Method and device for reinforcing cane juice neutralization reaction by hydraulic micro-oscillation

A reaction device and micro-oscillation technology, applied in the direction of purification with alkaline earth compounds, etc., to achieve the effects of strengthening transfer and reaction, improving clarification effect, and intensifying relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A method for strengthening the neutralization reaction of sugarcane juice by hydraulic micro-oscillation.

[0041] Such as Figure 7 As shown, the method for strengthening the neutralization reaction of sugarcane juice by hydraulic micro-oscillation is a kind of clarification process applicable to cane juice or sugar solution of sulfite method, except that the same process flow as the usual sugarcane juice clarification process includes: In addition to the pre-ashing, primary heating, sulfur fumigation neutralization, secondary heating and sedimentation processes, there is also a hydraulic micro-oscillation intensified sugarcane juice neutralization reaction process between the sulfur fumigation and secondary heating processes. The hydraulic micro-oscillation The enhanced cane juice neutralization reaction process is to use the cane juice or neutralized juice that has passed through the sulfur fumigation neutralization reaction process and the diffuser box...

Embodiment 2

[0043] Embodiment 2: A kind of hydraulic micro-oscillation strengthened sugarcane juice neutralization reaction device composed of two ends of a horn-shaped tube and a small round tube.

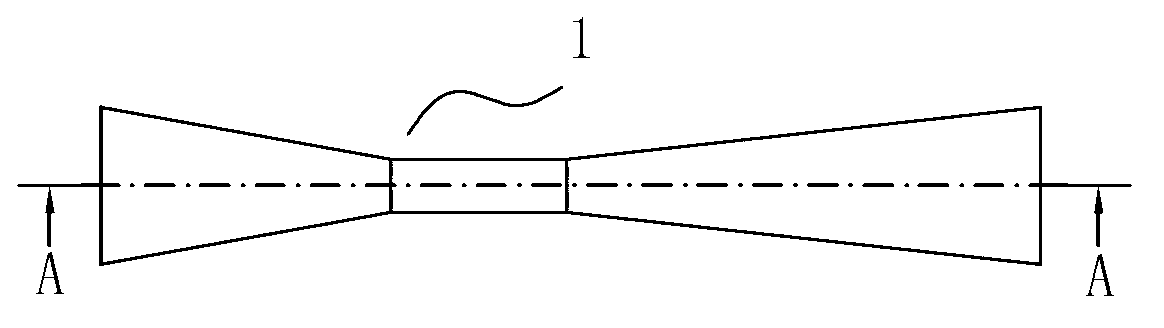

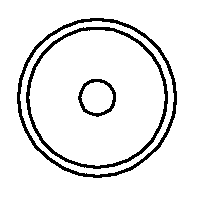

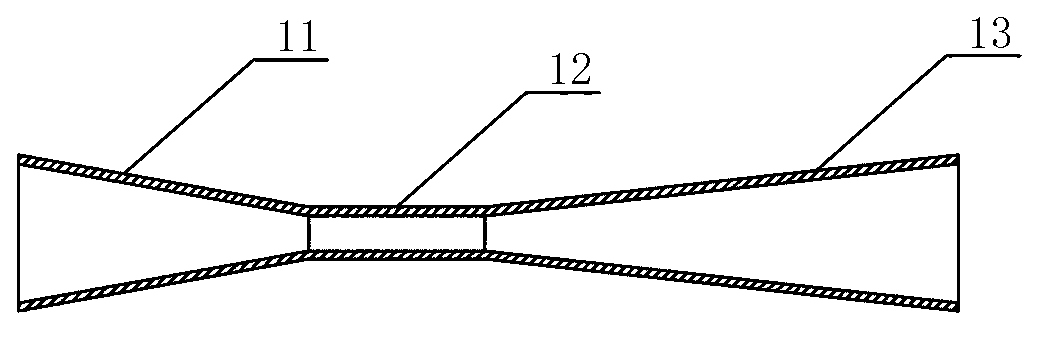

[0044] Such as Figure 1-1 to Figure 2-3 Shown, this hydraulic micro-oscillation strengthens sugarcane juice neutralization reaction device is a tubular container 1 whose two ends are horn-shaped tubes 11, 13 and the middle is a round tube 12. The cross-sectional area of the round tube is the same as that of the two ends The cross-sectional area of the small end of the shaped pipe is consistent, the ratio of the cross-sectional area of the small end of the trumpet-shaped pipes 11 and 13 at both ends to the cross-sectional area of the large end is 0.1 to 0.3, and the diameter of the cross-sectional area of the large end of the trumpet-shaped pipes at both ends is equal or not, Figure 2-1 to Figure 2-3 Flared pipe bands at both ends are equipped with flanges 14.

Embodiment 3

[0045] Embodiment 3: One end is a trumpet-shaped tube, the other end is a cylindrical tube, and the middle is a small circular tube connected to form a hydraulic micro-oscillation enhanced sugarcane juice neutralization reaction device.

[0046] Such as Figure 3-1 to Figure 3-3 As shown, the hydraulic micro-oscillation enhanced cane juice neutralization reaction device is a tube-shaped container 2 with a trumpet-shaped tube 21 at one end, a cylindrical tube 23 at the other end, and a small round tube 22 in the middle. The cross-section of the large end of the shaped pipe 21 is approximately equal to the cross-section of the cylindrical pipe 23, the ratio of the cross-sectional area of the small end of the trumpet-shaped pipe 21 to the cross-sectional area of the large end is 0.1~0.3, and the cross-section of the small round pipe 22 Corresponds to the cross-section of the small end of the flared tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com