Patents

Literature

84results about How to "High alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

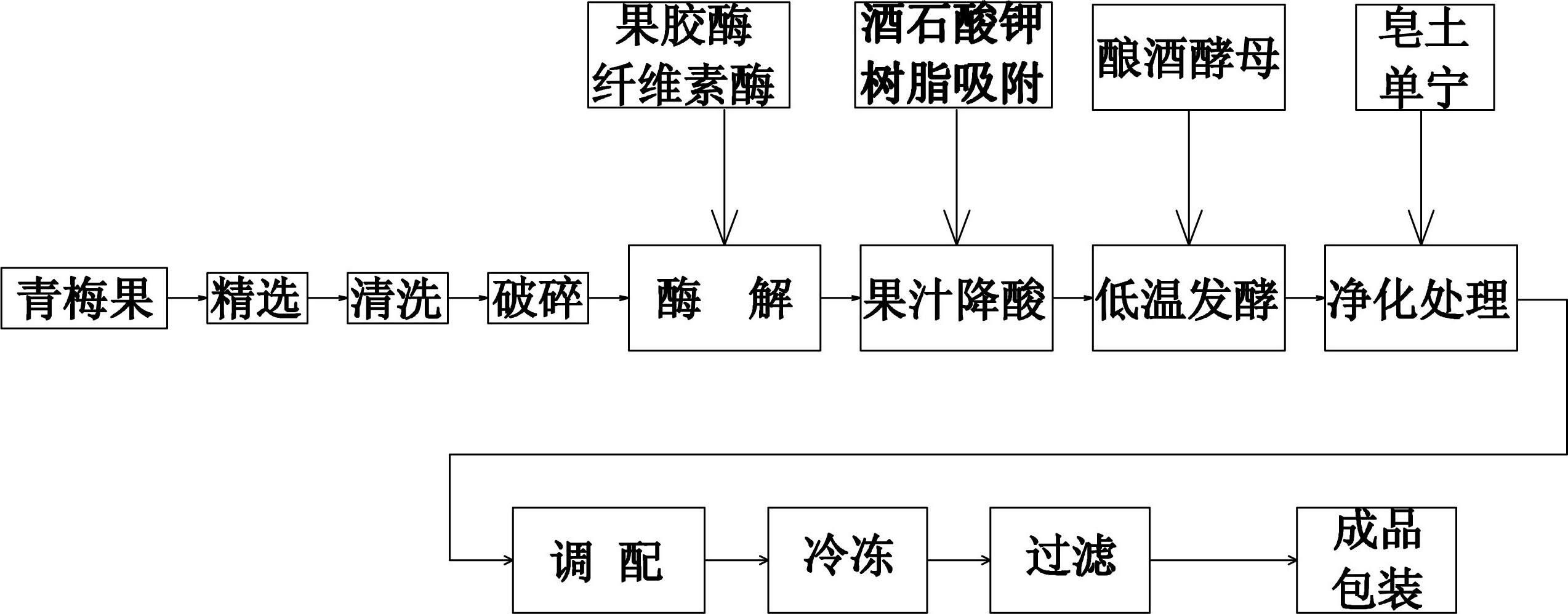

Production method and product of fermented green plum wine

InactiveCN102286320AReduce acidityPromote fermentationMicroorganism based processesAlcoholic beverage preparationFruit winePectinase

The invention discloses a production method of a fermented green plum fruit wine and a product thereof. The production method comprises the following steps: picking, cleaning and smashing on fresh green plum fruit utilized as a raw material, adding pectinase and cellulase to perform enzymolysis at 15-18 DEG C, then adding potassium tartrate to adjust and reduce the acidity at minus 6 DEG C to minus 8 DEG C, and using anion exchange resin to perform adsorption and reduce the acidity to 15g / L which is favorable for fermentation; placing clear juice in a fermentation tank, adding Saccharomyces cerevisiae to perform low-temperature fermentation; and adding bentonite and tannin in the fermented wine solution to perform compound purification, then performing low temperature freezing and clarification, blending, removing bacteria and filtering. The method has the advantages of good acidity-reducing effect and high composite enzymolysis juice yield; and by adopting the composite purification and freezing, the stability of the wine can be enhanced. The method is suitable for the production of the fermented green plum fruit wine.

Owner:YUNFU HUANAN LIQUOR

Manufacturing method of cane wine

InactiveCN101597555AOutstanding FeaturesHighlight significant progressMicroorganism based processesAlcoholic beverage preparationDistillationTwo step

The invention relates to the technical field of liquor production and provides a manufacturing method of cane wine, comprising the following steps: (1) preparing normal juice of cane; (2) culturing seed liquid A and seed liquid B of yeast; (3) preparing cane stalk trichosporon brassicae A and cane stalk trichosporon brassicae B; (4) fermenting: obtaining mature fermentation after the normal juice of cane is fermented in a two-step manner by trichosporon brassicae A and trichosporon brassicae B; (5) obtaining the cane wine by the way that the mature fermentation obtained in step (4) is decompressed and doubly distilled. The invention utilizes cane stalk as yeast wine carrier and normal juice of cane as raw material and adopts a reduced pressure distillation process, uses no cereals and other organic or inorganic nutrients, so that the white wine is entirely brewed by normal juice of cane. The brewed white wine reserves the unique aroma substance of cane, thus boasting rich cane flavour. The invention has far-reaching significance in saving cereals, improving the utility value of cane and promoting the development of agriculture of China.

Owner:GUANGZHOU SUGARCANE IND RES INST

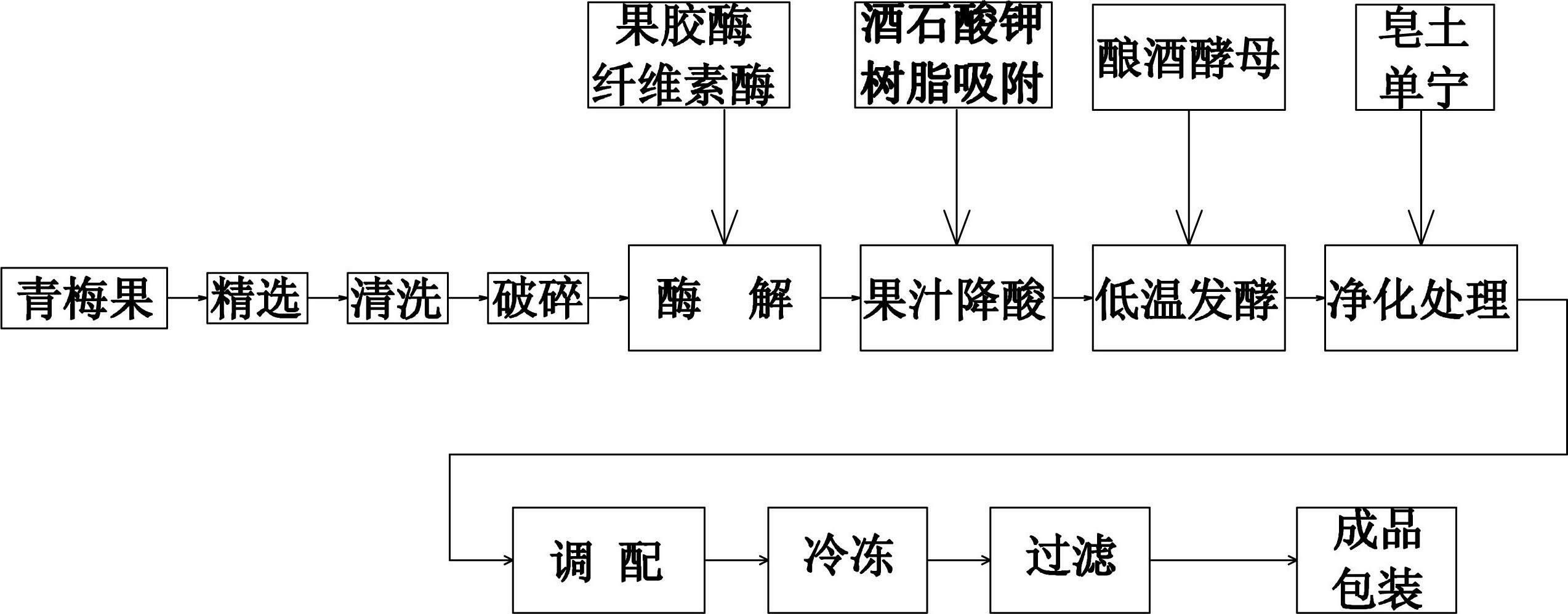

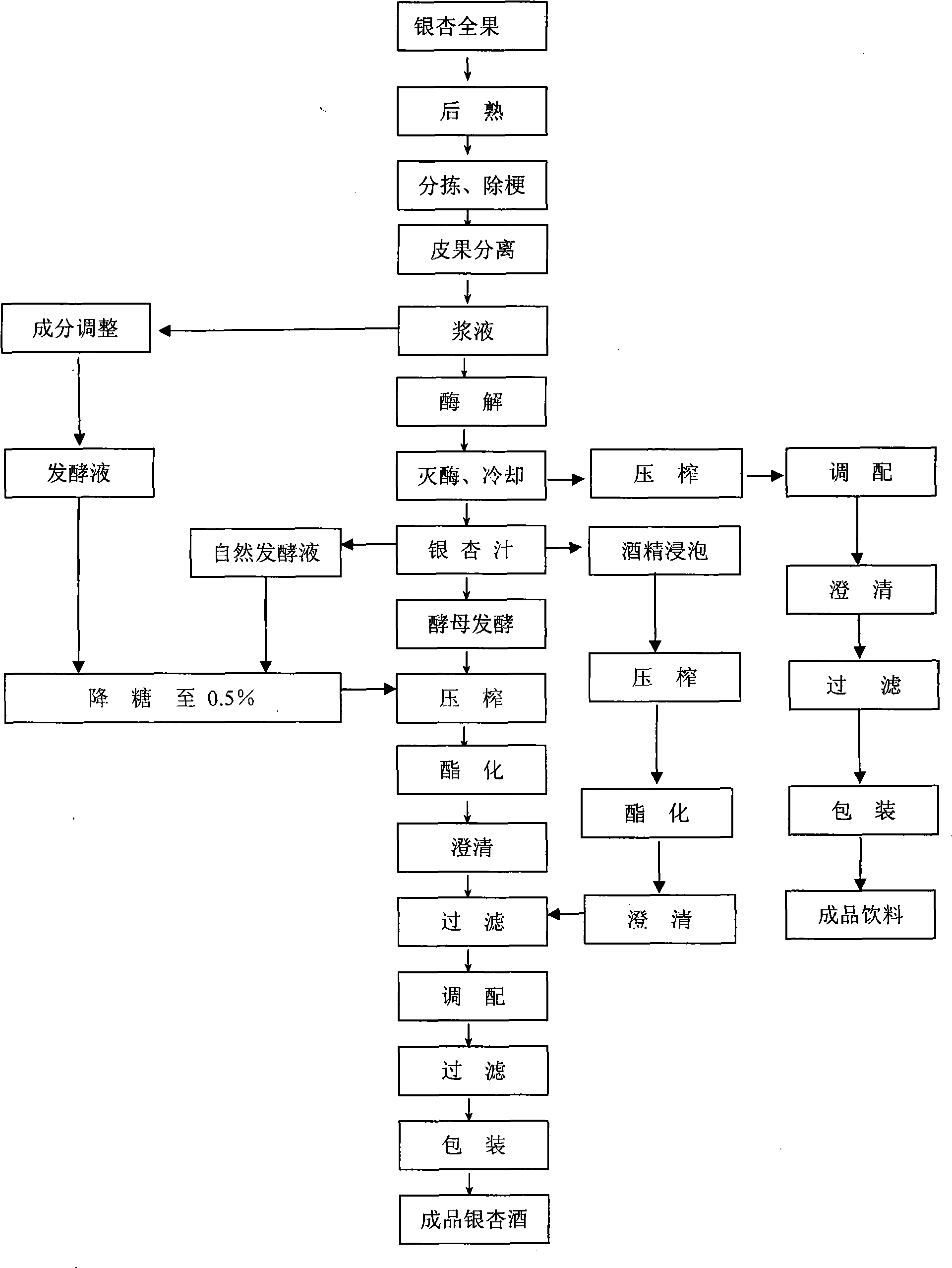

Gingko wine production process

InactiveCN101519629AShort production cycleHealth care functionAlcoholic beverage preparationCerebral vasospasmYeast

