Method for preparing microcapsules based on low-ester pectin and calcium ion gelatinization and application of microcapsules

A low-ester pectin, calcium ion technology, applied in the field of microcapsule preparation, can solve problems such as unfavorable production cost, influence, and the particle size of gel particles is difficult to reach micron level, etc., and achieves the effect of high-efficiency application effect and high-quality application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

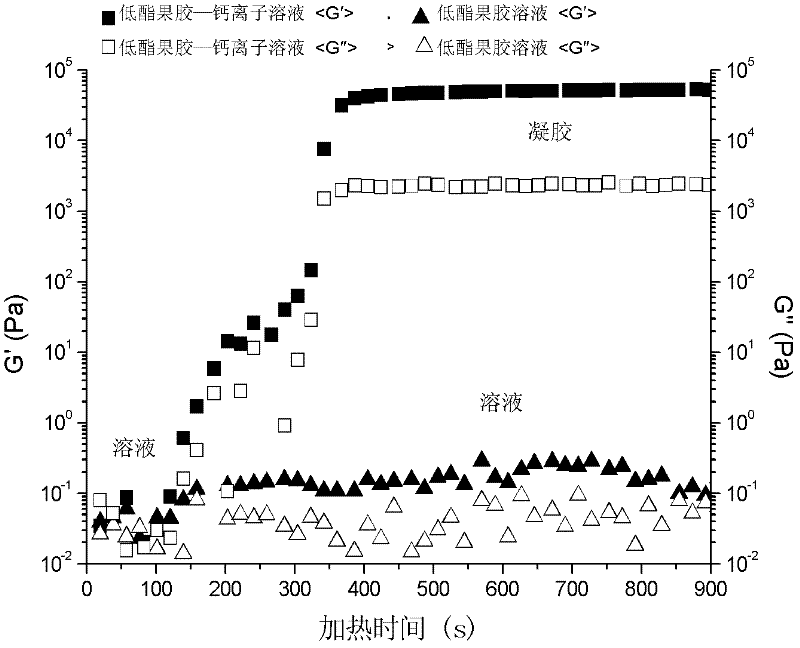

Method used

Image

Examples

Embodiment 1

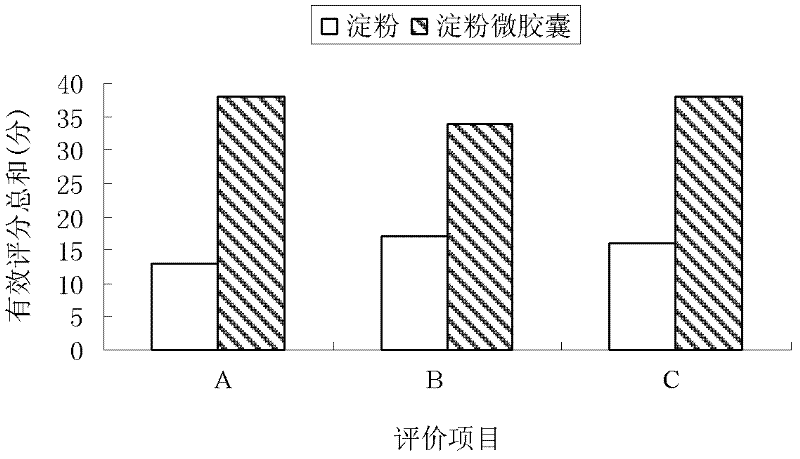

[0017] Starch microcapsule products: prepare low-ester pectin solution and CaCl 10% and 0.07% respectively by mass 2 Solution 250mL and 750mL, in CaCl 2 Add 100g cornstarch to the solution and stir evenly to form CaCl 2 - Starch suspension, then CaCl while stirring the low-ester pectin solution 2 - Slowly add the starch suspension and continue to stir until a low-ester pectin-calcium ion-starch mixture with good fluidity is formed, and the mixture can be spray-dried to obtain starch microcapsules with a good masking effect on the raw taste of starch Product (as the sensory evaluation standard and result of milk additive application are shown in table 1 and figure 2 shown).

[0018] Table 1 Sensory evaluation criteria for the application of starch microcapsule products as milk additives

[0019]

Embodiment 2

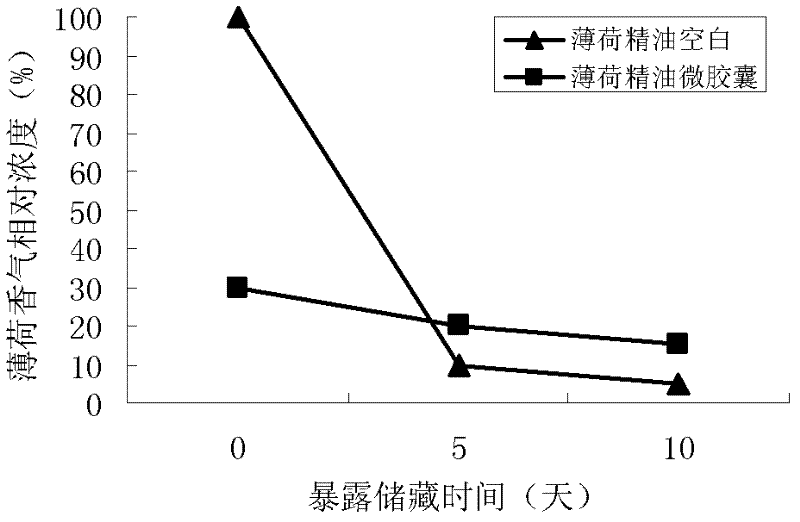

[0021] Peppermint essential oil microcapsule product: prepare low-ester pectin solution and CaCl 2 Solution 100mL and 300mL, while stirring the low-ester pectin solution, CaCl 2 Slowly add the solution and continue to stir to form a low-ester pectin-calcium ion solution, then add 40 mL of modified starch-peppermint essential oil emulsion to the solution and continue to stir until a mixed solution with good fluidity is formed, and the mixed solution is spray-dried The peppermint essential oil microcapsule product which has a good slow-release effect on the mint aroma can be obtained. Such as image 3 As shown, the relative concentration of peppermint aroma of the microcapsule product after storage for 10 days decreased from 30% to 15%, while the relative concentration of peppermint aroma of the equal amount of peppermint essential oil blank sample decreased from 100% to 5%.

Embodiment 3

[0023] Conjugated linoleic acid microcapsule products: prepare low-ester pectin solution and CaCl with 4% and 0.04% mass percentage respectively 2 Solution 50mL and 150mL, add 20mL of modified starch-conjugated linoleic acid emulsion to the low-ester pectin solution and stir evenly, then stir the low-ester pectin solution containing conjugated linoleic acid while adding CaCl 2 The solution is slowly added therein and continuously stirred until a mixed solution with good fluidity is formed, and the mixed solution is spray-dried to obtain a conjugated linoleic acid microcapsule product with better anti-acidolysis effect. Such as Figure 4 As shown, the conjugated linoleic acid release rate of the microcapsule product was 8% after being digested under simulated gastric digestion conditions for 4 hours, while the microcapsule control sample without low-ester pectin / calcium ions had no effect on conjugated linoleic acid The release rate is as high as 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com