Patents

Literature

332results about How to "Realize a high degree of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for processing high-definition remote sensing image data

InactiveCN101604018AImplement photogrammetry processingAchieve production tasksWave based measurement systemsArea networkData treatment

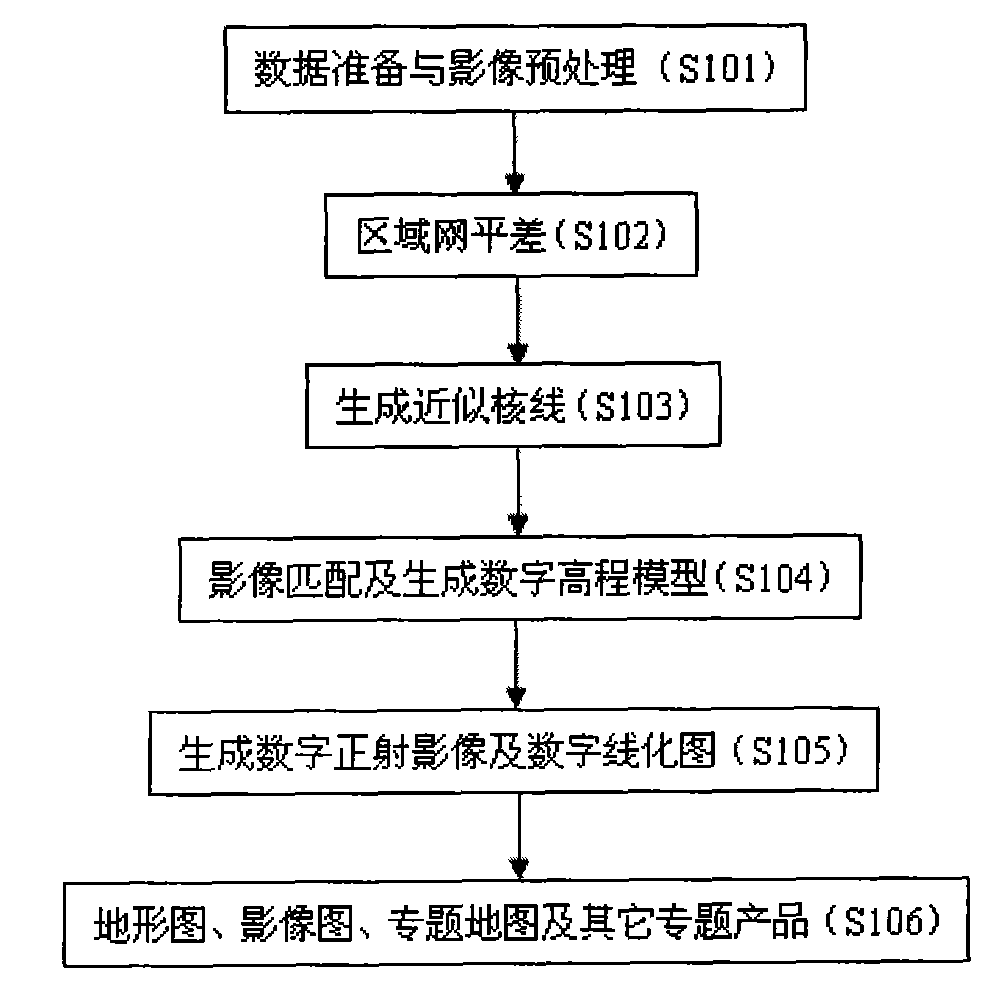

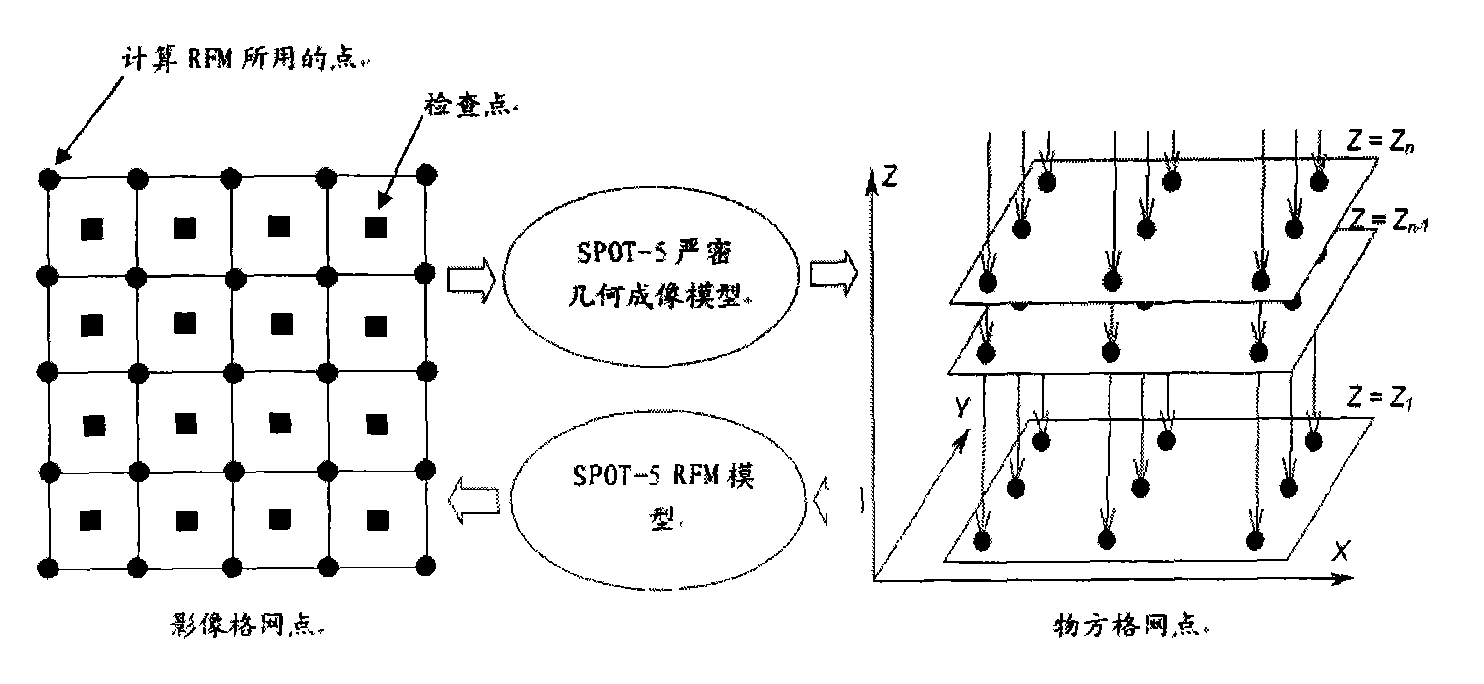

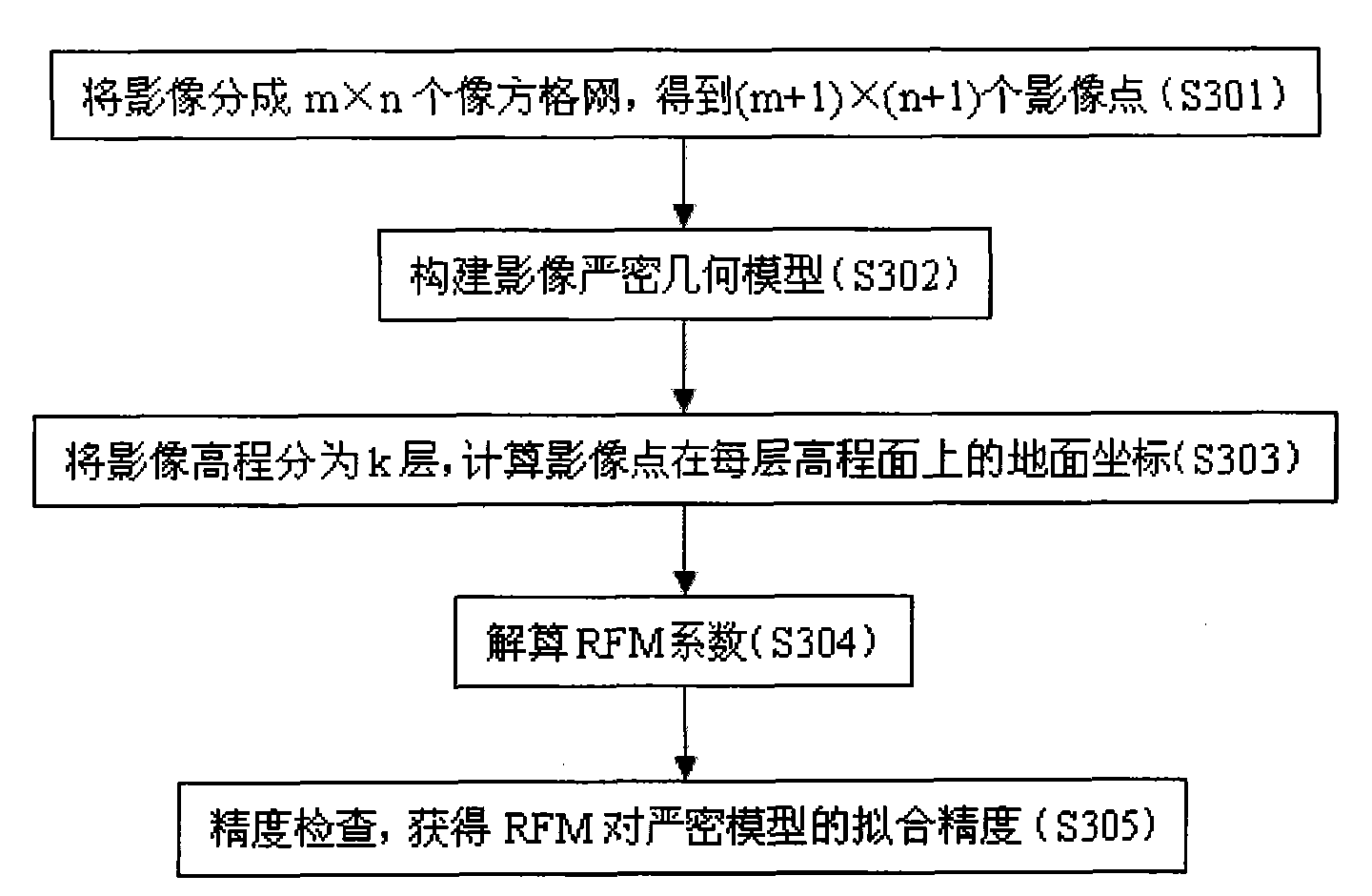

The invention provides a method and a system for processing high-definition remote sensing image data by applying a rational function model, a satellite image block adjustment and auto-match and distributed parallel processing technology. The method comprises the following steps: analyzing and processing input primary image data and computing parameters of the corresponding rational function model so as to obtain a stereo image pair by applying the computed rational function model; performing measurement and singlechip orientation of a control point and a connecting point on the primary image data, and performing block adjustment processing on an error between stereo image pixel data and the primary image data so as to improve the fit precision between the stereo image pixel data and the primary image data; generating an image similar to an epipolar ray, defining a matching template, measuring matched seed points and lines, performing automatic image matching and generating a digital elevation model; and respectively generating a digital orthophoto map and a digital line graph, and finishing manufacturing a product by applying the obtained data.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

Polymer-matrix electric conduction gradient function material and preparation method thereof

The invention discloses a polymer-matrix electric conduction gradient function material and a preparation method thereof. The content of electric conduction filler in the prepared polymer-matrix electric conduction gradient function material shows continuous gradient change along the thickness direction of the material from low to high, and the performance also changes correspondingly. The preparation of the material mainly uses rheology principle to realize the gradient of distribution of material components by controlling and influencing thermodynamic factor and dynamic factor in the deposition process.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

