processEasily incorporated into existing refineryPurification using alkaline earth metal compoundsSugar crystal separationFlue gasSugar refining

A sugar refining process uses carbon dioxide obtained from a module containing a plurality of gas-permeable polymeric membranes. Flue gas from a boiler is scrubbed, and then passed through the gas-separation module. The output of the module contains an enhanced concentration of carbon dioxide, in the range of about 20% by volume. The carbon dioxide enhanced gas is then directed into a reactor in which raw sugar is exposed to carbon dioxide to cause carbonation, an essential step in the decolorization of the raw sugar. The same boiler used to produce the carbon dioxide is also used to produce steam which drives the reaction. The present invention provides carbon dioxide for carbonation in a highly efficient manner, as the gas separation membrane has no moving parts and requires little maintenance. The invention is especially suited for retrofitting existing sugar refining plants, to improve their efficiency, at a relatively small cost.

Owner:AIR LIQUIDE AMERICA INC +1

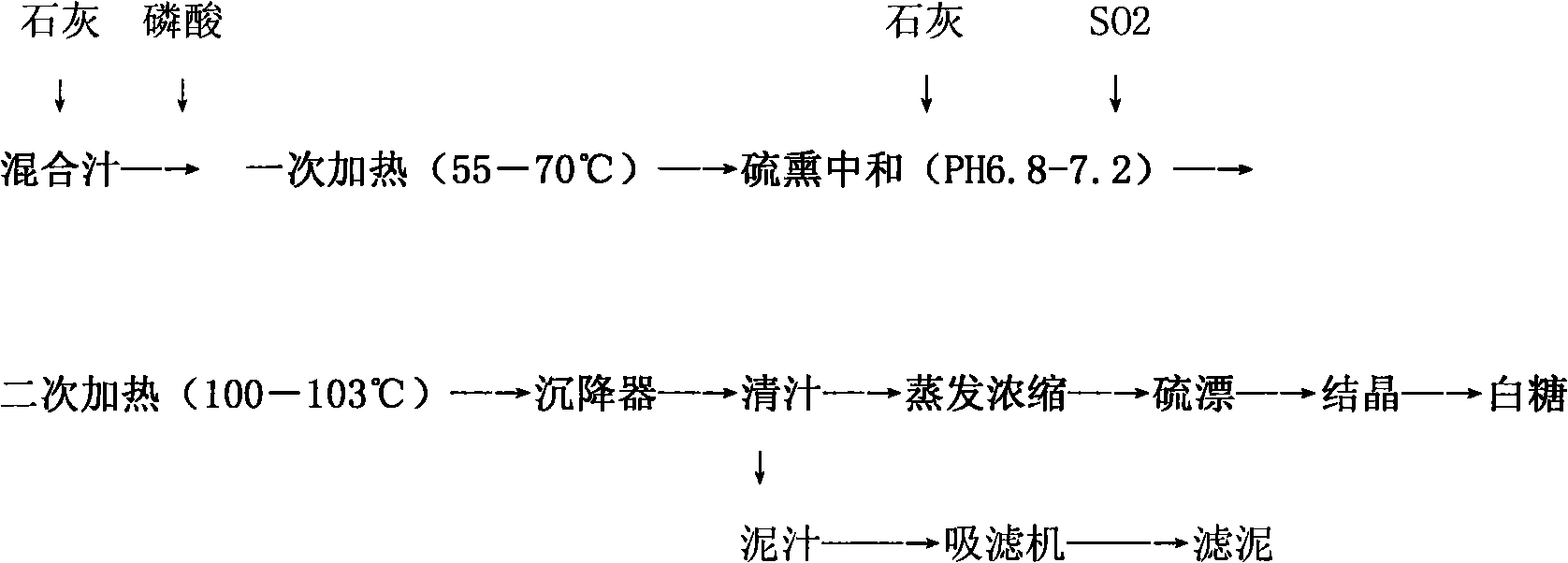

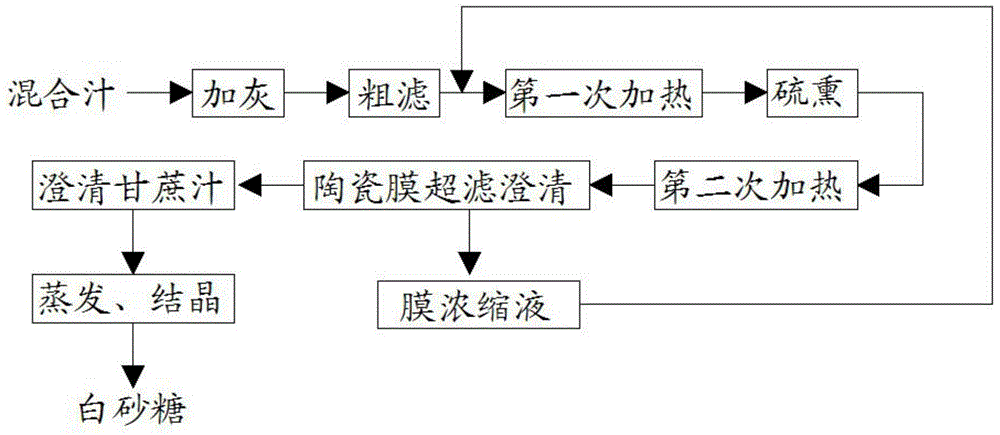

Sugar manufacture clarification process

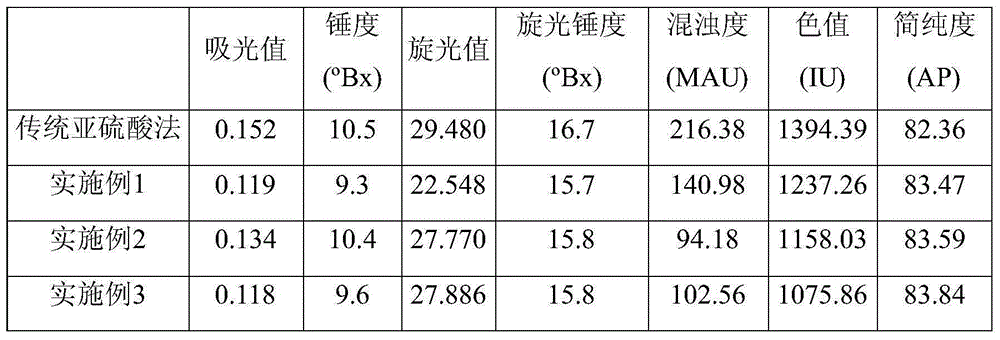

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

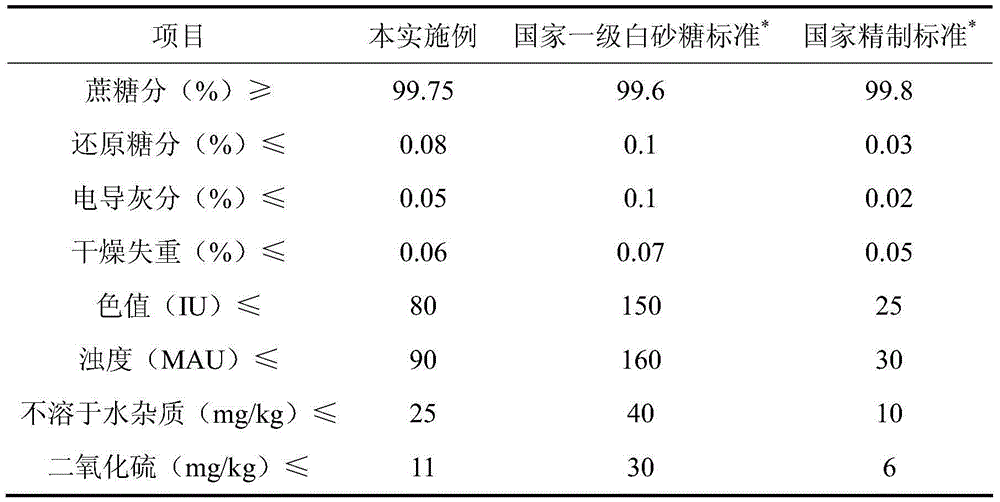

New sugaring and clarifying process of low-sulfur low-phosphorus sugarcane

ActiveCN103114156ASave resourcesShort processSugar productsPurification using alkaline earth metal compoundsPhosphatePhosphoric acid

The invention provides a new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane. The process comprises the following steps of: respectively adding an inorganic salt decoloring agent, polyquaternium and a zinc dihydrogen phosphate coagulant into the mixed sugarcane juice, feeding the mixed juice into a sedimentation tank or a floatation tank to separate out clear juice and mud juice after performing primary heating, the neutralization by adding lime milk and secondary heating; and obtaining a finished product of sugar after the clear juice is evaporated, concentrated, sugar boiled, crystallized and purged. Compared with the existing phosphate-sulfite clarification method, the new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane disclosed by the invention has the advantages of short process flow, low tone and good quality of the clear juice and good thermal stability, and is capable of saving the resources of lime, sulphur and phosphoric acid, shortening the process flow, improving the product quality and realizing the cleaned production by removing the sulphitation process and device.

Owner:广西糖业集团防城精制糖有限公司

Method for clearing, decoloring and decontaminating sugar juice

InactiveCN102260753AEfficient separationReduce usagePurification using alkaline earth metal compoundsCalcium hydroxideFlocculation

The invention relates to a method for clearing, decoloring and decontaminating sugar juice. The method comprises the following steps: heating the sugar juice to 25-35 DEG C; pre-liming until the pH value is 6.5-7.5; after preliming, heating the sugar juice to 55-75 DEG C; adding calcium hydroxide emulsion and a citric acid solution, stirring, and reacting for 15-35 minutes at the constant temperature of 55-75 DEG C, wherein the adding amount of calcium hydroxide is 0.10%-0,60% of weight of sugar juice, and the adding amount of citric acid is 0.10%-0.50% of weight of sugar juice; and further heating to 75-100 DEG C, adding 0.5-10ppm of flocculation auxiliary polyacrylamide, standing at the constant temperature, flocculating and precipitating so as to obtain the clear sugar juice. In the method, citric acid reacts with calcium hydroxide so as to obtain a regenerated calcium citrate precipitate particle which is used for decoloring, decontaminating and clearing the sugar juice; the clearing process is simple, is easy to control and is environmentally-friendly; and the method provided by the invention has the advantages of good clearing, decoloring and decontaminating effects, low cost, available raw materials and less filter mud.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Sugar juice settle low-ash low-temperature carbonating method

InactiveCN103233083AReduce dosageLow sulfur fumigation strengthPurification using alkaline earth metal compoundsCalcium contentSugar

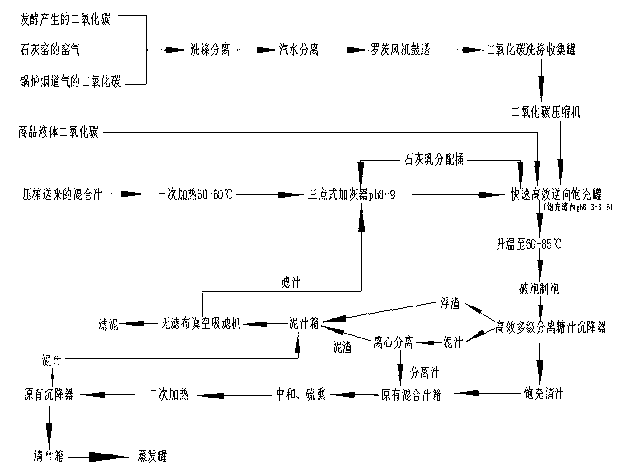

The invention provides a novel sugar juice settle low-ash low-temperature carbonating method. The method comprises the following steps of adding lime milk into squeezed mixed juice to be prelimed to the pH value of 7.2 to7.6, liming the mixture to the pH value of 8 to p9 in a three-point form after primarily heating the mixture to the temperature of 50 to 60 DEG C, adding effective calcium oxide to reach the sugarcane ratio of 0.2 to 0.35 percent of full calcium content, carrying out the carbonation in a fast high-efficiency reverse carbonating tank through the carbon dioxide to reach an end-point pH value of 7.8 to 8.2; heating to the temperature of 60 to 85 DEG C, adding the flocculating agent after breaking bubbles and making the foam, placing the juice into a high-efficiency multilevel separation juice settler to be settled and separated, centrifugally separating the separated low-carbon juice, ensuring the separated juice to enter a low-carbon juice tank, ensuring the floating slag and the slime to enter a mud juice tank to be filtered through a vacuum adsorption filter, and ensuring the obtained filter juice to flow back to a three-point liming device to be limed to the pH value of 8 to 9; and ensuring the low-carbon clear juice to enter an original sulphurous acid method settling step after adding 200 to 300ppm phosphoric acid.