The invention relates to the preparation field of alcoholic beverage, in particular to gingko wine preparation with high health care component content, which is produced by taking deserted ginkgo biloba sarcotesta as the raw material, and adopting biological enzyme degrading pectic substance, cellulose, amylum, and other substances, and adopting the processes of wine yeast and natural grape fermentation or off-flavor alcohol infusing after enzyme destruction and defecation. The problems of foreign flavor and toxic component are simultaneously solved. The health care function of the gingko wine is more powerful than that of grape wine, the wine body is unique, the fruit aroma is stronger, the gingko wine is golden-colored and full of nutriments, with pure taste; and the gingko wine has the effects of dilating coronary arteries, enhancing blood flow, inhibiting blood coagulation, activating plasmin system, improving cardiotrophin, promoting cholesterin conversion, maintaining blood vessel elasticity, preventing and treating thromboembolia, coronary heart disease, angina pectoris, cerebral vasospasm and preventing cancer and restraining cancer, and the like. The gingko wine has remarkable economic benefit and social benefit.

Owner:徐琛

Method for brewing white spirit by adopting red dates as major ingredient

ActiveCN102399659AReduce Methanol ContentMaterials are readily availableAlcoholic beverage preparationChinese JujubeMethanol

The invention discloses a method for brewing white spirit by adopting red dates as a major ingredient. In the invention, the white sprit is prepared by taking fresh or dry red dates as the major ingredient and bran as an auxiliary material and adopting the following steps of: selecting and soaking the red dates, crushing the major ingredient to obtain jujube paste, pre-steaming the auxiliary material, fermenting and distilling the major ingredient and the auxiliary material and the like. In the invention, traditional Chinese medicines are also added to the red dates for crushing during the process of crushing the red dates to obtain the jujube paste, wherein the traditional Chinese medicines contain polyphenol acid as an active component; as the traditional Chinese medicines are added for inhibiting the activity of pectin methyl esterase contained in the major ingredient, the purpose of reducing the generation amount of methanol is achieved. The method is simple to operate, is easy to control, and has a good methanol removing effect, and the quality of the spirit product is greatly improved. The method disclosed by the invention is used for brewing the white spirit with data flavor by adopting the red dates as the major ingredient and the bran as the auxiliary material; the content of methanol can be reduced to lower than 0.06%; all indexes of the white spirit product can meet standards of national level I spirit; and the white spirit product has rich jujube fragrance.

Owner:河北万果红酒业有限公司

Preparation method of apple vinegar

InactiveCN103243012AImprove qualityLiquid fermentation cycle is shortMicroorganism based processesVinegar preparationAlcoholSugar

The invention discloses a preparation method of apple vinegar, belongs to the technical field of food processing, and solves the problems of long solid-fermentation period and poor liquid-fermentation quality in the traditional technology. The preparation method comprises the following steps of: (1) cleaning and crushing apples, controlling the sugar degree to be 10-12%, then electrifying and magnetizing, so as to obtain magnetized apple juice; (2) adding yeast with the mass being 0.015-0.025% of the mass of the apple juice and alcohol with the mass being 0.5-1.5% of the mass of the apple juice, and fermenting for 2-3 days at the temperature of 33-37 DEG C, so as to obtain apple wine; (3) adding acetic acid bacteria with the mass being 0.1% of the mass of the apple juice into the apple wine, and fermenting for 2-3 days at the temperature of 23-27 DEG C, so as to obtain the apple vinegar; and (4) carrying out vinegar spraying sterilization on the apple vinegar, then adding methylglyoxal with the mass being 0.01% of the mass of the apple vinegar, ageing for 10-12 days, and adjusting the acidity to be 3.5-4%, so as to obtain finished apple vinegar. The preparation method disclosed by the invention has the advantages that the fermentation period is shortened, the quality of the apple vinegar is improved, the taste of the apple vinegar is soft and mellow, and nutrient substances are rich.

Owner:山西药科职业学院

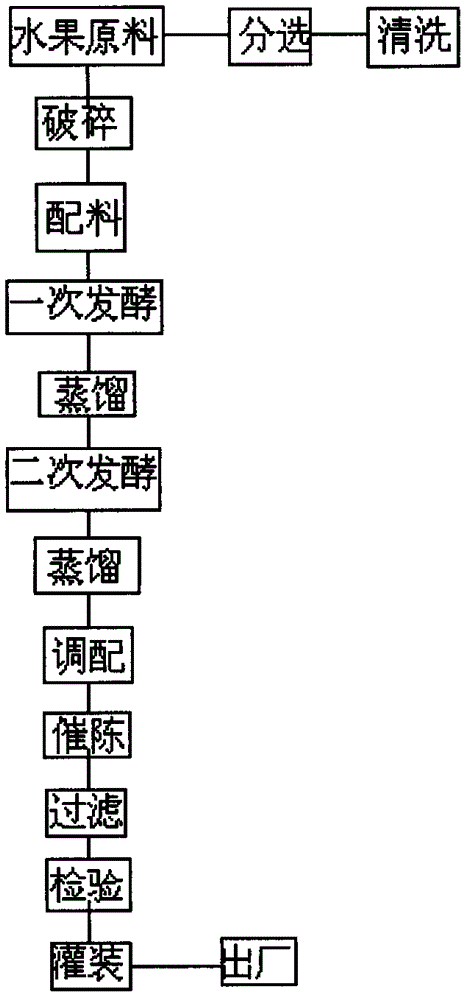

Manufacturing method of primitive blueberry distilled liquor

InactiveCN104059809AThere is no food consumptionHigh alcoholAlcoholic beverage preparationDistillationFiltration

The invention discloses a manufacturing method of primitive blueberry distilled liquor, which is characterized in that the method adopts fresh blueberry fruits as raw materials for liquor preparation, and comprises the steps of raw material sorting, cleaning, crushing, preparation, primary fermentation, distillation, secondary fermentation, distillation, aging acceleration, blending, filtration, examination, filling, releasing, and the like. The liquor has an alcoholic strength of 38% Vol-55% Vol, and is colorless, clear and transparent, free of suspensions, free of precipitates, elegant, pure and mild, sweet, fine, slightly sweet in aftertaste, and rich and endless in liquor liquid. The method of the invention produce liquor directly by using fruits as raw materials, and the liquor produced by the manufacturing process has both mellow fragrance of Chinese traditional liquor and delicate taste of fruit wine, and thus is generally acceptable for domestic people.

Owner:杨益

Process for brewing ginkgo wine

The invention discloses a process for brewing ginkgo wine. The process comprises the following steps of: washing shelled ginkgo, picking out floating fruits and mildewed fruits, boiling the ginkgo for 40 to 60 minutes by adding water, airing, cooling, mechanically removing shells, picking, and crushing the full ginkgo kernels into powder by using a crusher; and performing dry steaming and sterilization on the ginkgo powder, cooling, adding rice-aroma yeast, performing saccharification for 24 hours at the temperature of between 20 and 40 DEG C, adding the rice-aroma yeast and a proper amount of water after the saccharification, performing fermentation for 9 to 10 days, and performing distillation to obtain the ginkgo wine with alcohol content of 30 to 38 degrees; and performing secondary distillation on the obtained ginkgo wine to obtain the 45 to 55 percent ginkgo wine. The wine yield is high, and the alcohol content is high; the wine is colorless, clear and transparent and has no sediment; the wine has specific ginkgo aroma and mellowness; the wine is velvet and unique style; and after the wine is stored for one year, the quality of the wine is better by observation.

Owner:钟蕾 +1

Hair cosmetic composition

ActiveUS20100272666A1High alcoholAvoid separationCosmetic preparationsHair removalPeptideSulfur containing

A hair cosmetic composition containing the following components (a) and (b) and a hair treatment method in which the hair cosmetic composition is applied to the hair: (a) one or two or more peptides each having the number of amino acid residues being 5 to 50, and having neither a sulfur-containing amino acid residue nor a derivative thereof; and (b) a hair-swelling organic solvent.

Owner:KAO CORP

Making method for mulberry liquor

ActiveCN104694338AImprove stabilitySolve the problem of potential alcohol contentAlcoholic beverage preparationBiotechnologyLees

The invention discloses a making method for mulberry liquor. The making method includes the following steps that (1), mulberries are squeezed to obtain mulberry juice, and sulfurous acid is added into the mulberry juice in the squeezing process, wherein the amount of the added sulfurous acid is 60 ppm-80 ppm; (2) according to fermentation of the mulberry liquor, clarification is performed, a seed solution is prepared, inoculated fermentation is performed, post-fermentation is performed, and ageing is performed within a week after post-fermentation is completed; (5), tank inverting is performed for removing liquor lees; (6), blending and blending are performed; (7), aging is performed; (8), sterilization and filtering are performed, so that the mulberry liquor is obtained. By the adoption of the method, the mulberry juice is extracted at low temperature and clarified, supernatant liquor of the mulberry juice is extracted for fermentation, in this way, the problem that by the utilization of an existing manufacturing method, the content of methyl alcohol, aldehyde and higher alcohol in produced mulberry liquor is too high is solved, and the problem that by the utilization of the existing manufacturing method, in the fermentation process, people do not pay attention to fermentation control is solved.