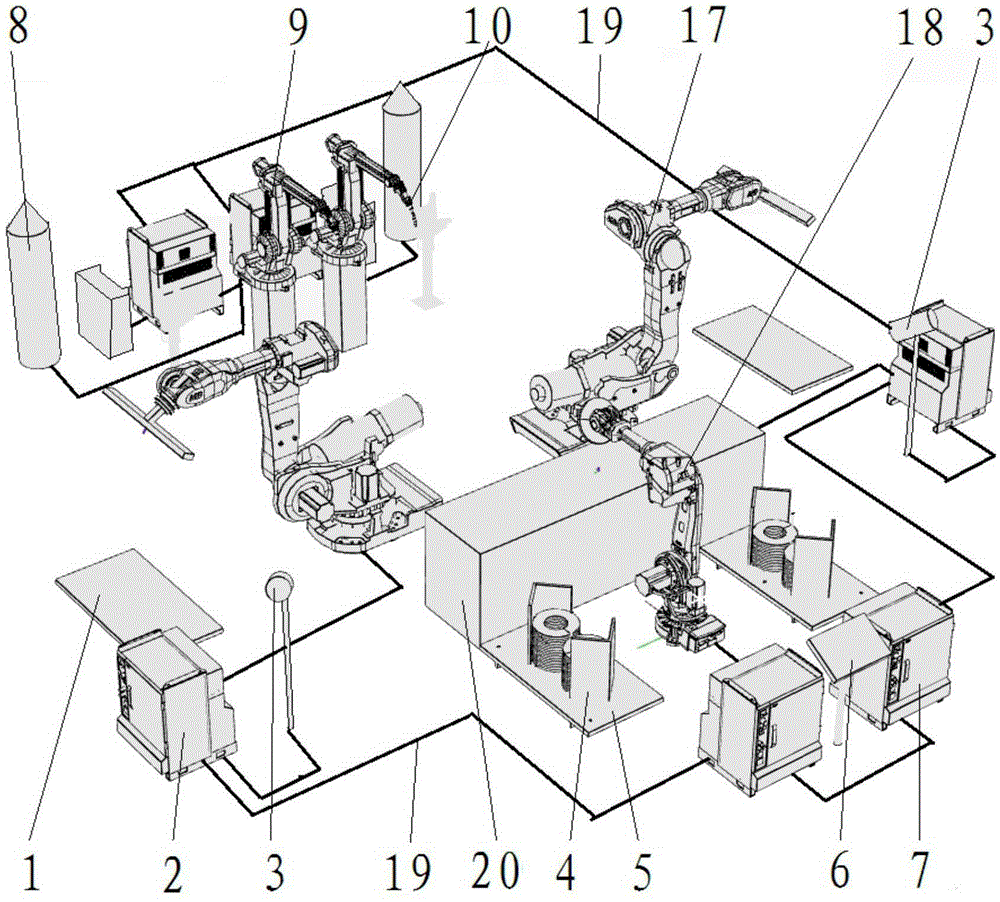

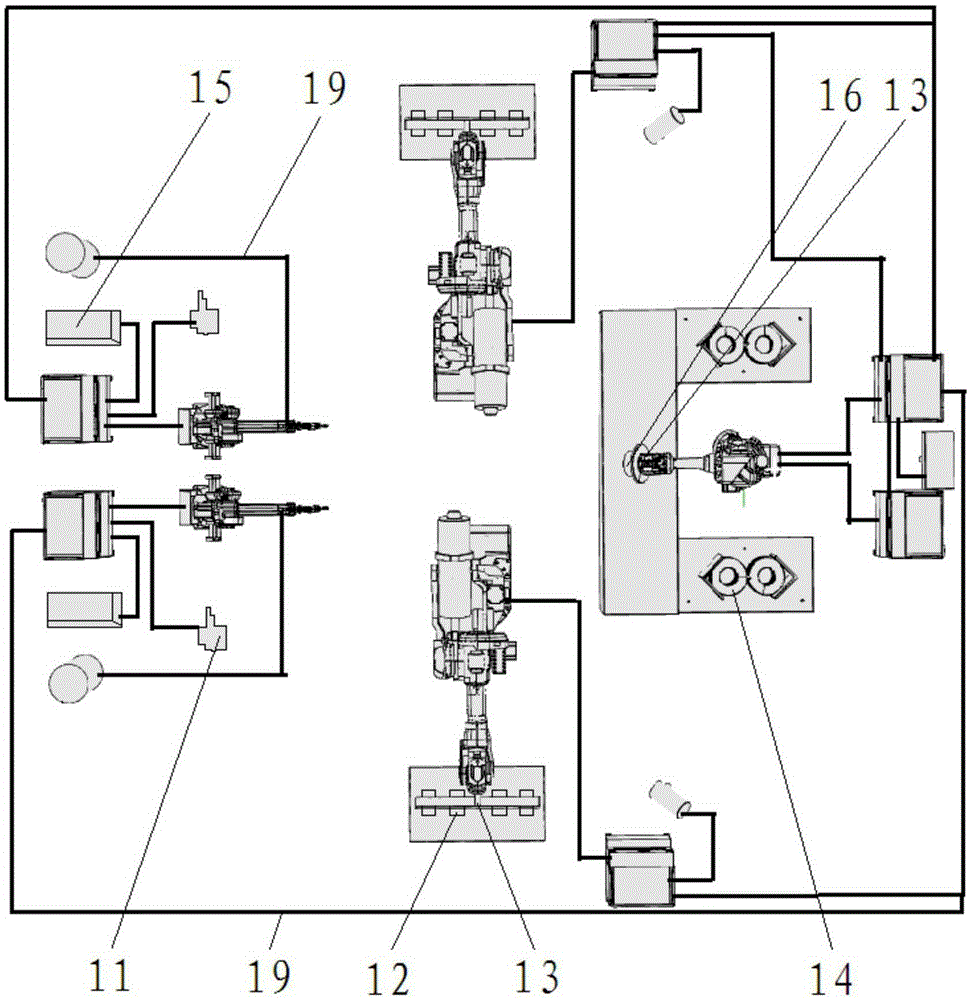

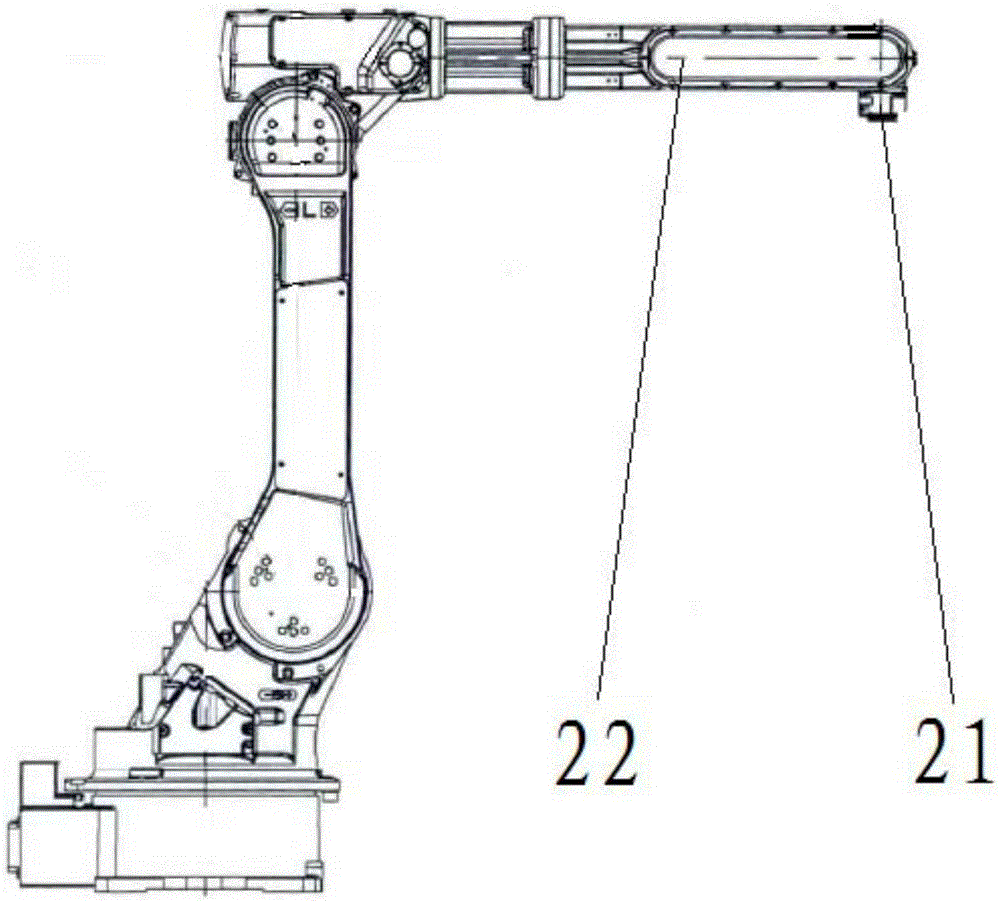

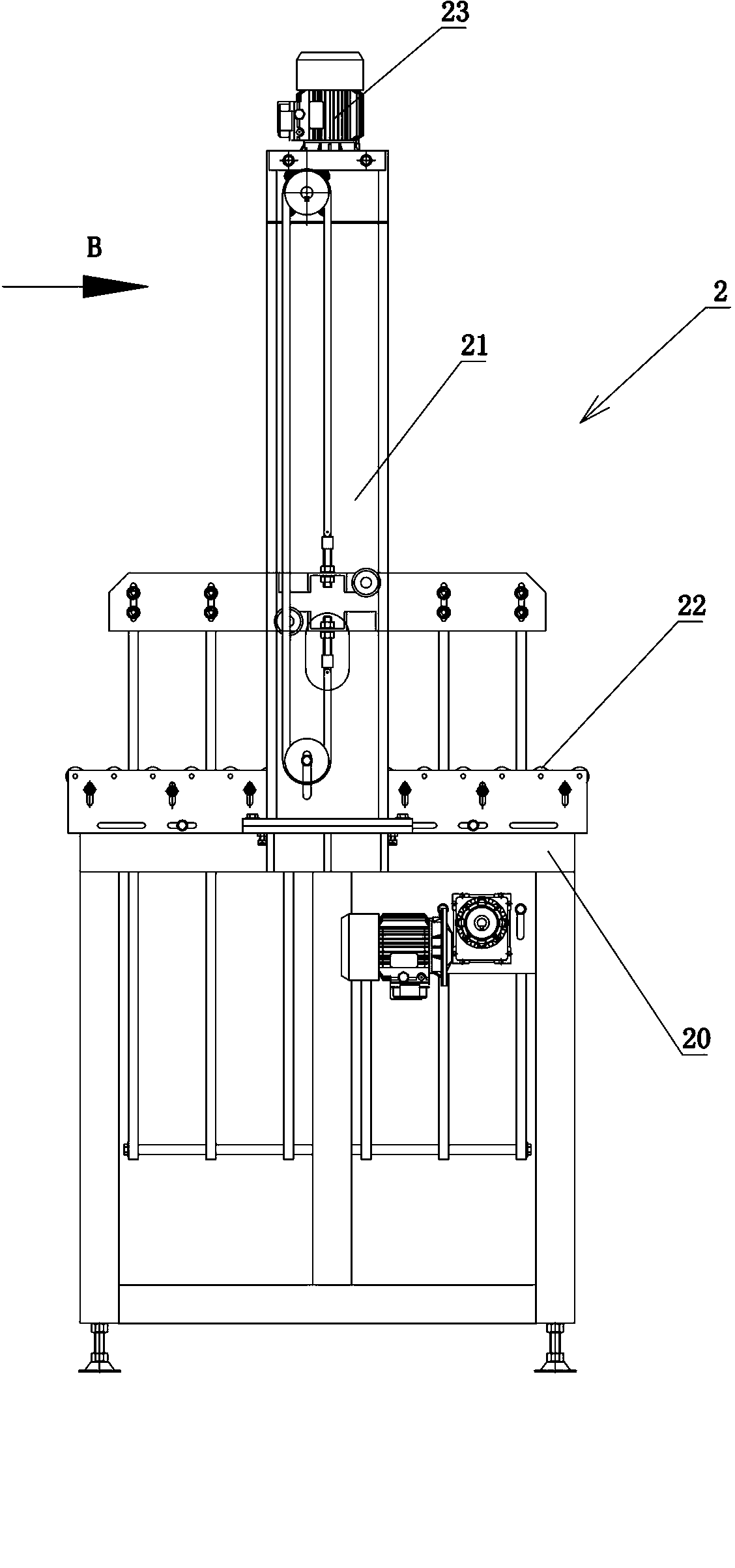

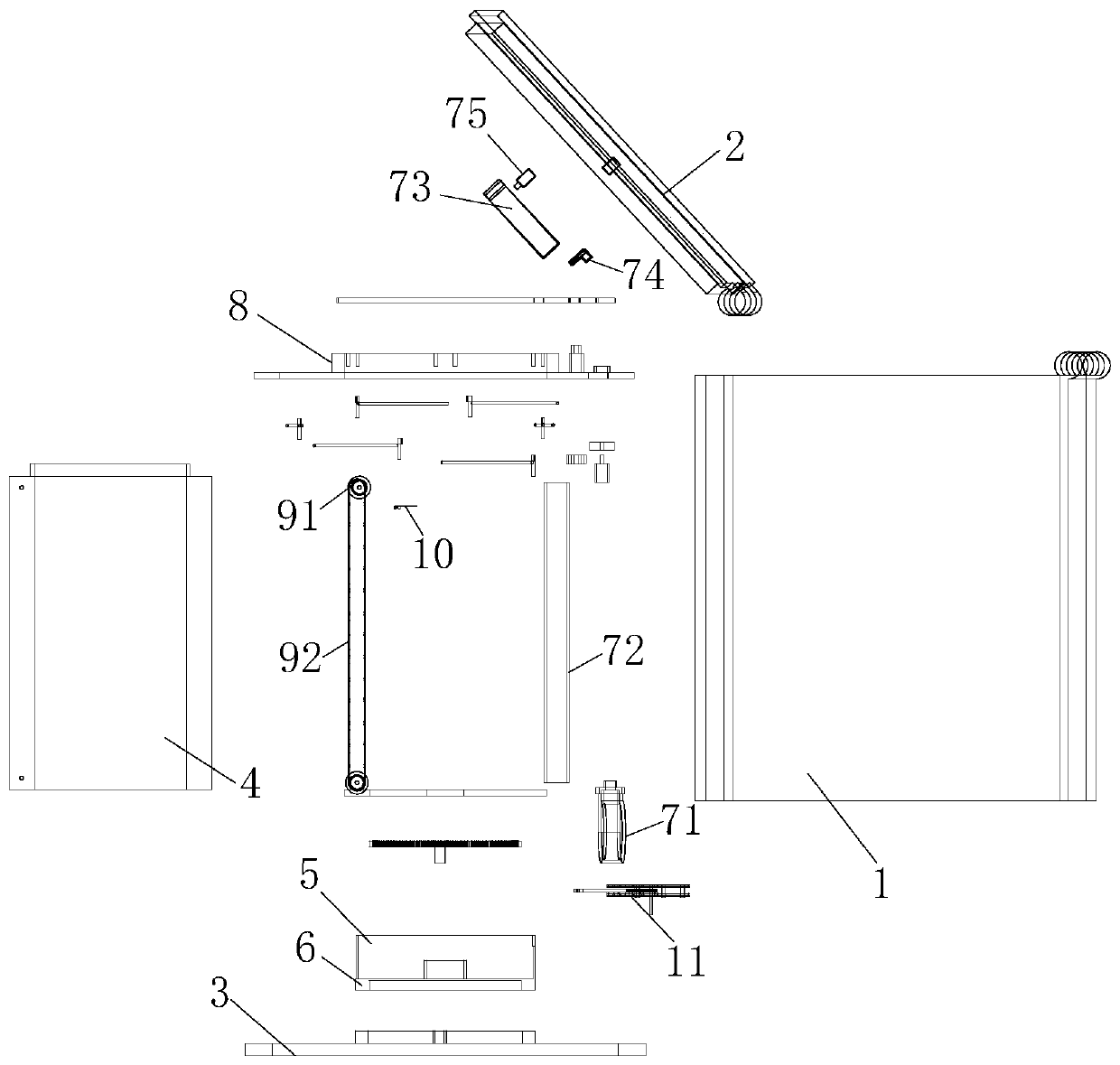

Multi-station robot intelligent welding system for pipe piling sheets

InactiveCN105397244ARealize the intelligentization of automatic identification of weld seam informationRealize intelligenceManipulatorWelding accessoriesRobotic systemsHuman–machine interface

The invention discloses a multi-station robot intelligent welding system for pipe piling sheets. The multi-station robot intelligent welding system comprises a control system, a clamp system, a machine vision system, a robot system, a welding system and a safety protection system, wherein the control system comprises a robot control cabinet, a PLC control cabinet, a machine vision system and a man-machine interface; the robot system comprises two supplying robots, two welding robots and a feeding robot; the two supplying robots are placed in a back-to-back manner; the two welding robots are placed at front middle positions of the two supplying robots side by side; the PLC control cabinet is in communication with the robot control cabinet; the robot control cabinet controls movement of a robot body; the welding system is connected with a welding robot control cabinet; and a welding robot body controls a welding gun to finish welding. By the multi-station robot intelligent welding system, positions and widths of welded joints can be recognized accurately, and information of the welded joints is recognized automatically; and the feeding robot feeds materials automatically, the labor intensity is reduced, and high automation of a whole process of feeding, supplying and welding is realized.

Owner:DALIAN UNIV OF TECH

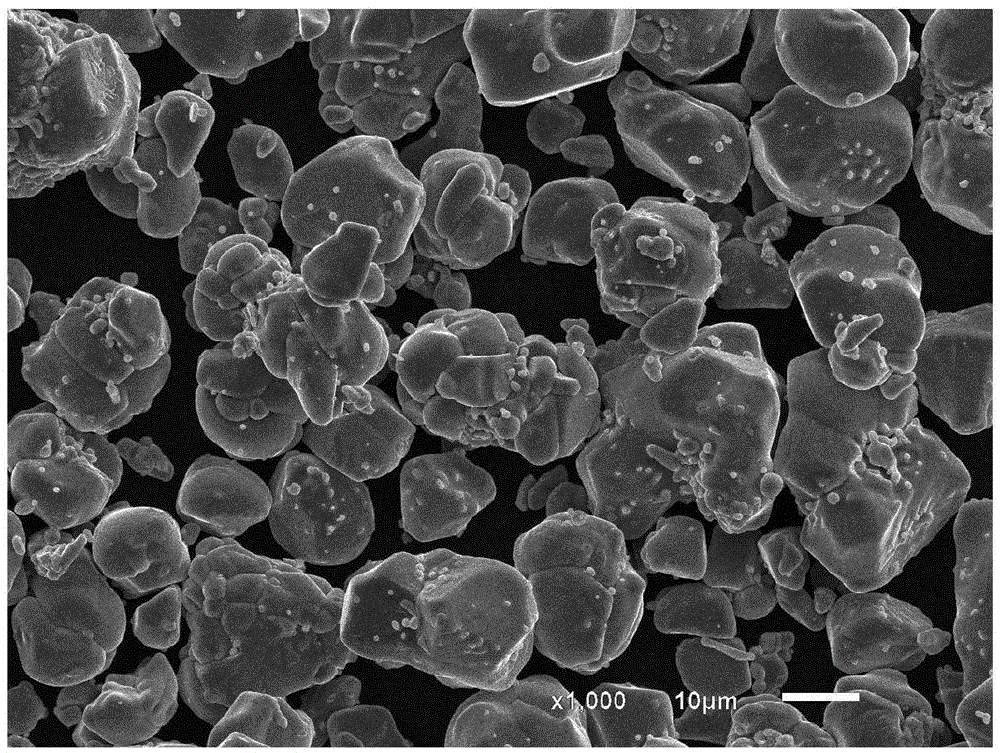

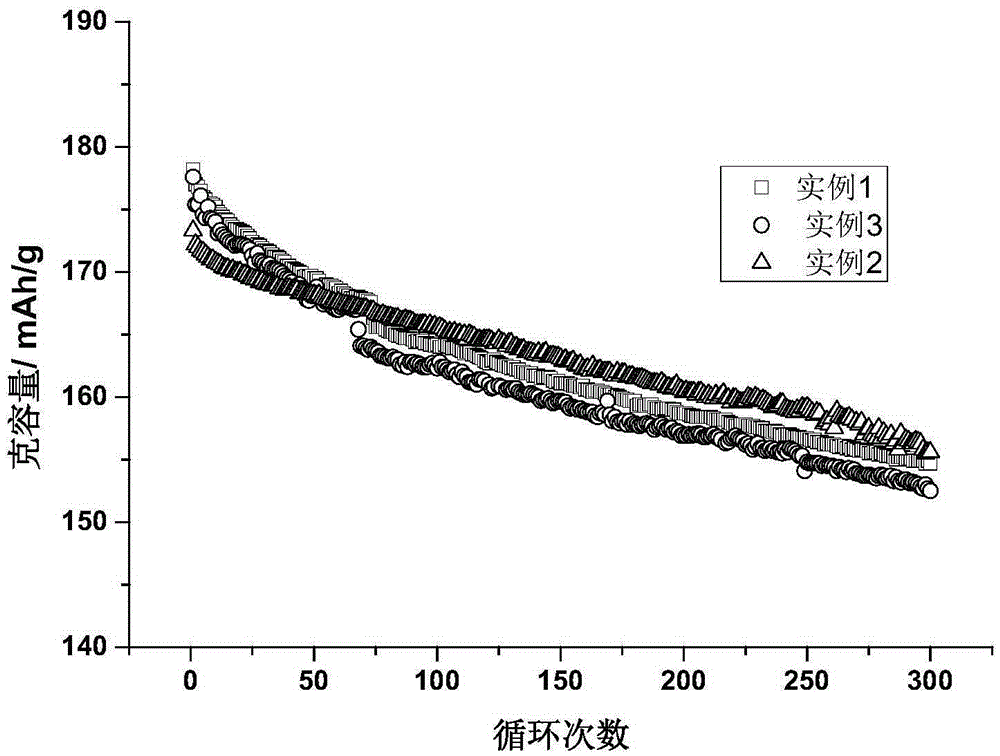

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

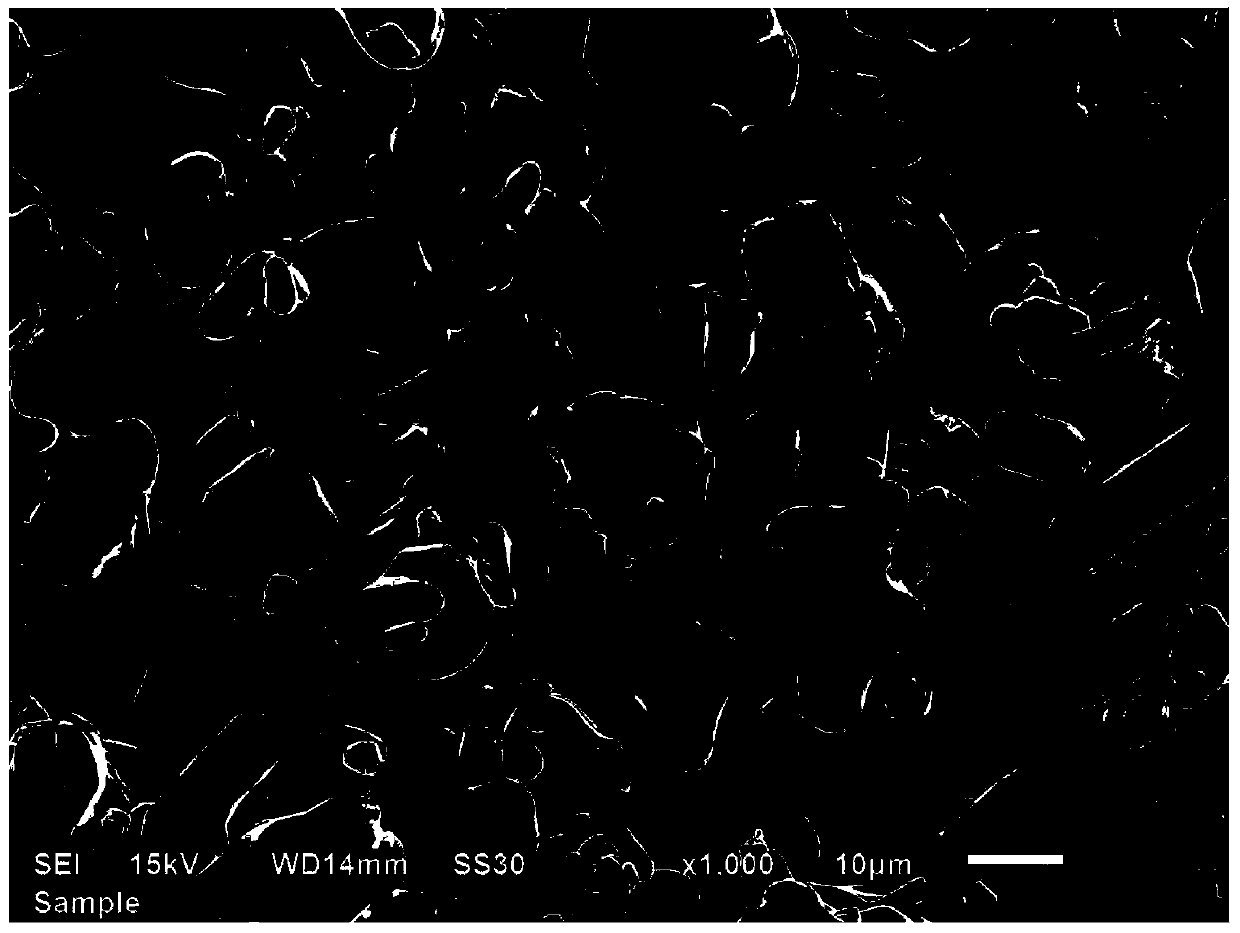

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

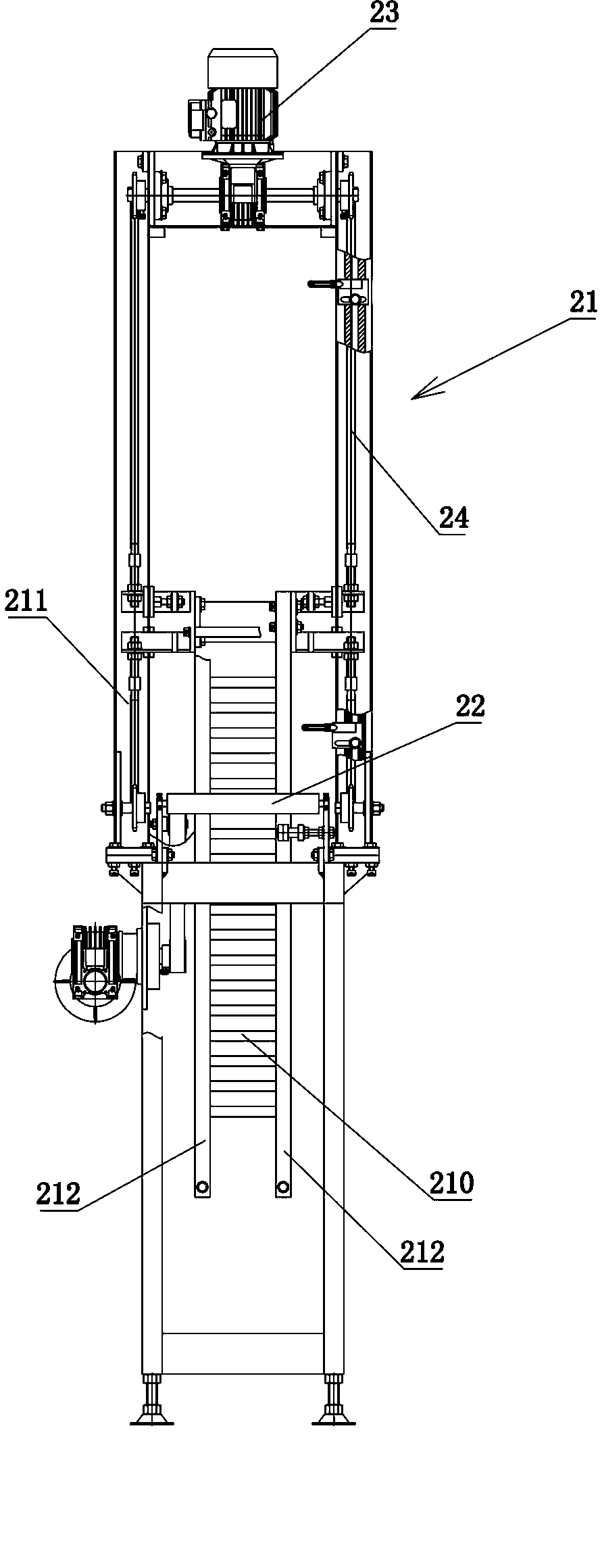

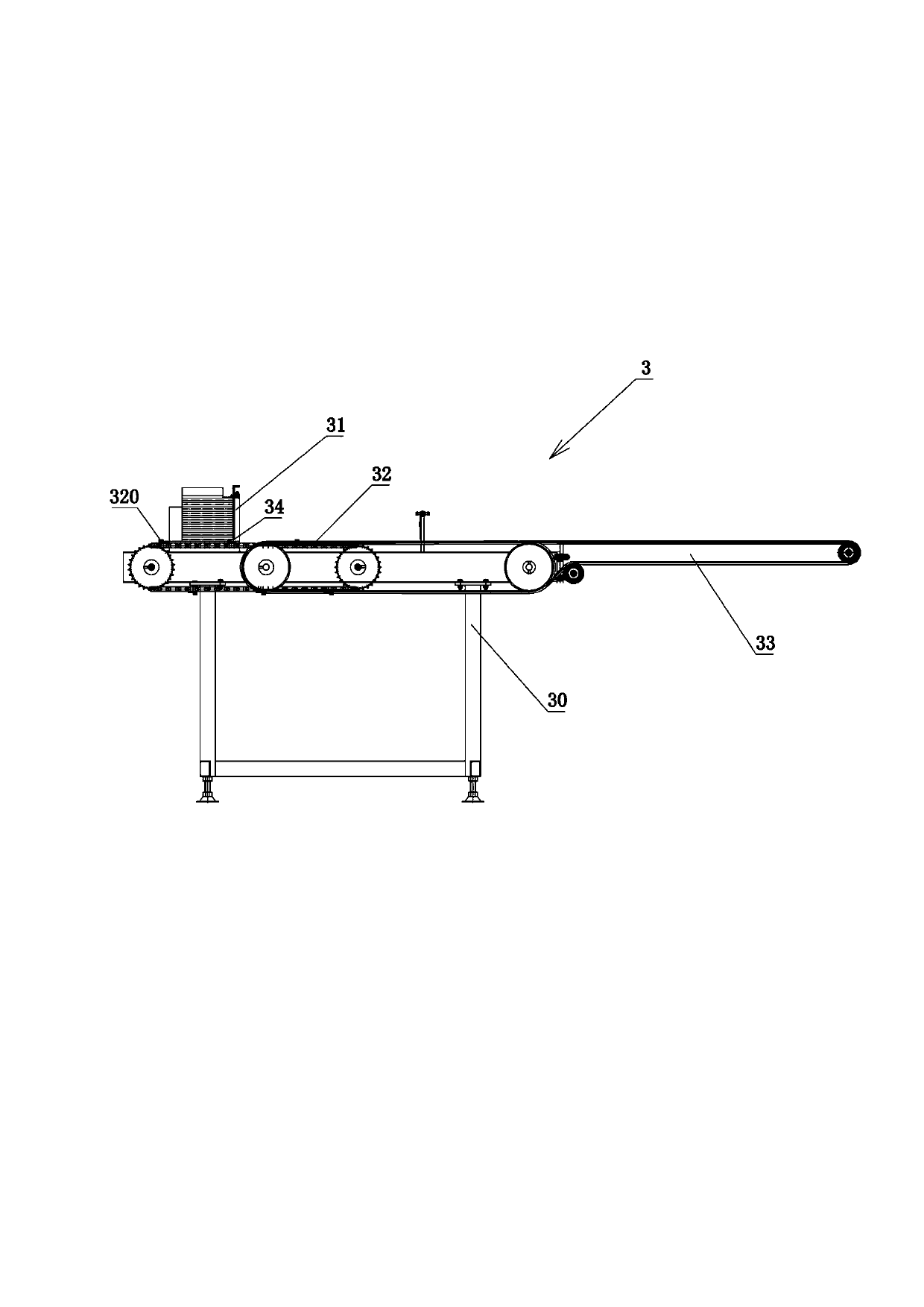

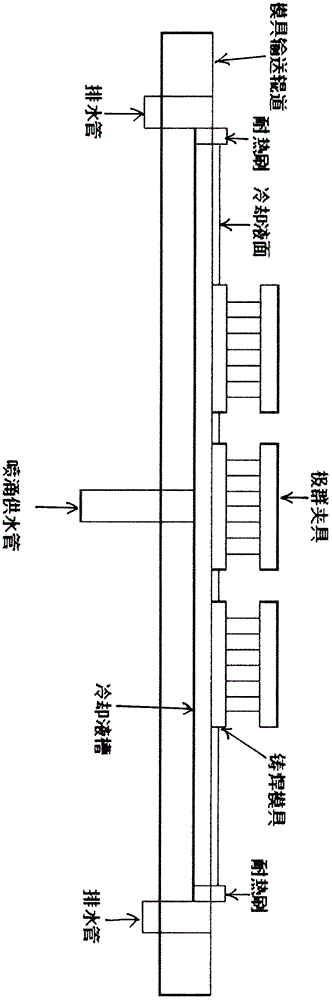

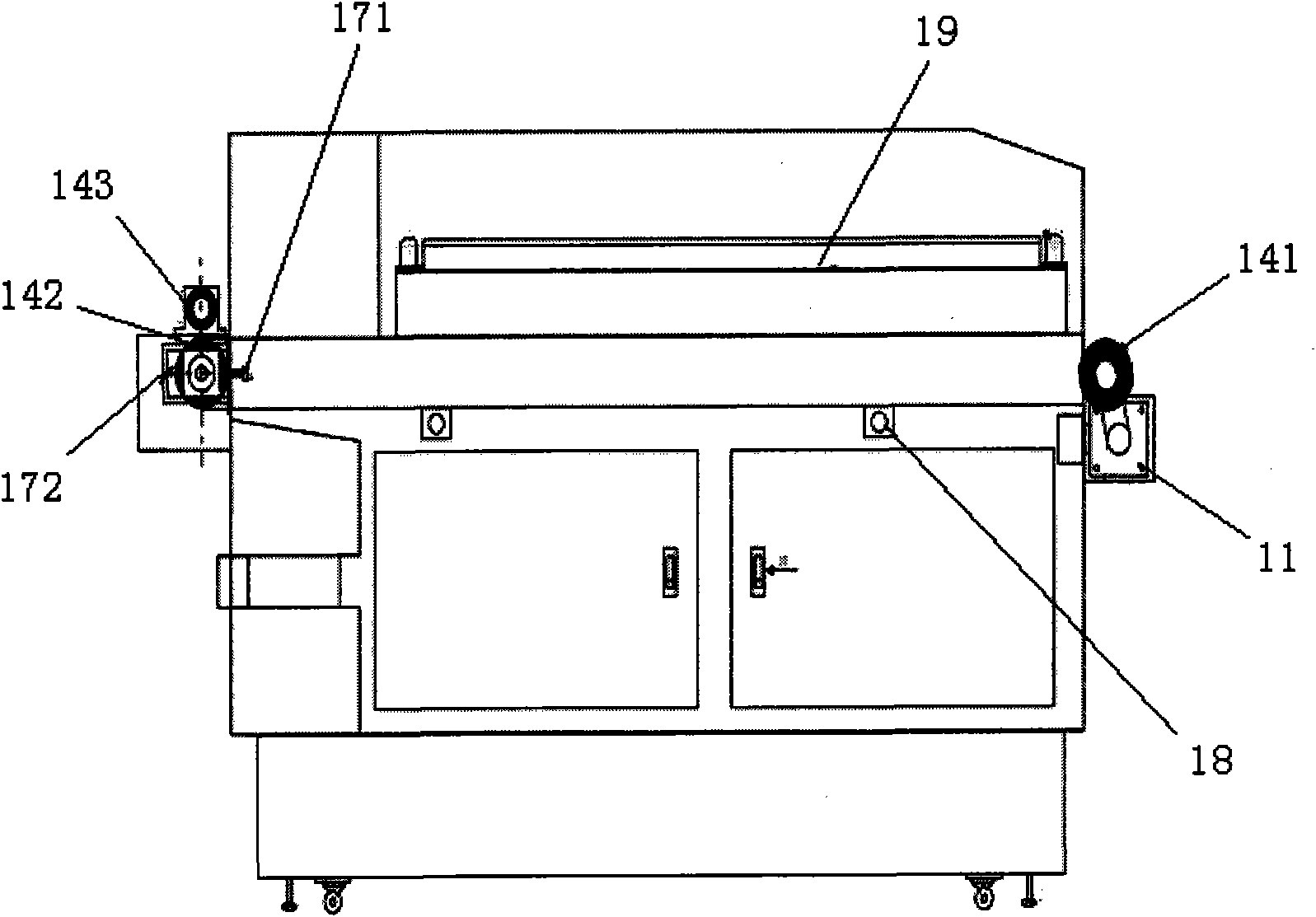

Novel full-automatic middle-small-size tile packaging production line

InactiveCN102730220ASimple structureHigh degree of automationPackaging automatic controlShock-sensitive articlesProduction lineBrick

