Pressure sensor self-correcting method and device, equipment and storage medium

A pressure sensor, self-calibration technology, applied in the field of sensors, can solve problems such as calibration and difficult pressure sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

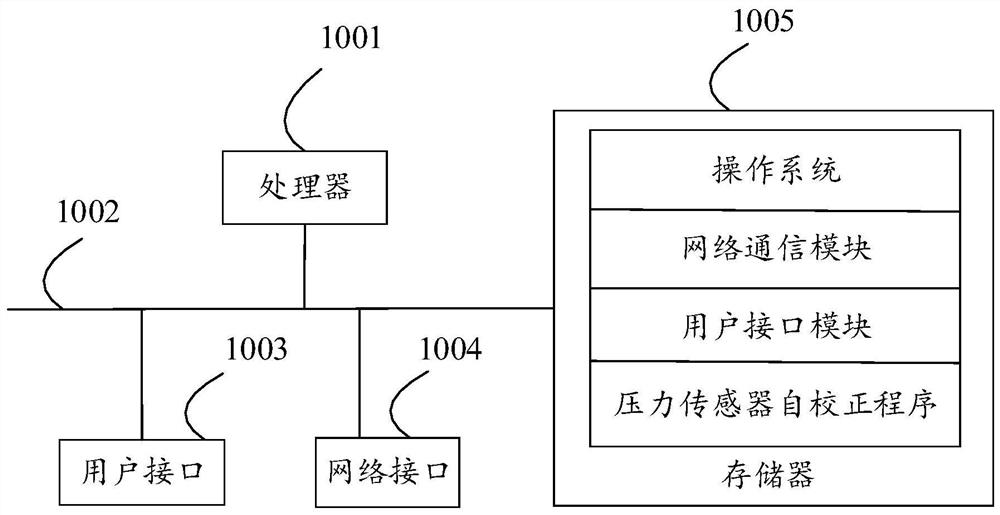

[0049] refer to figure 1 , figure 1 It is a schematic structural diagram of the self-calibration pressure sensor of the hardware operating environment involved in the solution of the embodiment of the present invention.

[0050] Such as figure 1 As shown, the self-calibrating pressure sensor may include: a processor 1001 , such as a central processing unit, a communication bus 1002 , a user interface 1003 , a network interface 1004 , and a memory 1005 . Wherein, the communication bus 1002 is used to realize connection and communication between these components. The user interface 1003 may include a display screen, and the optional user interface 1003 may also include a standard wired interface and a wireless interface. The wired interface of the user interface 1003 may be a USB interface in the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com