Owner:SICHUAN JINSEN FOOD TECH CO LTD

Rose sweet white wine beverage and preparation method thereof

ActiveCN103194352AKeep the aromaRetain nutritionAlcoholic beverage preparationSweet white wineFermentation broth

The invention provides a rose sweet white wine beverage and a preparation method of the rose sweet white wine beverage. The rose sweet white wine beverage comprises the following components in percentage by weight: 25 to 32% of rose sweet white wine fermentation broth, 0 to 5% of pure honey, 55 to 70% of water, 0 to 18% of sweetening agent, 0 to 1% of acidulant, and 0 to 0.01% of table salt. The preparation method comprises the following steps of: fully mixing glutinous rice with rose; keeping the temperature at 26 to 32 DEG C for 72 to 100 hours, adding a saccharifying agent and a leavening agent at the same time; adding water, the sweetening agent, the acidulant, the table salt and the pure honey to the filtrate to carry out secondary blending after leavening; uniformly stirring; filling; sterilizing; and cooling, thus accomplishing the preparation. According to the rose sweet white wine beverage, the tastes and the nutrition of the rose and the sweet white wine are organically combined, thus the beverage is rich in nutrition, has a certain anti-oxidation effect, is soft in color and luster, clear and transparent, and pure in taste, has the special tastes of the rose and the sweet white wine, and is simple in production process and relatively low in production cost.

Owner:SOUTHWEST FORESTRY UNIVERSITY

A brewing method of low-methanol-content Chinese date wine

ActiveCN106085699AIncrease contentIncrease the juice yieldAlcoholic beverage preparationPectin esteraseFruit juice

The invention relates to a brewing method of low-methanol-content Chinese date wine, and belongs to the technical field of brewing. The method includes sorting Chinese dates, cleaning, stoning, soaking with hot water, pulping, adding pectin esterase and cellulase, performing enzymatic hydrolysis, stirring and cooking in an air-lift combined mechanical manner, centrifuging, separating supernatant, adjusting the supernatant with white sugar and citric acid, sterilizing, inoculating, fermenting, clarifying, filtering, adding a clarifying agent, and aging by using an oak barrel. The method degrades cell walls of fruit tissues by using the pectin esterase and the cellulase, degrades polysaccharides to allow effective components inside the Chinese dates to dissolve out, and increases the content of juice nutrients and the juice yield. Through stirring and cooking in the air-lift combined mechanical manner, methanol produced by pectin substance zymolysis through the pectin esterase and methanol produced by other reasons are separated along with stirring, cooking and high-pressure air blowing, thus reducing the methanol content in Chinese date juice pulp.

Owner:河北九维生物科技开发有限公司

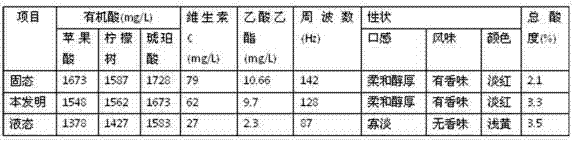

Pawpaw distilled liquor and preparation method thereof

ActiveCN103289871ALessen liver damageExtended shelf lifeAlcoholic beverage preparationExpiration dateOrganic acid

The invention discloses a pawpaw distilled liquor and a preparation method thereof, belonging to the technical field of food processing and biological fermentation. The preparation method comprises the steps of: biologically fermenting papaya juice so as to transform carbohydrate into ethyl alcohol fully; and then preparing the pawpaw distilled liquor through twice distillation, storage, aging, mixing and filtration, wherein the distillation can improve an alcohol content, reduce contents of organic acids and polyphenols, and guarantee a relatively long expiration date and good mouth feeling of a finished liquor; and the contents of effective components in the finished liquor can be improved by mixing and adding a fermentation wine base into the distilled liquor. According to the invention, the pawpaw distilled liquor has the total content of the acids of 1-3 g / L, the total polyphenol content of 0.5-1.5 g / L and the alcoholic strength of 42-52%vol, is clear, transparent and full-bodied, rich in nutrition, fine and smooth as well as pure and mild in taste, has a full-bodied pawpaw smell, a soft taste and a refreshing feeling, and can be preserved for a long term at a normal temperature.

Owner:许臣中

Brewing method of medlar grape dry red wine

InactiveCN102174348ARich and elegant tasteImprove sensory qualityMicroorganism based processesWine preparationGrape raisinLycium chinense

The invention relates to a brewing method of a medlar grape dry red wine, particularly relates to a method for brewing a medlar grape dry red wine by adopting Turpan grape dry and Ningxia red medlar as raw materials, and the flavor of the medlar grape dry red wine is similar with the flavor of the ice grape wine, belonging to the technical field of grape wine brewing. The method comprises the following steps: (1) evenly mixing the grape dry and the medlar in proportion to obtain the raw material; (2) adding water the mass of which is 1.0-1.5 times of the raw material in the raw material, evenly mixing to obtain a mixed solution; rehydrating the raw material, sterilizing, adding active yeast and fermenting to obtain a fermentation liquid; (3) squeezing and filtering the fermentation liquid, and taking the liquid to obtain a wine sample; and (4) ageing and clarifying the wine sample to obtain the medlar grape dry red wine. In the method, the grape dry and the medlar are adopted as raw materials to brew the grape wine, and the grape wine has higher alcohol content and sweetness, and mellow and elegant mouthfeel, and has much closer flavor to that of the ice wine.

