Wave absorbing material of Z-shaped ferrite flaky powder filled particulate powder and preparation method thereof

A wave absorbing material and flake powder technology, applied in the field of material science, can solve the problems of easy chemical reaction, complex interface effect, complex preparation process, etc., and achieve good material density and uniformity, good compactness, and equipment requirements simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

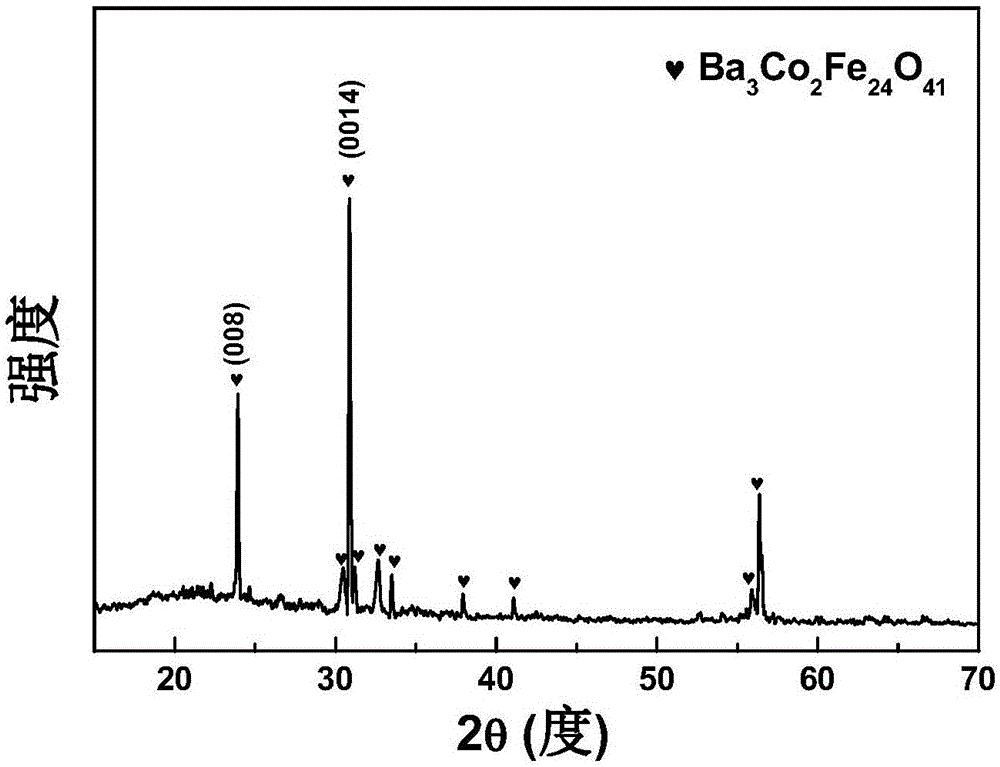

[0050] A (001) Ba 3 co 2 Fe 24 o 41 A wave-absorbing material filled with flake powder and a preparation method thereof, characterized in that the chemical expression of the wave-absorbing material is x(001)Ba 3 co 2 Fe 24 o 41 / (1-x)Ba 3 co 2 Fe 24 o 41 , where x is (001)Ba 3 co 2 Fe 24 o 41 The mass percentage of flake powder, and x=5%.

[0051] Above (001) Ba 3 co 2 Fe 24 o 41 / Ba 3 co 2 Fe 24 o 41 The preparation method of wave-absorbing material comprises the following steps:

[0052] (1) BaCO 3 , Fe 2 o 3 , NaCl is accurately weighed with an electronic balance, placed in a ball mill jar, mixed well, taken out and dried for later use. of which BaCO 3 , Fe 2 o 3 The mass ratio of the mass sum of NaCl to NaCl is 1:1, BaCO 3 with Fe 2 o 3 The amount according to the general chemical formula BaFe 12 o 19 Weighing; the mass ratio of the material used for ball milling, balls, and alcohol is 1:2:1, the speed of the ball mill is 500r / min, the bal...