Owner:彭思云 +2

Method for preparing CO2-N2 mixed gas from boiler flue gas to be used for clarification process of sugar production

InactiveCN101805804AGood clarificationHigh purityPurification using alkaline earth metal compoundsDispersed particle separationEcological environmentAir blower

The invention discloses a method for preparing CO2-N2 mixed gas from boiler flue gas to be used for a clarification process of sugar production. The method of the process comprises the following steps of: collecting the boiler flue gas by an air blower, making the boiler flue gas pass through a dust catcher, a heat exchanger and a gas-water separator; desulfurizing by alkaline water or in a pressure-swing adsorption tower to obtain pretreated gas; and adsorbing and desorbing the pretreated gas in the adsorption tower of a pressure-swing adsorption system to obtain the mixed gas containing 18%-40% of CO2 and 54%-74% of N2 in percentage by volume. The mixture is delivered into a mixed juice carbonating tower and an upward-floating clarifier or a syrup carbonating tank and the upward-floating clarifier, and the mixed juice or syrup is clarified by a clarifying method of half carbon and half sulfur. The invention is used for the clarification process of sugar production by a sulfurous method, and the clarification effect of the mixed juice or the syrup is good. By adopting the invention, CO2 discharged from the boiler flue gas is reduced, and the ecological environments are protected; meanwhile, filter mud generated in the production process can be used as a fertilizer for crops, thus the invention has an important meaning for making full use of resources and protecting environments.

Owner:GUANGXI UNIV +1

Clear-muddy separation settling technology of sugar production

InactiveCN1912143AReduce manufacturing costIncrease sugar yieldPurification using alkaline earth metal compoundsFlocculationPhosphoric acid

The invention relates to cane juice purifying separating technology of sugar making. It includes the following steps: separating the initial extraction liquid and the secondary at sugar cane juicing stage; adding lime cream or other basic compound into the secondary extraction liquid or their mixture to make the pH value equal to 8.0-13; once or many times clarifying of chemical coagulation, flocculation, and solid-liquid separation; mixing the clarified liquid with the initial extraction liquid to do further clarifying by limebase process, phosphoric acid and sulphitation process.

Owner:周少基

Method for Obtaining White Sugar from Cane Juice

InactiveUS20120216799A1Requires low equipmentReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsFruit juicePhosphoric acid

The invention relates to a method for obtaining white sugar from cane juice, characterized in that it involves: obtaining sugar colors of between 300 and 150 ICUMSA units, with a sulphite content no greater than 5 ppm and an ash content no greater than 0.2% in the case of white sugar and in the case of refined sugar with colors less than 40 UI, less than 5 ppm sulphites and less than 0.04% ash, using fewer chemical products and devices and comprising the formation of reducing sugars; as well as optimizing the production time, reducing deterioration, making the process and the chemical products more efficient and preventing SO2 contamination. The method is characterized in that it simplifies the traditional method of obtaining white sugar using elemental sulfur, eliminating prealkalinization and sulphiting and the respective machinery and equipment and reducing the number of chemical products, such as lime, phosphoric acid, sulfur and activated carbon, in order to aggregate only sodium metabisulphite optionally complemented with monosodium phosphate in juice with pH values of 4 to 6.6 prior to any process involving the clarification of juice, cane syrup or molten liquor.

Owner:BOLANOS MARIO ALAVES

Method for producing high-quality white granulated sugar by clarifying syrup

InactiveCN102021250AReduce color valueHigh purityPurification using adsorption agentsPurification using alkaline earth metal compoundsSulfurPhosphoric acid

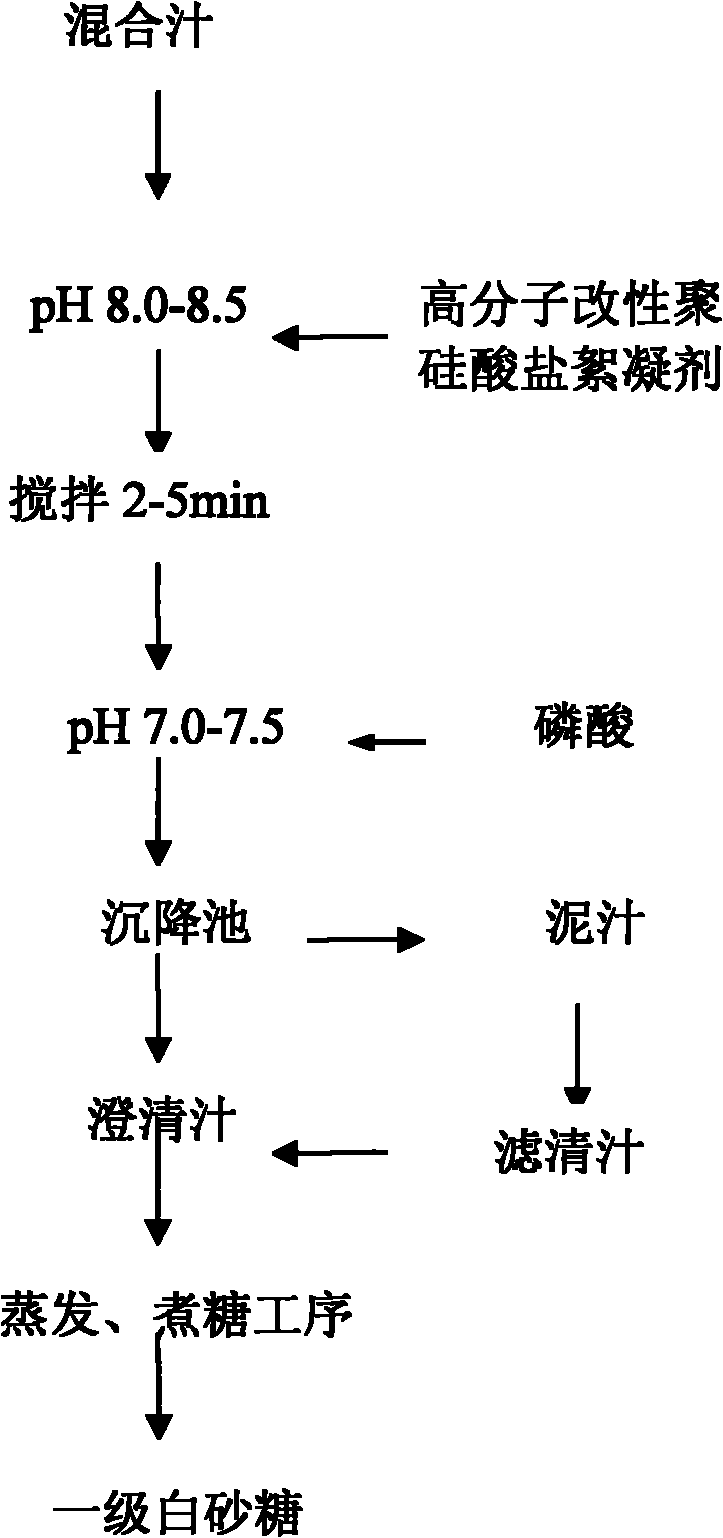

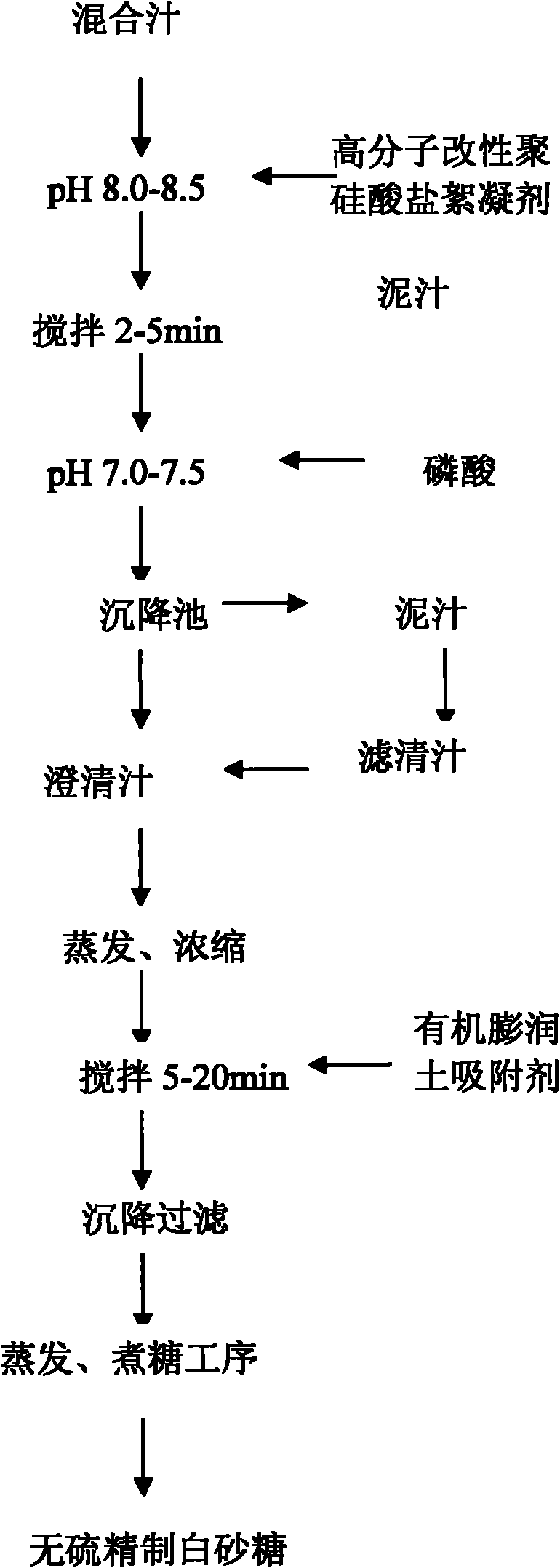

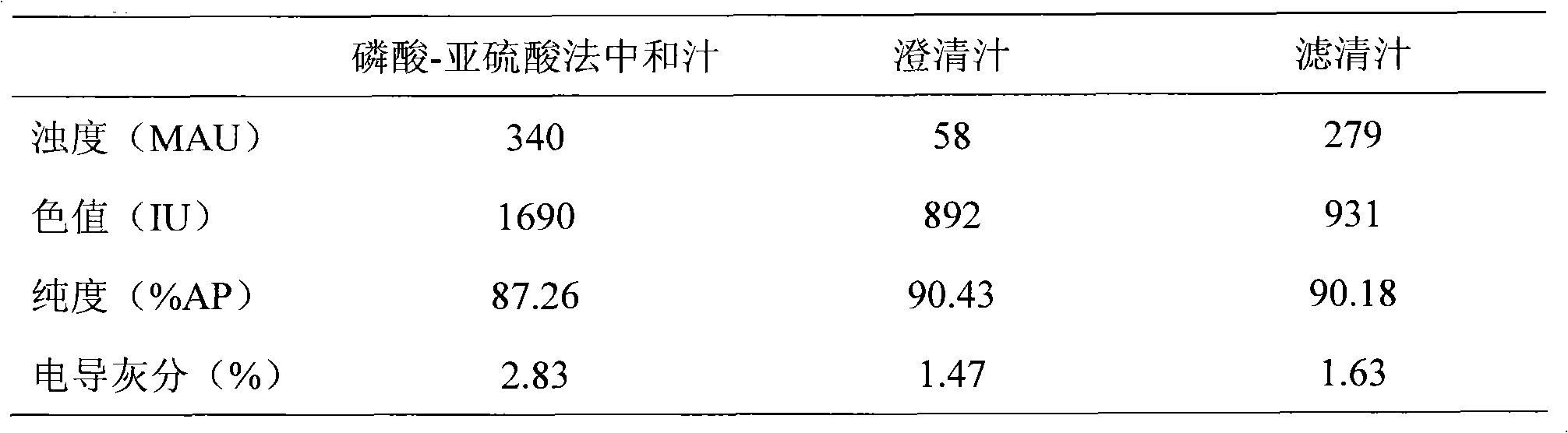

The invention relates to a method for producing high-quality white granulated sugar by clarifying syrup. The method comprises the following steps of: heating the syrup; adding lime milk; adjusting the pH value to be between 8.0 and 8.5; adding anionic inorganic gel serving as a flocculating agent in an amount which accounts for 0.01 to 0.05 percent of the amount of the syrup; keeping the pH value at 8.0 to 8.5 for about 2 minutes; adding phosphoric acid to reduce the pH value to be between 7.0 and 7.5; pouring the syrup into a sedimentation tank or a floatation tank to separate clarified juice and mud juice out; filtering the mud juice by using filtering cloth or a vacuum filter, and mixing the filtered clarified juice and the separated clarified juice; and evaporating, concentrating, boiling sugar, crystallizing and extracting the sugar to obtain the white granulated sugar of above first class; or evaporating and concentrating to obtain the syrup, adding organic bentonite in an amount which accounts for 0.2 to 1 percent of the amount of the syrup, stirring, adsorbing for 5 to 20 minutes, filtering by using the filtering cloth, boiling, crystallizing and extracting the sugar to directly produce sulfur-free refined sugar. The method has the advantages of good clarification effect, high clear juice purity, short process flow, high process operation safety and low labor intensity.