A novel full-automatic middle-small-size tile packaging production line comprises an initial conveyor platform, a blank storage machine, a tile arranging machine, a tile laminating machine, a box opening, bottom folding and box overturning machine, a bottom and cover sealing machine and a stacker through which the tile passes in sequence, wherein the initial conveyor platform, the blank storage machine, the brick arranging machine, the brick laminating machine, the box opening, bottom folding and box overturning machine, the bottom and cover sealing machine and the stacker are all connected with a terminal control system. Through the initial conveyor platform, the blank storage machine, the brick arranging machine, the brick laminating machine, the box opening, bottom folding and box overturning machine, the bottom and cover sealing machine, the stacker and the like, the packaging production line can realize actions such as ceramic brick conveying, temporary storage, arranging, laminating, boxing, overturning, automatic box sealing and packaging and automatic stacking and delivery. The production line is complete in structure, high in automation degree, low in fault rate, simple and convenient to operate, convenient to maintain, low in manufacturing cost and cheap in price, suitable for packaging of middle-small-size tiles, high in practicability, and efficient and fast, and facilitates wide popularization and use.

Owner:FUJIAN KEJIE ELECTROMECHANICAL

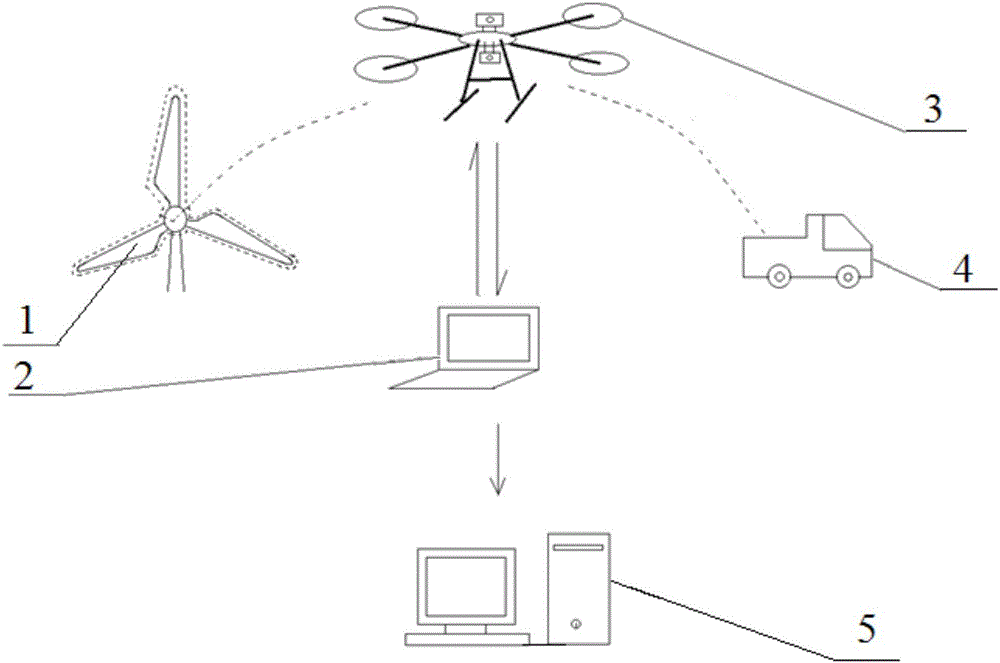

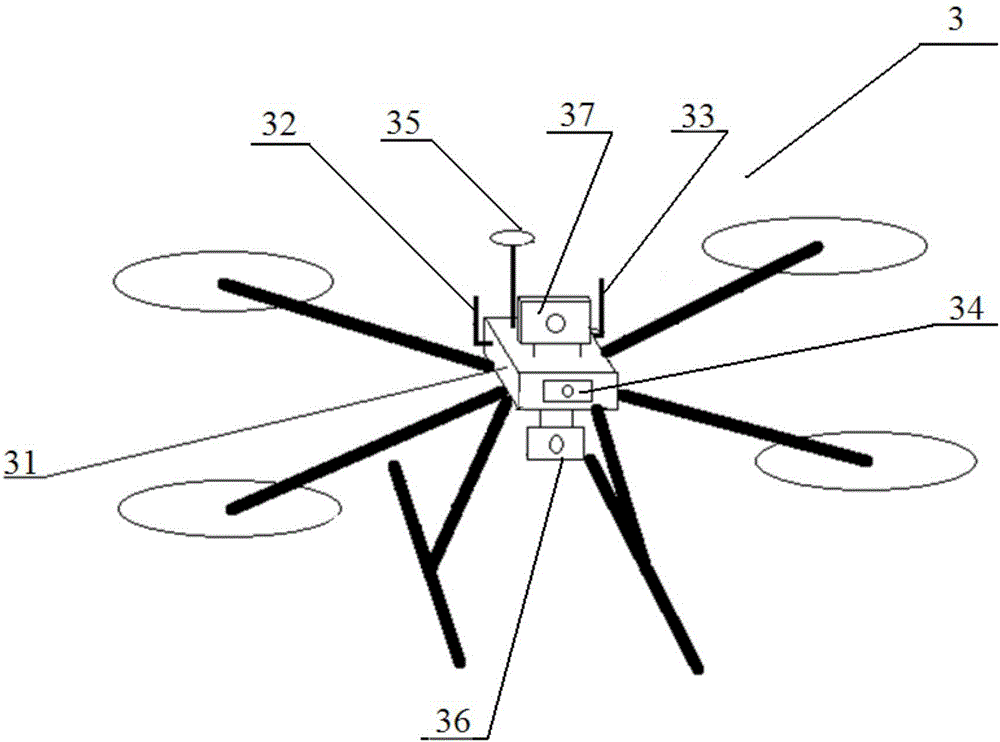

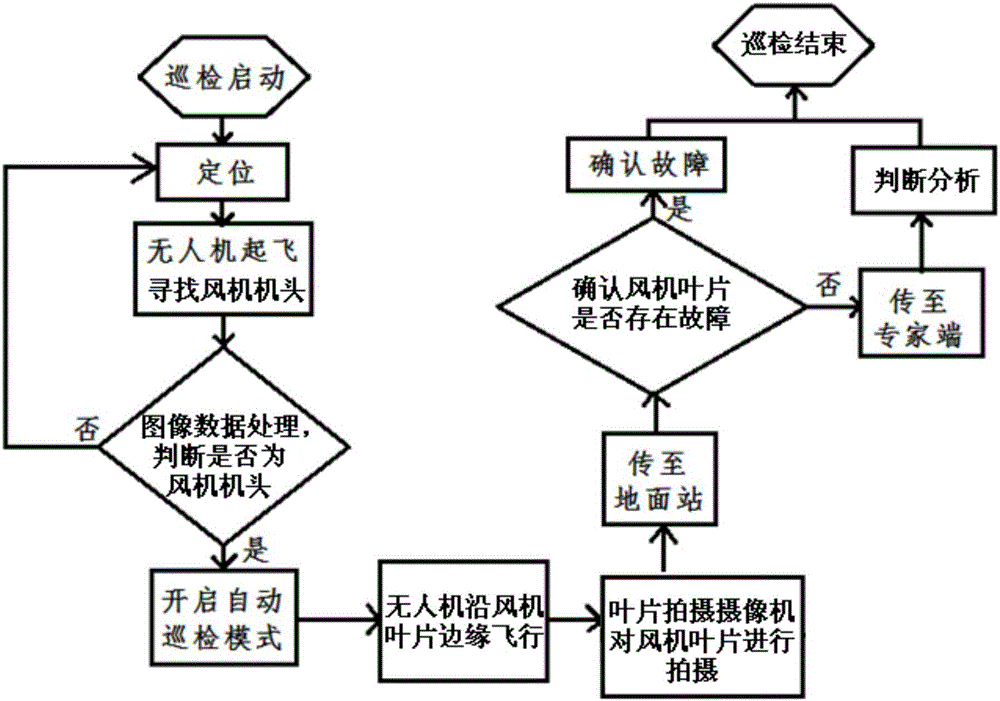

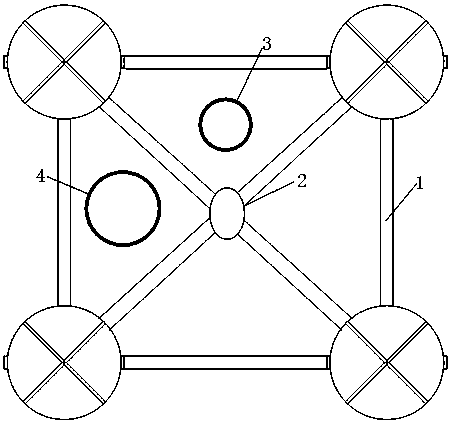

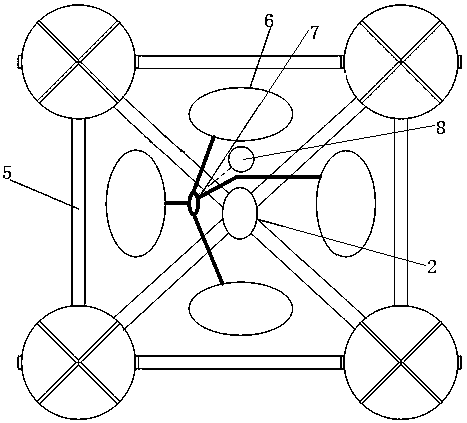

Autonomous unmanned aerial vehicle fan blade polling system and method

InactiveCN105717934AReliable diagnosisAvoid the influence of human factorsAttitude controlPosition/course control in three dimensionsPolling systemElectricity

The invention belongs to the technical field of wind power equipment detection and relates to an autonomous unmanned aerial vehicle fan blade polling system and method. The autonomous unmanned aerial vehicle fan blade polling system comprises an unmanned aerial vehicle used for carrying out automatic polling on fan blades, a polling vehicle used for stopping and placing the unmanned aerial vehicle, a ground station used for receiving and processing image data sent by the unmanned aerial vehicle to control the unmanned aerial vehicle and a specialist terminal used for judging and analyzing the image data of the ground station. The autonomous unmanned aerial vehicle fan blade polling method comprises the following steps: starting polling; positioning; finding a fan nose by the unmanned aerial vehicle after taking off; processing image data, and judging whether the fan nose is found or not; starting an automatic polling mode; shooting fan blades by the unmanned aerial vehicle flying along the edges of the fan blades, and transmitting blade image data to the ground station; determining whether the fan blades are in fault or not by a maintainer, transmitting the fan blades which can not be determined to the specialist terminal, and judging and analyzing by the specialist terminal; and finishing the polling. The autonomous unmanned aerial vehicle fan blade polling system and method have the advantages that on-the-spot control of the maintainer is not required, a vehicle collision accident can be avoided, manpower resource is saved and popularization and application are easy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

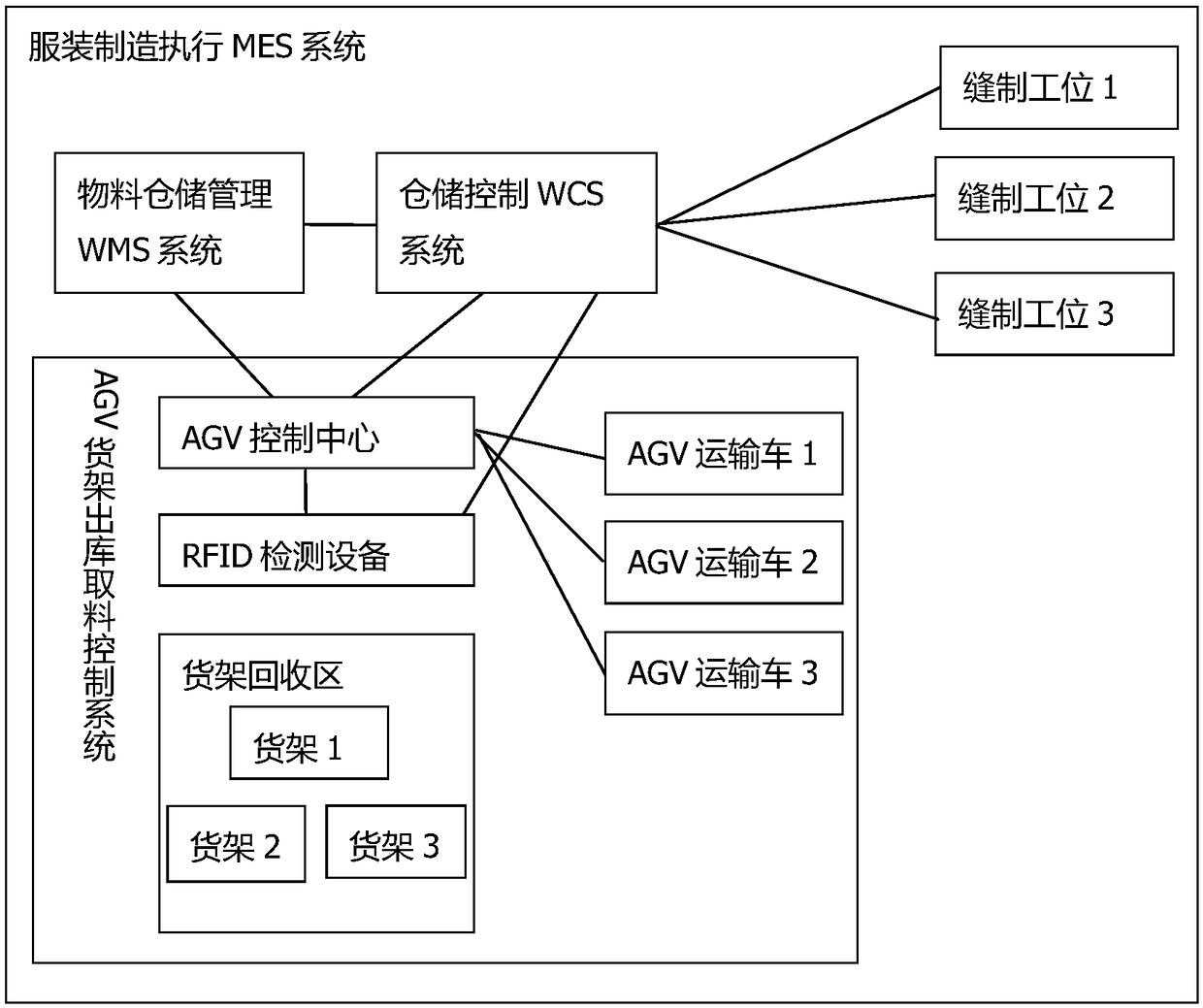

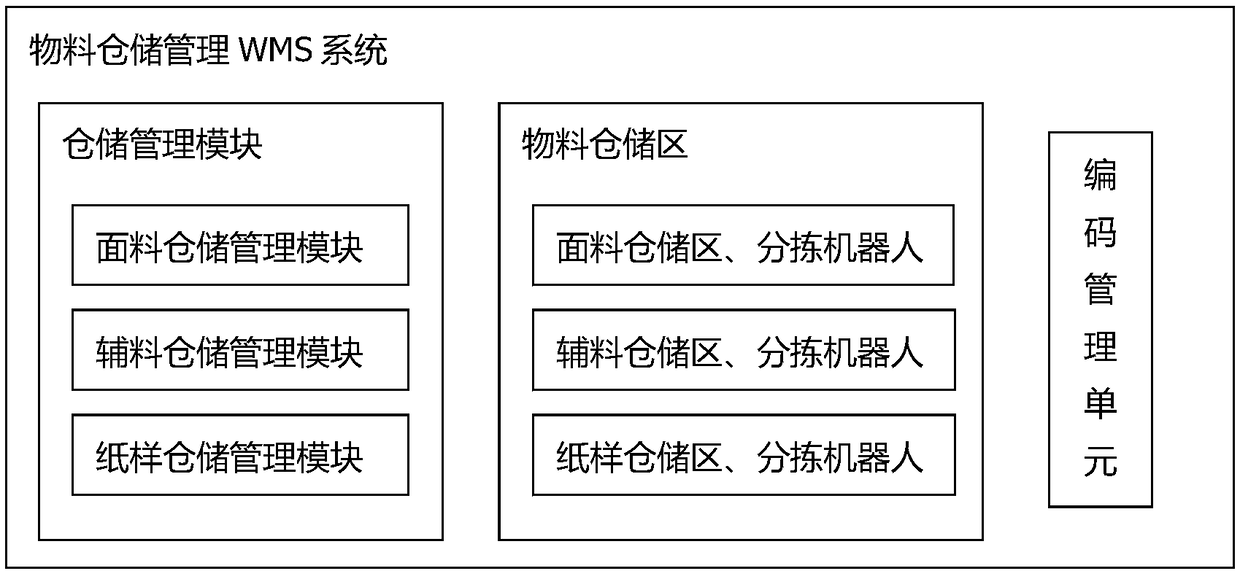

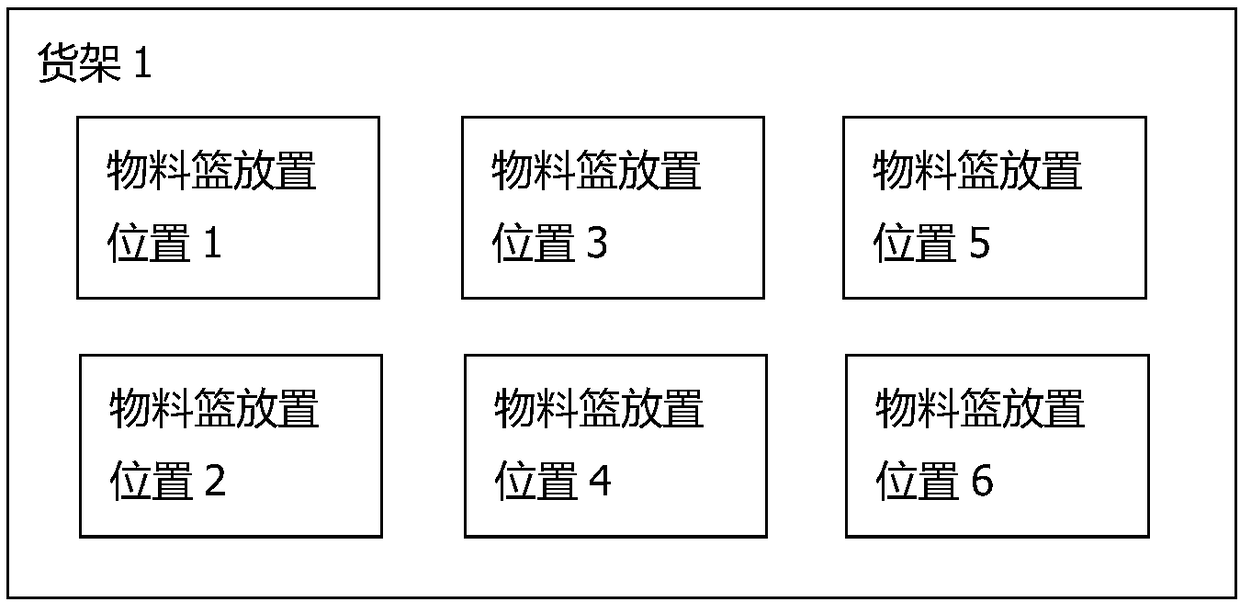

Method and system for controlling warehouse-out and material taking of AGV shelves

InactiveCN108089558ARealize a high degree of automationRealize automatic identificationElectric/hybrid propulsionTotal factory controlControl systemPosition Number

The invention discloses a method and a system for controlling warehouse-out and material taking of AGV shelves. A garment manufacturing and executing MES system issues a shelf warehouse-out and material taking instruction to an AGV control center according to a material application submitted by a sewing station; the AGV control center controls an AGV transport vehicle to go to a shelf collection area to load shelves and then to go to a material storage area to take target materials after empty material baskets are delivered out of a warehouse; an RFID detection device detects shelf codes, material basket codes and position number information on the shelves on the AGV transport vehicle and feeds them back to a WCS system; the WCS system binds the code of an empty material basket corresponding to the position number according to a material application priority of the sewing station, and sends binding information and the like to an MES system; and the MES system generates corresponding target material sorting and warehouse-out information, and the AGV transport vehicle arrives at a corresponding material storage area to complete target material sorting and loading to the basket. The method and system can realize highly automated AGV shelf warehouse-out and material taking in the garment production process and greatly improve the production efficiency.

