Autonomous unmanned aerial vehicle fan blade polling system and method

A technology for fan blades and unmanned aerial vehicles, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve the problems of inability to take pictures of fans, a large number of human resources, and long inspection time, so as to avoid the influence of human factors. , save human resources, and facilitate the use of the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

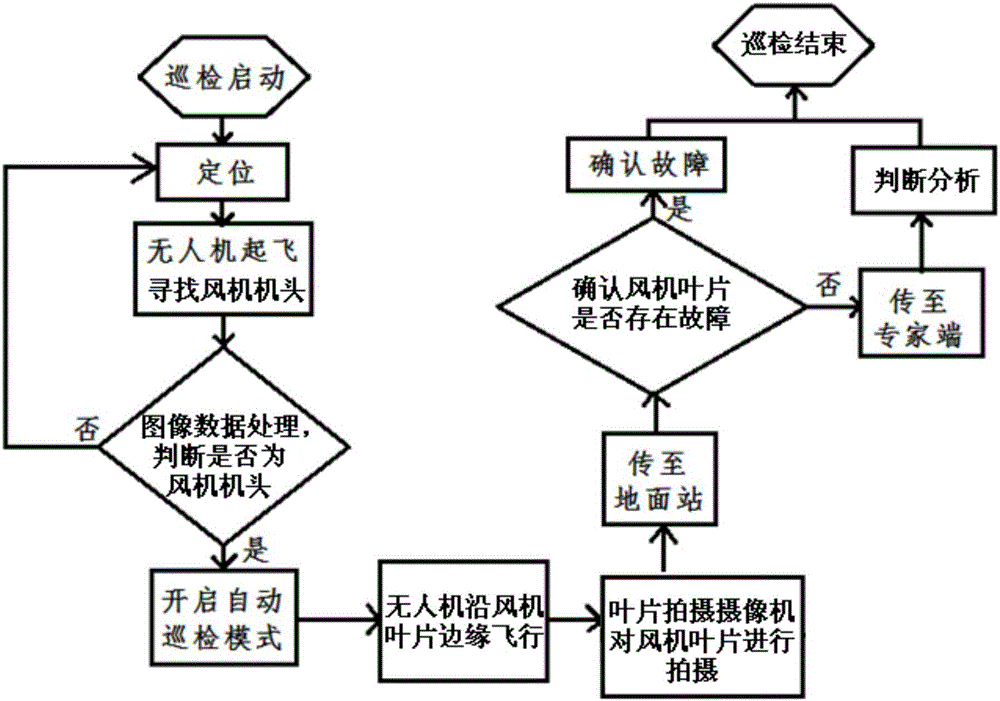

[0041] The present invention will be further described below with reference to the drawings and specific embodiments.