Owner:QILU UNIV OF TECH

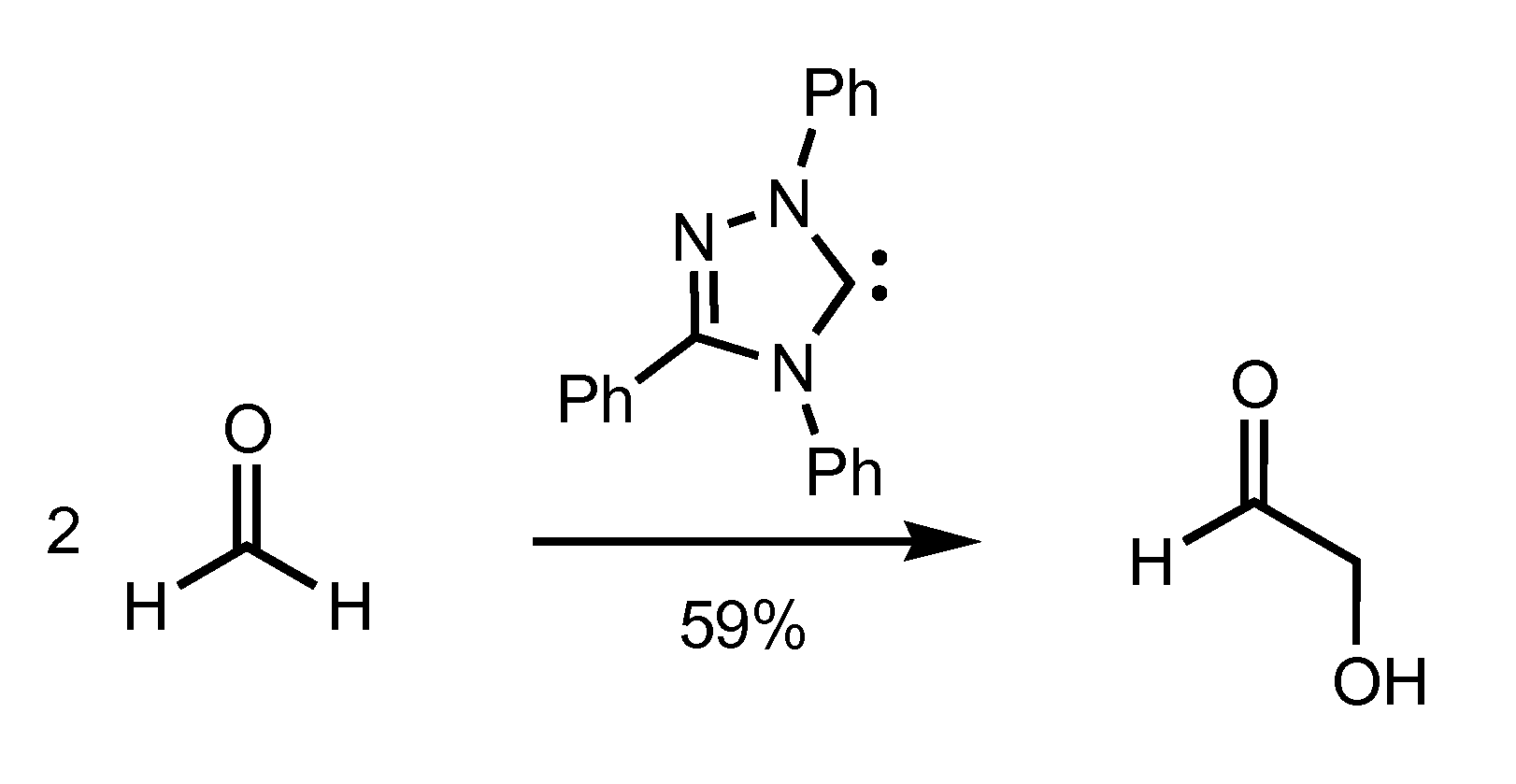

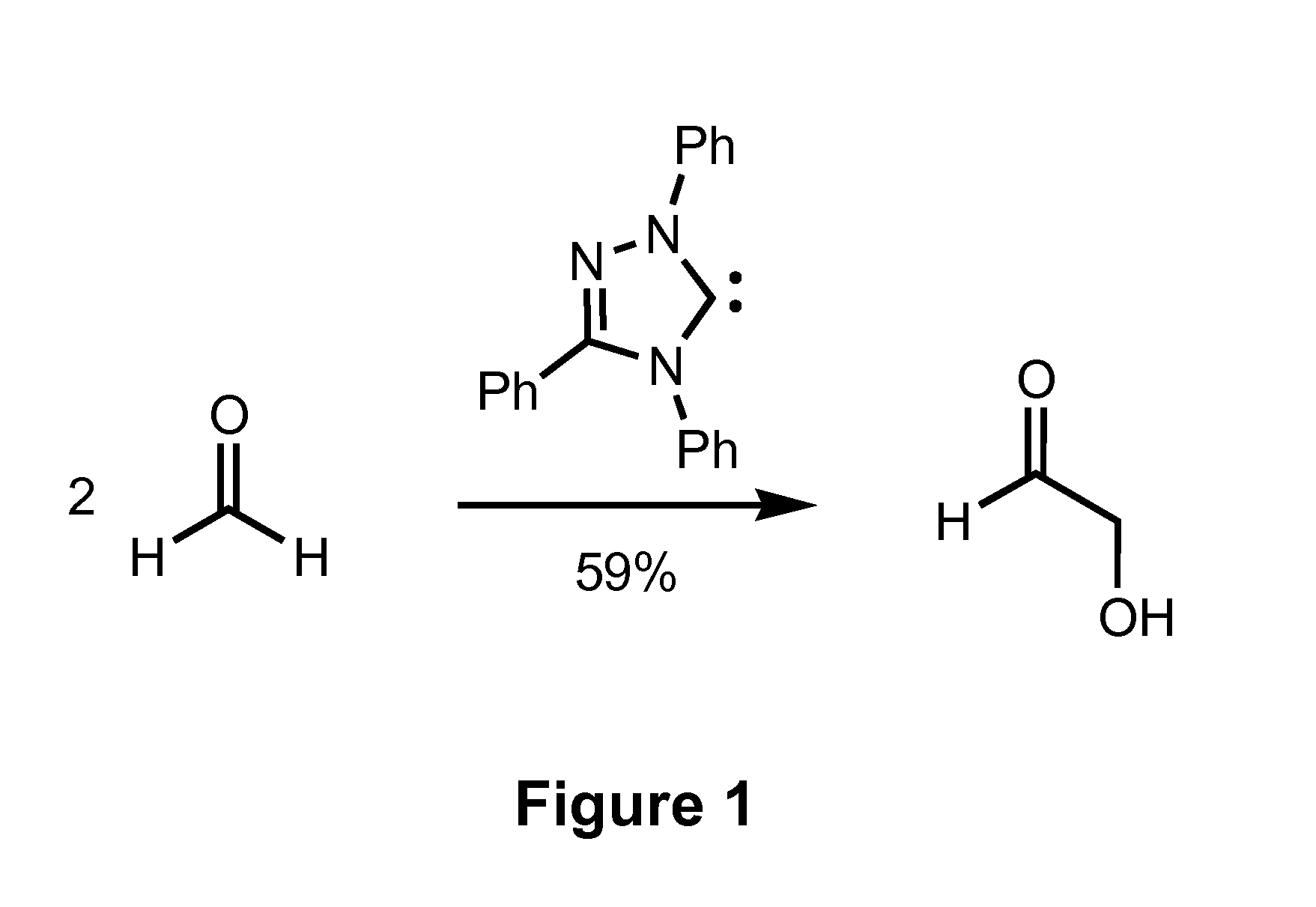

Combined Formose/Transfer Hydrogenation Process for Ethylene Glycol Synthesis

InactiveUS20100305368A1High selectivityHigh yieldOrganic compound preparationCarbonyl compound preparationSelf-condensationCarbene

The present invention provides a process for the production of a glycol via tandem self condensation of formaldehyde via formoin condensation and transfer hydrogenation of the reaction products of the formoin condensation. In some aspects, synthetic processes of the present invention utilize a combination of a N-heterocyclic carbene catalyst and a transition metal hydrogen-transfer catalyst providing enhanced selectivity and increased yields for the production of ethylene glycol relative to conventional synthetic approaches based on formoin condensation.

Owner:CALIFORNIA INST OF TECH

Rice-flavor Lonicera edulis fruit wine and manufacturing method thereof

InactiveCN102660429AReduce residual sugarHigh alcoholAlcoholic beverage preparationMicroorganism based processesAlcohol contentFruit wine

The invention discloses a manufacturing method of rice-flavor Lonicera edulis fruit wine. The rice-flavor Lonicera edulis fruit wine is obtained by letting wild Lonicera edulis fruits and glutinous rice be subject to saccharification, fruit wine fermentation, blending and other steps with the help of sweet distiller's yeast, Lonicera edulis fruit yeast liquid and wine yeast. The method is characterized by using sweet distiller's yeast to saccharify glutinous rice to obtain soluble sugar, using Lonicera edulis fruit yeast liquid and wine yeast to conduct alcoholic fermentation to obtain a first liquid, a second liquid, and a third liquid, and blending the obtained first liquid, second liquid, and third liquid in proportion to obtain the rice-flavor Lonicera edulis fruit wine. According to the invention, in the rice-flavor Lonicera edulis fruit wine manufactured by the method, white sugar is replaced by the saccharified glutinous rice to reduce the amount of residual sugar on the premise of controlling sugar-free extract to be not obviously reduced and increasing the alcohol content, the flavor is improved, and the Lonicera edulis fruit wine with a special rice and fruit flavor is obtained and recognized by consumers.

Owner:BEIHUA UNIV

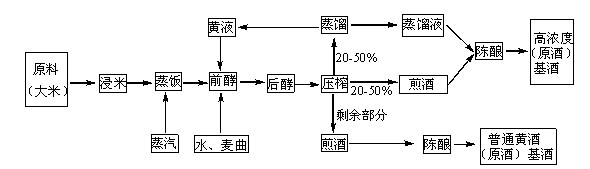

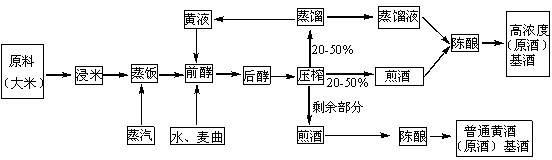

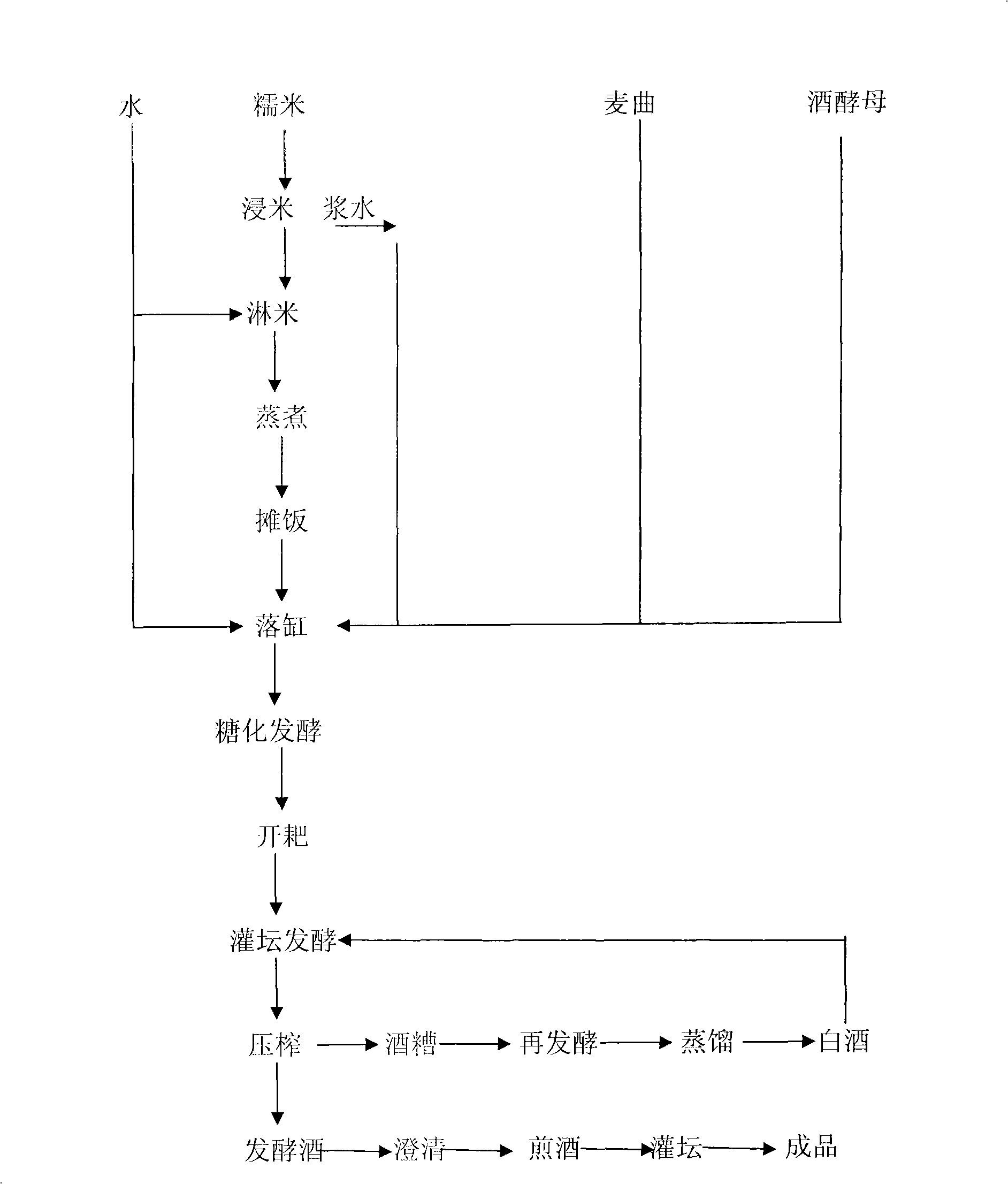

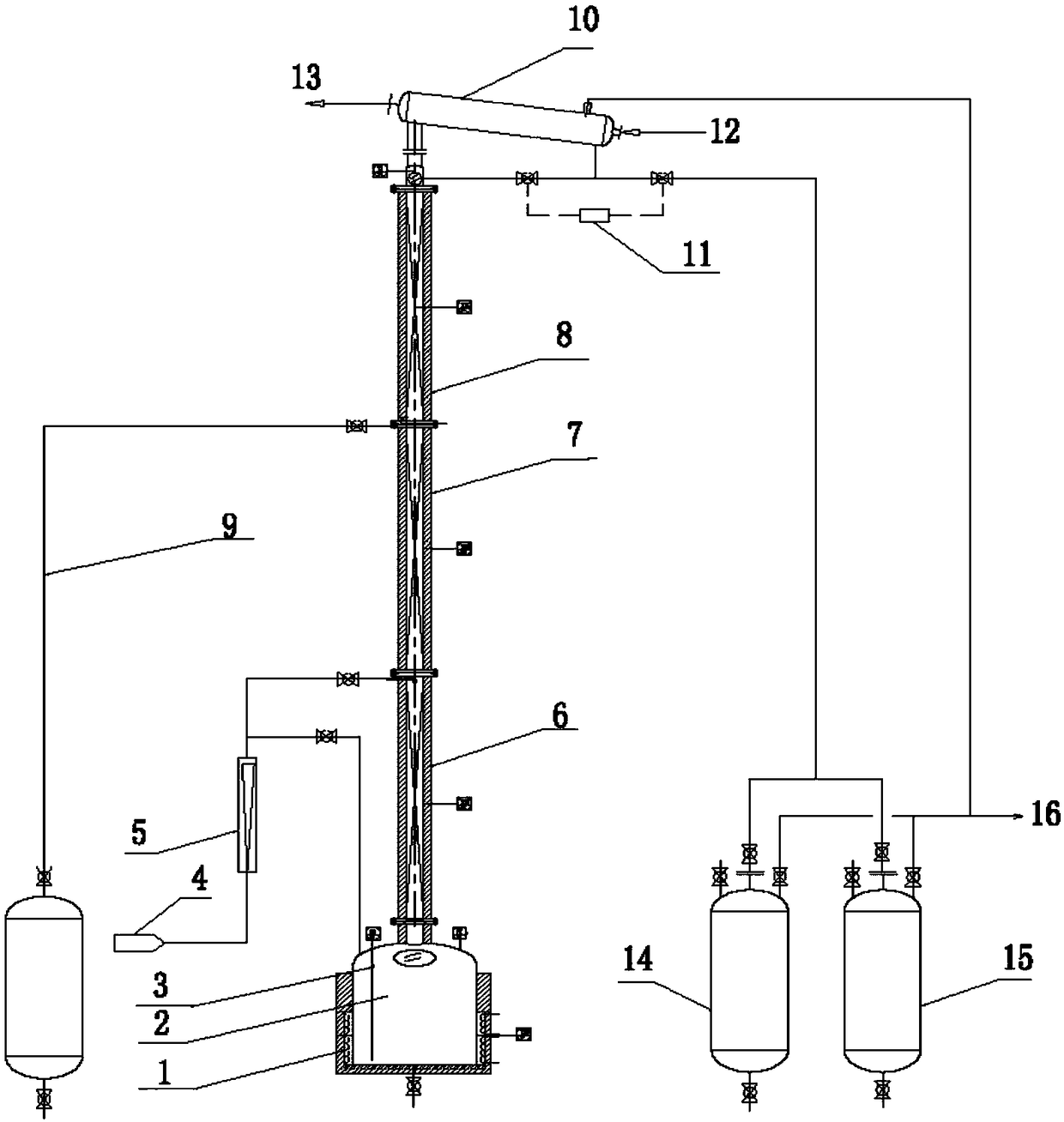

Brewing method of high-concentration yellow rice wine

ActiveCN102154074ASatisfy productionSave spaceAlcoholic beverage preparationBiotechnologyDistillation