Owner:ZENMME INTELLIGENT TECH SHENZHEN CO LTD

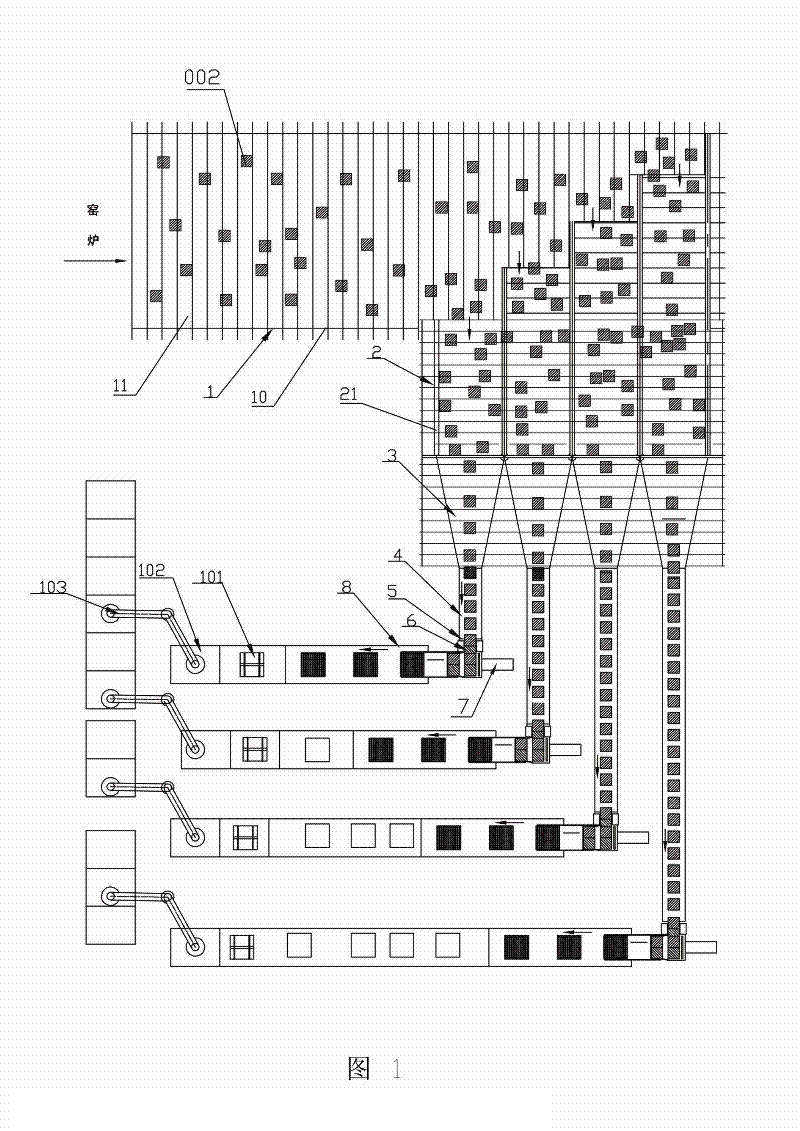

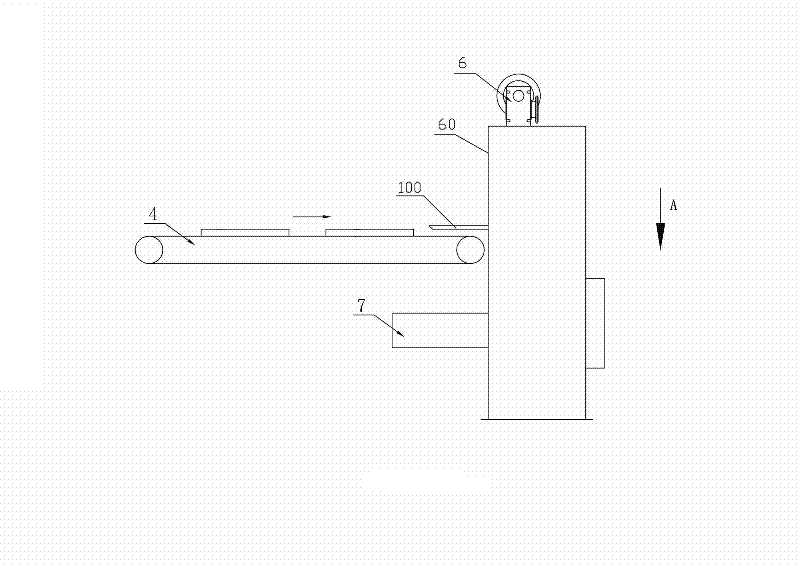

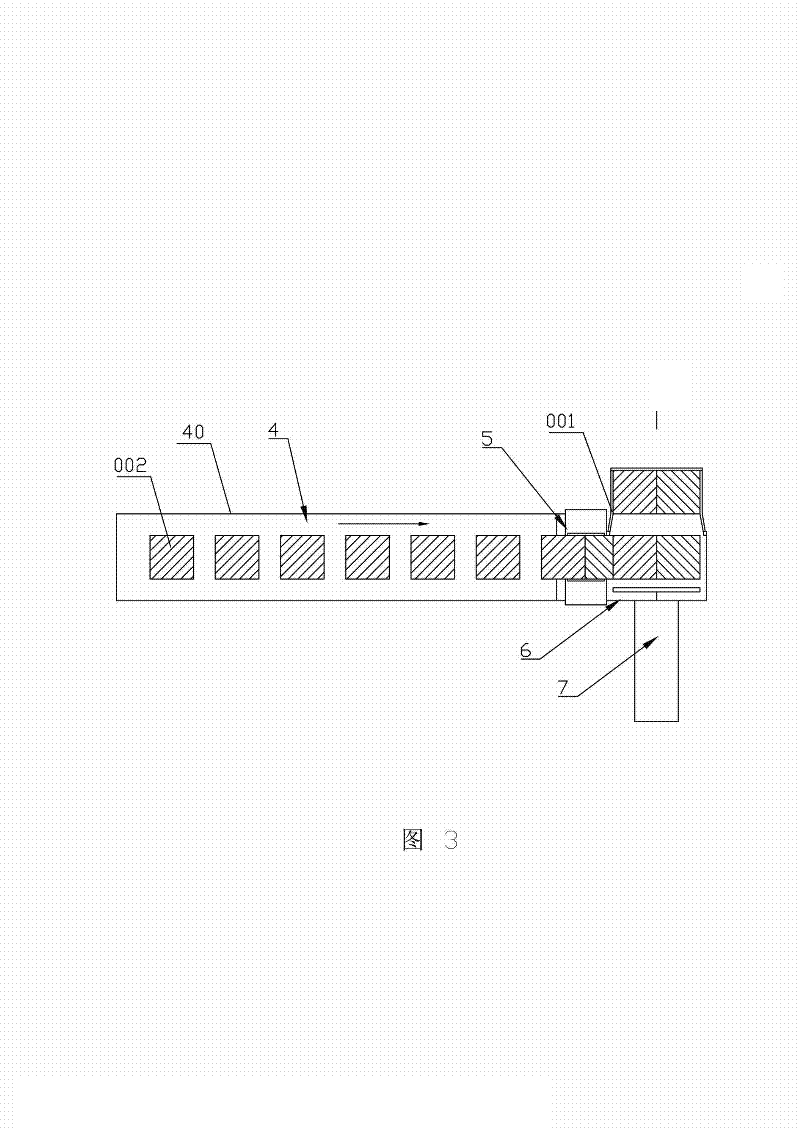

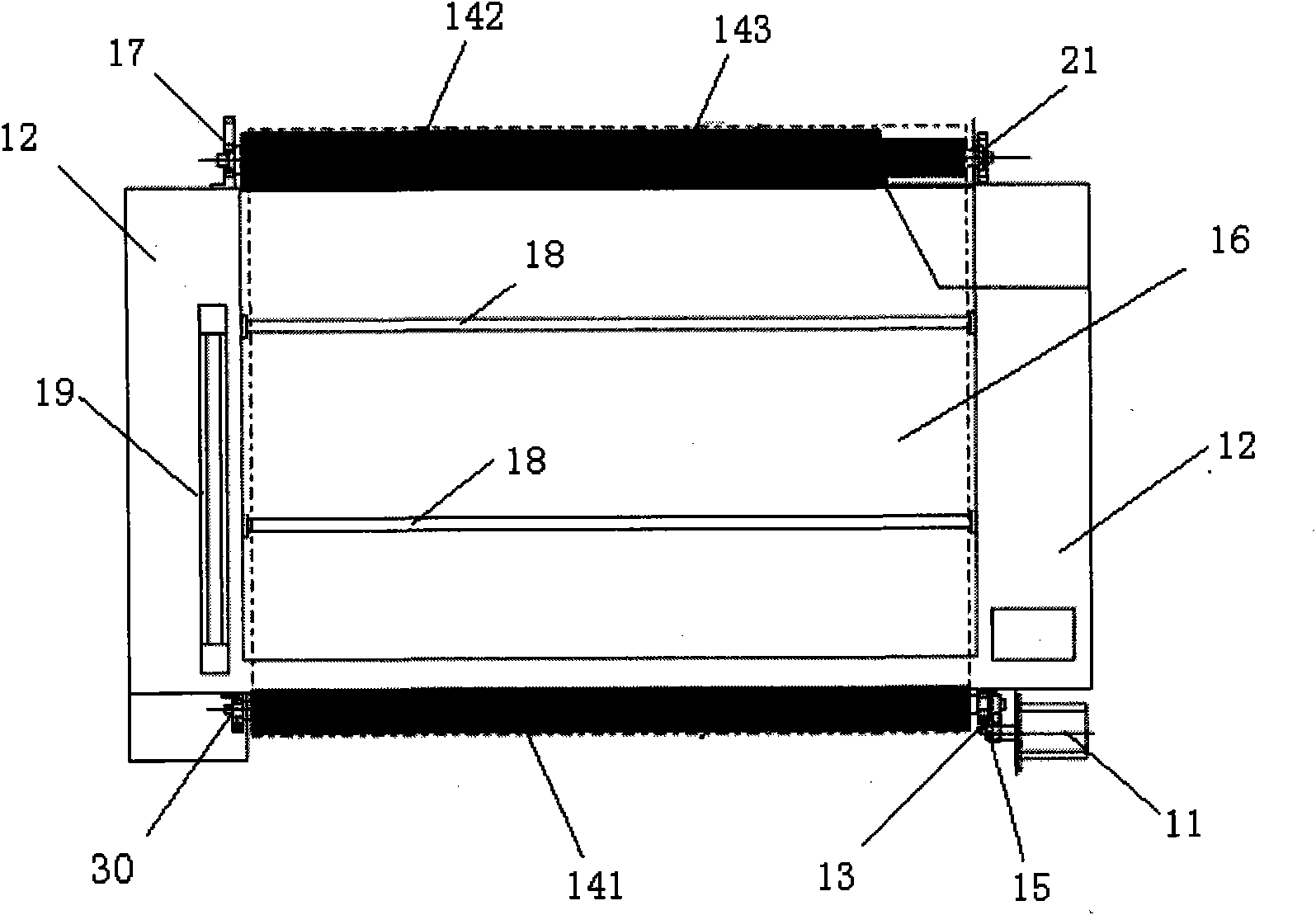

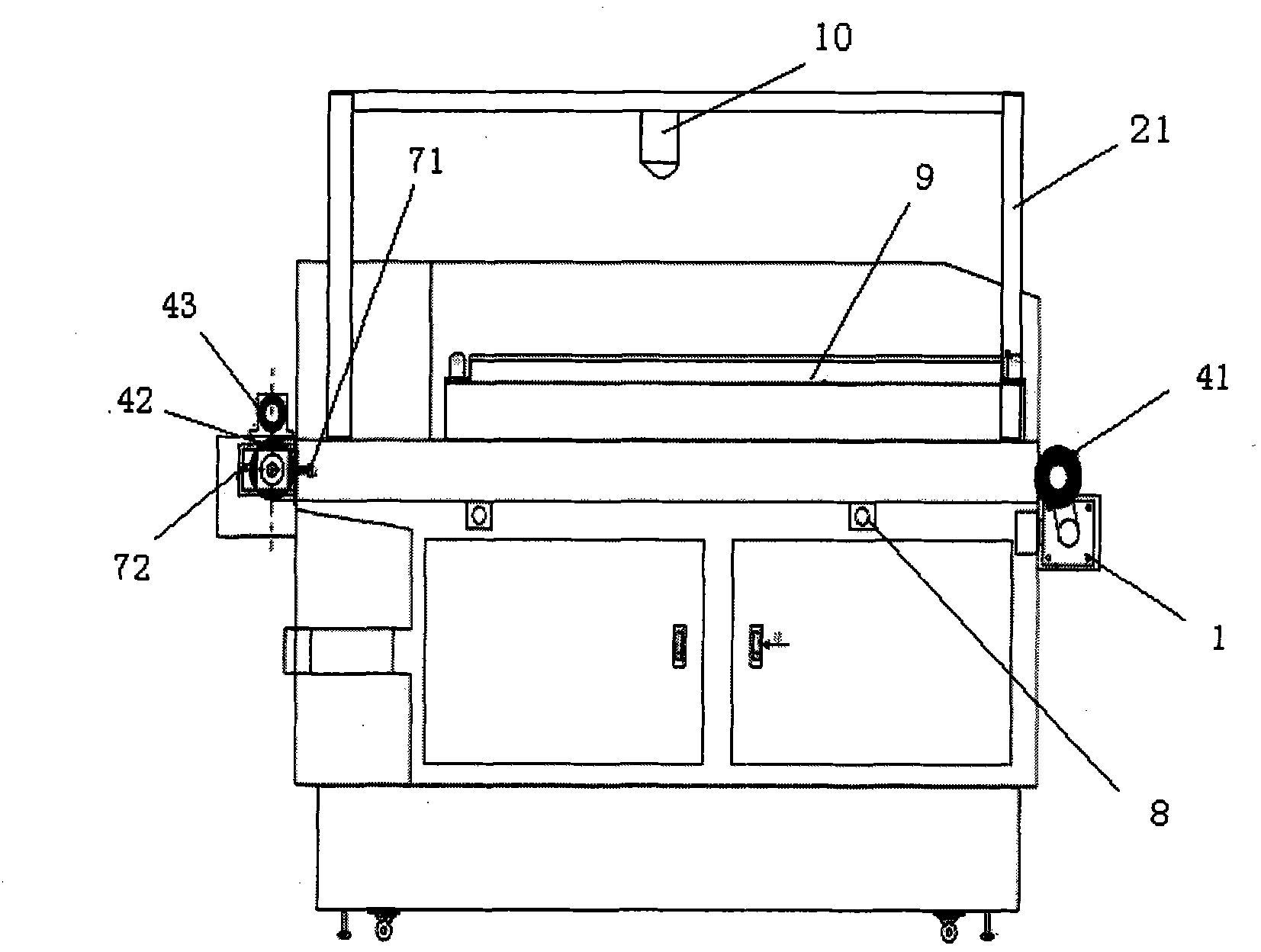

Novel full-automatic efficient ceramic tile package producing equipment

InactiveCN102241284ASimple equipment structureSimple and efficient operationPackaging automatic controlCeramic tilesEngineering

The invention provides novel full-automatic efficient ceramic tile package producing equipment. Through a conveying table behind a kiln, an automatic track lining mechanism, a division channel, a tile feed conveying mechanism, a tile stacking mechanism, a tile pushing mechanism, a tile receiving turnover conveying mechanism, an automatic carton sealing mechanism, an automatic code spraying mechanism, an automatic stacking machine and the like, the equipment can realize operations of automatic track lining division of ceramic tiles output by the kiln, stacking, cartoning, turnover, carton lifting and conveying, automatic carton sealing, automatic code spraying, automatic carrying and stacking and the like. The production line equipment has a simple structure, and is simple and convenient to operate, convenient to maintain, low in manufacturing cost and cheap; the equipment not only can be used for packing large-specification ceramic tiles, but also can be used for packing the ceramic tiles of various specifications such as relatively small-specification ceramic tiles and the like, is not only suitable for online ceramic tile package, but also suitable for offline ceramic tile package, especially suitable for automatically packing the ceramic tiles of different specifications on the same production line; and moreover, the equipment is widely applicable, convenient, practical, efficient and fast.

Owner:NANAN XINJIE MACHINERY

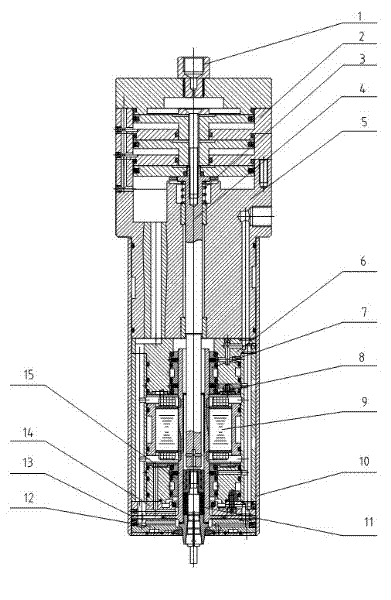

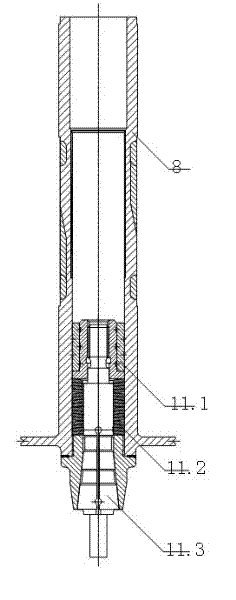

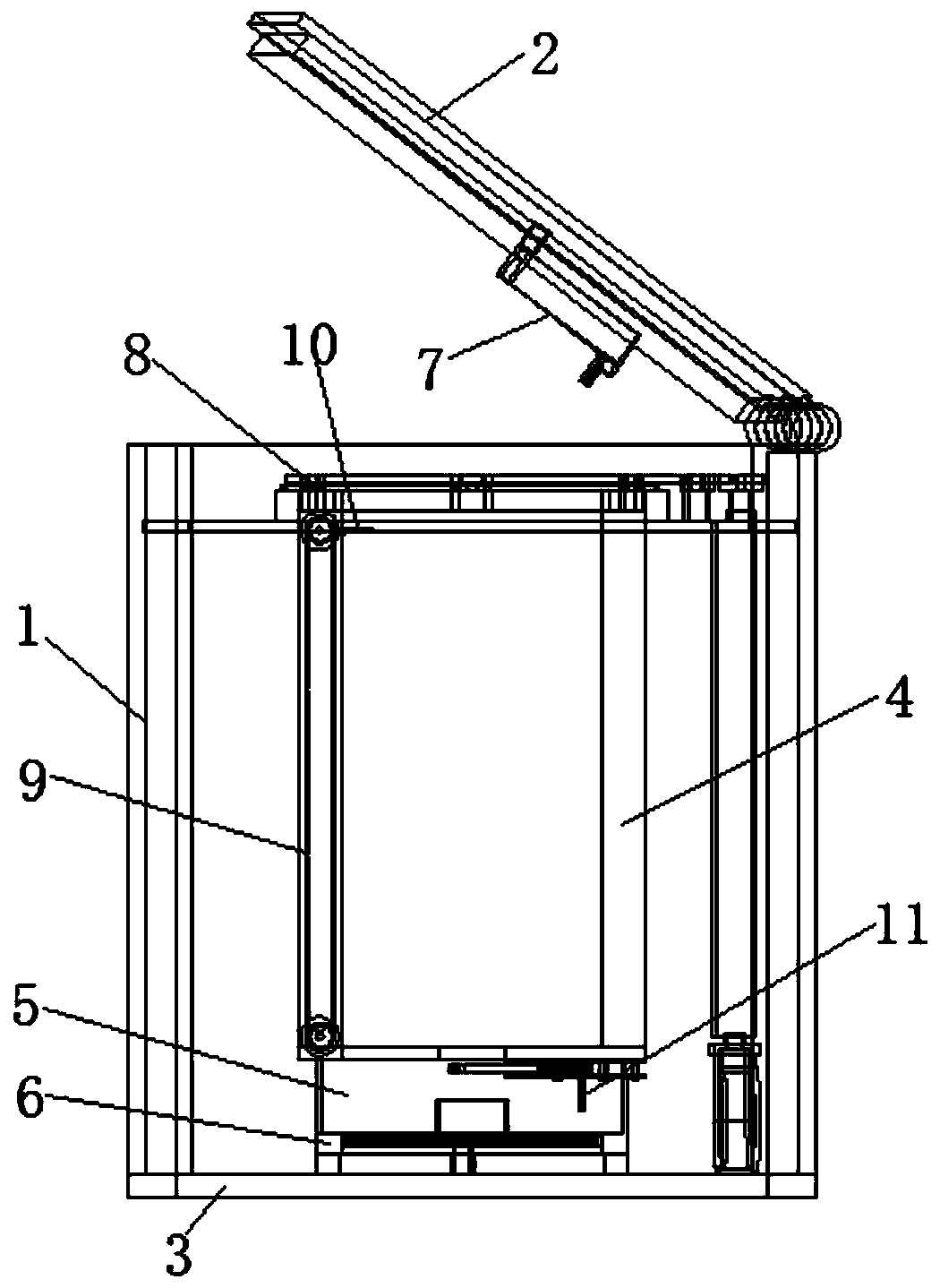

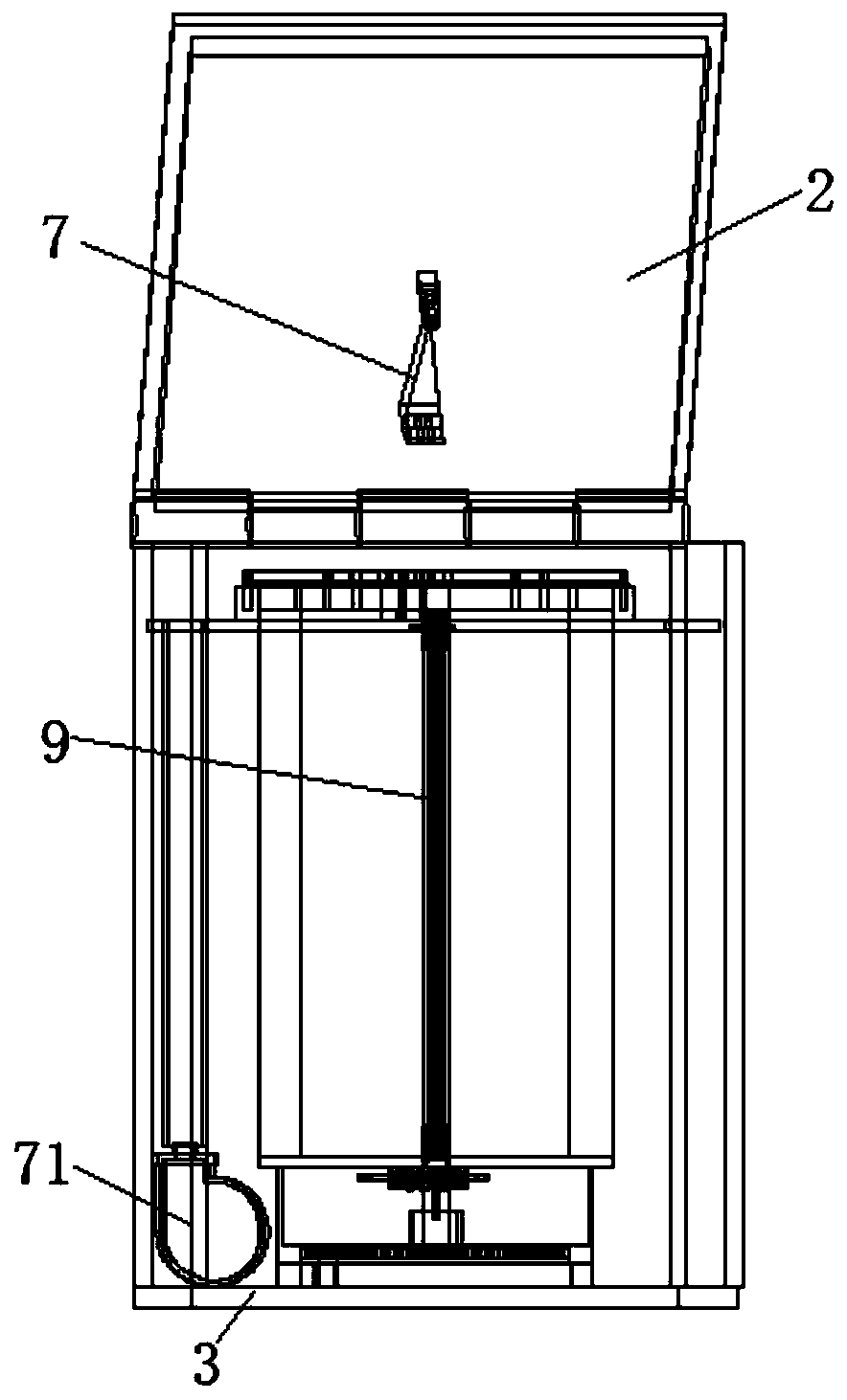

Air-floated high-speed motorized spindle

InactiveCN102489726AEliminate mechanical frictionReduce frictionMachine tool componentsLarge fixed membersStatorEngineering