Owner:杨鲁昆

Method for producing original ecologic colored sugar product

ActiveCN103757142ARetain trace elementsClearing away heat and promoting body fluidSugar dryingPurification using alkaline earth metal compoundsBiotechnologyO-Phosphoric Acid

The invention discloses a method for producing an original ecologic colored sugar product. The method comprises the following steps: preliming a mixture juice obtained by extruding sugarcanes till the pH value is 7.0-7.2, adding 100-150PPM (Parts Per Million) of phosphoric acid, subsequently performing primary heating, further adding lime milk into the heated mixture juice till the pH value is 7.6-8.2, adding activated calcium carbonate to fulfill, further performing dreg-foam separation to obtain floating clear juice, adding phosphoric acid and lime milk into the floating clear juice till the pH value is 8.4-8.6, wherein the addition amount of the phosphoric acid is 50-100PPM, subsequently performing secondary heating to obtain a neutral juice, sinking the neutral juice to separate a clear juice and a mud juice, filtering the mud juice by using a filter to obtain a filtrate, combining the filtrate with the clear juice, heating for three times, evaporating, filtering in rotational flow, boiling the sugar to crystallize, prompting crystal, purging, drying, deironing and the like so as to obtain the original ecologic colored sugar product. The method is low in production cost and preserves activated sugarcane antioxidant substances to the maximum extent, and the sugar product is safe to eat, good in environment-friendly effect and has good population values and social and economic benefits.

Owner:GUANGXI DUAN YONGXIN SUGAR CO LTD

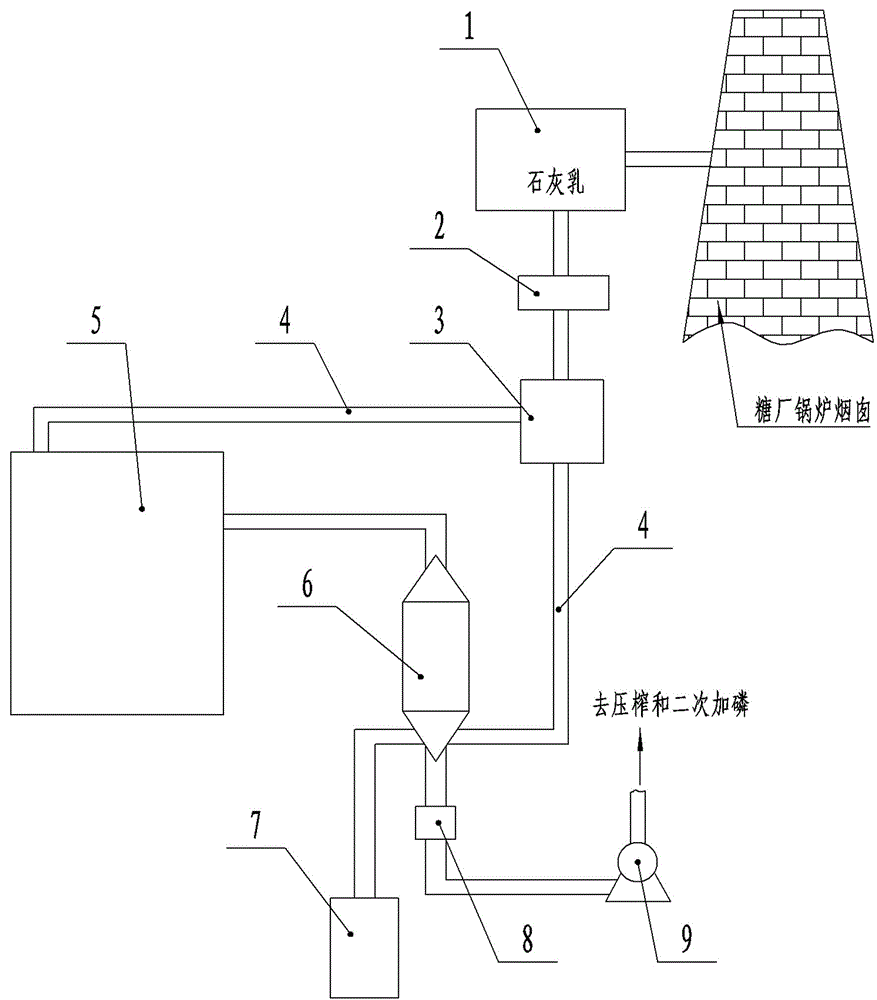

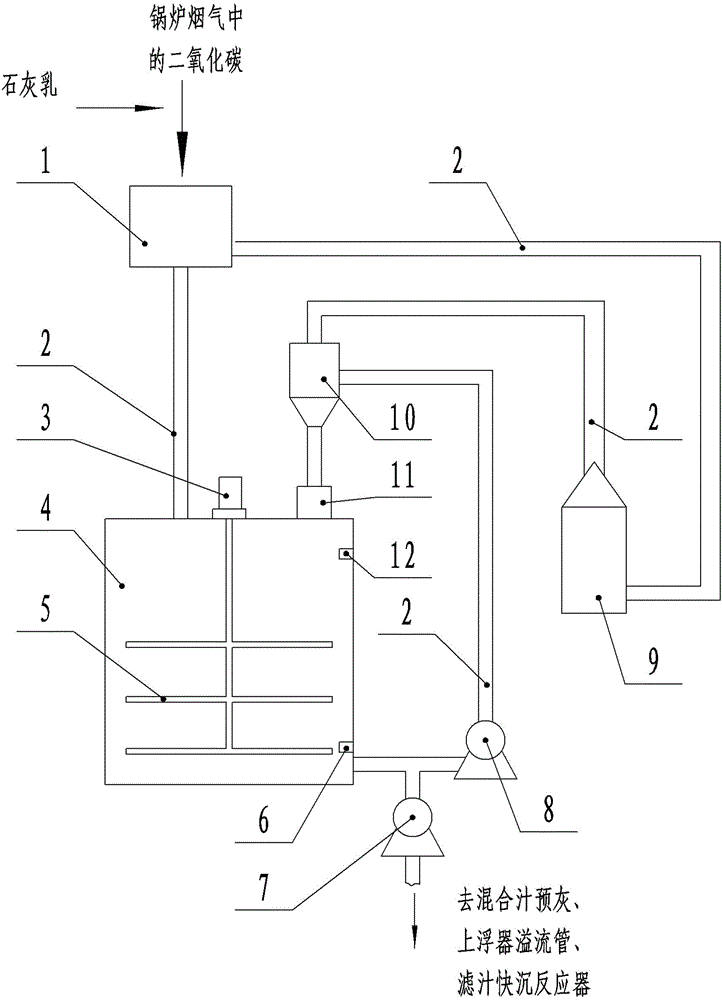

Method and equipment for recovering, activating and utilizing carbon dioxide from sugar refinery

InactiveCN104437060AIncrease profitEmission reductionPurification using alkaline earth metal compoundsDispersed particle separationCalcium bicarbonateJuice clarification

The invention discloses method and equipment for recovering, activating and utilizing carbon dioxide from a sugar refinery. The method comprises the following steps: introducing low-content carbon dioxide contained in flue gas of a boiler of the sugar refinery into a carbon dioxide adsorption tower, and reacting the carbon dioxide with lime cream inside the carbon dioxide adsorption tower to form a calcium carbonate solution; introducing a part of the calcium carbonate solution into phosphoric acid to generate calcium dihydrogen phosphate and the carbon dioxide, wherein the calcium dihydrogen phosphate is used for squeezing and secondary phosphorus addition; reacting the other part of the other part of the calcium carbonate solution with the carbon dioxide to generate calcium hydrogen carbonate, and pumping to mixed juice preliming, a floating device overflow pipe and a filtered juice quick-sinking reactor by using a calcium hydrogen carbonate pump. The method disclosed by the invention can be used for generating the calcium carbonate by reacting the low-concentration carbon dioxide contained in the flue gas of the boiler with the lime cream and preparing the calcium hydrogen carbonate and the calcium dihydrogen phosphate as clarifying agents used for the sugar refinery by utilizing the calcium carbonate and the phosphoric acid, thereby achieving the purpose of cane juice clarification by removing a part of colloid and non-sugar components in an adsorbing way, enhancing the CO2 utilization rate and reducing the discharge amount of the carbon dioxide from a chimney of the sugar refinery.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

Sugar juice sulfur-free efficient cleaning method

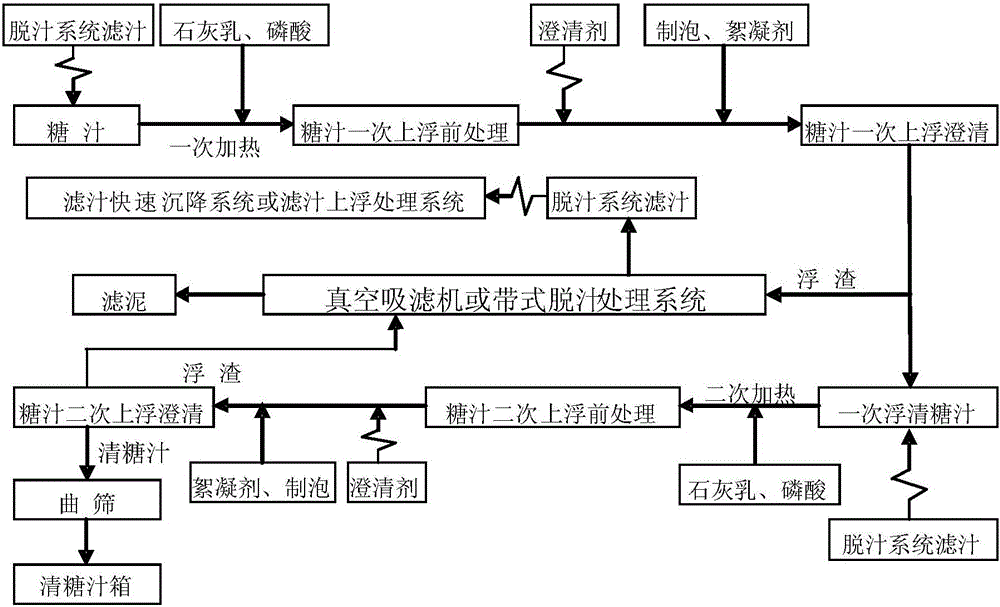

ActiveCN105002306AShort stayReduce lossesPurification using alkaline earth metal compoundsPurification by physical meansSulfurLarge particle

The invention belongs to the technical field of sugar industries and discloses a sugar juice sulfur-free efficient cleaning method. After preliming, heating, foaming and flocculant adding are conducted on sugar juice, one-time floating clarification is conducted, large-particle non-sugar components in the sugar juice are removed; after secondary preliming, heating, foaming and flocculant adding are conducted on the one-time floating clarification sugar juice, secondary floating clarification is conducted; the sulfur-free cleaning process of the sugar juice is completed on the sugar juice obtained through secondary floating clarification through a sugar juice filtering and separating system. According to the sugar juice sulfur-free efficient cleaning method, the cleaning method of two levels of floating of the sugar juice is mainly adopted, and clean and complete sufur-free and carbonic-acid-free processing is achieved on the sugar juice, the equipment technology is simple, automatic continuous production is convenient, and the production efficiency is obviously improved. The obtained clean sugar juice is high in quality and is superior to clean sugar juice obtained through a traditional sulfurous method, and a very good application prospect is achieved.