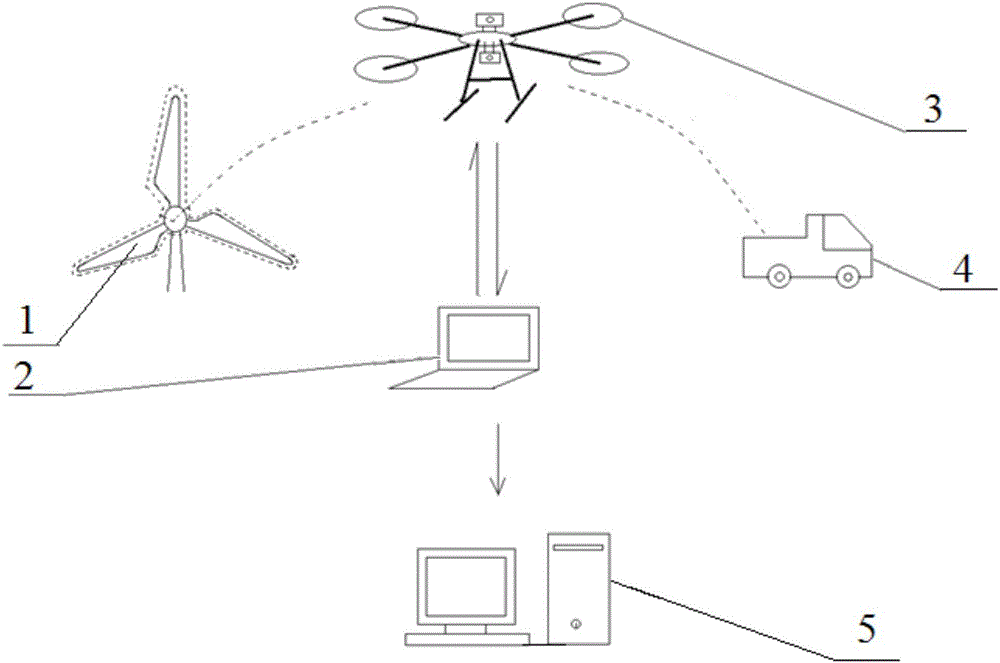

[0042] Such as Figure 1-Figure 3 As shown, the autonomous drone inspection fan blade system includes:

[0043] UAV 3 for automatic inspection of fan blade 1;

[0044] Inspection vehicle 4 for parking drone 3;

[0045] Used to receive and process the image data sent by the drone 3 to control the ground station 2 of the drone 3;

[0046] The expert terminal 5 used to judge and analyze the image data of the ground station 2;

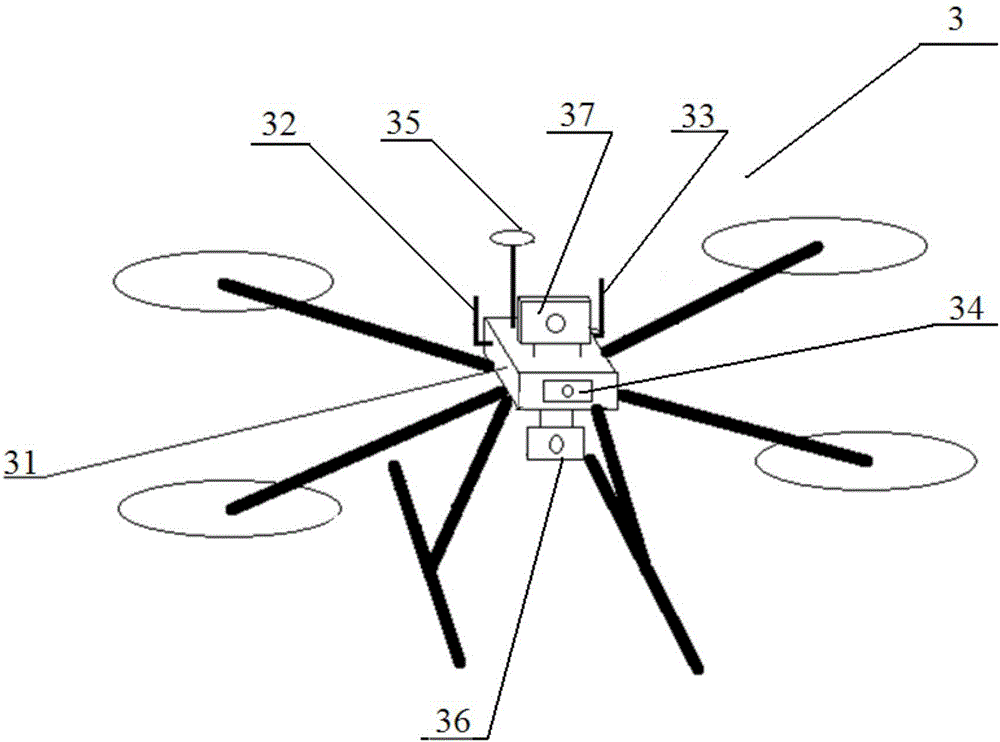

[0047] The UAV 3 and the ground station 2 are wirelessly connected, and the ground station 2 is connected to the expert terminal 5; the UAV 3 includes a flight control module 31 and a video transmission connected to the flight control module 31 respectively. Module 32, data transmission module 33, obstacle avoidance module 34, positioning module 35, blade shooting camera 36 and patrol camera 37.

[0048] The positioning module 35 is a GPS module.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com