Brewing method of medlar grape dry red wine

A technology of raisins and wolfberry, which is applied in the brewing of wolfberry raisin red wine and wolfberry raisin red wine, can solve the problems of unreachable sugar content and the taste of ice wine, and achieve mellow and elegant taste, high nutritional and health value, and strong aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A brewing method of wolfberry raisin red wine, comprising the steps of:

[0025] (1) 48kg of raisins and 12kg of wolfberry are mixed uniformly to obtain raw materials;

[0026] (2) Add 90kg of water to the raw material prepared in step (1), mix evenly to obtain a mixed solution, then add 9000mg of food-grade H 2 SO 3 (purchased from Tianjin Chemical Reagent Co., Ltd.), let it stand for 12 hours, complete the rehydration of the raw materials, and then add 45g of yeast in an amount of 0.3g / L (the yeast needs to be activated with warm water for 20min, and the amount of water used for activation is 10 times the mass of the yeast. water temperature 35-40°C), ferment for 120h under the condition of 20°C, and stop when there are no more bubbles in the fermentation liquid to obtain the fermentation feed liquid;

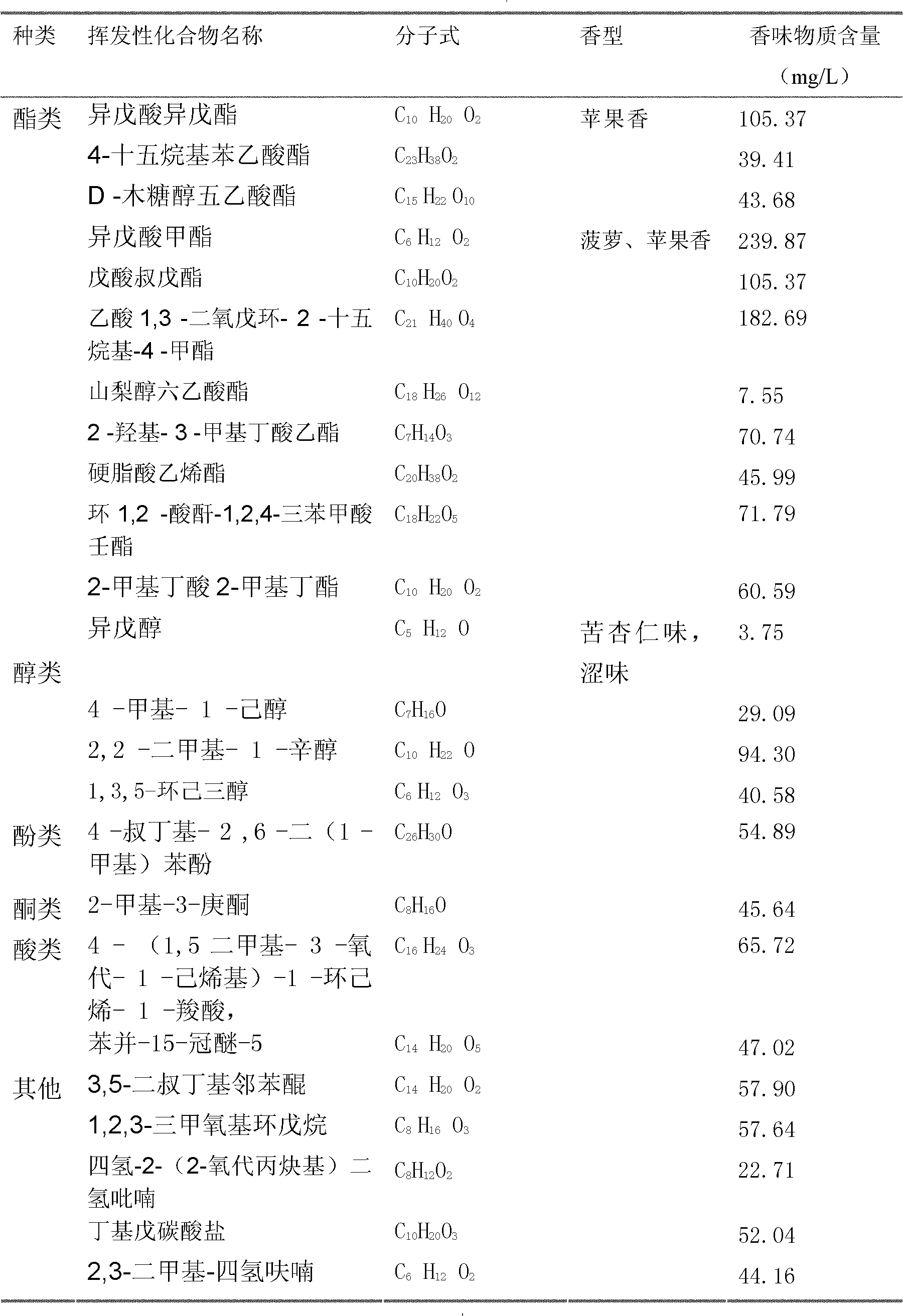

[0027] (3) transfer the fermented feed liquid obtained in step (2) into a squeezer and pass through an 80-mesh sieve to squeeze and separate, and get the precipitate...