The invention relates to an air-floated high-speed motorized spindle, particularly to a mechatronic basic part with high rotating speed and high precision. The air-floated high-speed motorized spindle disclosed by the invention is characterized in that an upper air-floated bearing (7) and a lower air-floated bearing (15) are respectively fixed in axial through holes of an upper air-floated bearing pedestal assembly (6) and a lower air-floated bearing pedestal assembly (14), and a central spindle (8) runs through an axial through hole among the upper air-floated bearing (7), a stator and the lower air-floated bearing (15); and a gap of 0.03-0.035 mm is formed between the outer wall of the central spindle (8) and the inner walls of the upper air-floated bearing (7) and the lower air-floated bearing (15). The air-floated high-speed motorized spindle disclosed by the invention has the advantages of simple and compact structure, convenience of installation, changeable rotating speed due to utilization of a variable-frequency power source, long service life and convenience for popularization and application.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Unmanned aerial vehicle pesticide spraying system based on a convolutional neural network chip

InactiveCN108541683AReduce usageRealize a high degree of automationAircraft componentsPicture taking arrangementsPositioning technologyPesticide use

The invention discloses an unmanned aerial vehicle pesticide spraying system based on a convolutional neural network chip, and relates to the field of intelligent agricultural machinery. The unmannedaerial vehicle pesticide spraying system comprises a mapping photographing unmanned aerial vehicle, a pesticide spraying unmanned aerial vehicle and an unmanned aerial vehicle console, wherein the unmanned aerial vehicle console controls the mapping and photographing unmanned aerial vehicle to map the farmland coordinate information and shoot the crop images, and transmit the information to the unmanned aerial vehicle console, the unmanned aerial vehicle console performs pest and disease judgment processing on the crop images in real time through the convolution neural network chip, and a coordinate positioning technology is adopted to control the pesticide spraying unmanned aerial vehicle to carry out automatic corresponding pest and disease crop spraying, so that the height automation and precision of farmland pesticide spraying are realized, the labor is saved, the pesticide use amount is reduced, and a technical guarantee is provided for green agriculture.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

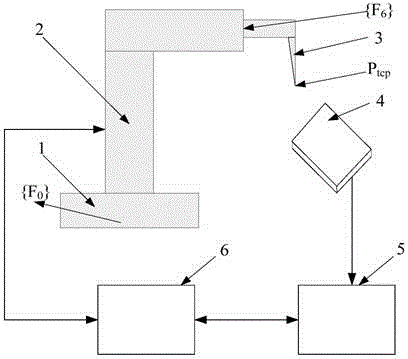

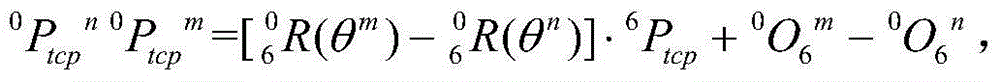

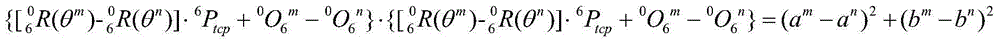

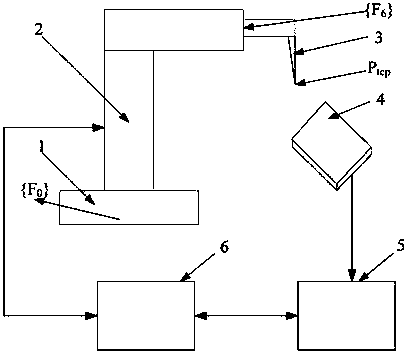

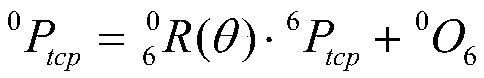

Robot tool central point calibration method using two-dimensional measurement functional tablet

ActiveCN104457645AAchieve coincidenceAvoid overlappingMeasurement devicesJoint coordinatesSimulation

The invention discloses a robot tool central point calibration method using a two-dimensional measurement functional tablet. A robot is controlled to enable a TCP to make contact with a measurement area of a calibration tool more than three times in different postures in the calibration process, joint coordinate information of the robot is recorded in the contact process, and the two-dimensional coordinates of the contact points in a measurement plane are output through the two-dimensional position measurement function of the calibration tool; the coordinates of the TCP in a robot tail end tool coordinate system are calculated according to measured joint rotation angle information of the robot and the coordinate data of the contact points on the tablet and in combination with the structural parameters of the robot, and the calibration accuracy is evaluated. According to the calibration method, the TCP of the robot does not need to coincide with the same fixed point multiple times, the point-point coincidence requirement is weakened to point-surface coincidence, and operation is easy. When the TCP of the robot has small deviation, autonomous calibration can be realized.

Owner:CENT SOUTH UNIV

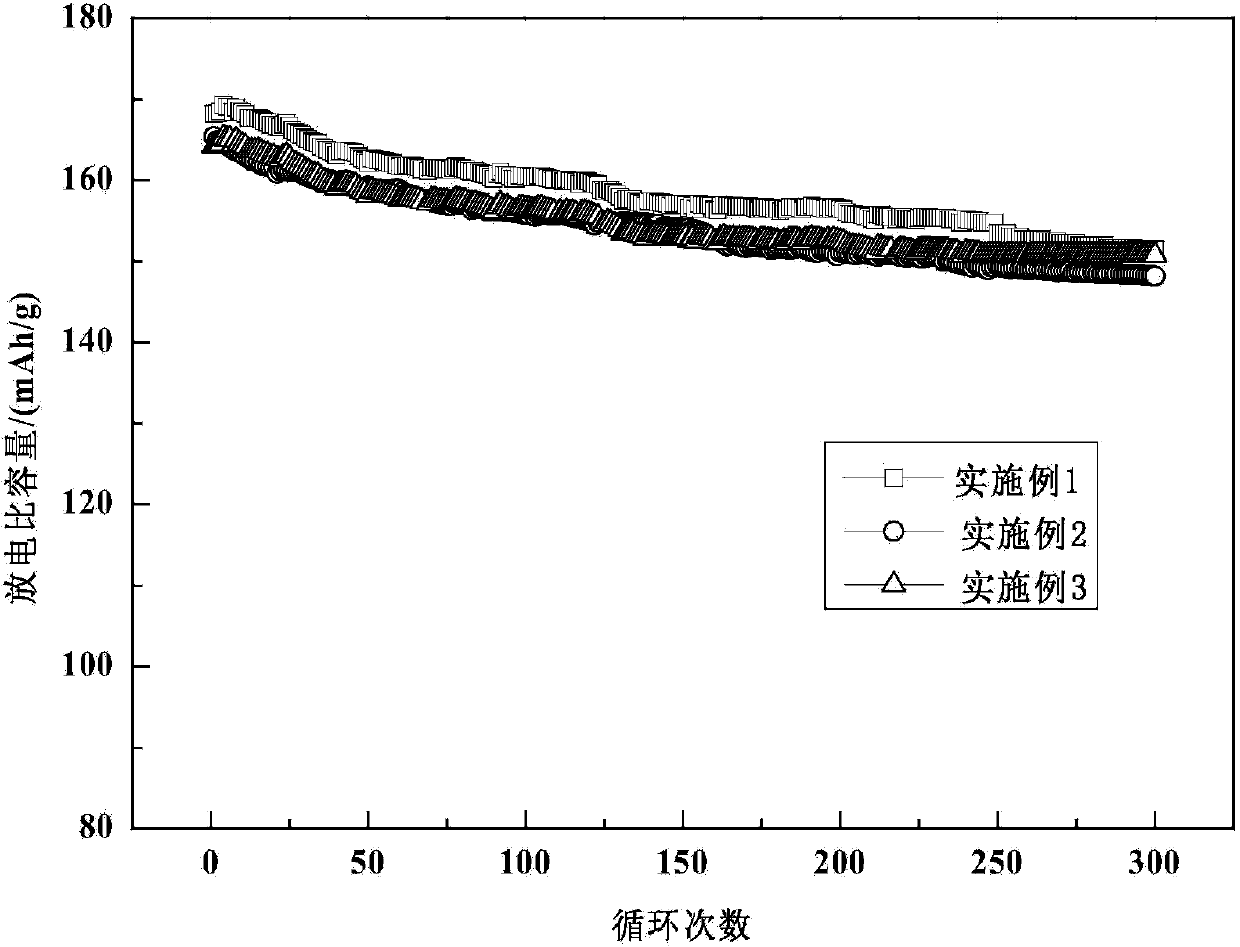

Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

The invention discloses a pretreatment method of cobaltosic oxide. The method comprises the steps of mixing a titanium-containing organic matter with an organic solvent so as to obtain a mixed liquid; adding cobaltosic oxide powder into the mixed liquid under a stirring condition so as to form a turbid liquid, adding deionized water into the turbid liquid, adequately stirring the turbid liquid and the deionized water until a uniform pulp-shaped fluid material is formed, and drying the uniform pulp-shaped fluid material so as to obtain a cobaltosic oxide compound. The high-voltage lithium cobalt oxide can be obtained by adequately mixing the obtained cobaltosic oxide compound, a lithium source and a dopant to obtain a mixture, and performing solid sintering and covering on the mixture at a high temperature. The tap density of the prepared high-voltage lithium cobalt oxide is more than 3.0g / cm<3>, the compaction density is more than 4.2g / cm<3>, the primary discharge gram capacity in the range of 2.8V to 4.34V can reach more than 164mAh / g, and the circulating capacity retention rate in 300 weeks is more than 89 percent. The prepared high-voltage lithium cobalt oxide has the advantages of good processing performance, high tap density, good circulating performance, high specific capacity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

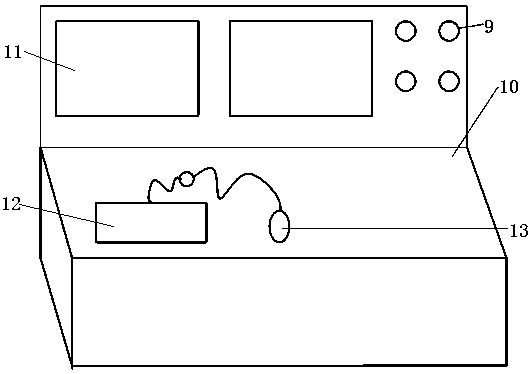

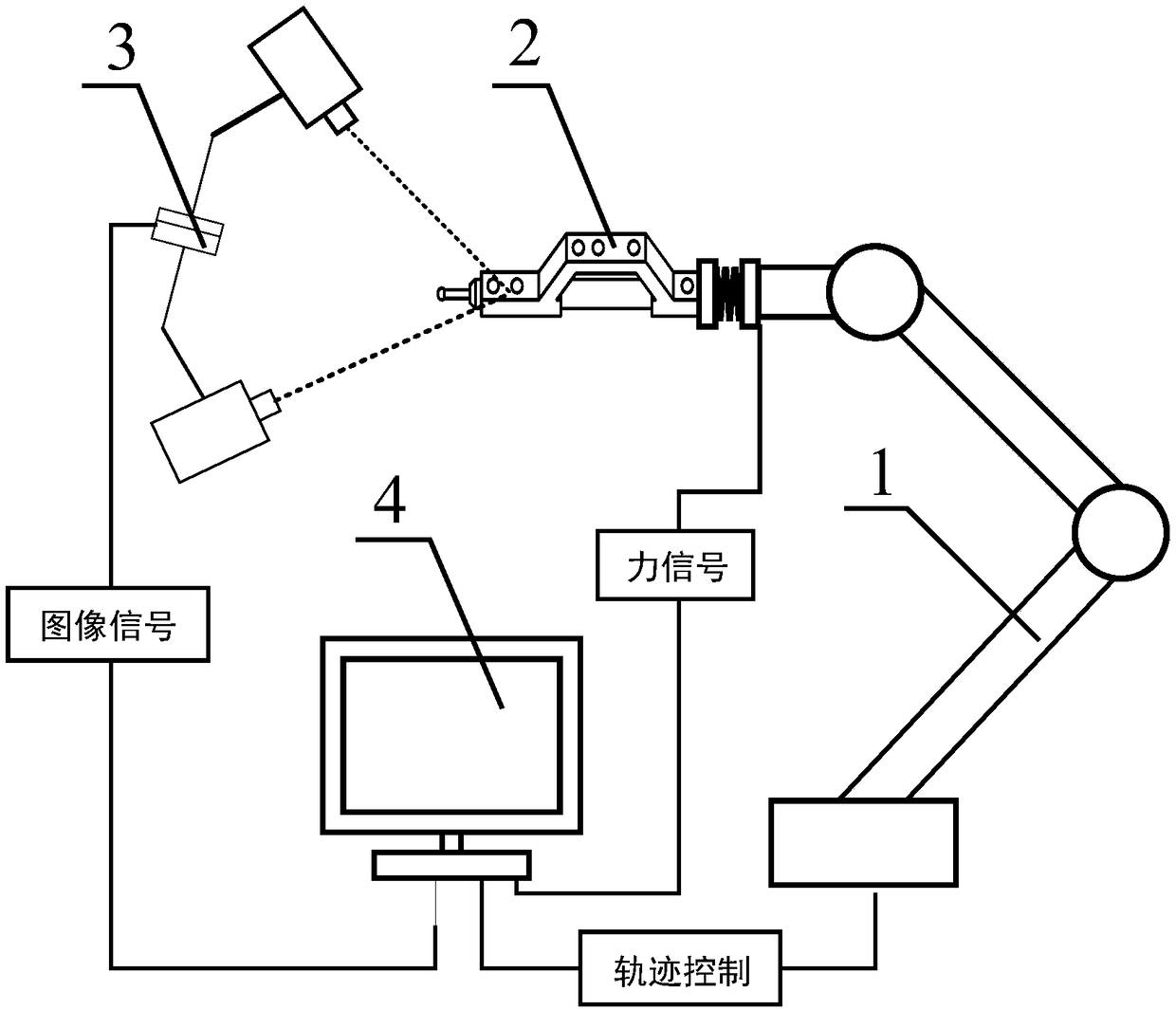

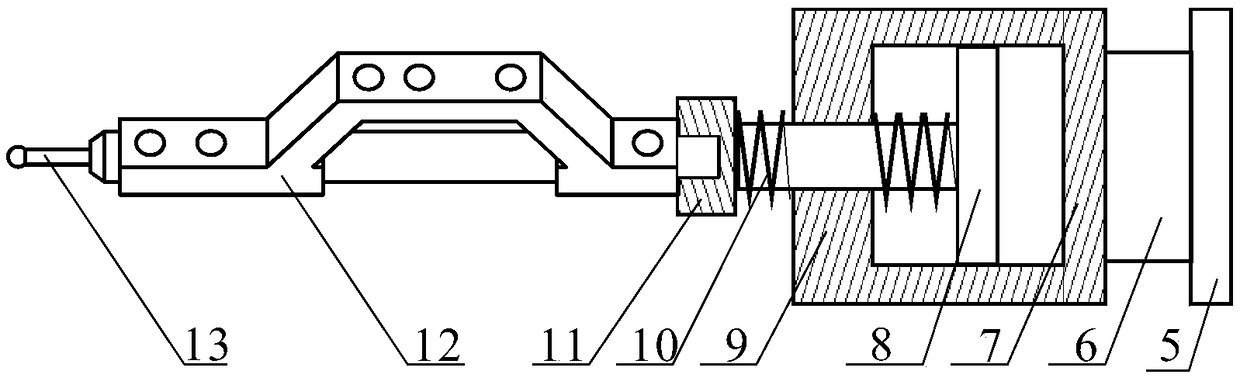

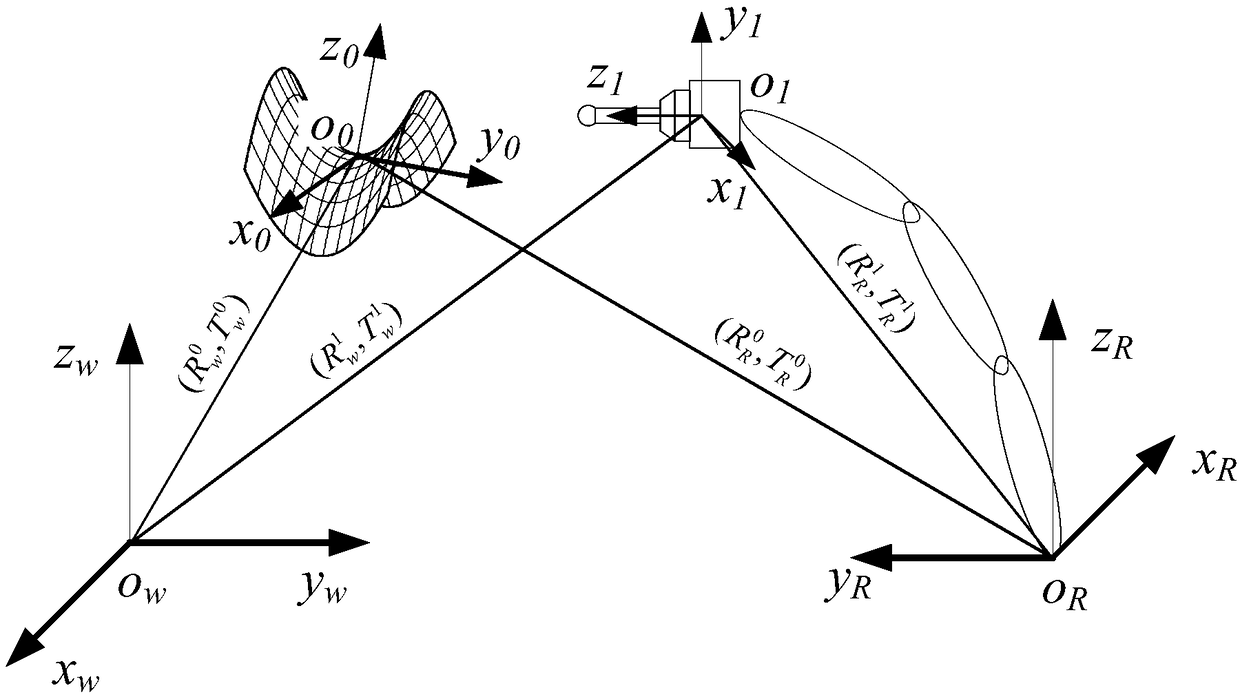

Light-pen-type robot in-situ measurement system and method

ActiveCN109443207ARealize a high degree of automationHigh measurement accuracyUsing optical meansImaging processingSimulation

The invention belongs to the precision measurement field and especially discloses a light-pen-type robot in-situ measurement system and method. The system mainly comprises an industrial robot, a lightpen measurement unit, a binocular visual unit and an industrial computer. A light pen, a probe, a spring, and a force sensor are arranged in the light pen measurement unit. The industrial robot clamps the light pen measurement unit to move according to a planned path so that the probe is flexibly contacted with a measured workpiece under the effect of the spring. At the same time, the binocular visual unit is used to collect light pen images in real time according to a set frame rate, and transmit to the industrial computer for image processing. A binocular visual three-dimensional reconstruction principle is used to calculate the position of a probe ball centre on a light pen, and based on this, probe ball head radius error compensation is performed at the combined force direction of a contact force collected by the force sensor, and then, the measurement result of a workpiece surface is acquired. The light pen measurement unit carries out automation measurement according to the planned path so that the efficiency and the precision of contour measurement are effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Preparation method of high-nickel-content anode material for lithium ion battery

The invention discloses a preparation method of a high-nickel-content anode material for a lithium ion battery. The method comprises the steps of calcining a synthesized high-nickel precursor, supplying non-reducing gas during calcining, obtaining high-valence nickel oxide, mixing high-valence nickel oxide with a lithium source in a wet mixing or dry mixing mode, obtaining a mixture, conducting segmented sintering on the mixture at an oxygen atmosphere, and obtaining the high-nickel-content anode material for the lithium ion battery. The high-nickel-content anode material for the lithium ion battery prepared with the method has the characteristic of high capacity, and also has good cycling stability and processability. The preparation method is high in production automation degree, avoids pollution to the environment, and has a very wide market prospect.

Owner:HUNAN CHANGYUAN LICO CO LTD

Method for calibrating central point of robot tool through employing plane calibration plate

InactiveCN105509671ARealize self-calibrationRealize automatic controlMeasurement devicesSimulationCoincidence

The invention discloses a method for calibrating a central point of a robot tool through employing a plane calibration plate. The method comprises the steps: controlling a robot to enable a TCP to carry out plane contact with a calibrating tool for more than six times at different attitudes during calibration; just recording the coordinate information of a robot joint; combing with the structure parameter of the robot to calculate the coordinates of the TCP in a flange coordinate system at the tail end of the robot; and evaluating the calibration precision. The method does not need to enable the TCP of the robot to repeatedly coincide with the same fixed point, and lowers the point-point coincidence to the point-plane coincidence. A calibration tool is simple, and the method is easy to implement. When the TCP of the robot deflects lightly, the method can achieve autonomous calibration.