Owner:广东省科学院生物与医学工程研究所

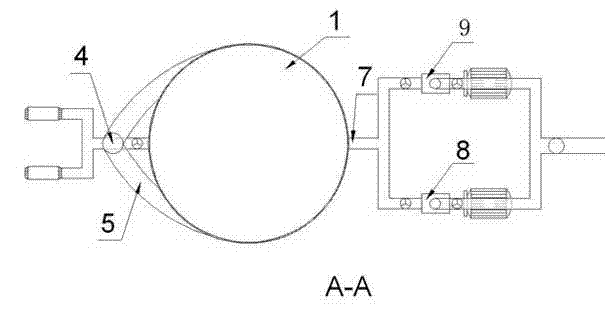

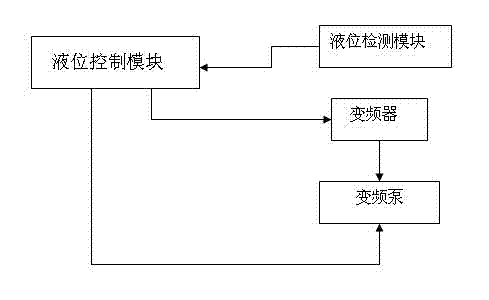

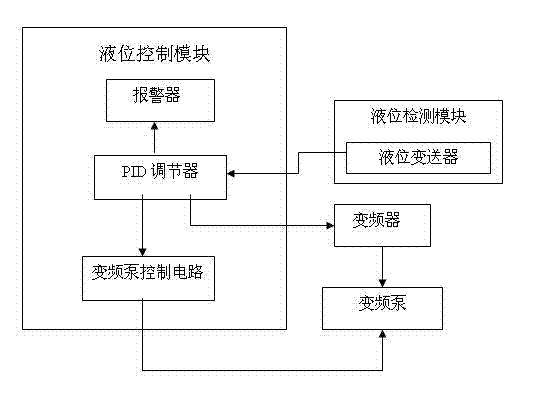

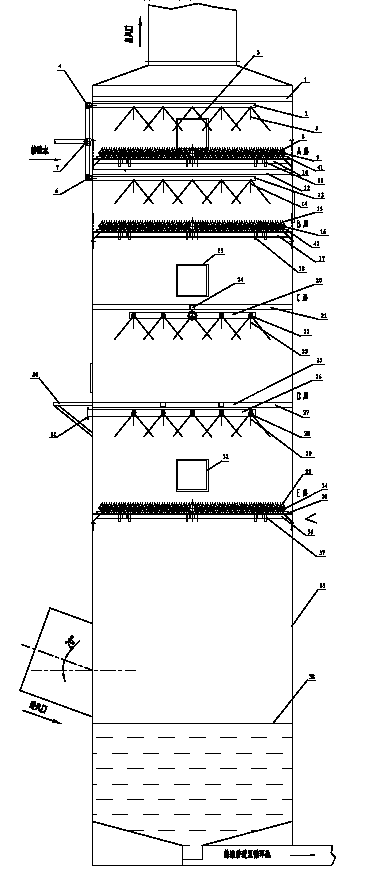

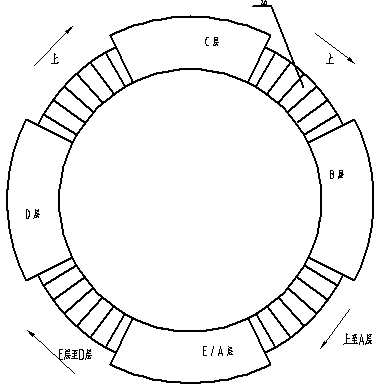

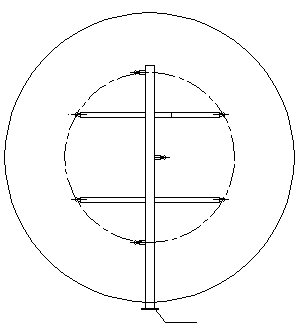

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

Low-carbon and low-sulphur syrup clarifying method

InactiveCN101660007AHigh purityReduce color valuePurification using alkaline earth metal compoundsChemical reactionCalcium carbonate precipitation

The invention discloses a low-carbon and low-sulphur syrup clarifying method. In the method, lime cream is added in syrup until pH is 6.0-9.5 and is pump to a heater to be heated to 50-80 DEG C; then,the syrup flows into a progressive liming tank, and lime cream is added until pH is 10-11; a great amount of impurities are condensed and separated out; lime cream is added again, and the mixture ispumped into a carbonic acid saturator; carbon dioxide is sucked in to perform chemical reaction to form lime deposit, a great amount of impurities are adsorbed and removed and pH reaches 8-9; the obtained product enters a convective quick depressor to separate serum; then the serum is pumped into a sulphitation neutralizer to suck sulfur dioxide to neutralize to be 7.2-7.8; the mixture is sent into a desilter after secondary heating to 102-105 DEG C; after separating high-quality serum, the serum is sent to the following working procedures; mud juice obtained by above two precipitations is mixed to filter and separate to obtain serum and filter mud. The lime amount of the method of the invention is one quarter of that of a normal carbonic acid method, sulphur amount is about one quarter ofthat of the normal sulphurous acid method, white sugar quality is obviously higher than that of the sulphurous acid method, and amount of generated filter mud is far lower than that of the carbonic acid method; the generated filter mud can be used as fertilizer and has no pollution problem.

Owner:霍汉镇

Method for settling extracted sugarcane juice by using weak base

InactiveCN103114155AShort stayShorten the timePurification using alkaline earth metal compoundsPurification by physical meansSaccharumSucrose

The invention aims to provide a method for settling extracted sugarcane juice by using a weak base. The method comprises the following steps of: filtering the extracted sugarcane juice, adding lime and phosphoric acid to adjust the pH value, heating for the first time, fumigating with sulphur, adding lime to neutralize, heating for the second time, settling the neutralized sugarcane juice, and separating a supernate from a puree. In the step of filtering the extracted sugarcane juice, the content of the absolute-dry sugarcane chaff in the filtered extracted sugarcane juice is controlled below 2.4g / L, and in the steps of fumigating with the sulphur and adding the lime to neutralize, the pH value of the extracted sugarcane juice is controlled at 7.8 to 9. The sucrose prepared by adopting the method has high quality, has a few impurities and is low in color value and high in yield. The scouring and recovering rate of the finally prepared sucrose can be improved by more than 2%, and the improvement is considerable to the enterprises making ten thousand tons of sucrose annually. The whole process dispenses with complex flows, and the cost is kept unchanged. The method has high practical and economic values.