Embodiment 2

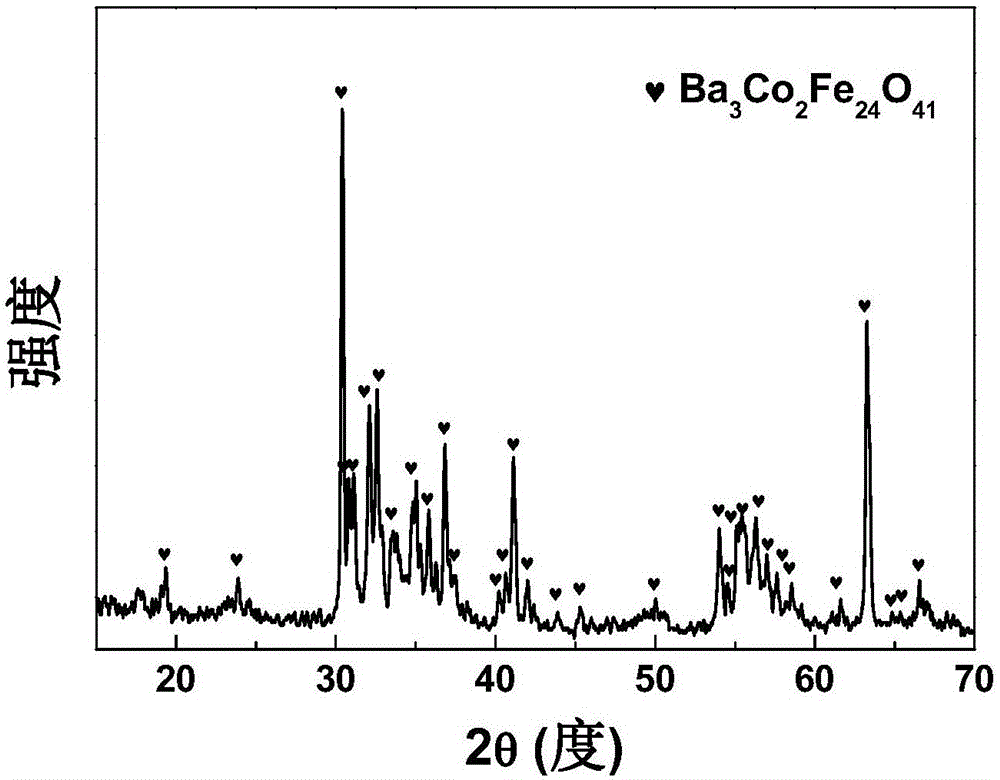

[0068] A (001) Ba 3 co 2 Fe 24 o 41 A wave-absorbing material filled with flake powder and a preparation method thereof, characterized in that the chemical expression of the wave-absorbing material is x(001)Ba 3 co 2 Fe 24 o 41 / (1-x)Ba 3 co 2 Fe 24 o 41 , where x is (001)Ba 3 co 2 Fe 24 o 41 The mass percentage of flake powder, and x=10%.

[0069] Above (001) Ba 3 co 2 Fe 24 o 41 / Ba 3 co 2 Fe 24 o 41 The preparation method of wave-absorbing material comprises the following steps:

[0070] (1) The raw material BaCO 3 , Fe 2 o 3 , NaCl is accurately weighed with an electronic balance, placed in a ball mill jar, mixed well, taken out and dried for later use. The raw material BaCO 3 , Fe 2 o 3 The mass ratio of the mass sum of NaCl to NaCl is 1:1, BaCO 3 with Fe 2 o 3 The amount according to the general chemical formula BaFe 12 o 19 Weighing; the mass ratio of materials, balls, and alcohol used for ball milling is 1:2:1, the speed of the ball mi...

Embodiment 3

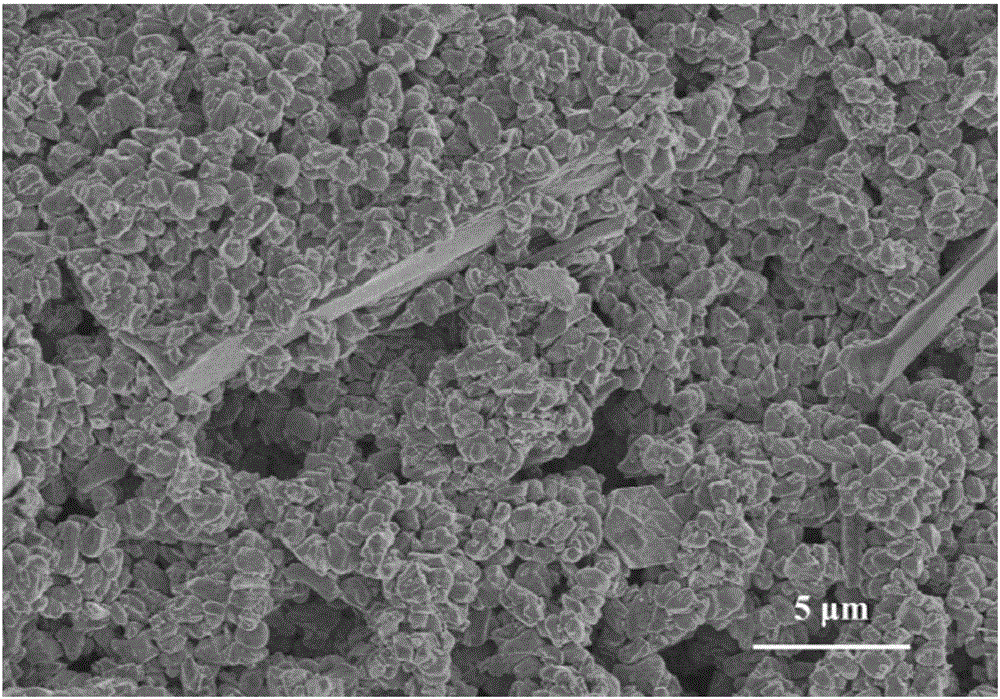

[0084] A (001) Ba 3 co 2 Fe 24 o 41 A wave-absorbing material filled with flake powder and a preparation method thereof, characterized in that the chemical expression of the wave-absorbing material is x(001)Ba 3 co 2 Fe 24 o 41 / (1-x)Ba 3 co 2 Fe 24 o 41, where x is (001)Ba 3 co 2 Fe 24 o 41 The mass percentage of flake powder, and x=15%.

[0085] Above (001) Ba 3 co 2 Fe 24 o 41 / Ba 3 co 2 Fe 24 o 41 The preparation method of wave-absorbing material comprises the following steps:

[0086] (1) The raw material BaCO 3 , Fe 2 o 3 , NaCl is accurately weighed with an electronic balance, placed in a ball mill jar, mixed well, taken out and dried for later use. The raw material BaCO 3 , Fe 2 o 3 The mass ratio of the mass sum of NaCl to NaCl is 1:1, BaCO 3 with Fe 2 o 3 The amount according to the general chemical formula BaFe 12 o 19 Weighing; the mass ratio of the material used for ball milling, balls, and alcohol is 1:2:1, the speed of the ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com