Owner:CENT SOUTH UNIV

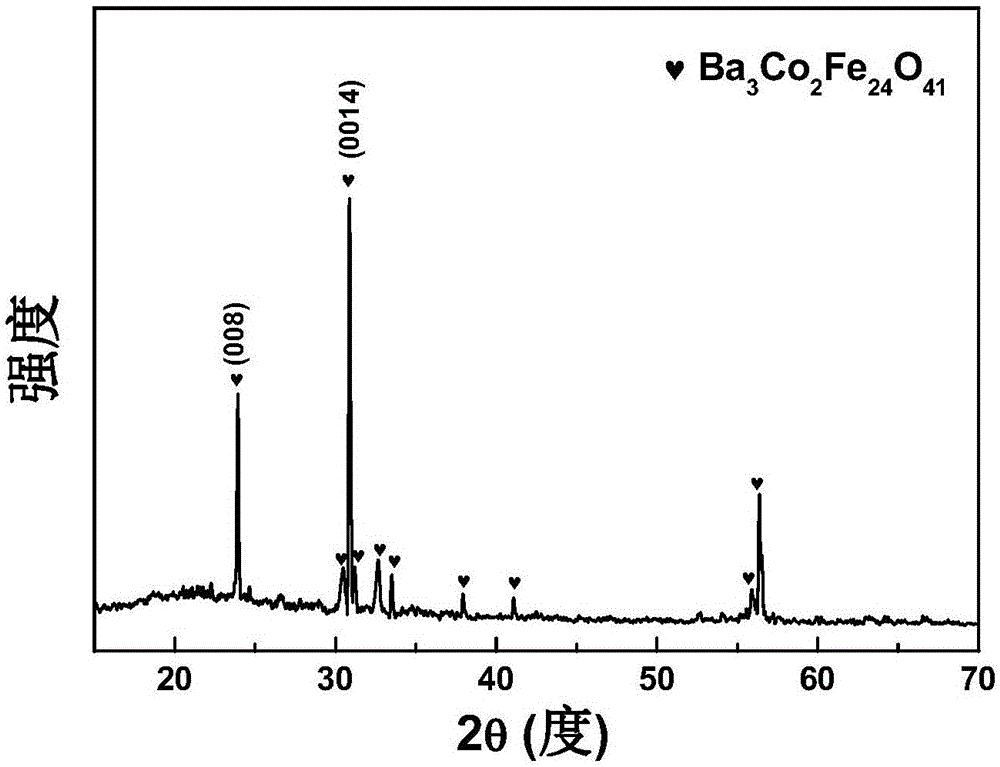

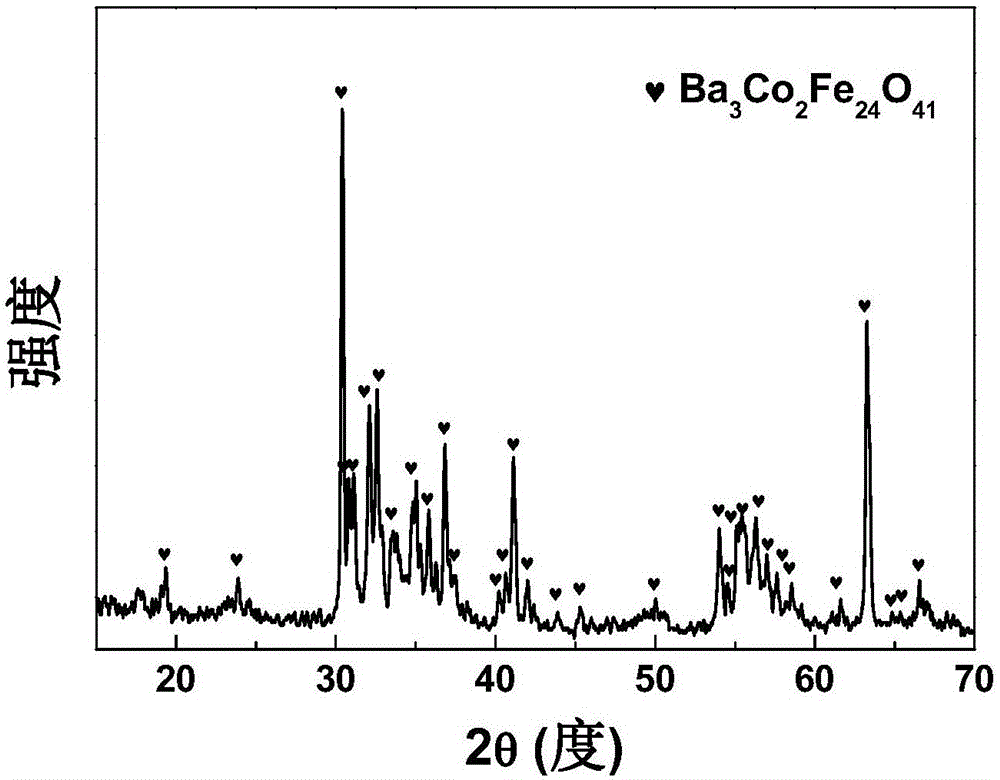

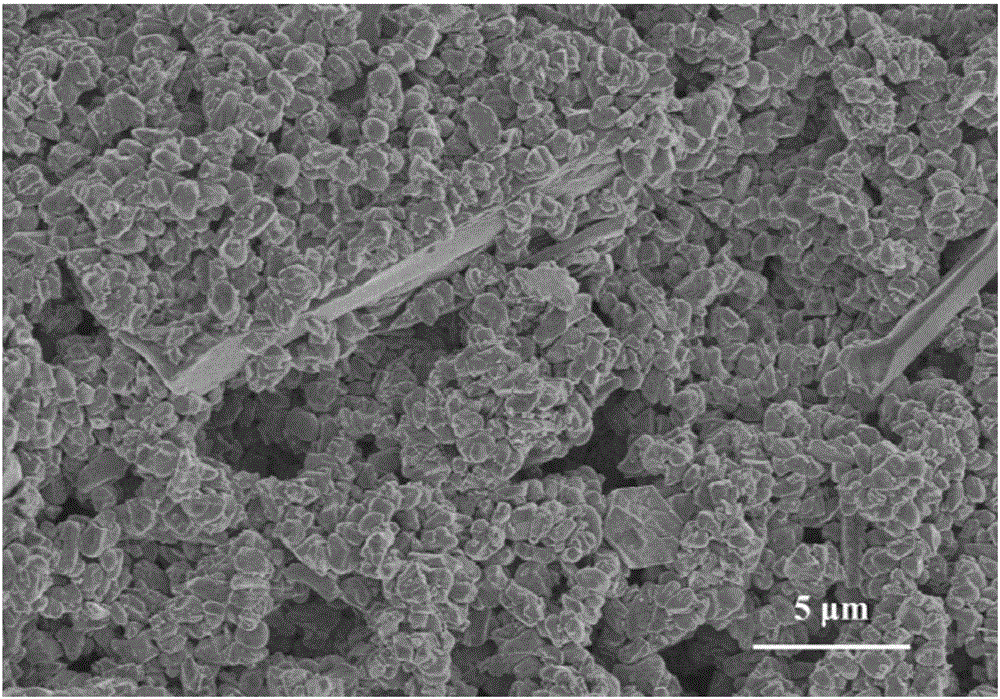

Composite wave absorbing material and preparation method thereof

ActiveCN108251054ALow densityHigh strengthOther chemical processesMagnetic/electric field screeningMXenesMaterials science

The invention relates to the field of wave absorbing materials, in particular to a composite wave absorbing material and a preparation method thereof. The composite wave absorbing material is characterized in that the surface of each of MXene layers is coated with a ferrite, and the different MXene layers and the ferrites on the surfaces of all the layers jointly form a sandwich structure. The composite wave absorbing material and the preparation method thereof provided by the invention have the benefits that MXene is prepared by adopting a chemical etching process, the ferrites prepared by adopting a hydrothermal preparation process are compounded with the MXene so as to grow in situ on the surface of MXene powder, the degree of integration between the ferrites and the MXene powder is high, and the coating is uniform and compact; the prepared MXene / ferrite composite wave absorbing material with the sandwich structure is light in density, high in strength, adjustable in dielectric constant and excellent in wave absorbing performance. In addition, the preparation method is simple, used equipment is simple, the process is stable, the production efficiency is high, the cost is reduced, the compactness and the uniformity of the material are good.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

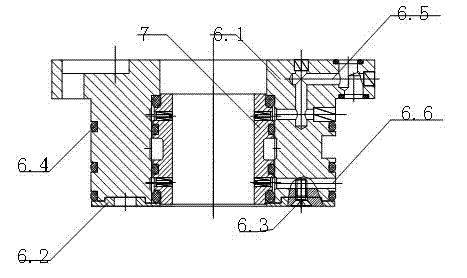

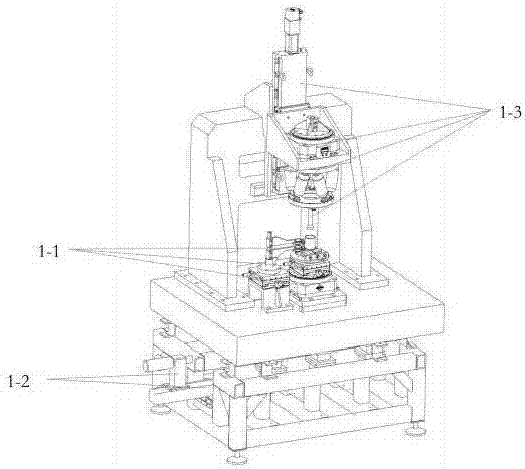

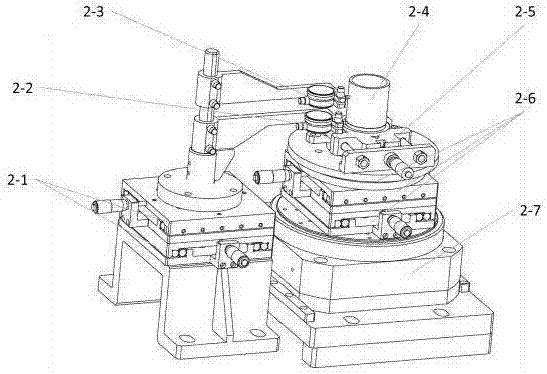

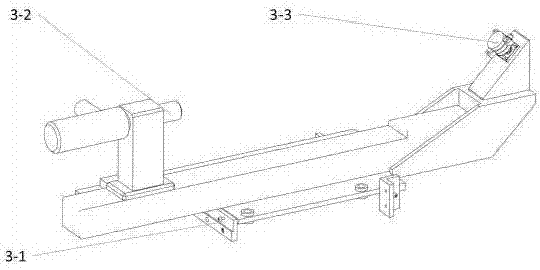

SDOF parallel automatic offset adjusting system and method for optical lens

ActiveCN107957626AImprove the efficiency of assembly and adjustmentRealize a high degree of automationOptical elementsOptical axisComputer science

The invention provides an SDOF (Six Degrees of Freedom) parallel automatic offset adjusting system and method for an optical lens and belongs to the technical field of precision automatic assembly ofoptical lens. Automatic offset adjustment is realized based on a measurement result of decentration and an SDOF parallel structure. The system is mainly composed of a lens barrier adjusting module, adecentration measuring module and an automatic offset adjusting module. The automatic offset adjustment method includes calculating two centers of sphere of a to-be-assembled lens based on the decentration measurement data and driving the SDOF parallel structure for offset adjustment. A method of alternative conduction of measurement and adjustment is employed; namely, whether an offset adjustmentresult meets requirements or not is verified through re-measuring the decentration after each process of offset adjustment. If the offset adjustment result does not meet the requirements, offset adjustment is performed again through refitting of optical axis until the precision meets requirements. According to the invention, integration of decentration measurement and lens automatic adjustment isachieved and measurement of lens decentration and offset adjustment can be realized quickly. Lens offset adjusting precision can be ensured to meet requirements and lens assembly efficiency is improved greatly.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

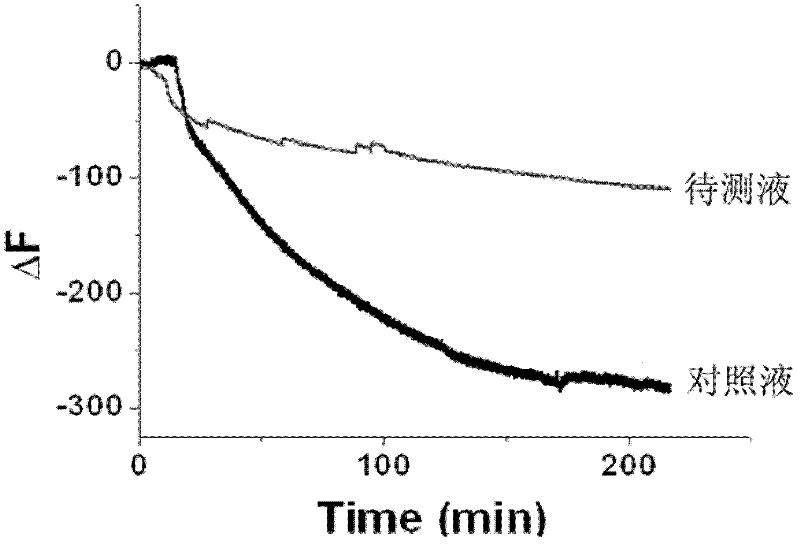

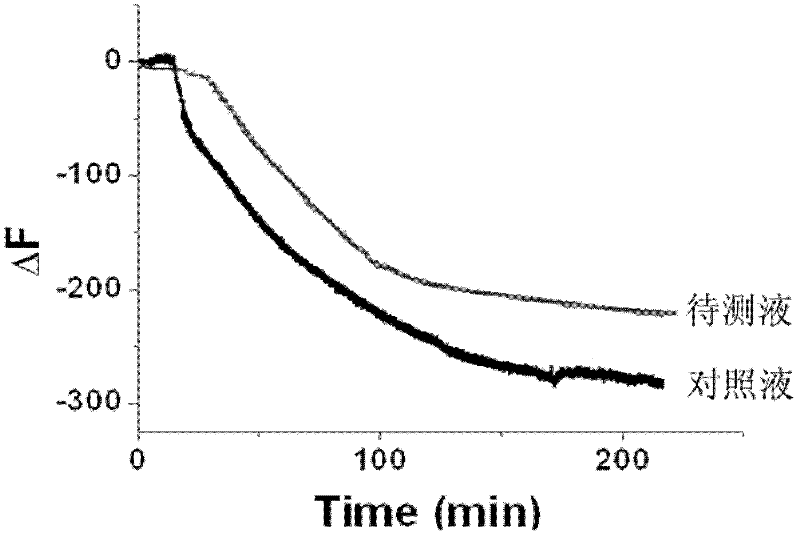

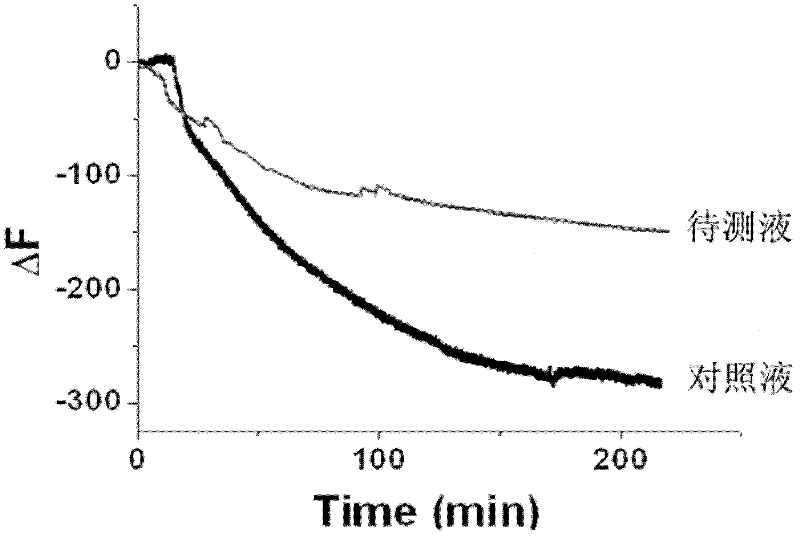

Method for screening telomerase inhibitor with quartz crystal microbalance

InactiveCN102393342ARealize a high degree of automationReduce false positive problemsWeighing by absorbing componentTelomeraseQuartz crystal microbalance

The invention discloses a method for screening a telomerase inhibitor with a quartz crystal microbalance. The method comprises the following steps: I, performing carboxyl-functionalizing of a chip surface; II, activating the chip surface; III, fixing a telomerase primer on the chip surface; IV, putting a chip on which the primer is fixed into a reactor of the quartz crystal microbalance, introducing a working solution into the reactor, reading the monitored frequency F1, then introducing a control solution, reading the monitored frequency F2, and calculating a difference (delta)F between F1 and F2; and V, putting the chip on which the primer is fixed into the reactor of the quartz crystal microbalance, introducing a working solution into the reactor, reading the monitored frequency F1', then introducing a liquid under test, reading the monitored frequency F2', calculating a difference (delta)F' between F1' and F2', and if F1' / (delta)F'<=50%, determining that the liquid under test contains the telomerase inhibitor. In the method disclosed by the invention, the quartz crystal microbalance is adopted as a detection tool, and the method has the advantages of no mark, real-time detection and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

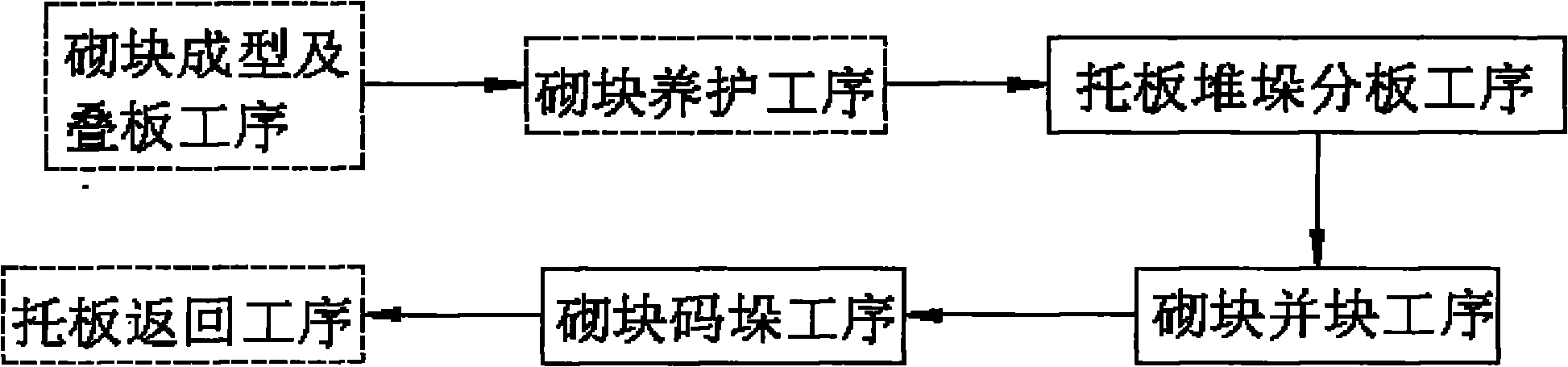

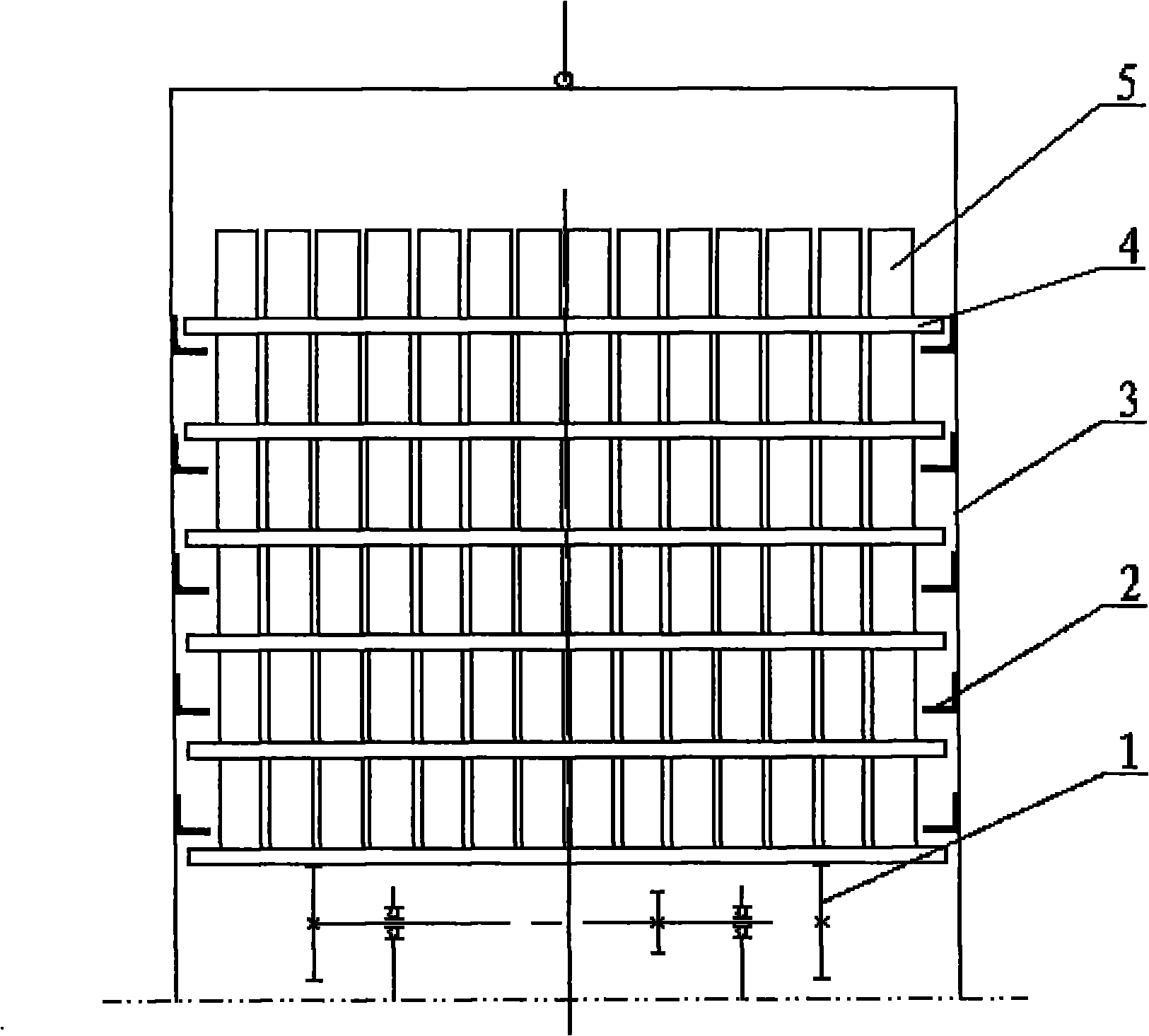

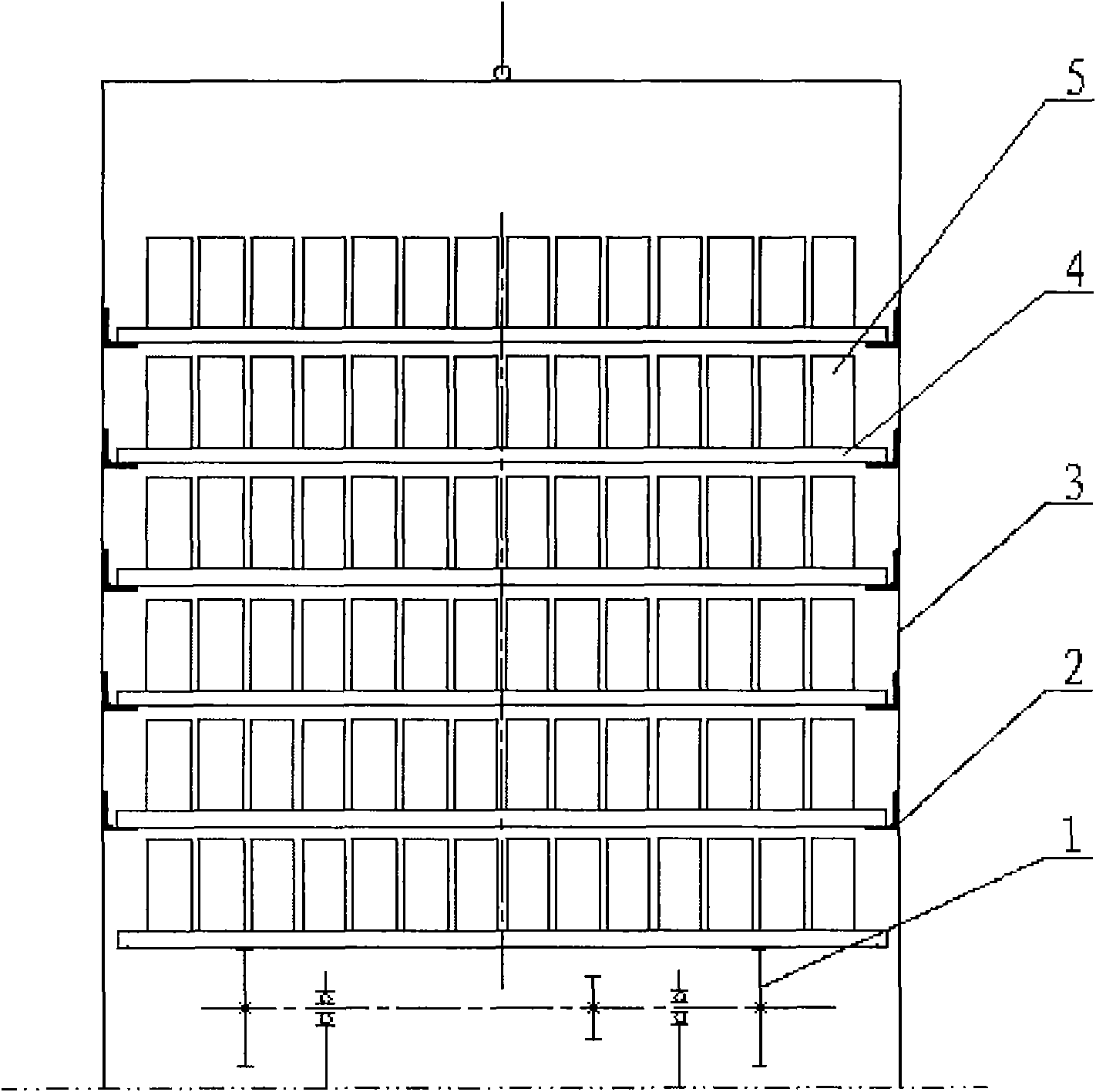

Automatic production process for post production flow of concrete blocks

InactiveCN102060183AIncrease productivityQuality improvementStacking articlesDe-stacking articlesL&D processPallet

The invention relates to an automatic production process for a post production flow of concrete blocks, comprising a pallet stack splitting procedure, a block blocking procedure and a block stacking procedure, wherein the pallet stack splitting procedure is used for automatically splitting pallets of each layer in pallet stacks, the block blocking procedure is used for horizontally combining the concrete blocks, and the block stacking procedure is used for stacking the concrete blocks. By virtue of the pallet stack splitting procedure, the block blocking procedure and the block stacking procedure with higher automation degree, the maintained pallet stacks are automatically split, and the blocks are automatically and horizontally combined and picked out to be stacked into stacks. The automatic concrete production process can be used for effectively realizing high automation of the concrete block production, thereby the labor intensity of an operator is significantly reduced, the production efficiency of the concrete blocks is obviously enhanced, and the quality of the concrete blocks is improved.