The invention discloses a brewing method of a high-concentration yellow rice wine, comprising the brewing processes of: immersing raw materials (rice), steaming, pre-fermenting, post-fermenting, squeezing, distilling 20-50% (Vol) of squeezed wine, separating bulk wine into distillate and yellow liquid having high alcoholic strength through distillation, adding the yellow liquid in the pre-fermenting process, carrying out wine decocting and sterilizing treatment on the 20-50% (Vol) of squeezed wine, then uniformly mixing with the distillate, and aging together to finally form a high-concentration yellow rice wine (bulk wine) base wine. The brewing method of the stable-quality high-concentration yellow rice wine has the advantages of labor and material resource saving, brewing space saving, production efficiency improvement, convenience for aging and meets the requirement of large-scale industrial production.

Owner:JIANGSU ZHANGJIAGANG BREWING

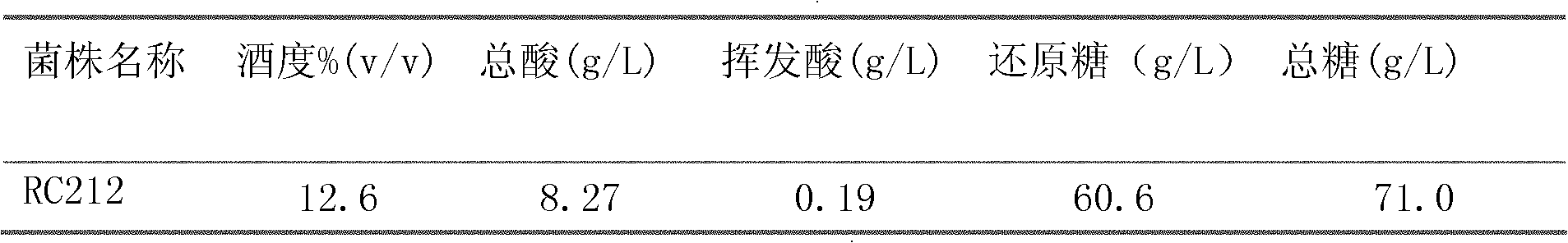

Method of fermenting dried lichee liquor with high sugar

ActiveCN104130900AReduce lossesInhibit browning reactionMicroorganism based processesAlcoholic beverage preparationBiotechnologyAcetic acid

The invention relates to a method of fermenting dried lichee liquor with high sugar. The method comprises the following steps: selecting fruits; cleaning; removing peels and denucleating; squeezing and taking juice; filtering; freezing and concentrating; freezing and defreezing; controlling temperature and fermenting; aging; clarifying and filtering; finally, obtaining the dried lichee liquor. According to the method, high sugar fruit juice is frozen and defrozen to separate out part of astringent matters in form of precipitates, so that the obtained dried lichee liquor is strong in fruity aroma, gentle and comfortable and tasty. The alcoholic strength of the dried lichee liquor is 14-15%vol, the content of total sugar is 2-4g / L, the total acid content is 6-7.5g / L (based on tartaric acid), the content of volatile acid is 0.4-0.6g / L (based on acetic acid), and the content of dried extracts is 20-30g / L.