Owner:南宁苏格尔科技有限公司

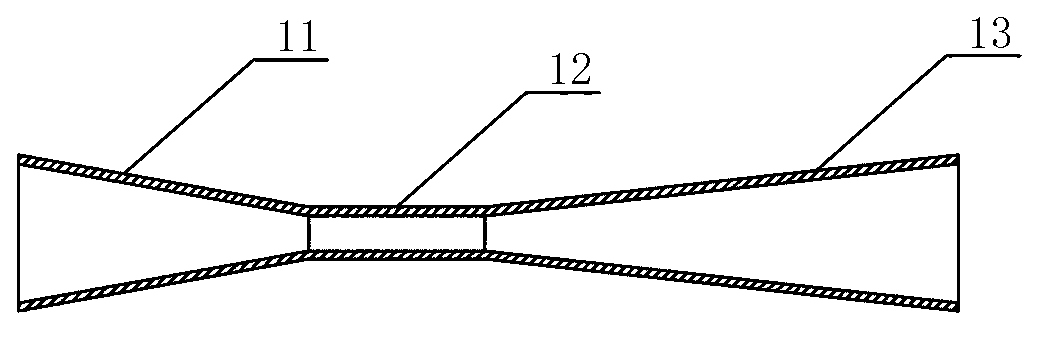

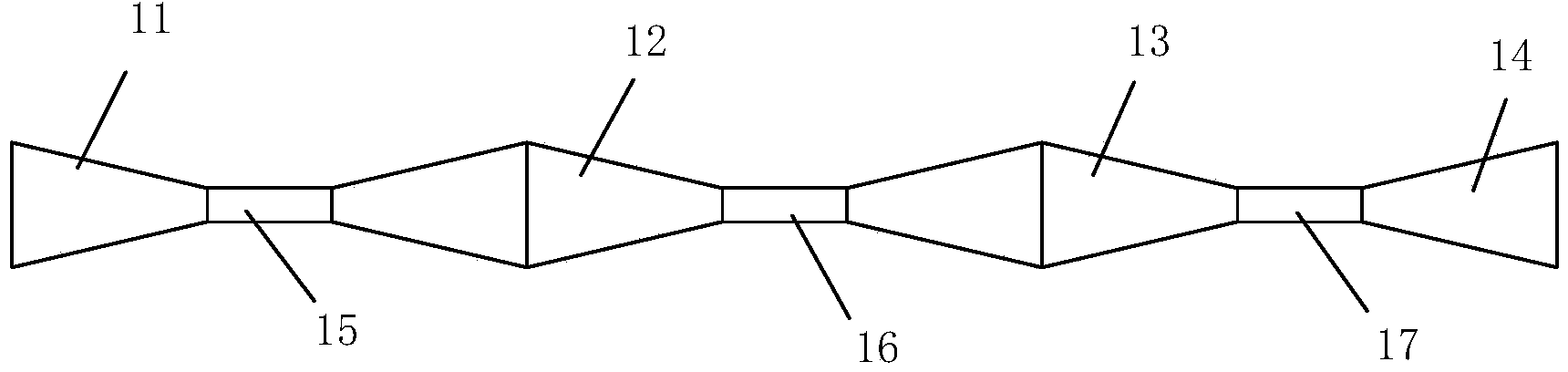

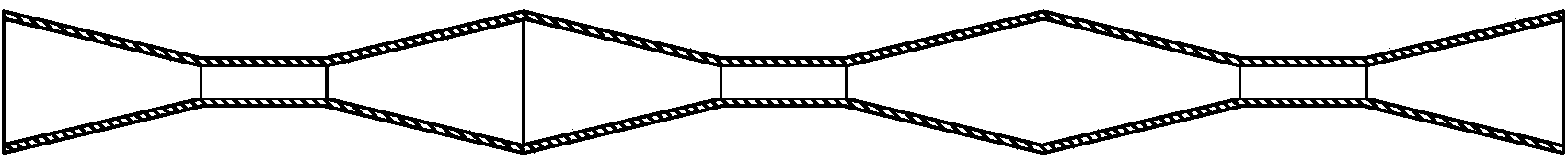

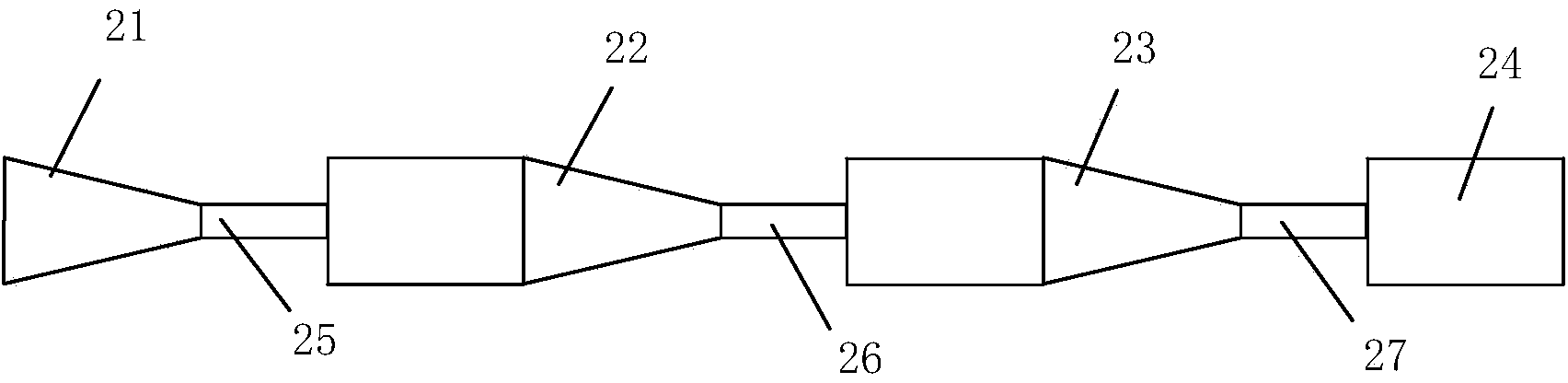

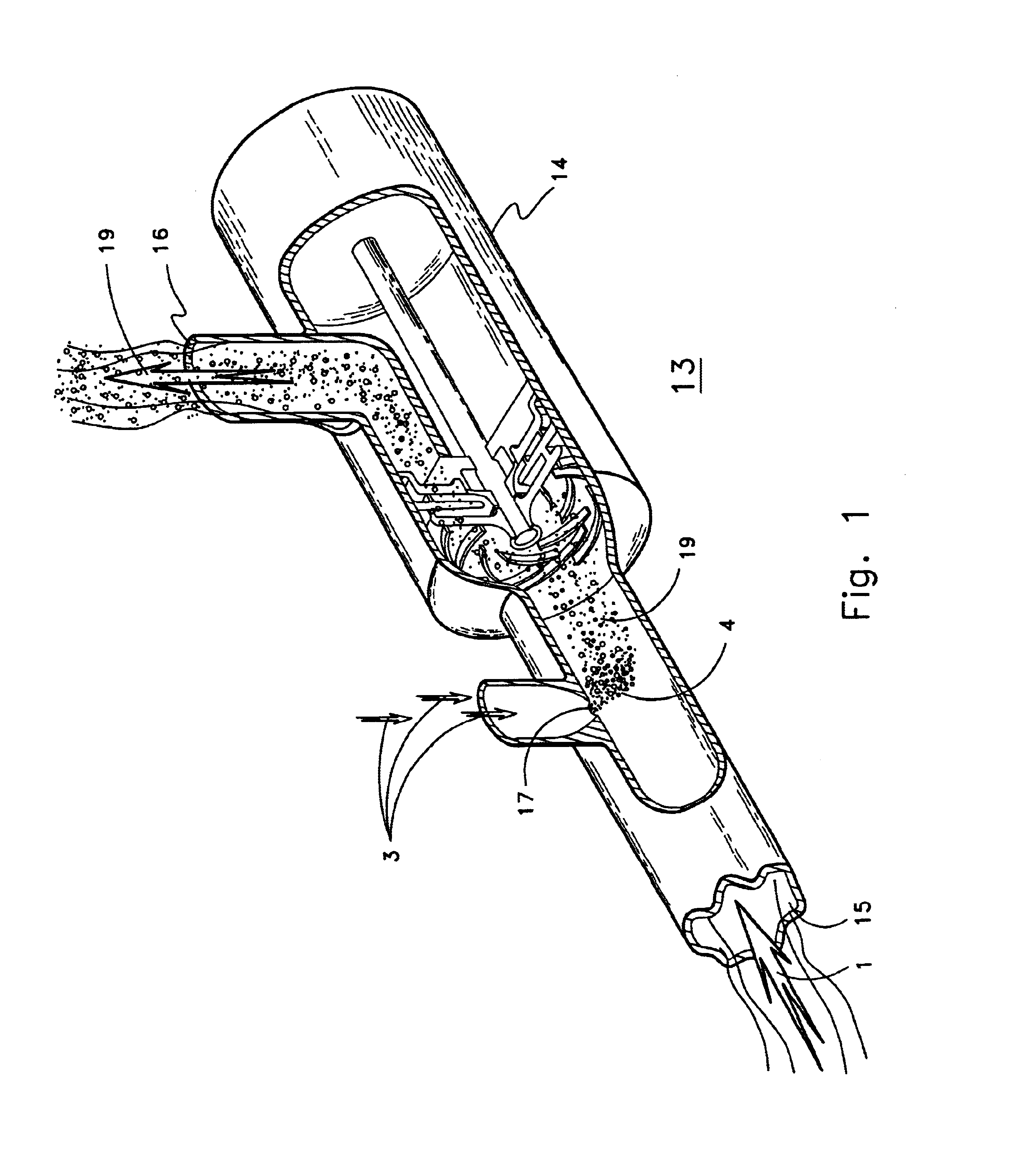

Method and device for reinforcing cane juice neutralization reaction by hydraulic micro-oscillation

InactiveCN103122397AGood clarificationResidue reductionPurification using alkaline earth metal compoundsLiquid glucoseEngineering

The invention relates to a method for reinforcing cane juice neutralization reaction by hydraulic micro-oscillation, which is applicable to a clarification technique of cane juice or liquid glucose by a sulfurous process. The method comprises the steps of preliming, primary heating, stoving neutralization, hydraulic micro-oscillation reinforced cane juice neutralization reaction, secondary heating and settling. The hydraulic micro-oscillation reinforced cane juice neutralization reaction is implemented in a way that: the cane juice or neutralized juice subjected to stoving neutralization reaction is pumped into a hydraulic micro-oscillation reinforced cane juice neutralization reaction device to subjected to hydraulic micro-oscillation reinforced cane juice neutralization reaction, and enters the steps of secondary heating and settling. The hydraulic micro-oscillation reinforced cane juice neutralization reaction device for implementing the method can change the size of the flow section of the cane juice or liquid glucose in the flowing process: the device is a cylindrical container or tubular container with inconsistent cross-sectional area. The method and device provided by the invention can reinforce the cane juice neutralization reaction, and enhance the purity of the clear juice by more than 1%; and the consumption of lime and sulfur is reduced by more than 20%.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