Owner:速世昌 +1

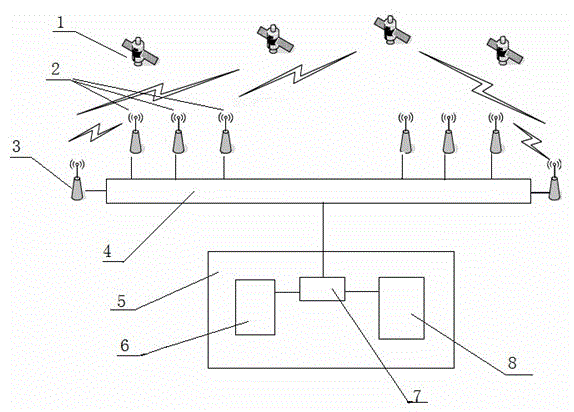

Dam detection device based on Beidou satellite

InactiveCN103558611ARealize automatic transmissionRealize a high degree of automationSatellite radio beaconingData transmissionSatellite

The invention provides a dam detection device based on a Beidou satellite. The dam detection device comprises a data collecting sub-device, a data transmission and communication sub-device, a data analyzing and processing sub-device and an auxiliary supporting sub-device. The data collecting sub-device comprises two receiver base stations and a plurality of monitoring stations, wherein each receiver base station is composed of a GNSS receiver and an antenna, the monitoring stations are arranged on different positions on a dam, and the receiver base stations are Beidou GPS two-satellite devices. The dam detection device can achieve high automation, greatly reduces filed intensity, and meanwhile can quickly obtain efficient and reliable three-dimensional point position monitoring data.

Owner:TELLHOW SCI TECH CO LTD

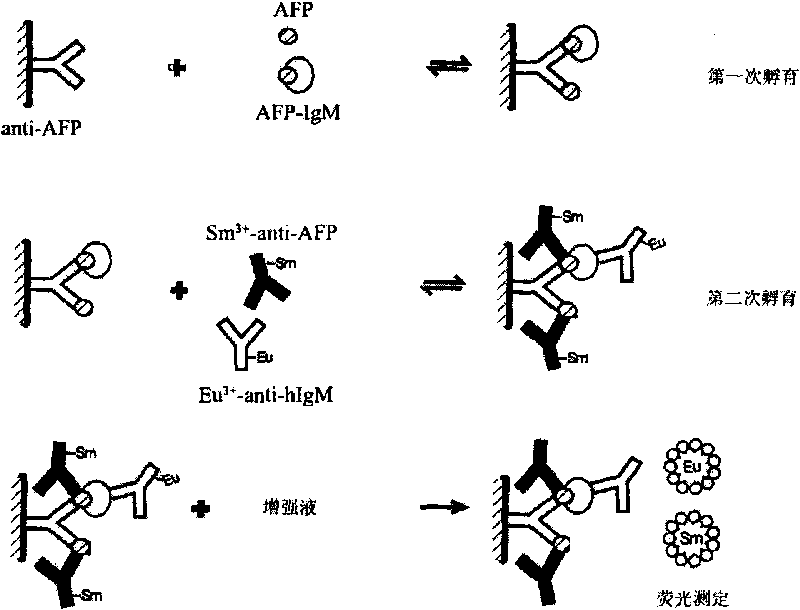

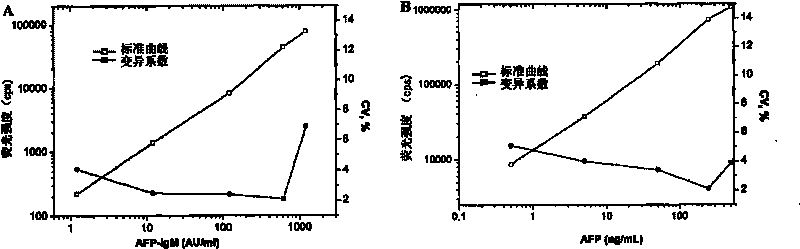

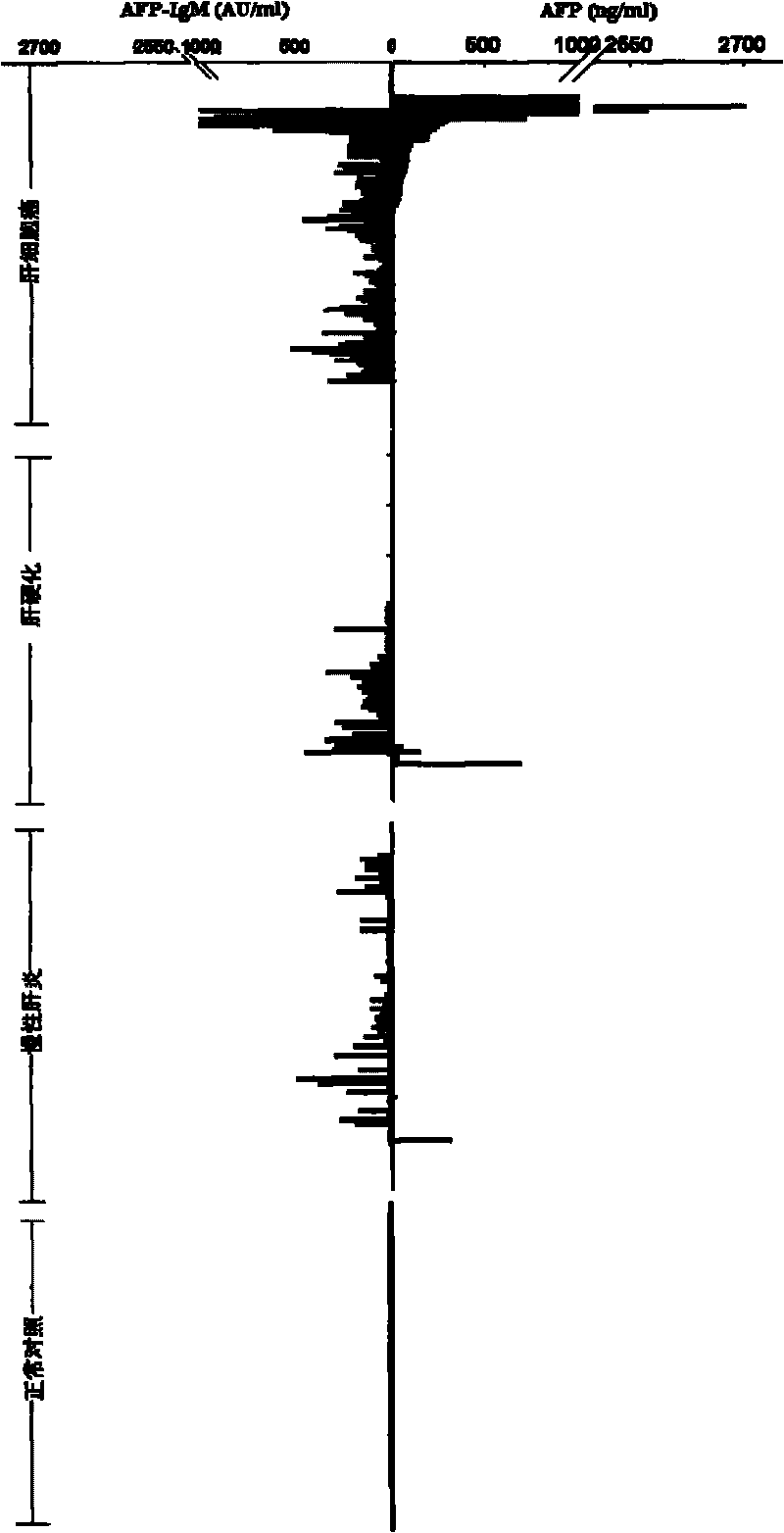

TRFIA for synchronously detecting AFP and AFP-IgM and reagent kit thereof

InactiveCN101750502AImprove diagnostic efficiencyLow costBiological testingEpitopeTime resolved fluorescence immunoassay

The invention discloses a time resolution fluorescence immunity analysis (TRFIA) method for synchronously detecting AFP and AFP-IgM and a reagent kit thereof. The reagent kit comprises the following reagents: 1) an AFP monoclonal antibody of a first epitope; 2) an AFP monoclonal antibody of a second epitope marked by a lanthanide element; 3) an IgM monoclonal antibody marked by another lanthanide element; 4) AFP / AFP-IgM mixed standard products; 5) a buffer solution; 6) washing liquid; and 7) enhancing liquid, wherein the lanthanide elements are selected from europium and samarium, and the AFP monoclonal antibody of the second epitope and the AFP monoclonal antibody of the first epitope have different epitopes. The invention adopts the TRFIA with the high sensitivity, the method for synchronously detecting AFP and AFP-IgM is established, the and the invention has the advantages of high sensitivity, strong specificity, good stability and simple operation, can realize the high atomization, can improve the speed of the clinical examination, can greatly reduce the artificial error, can improve the reliability of the detected results, and greatly improves the diagnosis efficiency.

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Novel detection method and kit for synchronously detecting concentration of free kappa light chain and free lambda light chain

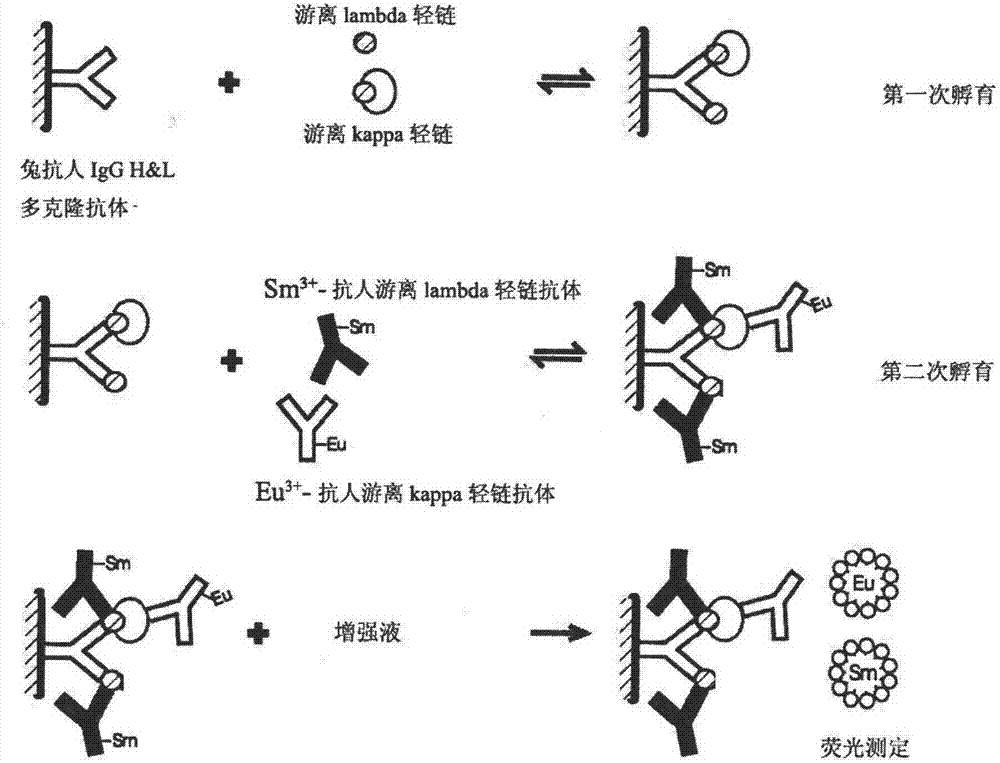

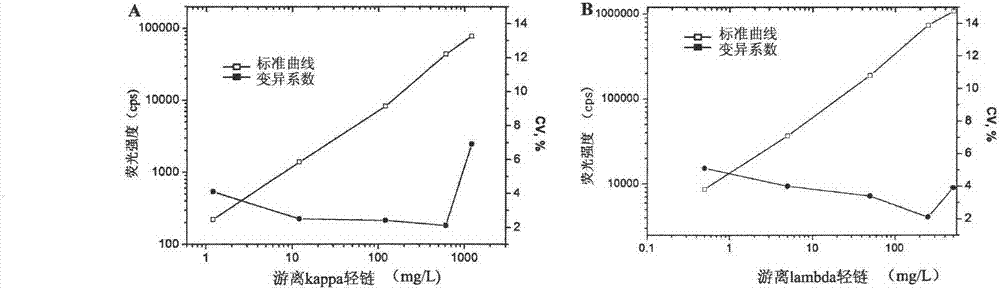

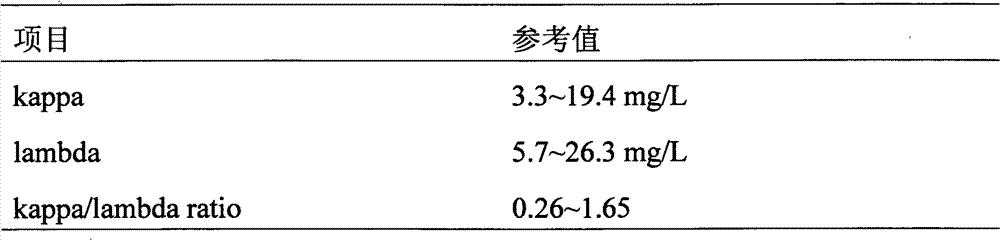

InactiveCN102735845ALow costHigh speedBiological testingTime resolved fluorescence immunoassayHeavy chain

The invention discloses a time-resolved fluoroimmunoassay (TRFIA) kit and a detection method thereof for synchronously detecting the concentration of a free kappa light chain and a free lambda light chain. The kit comprises: 1) an antibody synchronously aiming at a heavy chain and a light chain of a human antibody, 2) an anti-free kappa light chain antibody labelled by lanthanide, 3) an anti-free lambda light chain antibody labelled by another lanthanide, 4) a standard substance of the free kappa light chain and a standard substance of the free lambda light chain, 5) a buffer, 6) a washing liquid, and 7) an enhancement solution. According to the invention, the antibody synchronously aiming at the heavy chain and the light chain of the human antibody is used as a capture antibody, other two antibodies respectively aiming at the free kappa light chain and the free lambda light chain are used as the labelled antibodies, double labeling TRFIA detection principles are used, thus the novel detection method for synchronously detecting the concentration of the free kappa light chain and the free lambda light chain is established. The method provided by the invention has the advantages of high sensitivity, strong specificity and good stability, and can realize high degrees of automation.

Owner:SHANGHAI HUJING BIO TECH CO LTD +1

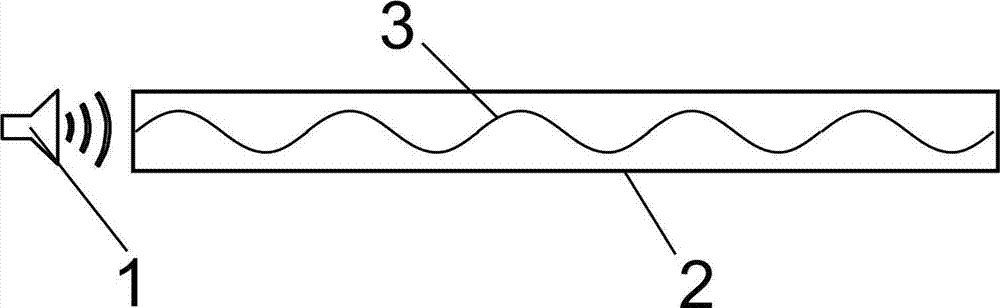

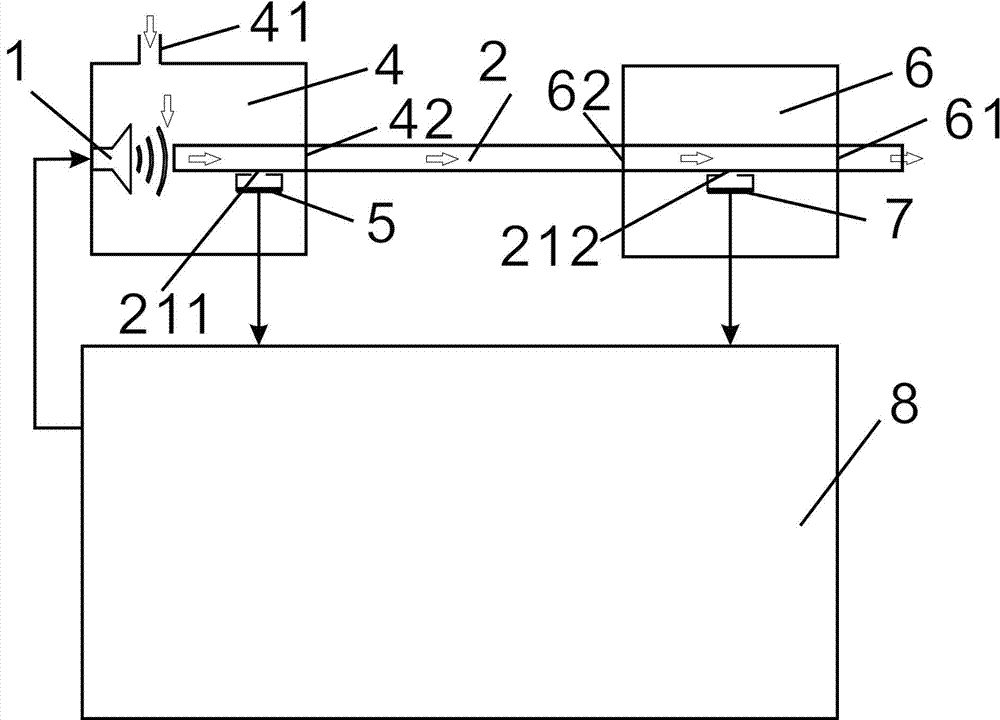

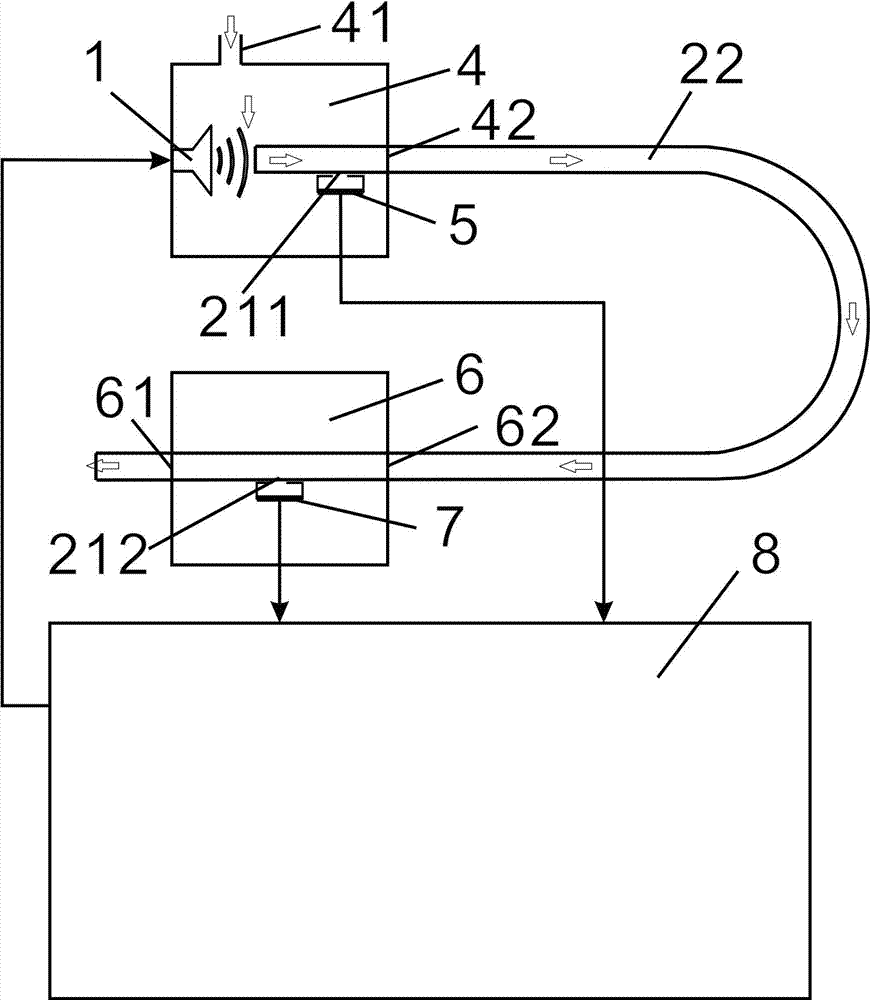

Method and device of sound velocity measurement

ActiveCN103196539AMeet technical needsRealize a high degree of automationVelocity propogationPhase differenceAcoustic wave

The invention relates to a measurement technology of sound velocity, in particular to a method and a device of sound velocity measurement. The method and the device of the sound velocity measurement are used for solving the technical problems that an existing sound velocity measurement device and an existing sound velocity measurement method are complex in operation, poor in measurement accuracy and the like. The method of the sound velocity measurement comprises the following steps of (a) inputting a sine sound wave with a frequency of fi through the front end of a sound wave guide tube, wherein the sound wave guide tube is filled with specific gas, and the length of the sound wave guide tube is 1, and recording a phase difference phi i, between the rear end and the front end of the sound wave guide tube, of the sine sound wave; (b) changing the frequency of the sine sound wave, and measuring at least one group of values from the fi to the phi i; and (c) calculating the value of 2pi l / vs using a linear fitting method according to the obtained values from the fi to the phi i, and obtaining a sound level vs. The device of the sound velocity measurement comprises a first air chamber and a second air chamber, and further comprises the sound wave guide tube. The front end of the sound wave guide tube penetrates through a first passing hole to enter the first air chamber. The rear end of the sound wave guide tube passes a third passing hole and a second passing hole, and penetrates through the second air chamber. The method and the device of the sound velocity measurement achieve high automation of measurement, and are simple in structure and low in cost.