Owner:GUANGDONG ZHENZHOU LYCHEE IND

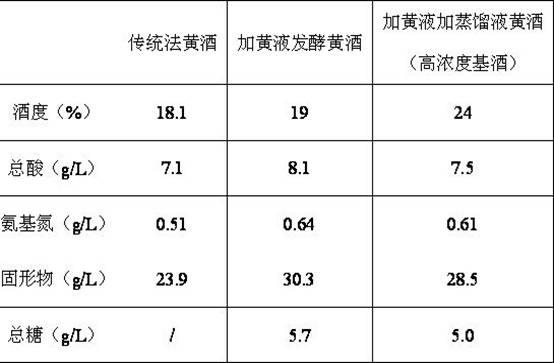

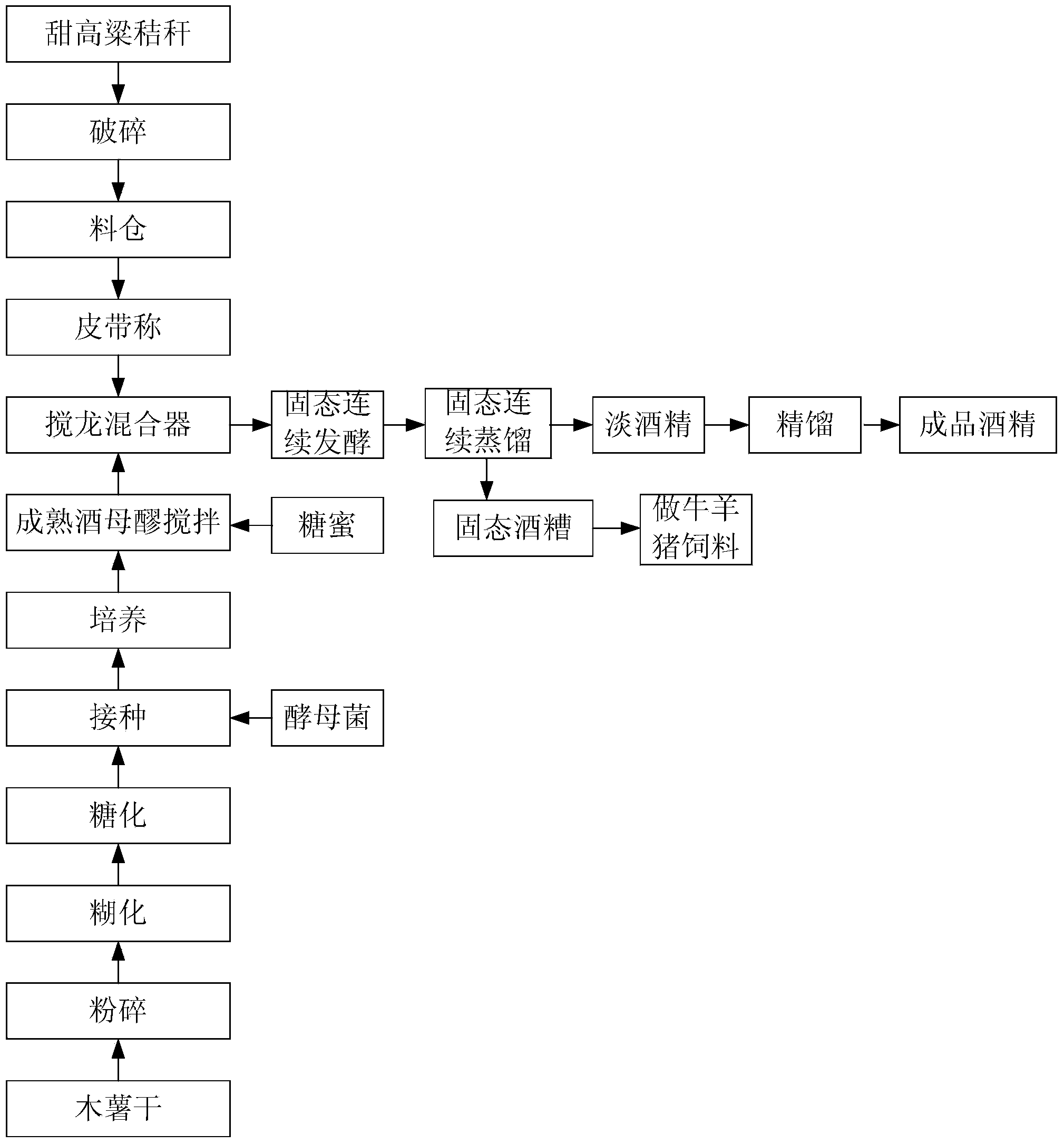

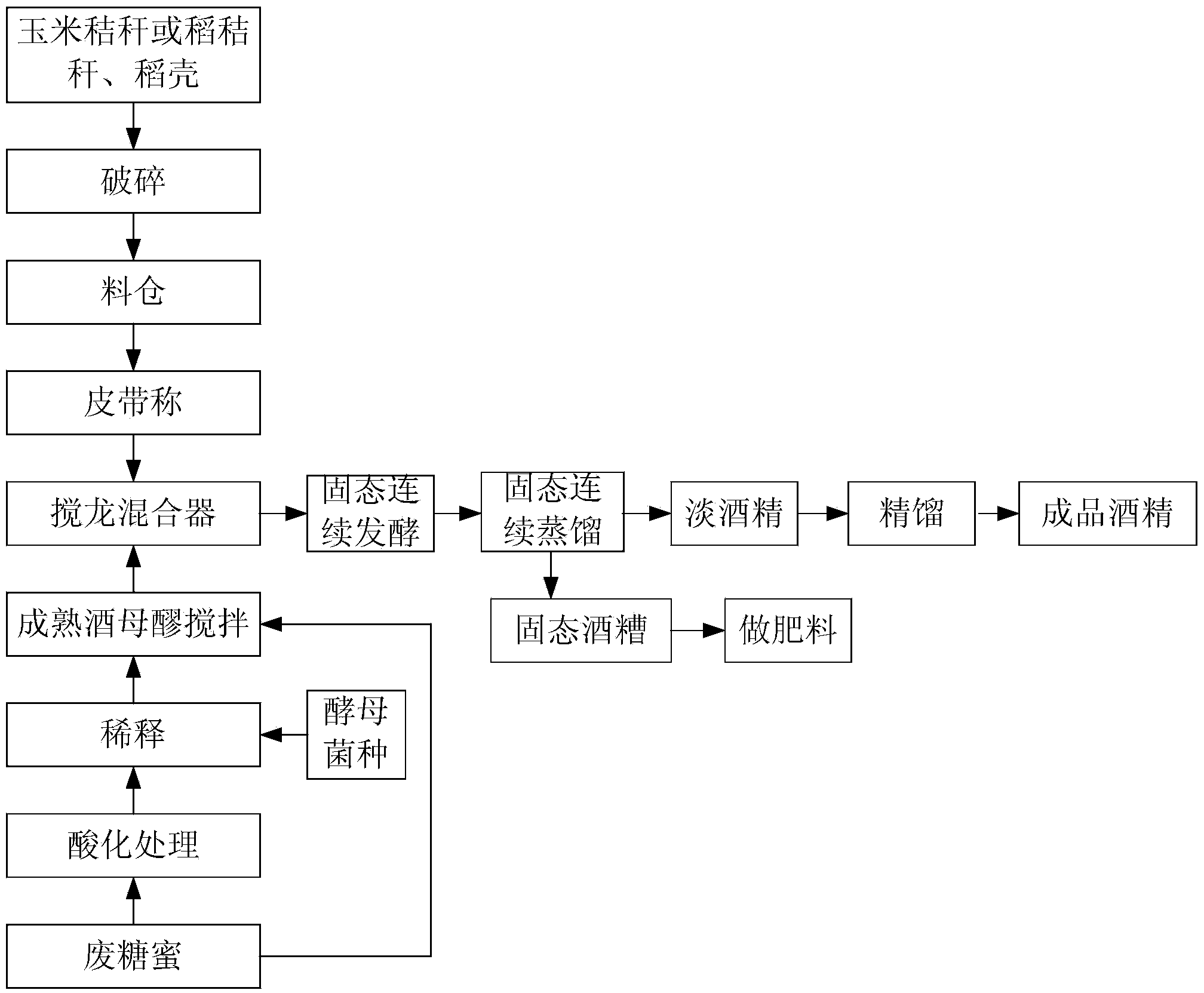

Method for producing alcohol through solid fermentation on mixed waste molasses containing cellulose substances

InactiveCN104109695ARaise the alcohol contentReduce manufacturing costBiofuelsFermentationCelluloseDistillation

The invention discloses a method for producing alcohol through solid fermentation on mixed waste molasses containing cellulose substances, belonging to the technical field of alcohol production and aiming to solve the problems of high production cost and high difficulty in treating pollution caused after production. The method comprises the following steps of crushing one or more of crop straws containing cellulose substances to obtain a crop straw raw material; preparing a yeast mash; mixing the yeast mash and waste molasses to obtain a mixture A; mixing the mixture A and the crop straw raw material to obtain a mixture B containing 15-30% of sugar; automatically and continuously fermenting the mixture B through a fermentation tank to obtain a solid fermentation finished mash; continuously feeding the solid fermentation finished mash into an alcohol distillation machine to distil diluted alcohol out; and treating the diluted alcohol by using a rectifying technology to obtain a finished product of alcohol. According to the method disclosed by the invention, different crops are selected as raw materials in different crop harvest seasons, so that the production cost is low; a proper amount of waste molasses is added, so that the fermented alcohol content is high; solid fermentation is adopted, so that no liquid distiller grains are generated, and no distiller grain pollution is caused.

Owner:梁利和 +1

Pear wine brewing method

The invention discloses a pear wine brewing method which comprises the following steps: removing impurities from pears, cleaning with water, and slicing the pears into pear slices with the thickness of 1-2cm; adding distiller's yeast into the sliced pear slices, stirring to be uniform, saccharifying the pear slices in a saccharifying box, fermenting the saccharified pear slices in a fermentation vat or tank for 20-25 days, taking out the pear slices, filtering the pear juice, pouring the pear juice into a wine roasting steamer for distilling, slowly steaming by using slow fire until the wine is completely roasted out, ageing the roasted pear wine in a storage tank, and blending the wine with liquor and sugar. Compared with the conventional brewing technology, the pear wine brewing method is high in alcohol content, good in taste, high in wine transparency and easy to store.

Owner:SHANGHAI SHUNYI WINE IND CO LTD

Low alcohol content health yellow rice wine and its preparation

InactiveCN1629280ALow alcoholImprove palatabilityAlcoholic beverage preparationAlcohol contentSteeping

The invention provides a health yellow rice wine and its preparation method, wherein each 1 kg of raw material comprises glossy ganoderma polysaccharide nutrient solution 4-20g, wolferry fruit extract 40-50g, longan pulp extract 40-60g, lotus extract 40-60g, sugar 20-50g, bee honey 2-10g, Shaoxing yellow rice wine 400-750g, water 100-450g. And the preparing process comprises boiling, steeping, mixing, clarifying, and in-depth filtration.

Owner:ZHEJIANG GUYUELONGSHAN SHAOXING WINE

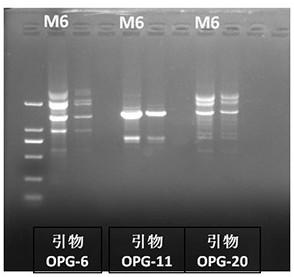

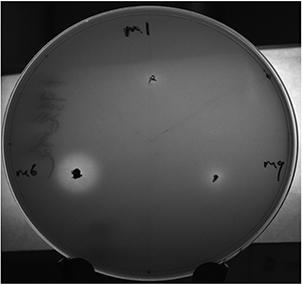

Eurotium chevalieri producing feruloyl esterase and application thereof in yeast for making hard liquor

ActiveCN109468232AObvious yellow plaqueHigh alcoholFungiAlcoholic beverage preparationYeastFeruloyl esterase activity

The invention relates to eurotium chevalieri producing feruloyl esterase and application thereof in yeast for making hard liquor and belongs to the biotechnical field. The eurotium chevalieri is separated from yeast for making hard liquor and has the characteristic of producing feruloyl esterase. The original number of the culture is M6 and the preservation number of the culture is CGMCC No.14125.The eurotium chevalieri has the advantages that the eurotium chevalieri producing feruloyl esterase is provided and is prepared into eurotium chevalieri powder. The eurotium chevalieri powder is applied to production of yeast for making hard liquor in a certain proportion to prepare high quality yeast for marking hard liquor with high feruloyl esterase activity. The center of the yeast has obvious eurotium chevalieri golden yellow spots. The liquor fermented by the yeast has the characteristics of high alcohol content, high content of caproic acid and ethyl caproate and the like compared withcontrast yeast.

Owner:SHANDONG BANDAOJING +1

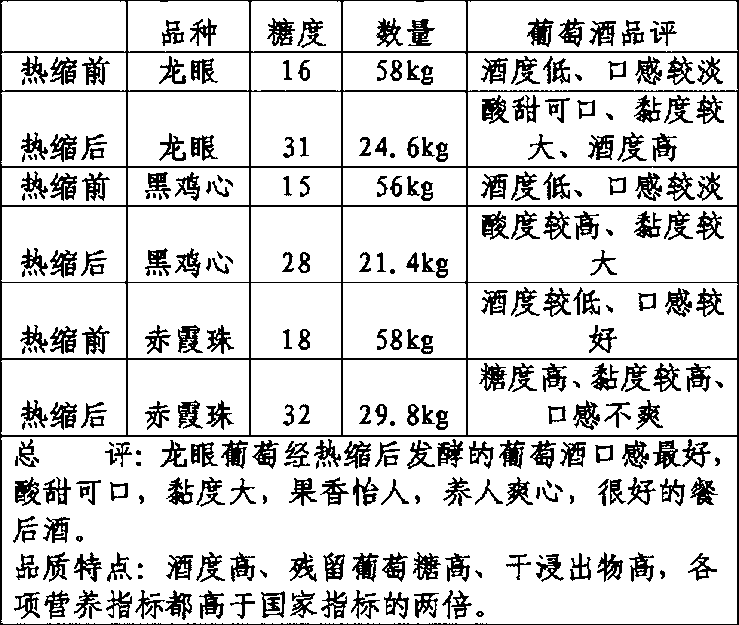

Thermal condensation grape wine and production method thereof

The invention discloses a thermal condensation grape wine belonging to the field of brewing. The thermal condensation grape wine is characterized by being prepared from raw materials, i.e., longyan grapes from trees with ages of 50-300 years in qingxu in shanxi through the following process steps of: manual picking, classification, crushing, pulping, separation and juice extraction, cooking and concentrating, natural fermentation, freezing and filtering, storage, raw grape wine blending, refined filtration as well as filling and sterilizing. The grape wine prepared by the invention is high in alcohol content, residual glucose and dry extract content, and all indexes of the grape wine are twice higher than natural indexes.

