Method for calibrating central point of robot tool through employing plane calibration plate

A tool center point and calibration method technology, which is applied in the field of robot tool center point calibration, can solve the problems of low precision and complicated calibration operation, and achieve the effect of automatic control, high calibration accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

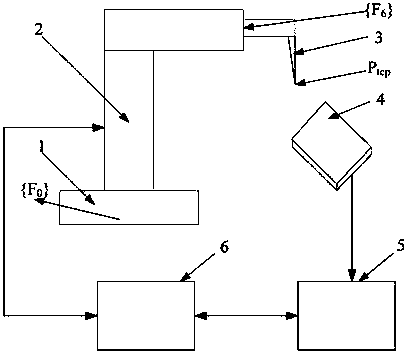

[0024] see figure 1 , {F 0} is the robot world coordinate system established in the space where the robot base is located, {F 6} is the coordinate system of the robot end flange fixed on the end flange of the robot. The computer 5 is used to collect the contact sensor signal of the calibration plate to determine whether the calibration plate is touched. The computer is connected to the robot controller 6 through the network. When the touch signal appears on the calibration board, it can send a stop motion signal to the robot, and the computer simultaneously reads the robot corner joint information from the robot controller and completes subsequent calculations.

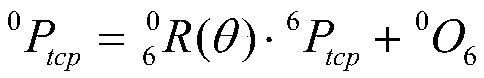

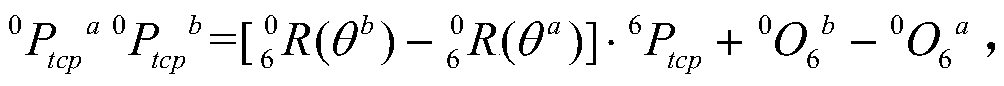

[0025] P tcp Set as the target setting point of TCP, the core of the calibration work is to find out the point at {F 6} coordinates in 6 P tcp ={ 6 x tcp , 6 the y tcp , 6 z tcp} T . The point is in the robot world coordinate system {F 0} coordinates are 0 P tcp ={ 0 x tcp , 0 the y tcp , 0 z tcp} ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com