Embodiment 2

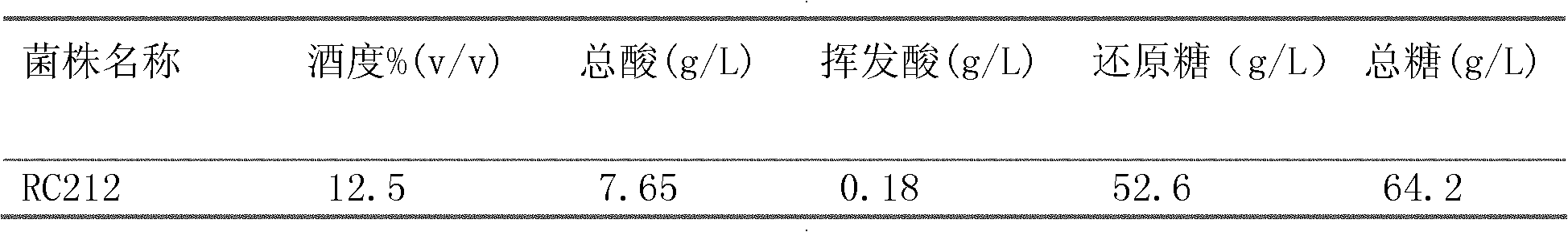

[0033] The brewing method of Lycium barbarum raisin red wine as described in Example 1, the difference is that after the raw material is rehydrated for 12 hours, the pasteurization method is used instead of adding food-grade H 2 SO 3 Sterilization, the sterilization temperature is 78°C, the time is 0.5h, cooling, see Example 1 for other operations. The physical and chemical indicators of the obtained wine sample are as follows:

[0034]

[0035] Through analysis above-mentioned embodiment 1-2 can know, in embodiment 2, the step of pasteurization after raw material rehydration has been increased on the process of Lycium barbarum raisin red wine, has saved SO 2 Sterilize. This somewhat avoids SO 2 Unpleasant smell and side effects on the body. The above differences lead to refreshing taste, pure aroma, and decreased bitterness and sourness. The fermentation process needs to be strictly aseptic to prevent browning and bacterial contamination.

Embodiment 3

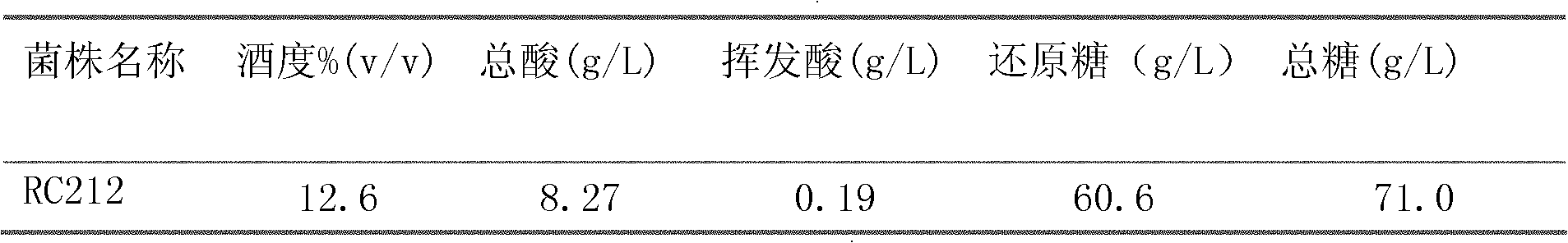

[0037] The brewing method of wolfberry raisin red wine as described in Example 1, the difference is that 48kg of raisins and 12kg of wolfberry are mixed evenly, and the amount of water added in the raw material is 120kg. The physical and chemical indicators of the obtained wine sample are as follows:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com