Owner:王计平

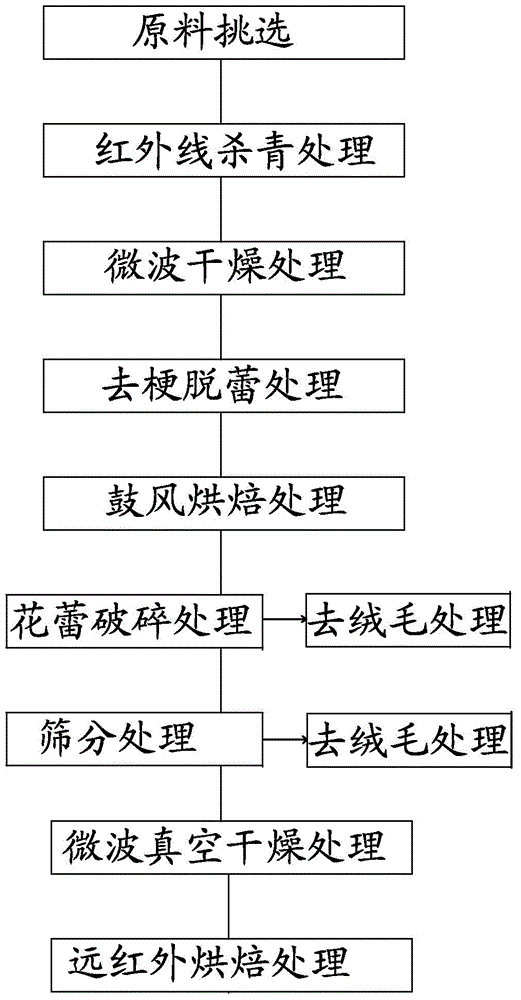

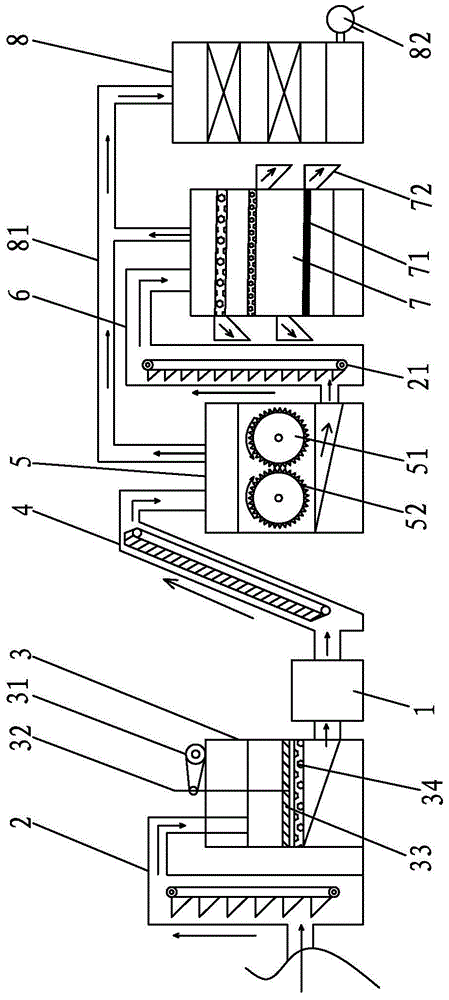

Preparation method for loquat flower bud tea

The invention relates to the processing field of health care tea, in particular to a preparation method for a loquat flower bud tea. The method is realized by the steps of: a. raw material selection; b. infrared enzyme deactivation treatment; c. microwave drying treatment; d. stalk removing and bud stripping treatment; e. blast baking treatment; f. flower bud crushing treatment; g. sieving treatment; h. fluff removal treatment at the same time of step f; h. microwave vacuum drying treatment; and i. far infrared baking process. Compared with the prior art, the invention has the advantage that the method gives consideration to the characteristic that loquat flower buds are rich in ursolic acid, oleanolic acid and other triterpene acid, 18 amino acids, and flavone active substances, during processing multiple low-temperature drying is carried out by stages, thus maximumly keeping the physiologically active ingredients of loquat flower buds. Also, the method provided by the invention has properly arranged processes, thus being convenient for large-scale industrial production.

Owner:HUAQIAO UNIVERSITY +1

Pear fruit wine brewing method

The invention provides a pear fruit wine brewing method, which comprises the following steps: cleaning pear fruit after removing impurities; then, cutting the pear fruit into slices and blocks with the thickness between 1 and 2 cm; adding mold culture into the pear fruit slices according to a ratio that 100 kg pear slices are uniformly stirred with 1.5 to 2.2 kg mold culture; placing the materials into a saccharification box for saccharification; placing saccharified pear slices into a fermentation tank or a fermentation can to be fermented after 3 to 4 days; controlling the fermentation temperature between 20 and 24 DEG C; taking out the pear slices after 20 to 25 days of fermentation; filtering the pear juice; pouring the pear juice into a wine roasting steaming vessel to be distilled; slowly steaming the pear juice with mild fire until the wine is roasted up; storing the roasted pear wine into a tank for aging for 365 to 380 days; taking out the wine for preparation according to the wine / sugar ratio of 100 / 10 to 15; and obtaining the pear fruit wine. The invention has the advantages of simple process, low cost and easy operation. The brewed pear fruit wine has the advantages of high alcohol content, good mouth feeling, difficult deterioration, easy storage and good transparency.

Owner:董自贵

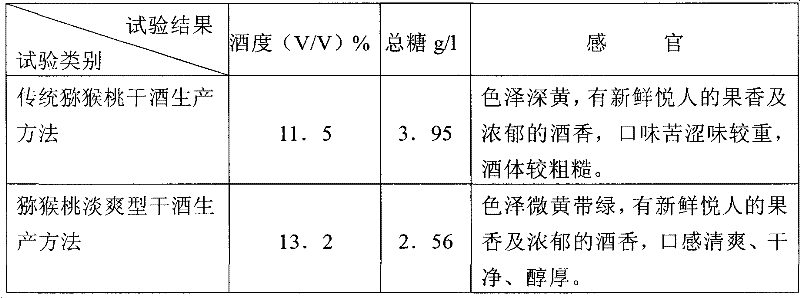

Kiwifruit light type dry wine and preparation method thereof

ActiveCN101709255BReduce bitternessHigh yieldAlcoholic beverage preparationMicroorganism based processesPectinaseYeast

Owner:沙洋中博猕猴桃生态发展有限公司

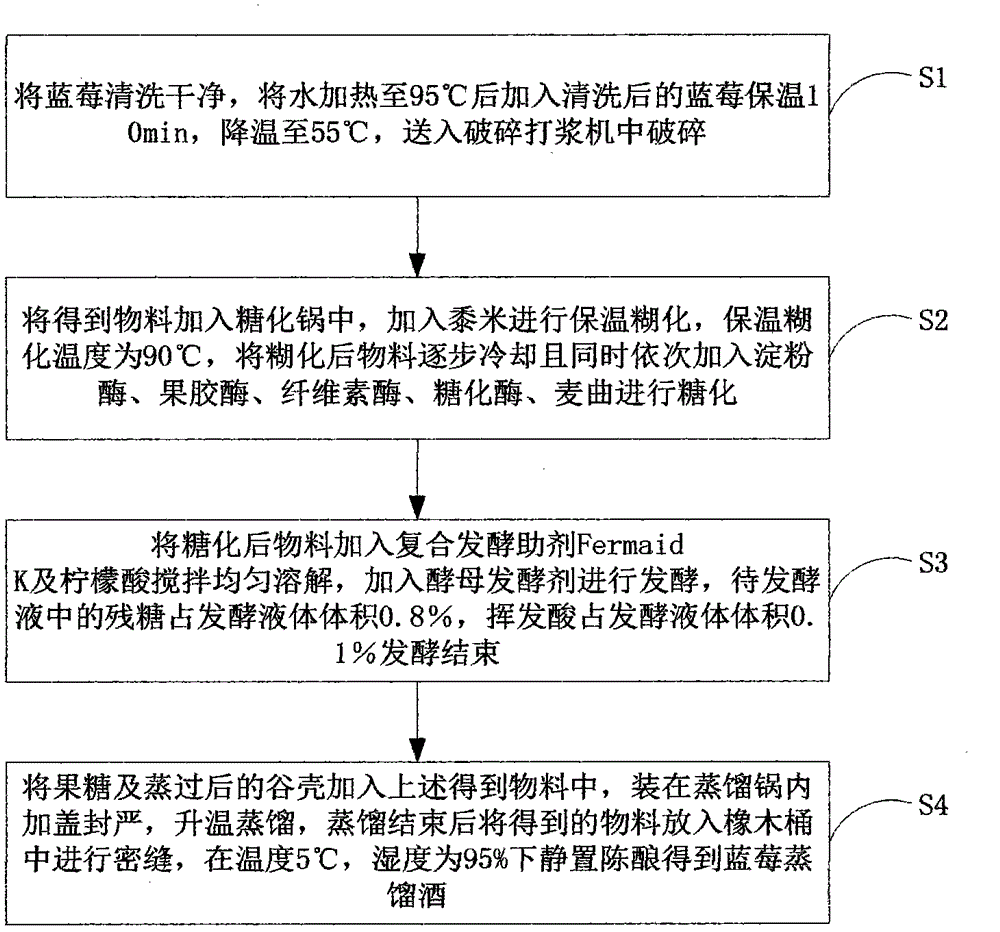

Blueberry distilled liquor and preparation method thereof

The invention discloses a blueberry distilled liquor. The blueberry distilled liquor comprises the following raw materials in parts by weight: 30-40 parts of blueberries, 1-5 parts of wheat koji, 2-8 parts of milled broomcorn millet rice, 2-3 parts of chaff, 0.1-0.2 part of amylase, 0.05-0.09 part of diastatic enzyme, 0.004-0.005 part of pectinase, 0.002-0.003 part of cellulase, 1-2 parts of a yeast starter, 0.2-0.4 part of a compound fermentation additive Fermaid K, 1-4 parts of fructose, 1-2 parts of citric acid and 50-80 parts of water. The invention also discloses a preparation method of the blueberry distilled liquor. The blueberry distilled liquor has the advantages of high nutrition, good taste and long guarantee period, and the preparation method has the advantages of high mechanization degree, high raw material utilization ratio, short production period, stable product quality and convenient industrial production.

Owner:李辉

Method for making papaya liquor

The invention discloses a method for making papaya liquor, and relates to the technical field of health-care liquor. According to the method, papayas, cereals and rice are fermented to obtain papaya fermented grains, cereal fermented grains and rice fermented grains respectively, and then three-stage distillation is carried out after the papaya fermented grains, the cereal fermented grains and the rice fermented grains are mixed; a method of respective fermentation of the papayas, the cereals and the rice is adopted, in the fermentation process, microorganisms in distiller's yeast take the papayas as raw materials, the papayas are saccharified and decomposed, nutritional components in the papayas are released fully, generated ester and acid substances are relatively large in quantity, the content of alcohol is relatively reduced, the prepared papaya liquor is high in yield, unique in flavor, mellow and sweet in taste, rich in aroma, pure and delicious.

Owner:陈圣明

Method for improving ferment distilled spirit degree by distilling with vinasse

InactiveCN101402908AHigh alcoholIncrease nutritionAlcoholic beverage preparationAlcohol contentVinasse

The invention utilizes a method for distilling spirit by vinasses so as to increase the alcohol content of fermented alcohol, which comprises the steps: sticky rice is taken as a raw material, dipped, steamed, cooked and put into a cylinder for diastatic fermentation; 5 days to 7 days after the diastatic fermentation, a post fermentation period starts; the spirit obtained in the last vinasse distilling is added in the post fermentation period; then, jar fermentation is carried out to obtain the fermented alcohol; and the obtained vinasse is fermented for anther 30 days to 45 days and then distilled to obtain a distilled alcohol with the alcohol content of 60 degrees to 65 degrees for the use in the next vinasse distilling. The method for distilling spirit by vinasses recycles waste vinasse, ferments and distills the waste vinasse again to obtain the distilled alcohol which is added into the last post fermentation period, thereby enhancing nutrition and reducing pollution. The method can obtain fermented alcohol with the alcohol content of 20 degrees to 30 degrees and increase the alcohol content by 5 degrees to 15 degrees when compared with common method.

Owner:湖北楚园春酒业有限公司

Distilling method for reducing fusel oil in baijiu

The invention discloses a distilling method for reducing fusel oil in baijiu. The method comprises the steps: firstly, distilling ripe mash at a slow speed under 0.2 to 0.3MPa steam, gathering fusel oil in foreshot and collecting the foreshot; rectifying the foreshot to remove the fusel oil to obtain base liquor. According to the method disclosed by the invention, the fusel oil can be gathered inthe foreshot through slow-speed distillation, so that only 10 to 30% volume foreshot is rectified in a following residue removing procedure, and 70 to 90% volume heart cut is prevented from being treated; thus, a rectifying amount is greatly reduced. as the alcoholic content of the foreshot is higher, enrichment and separation of the fusel oil are facilitated, and a rectifying reflux ratio can bereduced. Comprehensive results are that steam and electricity consumption is saved, a residue removing efficiency is improved, and easiness in production application is achieved.

