SDOF parallel automatic offset adjusting system and method for optical lens

A technology of optical lenses and degrees of freedom, applied in optics, optical components, instruments, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

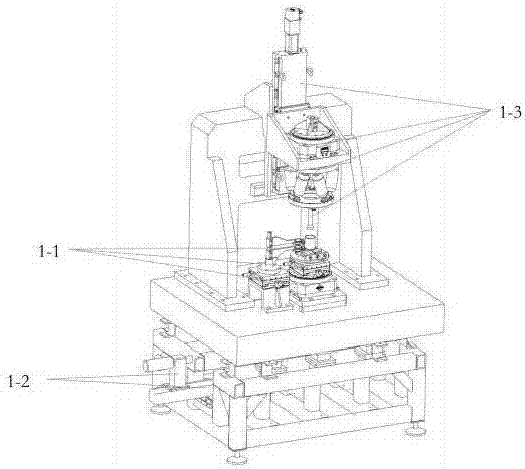

[0106] Refer to attached figure 1 , the optical adjustment system mainly includes three main parts: 1-1 lens barrel adjustment module, 1-2 center deviation measurement module and 1-3 automatic deviation adjustment module. Through the coordination and cooperation of various parts, a high degree of integration of center deviation measurement and lens adjustment can be realized.

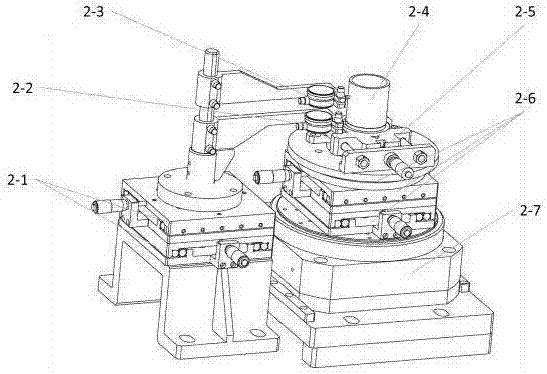

[0107] Taking the rotation axis of the 4-2 upper air-floating turntable as the reference axis of the whole system, respectively ensure that the coaxiality between the 2-7 lower air-floating turntable and the 3-2 autocollimator optical axis and the reference axis is within plus or minus 3 microns .

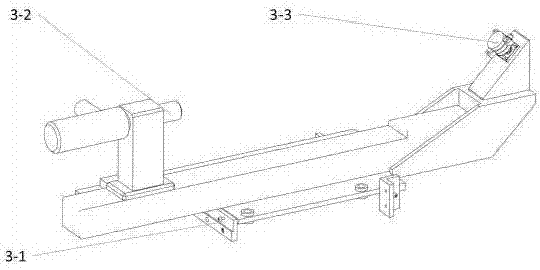

[0108] Refer to attached figure 2 , adjust the pose of the lens barrel through the 1-1 lens barrel adjustment module, the 1-1 lens barrel adjustment module includes a dial indicator measuring mechanism and a 2-6 four-dimensional adjustment table. Place the lens barrel on the 2-6 four-dimensional adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com