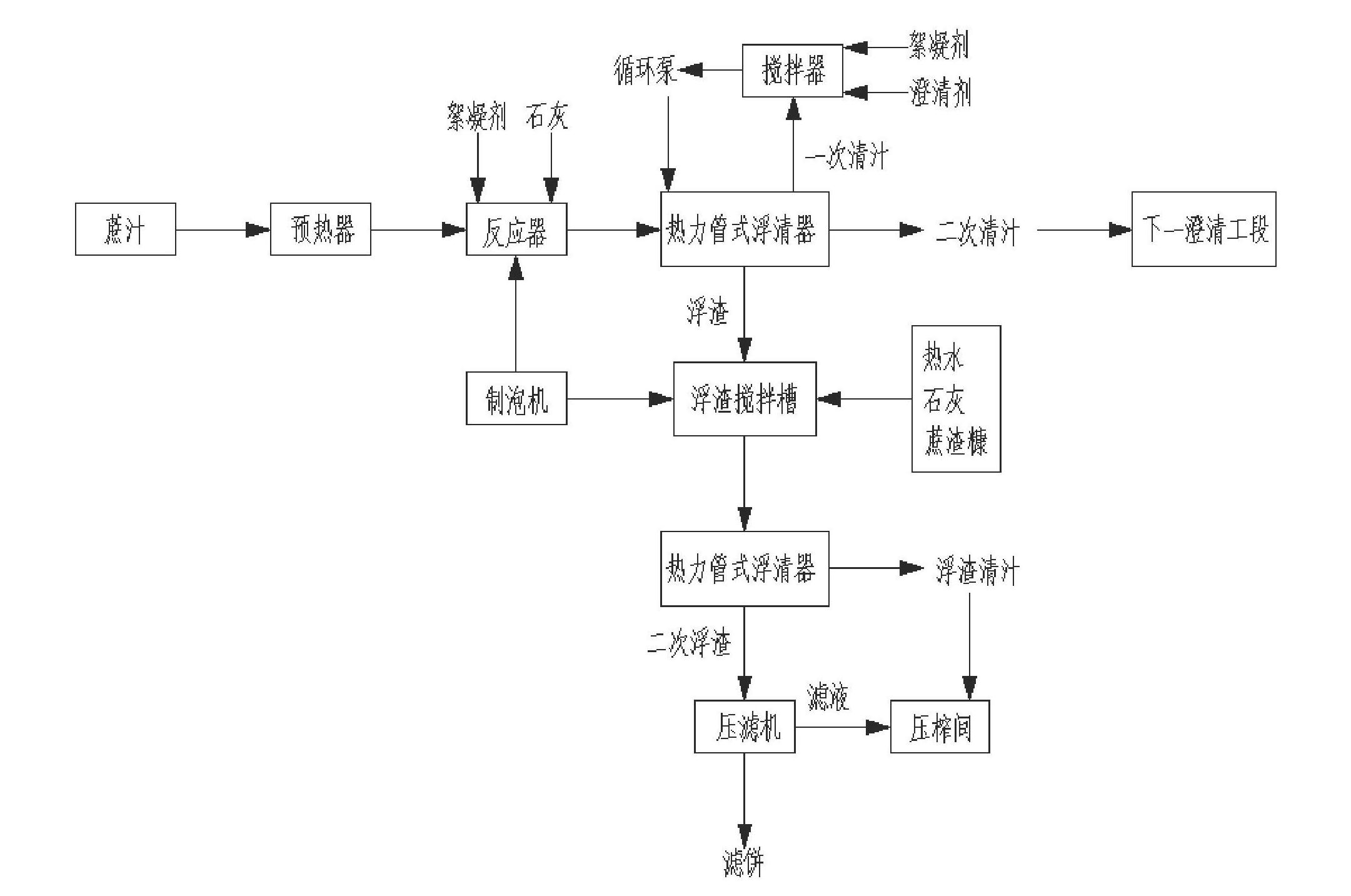

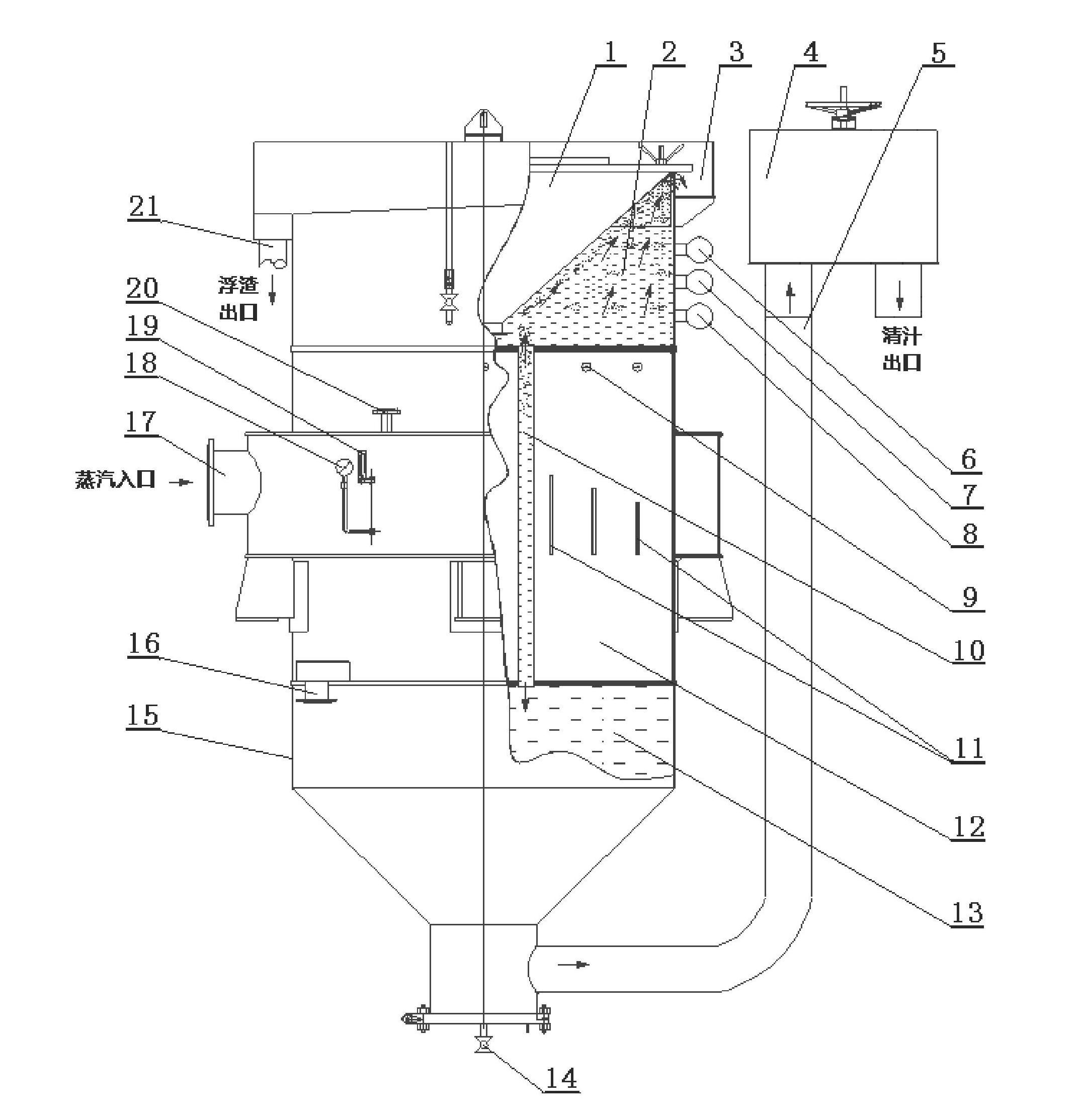

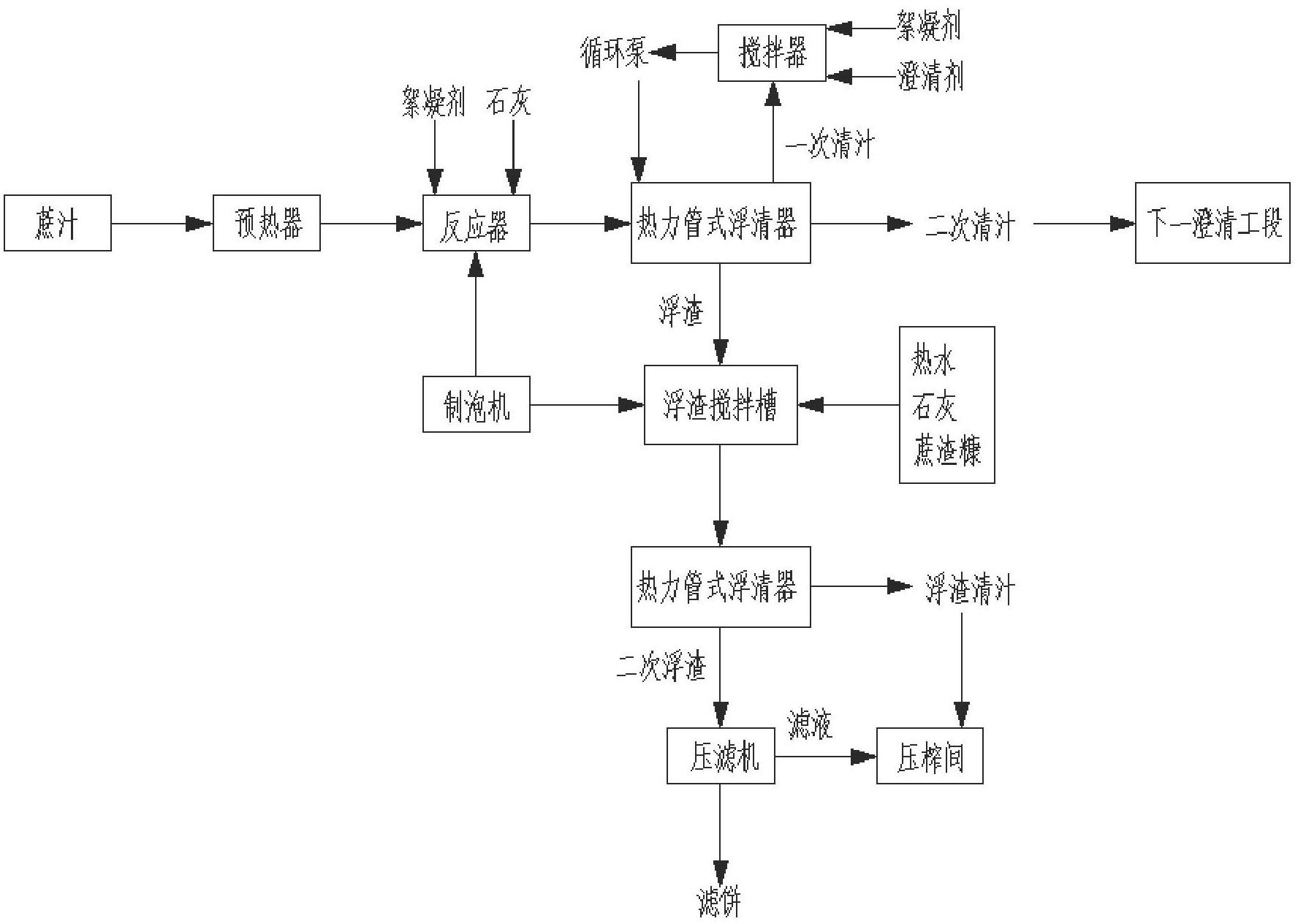

Method and equipment for clarifying cane juice by combining air floatation purification and thermal floatation purification

ActiveCN102676703AHigh gum contentHigh viscosityPurification using alkaline earth metal compoundsPurification by physical meansProcess engineeringClarifying agent

The invention discloses a method for clarifying cane juice by combining air floatation purification and thermal floatation purification. The method comprises the following steps of: preheating mixed juice to 45-55 DEG C, conveying into a reactor, and adding lime for adjusting the pH value to 5.6-6.6, wherein the adding amount of the lime is 0.02-0.05 percent of the weight of the mixed juice; and charging fine uniform air bubbles by using a bubble maker, adding a flocculating agent, mixing uniformly, adding into a thermal tubular purifier, performing air floatation purification in the thermal tubular purifier to obtain primary clear juice, extracting the primary clear juice into a stirrer, adding a clarifying agent and a flocculating agent simultaneously, and feeding into the thermal tubular purifier through a circulating pump for performing thermal floatation purification to separate secondary clear juice and floating slag out. An air floatation purification technology and a thermal floatation purification technology are combined, so that the clarifying efficiency and effect of the clarifying agent are increased, the quality of a white sugar product is improved simultaneously, and environmental pollution caused by lime sludge is lowered.

Owner:HUALAN DESIGN GRP CO LTD

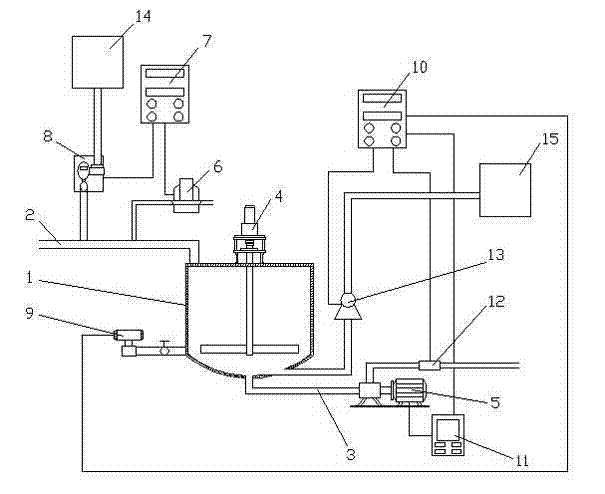

Preliming reactor and method

InactiveCN103695569AGuaranteed rotation speedGuaranteed spin performancePurification using adsorption agentsPurification using alkaline earth metal compoundsPh controlPhosphoric acid

The invention provides a preliming reactor, which comprises a cylinder, a juice inlet pipe, a juice outlet pipe, a stirring device, a pH control device, a flow control device, a phosphoric acid adder and a variable-frequency juice outlet pump; the variable-frequency juice outlet pump is communicated with the cylinder through the juice outlet pipe; the pH control device is used for detecting and controlling the pH of cane juice at the juice inlet pipe; the flow control device is used for detecting the flow information of the juice outlet pipe, and controlling the operating speed of the variable-frequency juice outlet pump according to the flow information, thus controlling output flow; and the phosphoric acid adder is used for adding phosphoric acid into the bottom of the cylinder or the juice outlet pipe. The invention further provides a preliming method by utilizing the preliming reactor. According to the preliming reactor and method, the large emergent flow change cannot occur in the follow-up procedures through the flow control of the preliming reactor, the stability of the follow-up procedures can be guaranteed, and further the output and quality of cane sugar can be guaranteed.

Owner:南宁苏格尔科技有限公司

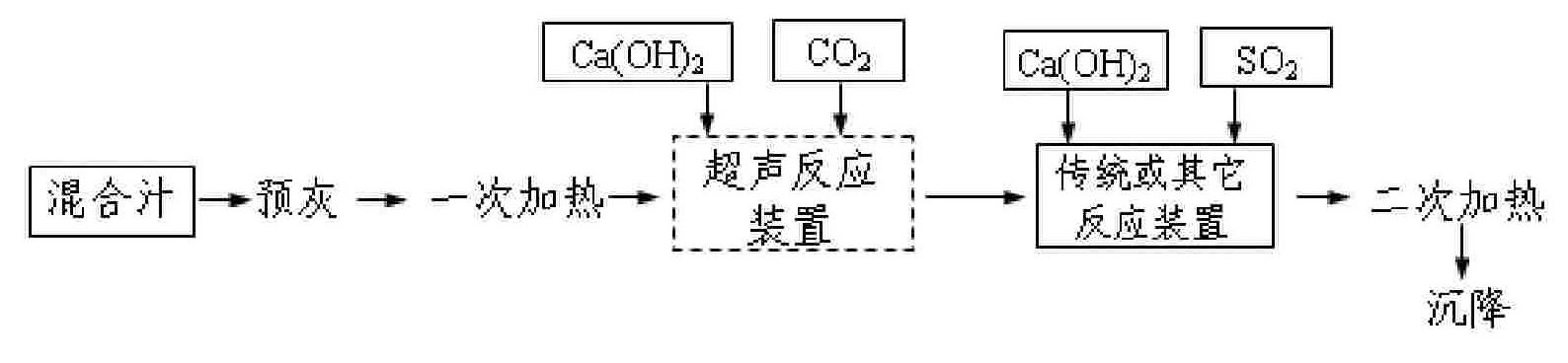

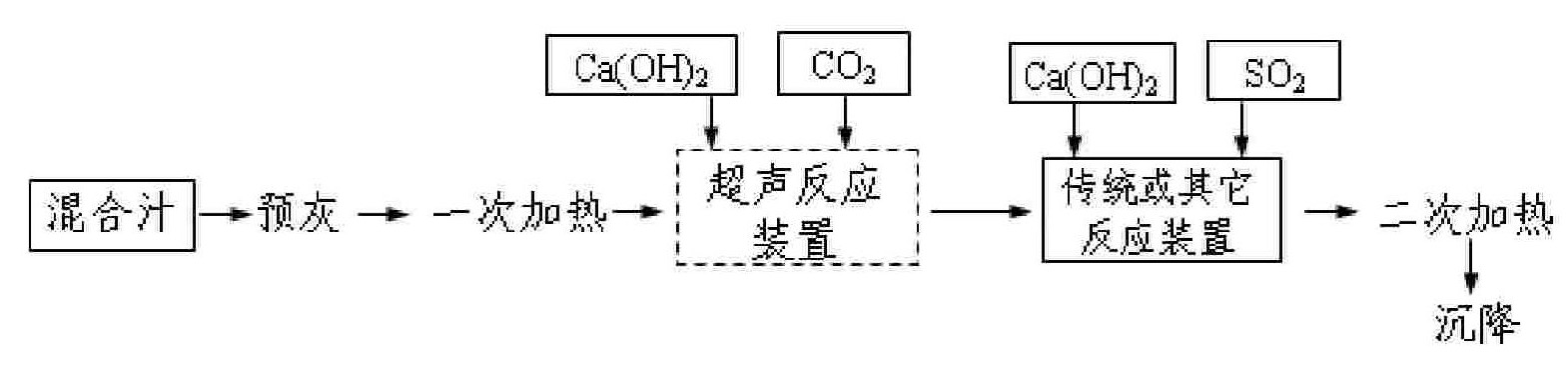

Method for clarifying ultrasonically-enhanced sugarcane juice

InactiveCN101805805ALow residual sulfurQuality improvementPurification by oxidation/reductionPurification using alkaline earth metal compoundsComing outSulfur

The invention discloses a method for clarifying ultrasonically-enhanced sugarcane juice, comprising the following steps: preliming the mixed sugarcane juice; heating the mixed sugarcane juice for the first time; leading CO2 and Ca(OH)2 to the mixed sugarcane juice to carbonize the mixed sugarcane juice in a ultrasonic reaction device, wherein the weight of the Ca(OH)2 is 0.01-0.3 percent of the weight of the mixed sugarcane juice, and the molar mass ratio of the CO2 to the Ca(OH)2 is 1:1; adding SO2 and Ca(OH)2 to enable the mixed sugarcane juice which comes out of the ultrasonic reaction device to be subjected to the sulphitation and the neutralization, or adding part of the mixed sugarcane juice which is not carbonized by the CO2 to the mixed sugarcane juice which comes out of the ultrasonic reaction device to enable the same two to be subjected to the sulphitation and the neutralization, where the addition amount of the SO2 and the Ca(OH)2 is 55-59 percent of the addition amount of the SO2 and the Ca(OH)2 which are added to enable the mixed sugarcane juice to be subjected to the sulphitation and the neutralization; heating the mixed sugarcane juice; and precipitating the mixed sugarcane juice. The method for clarifying the ultrasonically-enhanced sugarcane juice can improve the neutralization speed and the neutralization degree of the sugarcane juice and reduce the content of the residual sulfur.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