Owner:广东省九江酒厂有限公司 +1

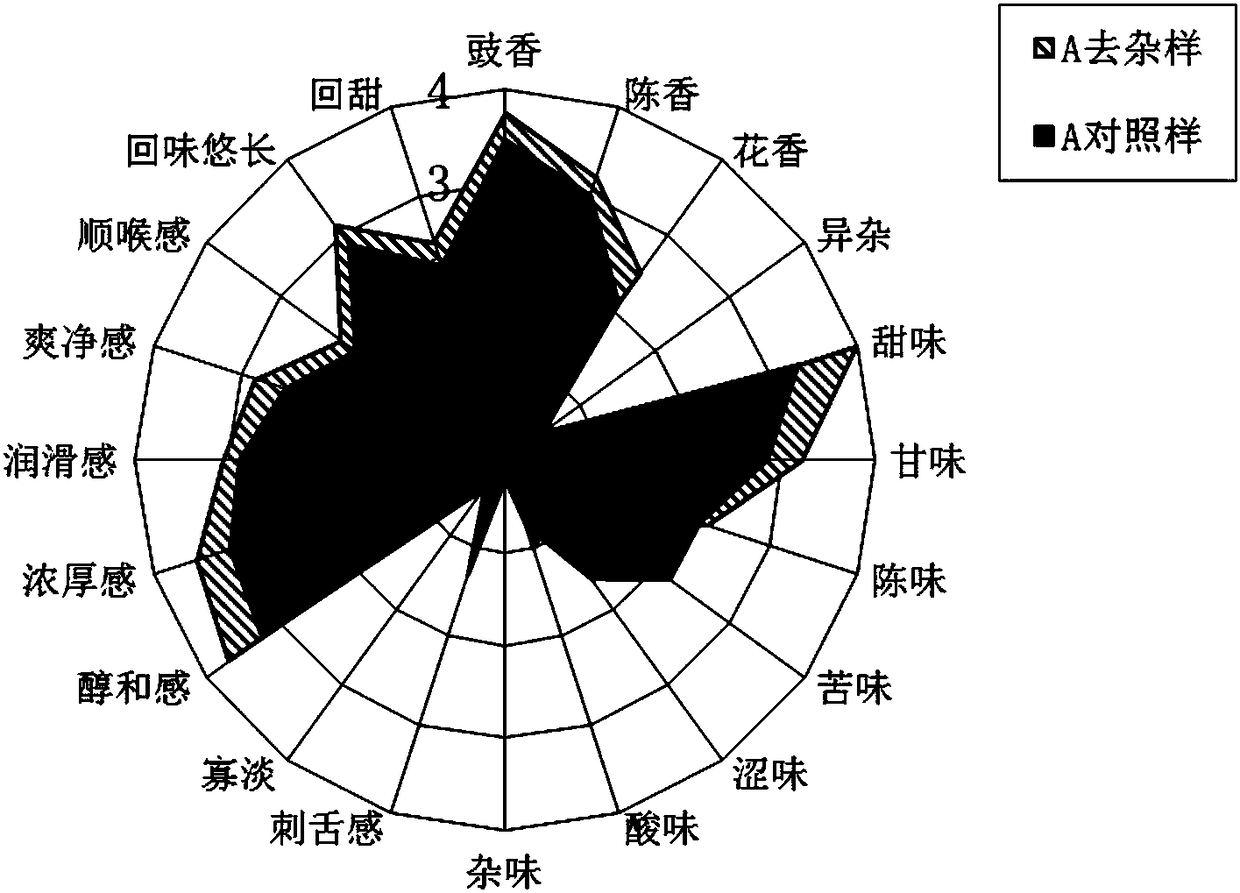

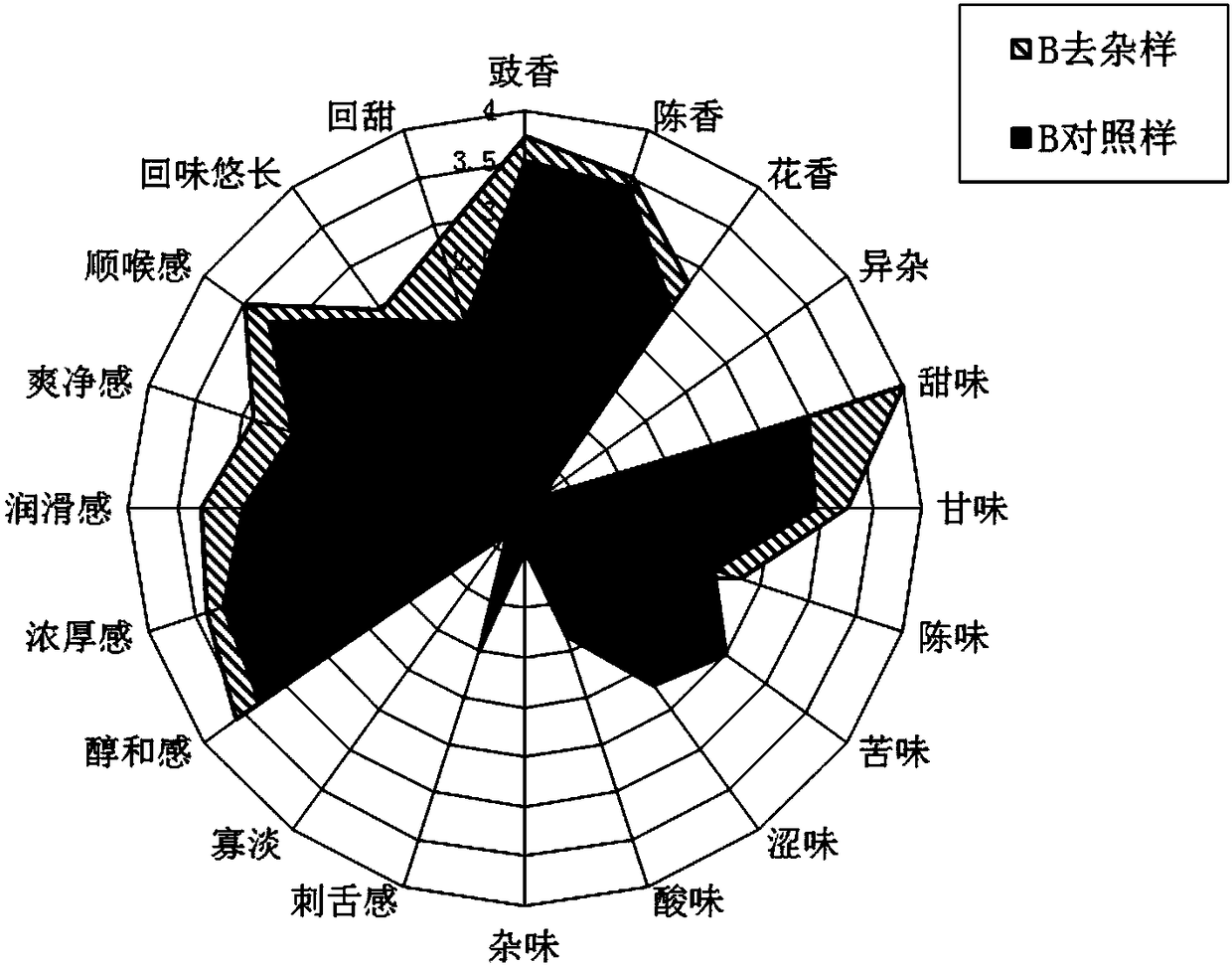

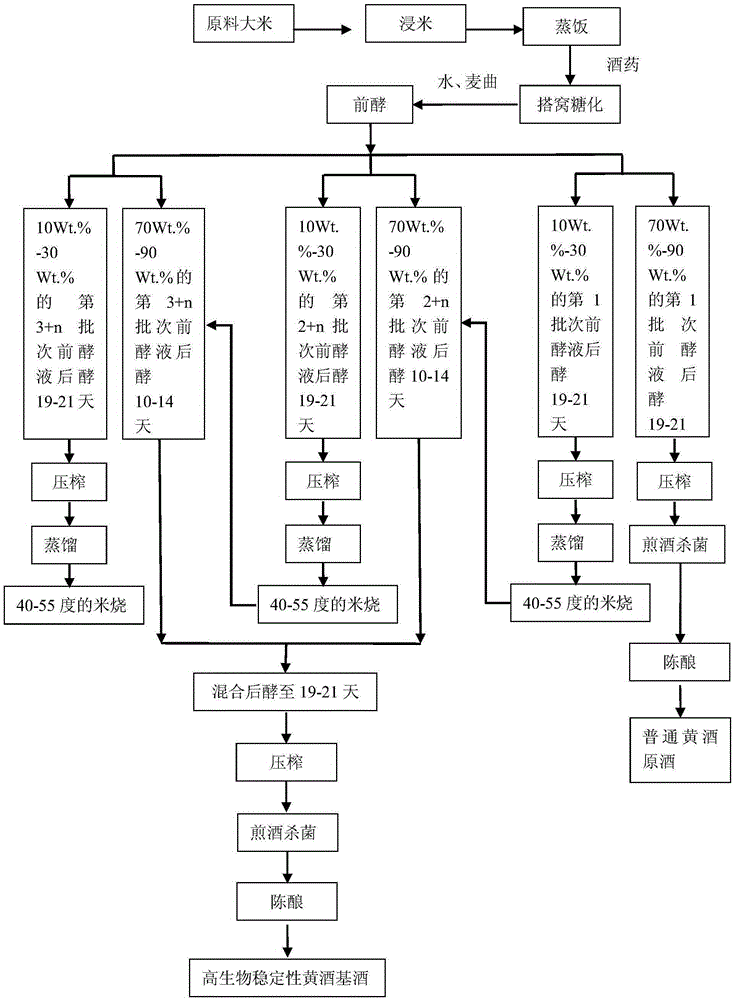

Brewing method for high-biostability yellow rice wine base wine

ActiveCN105420026ASatisfy productionImprove site utilizationAlcoholic beverage preparationYeastLactobacillus

The invention discloses a brewing method for high-biostability yellow rice wine base wine. The brewing process is as follows: the raw material rice is soaked in water for 24-48h, then is cleaned and steamed; after the rice is steamed, Chinese yeasts are added with stirring, nesting saccharification is carried out, front fermentation is carried out for 6-8 days, then rear fermentation is carried out 10-14 days, rice liquor with an alcohol degree of 40-55 degrees is added in the rear fermenting solution after rear fermentation for 10-14 days, the mixture is mixed uniformly, and then the mixture is subjected to rear fermentation until 19-20 days; squeezing, wine decocting sterilization and ageing are carried out, and high-biostability yellow rice wine base wine is prepared. The brewing method is a brewing method for high-biostability yellow rice wine, saves labor and material resources, saves the brewing space, raises the device usage efficiency, can inhibit growth and acid production of other bacterium indexes of lactic acid bacteria or the like effectively, facilitatesyellow rice wine alcoholization, and can meet large-scale industrial production requirements.

Owner:JIANGSU ZHANGJIAGANG BREWING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com