Owner:SHANXI UNIV

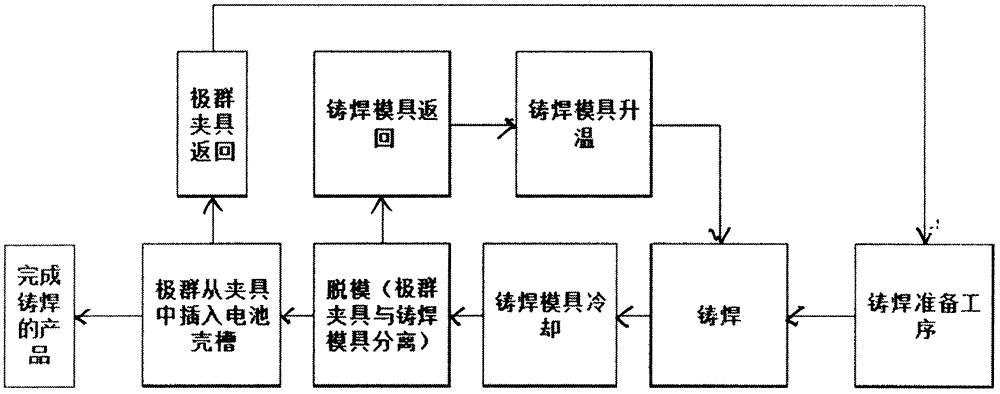

Continuous cast-welding device for busbar and polar column of lead-acid battery

InactiveCN106141145AShorten cycle timeReduce labor intensityCell component detailsLead smeltingDevice form

The invention discloses a continuous cast-welding device formed by units, independent from one another and automatically connected, for heating a cast-welding mould, cast-welding a plurality of polar plates and polar lugs, cooling the mould and a busbar after cast-welding, demoulding the busbar from the cast-welding mould, accommodating demoulded polar groups in a groove, returning the mould and a clamp and the like. The production cycle formed by adding centralized operation of a plurality of working procedures is decomposed and compressed into the production cycle time of operation of one work procedure so that the production efficiency can be improved greatly. A device used for increasing the temperature of lead alloy liquid is adopted for the cast-welding mould. A heating mechanism is arranged below the liquid level of a lead smelting furnace and used for sequentially feeding a plurality of cast-welding moulds into the mechanism by use of an automatic machine, maintaining the moulds below the lead alloy liquid level to heat the moulds, and providing cast-welding for the moulds sequentially. After the temperatures of the cast-welding moulds meet cast-welding requirements, the cast-welding moulds are then sequentially taken out of the heating mechanism according to the first in first out principle so that cast-welding of polar group busbars and polar columns of batteries can be conducted.

Owner:刘凡

Integral noodle processing and packaging device

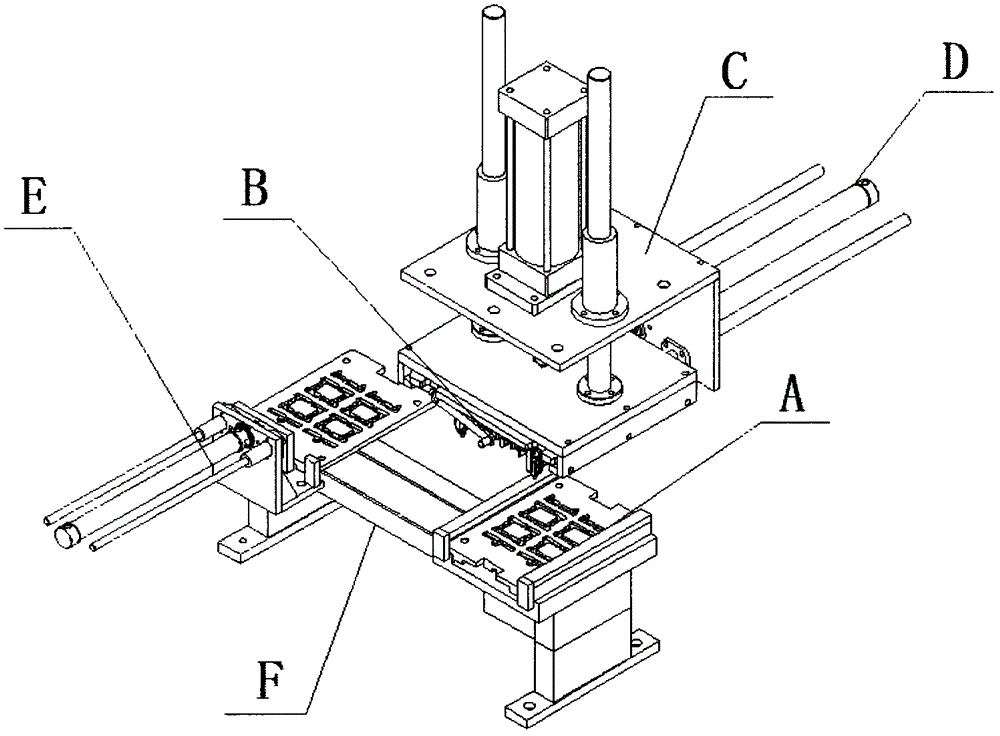

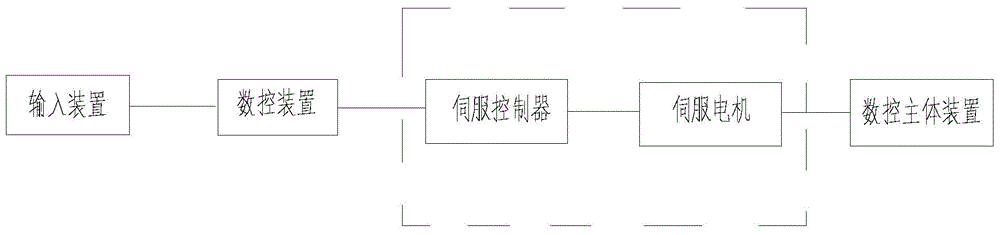

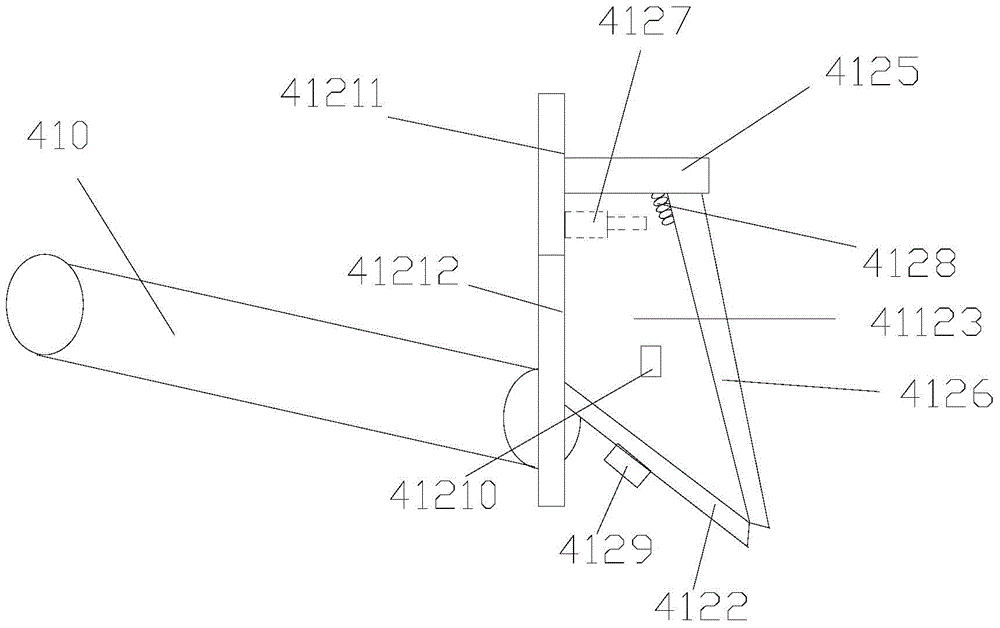

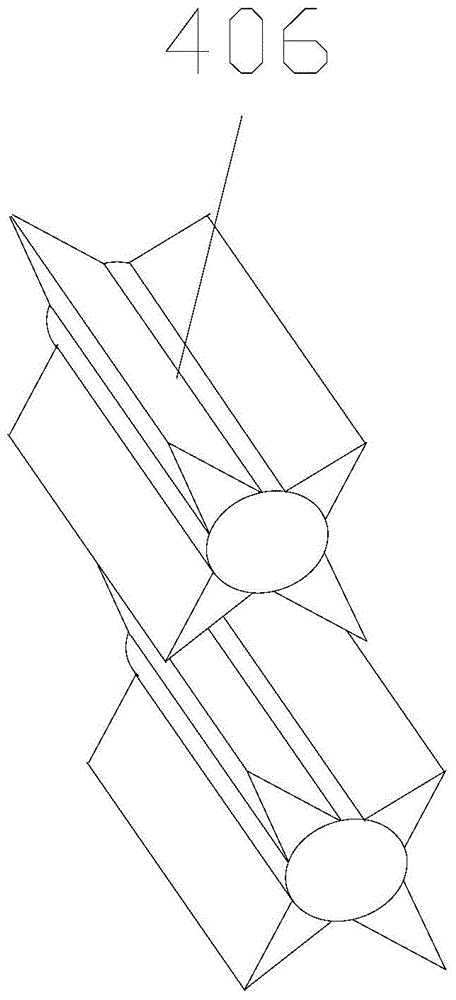

ActiveCN104886465AReduce lossSave floor spaceMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsNumerical controlSmall footprint

The invention discloses an integral noodle processing and packaging device. The integral noodle processing and packaging device comprises an input device, a numerical control device, a servo system, a machine tool mainframe device, a water supply system and a discharging device. The machine tool mainframe comprises a dough kneading device, a pre-rolling device, composite rolls, mill rolls, noodle cutters, cutoff tools, a first conveying device, an automatic weighing device, a second conveying device, a third conveying device, an alignment device, a packaging bag supply device, a packaging bag middle sealing device and a packaging bag end sealing and shearing device. The water supply system supplies water to the dough kneading device, and the discharging devices collects products processed by the packaging bag end sealing and shearing device. The integral noodle processing and packaging device has the advantages of high machining precision, small floor space, sufficient water supply power, uniformity in discharging after dough kneading and prevention of side leakage in noodle processing.

Owner:HUAIBEI XUYUAN FOOD CO LTD

Wave absorbing material of Z-shaped ferrite flaky powder filled particulate powder and preparation method thereof

InactiveCN106587978AImprove compactnessImprove uniformityOther chemical processesParticulatesPlasticizer

Owner:SHAANXI UNIV OF SCI & TECH

Full-view laser cutting bed

InactiveCN101913028AOvercome inaccuraciesOvercome inconsistencyLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a full-view laser cutting bed. An electrical machine is connected with a gear of a discharging rubber roller through a belt; a mesh belt is arranged on a frame through a mesh belt bracket and can slide along a guide rail; the guide rail is arranged on the frame; the electrical machine and the discharging rubber roller are arranged at the front part outside the frame, one end of the discharging rubber roller is connected with the electrical machine and the other end is arranged on the frame through a fixed mount; a feeding rubber roller is arranged at the rear part of the frame, one end of the feeding rubber roller is arranged on the frame through a rubber roller bracket and the other end is arranged on the frame through a tension adjustment device; and a material pressing roller is arranged above the feeding rubber roller, the frame is provided with a camera for shooting images to be cut on the mesh belt, and the camera is connected with a control device. The cutting bed can cut according to shaped pattern surfaces and materials, and can be widely applied to textiles, clothing, printing, trademarks, advertising and other industries.

Owner:江苏大华激光科技开发有限公司

Automatic garbage packaging and bag replacing device

PendingCN111591617ARealize a high degree of automationAvoid threatsRefuse receptaclesEngineeringStructural engineering

The invention discloses an automatic garbage packaging and bag replacing device. The automatic garbage packaging and bag replacing device comprises an outer barrel shell, an inner barrel, a bag opening unit, a bag sealing unit, a bag replacing unit and a control unit, wherein a barrel cover and a lower base are arranged on the top and at the bottom of the outer barrel shell respectively; a plurality of garbage bags connected in sequence are placed in the lower base; the inner barrel is rotationally arranged inside the outer barrel shell; the bottom of the inner barrel is connected with an upper base; a bottom plate is arranged at the bottom of the upper base; the bag opening unit is arranged below the barrel cover and inside the outer barrel shell; the bag sealing unit is used for sealingused garbage bags; the bag replacing unit comprises a lifting mechanism, a bag clamping mechanism and a cutting mechanism; and the control unit is connected with the bag opening unit, the bag sealingunit and the bag replacing unit respectively. According to the automatic garbage packaging and bag replacing device, automatic bag sealing and bag replacing are achieved through the bag sealing unit and the bag replacing unit respectively, so that the situation that human health is threatened due to the fact that people make contact with garbage during packaging and replacing is avoided, and highautomation of automatic packaging and replacing of the garbage bags is achieved.

Owner:ANHUI SCI & TECH UNIV

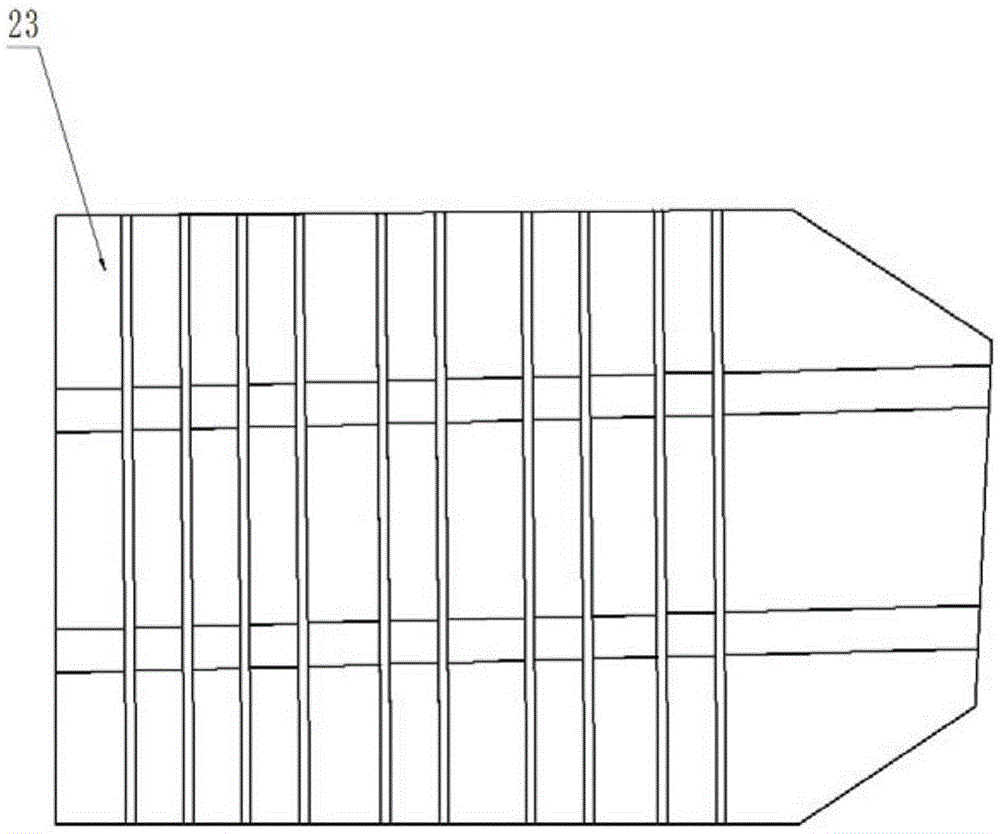

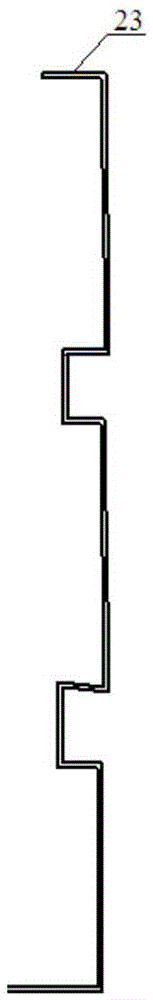

Automatic sampling system for logging rock waste

InactiveCN105626063AAutomatically achieves separabilityAutomatically achieves cleanabilityConstructionsBorehole/well accessoriesWell drillingControl system

The invention discloses an automatic sampling system for logging rock waste. The system comprises a control system and a sampling pump used for extracting drilling mud containing stratum rock waste. The sampling pump is connected with a power device used for separating rock waste from mud. The power device is connected with a rock waste cleaning device. A mud collection box is arranged below the power device. The sampling pump, the power device and the rock waste cleaning device are connected with the control system. According to the system, stratum rock waste can be automatically gained, separation and cleaning of rock waste and mud are automatically achieved, representative rock waste is rapidly and continuously obtained, logging sand gaining time is shortened, the labor cost of logging operation is saved, the rock waste logging data quality and rock waste collection precision are improved to the largest degree, the rock waste section coincidence rate is improved, influences of manual operation are reduced, the work intensity of logging data collection staff is lowered, and working efficiency and accuracy are improved; the number of logging on-site operation staff is reduced, the employment risk and the labor intensity are lowered, and high automation of logging work is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

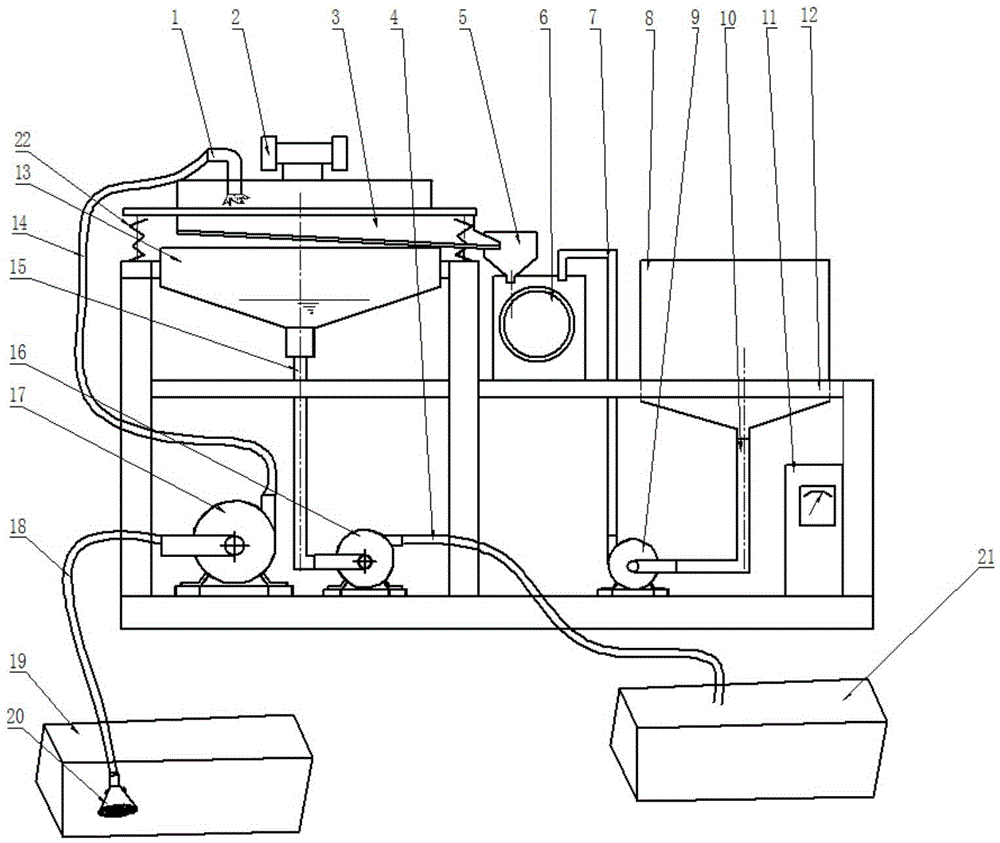

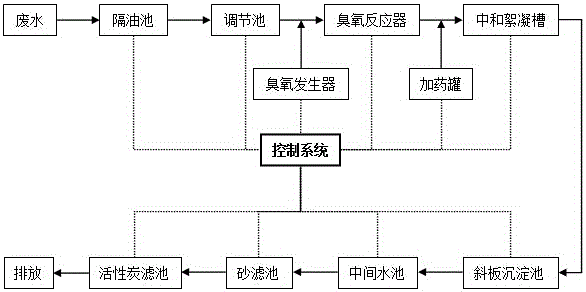

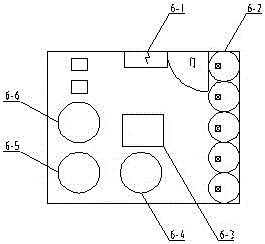

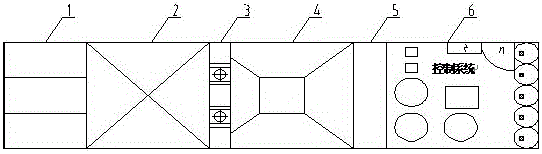

Multi-mode mobile integrated wastewater treating equipment for repairing polluted soil and groundwater

InactiveCN105000710ANo manual operationShort reaction timeMultistage water/sewage treatmentActivated carbon filtrationGroundwater remediation

The invention relates to multi-mode mobile integrated wastewater treating equipment for repairing polluted soil and groundwater. The equipment comprises an oil separating basin, a regulating basin, a neutralizing and flocculating tank, a sloped plate sedimentation basin, a middle water basin and an integrated control reaction chamber, wherein a control system, medicine adding pots, an ozone generator, an ozone reactor, an activated carbon filtering basin and a sand filtering basin are arranged in the integrated control reaction chamber; the oil separating basin, the regulating basin, the ozone reactor, the neutralizing and flocculating tank, the sloped plate sedimentation basin, the middle water basin, the sand filtering basin and the activated carbon filtering basin are sequentially connected through a pipeline, the ozone generator and the ozone reactor are connected through the pipeline, the medicine adding pots and the neutralizing and flocculating tank are connected through the pipeline, and the medicine adding pots, the ozone generator, the oil separating basin, the regulating basin, the ozone reactor, the neutralizing and flocculating tank, the sloped plate sedimentation basin, the middle water basin, the sand filtering basin and the activated carbon filtering basin are electrically connected with the control system and controlled by the control system. The multi-mode mobile integrated wastewater treating equipment disclosed by the invention can perform innocent treatments on wastewater generated during repairing the polluted soil and the groundwater, aiming at wastewater in different nature, different technologies are combined, technology parameters are regulated, and different medicine agents are added, so that the treated wastewater can reach a discharge standard or be used for other application.

Owner:SHANGHAI SUS ENVIRONMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com