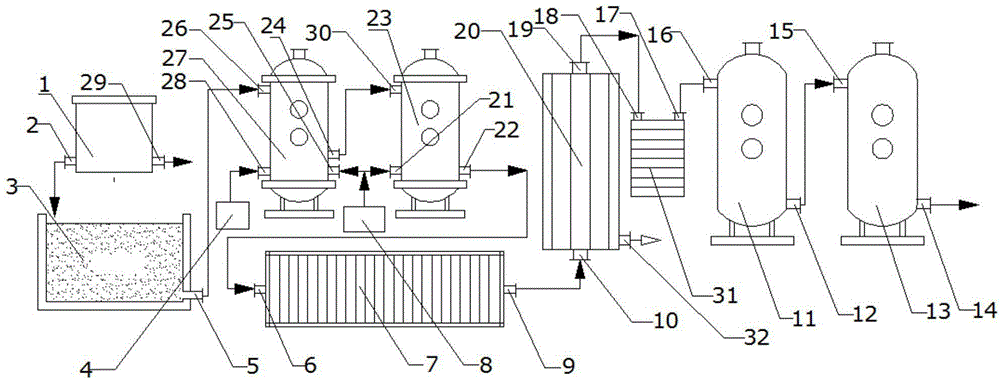

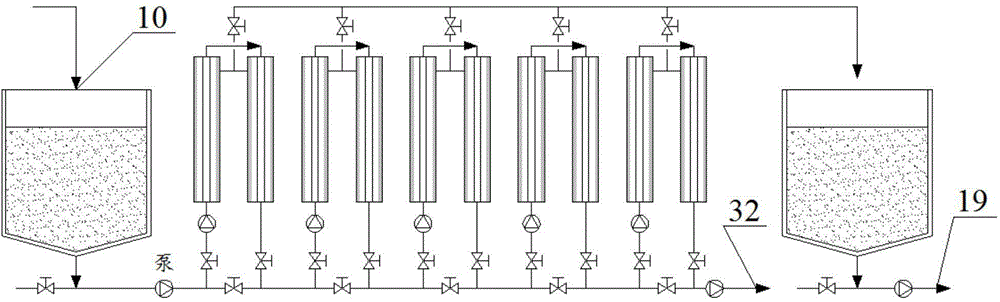

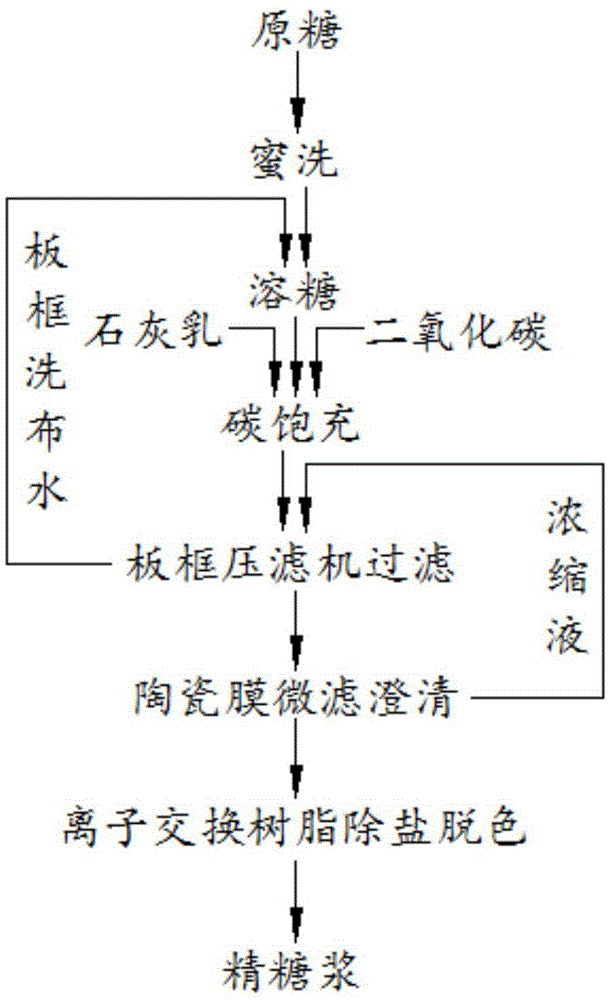

Refined sugar clarification device

ActiveCN104805222AExtended cleaning cycleReduce cleaning frequencySugar productsPurification using chemicalsMicrofiltration membraneTurbidity

The invention discloses a refined sugar clarification device which comprises a device for washing raw molasses, a sugar melting box, a first carbonating tank, a second carbonating tank, a plate-and-frame filter press, a multistage ceramic membrane microfiltration system, a plate heat exchanger, a first ion-exchange resin tower and a second ion-exchange resin tower, which are connected in sequence. Based on the conventional refined sugar clarification technologies and devices, the refined sugar clarification device is additionally provided with the ceramic microfiltration membrane which can clarify remelt syrup carbonated and filtered by the plate-and-frame filter press, so that the turbidity of the remelt syrup before entering the ion-exchange resin is reduced and the service life of the ion-exchange resin is prolonged.

Owner:GUANGXI UNIV

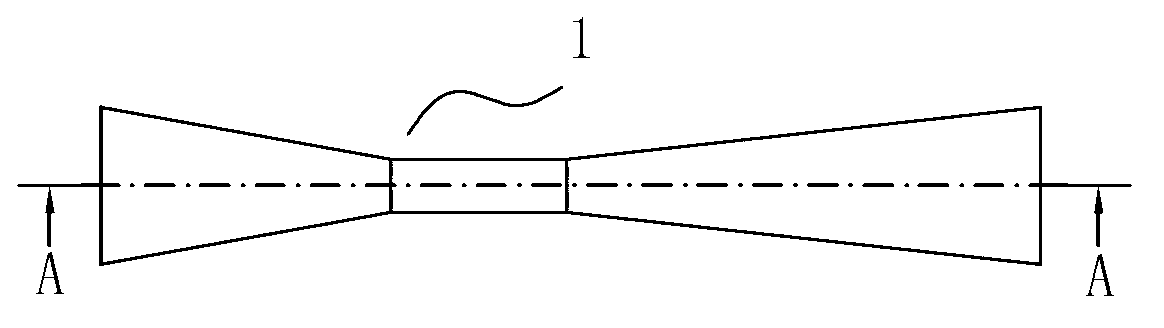

Cane juice neutralization reaction enhancing method based on multi-stage hydrodynamic cavitation

InactiveCN104004862AIncrease profitGood effectPurification using alkaline earth metal compoundsCavitationChemistry

The invention relates to a cane juice neutralization reaction enhancing method based on multi-stage hydrodynamic cavitation. The cane juice neutralization reaction enhancing method comprises a multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing procedure; the multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing procedure comprises the following step: cane juice obtained through a stoving neutralizer and a gas dispersing box is delivered into a multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing device through a pump so as to promote the continuous progress of cane juice neutralization reaction; the multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing device enables the cane juice to generate at least two-time hydrodynamic cavitation effect in a flowing process, and the one-time hydrodynamic cavitation effect indicates that the cane juice is subjected to a one-time contraction-expansion process. According to the cane juice neutralization reaction enhancing method based on multi-stage hydrodynamic cavitation, the adopted multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing device enables the cane juice to be subjected to multiple-time hydrodynamic cavitation effect in the multi-stage hydrodynamic cavitation cane juice neutralization reaction enhancing device, the neutralization reaction is more thoroughly carried out, the purity of clear juice is enhanced, the usage amount of lime and sulphur is reduced, and the SO2 content of the clear juice and a finished product is obviously lowered.

Owner:广西糖业集团红河制糖有限公司 +1

Method and equipment for activating calcium carbonate from sugar refinery

InactiveCN104437061AIncrease profitEmission reductionPurification using alkaline earth metal compoundsDispersed particle separationCalcium bicarbonateJuice clarification

The invention discloses method and equipment for activating calcium carbonate from a sugar refinery. The method comprises the following steps: introducing low-content carbon dioxide contained in flue gas of a boiler of the sugar refinery into a carbon dioxide adsorption tower, and reacting the carbon dioxide with lime cream inside the carbon dioxide adsorption tower to form a calcium carbonate solution; introducing a part of the calcium carbonate solution into a carbon dioxide generator to generate the carbon dioxide, reacting the other part of the calcium carbonate solution with the carbon dioxide to generate a calcium hydrogen carbonate solution, and pumping to mixed juice preliming, a floating device overflow pipe and a filtered juice quick-sinking reactor by using a calcium hydrogen carbonate pump. The method disclosed by the invention can be used for generating the calcium carbonate by reacting the low-concentration carbon dioxide contained in the flue gas of the boiler with the lime cream, then preparing the high-concentration carbon dioxide by utilizing a part of the calcium carbonate and finally preparing the calcium hydrogen carbonate as a clarifying agent used for the sugar refinery by using the carbon dioxide and the rest calcium carbonate, thereby achieving the purpose of cane juice clarification by removing a part of colloid and non-sugar components in an adsorbing way, enhancing the utilization rate of the carbon dioxide and reducing the discharge amount of the carbon dioxide from a chimney of the sugar refinery.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

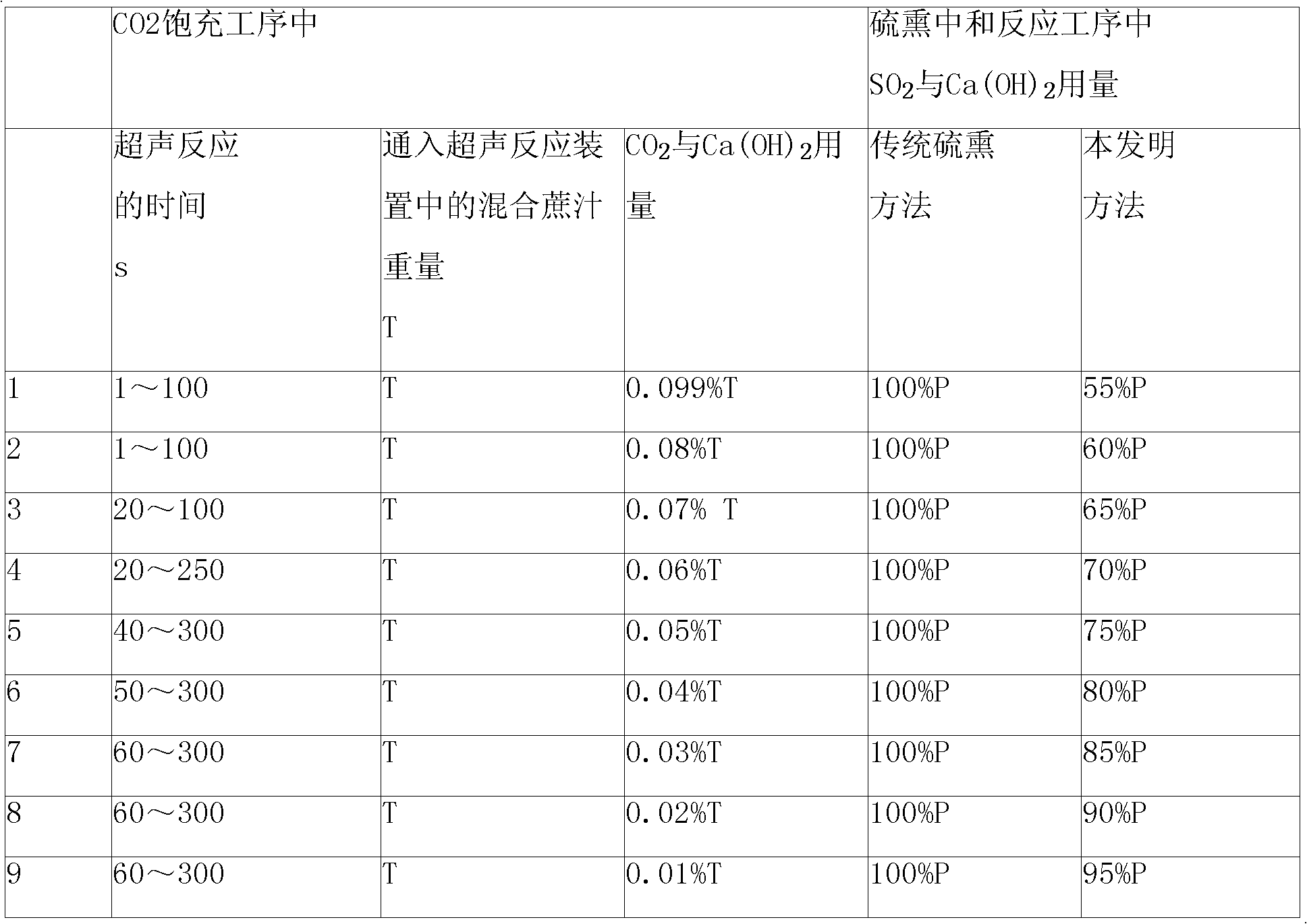

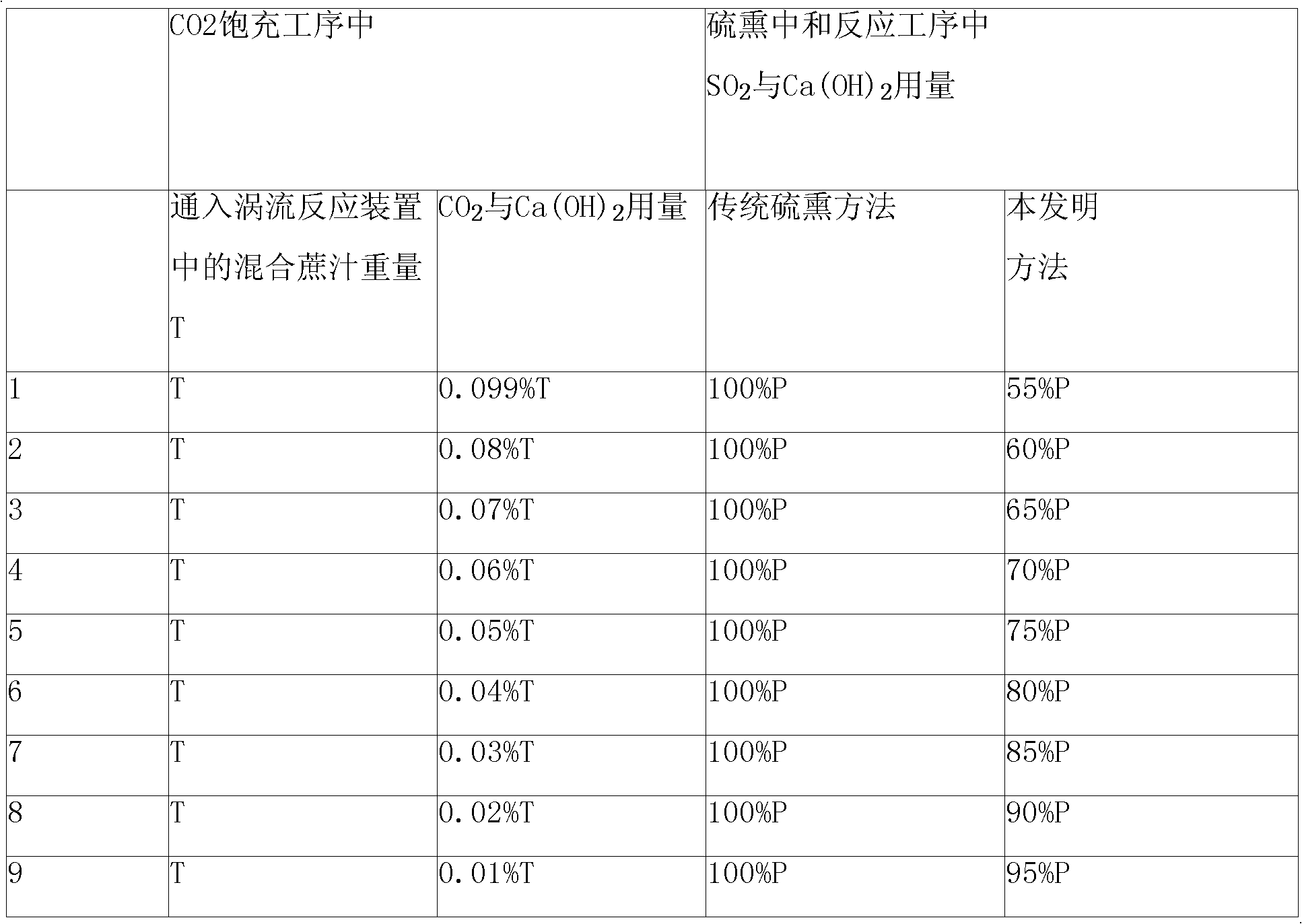

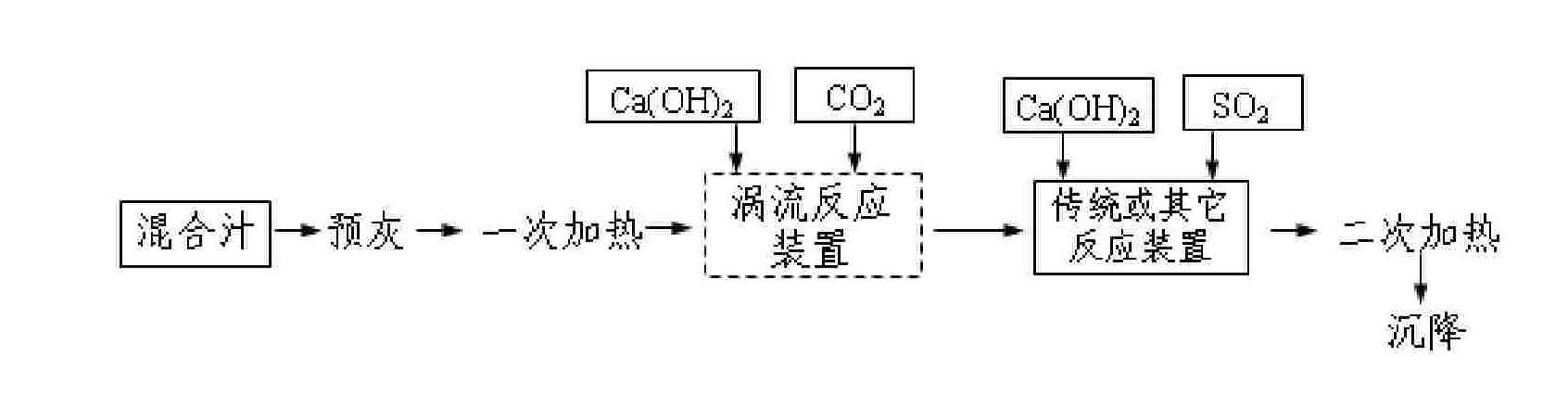

Intensified cane juice clarification method

InactiveCN101805806ALow residual sulfurQuality improvementPurification by oxidation/reductionPurification using alkaline earth metal compoundsJuice clarificationSulfur

The invention relates to an intensified cane juice clarification method which comprises pre-liming, primary heating, CO2 full filling, sulphitation and neutralization, secondary heating and settlement; the CO2 full filling procedure is as follows: pre-limed and primarily heated mixed juice is fed with CO2 and Ca(OH)2, the mixed juice is fed into an eddy reactor to have CO2 full filling reaction, and then the cane juice from the eddy reactor has sulphitation and neutralization reactions or is added with some the mixed juice which does not have CO2 full filling reaction to carry out the sulphitation and neutralization reactions; the amount of the Ca(OH2) which is fed into the mixed juice in the CO2 full filling procedure is about 0.05 percent of the weight of the cane juice, and the molar ratio of the amount of CO2 to the amount of Ca(OH)2 is 1:1, and the amount of SO2 and the Ca(OH)2 added in the sulphitation and neutralization reactions is 55 to 95 percent of the amount required in the traditional sulphitation and neutralization reactions. The method can improve the cane juice neutralization reaction speed and the reaction degree as well as the decolorization effect, and reduce the residual sulfur.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

System to produce sugar from plant materials

InactiveUS6656287B2Reduce the amount requiredReduce concentrationPurification by oxidation/reductionPurification using adsorption agentsProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

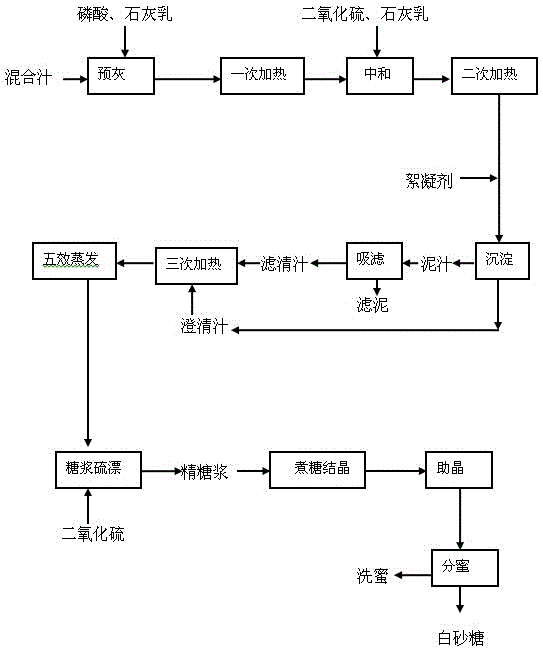

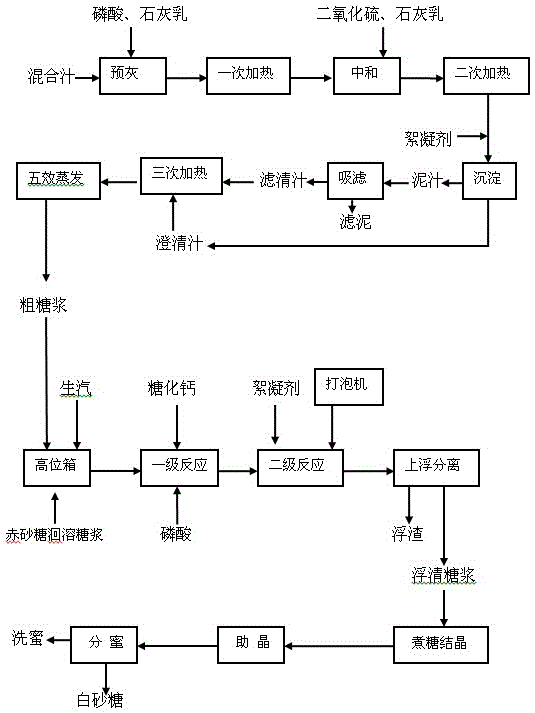

Sulfitation syrup floatation clarification process

InactiveCN105063241AQuality improvementEfficient removalSugar productsPurification using alkaline earth metal compoundsBoiling processFiltration

The invention discloses a sulfitation syrup floatation clarification process which comprises the following working procedures: preparing raw sugar, removing impurities through floatation, and preparing white granulated sugar; the procedure for preparing the raw sugar comprises the steps of preliming, primary heating, neutralization, secondary heating, precipitation, suction filtration, tertiary heating, five-effect evaporation and the like; the procedure for removing the impurities through floatation comprises the steps of heating in a high-level tank, primary reaction, secondary reaction and floatation separation. According to the sulfitation syrup floatation clarification process provided by the invention, the procedure for removing the impurities through syrup floatation is added on the basis of the conventional sulfitation sugar production process; high-quality materials can be provided for all stages in the subsequent sugar boiling process, so as to improve the product quality; moreover, brown granulated sugar remelt syrup can be processed according to a certain proportion, colloids and impurities in the brown granulated sugar remelt syrup can be effectively removed, and honey production factors and pigment substances can be reduced, so that the quality of an intermediate product is improved, and boiling of various series of massecuite and sugar recovery are facilitated; compared with the prior art, the sulfitation syrup floatation clarification process has the characteristics that the clarification efficiency is high, the effect of removing the impurities is good, and the content of sulfur dioxide in a product is low.

Owner:NANNING SUGAR INDUSTRY CO LTD

High-efficiency carbon-absorbing tower

InactiveCN103418225AIncrease profitWell mixed absorption reactionPurification using alkaline earth metal compoundsDispersed particle separationProcess engineeringSugar refinery

The invention discloses main equipment: a high-efficiency carbon-absorbing tower, for recovering low-content CO2 of flue gas of a cane sugar factory boiler to be applied to a modified sugar manufacturing process by a sulfurous acid method. The high-efficiency carbon-absorbing tower comprises a tower shell, a boiler flue gas extraction and discharge system, a filling system, a spraying absorption system device, a demister system device, a cleaning system device, a monitoring system and a material conveying system. The high-efficiency carbon-absorbing tower is a high-efficiency forced absorption reactor; the utilization ratio of carbon dioxide is increased more quickly when compared with that of the traditional natural saturation equipment; a structure in the tower is designed innovatively and optimally, so that the gas liquid mixing ratio and the retention time are reasonable, the low-content carbon dioxide is gathered by the high-efficiency carbon-absorbing tower and reacts with lime milk to form calcium carbonate solution, emission is reduced, and the carbon dioxide can be recovered to be applied to an improved traditional sugar manufacturing process by the sulfurous acid method. The high-efficiency carbon-absorbing tower is characterized in that the structure is simple; the mounting is convenient; airflow resistance is small; the carbon dioxide is easy to gather and absorb; is the maintance is convenient;, the operation is reliable; the cost is low; the recovery rate of the carbon dioxide is high.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com